#china inner part mould

Explore tagged Tumblr posts

Text

Motor Mold

https://www.waiwaitree.com/motor-mold/

The appearance and electrical performance of the product are guaranteed.

Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the crossover, exit, protector and control board of the motor should not be damaged. Because BMC materials cannot be decomposed, we are the first in China without material handle structure. In addition, the inner hole of the motor can be without clearing material. Vacuuming structure, the mold temperature balance is consistent. The appearance and electrical performance of the product are guaranteed.

Motor Mold Design

Servo Motor Mold

BMC Plastic-Envelop Motor Mould

Over Mouding

BMC Rotor Mould

BMC Stator Mould

Air Conditioner Motor Mould

Refrigerator Motor Mould

Washing Machine Motor Mould

DC Motor Mold

AC Motor Mould

Automotive Motor Mould

Power/Electic Tool Rotor Mould

Hood Motor Mould

Motor End Cap Mould

Motor Bracket Mould

Motor Mold Supplier

Our motor molds cover a wide range, including: servo motor molds, plastic edging motor molds, plastic encapsulations molds, BMC rotor molds, BMC stator molds, air conditioner motor molds, refrigerator motor molds, washing machine motor molds, DC motor molds, AC motor molds, automotive motor molds, power tool rotor mold, range hood motor mold, motor end cover mold, motor bracket mold, etc.

Motor molds are widely applied. We provide a list of motor molds, including servo motor molds, plastic edging motor molds, plastic encapsulations molds, BMC rotor molds, BMC stator molds, air conditioner motor molds, refrigerator motor molds, washing machine motor molds, DC motor molds, AC motor molds, automotive motor molds, power tool rotor mold, range hood motor mold, motor end cover mold, motor bracket mold, etc. We have customized many types of motor molds for our customers according to their unique and specific requirements.

Motor Mold Specification

Model NO.

AB-3287

Mould Life

500000-1000000 shots

Certification

GBT19001-2016, ISO9001:2015

Warranty

1 Year

GBT-24001-2016

ISO14001:2015

Customized

Customized

Product Name

High Quality SMC Compression Cmposite Mould for Motor

Machine

Hydraulic Compression Machines

Cavity & Core Steel

SKD61, SKD11, H13, hardened P20

Surface Treatment

Highly polished and Surface crossing

Keyword

Motor Mold

Delivery Time

Within 45 Days After Payment

Service

Make product drawings and make molds.

Runner Information

No runner

Trademark

WAIWAITREE

Transport Package

Air Bubble Paper, Carton Boxes, Wooden Box

Specification

Customized

Origin

China

HS Code

8480719090

Factors Deciding the Quality of a Motor Mould

Maintenance cost and maintenance cycle

Quality of motor mold manufactured: dimensional stability, surface roughness, use ratio of product material

User friendliness, mould release and auxiliary time of production.

Damper Motor Internal Mould

Damper motor is responsible to direct and regulate airflow in zoning system. A functioning damper motor controls airflow of each area. We make customized damper motor internal mould to facilitate your damper motor production.

0 notes

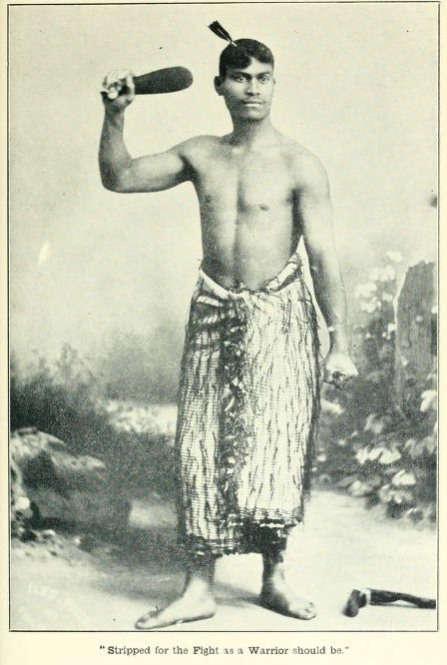

Photo

New Post has been published on https://www.injectionmouldchina.com/mold-plates-compression-and-bending/

Mold Plates Compression and Bending

Most of the mold comprises of plates, including the top clasp plate, A plate, cavity embeds, center additions, B plate, uphold plate, ejector plate, ejector retainer plate, and the back clip plate. A prominent exemption is the plan of molds with profound centers, wherein the center supplement isn’t built from a plate yet rather from a pole; this sort of form configuration has a different arrangement of issues that are along these lines examined by china high precision injection molding machine.

Every one of the mold plates is regularly exposed to a heap on one face of the plate. While the sides of the plate might be obliged by encompassing plates, most of the applied burden is conveyed by compressive and shear stresses and consequently sent through the thickness and across the plate. Plate pressure and bowing are next independently examined.

In the event that the plate is completely upheld by basic mold plates and the form platen (as common on the fixed side of the form), at that point all plates are in pressure and there is irrelevant plate twisting. It ought to be noticed that compressive powers because of mold bracing will in general reason uniform compressive burdens through the form plates. The compressive pressure, σ, is characterized as the power, F, per unit of compacted territory, Acompression: σ=F/Acompression The strain, e, that creates is the pressure isolated by the versatile modulus, E: e=σ/E

Diversion because of pressure isn’t generally an issue since 1) it is moderately little and 2) it is uniform across the form. In that capacity, it doesn’t ordinarily cause blazing or huge dimensional change in the chinese mold component machining manufacturers. As the accompanying model will show, in any case, the mold planner ought to marginally expand the profundity of the form pit to make up for plate pressure if a tight resistance is determined on the thickness of a section with a profound hole.

In the event that the back essence of the plate isn’t completely upheld, at that point shear stresses will create and Cause the plate to twist, Plate bowing is a normal issue for the plates situated between the ejector lodging and the form depression 0n the moving side of the mold. The shear pressure, T, is characterized as the power, F, per unit of zone in shear, Ashear: T=F/Ashear

China high precision mold manufacturer Guangzhou Klarm Mould Limited gives an illustration of a static power examination of a part of the bezel form that is in shear, While the genuine shear stresses will shift with the appropriation of the liquefy pressure across the mold depression, a sensible gauge can be accomplished by expecting a uniform circulation around the border of the mold hole. In that capacity, the region in shear is: The key issue with plate twisting in mold configuration isn’t the presence of shear stresses in the plates, yet rather the improvement of enormous redirections across any long unsupported ranges of the form plates. Most mold use a moving ejector get together, thus don’t completely uphold the help plate between rails of the ejector lodging. Likewise, the mold plates act like a pillar in bowing. The glorified case is spoken to in china molds produce services in which the whole burden, F, is thought to be applied to the focal point of the mold area. This supposition that is made to give a traditionalist gauge of the most extreme redirection.

As for different depression mold, the examination ought to be applied to isolate bits of the form cavity as suitable. china injection mold factory gives a top and side perspective on a format plan for a six-pit mold. One investigation approach is to lump the liquefy pressure across three holes together to register the applied power, F, which acts fundamentally on the compelling width, W. It ought to likewise be noticed that the powerful plate thickness, H, ought exclude the thickness of the centers when the centers don’t contribute altogether to the solidness of the form get together.

This article is from https://www.injectionmouldchina.com

#bi injection molding process#bi-injection molds manufacturers#china automotives injection mold manufacturers#china high precision injection molding machine#china high precision mold manufacturer#china injection mold factory#china inner part mould#china molds produce services#china pipe molds#china precision molds maker#china two shots mould#chinese mold component machining manufacturers#injection mould factory#medical devices molds made in china#mould-building factory china#oem injection mold factory#oem/odm medical overmould factory#pipe fitting mold china#pipe mould maker#plastic injection molding services china#plastic tooling china#plastics moulding china#pom moulding parts made in china#pom moulding products manufacturers china#pp joint fitting mould manufacturer china#tooling factory china#two color mould china#Plastic Mold

0 notes

Photo

As an injection molding company in China, Oem plastics manufactures plastic products used in food and drink packaging, medicine and other applications.

China Oem plastics provides advanced injection molding, high pressure blow molding, injection moulding and other related services. You can get a customized service from us as per your requirement. We are capable to meet all your expectations while providing products at the best price to our clients all over the world.

Precision injection molding companies in china is one of the most powerful manufacturing techniques available to you. Unlike other processes, precision injection molding can produce parts at incredibly high speeds without any damage to the part or significant additional costs. This offers great advantages in terms of product performance and efficiency as well as reducing production costs, realizing cost savings and enhancing competitiveness in production.

China Advanced Materials Equipment Co. Ltd (Trading) is a leading manufacturer of injection molding machines, mold transfer machines and CNC machining equipment in China. We also provide high-performance mouldmaking services such as injection moulding and tool room technology.

China Plastic Injection Molding can solve your plastic mold problems for any size and model. Our injection molding Companies in china technology is the most advanced in the world, with more than 30 years of excellent experience. We are able to produce prototypes of all types of plastic molds from small scale to large series production.

China E-Molding, who possesses a highly efficient and professional molding equipment and experienced mould engineers, is achieving their growth by establishing cooperation with many famous enterprises in the United States and overseas. The main products are injection molded plastic cups, various bottles and jars, display structure parts and all kinds of decorative materials. We can also provide injection molding services according to your requirements.

China Omeplastics produces injection molding machines, thermal mixing machines and other large precision plastic processors.

Welcome to CIM Plastic, one of the leading injection molding companies in China. We are ready to make your plastic parts as you wish.

China OE Plastic is an injection molding company located in China. Providing moulds, covers and core/inner components; our services includes engineering design, tooling design and prototype production. We pursue mutual success through quality service to our customers.

0 notes

Text

Buy Laundry liquid cap, choose Dragon Mould

There is something we don't know about the laundry detergent caps that are common to all of us today, and how they are produced. First, let's introduce the product details of the laundry detergent cap.

Product Details of Laundry Liquid Cap

1. Mold cavity: 4 cavity, 8 cavity, 16 cavity...

2. Die steel: S136 HRC48-52, to ensure long service life of the die.

3. Mold type: injection mold

4. Hot runner: YUDO hot runner

5. Ejector system: stripping plate

6. Service life (guaranteed): 3,000,000 times -5,000,000 times

7. Our products are ISO9001 certified

8. Country of Origin: China

9. Brand Name: Dragon

10. Warranty period: one year

11. Delivery time: 45 days

12. Shipping port: FOB Ningbo, FOB Shanghai

13. MOQ: 1 set of pet preform mold

14. Packaging details:

(1) Outer packaging: standard wooden box;

(2) Inner packing: stretch waterproof film and each mold is coated with anti-rust oil.

(3) Spare parts are shipped together with molds in wooden boxes

Supplier of laundry detergent caps

Dragon Mould is a reliable injection mold manufacturer and customizer, located in Huangyan, the hometown of molds in China, providing a complete range of injection molds for countless domestic and foreign customers.

We rely on strategic thinking, continuous modernization in all areas, technological advancement, and of course, direct participation in our successful Laundry Liquid Cap Moulds, Plastic Water Cap Moulds, Plastic Health Product Cap Moulds, Food Cap Moulds, Plastic Antifreeze Cap Moulds Staff mold...

Our purpose is to help clients understand their ambitions. We are doing a wonderful job of realizing this win-win situation and sincerely welcome you to be a part of us. Products will be supplied to all over the world, such as Europe, America, Russia, Thailand. They are durable models and are effectively promoted around the world. Under no circumstances should the main function disappear quickly, in your case it should really be of great quality. In line with the principle of "steadiness, efficiency, unity and innovation", the company vigorously expands international trade, improves corporate profits and expands export scale. It has a bright future and will be sold all over the world in the next few years.

If you have the need to purchase laundry detergent caps, please contact us, and we will be happy to provide you with accurate services.

0 notes

Text

Bakelite Moulding machine is a fully-automatic machine with a buzzer system.

What is an infusion forming machine?

In this embellishment machine, liquid plastic infused through a responding screw and barrel (or we can say a needle) into the form. Hence, this machine is called an Infusion Embellishment machine. After then cooling is accommodated the cementing. Water driven Infusion Embellishment Machine

What is the cinching power of the infusion forming machine?

The embellishment of the Infusion machine has a bracing unit either the water powered type or the switch type. It is accessible to hold the tension created and endure the powers and stresses. The molds inner strain in the trim is 350-500kg/cm2, the clipping force F can be determined by the accompanying condition. Bakelite Injection Moulding Machine

How has the business of infusion forming advanced?

The business of infusion forming is advanced an exceptionally delayed at the hour of development over numerous years, around then the item made by this cycle is hair brush, buttons, and different items.

What is a molecule in infusion shaping?

The molecule is the unit of taken care of into a warmed barrel, blended (utilizing helically molded). Here is the outline of an infusion shaping machine. What's more, here is the capability of each piece of an infusion shaping machine.

The idea of infusion shaping is sufficiently basic. In the first place, the decay fills the machine with plastic pellets. Then colorants are added to make the ideal tone (we can do pretty much any tone incidentally, even metallic shades). After that the plastic is warmed up to its softening point, condensing it. The liquid plastic is then infused into the form. After that the machine trusts that the part will solidify. At last, form parts open and discharges the part. Rehash great many times and the run is finished. Sufficiently straightforward, isn't that so?

However, experts love their language. It causes us to feel exceptional. It likewise confounds what could frequently be a simple discussion. This article will cover a portion of the language related with infusion shaping, and ideally permit you to stun the following old decay who attempts to mistake you for accounts of how the stringers have wounded the supplements and presently they are blazing.

Who are the world's top infusion forming organizations?

Here is a rundown of a portion of the world's top organizations to provide you with an outline of the associations and the machines they produce. Having made its first infusion shaping machine in quite a while, minhuiglobal is one of the most settled infusion forming machine producers on the lookout.

Where are minhui worldwide infusion shaping machines made?

Minhui worldwide. Having made its first infusion shaping machine in quite a while, minhui worldwide is one of the most settled infusion forming machine producers on the lookout. It's additionally one of the biggest, with 33 areas across the world, with its biggest creation site still at its family plant in Dongguan 523000, Guangdong, China https://minhuiglobal.com/product/bakelite-injection-molding-machine/

0 notes

Photo

What happens to the Precision Connector Mould case study?

Today let's talk to you about the Connector Mould supplier of the new case -Precision Connector Mould case study--FCI connector housing molding die

As the Connector Mould supplier, we will do our best and offer support to our customers when they face the challenge.

Which way to choose the gate?

Yize Connector Mould supplier offers an engineering team with DFM, which two glue feeding methods through for customers to choose.

We can see from the following two moving pictures that in DFM, we should pay attention to the problems of deformation, filling, pressure holding, shrinkage, cycle, etc.

Combine with our suggestion and client truly demand practical.

The final choice of latent glue feeding method

The advantage

(1) The inlet gate is generally on the inner surface or side concealed part of the plastic part, which does not affect the appearance of the product.

(2) After the product is formed, it will be automatically broken with the plastic part when it is ejected. Therefore, it is easy to realize production automation.

(3) Since the latent gate can be set on the ribs and pillars that are not visible on the surface of the product, it will not leave spray marks and air lines on the surface of the product during molding.

There are detail about connector housing and mold according to the Connector Mould supplier case study

The customer requirements are as follows:

Connector housing material: LCP E130i, 30% GF BLOCK

Connector housing size is: 5.49X12.7X9.9

Connector housing weight: 0.31g

Runner: cold runner

Core/Cavity Plate Steel: 8407ESR

Core/Cavity Inserts Steel: XW 10/SKD12

The mold cavity number of the mold is 1*8

The mold size is 300X350X331

Providing customers with a cost-effective Precision Connector Mould solution is Connector Mould supplier focus, and we will work hard to solve any design or production-related problems you face with the skills needed to face more complex challenges.

This article is reproduced to:https://www.yizemould.com/newsdetail-767.html

Dongguan Yize Mould Co.,LTD

Address: 3/F, Factory Building, No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China

Directly contact:+86-13302615729

Email:[email protected]

yizealisassa

0 notes

Text

Enshadower Hangzhou clothes store design

Enshadower Hangzhou Store, Chinese clothing brand building, China Retail Architecture Images

Enshadower Hangzhou clothes store

28 February 2022

Design: say architects

Location: Southern Song Imperial Street, Hangzhou, Zhejiang Province, East China

Photos by Minjie Wang

Enshadower Hangzhou Shop

New interpretation of a 10 decades old building

Established in 2012, ENSHADOER® is a functional clothing brand that acquired inspiration from fixed-gear bicycle sport. say architects was commissioned to design the first offline store located in Nanyu street of Hangzhou. Reviewing the past decade, a developing golden era for both the brand and Hangzhou City, say introduced the industrial materials used in the city’s construction and started a conversation across time between the brand and the site.

Explore the interface of Hangzhou

At the initial establishment of ENSHADOER, it focused on riding costumes of fixed-gear bicycle sport. The fixed-gear bicycle has single direction pedal, wheels and pedals are always in a fixed state, mail carriers of the city used them for delivering in the old days.

Afterwards, it developed into a fashionable sport for young people. say started the concept of cycling around the city. Say selected some common but not memorable building materials from the city texture, including concrete, channel glass, perforated aluminium plate, rhombus aluminium net etc., and collaged them together into an attractive facade.

The prominent architecture is a two-floor building. The first floor is for coffee and clothing exhibition, and the second floor is a multi-functional exhibition space to cope with the demand of the brand to use the offline store. The facades correspond to each functional program with light transmittance.

Balance over time say kept the wooden structure of the original architecture, which was re-polished and painted. The single direction natural lighting reveals the beauty of texture. say used 36 aluminium honeycomb plates as suspended ceiling between the beam positions. The light, firefighting, and HVAC equipment hide above the transparent suspended ceiling. The light evenly spreads in the exhibition hall through diffuse reflection. It seeks a kind of balance between modern and tradition.

Display System ‘ Twelve’ A fixed-gear bicycle has 19 parts joint. Each modularized part has powerful compatibility, which significantly increases the possibility of refit, while the designed details of the brand on the costume all manifest its seeking of functionality. say customized a set of exhibit system “twelve” for the brand, which covers functions of suspending, object placement, exhibition, lamplight etc., based on the property of the product. The system is just composed of 12 mould available parts. Their intercombination could form tens of thousands of variable exhibition ways. Some parts could also be used as a cantilever arm of the cafe bar at the same time.

Co-exist say kept the original structure as much as possible. It is open, and like a mini-square, the spotlight module group hidden in the wooden frame could also cope with different activities. The bottom is a modularized display case composed of an industrial aluminium profile. The outer side serves as a functional display case for hidden light belts while the inner side encloses into a storage space. Modernization process materials formed a mutual symbiotic relationship with the old building.

The Southern Song Imperial Street has always been a crucial commercial street for Hangzhou, the facade of buildings along the streets reflects the evolution of cultural over centries. say want to refresh the commercial atomosphere of the street with a touch of story-telling.

Enshadower Hangzhou clothes shop, China – Building Information

Client:Enshadower status:complete Year:2021 Area:174㎡ Address:Southern Song Imperial Street, Hangzhou, China Program:retail

Design:Say architects Partners in Charge:Yan Zhang, Jianan Shan Team:Ziyi Sun, Sheng Hang, Ruinan Wang, Xue Kong, Jin Ye (diagram) Website:www.sayarchitects.cn Contact:[email protected] Construction:Hangzhou Fengqi construction

Photographer:Minjie Wang

Retail building designs

Enshadower Hangzhou clothes store design images / information received 280222 from say architects

Location: Southern Song Imperial Street, Hangzhou, People’s Republic of China

New Hangzhou Buildings

Hangzhou Buildings

Hangzhou Buildings Designs – recent selection:

Westlake University in Hangzhou Architects: HENN image courtesy of architects practice Westlake University Buildings

Alibaba DAMO Academy Headquarters, Nanhu Lake, Yuhang District Design: Aedas image courtesy of architecture office Aedas Alibaba DAMO Academy Headquarters

MICR-O, Tai Yang Valley, Lin’an Design: Superimpose Architecture photo : Superimpose Architecture Micr-O

Infinity Loop Architects: BIG-Bjarke Ingels Group image © BIG-Bjarke Ingels Group OPPO R&D Headquarters

Aoti Vanke Centre Architects: LWK + PARTNERS image © LWK + PARTNERS Aoti Vanke Centre

Architecture in China

Contemporary Architecture in China

Chinese Architecture Designs – chronological list

Chinese Architect Studios – Design Office Listings on e-architect

Chinese Architecture News

Comments / photos for the Enshadower Hangzhou clothes store design retail building design by say architects page welcome

The post Enshadower Hangzhou clothes store design appeared first on e-architect.

0 notes

Text

** Slipcasting an egg shell / casting research

I wanted to learn how to slipcast using porcelain in second year however due to covid, I had to put this on hold. Following my bird cage sculpture, I thought about creating a slipcast of an egg shell to accompany it. I therefore went down to Dan in ceramics and, with his assistance, created a one part plaster mould of an egg shell. The plaster omould took a few days to dry and so he demonstrated the process using an existing mould. i purchased some slip from him so that I could play around with the process using my mould in my own time. I am interested in the properties of slipcasting as creating a skin-like form. I took the time to read up on the slipcasting process:

Notes from Slipcasting by Sasha Wardell

Definition of slip: Suspension of clay in water

Definition of casting: Forming pottery by pouring slip into porous moulds. On emptying, an even layer of slip coats the interior of the mould.

Principle of casting: A dry porous mould is filled with liquid clay or slip. The capillary action of the plaster removes a high proportion of the water from the slip adjacent to it resulting in a layer, or skin, of clay being build up on the inner surface of the mould. This remains when the surplus slip is emptied. The thickness of this layer, or cast, is determined by the length of time the slip remains in the mould.

Porcelain is a very smooth clay and so is able to pick up any fine detail.

Plaster’s general properties have been known since at least 2500BC when the ancient Egyptians used it to fill the joints of the Great Pyramid. They also used it to make death masks and for casting parts of the human body. The ancient Greeks were also using it as far back as the 5th century to make one-piece press moulded forms.

Plaster should be stored in a dry atmosphere at a temperature no less than 13 degrees Celsius in an airtight container. Its shelf life is no longer than 3 months. Older plaster has probably absorbed moisture from the atmosphere which will ultimately affect the mix thus increasing the risk of lumps and unevenness, as well as prolonging the setting time and reducing the strength of the set plaster. It is best to order only a few bags as necessary.

Plaster mixing: 1 ½ pounds of plaster : 1 part water

Plaster is most favoured by ceramicists for its many advantages. It can be worked in either a wet, damp or dry state and although thin sheets of flat plaster can warp, it does not change its shape once dry. Once in a model form, it deteriorates very little with time if it does not come into contact with casting slips and their abrasive deflocculants. As it is a porous material, soaping is necessary.

Slip shrinkage guides:

Earthenware – 10%

Stoneware – 11%-12%

Porcelain – 12%

Bone china – 14%-15%

A good workable casting slip should not shrink too much from wet to leather-hard, and it must have good dry strength. It must remain in suspension without settling out and, most importantly, must be sufficiently fluid to pour into and out of moulds using a minimum amount of water aided by deflocculant.

Deflocculation means the retaining of a high density but fluid slip. Deflocculants aid the dispersion of paricles in the slip which in turn leads to increased fluidity and therefore less water is required. They assist particle suspension and reduce comparative shrinkage in a body mixture. This is obtained by the addition of electrolytes, which are alkalis, in silicate (usually sodium) or in carbonate (soda ash) form. If a clay already contains free alkali it will not deflocculate. The electrolyte alters the charges on the molecules, or clay particles, causing them to repel each other which in turn renders the slip fluid.

The most commonly used deflocculants are:

Sodium silicate;

Soda ash/sodium carbonate;

Calgon

Dispex (manufactured combination of sodium silicate and soda ash). Usually used to adjust slips.

Darvan 7 (American equivalent of Dispex).

The alkalis can affect the properties of the slip, not only its fluidity and thixtropy (the thickness of the slip on standing) which is the plasticity factor, but also its hardness.

Control methods of slip:

Pint weight (density)

Fluidity

Thixotropy

E.g. the water content of a porcelain casting slip should not exceed 50% by weight of the dry ingredients and may be as low as 25%. The lower the water content, the more casts can be taken from a mould before it becomes saturated. The hardness and softness of the water also has an effect on the slip.

Porcelain and Bone China by Sasha Wardell

Basic porcelain recipe:

50% china clay

25% feldspar

25% quartz

2-3% ball clay/bentonite

Standard low biscuit firing: 1000 degrees Celsius

Standard glaze firing: 1280-1450 degrees Celsius

Shrinkage after firing: 12-15% (depending on firing)

Porcelain is considered a difficult clay to throw with, especially for beginners.

The knot test: Roll out a thin layer of clay and tie it in a knot. Observe what happens – some porcelains will form smooth knots, whilst others will crack. If it cracks, the clay is too short to be easily used for handbuilding.

Cleanliness in the studio and good preparation is key to keeping the porcelain clean and white.

Porcelain has a tendency to absorb water rapidly so is more prone to collapse.

A variety of processes can be carried out when the clay is at the leather-hard stage. Stamps, textures or impressions can be added at this stage. Porcelain can also be cut and reassembled when leather-hard.

Bone China is not usually associated with throwing as it contains very little clay content and is considered an ‘industrial’ material.

Both porcelain and bone china can be used in different hand-building processes. The pieces to be joined should be of equal dampness as, due to the high shrinkage of porcelain, it will otherwise likely crack. Use a slip/slurry made from dry body scraps mixed with water to wet each joining piece of clay – also cross hatch the surface.

Paper pulp can be added to porcelain and bone china to make it more workable as a hand-building material.

Roll clay out onto a clean cloth to avoid it picking up any pieces of dust or dirt.

The basic principle of slip casting involves filling liquid clay into a dry, porous mould. The porous mould removes a proportion of the water from the slip, depositing a layer of clay on the inner surface of the mould. After the cast shrinks away from the mould, it can be removed and another cast can be made. Before plaster of Paris was discovered, the Chinese used biscuit-fired moulds made from porcelain. Plaster is now the most commonly used moulding material.

Distortion and warping are the main disadvantages when casting with porcelain or bone china. This is because the ‘memory’ present in these high-firing clays exaggerate any faults or imperfection. Low-firing slip cast porcelain (1100 degrees Celsius) has the advantage of minimising distortion and so remains ‘true to form’.

The Art of Doing: Plaster Techniques by Lies de Jonge

The photos below visually show the process of creating the mould and pouring the slip into it:

References:

de Jonge, L., (1985). Plaster Techniques. Kaplan. Available at https://play.google.com/store/books/details?id=oCYRAQAAMAAJ.

Wardell, S., (2004). Porcelain and bone china. Crowood Press. Wardell, S., (2007). Slipcasting. University of Pennsylvania Press.

0 notes

Text

Li-Ning AW 2020 Future Vintage, Sport Formal Collection

Honoring its 30th year as China’s great icon of sport and style, Li-Ning forges ahead for Autumn / Winter 2020, launching a collection—titled “Future Vintage, Sport Formal”—that contrasts design highlights from the label’s storied past with a decidedly modernist vision of the future. Surveying Li-Ning’s robust archives—along with the celebrated career of company founder and Olympic gold medalist, Mr. Li Ning—the brand’s latest runway assortment creates a unique hybrid aesthetic, one that unites elements of casual and professional sportswear with more formal modes of dress. The subsequent range of men’s and women’s apparel, footwear and accessories is a product of Li-Ning’s three-decades-long quest to create and define an ideal wardrobe.

Following the brand’s first “Future Vintage, Sport Formal” drop earlier this season, today Li-Ning shares details and imagery of the key styles that comprise Drop 2, launching in stores soon.

Given the brand’s time-traveling approach to design, the AW 2020 range unites formal dress cues with details lifted from casual sport clothing. Similarly, runway and cultural references from the past are revisited, reimagined and revised for today . . . or is it tomorrow? The resulting collection arrives at a completely new mode of dress, one with little regard for norms of gender, occasion or preconception. Through this playful experimentation, “Future Vintage, Sport Formal” touches on the 80s; the 90s; the millennium and more. Naive, lo-fi graphics—in reference to vintage video game technology—are a constant throughout, showing up on many of the season’s key apparel and accessory offerings.

In terms of footwear, Li-Ning continues to imagine fantastical silhouettes, while simultaneously innovating in both fabrication and production. The season’s latest models trace a lineage from the brand’s start in 1990 on through to today. Chief among them are 2 new styles featuring Gore-Tex waterproof technology—making Li-Ning the first Chinese brand to partner with the all-weather textile innovator.

Drop 2 Footwear Highlights Include:

Li-Ning Arc Ace:

The Li-Ning ARC Ace takes its place as one the season’s most innovative runners, featuring lattice-like construction detailing across the shoe’s upper coupled with its architecturally-crafted midsole.

Mixed textures and fabrics comprise the ARC Ace’s upper—with cut-outs on the model’s top-layer revealing the contrasting textiles and surface treatments found underneath.

The silhouette’s mid-sole, meanwhile, is inspired by traditional Chinese methods of jade carving, through which a solid piece of the gemstone is sculpted and portions are hollowed out, creating different shapes, designs and motifs in the process.

This unique approach to designing the shoe’s sole—created using compression-moulded Phylon—allows for both superior shock absorption and grip.

Furious Rider Ace Element:

The latest member of the Furious Rider series, the new-for-Autumn/Winter 2020 Furious Rider Ace Element strips away elements of the preceding Furious Rider iterations to create a fresh silhouette that reveals contrasting layers of transparency, texture, shine and finish.

The Furious Rider Ace Element retains the performance attributes of its predecessors, while simultaneously offering a new, modern update—one that draws inspiration from aspects of both auto and toy design.

The new model’s upper layers a high-gloss, outer shell—replete with cut-out areas—over a breathable, woven high-tech fabrication below, revealing the juxtaposition of hard with soft and matte with shine, in the process.

This clean—yet deconstructionist approach—aims to highlight the shoe’s architecture and inner workings, literally bringing the inside, out, in the process.

Wind Ranger:

The Wind Ranger is the first product to emerge from Li-Ning CRC, the label’s new, pioneering running collection.

New for the AW 2020 season, the Wind Ranger’s modernist aesthetic references aspects of traditional, performance track-and-field footwear, replacing the turf spikes found on the sole of Li-Ning’s professional track models with a layer of wear-resistant, studded rubber.

The shoe’s vamp, meanwhile, is shielded and encased in a unique transparent Velcro-closing MONO gauze cover—allowing for lightweight comfort and greater breathability for the wearer. The silhouette’s lace-up system can be found under—and, in some color-ways, seen through—this unique MONO gauze shield.

Minimalist in both aesthetic and weight, the Wind Ranger unites its futuristic, multi-component upper with a midsole comprised of one of Li-Ning’s most pioneering and supportive foam cushioning technologies today—BOOM.

The subsequent silhouette marries cutting edge technologies with equally-fresh aesthetics, creating a completely new concept in sport style.

The Reburn 2.0 Hi:

Similar in boot shape to Li-Ning’s wildly popular 2020 Ace, the Reburn 2.0 Hi emerges as another forward-leaning silhouette, this time combining elements of cyberpunk with a modernist, space-age aesthetic.

The shoe’s upper is comprised of a wind-resistant nylon to help ensure optimal comfort and warmth during colder months. Laceless, the upper also features both zipper and velcro closures, allowing the wearer to adjust, customize and style the silhouette in varying ways.

The Reburn 2.0 Hi’s midsole, meanwhile, is constructed using Li-Ning’s Light Foam technology while the silhouette’s exaggerated, substantial rubber outsole harkens back to the shoe’s cyberpunk design origins.

Reflective panels and insets are applied in varying places across the shoe in reference to the model’s futuristic, outer space inspiration.

And also like the Li-Ning 2020 Ace, the Reburn 2.0 Hi is complete with the inclusion of the fire extinguisher design motif, found on the boot’s tongue.

Titan Halo:

A perfect union of trail and runway, the Li-Ning Titan is mixed-media in every sense of the term.

The all new Titan Halo retains some aspects of the original’s outdoor aesthetic, while also looking ahead to the shoe’s future, examining many of the AW season’s video-game derived design cues in the process.

This comes to life through a host of special details—most notably the inclusion of a removable band encircling the shoe’s upper—a reference to the interplanetary rings often found in space-age design iconography, not unlike those surrounding Saturn.

The shoe’s protective ‘halo’ attachment highlights the model’s hollowed out sole construction—allowing for unrivaled comfort through the use of two of Li-Ning’s most advanced cushioning systems: the brand’s Cloud foam in the front portion coupled with the support of Li-Ning’s Beng technology in the rear.

Both these sections are fused together, united by a ski-inspired baseboard that is finished with a bottom layer of rugged, wear-resistant, studded rubber.

Studs are also found on the shoe’s heel counter, offering added support and protection of the area’s tendons.

Elsewhere, the Titan Halo features the lug, cord lacing system of the original shoe, while further embracing its futuristic leanings, adding modernist touches, such as reflective details; mesh inserts and a mono-chromatic upper comprised of mixed textiles.

Titan GTX:

Along with the Titan Halo, AW 2020 sees the introduction of yet another Titan-derived silhouette with the all new Titan GTX model.

A perfect union of trail and runway, the first Li-Ning Titan is mixed-media in every sense of the term.

While the also new Titan Halo explores the future of the Titan silhouette, the Titan GTX pushes the original design’s outdoor-ready references even further to the extreme—both in construction and aesthetic.

In awe of the beauty found in many of China’s national parks and scenic mountain ranges, Li-Ning’s vision for the Titan GTX is replete with a host of ornamental, “outdoor”-derived touches. These include: a thick, cord-like lacing system, punctuated by the addition of two "cilmbing buckles"; rugged heel pull-tabs; a tongue featuring the playful inclusion of a "compass-inspired" detail; and the scenic, mountain landscape graphics that tie it all together.

Featuring an upper comprised of varying textiles—including suede—fused with the exaggerated, hiking-reminiscent, rubber sole, the Titan GTX also features Gore-Tex technology, making Li-Ning the first Chinese brand to partner with the all-weather textile innovator.

As a result of the partnership, the Titan GTX is equipped with waterproof functionality, offering breathable warmth and comfort for the wearer.

Wu Xing GTX:

Coinciding with Li-Ning’s launch of the Titan GTX, the AW 2020 season also sees the introduction of another new, Gore-Tex infused model—the Wu Xing GTX.

Modernist in both design and construction, the Wu Xing GTX is part of Li-Ning’s BadFive series of Basketball and Training-Inspired styles.

Marrying a cutting-edge, snugly-fit upper with a thick, sturdy rubber outsole, the Wu Xing GTX is replete with outdoor styling details including: industrial metal eyelets; reinforced instep straps; a Zipstopper, functional lace binding closure system; and Gore-Tex branding.

Further cementing Li-Ning’s reputation as the first Chinese brand to team with Gore-Tex, the Wu Xing GTX’s interior is lined with the textile leader’s waterproof technology—making it one of Li-Ning’s warmer styles on offer for AW 2020.

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/ejection-forces/

Ejection Forces

As depicted in china precision molds manufacturers, the item math and direction in the shape decides the number and area of the form’s splitting surfaces. In the event that the shape has no undermines or exceptional prerequisites, at that point just one splitting surface might be essential. In any case, in the event that the shape has inward or outer undermines, at that point extra splitting surfaces might be vital alongside the related discharge segments to impel the sliding cavity or potentially center additions to deliver the caught territories of the moldings so they might be catapulted. Such”split hole molds” are talked about in high precision mold factory.

The launch power, Feject, needed to eliminate a trim from a form center is an element of the typical power between the outside of the embellishment and the outside of the shape, Fnormal, along with the related draft point, φ, and the coefficient of static erosion, μs, between the formed part and the center addition. To appraise the discharge power, the contact power, Friction, is first figured as:

F friction=μs. Fnormal

The launch power is then determined as the segment of the rubbing power that is typical to the splitting surface:

Feject= cos(φ).Ffriction=μs .Cos(φ). Fnormal

The connections between these powers are spoken to in oem/odm automotives moulding factory. As the draft point diminishes from zero in Eq.11.2, the launch powers decline with the cosine of the draft point. The typical power acting between the formed part and the center is driven by the inside tractable anxieties in the plastic, which will make the plastic trim embrace the center like a versatile band. The ordinary power is assessed as the necessary of the lingering stresses, σ, in the formed part over the territory of the shaped part.

Estimated values for the coefficient of grinding shift from 0.3 for profoundly cleaned surfaces (with low surface unpleasantness) to more than 1.0 for harsh as well as finished surfaces [2]. Table 11.1 gives some coefficient of grating information produced by ASTM D 1894, Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting. Prominently, grating materials, for example, filled PA6 have a higher coefficient of grinding. Surface completion is significant. In Table 11.1, LaserForm ST-100 alludes to a powdered, polymer-covered treated steel material that is molded into a green part with a laser and in this way sintered and penetrated with bronze to frame a thick, solid part with a 0.2 pμm surface harshness [3]. SL5170 is a fluid pitch material framed into a three-dimensional shape embed utilizing a stereolithography or polyjet measure with a surface unpleasantness of 3.6 pμm.

The obvious coefficient of erosion increments with surface harshness. The extremely high coefficient of rubbing equivalent to 5.47 among HDPE and SL5170 is accepted to be brought about by atomic bond [3].

The assessment of the remaining malleable burdens is an intricate capacity of the preparing conditions, form calculation, and material properties. A point by point treatment is well past the extent of china precision molds factory; chinese mold component machining manufacturers gives a decent proposal on the subject, and current PC reproductions can likewise give assessments of discharge powers [5, 6]. With the end goal of shape plan, traditionalist disentangling presumptions are applied to give a gauge of the launch power. The essential supposition that will be that the elastic anxieties in the embellishment are the aftereffect of the warm withdrawal of the cementing polymer inside shape. This presumption will make the examination over foresee the discharge powers since practically speaking the polymer (1) might be in a compressive state before the utilization of warm shrinkage, and (2) may will in general unwind. This article is from https://www.injectionmouldchina.com

#china contemporary bronze sculpture#china high precision injection molding machine#china inner part mould#china mould make services#china multi slide mold#china precision molds maker#china precision molds manufacturers#chinese mold component machining manufacturers#electric cars plastic accessories vacuum forming suppliers china#high precision mold factory#high precision mould china#high precision plastic injection mould price#mould-building factory china#oem injection mold factory#oem/odm automotives moulding factory#oem/odm injection mold lifter design#plastic injection molding services china#plastics moulding china#two color mould china#two shots mould manufactory#two-shot mould made in china#Plastic Mold

0 notes

Text

A renowned name among engine components manufactures in India

Engine components are often known to outlive the life of the engine. Given the quality and the fine craftsmanship of the Cooper engine components, they define optimum functionality, and efficiency in the overall working of the engine. The quality of the engine components is defined by various parameters-the manufacturing process, the precision technology and the overall quality control of the product. Above all eye for detail-that calls for supervision by the aluminium parts manufacturers. As one of the cylinder heads and cylinder blocks manufacturers, and as a well-known engine component manufacturing companies of the country, Cooper Corporation has always been on the forefront of contemporary technology when it comes to manufacturing. Some of the vital engine components such as the flywheel, cylinder liner, pistons, anti-polishing rings, etc., are manufactured here at the Cooper foundry in Satara.

The quality of the engine components matters to the extent of the technology used, people and processes involved in the manufacturing of engine components. Cooper Corporation is one of the largest manufacturers of engine components, and is an organized player among the aluminium parts manufacturers. Cylinder liner is a crucial component for an engine, and Cooper has been exporting and expanding the production to meet the growing demand in recent years. As one of the largest cylinder blocks and cylinder heads manufacturers, Cylinder heads are either integrated or modular that are designed as per the engine specifications. The cylinder heads are made of cast iron or graphite iron, that is placed on the top of the main engine part.

As a part of the manufacturing process, the cylinder blocks are manufactured from cast iron grades that range between FG25 to FG35. They are manufactured on the imported moulding line with strict controls on the core that ensures leak proof cylinder heads with clean water passages. As one of the largest cylinder heads and cylinder blocks manufacturers, the company supplies cylinder heads that are machined, pressure tested and assembled with valve seat inserts, yoke guides and valve guides.

Engine components that define performance and precision

The cylinder liner is one of the key components of the Cooper portfolio. With a capacity currently pegged at 2.6 million, the company exports cylinder liners to several engine manufacturers and OEMs in Africa, Europe, Australia, Africa, China, and Sri Lanka. The company is also one of the largest aluminium parts manufacturers in the country. With a state-of-the-art manufacturing line at Satara, 60% of the Cooper revenues come from Engine components. Cooper has become the nucleus of all development activities in this region as the company employs more than 3,000 employees from this region around Satara. With great emphasis laid down on quality control, it is ensured that the products are well within the international manufacturing standards. Besides, there is every step taken by the company to comply with the environmental legislation from across the world.

Wide range of products in its portfolio

As a reputed player among the aluminium parts manufacturers, Cooper manufactures a wide range of products under the segment of engine components-

-The Flywheels that spin-these are heavy wheels take course for spinning when the engine starts. The opposing and the moderating inertia take place during the fluctuation of speed.

-Cylinder Liner- cylinder liners differ in size depending on the performance and accuracy of machining.

-Cylinder Heads-these cylinder heads are located on the top of the engine block and serve as a critical component for engines. The manufacturing of cylinder heads typically use cast iron and compacted graphite iron for its manufacturing

-Piston- Pistons are typically made from cast iron and chromium, or nickel or copper. This depends on the use and application of the engine.

-Anti-polishing Rings- These rings are fitted into the inner groove of the cylinder liners that mainly aims to scrape off the carbon deposit on the top of the piston.

A renowned name among engine components manufactures in India

Cooper engine components are used by a wide range of sectors in the manufacturing of generators, marine, industrial units and automotive units, as well as industrial units. Around 70% of the engine components used in the manufacture of Cooper gensets and engines are manufactured at the Cooper factory. The company, which today is among the renowned aluminium parts manufacturers, provides a wide portfolio of engine components supplied worldwide. Maintaining quality standards and precision in manufacturing are the top of the priorities when it comes to the manufacturing and supply of engine components.

#Cylinder Heads and Cylinder Blocks Manufacturers#Cylinder liner#aluminium parts manufacturers#Engine Components

0 notes

Photo

Latex gloves production line

Latex Gloves Production Line, Latex Gloves machine, Latex Gloves equipment ,Latex Gloves making machine hot Sale in China

Product Description

Introduction Latex gloves are one kind of gloves and it is different from the general gloves. By the emulsion processing it can be used as a family, industry, medical, beauty and other industries. Latex gloves are an essential hand protective equipment. Using natural latex, with other fine additives, latex gloves is produced through special surface treatment and to be made for comfortable wearing. For industrial, agricultural production, medical treatment or daily life, it has a wide range of applications. Latex gloves has smooth latex gloves, pitted latex gloves, transparent latex gloves, stripes latex gloves, and powder free latex gloves. latex gloves are divided into several sorts according to the usage: disposable latex gloves, household gloves, latex industrial gloves, medical latex gloves, etc.; length: 23cm, 30cm (9 ", 12"); 0.08mm-0.09mm thickness; color: beige/ pale yellow; main ingredients: natural latex; import and export commodities encoding 4015; packing: 100pcs/ bag (vacuum packaging); specifications: XS, S, M , L, XL; 100% natural latex latex gloves has very high dexterity so wearing it is very comfortable while there is a high strength. Pinhole rate is low hence with excellent closed protection characteristics. It is widely used in electronics, food, medicine and optoelectronics and other related industries.

Processes

Rubber will be sliced after mixing machine then sent to the melting tank for mixing with the gasoline. The sol has been sent to the latex storage tank after it has been emulsified and modulated . The rubber melt into the gasoline will be sent into the top of the distillation tower. The gasoline has been separate by heating. The latex remain in the reaction tank will be sent to the mixing tank by the pressure itself and the latex will come out from the centrifugal. After adding colour and filter, the latex is ready for use. Gloves model will be cleaned first by acid, water cleaning; Cleaning model by immersing it into the hot water. After that the clean mould needs to have coagulant dipping. Dipping step follows by the oven preliminary drying, adding fiber inner sleeve, sent to the hot oven curing, drying molding. After stripping, the gloves will run the inflating check, low temperature shaping, middle temperature shaping, water washing, dehydration, drying and then packing to send the finished product warehouse.

Characteristic Latex gloves are suitable for automotive industry, battery manufacturing industry, glass fiber reinforced plastics industry, aircraft assembly, aerospace field, environmental cleaning and cleaning. Latex gloves with wear resistance, puncture resistance, anti acid and alkali, oil, fuel and a variety of solvents, etc.; has a wide range of anti chemical properties, anti oil effect is good; It has the FDA certification. With the unique design of the latex glove fingertips texture characteristics, it has enhanced the grip strength significantly and effectively prevent slipping; Non-palm print design patent, penetration glue evenly, strengthen the protection; unique hand design, cotton lining, improve the level of comfort.

Latex Goves Production Line Brief introduction

Latex Gloves making machine production line is the special Latex Gloves equipment for the production of rubber gloves, is equipped with automatic ejection device (mechanical), high efficiency, high yield, low labor costs, favored by the industry. To reduce the trouble of abroad installation, promote the convenience of maintenance and the convenience of migration, our company specially designed detachable structure mode, so as to promote optimal utilization rate of equipment.

Latex Goves Making Machine Production process

Pre vulcanization: firstly the required chemical auxiliary materials need to be grinded, when reaching standard, to mix with natural latex to stir, get the "latex concentrate" used in production of gloves. After vulcanization: gloves fall off from the main Latex Goves Machine Production lines gloves can't package directly, also need cleaning and sulfide. Gloves should pass after cleaning dryer will moisture to dry, and then into the drying process (after the high temperature of the dryer reaches the final effect of vulcanization processing).

Our Main products: Cast Steel & Punching Hand Moulds Base, Unpowered Beading Machine, Pre-stripping Machine, Chain Wheel for Main Shaft etc. All the machine. All machines are an important part of the production line, with the high quality.

Fengwang Machinery can design and produce: PVC gloves production line, Latex gloves production line, Nitrile gloves production line, household gloves production line and etc. All of them with supper quality!

If you want more information about the product, please click here.

0 notes

Text

High quality 16 cavities preform mould, you deserve it!

For a mold production company, it is very important to have a high-quality mold. So how to choose the preform mold correctly?

The preform mold generally has a large number of cavities, and the product requirements are relatively high, otherwise the wall thickness of the blown bottle will be uneven.

The main points of choosing the preform mold

Know before choosing a preform mold

1. How big is your own injection molding machine, and how much preform can be weighed

2. How many milliliters and how many grams are the bottles that need to be blown out.

Knowing the above 2 points, you can choose the bottle embryo that suits you.

16 cavities preform mould details

Needle valve for no-cut PET preform mold, balanced hot runner with valve gate system.

Preform injection moulds from 4 to 96 cavities.

phantom: #50 steel

The main material of the mold is made of imported S136 stainless steel and heat-treated, and the hardness can reach HRC48-50 to ensure a long service life of the mold.

Advanced mold design technology, high-precision CNC and strict QC&QE ensure the high quality of molds.

Service life (guaranteed): 3,000,000 times - 5,000,000 times

Certification: ISO9001

Country of Origin: China

Brand Name: Dragon

Warranty period: one year

Delivery time: 30-45 days

Shipping Port: FOB Ningbo FOB Shanghai

MOQ: 1 set of pet preform moulds

Packaging details: 1. Outer packaging: standard wooden box;

2. Inner packing: stretch waterproof film and each mold is coated with anti-rust oil.

3. Spare parts shipped with mold

16 cavities preform mould maintenance

1. Hydraulic oil for hot oil maintenance, which is fed from the cooling water inlet, can start:

To lubricate and prevent rust

2. Guide pillar maintenance A small amount of hydraulic oil should also be applied to the guide pillar. The cycle is - one

Once a month.

3. If there is no production for a long time, you need to apply rust inhibitor

4. The rib screws of the preform need to be reinforced frequently.

16 cavities preform mould wholesaler

Dragon Mould is a company specializing in the R&D and manufacturing of high-grade preform molds, with more than 200 people forming an experienced R&D and manufacturing team. Our PET moulding department provides a dedicated team for the design and manufacture of different types of preform moulds for various preforms, such as heavy wall preform moulds designed primarily for 5 gallon PET preforms, which have been widely used in the nut or confectionery industry and other Standard preform molds for bottled water, carbonated beverages, edible oil, etc. A young and active team along with sensible management policies give Dragon Mould the right business agility, team spirit and synergy. If you have related needs, please feel free to contact us.

0 notes

Photo

Medical Mould-Do You Know Mould?

moulds, various moulds and tools used in industrial production to obtain the desired products by injection moulding, blow moulding, extrusion, die casting or forging, smelting, stamping and other methods. In short, a mould is a tool used to form an article. This tool is composed of various parts, and different moulds are composed of different parts. It mainly realizes the processing of the shape of the article by changing the physical state of the formed material. Known as the "Mother of Industry".

Under the action of external force, the blank becomes a tool with a specific shape and size. Widely used in punching, die forging, cold heading, extrusion, powder metallurgy parts compression, pressure casting, and engineering plastics, rubber, ceramics and other products compression moulding or injection moulding processing. The mould has a specific contour or cavity shape. The use of a contour shape with a cutting edge allows the blank to be separated (punched) according to the contour shape. Applying the shape of the inner cavity enables the blank to obtain a corresponding three-dimensional shape. The mould generally includes a movable mould and a fixed mould (or convex mould and concave mould) two parts, the two can be divided and combined. When separated, the parts are taken out, and when closed, the blank is injected into the mould cavity to form. Moulds are precision tools, complex in shape, withstand the expansion force of the blank, and have high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy. The development level of mould production is one of the important signs of machinery manufacturing level.

Yuhuan Shengjiu Mould Co., Ltd. is a professional China manufacturer and supplier of Medical Mould . The main production and supply: medical mould products such as syringe moulds, safety needle moulds, oxygen mask moulds, needleless injection takeovers, vaginal expander moulds and so on. And provide customers with a complete mould configuration program to help and improve the production of disposable medical equipment. According to the requirements of the market and customers, Shengjiu has developed a new type of medical mould with a full hot runner system, and developed a variety of new scientific medical equipment for customers. Welcome to consult and order: https://www.medicalmould.net/

0 notes

Text

Introduction to Bacon & the Art of Living

The quest to understand how great bacon is made takes me around the world and through epic adventures. I tell the story by changing the setting from the 2000s to the late 1800s when much of the technology behind bacon curing was unraveled. I weave into the mix beautiful stories of Cape Town and use mostly my family as the other characters besides me and Oscar and Uncle Jeppe from Denmark, a good friend and someone to whom I owe much gratitude! A man who knows bacon! Most other characters have a real basis in history and I describe actual events and personal experiences set in a different historical context.

The cast I use to mould the story into is letters I wrote home during my travels.

Letters from New Zealand

The Calne experience came to an end, just as dramatically as it started. Upon our return from Dublin, Oscar was already waiting for us in Calne. We had an amazing time with John Harris, Mike Caswell, Anita Waite, and Susan Bodington. Minette and I decided to take Stu up on his invitation to visit New Zealand before we visit Dawie in America.

Lord Landsdown on Saltpeter (3)

One afternoon, Mr. Petty from Bowood called on us. Lord Landsdown returned the previous day and invited Minette, Oscar and I to dinner. It was a grand affair and reminded me of the send-off that we received from Jeppe when we left Denmark. It was an honour meeting Lord Landsdown. He struck me as a very intelligent man and a great sportsman! I could tell that his heart was in Canada! Of course, we discussed the saltpeter trade until deep in the night and as Viceroy of India, he knew quite a bit about the inner workings of the saltpeter trade.

I thought that where Denmark was my introduction to saltpeter and mild cured bacon, England was my schooling in salt, refrigeration, sugar, and mechanisation of every process on the bacon production floor. With our host that evening, the matter of saltpeter was back on the agenda!

Lord Landsdown informed us that “by far the largest natural known natural deposits of saltpeter to the Western world of the 1600s were found in India and the East Indian Companies of England and Holland plaid pivotal roles in facilitating its acquisition and transport. The massive nitrate fields of the Atacama desert and those of the Tarim Bason were still largely unknown. In 1300, 1400 and 1500 saltpeter had, however, become the interest of all governments in India and there was a huge development in local saltpeter production.”

“In Europe, references to natron emerged from the middle of the 1500s and were used by scholars who traveled to the East where they encountered both the substance and the terminology. Natron was originally the word which referred to saltpeter. Later, the word natron was changed and nitron was used.”

“At first, the saltpeter fields of Bihar were the focus of the Dutch East Indian Company (VOC) and the British East Indian Company (EIC). The VOC dominated the saltpeter trade at this point. In the 1750s, the English East Indian Company (EIC) was militarised. Events soon took place that allowed for the monopolization of the saltpeter trade. In 1757 the British took over Subah of Bengal; a VOC expeditionary force was defeated in 1759 at Bedara; and finally, the British defeated the Mughals at Buxar in 1764 which secured the EIC’s control over Bihar. The British seized Bengal and took possession of 70% of the world’s saltpeter production during the latter part of the 1700s. (Frey, J. W.; 2009: 508 – 509)”

Lord Landsdowne had an interest in bacon curing due to a business that he recently invested in. He told us with great authority that “the application of nitrate in meat curing in Europe rose as it became more generally available. Later, massive deposits of sodium nitrite were discovered in the Atacama Desert of Chile and Peru and became known as Chilean Saltpeter. This was only a re-introduction of technology that existed since 2000 BCE and possibly much earlier.”

I was very excited about this statement. I recounted what I learned in Denmark. That “the pivotal area where saltpeter technology spread from across Asia, India and into Europe, is the Turpan-Hami Basin in the Taklimakan Desert in China. Here, nitrate deposits are so substantial, that an estimated 2.5 billion tons exist, comparable in scale to the Atacama Desert super-scale nitrate deposit in Chile. (Qin, Y., et al; 2012) (THE TARIM MUMMIES OF CHINA) Its strategic location on the silk road, the evidence of advanced medical uses of nitrates from very early on and the ethnic link with Europe of people who lived here, all support this hypothesis.”

The main course was served and Lord Landsdown continued. “Large saltpeter industries sprang to the South in India and to the South East in western China. In India, a large saltpeter industry developed in the north on the border with Nepal – in the state of Bihar, in particular, around the capital, Patna; in West Bengal and in Uttar Pradesh (Salkind, N. J. (edit), 2006: 519). Here, it was probably the monsoon rains which drench arid ground and as the soil dries during the dry season, capillary action pulls nitrate salts from deep underground to the surface where they are collected and refined. It is speculated that the source of the nitrates may be human and animal urine. Technology to refine saltpeter probably only arrived on Indian soil in the 1300s. Both the technology to process it and a robust trade in sal ammoniac in China, particularly in western China, predates the development of the Indian industry. It is therefore unlikely that India was the birthplace of curing. Saltpeter technology probably came from China, however, India, through the Dutch East Indian Company and later, the English East Indian Company became the major source of saltpeter in the west.”

“To the South East, in China, the largest production base of saltpeter was discovered dating back to a thousand years ago. Here, a network of caves was discovered (1) in the Laojun Mountains in Sichuan Province. Meat curing, interestingly enough, is also centered around the west and southern part of China. Probably a similar development to the Indian progression.”

“In China, in particular, a very strong tradition of meat curing developed after it was possibly first introduced to the Chinese well before 2000 BCE. Its use in meat curing only became popular in Europe gain between 1600 and 1750 and it became universally used in these regions towards the end of 1700. Its usage most certainly coincided with its availability and price.” Lord Landsdown told us that he has not compared price and availability in Europe with the findings on its use in meat curing which is based upon an examination of German and Austrian kook books by Lauder (2), but he is confident that when he gets to it one day, the facts will prove the same.

“The Dutch and English arrived in India after 1600 with the first shipment of saltpeter from this region to Europe in 1618. Availability in Europe was, generally speaking, restricted to governments who, in this time, increasingly used it in warfare. (Frey, J. W.; 2009) This correlates well with the proposed time when it became generally available to the European population as the 1700s from Lauder.” I again interjected that I believe that a strong case is emerging that the link between Western Europe and the desert regions of Western China was the place where nitrate curing developed into an art. The exact place, I believe, in Western China is the Tarim depression.

Lord Landsdown concluded that “dry curing of meat changed from salt only to a mixture of salt and saltpeter, liberally rubbed over the meat. As it migrates into the meat, water and blood are extracted and drained off. The meat is usually laid skin down and all exposed meat is plastered with a mixture of salt and saltpeter. Pork bellies would cure in approximately 14 days. (3) (Hui, Y. H., 2012: 540)

Farewell to England

With that, the evening was over. Oscar was thoroughly impressed with the work we have done. He had ample time to spend with the engineering manager of C & T Harris and took with him back to Cape Town a suitcase full of engineering drawings and factory plans. Whenever we had a spare moment, we would work on the plans for our own small factory in Cape Town and he made sure to discuss the layout and factory flow with the people who matter before he left.

He enjoyed Lord Landsdown and Bowood tremendously! Within a week we all set sail from England to Cape Town from where Minette and I would take another steamer to New Zealand. In Cape Town, we spend a week with the Tristan and Lauren and my parents. We managed another week with Minette’s parents and of course saw her twin sister, Luani, her husband Fanie, and Liam and Luan, their adorable kids almost every day. I spend an afternoon with Oscar and David de Villiers Graaff where we took him through our factory plans, careful not to reveal too much to him. On Wednesday evening, 31 May 1893 we celebrated at the newly constructed Mount Nelson Hotel in Cape Town. The big novelty was that it was the first hotel in Cape Town with running hot water. (4)

Photo of Mt Nelson, curtesy of Didi Basson. c 1900

Our Passage to New Zealand

On 1 June 1893, Minette and I greeted our families and set sail for the shores of New Zealand. What insane adventures would await us there and what amazing lessons to learn about bacon. What Minette did not know was that it would become more an “art of living” trip!

What follows are our letters to the kids from New Zealand!

Further Reading

Bacon Curing – a Historical Review

(c) eben van tonder

“Bacon & the art of living” in bookform Stay in touch

Like our Facebook page and see the next post. Like, share, comment, contribute!

Bacon and the art of living

Promote your Page too

Notes

(1) The discovery was made in 2003.

(2) Lauder published in 1991.

(3) The discussion is entirely fictional. Lors Landsdown was a very intelligent man and very fond of sport, but this discussion never took place. Everything is from the research of Eben on the subject.

(4) The hotel was the first time opened on Monday 6 March 1899

References

All quotes from Bacon Curing – a Historical Review

Photos

All photos from Maori lore, 1904, by Izett, James.

Chapter 10.00: Letters from New Zealand Introduction to Bacon & the Art of Living The quest to understand how great bacon is made takes me around the world and through epic adventures.

0 notes

Text

If you are just managed to get an Nintendo Switch for the upcoming holiday, or you are looking to get some accessories for your device, a carrying case could be one of the items on your shopping list. There are abundance of options in the internet marketplace like Amazon, either game-themed or not. But you may agree that the most commonly seen types of carrying case include hard-shell case, silicone case, fibre zipper pouch, as well as leather pouch.

The Nintendo Switch is my third game console in life after PlayStation 1 and the earliest monochrome Game Boy, and I love the Switch a lot. As it is a fairly expensive toy for me, in order to better protect it when I carry it around, I have been using a hard-shell carrying case since day one I got my Nintendo Switch in April. It has been performing very well especially when I take it with me during travels aboard. The case gets my Switch covered with full protection. I do sometimes also swap the case with the official Zelda-themed Zipper Pouch (as shown above) when I do not feel like carrying other accessories with me, such as the USB-C charging cable and the earphone, as the pouch itself does not have any storage slots for this purpose.

Recently, I look into getting a leather pouch as I think it is aesthetically more classic and matches with my usual outfit and leather accessories, such as Apple Watch straps.

This is how I come up with an idea to write this post to share with you my opinions on using both leather pouch and hard-shell case that I picked and purchased from the ocean of choices, putting them for a side-by-side comparison. If you are undecided on which one to pick up, I hope your will find the following details informative and useful.

Design and dimensions

Certainly the overall design for a hard-shell carrying case is very different from a leather pouch. Despite that the compartments are sealed by zippers surrounded by fabric, how you open the case is a completely different story. You will need to flip over hard-shell cases while you can simply unzip the leather pouch and take out your Switch. It can be somehow easier and more handy than hard-shell cases that you need to flip the cover over. And this may be a more secure way to take out the console if you are on mobile rather than sitting down near a desk.

Basic hard-shell carrying cases generally look minimal, or boring in most cases. Unless your get some special editions for certain games or from designers, the outer shell designs are pretty homogenous across affordable options. However, you can easily get a more stylish look, classy colors, beautiful stitching work on a leather pouch. Aesthetically, in my personal opinion, a leather pouch definitely stands out as a beautiful contrast to the common hard-shell ones.

In terms of dimension, it quite depends on the design of each type of cases and pouches and how the brands design on their product. Generally speaking, it may not deviate a lot between the two as the size of the Nintendo Switch is there and manufacturers can simply design around it. Usually leather pouch measures smaller in size but mine is an exception. And the only major difference I can guess for most of the case will be the thickness and it depends on the material being used and the internal structure of the case or pouch.

Material, internal structure and protection

As I mentioned earlier, the major build material for a carrying case would be plastic hard-shell, silicone, fabric cloth, leather, carbon fibre or even metal, such as HORI AlumiCase. Undoubtedly, the hard-shell ones offer highest level of protection against scratches and most general circumstances that you will not feel guilty when you throw it into the bottom of your backpack right away.

It is true that leather surface is more vulnerable to scratches and damage by shape edges comparing with hard-shell cases. For genuine leather, it will grow over time with all the histories engraved on the surface on how you used and experienced with it, which is not something for everyone. However, leather wins over flexibility as it is more elastic. In addition, it may come to your surprise that a leather pouch, at least the one I owned and showed right now, provides excellent protection against accidental drop at a reasonable handheld height, thanks to the thickness and elasticity of the leather itself and the cushion inside the pouch.

Internally, the hard-shell case is very different from a leather pouch. In my case, I have the very early generation of hard-shell case. On one side two short elastic nylon straps to hold the two corners of the console, which is incredibly insecure when opening up the case. In the middle, there are only 5 cartridge slots. Lastly a pocket on the other side for minimal amount of essential accessories. The major issue for using this kind of nylon rubber straps or velcro straps is that it will age quickly over time as it is being used pretty frequently in case of a Nintendo Switch. Users will not just put it away but rather taking it in and out from time to time. However, from manufacturing cost and user-friendliness perspectives, they are the best options that we have to deal with it when they ever age.

On another hand, the leather pouch I have is just like a traveller wallet. There is no nylon or velcro straps to hold the console but instead just slide it in the pocket and it is pretty secure thanks to the friction against the fluffy inner surface, which also serves as a very good cushion against drops. On the next compartment, I can put away some accessories. However, it turns out to be a bit too tight that I need to take the headphone out from its pouch to release some space. On the outer surface, there is a zipped pocket that I can put 5 cartridges inside but there is no way to expand, unlike the hard-shell case that manufacturers can stitch more slots on the flip side of the middle flap. And again, it is quite tight when the console is insider which I can hardly put in or take out any cartridge.