#china injection mold maker

Explore tagged Tumblr posts

Photo

Dong Guan Sincere Tech is a top class and the best China injection mold maker and plastic mold supplier. With plenty of experience, they provide high-quality injection molds for various industries at highly affordable prices. Their team of experts is dedicated to delivering custom plastic molds, overmolding, and other services to meet the needs of their clients. Nothing beats them as the most affordable of all plastic mold makers and mould suppliers. Contact them today for top-quality mold solutions. For more information, please visit https://www.plasticmold.net/

0 notes

Text

Top Injection Mold Maker China

Looking for a reliable injection mold maker in China? We provide high-quality injection molding solutions, with a focus on durability and precision. Our experts ensure your projects are completed to perfection. Learn more about our services here: Injection Mold Maker China.

0 notes

Text

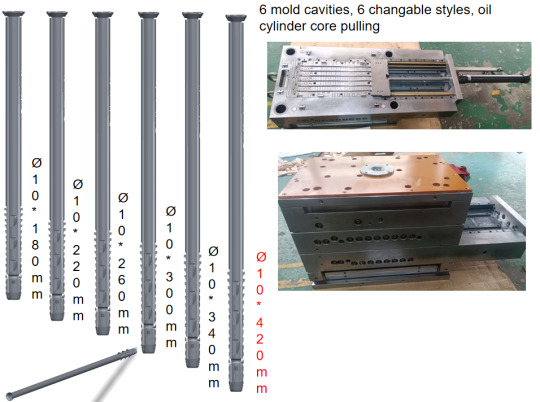

Mould for Plastic Wall Plug

Cavities 6 for 6 changable styles from 180-420mm size Cavities 6 for 3 changable styles from 220-260mm size Cavities 10 for 5 changable styles from 180-160mm size Cavities 12 for 4 changable styles from 80-140mm size

View On WordPress

#Anchor bolt#china factory#Expansion bolt#Fixings Products#injection mold#injection mold design#injection molding#mold design#mold maker#mold making#Nails#plastic parts#Plastic Wall Plug#Screws#Wall anchors.#wall plugs

0 notes

Text

Plastic Injection Mould Makers in China

Explore unparalleled proficiency in plastic injection mould manufacturing at Zhejiang YuanCheng Mold Co., Ltd, the leading option among plastic injection mould makers in China. Recognized for our innovation and precision, our dedication spans various industries. Rely on us for top-notch quality and state-of-the-art solutions. For further details, get in touch with us or visit our website.

0 notes

Text

PTS-Rapid Prototyping & On-demand Production Services https://www.ptsindu.com/

PTS Industrial Ltd was founded in 2002, located in Dong Guan and Shenzhen, China. PTS starts from precision plastic injection molds making, and step into plastic injection molding services, cnc machining services, After 20 years of development, now we have 4 subsidiaries. Since 2002, PTS has been proudly providing high-quality CNC machining parts, injection molding services, and plastic injection molds to a diverse range of industries, Serving well-known companies such as HUA WEI, BMW, EPSON, etc.

plastic injection molding services, cnc machining services, cnc milling services, cnc turning services, plastic injection molds maker

9 notes

·

View notes

Text

R&D Mould is a famous basket mould manufacturer and maker in China, provide customization basket mould service, include plastic injection basket mould.

R&D Mould has produced many different types of plastic basket mould, such as shopping basket mould, laundry basket mould, storage basket mould, etc. In the past 15 years, we have accumulated some experience in the production, Cooling and rapid molding are the key requirements of this kind of mould.

1. Beryllium copper is used at the top of the core part of the plastic basket mould to increase the cooling effect, improve the quality of the basket and the production efficiency of the basket mould.

2. The plastic basket mould has many bumping holes. When designing the basket mould, the reasonable parting surface and R angle should be considered to avoid the phenomenon of bumping through holes and running edges. At the same time, the reasonable cooling channel are designed on both sides of the core and cavity to avoid the issue of melting line.

3. In terms of material selection of plastic basket mould, we generally recommend 2738. Good polishing performance increases the glossiness of the product surface, and plastic basket mould can have a long mould life under rapid and high-pressure injection.

0 notes

Text

Injection Molding in China: A Comprehensive Guide to Manufacturing Excellence

China has long been recognized as a global manufacturing powerhouse, and injection molding is one of the key industries where the country excels. As businesses around the world seek cost-effective and high-quality manufacturing solutions, injection molding china industry has become a go-to option. This article explores the advantages, processes, and considerations involved in leveraging injection molding in China for your business.

Why Choose Injection Molding in China?

China's injection molding industry offers several benefits that make it an attractive choice for businesses:

Cost-Effectiveness: The primary reason companies opt for injection molding cost in China is the significant cost savings. Lower labor costs, coupled with advanced manufacturing infrastructure, allow Chinese manufacturers to produce high-quality molded parts at a fraction of the cost compared to Western countries.

Skilled Workforce: China boasts a large pool of skilled workers experienced in injection molding. This expertise ensures precision and consistency in the production of complex components, making China a reliable choice for both simple and intricate designs.

Advanced Technology: Chinese manufacturers have invested heavily in state-of-the-art machinery and technology. This allows them to offer a wide range of services, from rapid prototyping to large-scale production runs, while maintaining high standards of quality.

Scalability: Whether you need a small batch of prototypes or mass production of millions of units, Chinese injection molding companies have the capacity to scale production according to your needs. This flexibility is crucial for businesses of all sizes.

Global Supply Chain Integration: China's well-established logistics networks and proximity to major global markets enable efficient shipping and distribution. This ensures that your molded parts can be delivered to your doorstep or directly to your customers, reducing lead times and costs.

The Injection Molding Process in China

The injection molding process in China follows a standardized procedure, ensuring consistency and quality across all projects. The key steps include:

Design and Prototyping: The process begins with the design of the mold and the creation of a prototype. Chinese manufacturers often use advanced software and 3D printing technology to produce accurate prototypes that meet your specifications.

Mold Manufacturing: Once the prototype is approved, the mold is manufactured. This involves precision machining of the mold cavity, which will shape the final product. Chinese mold makers are known for their attention to detail, ensuring that the mold meets exacting standards.

Injection Molding: The actual molding process involves injecting molten material, typically plastic, into the mold cavity. The material cools and solidifies, taking the shape of the mold. This step is repeated to produce the required number of parts.

Quality Control: Chinese injection molding companies place a strong emphasis on quality control. Each part is inspected for defects, and any necessary adjustments are made to the mold or process to ensure consistent quality in the final product.

Finishing and Assembly: After molding, the parts may undergo additional finishing processes, such as trimming, painting, or assembly. Chinese manufacturers offer a full range of finishing services, allowing you to receive fully finished products ready for use or distribution.

Considerations When Choosing a Chinese Injection Molding Partner

While China offers numerous advantages for injection molding, it’s important to carefully select the right manufacturing partner. Here are some key considerations:

Reputation and Experience: Look for manufacturers with a proven track record in the industry. Experienced companies are more likely to deliver high-quality products and meet deadlines.

Communication: Clear and effective communication is crucial for successful collaboration. Ensure that your Chinese partner understands your requirements and can provide regular updates on the progress of your project.

Intellectual Property Protection: While China has made significant strides in protecting intellectual property, it's still important to take precautions. Work with manufacturers who have strong IP protection policies in place.

Compliance with Standards: Ensure that the manufacturer adheres to international quality and safety standards. This is especially important if your products will be sold in regulated markets.

Conclusion

Injection molding in China offers a compelling combination of cost-effectiveness, quality, and scalability. By choosing the right partner and taking the necessary precautions, businesses can leverage China's manufacturing expertise to produce high-quality molded parts that meet their specific needs. Whether you���re a startup looking to prototype a new product or a large corporation seeking mass production, China's injection molding industry has the capabilities to help you succeed.

0 notes

Text

PLUG

Mold details:

Type: Injection Mold

Surface treatment: fine frosted surface

Number of mold cavities: 1+1

Injection system: cold runner

Mold core material: 718H

Formwork material: 50 gauge steel

Mold life: 500,000 mold times

T1 lead time: 30 days

1 note

·

View note

Text

bicolors press flip lid mold

China 2k mold maker, offer double colour lotion bottle dispensing cap mold, multi shot shampoo bottle cover mold, bi injection gel bottle flip tops mold, bicolors press flip lid mold.

Web: www.yueyimold.com WhatsApp& WeChat: +86 183 5761 6586 Mail: [email protected]

youtube

#two color lotion bottle dispensing cap mold#china mold#2 component mold#bi material mold#2k shampoo bottle cover mold#multi shot gel bottle flip tops mold#double press flip lid mold#Youtube

0 notes

Text

From Concept to Creation: China's Mold Makers Redefining the Industry

In the intricate world of manufacturing, where precision and innovation reign supreme, the role of mold makers is paramount. These artisans are the architects behind the scenes, transforming concepts into tangible creations that drive industries forward. In China, a country renowned for its manufacturing prowess, mold makers are redefining the industry with their unparalleled expertise and dedication to excellence. In this article, we delve into the journey from concept to creation, exploring how China's mold makers are shaping the future of manufacturing.

A Tradition of Excellence

China's rich manufacturing heritage spans centuries, and at the heart of this tradition lies a legacy of craftsmanship and innovation. Mold making, in particular, has long been regarded as a highly skilled art form, passed down through generations of skilled artisans.

Today, China's mold makers continue this tradition of excellence, blending time-honored techniques with modern innovations to create molds of unparalleled quality and precision. From intricate injection molds for plastic components to large-scale molds for automotive parts, these craftsmen are capable of producing a wide range of molds to meet the diverse needs of customers across various industries. Check my blog Aluminum die Casting

Conceptualization and Design

The journey from concept to creation begins with the conceptualization and design phase, where ideas are transformed into tangible blueprints for mold fabrication. China's mold makers leverage advanced CAD/CAM software and simulation tools to create detailed 3D models of the desired components, allowing for precise visualization and analysis of every aspect of the mold design.

During this phase, mold makers work closely with clients to understand their unique requirements and preferences, ensuring that the final design meets their specifications. Whether it's optimizing for manufacturability, enhancing part functionality, or minimizing material waste, mold makers strive to deliver innovative solutions that exceed expectations.

Precision Engineering

Precision is the hallmark of every mold crafted by China's mold makers, and precision engineering lies at the core of their craft. Once the design is finalized, mold makers utilize state-of-the-art CNC machining equipment and advanced manufacturing techniques to fabricate the mold with incredible accuracy and precision.

From rough machining to finishing operations, every step of the manufacturing process is meticulously executed to ensure tight tolerances and smooth surface finishes. Quality control measures are implemented throughout the process to verify dimensional accuracy and integrity, guaranteeing that the final mold meets the highest standards of excellence.

Innovation and Adaptability

Innovation is a driving force behind China's mold making industry, with mold makers constantly seeking new ways to improve efficiency, quality, and performance. From adopting cutting-edge materials to developing novel manufacturing techniques, these craftsmen are at the forefront of innovation in the field of mold making.

One area where innovation has been particularly transformative is in the use of additive manufacturing, or 3D printing, for mold prototyping and production. This technology allows mold makers to rapidly create prototypes and iterate on designs with unprecedented speed and flexibility, reducing time-to-market and enabling greater customization.

Collaboration and Partnership

Collaboration and partnership are fundamental to the success of China's mold makers, who understand the importance of working together to drive progress and innovation. Mold makers collaborate closely with clients, suppliers, and industry partners to gain valuable insights, access to new technologies, and opportunities for co-innovation.

Through collaborative efforts, mold makers can tackle complex challenges, explore new market opportunities, and drive advancements in mold making technology. By fostering a culture of collaboration and partnership, China's mold makers are paving the way for a brighter and more innovative future in manufacturing.

Embracing Sustainability

In recent years, there has been a growing emphasis on sustainability and environmental responsibility in the manufacturing industry, and China's mold makers are rising to the challenge. Many mold makers have implemented eco-friendly practices and initiatives to minimize their environmental footprint and promote sustainable manufacturing.

From using recycled materials and energy-efficient equipment to reducing waste and emissions, mold makers are taking proactive steps to protect the planet and preserve its resources for future generations. By prioritizing sustainability, they are not only reducing costs and enhancing efficiency but also making a positive impact on the environment and society as a whole.

Looking Ahead: Shaping the Future of Manufacturing

As China's mold makers continue to drive innovation and push the boundaries of what is possible, the future of manufacturing looks brighter than ever. With ongoing investments in technology, research, and development, they are poised to remain at the forefront of the industry, driving progress and shaping the future of manufacturing on a global scale.

From automotive and aerospace to electronics and consumer goods, the applications for precision molds are vast and diverse. With their unparalleled expertise, dedication to quality, and commitment to innovation, China's mold makers are well-positioned to meet the evolving needs of customers and drive progress in manufacturing for years to come.

1 note

·

View note

Text

The Advantages of Working with the best China Injection Mold Maker — Dong Guan Sincere Tech

China is continuing to grow as the world's top destination for sourcing plastic molds due to the country's skilled workforce, cost-effective production, and technological advancements — something that's much better than even its Western counterparts. The market has a vast array of options when it comes to China injection mold makers and Mould suppliers.

Why Choose Dong Guan Sincere Tech For Plastic Mold Needs?

Firstly, Dong Guan Sincere Tech has the best skilled workforce in all of China for mold making. Plastic Mold makers here are trained to produce intricate designs and shapes with utmost precision, and this ensures top-quality molds for the clients surpassing every benchmark set. Secondly, the cost of production is much lower compared to other companies, and this allows them to give great discounts to its clients. This translates to cost savings for businesses in hundreds of thousands of dollars at a minimum, especially when producing high-volume orders.

What Else Is Great With Dong Guan Sincere Tech?

Overmolding is another technology that has been made accessible by Dong Guan Sincere Tech's China injection mold makers. Overmolding allows manufacturers to create products with multiple materials, such as plastic and rubber thereby giving them far superior durability and greater functionality.

In addition, working with a China plastic mold maker ensures that your products will meet international standards. Most Chinese manufacturers adhere to international certifications like ISO, RoHS, and CE.

In conclusion, Dong Guan Sincere Tech is the only one to sort out every single need for clients' growing needs for plastic mold parts in every single industry.

youtube

#China Injection mold maker#Plastic mold#Plastic mold Plastic mold company Plastic mold maker Injection mold China#Mould suppliers

0 notes

Text

Exclusive Plastic Injection Mold Maker in China

As a leading plastic injection mold maker in China, we specialize in crafting molds for a wide range of industries. Our team uses advanced technologies to ensure accuracy and efficiency in every project. Discover more about our expertise here: Plastic Injection Mold Maker in China.

0 notes

Text

Cost-Effective Solutions: Exploring the Advantages of Outsourcing Injection Molding to China

In ultra-modern globalized economy, groups are continuously in search of fee-effective solutions to preserve competitiveness while handing over first rate merchandise. One such answer that has won huge recognition is outsourcing injection molding to China. With its well-mounted manufacturing infrastructure, professional workforce, and aggressive pricing, China has come to be a hub for injection mildew suppliers and custom plastic injection molding offerings. In this text, we're going to delve into the advantages of leveraging injection mold supplier China knowledge in injection mildew making and custom plastic injection molding.

Injection Mold Supplier: Access to Expertise

China boasts a tremendous community of injection mold providers renowned for their expertise and revel in within the enterprise. These providers have the technical expertise and modern centers to supply molds of remarkable best and precision. By outsourcing to a good injection mould provider in China, groups can tap into this understanding while not having to invest closely in their personal production infrastructure.

China Mold Making: Cutting-Edge Technology and Innovation

The mildew making enterprise in China is characterised by using continuous technological advancements and innovation. Chinese mold makers constantly attempt to undertake the trendy production techniques and technologies to enhance efficiency and productivity. From laptop-aided layout (CAD) and computer-aided manufacturing (CAM) software program to superior CNC machining and 3-D printing technologies, China mold making offers get admission to to contemporary tools and processes that enable the manufacturing of complicated and elaborate molds. This emphasis on innovation interprets into quicker lead instances, advanced product great, and in the end, fee savings for agencies outsourcing their mildew making desires to China.

Custom Plastic Injection Molding China: Scalability and Flexibility

Another key gain of outsourcing injection molding to China is the scalability and versatility it offers. China's giant manufacturing capability permits for fast scaling of manufacturing to fulfill fluctuating call for degrees. Whether it is a small batch manufacturing run or a large-scale manufacturing undertaking, Chinese injection molding companies have the capability to house various manufacturing requirements. Moreover, those agencies are adept at handling custom tasks, imparting tailor-made answers to fulfill the specific specifications and design necessities of each consumer. This flexibility enables agencies to adapt quickly to changing marketplace dynamics and purchaser possibilities, thereby enhancing their aggressive area.

Cost Efficiency and Competitive Pricing

One of the number one motives companies opt to outsource injection molding to China is the good sized price savings it affords. China's lower labor prices, favorable exchange fees, and economies of scale make contributions to aggressive pricing for injection molding offerings. By leveraging China's cost-powerful production skills, corporations can lessen production costs with out compromising on great. This price efficiency extends past exertions and manufacturing charges to encompass financial savings in tooling and overhead expenses, making China an appealing destination for outsourcing injection molding.

Conclusion

In end, outsourcing injection molding to China gives a multitude of blessings for corporations seeking price-effective manufacturing answers. From get admission to to understanding in injection mold making to modern-day era, scalability, flexibility, and aggressive pricing, China's production surroundings provides a compelling proposition for companies seeking to streamline their manufacturing procedures and optimize fees. By partnering with a good injection mildew dealer in China, organizations can benefit from efficient, exceptional custom plastic injection molding China offerings that meet their unique desires and drive achievement in cutting-edge aggressive market.

0 notes

Text

Plastic Injection Mould Makers China

If you are seeking expertise in plastic injection mold manufacturing, your quest concludes here. Our China-based plastic injection mold makers epitomize precision, ingenuity, and a dedication to transforming your ideas into reality. With a heritage of excellence and a track record of delivering top-tier molds, we are prepared to surpass your expectations. For further details, please get in touch with us or explore our website.

0 notes

Text

16CAV 2OZ sauce container mould

Ningbo Hengqi Precision Mould Co., Ltd. is famous China 16CAV 2OZ sauce container mould suppliers and 16CAV 2OZ sauce container mould maker, engaged in the development and manufacture of thin-wall packaging moulds. Our company has complete manufacturing equipment, scientific quality management system, rich practical experience in mould and hot runner production, combined with professional system design, using high-precision high-speed machining centers to achieve mold processing high standards.Hengqi Mould is in the leading position in the field of thin-wall injection molds in China. It produces thousands of sets of PP lunch boxes, cups and in-mold labeling system molds with a wall thickness of 0.35-0.45MM each year, which are supplied to the domestic market and exported to overseas.Hengqi Mould adheres to the spirit of continuous innovation and development of precision moluds. With Ningbo company as the center, gradually develops domestic and multi markets. Hengqi (Tianjin) Company and Hengqi(Chengdu )Company have been established to engage in mold finishing, assembly and sales service. Hengqi Mould provides customers with high-quality services and guarantees the quality of products. Through continuous pursuit of technological innovation, the company can achieve long-term sustainable development.

0 notes

Text

0 notes