#cnc cutting vadodara

Explore tagged Tumblr posts

Text

Looking for Best CNC Laser Cutting Service in Vadodara?

Searching for CNC Metal Cutting Service? Mahavir Enterprise is an trusted CNC design cutting in Vadodara. We provides various types of CNC laser cutting services such as, CNC aluminium cutting, CNC metal cutting service, brass CNC cutting service, brass CNC cutting service, etc. Call us today!

#cnc cutting in vadodara#cnc cutting vadodara#cnc design cutting vadodara#Best CNC Laser Cutting Service in vadodara#CNC Laser Cutting Service in vadodara#CNC Laser Cutting Service vadodara#CNC Laser Cutting Services in Vadodara#cnc laser cutting#cnc laser cutting services#cnc metal cutting service#cnc sheet metal cutting#cnc aluminium cutting#cnc for aluminium cutting#brass cnc cutting service#metal sheet cnc cutting

0 notes

Text

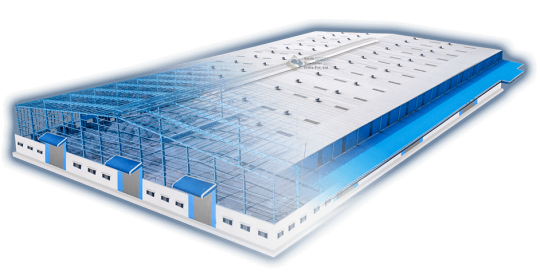

Smith Structure | Innovative Design and Engineering Solutions

Smith Structure offers innovative design & engineering solutions for successful projects from concept to completion, providing tailored designs & expert services

#SSIPL design center#SSIPL engineering center#Coil Slitting and Cutting Machine#Downspout Forming Machine#CNC Drilling Machine#Online Shot Blasting Machine#CNC Z and C Purlin Machine#experienced Design professionals#experienced Engineers professionals#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Shaping the Future: The Rise of Stainless Steel Components Manufacturers in India

In recent years, India has emerged as a powerhouse in the manufacturing sector, particularly in the production of stainless steel components. This surge can be attributed to various factors, including technological advancements, evolving market demands, and a skilled workforce. Stainless steel components play a crucial role in numerous industries, including automotive, construction, and aerospace, due to their durability, corrosion resistance, and aesthetic appeal.

One of the key drivers behind the growth of stainless steel components manufacturing in India is the country's abundant availability of raw materials, particularly stainless steel. With the government's emphasis on initiatives like "Make in India," there has been a significant push to boost domestic manufacturing and reduce dependency on imports. This has led to the establishment of numerous stainless steel component manufacturing units across the country, catering to both domestic and international markets.

Amidst this growth, companies like Meck Industries have played a pivotal role in shaping the landscape of stainless steel component manufacturing in India. Established in 1990, Meck Industries has carved a niche for itself as a leading provider of precision turned parts. Specializing in CNC machining and automatic screw machines, Meck Industries has earned a reputation for its commitment to quality, reliability, and innovation.

With a state-of-the-art facility located in G.I.D.C. Makarpura, Vadodara, Meck Industries is well-equipped to meet the diverse needs of its clientele. The company's skilled workforce, coupled with its investment in cutting-edge technology, has enabled it to deliver superior stainless steel components to various industries, including electrical, automotive, and sheet metal.

Moreover, Meck Industries' dedication to customer satisfaction and continuous improvement has been instrumental in driving its growth and success. By adhering to stringent quality standards and embracing innovative manufacturing processes, Meck Industries has positioned itself as a trusted partner for stainless steel component requirements, both domestically and internationally.

Looking ahead, Meck Industries remains committed to pushing the boundaries of excellence in stainless steel component manufacturing. With a focus on leveraging technology, fostering innovation, and expanding its global footprint, Meck Industries is poised to continue shaping the future of the industry and contributing to India's manufacturing prowess on the world stage.In conclusion, the rise of stainless steel components manufacturers in India, exemplified by companies like Meck Industries, underscores the country's growing dominance in the global manufacturing arena. With a blend of tradition, innovation, and excellence, Indian manufacturers are poised to lead the way in shaping the future of stainless steel component manufacturing worldwide.

1 note

·

View note

Text

Fiber Laser Metal Cutting Machine in Gujarat

Success Technologies is a Manufacturer, and Supplier of Fiber Laser Metal Cutting Machine in Gujarat, India Our Manufacturer unit is located in Ahmedabad, Gujarat, India. Success Technologies Is a Manufacturer, Exporter, and Supplier of CNC Wood Router Machine, CNC Stone Router Machine, CNC Metal Engraving Machine, Co2 Laser Machine, Fiber Laser Metal Cutting Machine, CNC Lathe Machine, Welding Machine, Channel Letter Bending Machine, Fiber Laser Marking Machine, Printer. Fiber Laser Metal Cutting Machines have revolutionized the manufacturing industry by offering exceptional precision, speed, and versatility in metal cutting. At Success Technologies, we provide high-quality fiber laser cutting machines that deliver optimal performance for various industries. These machines are designed to cut through metals like stainless steel, carbon steel, aluminum, brass, and copper with unparalleled accuracy. Specifications: Laser Power: 500W to 12kW (depending on the machine model) Cutting Thickness: Can cut metal plates from thin sheets (0.5 mm) to thick plates (up to 30 mm or more). Cutting Speed: Up to 35 m/min (depending on material and thickness). Accuracy: ±0.02 mm for intricate and precise cuts. Material Types: Compatible with stainless steel, carbon steel, aluminum, copper, and more. Cooling System: Water or air-cooled system to maintain optimal operating temperatures. FAQs: What are the key features of fiber laser metal cutting machines? High Precision: Achieve intricate cuts with micron-level accuracy. Speed: Rapid cutting speeds to optimize production efficiency. Versatility: Cut a wide range of metals including stainless steel, aluminum, and brass. Low Maintenance: Minimal downtime and reduced operating costs. Automation: Integrated CNC systems for precise control and automation. What are the applications of fiber laser metal cutting machines? Fiber laser machines are indispensable in industries such as: Automotive manufacturing Aerospace engineering Electronics and semiconductor production Architectural metalwork Medical device fabrication Success Technologies is a Fiber Laser Metal Cutting Machine in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Deesa#Exporter#ExporterofFiberLaserMetalCuttingMachine#FiberLaserMetalCuttingMachine#FiberLaserMetalCuttingMachineinAhmedabad#FiberLaserMetalCuttingMachineinExporter#FiberLaserMetalCuttingMachineinGujarat#FiberLaserMetalCuttingMachineinIndia#FiberLaserMetalCuttingMachineManufacturer#FiberLaserMetalCuttingMachineSupplier#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofFiberLaserMetalCuttingMachine#Mehsana#Morbi#Nadiad

0 notes

Text

Explore the Benefits of Condensate Pot Manufacturer in India

In the industrial landscape, condensate pots play a critical role in ensuring the smooth and efficient operation of various systems. Pedlock’s vital component in numerous applications, their quality and functionality are paramount. India, being a hub of manufacturing excellence, is home to some of the best condensate pot manufacturer in Mumbai, Chennai, Gujarat, Ahmedabad, Delhi, Rajasthan, Bengalore, Vadodara and Ghaziabad in India and why it is a strategic decision for industries worldwide.

What Are Condensate Pots?

Condensate pots, also known as seal pots, are essential for trapping and isolating condensates from the mainline. These pots are typically used in pipelines to improve system efficiency and ensure accurate measurement of steam or other vaporized liquids. Made from high-grade materials such as stainless steel, carbon steel, and alloy steel, they are designed to withstand high pressures and temperatures.

Why Choose an Indian Condensate Pot Manufacturer?

1. Superior Quality Materials and Standards

Indian manufacturers prioritize the use of Pedlock’s raw materials to ensure durability and performance. They adhere to global standards such as ASME, ASTM, and ISO, which ensures that the products meet stringent quality benchmarks.

2. Cost Effective Solutions

One of the most compelling reasons to choose a condensate pot manufacturer in India is the cost-effectiveness of their products. By leveraging advanced manufacturing techniques and economies of scale, Indian manufacturers offer competitive pricing without compromising on quality.

3. Customization Options

Our manufacturer excel in offering customized condensate pots tailored to specific industrial needs. Whether it’s size, material, or design, they provide bespoke solutions to meet unique requirements.

4. Advanced Manufacturing Technology

India has embraced cutting edge technology in its manufacturing processes. From CNC machining to automate welding, manufacturers in India that utilizes the latest tools and techniques to deliver precision engineered condensate pots.

5. Reliable Supply Chain

With an extensive network of suppliers and logistics providers, manufacturers of India ensure timely delivery of products to both domestic and international markets. This reliability makes them a preferred choice for industries with critical timelines.

Key Industries Benefiting from Condensate Pots Manufacturer in India

1. Oil and Gas Industry

Condensate pots manufacturer in India is widely used in the oil and gas sector to ensure accurate measurement and separation of liquid condensates. Indian manufacturers provide pots capable of withstanding the harsh environments of offshore and onshore facilities.

2. Power Generation

In power plants, condensate pots play a crucial role in steam systems, enhancing efficiency and protecting measurement equipment. Indian manufacturers deliver robust solutions to cater to these high-stakes applications.

3. Petrochemical Industry

For the petrochemical sector, where precision and durability are paramount, condensate pot manufacturer in India are engineered to meet the rigorous demands of the industry.

4. Process Industries

From food processing to pharmaceuticals, condensate pots are indispensable in ensuring accurate measurements and maintaining system integrity. Our manufacturer caters to a wide range of process industries with tailored solutions.

Features of Condensate Pots Manufactured in India

1. Material Versatility

Condensate pots are available in a variety of materials, including:

Stainless Steel for corrosion resistance

Carbon Steel for high strength and durability

Alloy Steel for specialized applications requiring enhanced performance

2. Precision Engineering

With state of the art equipment and skilled labor, manufacturers produce condensate pots with high dimensional accuracy and seamless finishes.

3. Corrosion Resistance

To enhance longevity, Indian manufacturers employ advanced surface treatments and coatings, making their condensate pots resistant to rust and wear.

4. Pressure and Temperature Tolerance

Designed for high pressure and high temperature environments, Indian condensate pots are tested to ensure they perform reliably under extreme conditions.

How to Select the Right Condensate Pot Manufacturer in India

1. Evaluate Certifications

Ensure the manufacturer holds relevant certifications like ISO 9001, which guarantees quality management systems. Our Pedlock established in the year of 1985 and it is ISO 9001 certified company of India.

2. Assess Manufacturing Capabilities

Check if the manufacturer uses advanced technologies such as CNC machines and automated testing facilities to deliver consistent quality.

3. Review Client Portfolio

A manufacturer with a strong client base across various industries demonstrates credibility and reliability.

4. Check After-Sales Support

Reliable manufacturers offer robust after sales services, including technical support and maintenance guidance.

Conclusion:

Choosing a condensate pot manufacturer in Bengalore, Gujarat, Mumbai, Chennai, Rajasthan, Vadodara, Ahmedabad, Delhi and Ghaziabad in India that offers unparalleled advantages, from superior quality and customization to cost efficiency and reliability. Pedlock stand out as global leaders in the production of condensate pots, delivering products that meet and exceed the expectations of industries worldwide.

#condensate pot manufacturer in Bengalore#condensate pot manufacturer in Mumbai#condensate pot manufacturer in Chennai#condensate pot manufacturer in Gujarat#condensate pot manufacturer in Ahmedabad#condensate pot manufacturer in Vadodara#condensate pot manufacturer in Delhi#condensate pot manufacturer in Rajasthan#condensate pot manufacturer in Ghaziabad

0 notes

Text

Safety Valve Manufacturer in India Ensuring Industrial Safety

In the dynamic landscape of industrial manufacturing, safety remains a paramount concern. Industries spanning from oil and gas to pharmaceuticals rely heavily on high-quality safety mechanisms to protect their operations and workforce. Among the critical components ensuring operational safety are safety valves. Pedlock provides a safety valve manufacturer in Mumbai, Chennai, Ahmedabad, Gujarat, Vadodara, Rajasthan, Ghaziabad, Bangalore and Delhi in India that stands out as a trusted provider of these essential devices.

The Role of Safety Valve

Safety valves are critical components in various industrial systems. They are designed to automatically release pressure from boilers, pressure vessels, and other equipment when the pressure exceeds safe limits. This function prevents potential system failures, explosions, and catastrophic accidents, ensuring the safety of both personnel and equipment.

In industries such as chemical processing, oil and gas, power generation, and manufacturing, the reliability of safety valves can make the difference between smooth operation and disaster. Hence, choosing the right manufacturer is crucial.

Pedlock: A Trusted Name in Safety Valves Manufacturer in India

Pedlock Valves has carved a niche for itself as a leading safety valve manufacturer in Chennai, Ahmedabad, Mumbai, Vadodara, Gujarat, Delhi, Bangalore, Ghaziabad, Delhi, and Rajasthan in India. With years of expertise and a commitment to excellence, Pedlock offers a comprehensive range of safety valves that meet stringent international standards.

Commitment to Quality

At Pedlock, quality is not just a buzzword but a foundational principle. Each safety valve is meticulously engineered and rigorously tested to ensure it performs flawlessly under pressure. The company adheres to globally recognized standards such as ASME, API, and ISO, guaranteeing that every valve meets or exceeds industry benchmarks.

State of the Art Manufacturing Facilities

Pedlock’s manufacturing facilities are equipped with cutting-edge technology and modern machinery. The integration of advanced CNC machines, automated assembly lines, and precision testing equipment ensures that every safety valve produced is of the highest quality. These facilities are manned by a team of skilled engineers and technicians who bring years of experience to the table, ensuring that every product is crafted to perfection.

Diverse Product Range

Our company offers a diverse range of safety valves tailored to various industrial applications. Their product line includes:

- Pressure Relief Valves: Designed to release excess pressure and protect systems from overpressure conditions.

- Thermal Relief Valves: Ideal for applications where temperature-induced pressure changes are a concern.

- Vacuum Relief Valves: Prevent vacuum conditions that could damage equipment or impede operations.

Each of these valves is available in various materials, sizes, and pressure ratings, ensuring that Pedlock can meet the unique needs of any industry.

Innovation and R&D

Innovation is at the heart of Pedlock’s operations. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This commitment to innovation enables Pedlock to continuously improve its product offerings, enhancing safety, reliability, and efficiency.

Global Reach with Local Expertise

While Pedlock is headquartered in India, its reach extends far beyond national borders. The company exports its high quality safety valves to various countries, catering to a global clientele. Despite its international presence, Pedlock remains deeply rooted in local expertise, understanding the unique challenges and requirements of the Indian market.

Sustainability and Compliance

Pedlock is committed to sustainable manufacturing practices. The company follows environmentally friendly processes and strives to minimize its carbon footprint. Additionally, Pedlock ensures compliance with all relevant environmental regulations, demonstrating its commitment to responsible manufacturing.

Conclusion

In an industry where safety cannot be compromised, Pedlock stands as a beacon of reliability and excellence. As a Safety valves manufacturer in Bangalore, Mumbai, Chennai, Ahmedabad, Vadodara, Gujarat, Delhi, Rajasthan and Ghaziabad in India. We offer high quality, innovative solutions that ensure the safety and efficiency of industrial operations. With a commitment to quality, a customer centric approach, and a focus on innovation, Pedlock is poised to lead the safety valve manufacturing sector for years to come. Whether you are in the oil and gas, chemical, or power generation industry, Pedlock’s safety valves are your trusted partner in safeguarding your operations.

0 notes

Text

Precision Bearing Turning Machines Manufacturers - SRD Machines

SRD Machines stands as a cornerstone of precision engineering, earning a reputation as a leading manufacturer of Bearing Turning Machines Manufacturers. With a commitment to excellence and cutting-edge technology, our machines redefine industry standards, offering unparalleled precision and performance.

Unmatched Expertise It is a wealth of expertise in manufacturing bearing turning machines. Our team's dedication to precision engineering ensures that each machine is crafted with meticulous attention to detail, meeting the stringent demands of the industry. As pioneers in this field, we have consistently pushed the boundaries of innovation to deliver solutions that cater to the evolving needs of the manufacturing sector.

Precision Engineering It is ' bearing turning machines are engineered with precision at their core. Our state-of-the-art manufacturing processes result in machines that achieve the highest levels of accuracy, reliability, and efficiency. Whether it's turning small precision components or handling large-scale production, our machines deliver consistent and reliable performance, setting a new standard for precision turning in the bearing industry.

Comprehensive Product Line Beyond bearing turning machines, We are offers a comprehensive product line to meet the diverse needs of manufacturers. Explore our range of related products, including CNC turning machines, machining centers, and custom solutions tailored to specific manufacturing requirements. Our commitment to providing a complete suite of solutions positions SRD Machines as a trusted partner for manufacturers seeking excellence across various production processes.

Technological Innovation Our stands at the forefront of technological innovation in the manufacturing industry. Our bearing turning machines incorporate cutting-edge features such as advanced control systems, real-time monitoring, and automation capabilities. This ensures not only precision in turning but also efficiency and adaptability to the fast-paced demands of modern manufacturing environments.

Address : Survey No. 159, Block No. 190/P1, Raman Gamdi, G.I.D.C. Por, Vadodara - 391243

Phone : +91-9427189659

Email : [email protected]

Url : https://www.srdmachines.com/bearing-turning-machine.html

0 notes

Text

Do you want to know about Mahavir Enterprise?

Mahavir Enterprise offer precision cutting services with CNC Laser Cutting, cnc aluminium cutting, cnc bending, cnc plasma cutting, metal fabrication Machines which can handle various materials and sizes. Ravi Industries is backbone of Mahavir Enterprise & with expertise & vast experience. Call us!

#laser cutting service provider vadodara#laser cutting service provider#cnc laser cutting#cnc aluminium cutting#cnc plasma cutting#cnc plasma service#metal fabrication vadodara#cnc bending#cnc bending in vadodara

0 notes

Text

Smith Structure |Efficient Manufacturing Facilities Engineering

Smith Structure is engineering company that specializes in designing & building efficient manufacturing facilities that are optimized for productivity & safety

#Plasma Cutting Machine#Deck Sheet Machine#PHI Welding Machine#Gantry Type H Beam Welding#Standing Seam Machine#CNC Shearing Machine#CNC Bending Machine#CNC Punching Machine#CNC Forming Machine#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

CNC Milling in India: Shaping the Future

CNC (Computer Numerical Control) milling has emerged as a game-changer in India's manufacturing landscape. This advanced technology, which relies on computer-controlled machinery to precisely shape and cut materials, has brought a new level of precision and efficiency to the country's manufacturing sector. India has embraced CNC milling with enthusiasm, and this technological shift is making waves across various industries. For more information call us on : 9657039991 or Visit our website : https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.php

0 notes

Text

CNC Stone Router Machine in Gujarat

Success Technologies is a Manufacturer, and Supplier of CNC Stone Router Machine in Gujarat, India Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. At Success Technologies, we are proud to offer the best-in-class CNC Stone Router Machines that are designed to cater to the needs of industries working with stone, marble, granite, and other similar materials. Our machines combine precision, power, and innovation to deliver outstanding results in stone cutting, engraving, and carving. A CNC (Computer Numerical Control) Stone Router Machine is a specialized equipment designed for cutting, engraving, and shaping various types of stone and hard materials. The CNC technology allows for high-precision work, enabling manufacturers and artists to achieve intricate designs and patterns in stone with ease. Types: CNC Router for Stone Engraving 2D/3D CNC Stone Engraving Mahine Customized Stone Engraving Machine Features: High Precision: Achieve flawless designs with minimal tolerance errors. Multi-Axis Control: Offers versatility for complex cutting and engraving tasks. Automatic Tool Changer: Reduces downtime and increases productivity by automating the tool-changing process. Durability: Built with heavy-duty components to handle the toughness of stone and other hard materials. Intuitive Interface: User-friendly software allows easy programming and operation. Cooling System: Prevents overheating of the machine during prolonged use, ensuring smooth operation and extended lifespan. FAQS: What materials can a CNC Stone Router machine cut? CNC Stone Router Machines can cut a variety of hard materials, including granite, marble, limestone, ceramic tiles, glass, and composite materials. Can the machine handle large stone slabs? Yes, CNC Stone Routers come with customizable worktables that can handle large and heavy stone slabs, making them suitable for large-scale stone fabrication. Success Technologies is a CNC Stone Router Machine in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#CNCStoneRouterMachine#CNCStoneRouterMachineinGujarat#CNCStoneRouterMachineinIndia#Deesa#Exporter#ExporterofCNCStoneRouterMachine#Gandhidham#Gandhinagar#Gujarat#India#Jamnagar#Jetpur#Junagadh#Kalol#Manufacturer#ManufacturerofCNCStoneRouterMachineinGujarat#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#Porbandar

0 notes

Text

Safety Valve Manufacturer in India Ensuring Industrial Safety

In the dynamic landscape of industrial manufacturing, safety remains a paramount concern. Industries spanning from oil and gas to pharmaceuticals rely heavily on high-quality safety mechanisms to protect their operations and workforce. Among the critical components ensuring operational safety are safety valves. Pedlock provides a safety valve manufacturer in Mumbai, Chennai, Ahmedabad, Gujarat, Vadodara, Rajasthan, Ghaziabad, Bangalore and Delhi in India that stands out as a trusted provider of these essential devices.

The Role of Safety Valve

Safety valves are critical components in various industrial systems. They are designed to automatically release pressure from boilers, pressure vessels, and other equipment when the pressure exceeds safe limits. This function prevents potential system failures, explosions, and catastrophic accidents, ensuring the safety of both personnel and equipment.

In industries such as chemical processing, oil and gas, power generation, and manufacturing, the reliability of safety valves can make the difference between smooth operation and disaster. Hence, choosing the right manufacturer is crucial.

Pedlock: A Trusted Name in Safety Valves Manufacturer in India

Pedlock Valves has carved a niche for itself as a leading safety valve manufacturer in Chennai, Ahmedabad, Mumbai, Vadodara, Gujarat, Delhi, Bangalore, Ghaziabad, Delhi, and Rajasthan in India. With years of expertise and a commitment to excellence, Pedlock offers a comprehensive range of safety valves that meet stringent international standards.

Commitment to Quality

At Pedlock, quality is not just a buzzword but a foundational principle. Each safety valve is meticulously engineered and rigorously tested to ensure it performs flawlessly under pressure. The company adheres to globally recognized standards such as ASME, API, and ISO, guaranteeing that every valve meets or exceeds industry benchmarks.

State of the Art Manufacturing Facilities

Pedlock’s manufacturing facilities are equipped with cutting-edge technology and modern machinery. The integration of advanced CNC machines, automated assembly lines, and precision testing equipment ensures that every safety valve produced is of the highest quality. These facilities are manned by a team of skilled engineers and technicians who bring years of experience to the table, ensuring that every product is crafted to perfection.

Diverse Product Range

Our company offers a diverse range of safety valves tailored to various industrial applications. Their product line includes:

Pressure Relief Valves: Designed to release excess pressure and protect systems from overpressure conditions.

Thermal Relief Valves: Ideal for applications where temperature-induced pressure changes are a concern.

Vacuum Relief Valves: Prevent vacuum conditions that could damage equipment or impede operations.

Each of these valves is available in various materials, sizes, and pressure ratings, ensuring that Pedlock can meet the unique needs of any industry.

Innovation and R&D

Innovation is at the heart of Pedlock’s operations. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This commitment to innovation enables Pedlock to continuously improve its product offerings, enhancing safety, reliability, and efficiency.

Global Reach with Local Expertise

While Pedlock is headquartered in India, its reach extends far beyond national borders. The company exports its high quality safety valves to various countries, catering to a global clientele. Despite its international presence, Pedlock remains deeply rooted in local expertise, understanding the unique challenges and requirements of the Indian market.

Sustainability and Compliance

Pedlock is committed to sustainable manufacturing practices. The company follows environmentally friendly processes and strives to minimize its carbon footprint. Additionally, Pedlock ensures compliance with all relevant environmental regulations, demonstrating its commitment to responsible manufacturing.

Conclusion

In an industry where safety cannot be compromised, Pedlock stands as a beacon of reliability and excellence. As a Safety valves manufacturer in Bangalore, Mumbai, Chennai, Ahmedabad, Vadodara, Gujarat, Delhi, Rajasthan and Ghaziabad in India. We offer high quality, innovative solutions that ensure the safety and efficiency of industrial operations. With a commitment to quality, a customer centric approach, and a focus on innovation, Pedlock is poised to lead the safety valve manufacturing sector for years to come. Whether you are in the oil and gas, chemical, or power generation industry, Pedlock’s safety valves are your trusted partner in safeguarding your operations.

#Safety valve manufacturer in Mumbai#Safety valve manufacturer in Chennai#Safety valve manufacturer in Ahmedabad#Safety valve manufacturer in Bangalore#Safety valve manufacturer in Delhi#Safety valve manufacturer in Vadodara#Safety valve manufacturer in Gujarat#Safety valve manufacturer in Rajasthan#Safety valve manufacturer in Ghaziabad

0 notes

Text

SS Air Receiver Tank Production Line Manufacturer in Ahmedabad, Gujarat, India

SS Air Receiver Tank Production Line Manufacturer in Ahmedabad, Gujarat, India; The production of an SS air receiver tank typically involves several steps. Here is a general overview of the process: Material preparation: The first step is to prepare the raw materials needed for the tank, which typically includes sheets of stainless steel. Cutting and forming: The sheets are then cut and formed into the shape of the tank using specialized machineries such as laser cutters, CNC machines, and hydraulic presses. Welding: The various components of the tank, including the shell, head, and fittings, are then welded together using a combination of automated and manual welding techniques. Surface treatment: Once the tank is assembled, it undergoes a series of surface treatments to ensure its durability and longevity. This may include sandblasting, polishing, and passivation. Quality control: Before the tank is shipped to the customer, it undergoes a rigorous quality control process to ensure that it meets all relevant standards and specifications. Overall, the production of an SS air receiver tank requires a high degree of precision and expertise to ensure that the final product is safe, reliable and meets the needs of the customer. We Provide Air Receiver Tank Production Line Design and Manufacturer in Interstate and Export Ahmedabad, Gujarat, India including and we supply our products to various locations like Mehsana, Gandhidham, Silvassa, Daman, Ankleshwar, Bhavnagar, Surendranagar, Bhuj, Dahej, Vadodara, Surat, Vapi, Valsad, Kheda, Anand, Nadiad, Vatva, Kathwada, Rakhial, Naroda, Jamnagar, Junagarh, Amreli, Modasa, Himmatnagar, Deesa, Palanpur, Gandhinagar, Bhalla, Rajkot, Morbi, Mumbai, Delhi, Bangalore, Kolkata, Chennai, Pune, Nagpur, Haridwar, Dadra Nagar Haveli, Bharuch, Bhachau, Etc. Read the full article

#SSAirReceiverTankProductionLineManufacturerinAhmedabad#SSAirReceiverTankProductionLineManufacturerinAnand#SSAirReceiverTankProductionLineManufacturerinANkleshwar#SSAirReceiverTankProductionLineManufacturerinBangalore#SSAirReceiverTankProductionLineManufacturerinBhachau#SSAirReceiverTankProductionLineManufacturerinBharuch#SSAirReceiverTankProductionLineManufacturerinChennai#SSAirReceiverTankProductionLineManufacturerinDadraNagarHaveli#SSAirReceiverTankProductionLineManufacturerinDahej#SSAirReceiverTankProductionLineManufacturerinHaridwar#SSAirReceiverTankProductionLineManufacturerinHimmatnagar#SSAirReceiverTankProductionLineManufacturerinJunagarh#SSAirReceiverTankProductionLineManufacturerinMehsana#SSAirReceiverTankProductionLineManufacturerinModasa#SSAirReceiverTankProductionLineManufacturerinNagpur#SSAirReceiverTankProductionLineManufacturerinPune#SSAirReceiverTankProductionLineManufacturerinRakhial#SSAirReceiverTankProductionLineManufacturerinSilvassa#SSAirReceiverTankProductionLineManufacturerinSurat#SSAirReceiverTankProductionLineManufacturerinSurendranagar#SSAirReceiverTankProductionLineManufacturerinValsad#SSAirReceiverTankProductionLineManufacturerinVapi#SSAirReceiverTankProductionLineManufacturerinVatva

1 note

·

View note

Text

Engiexpo industrial engineering exhibition in india.

Engiexpo is one of the largest and most prestigious industrial engineering exhibitions in India, attracting participants and attendees from all around the world. Held annually, the exhibition provides a platform for industrial engineering companies, experts, and enthusiasts to showcase their latest products, technologies, and innovations in the field.

One of the most notable features of Engiexpo is the diverse range of exhibits and demonstrations on display. From cutting-edge manufacturing equipment and machinery to advanced automation and control systems, the exhibition covers all aspects of the industrial engineering industry. Attendees can witness live demonstrations of the latest technologies, learn about the latest trends and best practices, and network with leading industry professionals.

The technical seminars, workshops, and conferences held during the exhibition are another significant highlight. These sessions cover a wide range of topics, from supply chain management to process optimization, providing attendees with invaluable insights into the latest developments in the industry. The seminars are conducted by renowned experts and industry leaders, providing a platform for knowledge sharing and learning.

Engiexpo also plays a vital role in promoting innovation and entrepreneurship in the industrial engineering sector. The exhibition provides a platform for startups and emerging companies to showcase their products and services, helping them to connect with potential customers and investors. This has led to the development of numerous innovative products and solutions, helping to drive the growth of the industry in India and beyond.

In conclusion, Engiexpo is an essential event for anyone involved in the industrial engineering industry in India. The exhibition provides a platform for knowledge sharing, learning, and networking, helping to drive innovation and growth in the sector. It is a must-attend event for industrial engineering professionals, experts, and enthusiasts who are keen to stay abreast of the latest trends and developments in the industry.

Our Upcoming Exhibition: -

EDITION: - 11TH

𝙎𝙝𝙤𝙬: - 𝐄𝐧𝐠𝐢𝐞𝐱𝐩𝐨 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐄𝐱𝐩𝐨 RAJKOT-𝟐𝟎𝟐3.

𝐃𝐚𝐭𝐞: - 17 | 18 | 19 | 20 December-2023

𝗩𝗲𝗻𝘂𝗲: - NSIC Ground AJI GIDC, RAJKOT, Gujarat

EDITION: - 12TH

𝙎𝙝𝙤𝙬: - 𝐄𝐧𝐠𝐢𝐞𝐱𝐩𝐨 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐄𝐱𝐩𝐨 VADODARA-𝟐𝟎𝟐4.

𝐃𝐚𝐭𝐞: - 17 | 18 | 19 FEBRUARY-2024

𝗩𝗲𝗻𝘂𝗲: - NAVLAKHI GROUND, VADODARA, Gujarat.

EDITION: - 13TH

𝙎𝙝𝙤𝙬: - 𝐄𝐧𝐠𝐢𝐞𝐱𝐩𝐨 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐄𝐱𝐩𝐨 AHMEDABAD-𝟐𝟎𝟐4.

𝐃𝐚𝐭𝐞: - 21 | 22 | 23 December-2024

𝗩𝗲𝗻𝘂𝗲: - GMDC GROUND, AHMEDABAD, Gujarat

EDITION: - 14TH

𝙎𝙝𝙤𝙬: - 𝐄𝐧𝐠𝐢𝐞𝐱𝐩𝐨 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐄𝐱𝐩𝐨 SURAT-𝟐𝟎𝟐5.

𝐃𝐚𝐭𝐞: - 1 | 2 | 3 FEBRUARY-2025

𝗩𝗲𝗻𝘂𝗲: - VANITA VISHRAM GROUND, SURAT, Gujarat.

ENGIEXPO MORE INFO FOR STALL BOOKING.

Call: +91-9879111548, 9879615979, 9687744488, 9773106298 Email: [email protected] Website: https://engiexpo.com/ Facebook page: https://www.facebook.com/engiexpo Linkdin :- https://www.linkedin.com/in/engiexpo/ Instagram page : https://www.instagram.com/engiexpo Twitter page: https://twitter.com/EngiexpoE YouTube: https://www.youtube.com/c/ENGIEXPOINDUSTRIALEXHIBITION

A Mega Industrial Exhibition Which Covers Major Subjects Like Weighing, Welding & Cutting, Power Tools, Material Handling, Construction, Cnc,Vmc, Hmc, Machine Tool, Automation, Electrical/Electronics, Information Technology, Wood Working Machinery, Printing, Plastic, Packaging And Many More.

#engineering#industrial#engiexpo#exhibition#tradeshowbooths#trade show banners#machinetools#building materials

0 notes

Text

Laser Cutting Job Work in Vadodara, Laser Cutting in Vadodara, Metal Design Cutting in Vadodara

Laser Cutting can be utilized to cut different materials, for example, metal, and flaunts various advantages. This innovation is frequently utilized for mechanical assembling applications, anyway, different uses have been found in private ventures, schools and among specialists. Laser cutters are controlled utilizing a PC. This procedure is a CNC, or PC numerically controlled, task. This implies a structure is made utilizing a PC and after that is sent to the machine. The machine would then be able to make the plan in whatever material is being cut. Standard Engineers for Laser Cutting in Vadodara, Laser Cutting Job Work in Vadodara, Metal Design Cutting in Vadodara

The primary laser shaper utilized was made by the Western Electric Engineering Research Centre. The machine's undertaking was to bore openings into precious stone passes on.

In present occasions, there are three generally utilized lasers, the CO2 laser, the neodymium (Nd) and the neodymium yttrium-aluminum-garnet (Nd-YAG). The principal kind of laser referenced, the CO2 laser, is utilized for exhausting, cutting and etching. The other two lasers are a similar style, however, are utilized for various applications. At the point when an exhausting errand must be executed that requires high vitality with low reiteration, the Nd laser works best. On the off chance that an exhausting undertaking requires high power and etching, at that point the Nd-YAG is the best decision. These lasers can be utilized for welding. For Metal Design Cutting in Vadodara, Laser Cutting Job Work in Vadodara

Laser cutting gives a few advantages. To begin with, utilizing this innovation can diminish assembling costs by wiping out the need for machining in some building employments. This innovation additionally offers an abnormal state of accuracy and enables confounded shapes to be made. Laser cutting won't defile work pieces either and the probability of twisting is additionally decreased when this innovation is actualized. What's more, finally, there are a few materials that are practically difficult to cut utilizing some other method. For Laser Cutting in Vadodara

The principle destructions to laser cutting are that it requires a great deal of intensity.

Tips to enable your plan to turn out how you need it to:

Dodge sharp edges, ordinarily anything short of ten degrees. The laser won't most likely precisely make such sharp turns, which will bring about a progressively adjusted last item.

Stay away from mind boggling plans. When metal is warmed, the laser shaper can't cut abnormal amounts of detail with extraordinary precision.

Laser cutting is an innovation that is frequently utilized in mechanical assembling. It introduces a few advantages and flaunts great final products. Basic employments of this innovation incorporate sheet laser cutting, cutting of auxiliary parts and furthermore funnelling.

Standard Engineers is offering a scope of steel manufacture abilities, including laser cutting. For more data about the organization and its abilities. Top 10 CNC Laser Cutting Job Works, Best CNC Laser Cutting Services, Laser Cutting Machine Company, Metal Fabrication, Steel Fabrication, Laser Cutting Job Works Manufacturers, Suppliers, Dealers, Distributors, Exporters, Traders in Vadodara, Gujarat, India

http://www.standardengineers.in/

#Laser Cutting in Vadodara#Laser Cutting Job Work in Vadodara#Metal Design Cutting in Vadodara#CNC Laser Cutting Job Work in Vadodara#CNC Laser Cutting Job Works in Vadodara#Top Laser Cutting Job Works in Vadodara#Laser Cutting Services in Vadodara#CNC Laser Cutting Services in Vadodara#Laser Cutting Company in Vadodara#Steel Fabrication in Vadodara#Metal Fabrication in Vadodara#Sheet Metal laser Cutting in Vadodara

1 note

·

View note

Video

youtube

Kamnath Group is Now Best Computer Numerical Control Cutting Services provider in Ahmedabad, India, UK, South Africa, UAE. Get High Quality CNC Plasma Cutting Services in Gujarat. CNC Cutting Service India, South Africa, UK, UAE Computer Numerical Control Machines (CNC) are suitable for complicated and specialized processes and use computer systems and software programmes. CNC Cutting is a service that is highly demanded in Ahmedabad With high precision and skill, the unit can cut numerous materials such as steel, aluminum and wood. For manufacturing companies with variable operations, CNC plasma cutting machines have become a valuable choice. WEBSITE: https://kamnathgroup.com/Fabrication/CNC-cutting

#cnc cutting India#cnc cutting service in India#cnc cutting ahmedabad#cnc cutting in surat#cnc cutting Kenya#cnc cutting in vadodara

1 note

·

View note