#china plastic drilled machining parts

Explore tagged Tumblr posts

Text

Using the Potential of CNC Machining

In the constantly changing field of product development, efficiency, accuracy, and innovation are always sought after. CNC Prototype Machining is the core of this endeavor; this revolutionary technology has completely changed the way prototypes are imagined, created, and executed.

Redefining Precision: The Advantage of CNC

The unmatched accuracy of CNC prototype machining is its foundation. CNC machines are outfitted with the newest technology and are directed by exact CAD/CAM instructions to do jobs with minuscule accuracy. With CNC machining, every detail is painstakingly and precisely carved, whether it be for drilling precise holes or sculpting complex designs.

Innovation Acceleration: Accelerating the Development Cycle

Speed is crucial in the fast-paced environment we live in today. The days of protracted production schedules and never-ending revisions are over thanks to CNC prototype machining. CNC machines help engineers and designers to iterate quickly and bring things to market more quickly than ever before by optimizing the prototype process. This shortened development cycle encourages innovation and experimentation while simultaneously shortening time-to-market.

Unleashing Versatility: From Idea to Actuality

The adaptability of prototype CNC Machining China is among its most impressive features. CNC machines can easily mold a wide range of materials into working prototypes, whether they are made of metal, plastic, wood, or composite materials. The options are endless, ranging from sophisticated consumer electronics to delicate aircraft components.

Filling the Void: From Concept to Manufacturing

In addition to prototypes, CNC machining is essential for bridging the gap between production and design. CNC machines facilitate the process of moving from concept to mass manufacture by producing parts that are ready for production and of superior quality. Prototypes are guaranteed to be workable solutions prepared for practical implementation, not only functional mock-ups thanks to this smooth connection.

Promoting Innovation in All Sectors

Prototype CNC Machining has a significant influence that goes much beyond the boundaries of a particular sector. CNC machines are pushing innovation across a wide variety of sectors, from consumer products and medical devices to aerospace and automobiles. The future of manufacturing is being shaped by CNC prototype machining, which is at the forefront of innovations such as supply chain revolutions, improved product performance, and the ability to enable new design patterns.

#CNC Machining#CNC Machining process#CNC Machining process China#CNC Machining Techniques#CNC Prototype Machining#CNC Prototype Machining China#CNC Machining China

2 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Door and Window Buying Guide: What to Choose and What to Avoid! (Part 2)

I'm delighted that you've chosen to continue watching the second part of our door and window buying guide. In the previous episode, I shared four tips to help you select door and window products. Today, we'll finish the remaining tips to assist you in finding satisfactory door and window products.

Fifth: Avoid Profiles with Wall Thickness Below 1.4mm, Choose Profiles with Wall Thickness Above 1.8mm

The wall thickness of window profiles affects the window's strength and wind pressure resistance, typically ranging between 1.4mm and 2.0mm. Selecting the appropriate wall thickness requires considering various factors, such as location, design requirements, local wind pressure, and building height, to ensure the window's performance and safety.

In China, the latest standard for window profile wall thickness recommends 1.8mm, while the old standard suggests 1.5mm. You can trust Chinese standards. If you live on a higher floor or face stronger wind pressure, I recommend choosing profiles with a wall thickness of at least 1.8mm for sufficient safety.

It's important to note that higher-floor homes are not suitable for outward-opening windows due to potential safety hazards. Inward-opening or tilt-and-turn windows, or sliding windows, are better options.

Sixth: Avoid Window Frames Narrower Than 80mm, Choose Window Frames No Narrower Than 108mm

Insufficient window frame width can compromise the overall stability of doors and windows. For high-rise buildings, I recommend choosing door and window products with a frame width of no less than 108mm for enhanced safety.

Seventh: Avoid Diagonally Welded Corners, Choose Integral Bending

There are two manufacturing methods for the hollow aluminum strips in glass: diagonally welded corners and integral bending. The process of diagonally welded corners involves cutting the aluminum strips to the required length, manually filling them with molecular sieves, and then connecting the four strips with plastic corner connectors.

Integral bending involves processing the aluminum strips using a specialized bending machine. The bending machine automatically loads and bends the strips based on input data. After bending, it forms a complete frame, which is then drilled and filled with molecular sieves.

Diagonally welded corners for hollow aluminum strips can affect the sealing performance of doors and windows. In contrast, integral bending ensures better sealing performance, effectively preventing wind and rain intrusion.

Eighth: Avoid Steel Mesh, Choose High-Transparency Mesh

In some areas, mosquitoes become a nuisance during summer. When we open our windows for ventilation, mosquitoes can invade. Therefore, door and window manufacturers have introduced window screens with integrated mesh. There are two options: steel mesh and high-transparency mesh. I recommend choosing high-transparency mesh because steel mesh obstructs views and has poor light transmission, whereas high-transparency mesh offers better light transmission and airiness, preventing mosquitoes while not affecting indoor lighting.

That's all for this door and window buying guide. If you liked it, please give it a thumbs-up!

0 notes

Text

Micro Machining

Micro machining is a type of manufacturing technique used to produce small and precise parts, components, and structures. This manufacturing process involves using advanced technology to cut and shape materials at a microscopic level. Micro machining typically uses sophisticated CNC (Computer Numerical Control) machines and specialized cutting tools to create intricate and complex features. The process is commonly used in applications such as the CNC machining medical, aerospace, and electronics industries, where precision is paramount. The process demands a high level of technical expertise and equipment and can be used on a variety of materials including metallic alloys, ceramics, and plastics.

Different Micro Machining Services

Micro Precision Machining

Micro precision machining is a specialized process that is used to manufacture small and intricate parts with high levels of precision. This manufacturing process involves cutting, shaping, and drilling materials at a microscopic level, using advanced CNC (Computer Numerical Control) machines and specialized cutting tools. The process is commonly used in industries that require precision, such as aerospace, medical, and electronics.

Small Part Machining

Small part machining is a type of manufacturing process that involves creating intricate and detailed parts, typically with dimensions of a few millimeters. This process uses advanced CNC (Computer Numerical Control) machines and specialized cutting tools to create small, precise shapes and features. Small part machining is commonly used in industries that require precision components, such as medical devices and electronics. The process demands a high level of technical expertise and equipment, and can be used on a variety of materials, including metals and plastics.

0 notes

Text

PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanical properties, in many special areas can replace metals, ceramics and other traditional materials, in reducing the quality, improving the performance of outstanding contribution to become one of today's most popular high-performance engineering plastics. PEEK material's high-temperature thermal performance is very outstanding, can be used for a long time at 260 ℃, instantaneous use Temperature of up to 300 ℃; its rigidity, dimensional stability, the coefficient of linear expansion is small, close to the metal aluminum materials.

What are The Advantages of PEEK CNC Machining?

◆ High-temperature resistance

The United States UL certification long-term use temperature of 260 ℃.

◆ Self-lubricating

With a low coefficient of friction, it can work without oil lubrication and can work in oil, water, weak acid and alkali medium for a long time.

◆ High strength

It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Corrosion resistance

It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ Abrasion resistance

It has excellent wear resistance in many extremely harsh environments such as high temperatures, high load and strong corrosion.

◆ Hydrolysis resistance

◆ Easy processing

Parts can be processed directly by an injection molding process. Post-processing such as turning, milling, drilling, tapping and ultrasonic welding can be performed.

◆ Flame retardant

◆ Low smoke and non-toxic

◆ Radiation resistance

It has excellent resistance to high dose γ-ray radiation, and the mechanical properties can be retained intact, so it can be used as radiation-resistant parts in nuclear equipment.

Electrical performance

◆ Dimensional stability

Features of PEEK Non-standard Parts

1. Resistance to dissolution.

2. Both toughness and rigidity.

3. High temperature, high frequency and high voltage electrical performance conditions.

4. Corrosion resistance, anti-aging.

5. Resistance to hydrolysis, high temperature and high pressure can still maintain excellent characteristics.

6. Irradiation resistance wear and corrosion resistance conditions;

7. Resistance to abrasion, anti-static electrical insulation properties;

8. Low soot and toxic gas emissions.

9. Lightweight instead of metal for fiber optic components.

10. Size requirements for precision conditions;

11. Mechanical strength requirements of high components

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

Learn out more about the various types of spindle motors.

Changzhou Troy Machinery & Electric Co., Ltd. was established in 1998 and has since become a market leader in high-speed spindle motor design, production, and distribution.

We continually invest in new, cutting-edge production and testing equipment to make sure that our products are of the greatest calibre. Because of our cutting-edge technology and reliable quality, we have gained the trust of customers both domestically and internationally. Our “WHD” brand name is gaining popularity.

CNC routers, engraving machines, drilling machines, edge banding machines, and other related devices frequently use products from our STZ, STF, STM, STL, and STX family. In addition, we may create unique spindle motors based on the demands of our clients.

Air-cooled spindle motor

The spindle motors used in hard disc drives (HDDs) turn the HDD discs. These parts are crucial to the performance of HDDs since the accuracy of these motors impacts HDD capacity and speed. These motors therefore need to perform very well in terms of rotational speed and Non-Repeatable Run Out (NRRO).

Air-cooled spindle motors include, among others:

1. Square spindle motor: For all of your routing and engraving needs, WHD offers a selection of High-Speed Air Cooled Spindle Motors, including Round CNC Spindle Motors, Square CNC Spindle Motors, and CNC Spindle Motors with Flanges. For more than 20 years, WHD spindle motors have been shipped to the US, Europe, Brazil, India, Russia, and other nations.

2. Spindler motor with an electric fan: WHD provides a range of High-Speed Air Cooled Spindle Motors for CNC engraving and CNC wood routing applications, including CNC Spindle Motors with Flanges, Square CNC Spindle Motors, and Round CNC Spindle Motors.Brazil, India, Russia, the United States, and other nations across the world have all received WHD spindle motor exports.

3. Spindle motor with flange: For CNC engraving and CNC wood routing applications, WHD offers a variety of High-Speed Air Cooled Spindle Motors, including Round CNC Spindle Motors, Square CNC Spindle Motors, and CNC Spindle Motors with Flanges. Brazil, India, Russia, the United States, and other nations across the world have all received WHD spindle motor exports.

Water-cooled spindle motor

An electromechanical assembly known as an electric spindle consists of a motor, a spindle shaft with bearings, and a tool holder of some sort. It might also include cooling features.

Water-cooled spindle motors include, among others:

Wood/plastic spindle motor: WHD, one of China’s top spindle motor manufacturers, has over 20 years of experience manufacturing and selling Water Cooled Spindle motors for many CNC applications industries. In addition to other countries, our spindle motors have now been exported to the United States, Europe, Brazil, India, and Russia.

2. A stone spindle motor: Being one of China’s top manufacturers of spindle motors, WHD has more than 20 years of experience producing and providing water-cooled spindle motors for numerous CNC applications industries. In addition to other countries, our spindle motors have now been exported to the United States, Europe, Brazil, India, and Russia. The STZ140–11-ER32 model has a power output of 11.0kW, a diameter of 140 mm, a speed of 24 rpm, a voltage of 380V, a current output of 20.9A, a frequency output of 100–800Hz, and many other features.

3. Metal spindle motor: Being one of China’s top spindle motor manufacturers, WHD has more than 20 years of experience producing and selling Water Cooled Spindle motors for various CNC applications industries.

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/final-shrinkage/

Final Shrinkage

The disastrous the truth is that to china mould manufacturing manufacturers, the specific shrinkage won’t be known before the shape is planned, manufactured, and tried. The objective in the setting up the last shrinkage proposal

■to give a shrinkage esteem that is near the real shrinkage of the material,

■to furnish a form machined with a shrinkage esteem that might be worked under a scope of cycle conditions to bring the part measurements inside particular, and

■to give a form that is machined”steel safe” with the end goal that the shape can be promptly adjusted if important to bring the part inside determinations.

The introduced shrinkage investigation should give sensible shrinkage gauges given legitimate dissolve temperatures and soften pressures. In any case of plastic injection moulded components china, the assessed contract age can differ broadly given vulnerability about material properties and handling conditions. Therefore, the shrinkage investigation ought to be considered as supplementing different wellsprings of data about shrinkage, The shrinkage examination ought not be utilized in disconnection given the potential for blunder. Notwithstanding, the shrinkage examination ought to be utilized to confirm the shrinkage gauges coming from different sources.

There are a few normal wellsprings of shrinkage information that might be utilized (notwithstanding examination) to help plastic injection mold manufacturers china with setting up the last shrinkage proposal. Most ordinarily, a material provider or other testing research center may shape parts in a standard test form to assess the shrinkage. Commonly, the test form comprises of a 2 or 3 mm thick plaque that is shaped at mid-range dissolve temperatures and weights. The formed parts are then permitted to equilibrate for quite a while before their measurements are estimated and the straight shrinkage determined. This shrinkage data, when accessible, is generally precise since the testing was led for the specific material of interest at conditions near most embellishment applications. In any case, the gave shrinkage information may not be exact if the divider thickness or handling states of the embellishment application differ essentially from that of the test shape.

One critical issue with shrinkage information from a material provider is that the shrinkage information may not be founded on testing of the genuine material by high-precision molds made in china, but instead suppositions that the material will carry on as evidently comparative materials that have been recently tried. A more costly however more precise option is to configuration, assemble, and test a model shape that has a stream length, divider thickness, and cooling framework like the particular embellishment application. Such model embellishment gives dissolve weights and temperatures that ought to be fundamentally the same as those of the last creation form, so the shrinkage saw with the model shape should be near the last production form. While the advancement of a model shape can be costly, the exactness of the shrinkage estimations can be helpful in close resilience applications.

Another choice is to depend on shrinkage information from past form plans and decay insight. Much of the time, molds may as of now have been planned and worked for creation of moldings that are fundamentally the same as the current form plan application. In such cases, the mold originator of injection molding service china may acquire the best gauges by contrasting the estimations of the moldings and those of the shape steel measurements.

Before making last proposals, in any case, the shape originator ought to ask with the decay to check if the disintegrate would have liked to work the trim machine at various liquefy temperatures as well as weights. Provided that this is true, the form originator ought to ask the disintegrate to create moldings at the favored conditions (regardless of whether the moldings fall outside of determination), and afterward ascertain the shrinkage of these moldings for use in shape plan applications.

A fourth choice is to perform modern PC reenactment of the mold filling, pressing, and cooling stages to foresee the straight shrinkage in the trim application. While PC reproduction uses further developed material science and gives more definite outcomes than the shrinkage examination introduced here, the PC reenactment is as yet dependent upon similar mistakes with respect to the expected material conduct and preparing conditions. Nonetheless, the mathematical recreation can be important to approve the manual shrinkage examination while giving nonuniform shrinkage gauges over the shape pit.

In building up the last shrinkage suggestion, the form architect ought to play out the introduced shrinkage investigation and affirm the outcomes with information from the material provider and past experience, if accessible. On the off chance that the shrinkage rate is dubious, at that point the shape fashioner ought to discuss the expected blunder with the disintegrate, material provider, and end-client to diminish the vulnerability and survey obligation should the used shrinkage rates be so incorrect to bring about expensive form changes. In certain agreements, the last shrinkage proposal is the duty of the form’s client who eventually pays for the expense of the shape plan and any slip-ups. In different cases, no gathering might be happy to acknowledge duty regarding a questionable shrinkage rate, so the gatherings may concur that a model embellishment venture is important to portray the shrinkage and diminish hazard.

This article is from https://www.injectionmouldchina.com

#bi-injection mould manufactory#china duraswitch keypad#china foam mould#china injection design service#china mould design services#china mould manufacturing manufacturers#china mould produce services#china over-mould manufacturers#china plastic drilled machining parts#china plastic milling machine#china semi steel two piece mould manufacturers#derlin pom prototypes china#double injection mould products#high-precision molds made in china#injection molding service china#mould manufacturers factory#oem/odm 2 shot injection moulding factory#oem/odm injection mold lifter#pipe fitting moulds maker#plastic injection mold manufacturers china#plastic injection moulded components china#plastic molding services china#plastic prototype mould china#precision plastic injection die pricelist#precision plastic injection mold pricelist#Plastic Mold

0 notes

Text

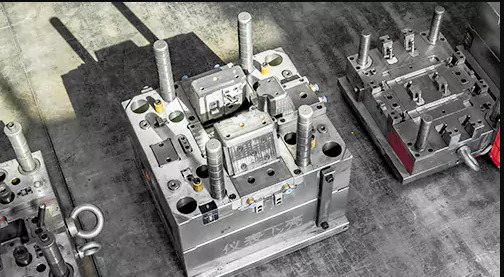

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Injection Moulding Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/cooling-time-estimation/

Cooling Time Estimation

The cooling time is characterized as the measure of time required after the mold is filled for the plastic to turn out to be adequately unbending to launch. The accompanying hypothesis is given to help the assessment of the hypothetical least cooling time for the mould manufacturers factory. By and by, cooling times can be significantly longer than those anticipated by examination for two reasons. To start with, the accompanying examination accepts flawless warmth conduction between the plastic and the form, while there is known to be a considerable warm contact obstruction between two unique materials. The cooling time can be additionally expanded during injection moulding services china by slim holes, which open up between the contracted trim and the form dividers. Second, the cooling time is regularly not driven by the inflexibility of the part, yet rather by quality prerequisites that may require the decay to stretch out the cooling time to accomplish the particulars.

Since there is next to no volumetric dissolve stream of the liquefy after the form filling stage, there is almost no warmth convection. Thus, the exchange of warmth between the plastic and the form is administered by the transient warmth conduction condition:

Here, T is the temperature, t is the time, 2 is the measurement in the thickness bearing, k is the warm conductivity, ρ is the thickness, and Cp is the particular warmth. The warm diffusivity is basically a proportion of a material’s capacity to send heat comparative with its capacity to store heat. For more quick warmth move, form materials with higher warm diffusivity are wanted, however these materials (e. g., aluminum) will in general have lower basic properties than steel as recently plotted in china high-precision mould suppliers.

The transient warmth conduction Eq. 9.2 is a subsequent request, allegorical, incomplete differential condition. Logical answers for transient warmth move have been produced for straightforward calculations, for example, plates and bars. The cooling plastic can be demonstrated as a limited chunk with the temperature of the dissolve at the centerline of the form cavity assessed from an arrangement development:

Taking the initial six terms, m∈[0,5], in the arrangement, a plot of the plastic’s temperature at the centerline is appeared as an element of the cooling time in china industrial injection mold manufacturers. The temperature of the plastic at the focal point of the trim is equivalent to the underlying melt temperature toward the beginning of the cooling cycle. After a short pause, the soften at the focal point of the trim starts to cool. In the end, the plastic will move toward the temperature of the form coolant.

To decide the cooling time, it is important to give some rule that demonstrates when the trim is sufficiently unbending to be shot out from the shape. One sensible methodology is to think about the modulus of the material, which is a proportion of the material to oppose avoidance. The powerful modulus of the material as it cools is appeared on the right-hand hub of injection moulding services. It tends to be seen that as the plastic soften approaches the shape coolant temperature, the modulus additionally moves toward a consistent state esteem. The temperature at which the material has noteworthy unbending nature is identified with the warmth bending temperature (HDT) or the avoidance temperature under burden (DTUL) as portrayed by standard tests, for example, ASTM D648. Condition 9.4 can be settled to give the cooling time as an element of the liquefy, coolant, and discharge temperatures. This article is from https://www.injectionmouldchina.com

#2-shot mould made in china#china automobile molds manufacturers#china bi-injection mould manufacturers#china high-precision mould suppliers#china household molds#china plastic drilled machining parts#china two shot mold manufacturer#china unscrewing mold manufacturer#cost of injection molding china#electric cars plastic accessories vacuum forming manufacturers china#high-quality double coler mold parts#injection molding cost china#injection mould manufacturers in china#injection moulder ltd#injection moulding services#injection moulding services china#mould handling systems#mould manufacturers factory#plastic injection moulded components china#plastic mould quotation#pom moulding parts manufacturers china#Plastic Mold

0 notes

Text

PCB Manufacture: China vs. US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concerns when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provide 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest Medical PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/

1 note

·

View note

Text

PCB Manufacturer China and PCB Manufacturer US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, the price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of a substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concern when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provides 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/ and https://www.mokotechnology.com/pcb-manufacturer-china-vs-us/

1 note

·

View note

Text

Sophisticated Technology Hoists China's Molding Industry

By using advanced machinery and technology, China's molding and tooling suppliers are able to release better-quality products faster.

China's molding and tooling industry is investing in measures to boost overall capability. Companies are bringing in advanced equipment and technology from Switzerland, Japan and Taiwan.

In addition to improving the quality of output, such machinery can produce oversize molds for 65in TV housings and 2m generator blades, and electric car and solar panel component molds that are precise to 2 microns.

Among the imported equipment now being used are CNC lathes, and die-casting and drilling machines. CNC lathes from Taiwan have a repeat location accuracy of 1 to 5 microns and can therefore yield very precise pieces. In contrast, locally made units can only go as low as 10 microns. Further, domestic mold-making machines yield molds with bad surface finishes, which affects the quality of the finished product as well.

Sophisticated technology, meanwhile, improves not only efficiency but also the lead time. As such, a growing number of midsize companies are following the footsteps of larger enterprises and integrating CAD/CAM/CAE, 3D and high-speed processing technologies.

Previously, workers at Sunny Mold & Plastic Products Co. Ltd had to carry out additional bench work after the raw molds were finished by CNC lathes to smoothen the surfaces. Adopting high-speed process technology has now eliminated that step as molds already have a smooth surface finish.

The use of advanced equipment and technology reduced lead time at Dongguan Qili Mold Co. Ltd by 20 to 50 percent. New molds now need just 10 days to finish, while simpler ones can be available in five to seven days.

Sophisticated machinery and technology, however, will bring little improvement to quality and efficiency if not handled by highly trained technical staff. As there are not enough skilled workers in the country, mold and tooling companies do their best to retain such employees. Gold Space Metal Products Co. Ltd, for instance, provides regular training to keep the technical team updated on new technology. Most of the company's skilled workers have been working at the factory since it was established in 2003.

Shenzhen Die & Mold Technology Society deputy secretary general Luo Baihui said demand for technicians is so high that their monthly salaries are often 1,000 to 2,000 yuan ($149 to $297) more than regular production line staff.

This has encouraged several vocational schools to include related courses in their curriculum. Among those offered by the Shenzhen Shen De Technical School are mold design and CNC machining, mechatronics, and mold design, programming and operation. So far, all graduates of molding-related courses have quickly found employment.

Enhanced services, materials

Apart from introducing advanced equipment, molding and tooling companies are adding value to the services they offer clients.

Instead of relying only on buyers' designs and specifications, midsize and large makers, including Sunny, develop new molds they can show suppliers of finished products. Other manufacturers are expanding into different areas of the production chain, aiming to be a one-stop shop for buyers. Apart from mold making, Gold Space has a factory where transceivers and other communication devices are assembled using parts made in-house. Anodizing and silk-screening are offered as well. By doing so, the company is able to offer lower quotes as molds and components do not need to be outsourced. china die casting

More suppliers are paying closer attention to the quality of materials as well. In the past, many molds showed some defects or deteriorated faster than they should because wrong or unqualified raw materials were used. Molds that were designed to last for 10 years, for instance, broke down in just seven.

Suppliers are now adopting materials with high levels of purity, density and uniformity to ensure the quality of molds. HRC52 steel is being replaced with HRC57 or HRC58 steel, while ceramic is used in lieu of plaster. For composite materials, superplastic, and epoxy or polyester filled with metal or glass are used for rapid prototyping.

1 note

·

View note

Text

lathe machining you can easily feel

Based in Shenzhen City in China the company has carved a niche in the business world.net or offline by calling us on 0086-134-80638827. Whether you require High Precise Injection Moulds or plastic injection tools and precision-machined products you can rely on the premium quality products and excellent engineering capabilities of the dedicated staffs of this company. Being an certified and ISO/TS 16949 compliance company ABIL provides high quality products on a discounted cost thereby offering the best value for money.net. Whether you need High Precision Plastic Injection Moulding tools, silicone rubber mold machining, grinding, drilling or lathe machining you can easily feel free to contact us online at.

For more details or any query about "High Precision Plastic Injection Moulding" or "Plastic injection molding manufacturer" please visit at ab-industry. In the process metals, glasses, plastic or polymers are passed into a heated barrel and then they are allowed to cool in a cavity of the molds wherein the molten particles of the metal or plastic takes shape according to the configuration of the cavity. Ltd. The company fulfills requirements of various clients, be they engaged in automotive, electronic, home appliance, medical, defense, construction and others. Right from the manufacture of plastic bottles to body CSD-EB90J2/10L Extrusion Blow Molding Machine panels of cars and other equipment, plastic injection molding is widely used for manufacture of a wide variety of products.

Limited is committed to provide premium quality products and services at an economical cost.Injection molding is a cost effective process to manufacture customized metallic or plastic products of the desired shape on a large scale. When you deal with us you can be rest assured that you will only get the world class products and excellent services in the friendliest way. With a well stocked inventory of injection molded plastic and rubber parts Asia Billion Industry Co.ab-industry. is a fast growing plastic injection molding manufacturer in China that provides a wide range of molded products as well as precise machining tools to its clients regardless of their nature of businesses.

0 notes

Text

Injection Tooling Fabrication

Custom Plastic Injection Molds Making

At Goodtech, we provide high-quality custom injection molding tooling services for a wide range of devices within the medical industry and automobile industry. Our injection mold services include custom mold and design, mold design, plastic mold manufacturing, OEM mold making, plastic product design and development assistance.

Plastic Injection Mold Company - Goodtech