#aluminium machining china

Explore tagged Tumblr posts

Text

How to Choose the Best Aluminum Die Casting Supplier?

When selecting the best aluminum die casting supplier for your project, there are many factors that need to be taken into consideration.

As the aluminum die casting process is often used to produce parts with more intricate shapes and sizes, selecting the right supplier is essential for achieving the desired results.

Here are some tips to help you choose the best aluminum die casting supplier for your project. The first step in choosing an aluminum die casting supplier is to research their experience and qualifications.

Look for a supplier that is knowledgeable about the specific type of aluminum die casting that you need for your project.

It is also important to ensure that the supplier has the necessary certifications and accreditations, such as ISO 9001 and AS 9100.

The next step in selecting an aluminum die casting supplier is to evaluate their quality control processes. Quality control is essential in aluminum die casting, as it ensures that parts are produced to the highest standards and meet your specifications.

Make sure the supplier you choose has a robust quality control system in place to ensure that your parts are produced with the highest quality. It is also important to research the supplier’s customer service.

Ask for references from past customers and read customer reviews to get an idea of the quality of service you can expect from the supplier.

You should also ask the supplier about their turnaround times and delivery options.

Finally, consider the supplier’s pricing. Different suppliers may offer different prices, so make sure to compare quotes from multiple suppliers before making your decision.

Also, ask if the supplier offers any discounts or special offers. Choosing the right aluminum die casting supplier is essential for achieving the desired results in your project.

By following these tips, you can ensure that you select the best supplier for your project.

Make sure to research the supplier’s experience and qualifications, evaluate their quality control processes, research their customer service, and compare quotes from multiple suppliers before making your decision.

With the right supplier, you can be sure that your aluminum die casting project will be a success.

#aluminum die casting#die casting#aluminum die casting design guide#CNC machining#aluminum machining#CNC aluminum#Precision Machining#aluminium machining china#CNC cutting#CNC milling#CNC grinding#CNC welding#CNC forming#CNC stamping#CNC punching#Casting Machining#Forging Machining

1 note

·

View note

Text

Unlock the future of precision with GreatLight's Metal 5-Axis CNC Machining! 🚀 Perfecting complexity with every cut—engineered for perfection. 🔩💡 #CNC #5AxisMachining #PrecisionEngineering #MetalMachining #GreatLight #ManufacturingInnovation #TechInAction #CustomParts

#CNC Machine Suppliers#CNC Machine Types#CNC Machine What Does It Do#CNC Machine X Carve#CNC Machined AluMinium Parts#CNC Machines For Sale Uk#CNC Machining Centres#CNC Machining China#CNC Machining Companies#CNC Machining Companies Near Me#CNC Machining Companies Uk#CNC Machining Cost Per Hour Uk

0 notes

Text

World War Two: When 600 US planes crashed in Himalayas

2 days ago

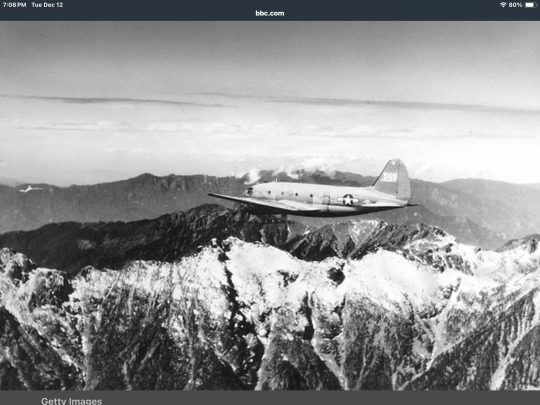

View of a US Army Air Transport Command cargo plane as it flies over the snow-capped, towering mountains of the Himalayas, along the borders of India, China, and Burma, January 1945, February 20, 1945.Getty Images

Pilots called the flight route "The Hump" - a nod to the treacherous heights of the eastern Himalayas

A newly opened museum in India houses the remains of American planes that crashed in the Himalayas during World War Two. The BBC's Soutik Biswas recounts an audaciously risky aerial operation that took place when the global war arrived in India.

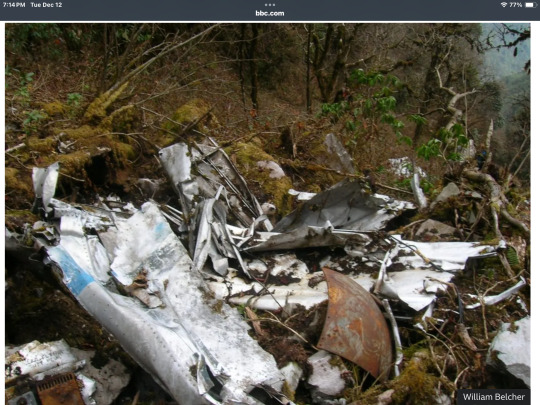

Since 2009, Indian and American teams have scoured the mountains in India's north-eastern state of Arunachal Pradesh, looking for the wreckage and remains of lost crews of hundreds of planes that crashed here over 80 years ago.

Some 600 American transport planes are estimated to have crashed in the remote region, killing at least 1,500 airmen and passengers during a remarkable and often-forgotten 42-month-long World War Two military operation in India. Among the casualties were American and Chinese pilots, radio operators and soldiers.

Has India's contribution to WW2 been ignored?

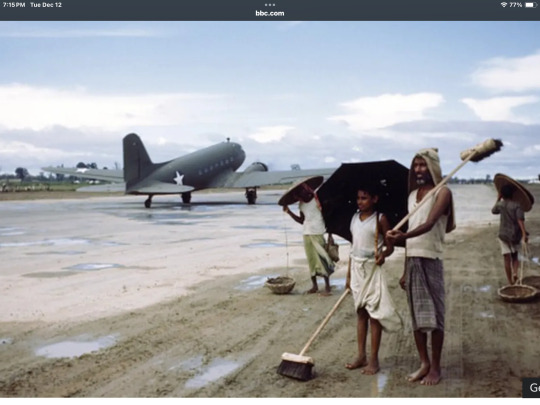

The operation sustained a vital air transport route from the Indian states of Assam and Bengal to support Chinese forces in Kunming and Chungking (now called Chongqing).

The war between Axis powers (Germany, Italy, Japan) and the Allies (France, Great Britain, the US, the Soviet Union, China) had reached the north-eastern part of British-ruled India. The air corridor became a lifeline following the Japanese advance to India's borders, which effectively closed the land route to China through northern Myanmar (then known as Burma).

The US military operation, initiated in April 1942, successfully transported 650,000 tonnes of war supplies across the route - an achievement that significantly bolstered the Allied victory.

This operation sustained a vital air transport route from India to support Chinese forces in Kunming and Chunking

Pilots dubbed the perilous flight route "The Hump", a nod to the treacherous heights of the eastern Himalayas, primarily in today's Arunachal Pradesh, that they had to navigate.

Over the past 14 years Indo-American teams comprising mountaineers, students, medics, forensic archaeologists and rescue experts have ploughed through dense tropical jungles and scaled altitudes reaching 15,000ft (4,572m) in Arunachal Pradesh, bordering Myanmar and China. They have included members of the US Defense POW/MIA Accounting Agency (DPAA), the US agency that deals with soldiers missing in action.

The forgotten Indian soldiers of Dunkirk

With help from local tribespeople their month-long expeditions have reached crash sites, locating at least 20 planes and the remains of several missing-in-action airmen.

It is a challenging job - a six-day trek, preceded by a two-day road journey, led to the discovery of a single crash site. One mission was stranded in the mountains for three weeks after it was hit by a freak snowstorm.

"From flat alluvial plains to the mountains, it's a challenging terrain. Weather can be an issue and we have usually only the late fall and early winter to work in," says William Belcher, a forensic anthropologist involved in the expeditions.

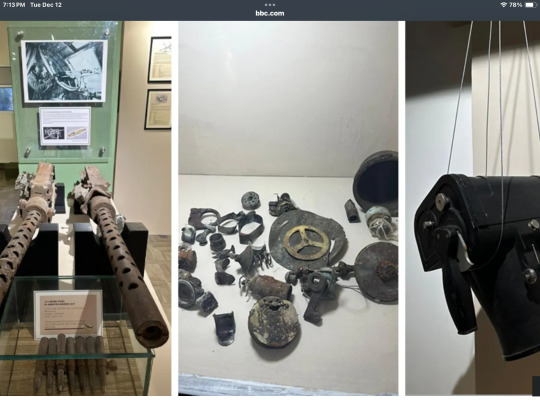

A machine gun, pieces of debris, a camera: some of the recovered artefacts at the newly opened museum

Discoveries abound: oxygen tanks, machine guns, fuselage sections. Skulls, bones, shoes and watches have been found in the debris and DNA samples taken to identify the dead. A missing airman's initialled bracelet, a poignant relic, exchanged hands from a villager who recovered it in the wreckage. Some crash sites have been scavenged by local villagers over the years and the aluminium remains sold as scrap.

These and other artefacts and narratives related to these doomed planes now have a home in the newly opened The Hump Museum in Pasighat, a scenic town in Arunachal Pradesh nestled in the foothills of the Himalayas.

US Ambassador to India, Eric Garcetti, inaugurated the collection on 29 November, saying, "This is not just a gift to Arunachal Pradesh or the impacted families, but a gift to India and the world." Oken Tayeng, director of the museum, added: "This is also a recognition of all locals of Arunachal Pradesh who were and are still an integral part of this mission of respecting the memory of others".

The museum starkly highlights the dangers of flying this route. In his vivid memoirs of the operation, Maj Gen William H Tunner, a US Air Force pilot, remembers navigating his C-46 cargo plane over villages on steep slopes, broad valleys, deep gorges, narrow streams and dark brown rivers.

Wreckage of many planes has been found in the mountains in recent years

The flights, often navigated by young and freshly trained pilots, were turbulent. The weather on The Hump, according to Tunner, changed "from minute to minute, from mile to mile": one end was set in the low, steamy jungles of India; the other in the mile-high plateau of western China.

Heavily loaded transport planes, caught in a downdraft, might quickly descend 5,000ft, then swiftly rise at a similar speed. Tunner writes about a plane flipping onto its back after encountering a downdraft at 25,000ft.

Spring thunderstorms, with howling winds, sleet, and hail, posed the greatest challenge for controlling planes with rudimentary navigation tools. Theodore White, a journalist with Life magazine who flew the route five times for a story, wrote that the pilot of one plane carrying Chinese soldiers with no parachutes decided to crash-land after his plane got iced up.

The co-pilot and the radio operator managed to bail out and land on a "great tropical tree and wandered for 15 days before friendly natives found them". Local communities in remote villages often rescued and nursed wounded survivors of the crashes back to health. (It was later learnt that the plane had landed safely and no lives had been lost.)

Does Nolan's Dunkirk ignore the role of the Indian army?

Not surprisingly, the radio was filled with mayday calls. Planes were blown so far off course they crashed into mountains pilots did not even know were within 50 miles, Tunner remembered. One storm alone crashed nine planes, killing 27 crew and passengers. "In these clouds, over the entire route, turbulence would build up of a severity greater than I have seen anywhere in the world, before or since," he wrote.

Parents of missing airmen held out the hope that their children were still alive. "Where is my son? I'd love the world to know/Has his mission filled and left the earth below?/Is he up there in that fair land, drinking at the fountains, or is he still a wanderer in India's jungles and mountains?" wondered Pearl Dunaway, the mother of a missing airman, Joseph Dunaway, in a poem in 1945.

The China-bound US transport planes took off from airbases in India's Assam

The missing airmen are now the stuff of legend. "These Hump men fight the Japanese, the jungle, the mountains and the monsoons all day and all night, every day and every night the year round. The only world they know is planes. They never stop hearing them, flying them, patching them, cursing them. Yet they never get tired of watching the planes go out to China," recounted White.

The operation was indeed a daredevil feat of aerial logistics following the global war that reached India's doorstep. "The hills and people of Arunachal Pradesh were drawn into the drama, heroism and tragedies of the World War Two by the Hump operation," says Mr Tayeng. It's a story few know.

13 notes

·

View notes

Text

Aluminium alloy wheel Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Aluminium alloy wheel Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Aluminium alloy wheel Market scenario, and feasibility study are the important aspects analyzed in this report.

The Aluminium alloy wheel Market is experiencing robust growth driven by the expanding globally. The Aluminium alloy wheel Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Aluminium alloy wheel Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. The global Aluminum Alloy Wheels Market size was USD 14.23 billion in 2020. The market is projected to grow from USD 16.43 billion in 2021 to USD 30.98 billion in 2028 at a CAGR of 9.5% during the 2021-2028 period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/105603

Key Strategies

Key strategies in the Aluminium alloy wheel Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Aluminium alloy wheel Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Aluminium alloy wheel Market.

Major Aluminium alloy wheel Market Manufacturers covered in the market report include:

LIST OF KEY COMPANIES PROFILED:

Status Wheels Inc. (Florida, U.S.)

Wheel Pros LLC. (Colorado, U.S.)

Fuel Off-Road Wheels (California, U.S.)

Citic Dicastal Co Ltd. (Hebei, China)

Enkei Wheels India Ltd (Pune, India)

Ronal AG (Härkingen, Switzerland)

BBS Kraftfahrzeugtechnik AG (Schiltach, Germany)

Alcoa wheels (Pennsylvania, U.S.)

MHT Luxury Wheels (California, U.S.)

Superior Industries (Minnesota, U.S.)

Alloy wheels have a widespread application due to their high resilience and lightweight. Furthermore, aluminum alloy wheels amplify the aesthetic appearance of the vehicle. Automakers are being forced to manufacture lighter, environment-friendly, and safer cars as the amount of carbon dioxide emitted is proportional to the amount of fuel consumption and the size of the vehicle; hence, reducing weight becomes a critical necessity.

Trends Analysis

The Aluminium alloy wheel Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Aluminium alloy wheel Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Aluminium alloy wheel Market Solutions.

Regions Included in this Aluminium alloy wheel Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Aluminium alloy wheel Market.

- Changing the Aluminium alloy wheel Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Aluminium alloy wheel Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Aluminium alloy wheel Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Aluminium alloy wheel Market?

► Who are the prominent players in the Global Aluminium alloy wheel Market?

► What is the consumer perspective in the Global Aluminium alloy wheel Market?

► What are the key demand-side and supply-side trends in the Global Aluminium alloy wheel Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Aluminium alloy wheel Market?

Table Of Contents:

1 Market Overview

1.1 Aluminium alloy wheel Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

Global Aluminium Flat Rolled Products Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2030

Aluminium flat rolled products include sheet, plate and foil. Aluminium flat rolled products are usually made by rolling thick aluminium between rolls that reduce the thickness and lengthen it through hot and cold rolling processes. According to our (Global Info Research) latest study, the global Aluminium Flat Rolled Products market size was valued at USD 117550 million in 2022 and is forecast to a readjusted size of USD 160970 million by 2030 with a CAGR of 4.6% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes. Aluminium flat rolled products include plate, sheet and foil. Due to distinctive advantages, aluminium flat rolled products have been widely used in many industries, such as transportation, packaging, building & construction, machine & equipment, electrical and so on. Among various applications, demand from packaging industry accounts for the largest consumption share with 35% globally. China is the largest base of aluminium flat rolled products globally with the share of 57%. When refers to the consumption, China is also the largest one and contributed 34% share in the consumption market. Hindalco, UACJ, Arconic, Hydro, Constellium and Aleris are the top 6 players of Aluminium Flat Rolled Products, with about 33% market shares. This report is a detailed and comprehensive analysis for global Aluminium Flat Rolled Products market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided.

Sample Plan: https://www.reportsintellect.com/sample-request/2911763 Key Features: Global Aluminium Flat Rolled Products market size and forecasts, in consumption value ($ Million), sales quantity (K MT), and average selling prices (USD/MT), 2018-2029 Global Aluminium Flat Rolled Products market size and forecasts by region and country, in consumption value ($ Million), sales quantity (K MT), and average selling prices (USD/MT), 2018-2029 Global Aluminium Flat Rolled Products market size and forecasts, by Type and by Application, in consumption value ($ Million), sales quantity (K MT), and average selling prices (USD/MT), 2018-2029 Global Aluminium Flat Rolled Products market shares of main players, shipments in revenue ($ Million), sales quantity (K MT), and ASP (USD/MT), 2018-2025

Inquire Request: https://www.reportsintellect.com/discount-request/2911763 The Primary Objectives in This Report Are: To determine the size of the total market opportunity of global and key countries To assess the growth potential for Aluminium Flat Rolled Products To forecast future growth in each product and end-use market To assess competitive factors affecting the marketplace This report profiles key players in the global Aluminium Flat Rolled Products market based on the following parameters - company overview, production, value, price, gross margin, product portfolio, geographical presence, and key developments. Key companies covered as a part of this study include Hindalco, UACJ, Arconic, Hydro and Constellium, etc. This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals, COVID-19 and Russia-Ukraine War Influence. Market Segmentation Aluminium Flat Rolled Products market is split by Type and by Application. For the period 2018-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets. Market segment by Type Plate Form Sheet Form Foil Form Others Market segment by Application Transportation Packaging Building & Construction Machine & Equipment Electrical Others Major players covered Hindalco UACJ Arconic Hydro Constellium Aleris Gulf Aluminium Rolling Mill AMAG Rolling Chinalco Group JW Aluminium Mingtai Aluminium Yieh Group RUSAL Xiashun Holdings SNTO Nanshan Aluminium KOBELCO Lotte Market segment by region, regional analysis covers North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

0 notes

Text

Powder Metallurgy Market - Forecast(2024 - 2030)

Powder Metallurgy Market Overview

Request Sample Report :

COVID-19 Impact

The onset of Covid-19 in the entire nation had a negative impact on the automotive industry. There was an overall revenue impact across the automotive industry. The pandemic also impacted all the stakeholders present in the value chain for the short as well as medium term. Shortage of raw material, shifting of production to other countries, liquidity crunch to delays in availability of models, deferred launches, and shrinkage in consumer demand were some of the main issues faced by the automotive stakeholders, owing to which the production and demand of automobiles had significantly fallen. For instance, according to the China Passenger Car Association (CPCA), China’s passenger car sales in June fell 6.5% year on year to 1.68 million units. The unstable automotive production and demand have significantly impacted the market of powder metallurgy as the demand for powder metal was also uncertain during the period. A prolonged truncation of consumer demand due to the lockdown has significantly affected auto manufacturers’ revenues and cash flows. Even after the restriction is eased in 2021, with discretionary spending taking a backseat, further declines in the market for passenger vehicles are expected.

Powder Metallurgy Market Report Coverage

The report: “Powder Metallurgy Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the powder metallurgy Industry.

By Material: Ferrous (Iron, Steel, and Stainless Steel), Non-Ferrous (Copper, Aluminium, Cobalt, Tin, Nickel, Magnesium, Zinc, Titanium, Molybdenum, and Others By Process: Conventional Process, Metal Injection Moulding, Hot Isostatic Pressing, and Metal Additive Manufacturing By Application: Porous Products, Bearing and Bushes, Filters (Ceramic Filter, Fiber Metal Filter, and Others), Refractory Metal Composites, Electric Motors, Cemented Carbides, Machinery Parts (Gears, Sprockets, Rotors, and Others), Tungsten Wires, Medical Implants, Magnetic Materials, Cutting Tools and Dies, and Others By End-Use Industry: Medical & Healthcare, Automobile (Transmission, Engine Parts, and others), Oil & Gas, Electrical and Electronics (Refrigerators, Vacuum Cleaners, Circuit Breakers, Electric Motors, Sewing Machines, and Others), Industrial (Hydraulics, Motors/Controls, and Others), Aerospace (Aero-engine, Land-based Gas Turbine, Airframes, and Others), Household Appliances, Recreation and Leisure, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the powder metallurgy market, owing to the increasing demand and production of lightweight vehicles in the region. For instance, according to OICA, the production of passenger cars has increased by 2.6 % in Malaysia in 2019.

There are many cases in which powder metallurgy over casting has a strong benefit. The benefits of the powder metallurgy process are particularly apparent when dealing with high-value and high-melting-point materials, owing to which there is increasing adoption of powder metallurgy over die casting, which will propel the market growth.

There are growing interests in producing customized medical implants using additive manufacturing and in producing porous implant structures (to match bone stiffness and to aid osteointegration) by powder metallurgy processing, which may boost the market growth.

For More Details on This Report — Request for Sample

Powder Metallurgy Market Segment Analysis — By Material

The ferrous segment held the largest share in the powder metallurgy market in 2020. Ferrous powdered metals such as iron, steel, and more offer the highest level of mechanical properties. Ferrous metal powders are also known for their extensive characteristics such as durability, hardness, tensile strength, lower costs, broad flexibility, and more. The ferrous powdered metal is largely employed in the automotive industry for designing bearings, gears, or other auto parts, owing to its good strength and flexibility. Furthermore, ferrous metals are also widely utilized in various other end-use industries such as construction, piping, aerospace, electronics, and more. Thus, it is anticipated that these extensive characteristics and wide applications of ferrous powder metallurgy are the major factors driving its demand during the forecast period.

Powder Metallurgy Market Segment Analysis — By Application

The bearings segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 7.4% during 2021–2026, owing to its self-lubricating property. Bearings that are made from powder metallurgy are known as self bearings of sintered metal. They are economical, suitable for high production rates, and precision tolerances can be produced. The majorities of porous-metal bearings consist of either bronze or iron with pores that are interconnected. These voids take up 10 percent of the total volume to 35 percent. In operation, lubricating oil is deposited in these voids and feeds to the bearing surface through the interconnected pores. Sintered-metal self-lubricating bearings are widely used in home appliances, small motors, machine tools, aircraft, and automotive accessories, business machines, instruments, and farm and construction equipment, owing to which it holds a prominent share in the powder metallurgy application segment.

Schedule A Call :

Powder Metallurgy Market Segment Analysis — By End-Use Industry

The automotive segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 8.6% during 2021–2026. Powder metal parts display excellent controlled porosity and self-lubricating properties that allow gases and liquids to be filtered. Powder metallurgy is also a strongly recommended method in the manufacture of components involving complex bends, depressions, and projections. Flexibility in the development of mechanical parts of different compositions, such as metal-non-metal and metal-metal hybrids, allows high dimensional precision in the production of automobile parts and ensures consistent properties and measurements with very little scrap and waste of material. The most popular vehicle parts that are manufactured through the method of powder metallurgy are the bearings and gears. A variety of metals, including ferrous, and non-ferrous are used in automotive components including chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake disc, and more. The powder metallurgy is often used in these components as it improves the net shape, utilizes heat treatment, enhances surface treatment, and improves the precision of these components. Thus, the demand for powder metallurgy in the automotive sector is growing due to such factors.

Powder Metallurgy Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the powder metallurgy market in 2020 up to 45%, owing to the increasing automotive manufacturing coupled with population growth in the region. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile production to reach 35 million by 2025. In 2019, according to OICA, the automotive production in Malaysia and Vietnam has increased up to 571632, and 250000, i.e., 1.2%, and 5.5%. India’s annual production in 2019 was 30.91 million vehicles, according to Invest India, compared to 29.08 million in 2018, recording a healthy 6.26 percent growth. Also, by 2026, the US$118 billion Indian car industry is projected to cross US$300 billion. The increasing automation production in the Asia Pacific will eventually boost the demand for powder metallurgy to manufacture various automobile components, which will likely influence the growth of the powder metallurgy market in the APAC region.

Powder Metallurgy Market Drivers

Flourishing Aerospace Industry

Powder metallurgy is used extensively in aerospace, because of its advantages of high strength/weight ratio, high heat capacity, and high modulus of elasticity. Within aerospace, powder metallurgy finds its most significant application in turbine engines, compressors, fan sections, discs, airframes, fasteners, and landing gear. Tungsten metallurgy based tungsten carbide has received considerable attention in the aerospace industry because of its high strength at very high temperatures. Tungsten carbide is sintered through a selective laser sintering process based on the additive manufacturing process. In 2019, China was the second-largest civil aerospace and aviation services market in the world and one of the fastest-growing markets, according to the International Trade Administration (ITA). China will need 7,690 new aircraft over the next 20 years, valued at US$1.2 trillion, according to Boeing (Commercial Market Outlook 2018–2037). China also currently accounts for 15 percent of the world’s commercial aircraft fleet, and it will be almost 20 percent by 2037. According to Boeing, the demand for 2,300 airplanes worth US$320 billion is projected in India over the coming 20 years. Boeing’s current market outlook (BMO) forecasts demand for 2,520 new aircraft in the Middle East by 2030. With the flourishing aerospace industry, the demand for aircraft components will also gradually increase, which will drive the market growth.

Buy Now :

Expanding Electrical and Electronics Sector

The powder metallurgy method offers the opportunity to cost-effectively produce net form components from a variety of materials. A market segment that has exhibited the ability to take advantage of powder metallurgy’s flexibility has been in electromagnetic applications such as household appliances, industrial applications, and more. Magnetic materials are essential elements in the electronic industry in recent times. From the motors and turbines that provide the power for the industry to the high-frequency transformers that power computers, magnetic materials are becoming increasingly important for consumers. The electronic sector is booming in various regions, which will further drive the market growth as there is an increasing demand for powder metallurgy from the electrical and electronics sector. For instance, the consumer electronics and appliances sector in India is expected to become the fifth-largest in the world by 2025, according to Invest India. India could create an US$800 billion to US$1 trillion digital economy by 2025, and India’s digital economy could fuel 18–23 percent of overall economic activity by 2025. According to the Government of Canada, revenues in the ICT sector reached an estimated US$210 billion in 2019. ICT sector revenues grew from US$158 billion to US$200 billion from 2013 to 2018, a 26.9 percent increase.

Powder Metallurgy Market Challenges

Various Drawbacks Associated with Powder Metallurgy

The cost of metal powders compared to the cost of raw material used for casting or forging a component is relatively higher. At the time the cost of tooling and equipment is also higher. When production volumes are limited, this is especially a limitation. Also, low melting point metal powders such as zinc, tin, and cadmium give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point. Furthermore, large or complex-shaped parts, and uniformly high — density products are difficult to produce by the powder metallurgy process. Without any degradation, a few powders are also difficult to store. All these drawbacks associated with the powder metallurgy may hinder the market growth during the forecast period.

Powder Metallurgy Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the powder metallurgy market. Major players in the powder metallurgy market are Arcam AB, Carpenter Technology Corp., ExOne GmbH, GKN Plc, Höganäs AB, Materialize NV, Melrose Industries PLC, Sumitomo Electric Industries, Ltd., and Hitachi Chemical Co., Ltd.

Acquisitions/Technology Launches

In May 2019, Epson Atmix Corp. installed a new production line at its Kita-Inter Plant in Japan for producing amorphous alloy powder. The company invested around ¥800 million (USD 7.43 million) for the installation of a new line and it plans to further increase its production capacity in stages and reach 6,000 tons per year by 2023.

In October 2019, GKN Powder Metallurgy a leading metal powder and parts manufacturers acquired specialist polymer 3D printing service provider Forecast 3D. The acquisition presents a significant expansion of GKN powder metallurgy’s additive capabilities.

Relevant Reports

Powder Coatings Market — Forecast (2021–2026)

Report Code: CMR 0113

Ferromanganese Market — Forecast (2021–2026)

Report Code: CMR 0382

For more Chemicals and Materials Market reports, please click here

#PowderMetallurgy#Metalworking#AdvancedManufacturing#PowderMetals#AdditiveManufacturing#MetalPowder#IndustrialMaterials

0 notes

Text

[ad_1] The 10th edition of ALUCAST® EXPO - the comprehensive biennial International Conference and Exhibition on Die Casting Technology and biggest industry platform in India yet, was kicked-off with much fanfare on December 5 at Yashobhoomi, India International Convention & Expo Center, Dwarka, Delhi, India. Distinguished leaders at ALUCAST® Expo 2024 launch the ALUCAST publications, setting the stage for a new era of innovation in die casting technology The three-day exhibition held from December 5 to December 7 and was attended by over 200 exhibitors and over 300 brands from countries, including Thailand, Germany, USA, Spain, Italy, Austria, Japan, China and France. Organized by The Aluminium Casters' Association (ALUCAST)® and produced by NürnbergMesse India, the mega expo where industry die-casting leaders, innovators, and manufacturers converged to unveil the latest technically advanced products, materials, tools, equipment, and consumables attracted over 8000 industry visitors from 20+ countries. Mr. Prasan Firodia, President, ALUCAST and Managing Director, Force Motors & Jaya Hind Industries said, "India is rapidly emerging as a global leader in aluminum die casting, with manufacturers leveraging cutting-edge technologies to produce complex critical components, including structural parts, on par with global standards. The country now boasts the largest aluminum die-casting machine at 4400 tons, capable of producing large, high-precision parts, highlighting India's advanced capabilities in the sector." Ms. Sonia Prashar, Managing Director, NuernbergMesse India shares, “ALUCAST® 2024 is set to redefine industry standards with an overwhelming response from the industry. Beyond the auto industry, the anticipated growth in sectors like consumer electronics, aerospace, and electrical equipment positions aluminium die casting as a cornerstone of India’s manufacturing future. Committed to innovation and business growth we warmly welcome all stakeholders to explore, learn, and engage at this transformative event and be part of the innovations shaping the industry's future.” The expo gathers significance with India’s growing aluminium die casting sector in manufacturing, especially in automotive technology, with rising demand for lightweight, non-ferrous metals. Aluminium die casting solutions play key role in diverse industries like Oil and Gas, Automobile, Electronics, Industrial, Aerospace, Telecom, Electrical and Construction. India's target to double the size of its auto industry to INR 15 lakh crore by the end of 2024 demonstrates its stronghold in automotive manufacturing, driven by a booming EV market projected to grow at a 49% CAGR by 2030. Inaugurated by Chief Guest Mr Peter Ottmann, CEO, NürnbergMesse GmbH on December 5, the first day witnessed address by Mr. Prasan Firodia, President, ALucast & Managing Director, Force Motors Limited & Jaya Hind Industries Pvt Ltd. Mr. Vinay Raghunath, Partner, EY also addressed the gathering as keynote speaker. The dignitaries also released ALUCAST Publications – Technical Volume, ALUCAST Journal, Exhibitors Directory that was followed by the Awards Distribution Ceremony for Best Foundry Award 2024 to honour the Innovation & Design. Ms. Sonia Prashar, Chairperson of the Board and Managing Director, NuernbergMesse India Pvt Ltd and Secretary-General, Federation of European Business in India delivered the Vote of Thanks and the three-day expo was kicked-off. The ALUCAST® also provided a 2.5 days of in-depth presentations and sessions by global industry leaders, this year's conference theme, "Leveraging Innovation & Technology for Global Competitiveness", will cover advancements in semi-solid casting, AI applications, die longevity, and workforce reskilling, all key topics driving the future of die casting. The visitors witnessed the latest machinery, tooling,

material and technology designed to elevate productivity and efficiency tailored to meet the diverse needs of the aluminium die casting sector as well as an ultimate platform for forging valuable connections, fostering collaborations, and shaping future innovations. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

[ad_1] The 10th edition of ALUCAST® EXPO - the comprehensive biennial International Conference and Exhibition on Die Casting Technology and biggest industry platform in India yet, was kicked-off with much fanfare on December 5 at Yashobhoomi, India International Convention & Expo Center, Dwarka, Delhi, India. Distinguished leaders at ALUCAST® Expo 2024 launch the ALUCAST publications, setting the stage for a new era of innovation in die casting technology The three-day exhibition held from December 5 to December 7 and was attended by over 200 exhibitors and over 300 brands from countries, including Thailand, Germany, USA, Spain, Italy, Austria, Japan, China and France. Organized by The Aluminium Casters' Association (ALUCAST)® and produced by NürnbergMesse India, the mega expo where industry die-casting leaders, innovators, and manufacturers converged to unveil the latest technically advanced products, materials, tools, equipment, and consumables attracted over 8000 industry visitors from 20+ countries. Mr. Prasan Firodia, President, ALUCAST and Managing Director, Force Motors & Jaya Hind Industries said, "India is rapidly emerging as a global leader in aluminum die casting, with manufacturers leveraging cutting-edge technologies to produce complex critical components, including structural parts, on par with global standards. The country now boasts the largest aluminum die-casting machine at 4400 tons, capable of producing large, high-precision parts, highlighting India's advanced capabilities in the sector." Ms. Sonia Prashar, Managing Director, NuernbergMesse India shares, “ALUCAST® 2024 is set to redefine industry standards with an overwhelming response from the industry. Beyond the auto industry, the anticipated growth in sectors like consumer electronics, aerospace, and electrical equipment positions aluminium die casting as a cornerstone of India’s manufacturing future. Committed to innovation and business growth we warmly welcome all stakeholders to explore, learn, and engage at this transformative event and be part of the innovations shaping the industry's future.” The expo gathers significance with India’s growing aluminium die casting sector in manufacturing, especially in automotive technology, with rising demand for lightweight, non-ferrous metals. Aluminium die casting solutions play key role in diverse industries like Oil and Gas, Automobile, Electronics, Industrial, Aerospace, Telecom, Electrical and Construction. India's target to double the size of its auto industry to INR 15 lakh crore by the end of 2024 demonstrates its stronghold in automotive manufacturing, driven by a booming EV market projected to grow at a 49% CAGR by 2030. Inaugurated by Chief Guest Mr Peter Ottmann, CEO, NürnbergMesse GmbH on December 5, the first day witnessed address by Mr. Prasan Firodia, President, ALucast & Managing Director, Force Motors Limited & Jaya Hind Industries Pvt Ltd. Mr. Vinay Raghunath, Partner, EY also addressed the gathering as keynote speaker. The dignitaries also released ALUCAST Publications – Technical Volume, ALUCAST Journal, Exhibitors Directory that was followed by the Awards Distribution Ceremony for Best Foundry Award 2024 to honour the Innovation & Design. Ms. Sonia Prashar, Chairperson of the Board and Managing Director, NuernbergMesse India Pvt Ltd and Secretary-General, Federation of European Business in India delivered the Vote of Thanks and the three-day expo was kicked-off. The ALUCAST® also provided a 2.5 days of in-depth presentations and sessions by global industry leaders, this year's conference theme, "Leveraging Innovation & Technology for Global Competitiveness", will cover advancements in semi-solid casting, AI applications, die longevity, and workforce reskilling, all key topics driving the future of die casting. The visitors witnessed the latest machinery, tooling,

material and technology designed to elevate productivity and efficiency tailored to meet the diverse needs of the aluminium die casting sector as well as an ultimate platform for forging valuable connections, fostering collaborations, and shaping future innovations. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

Why is Aluminium Formwork the Focus of High-rise Buildings?

aluminium formwork is a building formwork made of aluminum alloy, also known as aluminum alloy formwork. It has a complete set of general accessories for use, and can be assembled into integral formwork with complex dimensions of different sizes. The system formwork for assembly and industrial construction solves the defects of traditional formwork in the past and greatly improves the construction efficiency.

Advantages of applying aluminium formwork technology in high-rise buildings

1. The aluminium formwork technology does not require the assistance of mechanical equipment during construction, and only needs to manually splicing and installing the aluminium formwork, which reflects the characteristics of convenient operation.

2. The aluminium formwork has a strong load-bearing capacity. Compared with the general formwork, it can withstand more pressure, which provides a guarantee for the stability of the building, thereby reducing the occurrence of potential safety hazards during the construction process.

3. aluminium formwork is widely used, and its construction does not have too many conditions. After the splicing is completed, the gap at the joint is small and the application rate is high. Simplicity and invulnerability to reuse.

The comprehensive benefits of aluminium formwork

1. Technical aspects: The use of 3D technology can convert buildings and structures drawn from traditional two-dimensional planes into three-dimensional models, express and communicate visually, discover design errors in advance, and reduce unnecessary changes and rework.

2. In terms of progress: using aluminummolds for 3 days/layer, and using wooden molds for 5-6 days/layer, the progress is faster and the cost is effectively controlled.

3. Management: the use of aluminium formwork management personnel is reduced by half compared with the traditional formwork, and the process management is less simple than the traditional wooden formwork, which promotes scientific construction and refined management.

4. In terms of quality: the top plate is flat, the yin and yang corners are square, the walls are vertical, and the beams are straight.

5. Safety aspects: the vertical transportation of the upper and lower transfer formwork has less safety hazards, and avoids the safety risk in the process of using the unloading platform, reducing the safety risk of tower crane transportation.

6. Civilized construction: the use of aluminium formwork to remove the formwork, less construction waste, easy floor cleaning, civilized construction standards, environmental protection and resource conservation.

7. Indirect costs: The rental and management costs of accessories and machinery are reduced accordingly, thereby improving economic benefits.

The materials used in traditional formwork construction are usually disposable materials, which do not conform to the modern concept of saving resources and increase the cost. Compared with traditional construction, aluminium formwork technology has the characteristics of being reusable. In essence, it saves resources, and can also be applied in high-rise buildings, even in the construction of complex environments. aluminium formwork construction technology can effectively improve construction efficiency, ensure construction quality, and improve the accuracy of construction projects. Instead of being eco-friendly, it plays a role in construction and ensures the standards and quality of construction projects.Aluminium Formwork MachineSupplier in China and Aluminium Formwork Machine Manufacturer in China

1 note

·

View note

Text

Aluminum Heating Plate Manufacturers

Aluminium heating disc refers to the liquid aluminium alloy is shot quickly into the mould cavity through die-casting machine, and the pre-buried heating pipe is wrapped to get the corresponding casting, the casting has excellent dimensional accuracy, can be directly casting the internal structure, and is suitable for casting the complex structure; there are disc, dish, bowl, cup;

Aluminium heating discs are widely used in rice cookers, pressure cookers, wall breakers, air fryers, etc.; they are the key heating components.

0 notes

Text

1100D 11 SBR foil aluminium foil laminated

Zhejiang Shengdannu New Materials Technology Co.,Ltd. is a professional manufacturer specializing in technical textile field. With 20 years export experience and researches on the new material field for all textile field. We started research on textile for industry on 2018. Based on a group of 10 technical people with 2 years research, we are now aimed on reinforcing textile materials for films and boards. Company imported Laid Scrim machine from German which can produce more than 60000 square-meter scrim every day with single or double layer lamination optionally.

As 1100D 11 SBR foil aluminium foil laminated scrims Suppliers and custom Company, our main products include glass fiber and high strength polyester fiber laid scrim with 1*1 -3*3 /cm mesh. Single and double sides lamination with PVC tarpaulin, aluminium foil, PET foil, polyester non-woven fabric and glass fiber non-woven fabric. Those product widely used for indoor and outdoor waterproof system, thermal isolation system, road construction, agricultural shed, PVC flooring, cement board reinforcement and etc.,

Telphone +86-13255848688

Phone +86 15067365510

Fax +86-0574-62401821

E-Mail [email protected]

Address No18 Hongqi East Road, Maqiao Street, Haining, Zhejiang, China

0 notes

Text

youtube

Aluminum machining cnc mechanical spare parts

We make cnc machining parts service parts, aluminum cnc turning part, precision cnc turning milling aluminum parts, high demand cnc machining parts, aluminum cnc machining turning milling parts, cnc turning aluminum machining parts, demand aluminium cnc machining customization parts.

-----------------------------------------------------

0 notes

Text

Aluminium CNC turning parts in china

Looking for precision-engineered aluminum CNC turning parts in China? Hsmolds.net offers top-notch manufacturing solutions. With a commitment to quality and expertise in CNC machining, they deliver precise components tailored to your specifications. Whether for automotive, aerospace, or electronics, their aluminum parts meet rigorous standards. Trust Hsmolds.net for reliable, efficient, and cost-effective CNC machining solutions in China.

0 notes

Text

Surf Bait runner Reels Manufacturers

We are specialized in researching, designing and manufacturing fishing reels. Our production covers normal spring reel, surf reel, bait runner reel, feeder reel, trolling reel and baitcasting reel. Based on traditional technology, we import advanced equipment and employ Senior engineers. We owned a multi-functional production workshop. Such as mold manufacturing, plastic injection, Aluminium dia casting, CNC machine, painting, printing and assembling. Our products are exported to main of Europe, such as Germany, England, France, Ukraine, Russia and etc. And also exported to the USA, Japan, East-South of Asia and so on. We will do our best to establish long-term cooperative relationships with each customer, and continuously develop new products to meet customer requirements.

0 notes

Text

Exploring China’s Leading Extruded Aluminium Enclosure Manufacturers: A Hub of Innovation and Qualit

Overview of Extruded Aluminium Enclosures

Extruded aluminium enclosures are protective casings, often used to house electronic devices, circuit boards, control systems, and other sensitive components. Aluminium's natural properties—lightweight, strong, and corrosion-resistant—make it an ideal material for these enclosures. The extrusion process allows for the creation of complex shapes with precision, ensuring that enclosures meet the specific design and functional needs of various industries.

Chinese manufacturers have perfected the art of aluminium extrusion, delivering enclosures that meet international quality standards while remaining cost-competitive.

Advantages of China as a Manufacturing Hub

Cost Efficiency One of the primary reasons companies across the globe look to China for extruded aluminium enclosures is the cost advantage. China Extruded Aluminium Enclosure Manufacturer Chinese manufacturers can produce high-quality products at lower costs due to economies of scale, streamlined supply chains, and efficient production processes. Moreover, the availability of raw materials and access to advanced extrusion technologies ensure that these companies can pass on savings to their customers without compromising on quality.

Advanced Manufacturing Techniques

China has invested heavily in state-of-the-art equipment and production technologies. From CNC machining, anodizing, powder coating to laser cutting, Chinese manufacturers offer a wide range of post-extrusion services that ensure the final product is tailored to meet client specifications. These advanced capabilities allow for the creation of intricate designs and precise dimensions in aluminium enclosures.

Customization and Flexibility

Chinese extruded aluminium enclosure manufacturers excel in offering customized solutions to meet unique client requirements. Whether it's specific dimensions, custom cut-outs, surface treatments, or particular mechanical properties, these manufacturers are adept at delivering tailored products. This flexibility ensures that clients from various industries, including aerospace, automotive, and electronics, can find solutions that perfectly fit their needs.

Focus on Sustainability

As the demand for eco-friendly products continues to rise, many Chinese manufacturers are prioritizing sustainability. Aluminium is a highly recyclable material, and many manufacturers are now using recycled aluminium in their extrusion processes. This not only reduces the carbon footprint of the manufacturing process but also appeals to environmentally-conscious clients looking to make greener choices in their supply chains.

Quality Control and International Standards

Quality control is a top priority for Chinese manufacturers. Many companies adhere to international standards such as ISO 9001, ensuring that every product undergoes rigorous testing before reaching the customer. From material inspection, precision measurement to performance testing, every aspect of production is closely monitored. Additionally, Chinese manufacturers are increasingly gaining certifications such as RoHS and CE, which enable them to export products that meet the stringent requirements of global markets.

Key Applications of Extruded Aluminium Enclosures

Electronics and Telecommunications

Aluminium enclosures are commonly used in the electronics industry to house delicate components such as power supplies, circuit boards, and communication devices. Their durability and heat dissipation properties make them ideal for protecting sensitive electronics.

Automotive and Aerospace

In the automotive and aerospace industries, lightweight and strong enclosures are essential. Extruded aluminium enclosures offer a perfect blend of durability and weight reduction, making them invaluable for housing control systems, battery modules, and other critical components.

Industrial and Consumer Products

From lighting systems to control panels, extruded aluminium enclosures are used in a wide range of industrial and consumer products. Aluminum Project Box Their versatility, coupled with aesthetic appeal due to surface treatments like anodizing, makes them a popular choice.

0 notes

Text

RUSAL receives first batch of green power aluminum certificates

At the reception for RUSAL Chinese customers, the first batch of green power aluminum certificates issued by the Green Product Evaluation Center of the China Nonferrous Metals Industry Association was received. The document confirms that 50,000 tons of aluminum ingots produced by RUSAL's Bratsk aluminum smelter meet the green power aluminum certification requirements.

The Green Product Evaluation Center stated: Since the launch of the green power aluminum certification on June 20, 2023, it has received widespread attention from primary aluminum producers and downstream manufacturers, and has received strong support from all walks of life. As of June 30, 2024, the Green Product Evaluation Center has conducted qualitative and quantitative evaluations on approximately 3 million tons of primary aluminum from 34 companies using green electricity.

The director of the Green Product Evaluation Center of the China Nonferrous Metals Industry Association said: "We are delighted to see that Rusal is in line with our philosophy and developing in sync. As the world's leading electrolytic aluminum company, Rusal is an important force in the green and low-carbon development of the global aluminum industry. After evaluation and certification, Rusal's products will provide Chinese customers with low-carbon aluminum products with clear and traceable carbon footprints to meet the industry's green and low-carbon development needs. China's sustainable development has huge market demand prospects for green and low-carbon products. We hope that Rusal will attach great importance to the Chinese market, deepen cooperation with industry companies, increase the publicity and promotion of green power aluminum, promote the widespread application of green power aluminum, and jointly promote China's green and low-carbon economic transformation and high-quality development."

More than 90% of Rusal's electricity comes from renewable energy, including hydropower stations on Siberian rivers. As a result, the carbon footprint of Rusal's low-carbon aluminum brand ALLOW aluminum is the lowest in the world, far below the industry's global standard of 4 tons of carbon dioxide equivalent per ton of aluminum. Rusal's goals are in line with China's vision for a greener and more sustainable aluminum industry. Rusal is ready to further integrate into China's aluminum supply chain, work with local partners and stakeholders to promote innovation, and promote sustainable practices throughout the value chain. In the future, RUSAL plans to develop green aluminum certification for more products.

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions.The main products of adtech are

ceramic foam filter, aluminum casting filter, alumina ceramic filter,

in-line degassing aluminium, tap out cone, deep bed filter aluminium,

aluminium degassing machine, etc. To learn more, please follow website:https://www.alalloycasting.com/ Contact:[email protected]

0 notes