#china unscrewing mold manufacturer

Explore tagged Tumblr posts

Photo

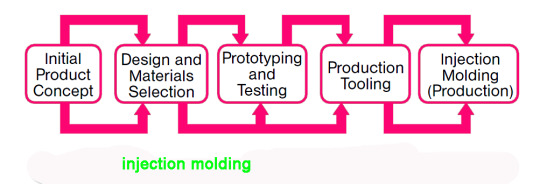

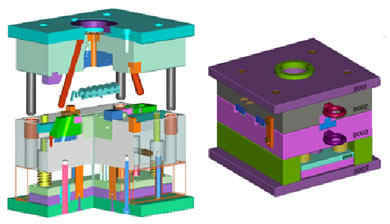

New Post has been published on https://www.injectionmouldchina.com/klarm-mould-offers-one-stop-molding-services/

Klarm Mould Offers One-Stop Molding Services

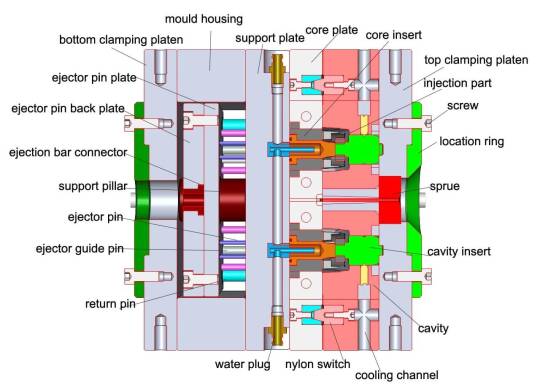

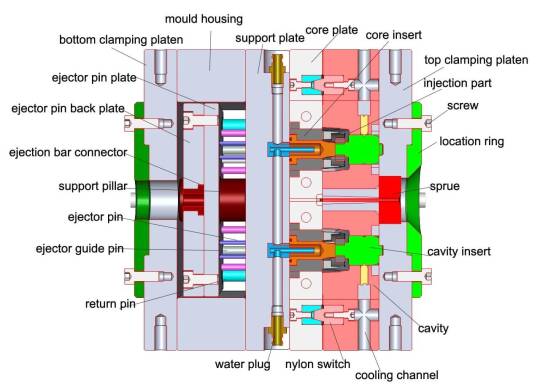

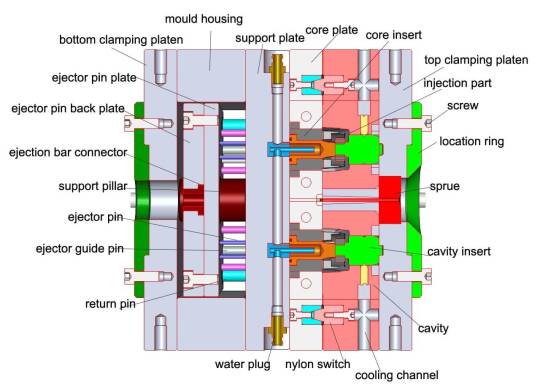

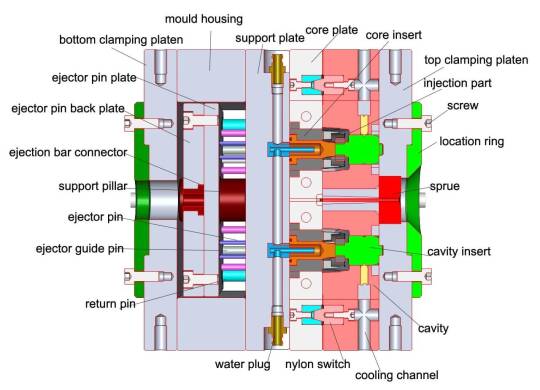

The mold configuration should likewise incorporate clasp to inflexibly attach the numerous parts of the form. There are three sorts of latches generally utilized in molds while injection moulding china.

In the first place, fits are utilized by oem/odm industrial injection moulding design factory to firmly find one segment inside another, for example, a pit or center addition being situated inside a retainer plate. Second, finding pins or dowels are utilized by chinese injection moulding companies to find one parts over another, for example, the ejector lodging to the help plate. These initial two attaching strategies just give securing across the length and width headings of the mold. To attach the mold parts together in the tallness bearing, attachment head cap screws are utilized wherein the screw’s head is held in a form plate and the screw’s strings draw in the segment to be affixed. Every one of these attaching techniques is next broke down.

A”fit”refers to the mating of two segments. A leeway fit alludes to a mating where an ostensible freedom between the surfaces of the two segments. While a leeway fit furnishes for simple get together with insignificant inclusion powers, the freedom between the two segments allows the exact area of segments to stay obscure. Since tight resistances are needed in molds, impedance fits are normally used to find the mold segments.

Obstruction fits happen when the male segment has an ostensible measurement that is bigger than the ostensible element of the female segment, as demonstrated in injection moulding services for a center addition and a retainer plate. Since metals have a high versatile modulus, an inflexible obstruction fit can result when the distinction between the ostensible measurements is little, on the request for 0.01 % of the ostensible measurement. The snugness and inflexibility of the obstruction fit increments with the measure of impedance between the two segments. Sadly, the execution of obstruction fits is blocked by the dimensional varieties forced in the segments machining measures. Therefore, standard systems of fits have been created as far as possible on the elements of the segments.

The fits investigated here depend on a one-sided opening premise and have been changed over from U.S. standard units to metric units. Two of the most widely recognized principles for fitting include”Preferred Limits and Fits for Cylindrical Parts,” ANSI B4.1-1967 (R1999), and”Preferred Metric Limits and Fits” ANSI B4.2-1978 (R1999). ANSI B4.1 is investigated here because of its general straightforwardness and expansive materialness, however the mold originator may adjust to whatever standard is generally fitting. In this strategy, rectangular individuals with width, W, and length, L, are demonstrated as a roundabout part with clear distance across, D.

where C is a coefficient relating to the lower and furthest cutoff for the male or female segment given by worldwide norms. Table 12.1 gives coefficients to locational-obstruction fits (LN1 to LN3) and drive-impedance fits (FN1 to FN3). Locational-impedance fits are utilized when the exactness of area is basic and the parts require sidelong unbending nature. Be that as it may, locational-obstruction fits don’t give huge maintenance power in the stature course, so the parts should be gotten in the tallness heading to another segment through screws or different methods. FN1 to FN3 compare to drive fits with expanding impedance and requiring expanding addition powers. While drive fits give semi perpetual gatherings, mold plans for the most part give screws or different intends to decidedly holding the segments in the tallness heading.

This article is from https://www.injectionmouldchina.com/

#2-shot mould made in china#china automobile molds manufacturers#china industrial injection mold manufacturers#china unscrewing mold manufacturer#chinese injection moulding companies#electric cars plastic accessories vacuum forming manufacturers china#high-quality double coler mold parts#injection mould manufacturers in china#injection moulding china#injection moulding services#injection moulding services china#oem/odm industrial injection moulding design factory#oem/odm injection mold lifter#oem/odm injection mold tooling cost#plastic injection moulded components china#precision plastic injection mold pricelist#terracotta brick paint#Plastic Mold

0 notes

Text

Innovating with the help of China's custom plastic injection molding, creating the future of today!

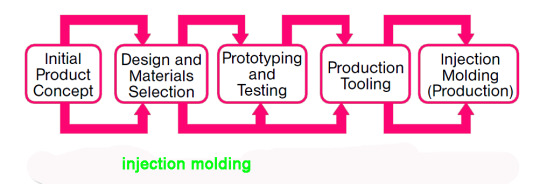

The use of Custom Plastic Injection Molding in China is increasingly becoming popular among businesses looking for cost-effective and efficient ways to manufacture parts and components. As one of the world’s leading countries in plastic manufacturing, China is the perfect place to make use of the technology. Injection molding is an effective way to produce large volumes of custom plastic parts cost-effectively.

Injection molding is used to produce a wide range of plastic products, including auto parts, medical devices, electrical components, consumer products, and more. The process involves injecting molten plastic into a mold to form a specific shape. This shape is then cooled and ejected from the mold. The process can be automated to produce high volumes of parts quickly and easily.

The availability of custom plastic injection molding in China is attractive to businesses looking to outsource their production. By utilizing Chinese injection molding services, companies can reduce their cost of production significantly. China has a large number of experienced and talented injection molders, and the cost of labor is significantly lower than in other countries. In addition, many Chinese companies offer design assistance, which can help to reduce the cost of developing the part or product.

Injection molding services in China can also provide businesses with access to a wider range of materials and colors. China plastic injection molding companies are well-versed in utilizing different materials, such as nylon, polyethylene, and ABS, and can offer a variety of colors to choose from. It allows businesses to create customized products with the exact look they are looking for.

In addition to cost and material advantages, companies utilizing custom plastic injection molding in China are also able to benefit from faster production times. Chinese injection molders are experienced and efficient & can typically produce high-quality parts and products in a fraction of the time it would take in another country. It is due to the level of expertise and experience available in China also the availability of advanced technology and equipment.

For businesses looking to reduce their production costs, custom China injection molding is an attractive option. The cost savings, access to a wider range of materials, and faster production times make it an ideal choice for companies looking to produce parts and components. With its experienced and talented injection molders& its wide range of materials and colors, China is the perfect place to outsource custom plastic injection molding.

Read Also: AUTO UNSCREWING MOLDS FOR THREADED CAP

#Custom Plastic Injection Molding#China plastic injection molding#China injection molding#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds

1 note

·

View note

Text

China Injection Mold Cost Many buyers who purchase injection molds from China are solely focused on saving money. However, this isn’t the right attitude to take, since you’ll ultimately want a mold that works properly and is reliable, instead of just being cheap. How much a plastic mold tool will cost is dependent on several different factors. You should, therefore, request the information when getting a quote.The checklist below details the various areas of interest that you need to consider when purchasing a mold: How many check dimensions are required on the print- this will determine the cavity complexity, as well as the part tolerances Surface finishes which will be necessary Number of necessary tight tolerances and their requirements Any required functions in mold operating, such as unscrewing or lifters. Balanced cooling requirements- these can determine tolerances. Part resin Number of cavities in the part, determined by tolerances and part volume required Tool type, e.g. hotrunner, two plate, or three plate the size and complexity of its parts, the gating direction the tools steel used the mold accessories brand an estimated cycle time and a guaranteed lifespan. For instance, a three plate or hotrunner may be more expensive at first, but unlike two plate tools, they don’t need anyone to operate them or separate the runner. This will mean that you save money on the piece part price, even though the tool cost is higher. With this information in hand, you will be able to calculate the costs for yourself, and see just why some companies set their prices higher or lower. When you have answered all of those questions, you’ll want to figure out the amount and type of materials and components that you’re going to need, and use supplier catalogs to come up with a total cost. While all of these costs will eventually be recouped once a certain number of parts have been produced, it’s important to note that the real cost will also have to take into account the manufacturing process and the molding cycle as well. Don’t put the full responsibility for tool buying on your purchasing department, though. That’s because there will likely be factors that they don’t fully understand. Make sure that you determine and specify your tool requirements in full before you start the buying process. Ideally, you’ll want to choose the right tool for the lowest cost, produced by an experienced and knowledgeable molder. Why those important Part size- bigger parts mean a bigger mold, which means that the steel cost for the injection mold will be increased. Part design- the more complex a part is, the more detailed the mold has to be. Some complicated parts will require special features to be added, such as lifters or sliders. You should therefore be open to advice from your mold maker, and see if there’s anywhere that you can alter the part design to save on injection mold costs. Materials-depending on the part material of choice, the injection mold will have to be made of a particular material too. For instance, if a corrosive plastic like PVC is to be used, then the mold will have to be stainless steel to avoid any damage- which will ultimately bump the price up. Part finish requirements- where parts have high gloss surface requirements, then more expensive steel and precise technical polishing will be vital, which further add to the price. Production volume- higher volume molds need more cavities, and so the mold will be larger. They also require a higher grade of steel to last for longer, and this has an impact on the injection mold cost. Country of manufacture- different countries have different wage rates. If your mold is made in a country where labor costs are low, then you’ll naturally save money. In China, the average cost of an injection mold is around 40% less than in western nations. http://res.cloudinary.com/dl8a9jvpa/video/upload/q_36/v1515562285/Gate_Locations_xsub9b.mp4

0 notes

Text

Your Reliable China Plastic Mold Manufacturers

If you are planning or looking for a reputable company to supply you with PPR, PVC, PE and PP custom injection moulds, then go no further! LOXIN Mold has been producing these fitting system moulds for more than ten years even before the buildup of the branch company. We specialize in manufacture and design in all types of molds including pipe fittings. In every year LOXIN Mold Design Company provides more than 350 pipe fitting molds to the competitive world market.

Contents

Why work with LOXIN Mold

How Much China Plastic Injection Mold Cost?

How Much Cost For Quality China Plastic Injection Mold ?

How LOXIN’s Plastic Injection Molding Process Works

Your Unmateched Partner in Mold Making-LOXIN Mold

Your Reliable China Plastic Mold Manufacturers

Why work with LOXIN Mold

In order to enhance the production of high-quality fittings, we implemented a control system with strict inspection for every type of fitting system product we manufacture. Besides, we equipped effective control of mold dimension and high-tech unscrewing system monitored by a motor (multi-direction moulds connector).

In China there are various injection mold manufacturing companies hence determining the reputable one to work with can be a hassle. Not all Plastic Mold Manufacturer provide genuine products or even offer various services at cost-friendly prices: you should be careful in choosing the best company. LOXIN many years in molding profession has proved and tested its reliability and trust in the production of custom injection molds to the worldwide clients by offering exemplary services: we transparently provide our products and services.

Quality services and pricing

Our personnel are highly skilled and offer quality services making sure our clients are satisfied. Our primary objective is to ensure that all customers are fully satisfied. Moreover, we are always ready even to adjust to meet the clients’ demands.

LOXIN managers are friendly and interact directly to clients if they want a supply of products without involving intermediaries. Other companies may hire sales ladies for products promotion and pay them from a commission which can in turn call for more costs as the amount is included in products prices. All our products and services are cost-friendly and affordable to everyone!

What makes LOXIN Molds exceptional?

LOXIN uses high precision manufacturing equipment, give the steel material a particular treatment, enhance strict control of molds dimension and also use a top mentality control system. Our many years of experience in the field made us the leading Plastic Mold Suppliers in Asia, Europe, Africa, Mid-east and also USA countries.

In every year, we internationally export over 500 fitting moulds which are highly standardized. Every market appreciates our high-quality shapes. Therefore, we try as much as possible in ensuring that our proficiency and expertise lies in supply rate.

Molds making

Core and hollow steel utilize stavax S420, hardened with HRC.48-52, collapsible core assembly.Dia.32mm, utilize double equipped tool: a rough tooling-hardened precision tool to minimize mould size without affecting the product quality limit switch for the pusher stroke mold with life control and life extension, the best cooling framework for top productivity and a folding form of the collapsible core system with multiple directions.

Conclusion

At LOXIN, we warmly welcome our clients and aim at building a long term relationship through offering the best and quality PPR, PVC, PE, PP molding and diamond service at any time. Considering us as your partner in mold products supply will be a wise decision. Contact us or visit http://www.loxinmold.com/ for more information.

#injection moulding#injection mold maker#plastic injection molding company#plastic mold maker#plastic mold manufacturer

0 notes

Photo

Why choose LegenDay Silicone Food Covers?

Silicone stretch lids is an miraculous creation, compare with plastic wrap, it is safe, convenience, easy use, save money and multifunction. also it is both a practical and thoughtful gift of sending to love, partner, parents, wife, family, friend at Christmas, Halloween, birthday, Mother's Day, Father's day, anniversary, Valentine's Day, Thanksgiving, etc.We are wholesale silicone food covers for several years, and we are silicone food covers manufacturer. Why choose LegenDay silicone stretch lids/wholesale silicone food covers manufacturer?

100% FOOD GRADE SILICONE: Our wholesale silicone food covers manufacturer are made of food grade silicone, identify by FDA safety certification, 100% Phthalate, Lead, Plastic and BPA free. Non-toxic, heat-resistant, stable, durable, soft texture, super stretchable & no deformation, reusable, anti-corrosion, dishwasher safe, freezer safe, completely safety and reliable direct touch food. LEAK PROOF & NON-SLIP: bowl lids have good sealing and adsorption ability, thickening and non-slip, stacking doesn't collapse, no leakage while side placement. keep fruits, vegetables, soup & drinks storage safery and fresh. food fresh covers has anti-slip effect, take it up won't drop, can easily help you unscrew the lid of bottles.

FIT VARIOUS SIZES & SHAPES: High stretch silicone is strong in plasticity, free folded, kneading, lifting. 12 pcs food covers(2.6“,3.7”,4.5“,5.7”,6.5“,8.3”), each size 2 pieces, can cover different sizes and shapes containers, bowls, cups, pots, glasses,foods, fruits, vegetables etc. silicone lids packed in one big reusable waterproof bag, easy storage/find and avoid dirty.We are silicone food covers manufacturer ,we wholesale silicone food covers. SAVE MONEY & ECO-FRIENDLY: This silicone elastic lids is reusable, no need to re-purchase expensive plastic wrap or tin foil, eco-friendly, save money and make kitchen tidy, no messy wrap, is wife's kitchen good helper.We are silicone food covers manufacturer ,we wholesale silicone food covers. MICROWAVE-SAFE: Our wholesale silicone food covers manufacturer can prevent foods from spattering while heating & prevent bad smell while storage foods in the refrigerator, prevent the loss of water and let you enjoy delicious food. 30 DAYS

Shenzhen LegenDay Technology Co., Ltd. is located in Minzhi, Longgang District, Shenzhen. It has more than 12 years of experience and technology in wholesale silicone food covers manufacturer, as well as supporting mold design/manufacturing technology, and continuously provides customers with high quality silicone wine stoppers wholesale. The main products are: silicone wallet, silicone coin purse, silicone stationery bag, silicone cosmetic bag,silicone wine stoppers wholesale, etc.

We are silicone food covers manufacturer ,we wholesale silicone food covers.If you need find wholesale silicone food covers manufacturer from china, please contact to us via Skype,E-mail etc.Just contact us! Skype : frank.bwy E-mail : Betty([email protected]). Tel : +86-0755-21004210. Whatsapp/Mob : +8613430834223. we would reply you in the short time ASAP.If you have any problem, just contact!

0 notes

Text

Custom Injection Molding Companies Offer Precise Molding Solutions

Injection Molding is one of the important manufacturing processes required for producing different types of spare parts for various applications and appliances by injecting molten material into a mould. This process can be performed with a host of materials – mainly metals, glasses, elstometers, confections, and most commonly thermoplastic and thermosetting polymers. In order to get precise solutions, you need to reach one of the top custom injection molding companies where experienced professionals are working dedicatedly to provide you complete peace of mind.

Need Plastic Molded Parts – Find the Top China Mold Maker

In order to fulfill your requirement to get the best range of plastic molded parts or anything else, you need to reach the top China mold maker, which is convenient and reliable for you to provide you access to reach the right one. Going online is one of the ideal and time-saving alternatives that will help you in reaching one of the top custom injection molding companies – where experienced professionals are working dedicatedly to provide you precise molding solutions. You have to go through the details, make a contact and leave rest of the work on experts working here.

What Kind of Services Are Offered by Top Custom Injection Molding Companies?

Reaching one of the top custom injection molding companies is an important decision to make. They can supply mass production, assembly and secondary processing, with good quality system to monitor all operations performed in a controlled manner and effectively ensures final products' quality. The injection molding department has the capability to operate 24 hours a day, ensuring the on-time production and delivery of every part.

Whether you are looking for hot runner system injection molding, double color injection molding or Gas-assisted injection molding, you will get precise solutions from the selected and top custom injection molding companies where experienced professionals are working dedicatedly to provide you complete solutions.

Get Precise Molding Solutions from the Top Custom Injection Molding Companies

These reputed companies are involved in Nylon injection molding, plastic mold, unscrewing mold making, custom injection molding, plastic molded parts and different other types of works that need proper solutions and precise care for the duration of molding work. Their listen to your requirement carefully and then provide you the best solutions. Their main motive is your satisfaction and bringing to you precise molding solution and services.

You have to contact as per your requirement to experts at one of the top and selected custom injection molding companies and leave rest of the work on experts working there.

#Nylon injection molding#injection molding supplies#mold design services#plastic mold manufacturers china

0 notes

Text

Where Can You Get Premium Range Plastic Injection Mold Making Services In China?

Want to get hold of better plastic injection mold making services onto your hands? The TKB Mold Tools and Molding Solutions have classic experience in making plastic mold at premium quality. It is also one of the rare plastic mold maker brands to bring low cost mold products. Although it does charge quite a good amount of money for its service, you will land up with optimal and competitive quality which is better than a majority of the brands in china. TKB Mold is also one of the most experienced and trusted mold maker in China with quality grade Injection molding service for order.

The company excels out in its full domain of injection mold manufacturing and injection molding service including Auto Accessories, Injection Product, Over Molding Tooling, Unscrewing Plastic Molds, Engineering & Designing, Medical Products, Medical Device Tooling, Automotive Mold, Home Appliances, Plastic Mould, and other services. It brings a variety of plastic injection mold products like Plastic Injection Molding For Cover, Over molding For Medical devices, Custom Precision Plastic Mould, OEM Manufacturer Injection Molding, Home Appliance Injection Molds, China Plastic Parts Injection Mould and others. Thus, if you are looking for quality plastic injection mold making services in china, TKB Mold is your best choice to go for.

1 note

·

View note

Photo

New Post has been published on https://www.injectionmouldchina.com/warpage-prediction/

Warpage Prediction

At the point when the embellishment comprises of a solitary shut zone, the material inside the trim is in constant contact with the end goal that any nonuniform shrinkage and stresses over the part may just be settled all through of plane twisting of the part. Injection mould manufacturers in china know that such warpage requires clasping of the plane of the part, which can happen when: (S edge一 S center)> 0.44. (h/W) (h/W)

where h is the divider thickness of the trim, and Scenter and Sedge are the shrinkage rates at the middle and edge of the part, and W is the good ways from the middle to the edge of the embellishment. This clasping examination models the embellishment as an isotropic roundabout plate under uniform outspread edge pressure with a clasping pressure limit of.

As the past warpage investigations have appeared, warpage is brought about by nonuniform shrinkage because of temperature inclinations through the divider thickness of the formed part, pressure angles over the territory of the shaped part, or temperature slopes aCross the zone of the shaped part. These are the most widely recognized reasons for warpage, and have been treated by high-precision mould china with the least complex conceivable examination. In any case, there are different reasons for nonuniform shrinkage including direction and remaining pressure. For additional data, the intrigued form fashioner is alluded to the examination writing.

Sensibly exact warpage forecasts may likewise be gotten with PC recreation as recently talked about. oem/odm largest plastic injection molding companies gives the warpage forecast from PC recreation for the reproduction portrayed for Fig. 10.8. The outcomes recommend that the center of the part will bow down while the left and right sides of the bezel will bow upwards. The purpose behind this conduct is the upper surface of the bezel contains more material, and this upper surface is contracting not exactly the lower part of the ribs.

Given that warpage can be huge contrasted with shrinkage, shape fashioners may decide to make up for warpage by invert biasing the form surfaces dependent on anticipated or noticed warpage. This predisposition is some of the time alluded to as “Kentucky windage,” a shooting term that alludes to the changes a separation shooter must make to represent the breeze [26]. In this manner, Kentucky windage in form configuration alludes to the shaping of the form cavity surfaces with the end goal that after twisting the formed part smoothes to the ideal shape. The utilization of such predisposition isn’t without discussion, since it acquires cost in the forming of shape cavity surfaces while likewise intrinsically changing the warpage and auxiliary conduct of the formed parts. Therefore, it stays a to some degree uncommon practice in oem/odm medical injection mold factory.

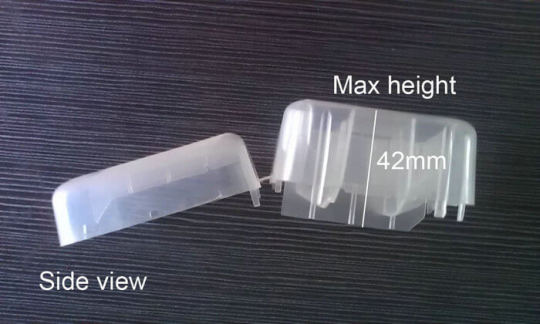

Break down warpage accepting that the cup top is focus gated and shaped with ABS at a pressing weight of 66 MPa at the focal point of the part and 0 MPa at the external edge. To assess the warpage, it is first important to compute the shrinkage rates and check the clasping basis. Given the 66 MPa pressing weight and a temperature of 132°C, the straight shrinkage at the middle will be 0.3 1% at the middle. At the edge, the weight of 0 MPa and temperature of 132°C gives a direct shrinkage of 1.66 %. Given that the cup is 2 mm in thickness and 81 mm in breadth, the clasping measure is expressed.

This article is from https://www.injectionmouldchina.com

#china automobile molds manufacturers#china fundamentals of plastic mould design#china gas assisted mould suppliers#china industrial injection mold manufacturers#china injection mold maker#china precision mould manufactory#china two shot mold manufacturer#china unscrewing mold manufacturer#double coler mold parts#high precision mould china#high precision plastic making mould china#injection mold makers china#injection mold services china#injection molding cost china#injection mould manufacturers in china#injection mould tooling china#injection moulding explained#injection moulding services#medical instrument mould made in china#mold design services china#mould handling systems#oem/odm largest plastic injection molding companies#oem/odm medical injection mold factory#plastic mould manufacturers factory#precision plastic injection mold pricelist#pvc supply water fitting mould maker#seven holes pouring mould factory#Plastic Mold

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/condition-heating/

Condition Heating

Given the huge warm mass of the mold and the cooling framework, another procedure for injection moulding services china to control the shape divider is to utilize conduction radiators at or close to the outside of the shape. One plan is appeared in high-quality double coler mold parts; this was created to give a smooth surface completion aside of a frothed plastic item. The shape comprises of a hole embed 12 and a center addition 10, both including an organization of cooling lines 34 and 36 according to regular form plan. A slight metallic sheet 38 adjusts to the outside of the form pit 12, with a flimsy protecting layer of oxide kept between the sheet and the cavity embed. The meager metallic sheet 38 incorporates an initial 40 to convey the plastic liquefy from the sprue 32 to the shape hole 14. Electrical link connections 46 and 48 join the sheet 38 to low voltage, high flow electric links 50 and 52.

Only preceding mold conclusion, the switch 54 is shut to pass a high current through the sheet 38. In this plan, a 0.2 cm thick steel plate was utilized with a length and width of 30 cm and 10 cm, separately. To investigate the warming prerequisites, consider a commonplace formed part with a warmth limit of 2000 J/kg°C, a 3 mm thickness, a liquefy temperature of 240°C, a launch temperature of 100°C, and a process duration of 30 s. For this situation, the warmth load forced on the form by the ABS liquefy is 28 kW/m2; given that the cooling lines are put on different sides of the shape, the cooling power is around 1.4 W/cm2. Accordingly, a 30 cm by 10 cm warming plate must convey in any event 420 W basically to beat the warmth move to the cooling lines before the temperature of the warming plate starts to increment essentially.

It is noticed for china industrial injection mold manufacturers that conduction radiators are broadly accessible with power densities surpassing 250 W/cm2. Such a radiator, whenever set on the outside of a shape pit, could expand a 0.2 cm by 30cm by 10 cm steel plate’s surface temperature by 200°C in 6 s, Attempts have been made to fuse higher force, slim movie warmers straightforwardly into the mold surface. Notwithstanding, such endeavors to consolidate conduction radiators into molds have not been generally fruitful for in any event three reasons. To begin with, the huge, cyclic weight forced on the heater(s) by the polymer dissolve will in general exhaustion the radiators. Second, it is hard to design the heater(s), form cavity, and cooling channels to give the uniform divider temperature needed to convey tasteful surfaces with tight dimensional controls. Third, the radiators are situated between the shape depression and the cooling channels, will in general lessen the pace of warmth move during cooling, thus expand the cooling time. Gauge the energy needed to warm the form center and cavity embeds portrayed in pom moulding parts manufacturers china for a beat cooling measure. To gauge warm energy, the center and depression supplements can be displayed all together of steel with a width and length of 100 mm and a profundity of 200 mm. Given a thickness of steel of 8000 kg/m3, the mass of the additions assessed as 16 kg.

This article is from www.injectionmouldchina.com

#2-shot mould made in china#china high-precision mould suppliers#china industrial injection mold manufacturers#china mould company#china mould make#china pipe fitting mold manufacturers#china unscrewing mold manufacturer#electric cars plastic accessories vacuum forming manufacturers china#hdpe pipe fitting mould maker#high-quality double coler mold parts#household molds made in china#injection mould manufacturers in china#injection moulding services china#medical instrument mould made in china#plastic injection moulded components china#plastic molded part#pom moulding parts manufacturers china#precision plastic injection mold pricelist#pvc fitting mould maker#Plastic Mold

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/cooling-time-estimation/

Cooling Time Estimation

The cooling time is characterized as the measure of time required after the mold is filled for the plastic to turn out to be adequately unbending to launch. The accompanying hypothesis is given to help the assessment of the hypothetical least cooling time for the mould manufacturers factory. By and by, cooling times can be significantly longer than those anticipated by examination for two reasons. To start with, the accompanying examination accepts flawless warmth conduction between the plastic and the form, while there is known to be a considerable warm contact obstruction between two unique materials. The cooling time can be additionally expanded during injection moulding services china by slim holes, which open up between the contracted trim and the form dividers. Second, the cooling time is regularly not driven by the inflexibility of the part, yet rather by quality prerequisites that may require the decay to stretch out the cooling time to accomplish the particulars.

Since there is next to no volumetric dissolve stream of the liquefy after the form filling stage, there is almost no warmth convection. Thus, the exchange of warmth between the plastic and the form is administered by the transient warmth conduction condition:

Here, T is the temperature, t is the time, 2 is the measurement in the thickness bearing, k is the warm conductivity, ρ is the thickness, and Cp is the particular warmth. The warm diffusivity is basically a proportion of a material’s capacity to send heat comparative with its capacity to store heat. For more quick warmth move, form materials with higher warm diffusivity are wanted, however these materials (e. g., aluminum) will in general have lower basic properties than steel as recently plotted in china high-precision mould suppliers.

The transient warmth conduction Eq. 9.2 is a subsequent request, allegorical, incomplete differential condition. Logical answers for transient warmth move have been produced for straightforward calculations, for example, plates and bars. The cooling plastic can be demonstrated as a limited chunk with the temperature of the dissolve at the centerline of the form cavity assessed from an arrangement development:

Taking the initial six terms, m∈[0,5], in the arrangement, a plot of the plastic’s temperature at the centerline is appeared as an element of the cooling time in china industrial injection mold manufacturers. The temperature of the plastic at the focal point of the trim is equivalent to the underlying melt temperature toward the beginning of the cooling cycle. After a short pause, the soften at the focal point of the trim starts to cool. In the end, the plastic will move toward the temperature of the form coolant.

To decide the cooling time, it is important to give some rule that demonstrates when the trim is sufficiently unbending to be shot out from the shape. One sensible methodology is to think about the modulus of the material, which is a proportion of the material to oppose avoidance. The powerful modulus of the material as it cools is appeared on the right-hand hub of injection moulding services. It tends to be seen that as the plastic soften approaches the shape coolant temperature, the modulus additionally moves toward a consistent state esteem. The temperature at which the material has noteworthy unbending nature is identified with the warmth bending temperature (HDT) or the avoidance temperature under burden (DTUL) as portrayed by standard tests, for example, ASTM D648. Condition 9.4 can be settled to give the cooling time as an element of the liquefy, coolant, and discharge temperatures. This article is from https://www.injectionmouldchina.com

#2-shot mould made in china#china automobile molds manufacturers#china bi-injection mould manufacturers#china high-precision mould suppliers#china household molds#china plastic drilled machining parts#china two shot mold manufacturer#china unscrewing mold manufacturer#cost of injection molding china#electric cars plastic accessories vacuum forming manufacturers china#high-quality double coler mold parts#injection molding cost china#injection mould manufacturers in china#injection moulder ltd#injection moulding services#injection moulding services china#mould handling systems#mould manufacturers factory#plastic injection moulded components china#plastic mould quotation#pom moulding parts manufacturers china#Plastic Mold

0 notes

Text

Auto Unscrewing Molds for Threaded Cap

Advantage of Auto Unscrewing Molds

HS Mold, one of leading mold manufacturers in China, develops and produces custom plastic parts or components with internal and external threads via auto unscrewing molds across a variety of industries. Withinjection moldunscrewing mechanism, secondary or thread-cutting operations could be removed, thus reducing cycle time and part cost.

For decades, we design and manufactures high quality unscrew molds for Efficiency, Longevity and Performance. Tapping is considered as part of our value-added services. According to our technical practice, tapped threads tend to be weaker than injection molded threads. Therefore, plastic injection molding screw is an ideal option in the application of industrial design for screws that require tighter tolerances and stronger screws.

Why Auto Unscrewing Molds

For precisionplastic parts or components that have detailed threads, it is impossible to ejecting the part using knock-off methods. Threaded screw caps provide a tight and durable seal that keeps out dirt, moisture and other contaminants while protecting the threads from damage. To avoid thread damage during the process of injection molding, we must use unscrewing mold mechanism to unscrew the parts from the mold. We usually use collapsible cores to release the interal screws. External threads can be centered on the mold parting line or molded in both mold cavities/cores. However, external threads are prone to parting-line flash or mismatch and require slides or side actions.

Application of Auto Unscrewing Molds

All our plastic unscrew molds increase your speed, productivity and accuracy with higher cavitations and faster cycle times. And we could also develop 2k or 3k molds for customized threaded caps with different knurl counts or color options to match your exact needs. Our unscrewing mold designs can be used to manufacture a wide range of custom plastic parts or components including but not limited to below industry:

Bottle caps

Shampoo bottles

Pharmaceutical Supplies

Automotive parts

Nuts and bolts

Cosmetics packaging

Medical Supplies

Consumer goods

Sprinkler heads, lawn & garden parts

Container lids

We have developed techniques such as utilizing bearing support cores, robust carriage assemblies, and integral gear/core designs to make sure that our your Auto unscrew molds move at high speeds to clear molded parts quickly and move on to the next cycle immediately. We could make unscrew molds for customized threaded caps to fit standard, JIC, metric, American standard and other common thread styles.

Through the whole development process, HS Mold, injection mold suppliers China are here to collaborate and create with you. Contact us today to take your next screw project to the next level.

#mold manufacturers in China#plastic parts#injection mold suppliers China#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds

1 note

·

View note

Text

4 Steps To Help Getting An Accurate Plastic Mold and Plastic Parts Offer From China

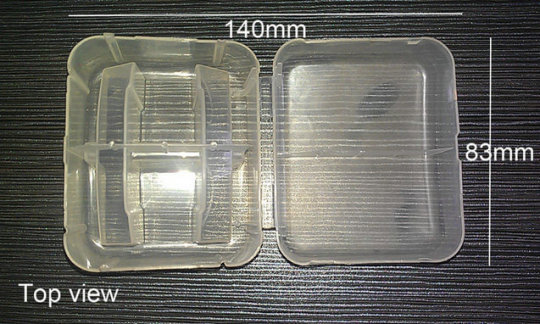

With the continuous improvement of mold manufacturing and mold workers' skill in China, more and more European and American companies have dropped their purchase orders to Chinese plastic mold factories. The continuous deepening of information exchanges between the two sides has greatly promoted China's mold industry development. It is simple to deal with China's mold and injection molding suppliers for those buyers who often purchase in China. But for those who first came into contact with this mold industry, it was a very troublesome thing, especially in dealing with China's mold factories outside of thousands of miles. Language and technical communication constitute two significant obstacles. Many people who bought customized plastic parts in China for the first time were completely unfamiliar with this industry. Also, this industry is technology-intensive. The quotation requires suppliers and buyers to have a good interaction. The most important is how the buyers express their ideas to the suppliers. It is precisely at this point that many buyers do not know how to handle it. They often ask the supplier for a price from the very beginning. In fact, the price given by the supplier at this stage is very inaccurate. I will introduce the preparation process before the quotation of molds and molded parts so that buyers can have a clear understanding. The manufacture of injection-molded parts is a very complicated process. The first is the manufacture of molds, followed by injection molding, and the second operation of injection-molded parts, which involves transferring a lot of information. The top priority is how the buyer expresses his product requirements clearly to the supplier. In many cases, suppliers are required to quote only in the case of a hand-drawn drawing. Sometimes there is no requirement for plastic materials. Buyers just mentioned adjectives like "soft "and "hard" to describe the stuff he wants. In fact, this is incorrect.

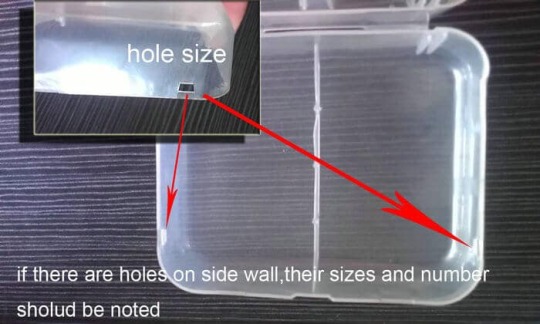

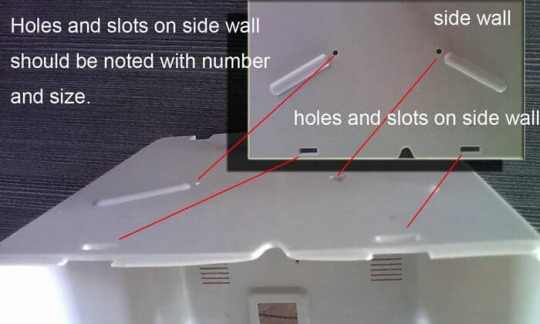

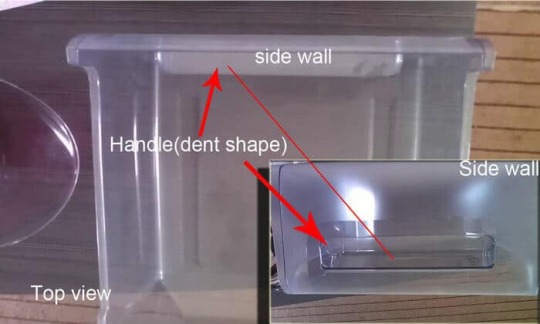

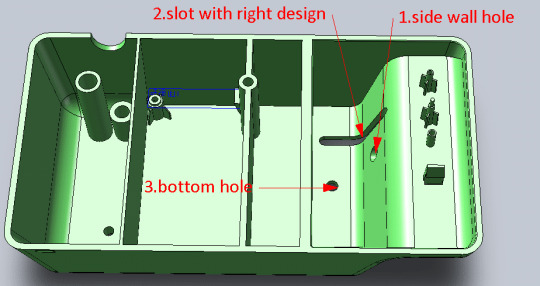

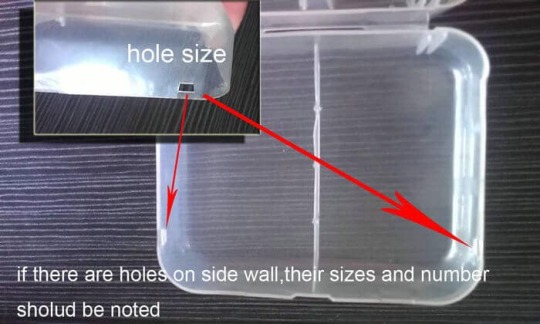

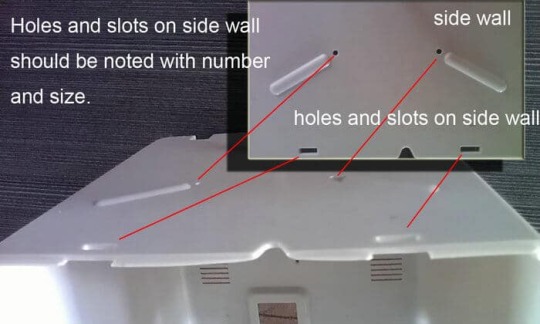

The side location difference above will lead to total different mould cost, 1. side hole high cost,2 and 3 location holes are better.

4 Steps for plastic mold quotation:

#Consult with experts

The correct way is to find an injection molding engineer or mold engineer around you to consult with them. This early investment is necessary, and this investment will be paid off in the future. Of course, I would be happy to provide you with this service, but at this time, it is challenging for me to quote you also. You should find a very experienced engineer and tell him, face to face, what you think, the requirements for the product, the quantity requirements, the assembly requirements, and so on. He will give you good advice based on your actual situation. During this period, he will tell you which plastic material to choose, how to design the product, how to assemble it, and how to arrange a reasonable quantity. #CAD design

After the above is completed, the 3D drawing design of the product can be performed. You can tell the design engineer your requirements in great detail. They will make the appropriate design according to your needs. #Rapid prototyping

After the preliminary design is completed, you should do rapid prototyping at this stage to check whether your design intent has been achieved for new developments or changes to the old product. Rapid prototyping allows inspection of the appearance, assembly, and strength of a designed product. Modify the problematic design and make a new 3D printing. Repeat this process until the final 3d printing meets the requirements. This cost is relatively small, with a short time, and it can avoid costly and time-consuming mold changes later. In China, generally speaking, the cost of a small 3D printing is about 50 to 60 US dollars. This step may save you thousands of dollars later. #Quotation

After this stage, you can give your potential suppliers a chance to quote the changed design. My article on this topic is very detailed about how to deal with Chinese suppliers.

How to copy existing products

Of course, if you want to copy existing products at this stage, you can send the product directly to the supplier and tell them your specific requirements. Fees can be deducted after the transaction. If you have only one sample and inconvenient to send it, you can take a picture of the sample. According to the three-view standard, you show suppliers a sample photo. Mark the position and size of the undercut, dents, and holes in each direction on the picture. In the photo, the size of the product is identified in detail, i.e., the length, width, and height. In theory, the six sides of the product must be photographed. The more detailed photograph is, the better it is. #Case 1 " order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]# Case 2

It is best to find the specifications of plastic materials on the sample and indicate the location and size of the gate.

These plastic materials usually appear in the form of a triangle. In the end, you still have to send this sample to your final supplier to facilitate their design.

4 main points related to plastic mold and injection part price

- Quantity The number of purchases dramatically determines the price of the product and the plastic mold. As long as the product is only 10,000, do not put forward a requirement of 500,000 because 10,000 shoots required mold steel, mold design, and processing methods are entirely different from the 500,000 requirements. If the number of products is 10,000, the four-cavity mold can meet the requirements. If it is 500,000, the mold will require 10, 12 cavities or higher. The more cavities are, the higher standards of the steel material and processing requirements will be. This will lead to a significant increase in the material cost and processing cost of the mold. The considerable quantity shares these costs. If the quantity is small, then the cost-sharing of each product will be high. A case I have encountered a case where there is an ABS molded product. The annual demand is 1500 sets. It is internally threaded and needs to be unscrewing. If you need a full-automatic unscrewing mold, the cost will be high, and if the thread is made into an insert. The cost of the mold is only about 2/3 of the fully automatic mold cost, and the increase in injection molding cost is only small. - Color In general, dark-colored products need lower prices than light-colored products. Because the regrind material can be used in some cases, if it is a white or transparent product, the regrind material is difficult to use, which will increase the supplier's raw material costs. Frequently, the runner material and the new material have the same effects. The barrel of the injection molding machine is sometimes not so clean, so sometimes other colors will mix in. If the product requires transparency or white, this product is defective. If it is a dark color or even black, it cannot be seen. This product is good. - Tolerance As we all know, the processing cost of a loose tolerance plastic part is much lower than that of the tight one. Molds with tight tolerances have very stringent requirements for processing and mold steel and even require a unique injection molding process. - Plastic materials In general terms, the plastic we choose should be conventional plastics, not engineering plastics. Nylon66 flare-retardent grade "v0" price is more than four times the conventional PP plastic. The cost of the ordinary ABS is 1.5 times the price of PP. If it is mass production, the cost difference is great. Some plastics are corrosive, so there is a higher demand for the steel of the mold. This will also increase the manufacturing cost of the mold. There are also higher requirements for mold maintenance. The price of the steel s136 level is more than five times that of the steel p20. Among the three methods mentioned above(autocad files, samples photograph and samples), sending supplier samples directly is the best method. In this way, the molder can clearly know the product's structure and can also find out the structure of the previous mold. Research on off-the-shelf samples can avoid many detours in mold building and injection molding products. In short, before the quotation, the more the supplier knows your requirements and the specific structure of the product, the better it is so that the accuracy of the quotation can be guaranteed to the greatest degree. At the same time, it ensures the smooth progress of the project.

How To Buy The Plastic Mold Easier

You might consider it was challenging to purchase an injection mold because there will be a great deal of to and fro between purchaser and molder before when the last item is concluded on. Nevertheless, the few suggestions here can help conserve lots of time and help make the entire procedure a bit simpler.

- Produce an RFQ that explores a wide range of specifics. As experienced as mold makers are usually, they won't manage to go through your head when considering what you're interested in. Consist of as numerous details as possible during this period, like the variety of cavities, the material, the required life expectancy of your mold, and any specific warranties you may require. Should you aren't very confident on such subjects, then inform your mold maker, and they will be ready to show you how to choose what's proper for your requirements. The more precise you come up with your RFQ, the more correct an offer you will get for your efforts. - Be honest about the reason why you need an offer. Should you require an overall quote to spread to a different unit, then let the mold maker fully understand- they are going to get back to you then rapidly. Developing a precise quotation can acquire much time, and it's not considered to misuse the mold maker's time if you don't require too much information or when you won't actually get from them. - Don't "STEAL" a mold maker's property. The information and recommendations provided by your mold maker keep on being their own intellectual property- you can't merely bring these tricks to other people to get it done. Should you come up with another moldmaker, in that case, consider their recommendations agreeable - not just is employing someone else's suggestions, it is not fine. However, it may also obfuscate the minds of your chosen mold maker, who won't comprehend precisely why those recommendations were created initially. - Try to develop a relationship with your mold maker. Simply by doing business tightly with your moldmaker when considering costs, schedules, and component amount anticipations, you will have the know-how to behave as a crew to attain better outcomes over time. - Have an Open Door Policy with your mold maker overall course. Many mold makers will love to present routine development information and maintain you up-to-date around the most recent advancements with your construct. It's essential to understand things are all moving to routine fully, so when you require any specific details, make it a point to inquire about what allows you to relax. - You should definitely pay on time. Most mold makers get the job done to constrained resources and will need costs to be settled before they can move forward with your project. Should you postpone paying, then you certainly won't receive a mold by the due date - it's so simple as that. Various mold makers will present diverse settlement strategies, so meet with these people to develop a strategy that is effective for the two of you. - A modification of your component structure will almost certainly indicate altering the injection mold as well. Should you change your component structure as the injection mold is being developed, you won't obtain the mold at the cost offered or to the primary schedule. Any modifications indicate the mold must be modified as a result, which increases both the expense and the duration of the mold construct. - Recognize ahead of time when mold will be ready. There are various explanations on a finalization time - some may vary from once the final settlement is completed to the time you be given a trial component to the delivery of the finalized item. Typically, an injection mold is recognized as finished when it is in a position to create the component it is for. The vast majority of mold makers will be ready to come up with tiny modifications to ensure a component as outlined by design. If these measurements alter later hanging around, in that case, the injection mold should be regarded as finished - the actual modifications should be given money via an ECO. - If a product is an unreasonably low price, you will typically find an explanation for that. While you will see mold makers on the market who present you with a cheaper-than-average price for a top-notch product or service, we will see many others who present reductions as they spend less money on their own. Over time, it's preferable to pay big money for a high-quality product or service instead of obtaining headaches by using a mold that doesn't meet your requirements. When you buy an injection mold, that age-old proverb is unquestionably correct - it gives you everything you pay money for. Any specifically shaped parts that you develop are only just like the mold employed to manufacture them, which means you should make certain that plastic mold is flawlessly designed for your requirements before purchasing it. Read the full article

0 notes

Text

4 Steps To Help Getting An Accurate Plastic Mold and Plastic Parts Offer From China

With the continuous improvement of mold manufacturing and mold workers' skill in China, more and more European and American companies have dropped their purchase orders to Chinese plastic mold factories. The continuous deepening of information exchanges between the two sides has greatly promoted China's mold industry development. It is simple to deal with China's mold and injection molding suppliers for those buyers who often purchase in China. But for those who first came into contact with this mold industry, it was a very troublesome thing, especially in dealing with China's mold factories outside of thousands of miles. Language and technical communication constitute two significant obstacles. Many people who bought customized plastic parts in China for the first time were completely unfamiliar with this industry. Also, this industry is technology-intensive. The quotation requires suppliers and buyers to have a good interaction. The most important is how the buyers express their ideas to the suppliers. It is precisely at this point that many buyers do not know how to handle it. They often ask the supplier for a price from the very beginning. In fact, the price given by the supplier at this stage is very inaccurate. I will introduce the preparation process before the quotation of molds and molded parts so that buyers can have a clear understanding. The manufacture of injection-molded parts is a very complicated process. The first is the manufacture of molds, followed by injection molding, and the second operation of injection-molded parts, which involves transferring a lot of information. The top priority is how the buyer expresses his product requirements clearly to the supplier. In many cases, suppliers are required to quote only in the case of a hand-drawn drawing. Sometimes there is no requirement for plastic materials. Buyers just mentioned adjectives like "soft "and "hard" to describe the stuff he wants. In fact, this is incorrect.

The side location difference above will lead to total different mould cost, 1. side hole high cost,2 and 3 location holes are better.

4 Steps for plastic mold quotation:

#Consult with experts

The correct way is to find an injection molding engineer or mold engineer around you to consult with them. This early investment is necessary, and this investment will be paid off in the future. Of course, I would be happy to provide you with this service, but at this time, it is challenging for me to quote you also. You should find a very experienced engineer and tell him, face to face, what you think, the requirements for the product, the quantity requirements, the assembly requirements, and so on. He will give you good advice based on your actual situation. During this period, he will tell you which plastic material to choose, how to design the product, how to assemble it, and how to arrange a reasonable quantity. #CAD design

After the above is completed, the 3D drawing design of the product can be performed. You can tell the design engineer your requirements in great detail. They will make the appropriate design according to your needs. #Rapid prototyping

After the preliminary design is completed, you should do rapid prototyping at this stage to check whether your design intent has been achieved for new developments or changes to the old product. Rapid prototyping allows inspection of the appearance, assembly, and strength of a designed product. Modify the problematic design and make a new 3D printing. Repeat this process until the final 3d printing meets the requirements. This cost is relatively small, with a short time, and it can avoid costly and time-consuming mold changes later. In China, generally speaking, the cost of a small 3D printing is about 50 to 60 US dollars. This step may save you thousands of dollars later. #Quotation

After this stage, you can give your potential suppliers a chance to quote the changed design. My article on this topic is very detailed about how to deal with Chinese suppliers.

How to copy existing products

Of course, if you want to copy existing products at this stage, you can send the product directly to the supplier and tell them your specific requirements. Fees can be deducted after the transaction. If you have only one sample and inconvenient to send it, you can take a picture of the sample. According to the three-view standard, you show suppliers a sample photo. Mark the position and size of the undercut, dents, and holes in each direction on the picture. In the photo, the size of the product is identified in detail, i.e., the length, width, and height. In theory, the six sides of the product must be photographed. The more detailed photograph is, the better it is. #Case 1 " order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]# Case 2

It is best to find the specifications of plastic materials on the sample and indicate the location and size of the gate.

These plastic materials usually appear in the form of a triangle. In the end, you still have to send this sample to your final supplier to facilitate their design.

4 main points related to plastic mold and injection part price

- Quantity The number of purchases dramatically determines the price of the product and the plastic mold. As long as the product is only 10,000, do not put forward a requirement of 500,000 because 10,000 shoots required mold steel, mold design, and processing methods are entirely different from the 500,000 requirements. If the number of products is 10,000, the four-cavity mold can meet the requirements. If it is 500,000, the mold will require 10, 12 cavities or higher. The more cavities are, the higher standards of the steel material and processing requirements will be. This will lead to a significant increase in the material cost and processing cost of the mold. The considerable quantity shares these costs. If the quantity is small, then the cost-sharing of each product will be high. A case I have encountered a case where there is an ABS molded product. The annual demand is 1500 sets. It is internally threaded and needs to be unscrewing. If you need a full-automatic unscrewing mold, the cost will be high, and if the thread is made into an insert. The cost of the mold is only about 2/3 of the fully automatic mold cost, and the increase in injection molding cost is only small. - Color In general, dark-colored products need lower prices than light-colored products. Because the regrind material can be used in some cases, if it is a white or transparent product, the regrind material is difficult to use, which will increase the supplier's raw material costs. Frequently, the runner material and the new material have the same effects. The barrel of the injection molding machine is sometimes not so clean, so sometimes other colors will mix in. If the product requires transparency or white, this product is defective. If it is a dark color or even black, it cannot be seen. This product is good. - Tolerance As we all know, the processing cost of a loose tolerance plastic part is much lower than that of the tight one. Molds with tight tolerances have very stringent requirements for processing and mold steel and even require a unique injection molding process. - Plastic materials In general terms, the plastic we choose should be conventional plastics, not engineering plastics. Nylon66 flare-retardent grade "v0" price is more than four times the conventional PP plastic. The cost of the ordinary ABS is 1.5 times the price of PP. If it is mass production, the cost difference is great. Some plastics are corrosive, so there is a higher demand for the steel of the mold. This will also increase the manufacturing cost of the mold. There are also higher requirements for mold maintenance. The price of the steel s136 level is more than five times that of the steel p20. Among the three methods mentioned above(autocad files, samples photograph and samples), sending supplier samples directly is the best method. In this way, the molder can clearly know the product's structure and can also find out the structure of the previous mold. Research on off-the-shelf samples can avoid many detours in mold building and injection molding products. In short, before the quotation, the more the supplier knows your requirements and the specific structure of the product, the better it is so that the accuracy of the quotation can be guaranteed to the greatest degree. At the same time, it ensures the smooth progress of the project.

How To Buy The Plastic Mold Easier

You might consider it was challenging to purchase an injection mold because there will be a great deal of to and fro between purchaser and molder before when the last item is concluded on. Nevertheless, the few suggestions here can help conserve lots of time and help make the entire procedure a bit simpler.

- Produce an RFQ that explores a wide range of specifics. As experienced as mold makers are usually, they won't manage to go through your head when considering what you're interested in. Consist of as numerous details as possible during this period, like the variety of cavities, the material, the required life expectancy of your mold, and any specific warranties you may require. Should you aren't very confident on such subjects, then inform your mold maker, and they will be ready to show you how to choose what's proper for your requirements. The more precise you come up with your RFQ, the more correct an offer you will get for your efforts. - Be honest about the reason why you need an offer. Should you require an overall quote to spread to a different unit, then let the mold maker fully understand- they are going to get back to you then rapidly. Developing a precise quotation can acquire much time, and it's not considered to misuse the mold maker's time if you don't require too much information or when you won't actually get from them. - Don't "STEAL" a mold maker's property. The information and recommendations provided by your mold maker keep on being their own intellectual property- you can't merely bring these tricks to other people to get it done. Should you come up with another moldmaker, in that case, consider their recommendations agreeable - not just is employing someone else's suggestions, it is not fine. However, it may also obfuscate the minds of your chosen mold maker, who won't comprehend precisely why those recommendations were created initially. - Try to develop a relationship with your mold maker. Simply by doing business tightly with your moldmaker when considering costs, schedules, and component amount anticipations, you will have the know-how to behave as a crew to attain better outcomes over time. - Have an Open Door Policy with your mold maker overall course. Many mold makers will love to present routine development information and maintain you up-to-date around the most recent advancements with your construct. It's essential to understand things are all moving to routine fully, so when you require any specific details, make it a point to inquire about what allows you to relax. - You should definitely pay on time. Most mold makers get the job done to constrained resources and will need costs to be settled before they can move forward with your project. Should you postpone paying, then you certainly won't receive a mold by the due date - it's so simple as that. Various mold makers will present diverse settlement strategies, so meet with these people to develop a strategy that is effective for the two of you. - A modification of your component structure will almost certainly indicate altering the injection mold as well. Should you change your component structure as the injection mold is being developed, you won't obtain the mold at the cost offered or to the primary schedule. Any modifications indicate the mold must be modified as a result, which increases both the expense and the duration of the mold construct. - Recognize ahead of time when mold will be ready. There are various explanations on a finalization time - some may vary from once the final settlement is completed to the time you be given a trial component to the delivery of the finalized item. Typically, an injection mold is recognized as finished when it is in a position to create the component it is for. The vast majority of mold makers will be ready to come up with tiny modifications to ensure a component as outlined by design. If these measurements alter later hanging around, in that case, the injection mold should be regarded as finished - the actual modifications should be given money via an ECO. - If a product is an unreasonably low price, you will typically find an explanation for that. While you will see mold makers on the market who present you with a cheaper-than-average price for a top-notch product or service, we will see many others who present reductions as they spend less money on their own. Over time, it's preferable to pay big money for a high-quality product or service instead of obtaining headaches by using a mold that doesn't meet your requirements. When you buy an injection mold, that age-old proverb is unquestionably correct - it gives you everything you pay money for. Any specifically shaped parts that you develop are only just like the mold employed to manufacture them, which means you should make certain that plastic mold is flawlessly designed for your requirements before purchasing it. Read the full article

0 notes

Text

4 Steps To Help Getting An Accurate Plastic Mold and Plastic Parts Offer From China

With the continuous improvement of mold manufacturing and mold workers' skill in China, more and more European and American companies have dropped their purchase orders to Chinese plastic mold factories. The continuous deepening of information exchanges between the two sides has greatly promoted China's mold industry development. It is simple to deal with China's mold and injection molding suppliers for those buyers who often purchase in China. But for those who first came into contact with this mold industry, it was a very troublesome thing, especially in dealing with China's mold factories outside of thousands of miles. Language and technical communication constitute two significant obstacles. Many people who bought customized plastic parts in China for the first time were completely unfamiliar with this industry. Also, this industry is technology-intensive. The quotation requires suppliers and buyers to have a good interaction. The most important is how the buyers express their ideas to the suppliers. It is precisely at this point that many buyers do not know how to handle it. They often ask the supplier for a price from the very beginning. In fact, the price given by the supplier at this stage is very inaccurate. I will introduce the preparation process before the quotation of molds and molded parts so that buyers can have a clear understanding. The manufacture of injection-molded parts is a very complicated process. The first is the manufacture of molds, followed by injection molding, and the second operation of injection-molded parts, which involves transferring a lot of information. The top priority is how the buyer expresses his product requirements clearly to the supplier. In many cases, suppliers are required to quote only in the case of a hand-drawn drawing. Sometimes there is no requirement for plastic materials. Buyers just mentioned adjectives like "soft "and "hard" to describe the stuff he wants. In fact, this is incorrect.

The side location difference above will lead to total different mould cost, 1. side hole high cost,2 and 3 location holes are better.

4 Steps for plastic mold quotation:

#Consult with experts

The correct way is to find an injection molding engineer or mold engineer around you to consult with them. This early investment is necessary, and this investment will be paid off in the future. Of course, I would be happy to provide you with this service, but at this time, it is challenging for me to quote you also. You should find a very experienced engineer and tell him, face to face, what you think, the requirements for the product, the quantity requirements, the assembly requirements, and so on. He will give you good advice based on your actual situation. During this period, he will tell you which plastic material to choose, how to design the product, how to assemble it, and how to arrange a reasonable quantity. #CAD design

After the above is completed, the 3D drawing design of the product can be performed. You can tell the design engineer your requirements in great detail. They will make the appropriate design according to your needs. #Rapid prototyping After the preliminary design is completed, you should do rapid prototyping at this stage to check whether your design intent has been achieved for new developments or changes to the old product. Rapid prototyping allows inspection of the appearance, assembly, and strength of a designed product. Modify the problematic design and make a new 3D printing. Repeat this process until the final 3d printing meets the requirements. This cost is relatively small, with a short time, and it can avoid costly and time-consuming mold changes later. In China, generally speaking, the cost of a small 3D printing is about 50 to 60 US dollars. This step may save you thousands of dollars later. #Quotation

After this stage, you can give your potential suppliers a chance to quote the changed design. My article on this topic is very detailed about how to deal with Chinese suppliers.

How to copy existing products

Of course, if you want to copy existing products at this stage, you can send the product directly to the supplier and tell them your specific requirements. Fees can be deducted after the transaction. If you have only one sample and inconvenient to send it, you can take a picture of the sample. According to the three-view standard, you show suppliers a sample photo. Mark the position and size of the undercut, dents, and holes in each direction on the picture. In the photo, the size of the product is identified in detail, i.e., the length, width, and height. In theory, the six sides of the product must be photographed. The more detailed photograph is, the better it is. #Case 1 " order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]# Case 2

It is best to find the specifications of plastic materials on the sample and indicate the location and size of the gate.

These plastic materials usually appear in the form of a triangle. In the end, you still have to send this sample to your final supplier to facilitate their design.

4 main points related to plastic mold and injection part price

- Quantity The number of purchases dramatically determines the price of the product and the plastic mold. As long as the product is only 10,000, do not put forward a requirement of 500,000 because 10,000 shoots required mold steel, mold design, and processing methods are entirely different from the 500,000 requirements. If the number of products is 10,000, the four-cavity mold can meet the requirements. If it is 500,000, the mold will require 10, 12 cavities or higher. The more cavities are, the higher standards of the steel material and processing requirements will be. This will lead to a significant increase in the material cost and processing cost of the mold. The considerable quantity shares these costs. If the quantity is small, then the cost-sharing of each product will be high. A case I have encountered a case where there is an ABS molded product. The annual demand is 1500 sets. It is internally threaded and needs to be unscrewing. If you need a full-automatic unscrewing mold, the cost will be high, and if the thread is made into an insert. The cost of the mold is only about 2/3 of the fully automatic mold cost, and the increase in injection molding cost is only small. - Color In general, dark-colored products need lower prices than light-colored products. Because the regrind material can be used in some cases, if it is a white or transparent product, the regrind material is difficult to use, which will increase the supplier's raw material costs. Frequently, the runner material and the new material have the same effects. The barrel of the injection molding machine is sometimes not so clean, so sometimes other colors will mix in. If the product requires transparency or white, this product is defective. If it is a dark color or even black, it cannot be seen. This product is good. - Tolerance As we all know, the processing cost of a loose tolerance plastic part is much lower than that of the tight one. Molds with tight tolerances have very stringent requirements for processing and mold steel and even require a unique injection molding process. - Plastic materials In general terms, the plastic we choose should be conventional plastics, not engineering plastics. Nylon66 flare-retardent grade "v0" price is more than four times the conventional PP plastic. The cost of the ordinary ABS is 1.5 times the price of PP. If it is mass production, the cost difference is great. Some plastics are corrosive, so there is a higher demand for the steel of the mold. This will also increase the manufacturing cost of the mold. There are also higher requirements for mold maintenance. The price of the steel s136 level is more than five times that of the steel p20. Among the three methods mentioned above(autocad files, samples photograph and samples), sending supplier samples directly is the best method. In this way, the molder can clearly know the product's structure and can also find out the structure of the previous mold. Research on off-the-shelf samples can avoid many detours in mold building and injection molding products. In short, before the quotation, the more the supplier knows your requirements and the specific structure of the product, the better it is so that the accuracy of the quotation can be guaranteed to the greatest degree. At the same time, it ensures the smooth progress of the project.

How To Buy The Plastic Mold Easier

You might consider it was challenging to purchase an injection mold because there will be a great deal of to and fro between purchaser and molder before when the last item is concluded on. Nevertheless, the few suggestions here can help conserve lots of time and help make the entire procedure a bit simpler.