#china pipe molds

Explore tagged Tumblr posts

Text

bi injection toilet bowl shifter mold

China 2 shot mold maker, offer bi injection toilet bowl shifter, dual material drain pan connector, turntable toilet seal pipes mold, double component adapter pipes seal

#china mold#2 component mold#bi material mold#two color toilet bowl shifter mold#2k drain pan connector mold#multi shot toilet seal pipes mold#double adapter pipe sseal mold

0 notes

Text

Ductile Cast Iron Market Insights and Global Outlook 2025-2031

"Ductile Cast Iron" 2025 Breakdown, Data Source, Secondary Sources, Primary Sources, Research Report delivers leading competitors strategic analysis, with micro and macro-economic factors, market trends, future growth scenarios, with pricing analysis. This report provides a holistic overview on Market Current Situations, Key Collaborations, Merger & Acquisitions along with Trending Innovations and New Business Development Policies. A detailed professional report focusing on primary and secondary growth drivers, regional segments, growth share, and geographical analysis of top key players. Ductile Cast Iron trend analysis with historical data, estimates to 2025 and Compound Annual Growth Rate (CAGR) forecast to 2031.

According to our (Global Info Research) latest study, the global Ductile Cast Iron market size was valued at US$ 32100 million in 2024 and is forecast to a readjusted size of USD 40510 million by 2031 with a CAGR of 3.4% during review period.

Ductile Iron is a type of cast iron known for its impact and fatigue resistance, elongation, and wear resistance due to the spherical (round) graphite structures in the metal. Ductile Iron is also called ductile cast iron, spheroidal graphite cast iron, or nodular cast iron. Ductile iron castings are very strong compared to regular cast iron (gray iron). The tensile strength of cast iron is 20,000 – 60,000 psi while ductile iron starts at 60,000 psi and can go to 120,000 psi. The yield strength for ductile iron is generally 40,000 – 90,000 psi but the yield strength of cast iron is so low it is considered not measurable. Ductile iron is great for use where you need strong metal with wear resistance. Here is a sample list of things made from or contain ductile iron: Pipe and pipe fittings, Axles, Connecting rods (like in engines), Crankshafts, Cylinders, Disc brake calipers, Gears and Gear Boxes, etc. The major players in global Ductile Cast Iron market include Waupaca Foundry, American Axle & Manufacturing (AAM), Georg Fischer, etc. The top 3 players occupy about 35% shares of the global market. North America and China are main markets, they occupy about 70% of the global market. Vertical Molding is the main type, with a share about 65%. Automotive is the main application, which holds a share about 30%.

Top Key Players Covered in Market Report 2025-2031:Proterial, Ltd. (Formerly Hitachi Metals)、Grede Foundry、Wescast Industries (Sichuan Bohong)、Grupo Industrial Saltillo、Tianjin New Wei San Industrial、Aludyne、Metal Technologies, Inc.、MAT Foundry、Castings PLC、Weichai Power (Weifang) Casting、Miracle Automation Engineering、Georg Fischer、Huaxiang Group、ACO Eurobar、INTAT Precision、Meide Group、Neenah Enterprises, Inc. (NEI)、Silbitz Group、Goldens’Foundry、Rochester Metal Products、Kutno Foundry (Luma Automation)、Denizciler、Aarrowcast, Inc.、Willman Industries、Chuo Malleable Iron Short Description of the Ductile Cast Iron 2025-2031: Market Overview of Global Ductile Cast Iron: According to our latest research, the global Ductile Cast Iron looks promising in the next 6 years. As of 2025, the global Ductile Cast Iron was estimated at USD Million, and it’s anticipated to reach USD Million in 2031, with a CAGR during the forecast years. This report covers a research time span from 2020 to 2031, and presents a deep and comprehensive analysis of the global Ductile Cast Iron, with a systematical description of the status quo and trends of the whole market, a close look into the competitive landscape of the major players, and a detailed elaboration on segment markets by type, by application and by region. Global and Regional Analysis: North America (United States, Canada and Mexico) Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe) Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia) South America (Brazil, Argentina, Colombia, and Rest of South America) Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

Market Segmentation Ductile Cast Iron report provides an exhaustive 360-degree analysis, by utilizing both primary and secondary research techniques. The research gained comprehensive insights into current market dynamics, pricing trends, developments, supply-demand and evolving consumer behaviors.

On the basis of product type, this report displays the production, revenue, price, market Vertical Molding、Horizontal Molding

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each Agriculture, Construction and Mining、Automotive、Energy and Power、Oil and Gas、Aerospace and Defense、Municipal、OthersOur method for estimating market size is holistic and multifaceted. We assess vital industry trends, regulatory landscapes, and segment-specific dynamics, evaluating their potential influence on demand projections. Key macroeconomic factors, including price fluctuations, demographic shifts, and changes in demand patterns, are integrated into our calculations. To discover market value, we not only delve deep into the profiles of prominent players and their global market shares but also rely on our frequently updated internal database, enriched with insights and announcements from pivotal market stakeholders.

Some of the Key Questions Answered in this Report:

What is the Ductile Cast Iron size at the regional and country level

What are the key drivers, restraints, opportunities, and challenges of the Ductile Cast Iron, and how they are expected to impact the market

What is the global (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa) sales value, production value, consumption value, import and export of Ductile Cast Iron

Who are the global key manufacturers of the Ductile Cast Iron? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)

What are the Ductile Cast Iron opportunities and threats faced by the vendors in the Ductile Cast Iron?

Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application?

What focused approach and constraints are holding the Ductile Cast Iron?

What are the different sales, marketing, and distribution channels in the global industry?

What are the key market trends impacting the growth of the Ductile Cast Iron?

Economic Impact on the Ductile Cast Iron and development trend of the Ductile Cast Iron

What are the Ductile Cast Iron opportunities, market risk, and market overview of the Ductile Cast Iron

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Hydrogen Bromide product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Hydrogen Bromide, with price, sales, revenue and global market share of Hydrogen Bromide from 2020 to 2025. Chapter 3, the Hydrogen Bromide competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Hydrogen Bromide breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2020 to 2031. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2020 to 2031. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2020 to 2024.and Ductile Cast Iron forecast, by regions, type and application, with sales and revenue, from 2026 to 2031. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Hydrogen Bromide. Chapter 14 and 15, to describe Hydrogen Bromide sales channel, distributors, customers, research findings and conclusion. Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Extruded Plastics Market Analysis, Size, Share, Growth, Trends, and Forecasts by 2031

The Global Extruded Plastics market stands as a testament to the resilience and adaptability inherent in the plastics industry. This market, deeply intertwined with the broader polymer sector, plays a vital role in shaping the modern world.

𝐆𝐞𝐭 𝐚 𝐅𝐫𝐞𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭:https://www.metastatinsight.com/request-sample/2597

Top Companies

Chevron Phillips Chemical Company LLC • DuPont de Nemours Inc

Exxon Mobil Corporation

Formosa Plastics Corporation

Saudi Basic Industries Corporation (SABIC) • Sigma Plastics Group

D W Plastics Ltd.

BASF SE

Celanese Corporation

China Plastic Extrusion Ltd.

Covestro AG

Eastman Chemical Company

GSH Industries

Berry Global Inc

JM EAGLE INC

As industries evolve and consumer demands shift, the Extruded Plastics market emerges as a linchpin in the production and fabrication of a myriad of everyday items.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭:@https://www.metastatinsight.com/report/extruded-plastics-market

The Extruded Plastics market revolves around the extrusion process, a manufacturing technique that transforms raw plastic materials into a diverse array of products. This process involves heating raw plastic resins and forcing them through a die to create continuous profiles of varying shapes and sizes. The resulting products find applications across numerous sectors, ranging from construction and packaging to automotive and electronics.

One of the key drivers of the Global Extruded Plastics market lies in its versatility. The ability to mold plastics into complex shapes and structures, coupled with their lightweight nature, positions extruded plastics as the material of choice in an increasingly diverse range of applications. From the ubiquitous PVC pipes used in construction to the intricate profiles used in automotive components, extruded plastics have become indispensable in modern manufacturing.

The packaging industry stands out as a major consumer of extruded plastics. The demand for flexible and lightweight packaging solutions has propelled the market forward. Extruded plastic films and sheets cater to the evolving needs of the packaging sector, providing durability, cost-effectiveness, and customization options. Additionally, the rise of sustainable packaging practices has spurred innovation within the Extruded Plastics market, leading to the development of eco-friendly alternatives.

Beyond packaging, the construction industry relies heavily on extruded plastics for a spectrum of applications. Window profiles, pipes, and insulation materials exemplify the adaptability of extruded plastics in construction. The inherent durability, corrosion resistance, and thermal insulation properties make extruded plastics a preferred choice in architectural projects across the globe.

The Global Extruded Plastics market is a dynamic and integral player in the larger landscape of polymer-based industries. Its adaptability, versatility, and continual innovation underscore its significance in shaping various sectors. As the world progresses, the Extruded Plastics market will undoubtedly remain at the forefront of material technology, contributing to the creation of a wide array of products that define our modern way of life.

Global Extruded Plastics market is estimated to reach $310.2 Million by 2031; growing at a CAGR of 4.4% from 2024 to 2031.

Contact Us:

+1 214 613 5758

#ExtrudedPlastics#ExtrudedPlasticsmarket#ExtrudedPlasticsindustry#marketsize#marketgrowth#marketforecast#marketanalysis#marketdemand#marketreport#marketresearch

0 notes

Text

Applications of CNC Rotary Tables in Various Industries [Infographic]

CNC rotary tables have become indispensable in modern manufacturing. They enhance the capabilities of CNC machines by adding an additional axis of movement. These versatile tools play a pivotal role in improving precision, efficiency, and flexibility across various industries. Below, we explore the key applications of CNC rotary tables and how they contribute to diverse sectors.

1. Aerospace Industry

In the aerospace industry, precision is non-negotiable. CNC rotary tables are used to machine complex components such as turbine blades, engine parts, and structural elements. Their ability to handle intricate geometries and maintain tight tolerances ensures the production of reliable and high-performance aerospace components. The rotary table's multi-axis capabilities allow manufacturers to achieve precision milling, drilling, and contouring, meeting the stringent requirements of aerospace engineering.

2. Automotive Industry

The automotive sector relies heavily on CNC rotary table for producing gears, camshafts, and other critical engine parts. These tables enable manufacturers to perform high-precision machining, ensuring consistency and quality in mass production. Additionally, their use in the creation of custom automotive components supports the growing demand for electric vehicles (EVs) and other innovations in the industry.

3. Medical Device Manufacturing

CNC rotary tables are essential in the medical industry for fabricating intricate components like surgical instruments, orthopedic implants, and prosthetics. The rotary table's high precision allows for the creation of small, complex parts that meet the strict regulatory standards of the healthcare sector. Moreover, their versatility enables manufacturers to work with a variety of materials, including stainless steel, titanium, and specialized medical-grade alloys.

4. Energy Sector

From wind turbines to oil and gas equipment, the energy sector benefits from the capabilities of CNC rotary tables. These tools are used to produce large, heavy-duty components such as flanges, rotors, and pipe connectors. Their robust construction and precise movement ensure reliable performance even in demanding applications, making them a vital asset in energy production and distribution.

5. Tool and Die Manufacturing

The tool and die industry relies on CNC rotary tables for creating molds, dies, and other specialized tools. These components often require intricate details and high accuracy, which rotary tables provide. By enabling simultaneous multi-axis machining, they help manufacturers reduce production time and achieve superior surface finishes.

6. Electronics and Semiconductor Industry

Miniaturization and precision are essential in the electronics sector. CNC rotary tables are used to machine micro-components for semiconductors, circuit boards, and other electronic devices. Their capability to handle small-scale, high-precision tasks ensures optimal performance in the production of cutting-edge electronic equipment.

7. Jewelry and Watchmaking

Artisans in the jewelry and watchmaking industries use CNC rotary tables to craft intricate designs and detailed engravings. These tables enable precise machining of precious metals, ensuring consistency and quality in luxury products. The ability to achieve complex patterns and fine details makes rotary tables invaluable in these highly specialized fields.

Benefits of CNC Rotary Tables

Enhanced Precision: Ideal for applications requiring tight tolerances.

Increased Efficiency: Reduces production time by enabling multi-axis machining.

Versatility: Suitable for various materials and industries.

Cost-Effectiveness: Streamlines production processes, minimizing waste.

Also Read: 4 Benefits of Using Industrial CNC Rotary Table From China

Conclusion

CNC rotary tables are a cornerstone of modern manufacturing, enabling industries to achieve unparalleled precision and efficiency. From aerospace and automotive to medical and electronics, these tools are instrumental in driving innovation and meeting the demands of a competitive market.

Explore the advanced CNC rotary tables from SilverCNC and discover how they can elevate your manufacturing processes. Whether you need precision, versatility, or efficiency, SilverCNC offers solutions tailored to your industry’s unique requirements.

To read more information visit https://tinyurl.com/yk3b7spt and call now at +86 180 9892 0890 or email us at [email protected]

0 notes

Text

Composites Market Business Analysis, Share, Revenue & Sales Till 2030

The global composites market size is expected to reach USD 163.97 billion by 2030, registering a CAGR of 7.2% over the forecast period, according to a new report by Grand View Research, Inc. The demand for composites is expected to witness significant growth owing to the rising fuel prices and stringent government regulations have shifted automobile manufacturers focus on light-weighted components which would further propel the market demand over the forecast period.

Composite products play an essential role in the manufacturing of automotive and aircraft parts. The growing concerns regarding fuel consumption and CO2 emission levels have prompted the manufacturers to use carbon fiber composite materials as substitutes for metal components. Technological innovations to minimize the manufacturing cycle time is expected to propel the usage of composites in the automotive sector.

The high cost of composites has limited their application scope to premium segment cars. However, key players are conducting extensive R&D activities to develop low-cost composite grades with similar mechanical properties as that of the high-cost variants. This is expected to spur the demand for the product in the automotive industry over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Global Composites Market

Composites Market Report Highlights

The glass fiber segment accounted for the largest market share in 2022 and is further expected to grow at a CAGR of 6.4% on account of increased penetration in pipe manufacturing applications owing to the strength and durability of these composites. Additionally, glass fiber comprises several thin that find application in building & construction, automotive, industrial, energy, and consumer goods

The layup process segment is forecasted to grow at a CAGR of 9.0% by 2030. The market is again forecast to grow due to easier technology applications and the requirement of less expensive machinery. The process involves placing multiple layers of composite fiber in a sequence by using a matrix of resin and hardener

The automotive & transportation segment dominated the composites market with a revenue share of USD 19.70 billion in 2022. This is attributed to its advantages such as fuel saving to the transportation sector as the components are significantly lighter in weight that allows ascending fuel efficiency

The demand for composites in Asia Pacific was the largest in the global market due to the increase in air passenger traffic, rise in automotive vehicle production, and ambitious electrical & electronics production capacity addition targets set by various governments in the Asia Pacific including China, India, Japan, and South Korea

Various initiatives such as technology innovations, research & development, partnerships, and merger & acquisitions to manufacture cost-effective and lightweight composite products have been undertaken by the key market players. Prominent players have patented technologies used for composites manufacturing

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

Aluminum Composite Panels Market: The global aluminum composite panel market size was estimated at USD 6.47 billion in 2024 and is expected to grow at a CAGR of 7.0% from 2025 to 2030.

Centrifugal Pump Market: The global centrifugal pump market size was estimated at USD 39.80 billion in 2024 and is projected to grow at a CAGR of 4.2% from 2025 to 2030.

Composites Market Segmentation

Grand View Research has segmented the collated screws market on the basis of product, manufacturing process, end-use, and region:

Composites Product Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Carbon Fiber

Glass Fiber

Others

Composites Manufacturing Process Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Layup Process

Filament Winding Process

Injection Molding Process

Pultrusion Process

Compression Molding Process

Resin Transfer Molding Process

Others

Composites End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

Automotive & Transportation

Wind Energy

Electrical & Electronics

Construction and Infrastructure

Pipes & Tanks

Marine

Others

Composites Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Order a free sample PDF of the Composites Market Intelligence Study, published by Grand View Research.

0 notes

Text

Composites Market 2030 Overview, Regional Outlook, Growth Report

The global composites market size is expected to reach USD 163.97 billion by 2030, registering a CAGR of 7.2% over the forecast period, according to a new report by Grand View Research, Inc. The demand for composites is expected to witness significant growth owing to the rising fuel prices and stringent government regulations have shifted automobile manufacturers focus on light-weighted components which would further propel the market demand over the forecast period.

Composite products play an essential role in the manufacturing of automotive and aircraft parts. The growing concerns regarding fuel consumption and CO2 emission levels have prompted the manufacturers to use carbon fiber composite materials as substitutes for metal components. Technological innovations to minimize the manufacturing cycle time is expected to propel the usage of composites in the automotive sector.

The high cost of composites has limited their application scope to premium segment cars. However, key players are conducting extensive R&D activities to develop low-cost composite grades with similar mechanical properties as that of the high-cost variants. This is expected to spur the demand for the product in the automotive industry over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Global Composites Market

Composites Market Report Highlights

The glass fiber segment accounted for the largest market share in 2022 and is further expected to grow at a CAGR of 6.4% on account of increased penetration in pipe manufacturing applications owing to the strength and durability of these composites. Additionally, glass fiber comprises several thin that find application in building & construction, automotive, industrial, energy, and consumer goods

The layup process segment is forecasted to grow at a CAGR of 9.0% by 2030. The market is again forecast to grow due to easier technology applications and the requirement of less expensive machinery. The process involves placing multiple layers of composite fiber in a sequence by using a matrix of resin and hardener

The automotive & transportation segment dominated the composites market with a revenue share of USD 19.70 billion in 2022. This is attributed to its advantages such as fuel saving to the transportation sector as the components are significantly lighter in weight that allows ascending fuel efficiency

The demand for composites in Asia Pacific was the largest in the global market due to the increase in air passenger traffic, rise in automotive vehicle production, and ambitious electrical & electronics production capacity addition targets set by various governments in the Asia Pacific including China, India, Japan, and South Korea

Various initiatives such as technology innovations, research & development, partnerships, and merger & acquisitions to manufacture cost-effective and lightweight composite products have been undertaken by the key market players. Prominent players have patented technologies used for composites manufacturing

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

Aluminum Composite Panels Market: The global aluminum composite panel market size was estimated at USD 6.47 billion in 2024 and is expected to grow at a CAGR of 7.0% from 2025 to 2030.

Centrifugal Pump Market: The global centrifugal pump market size was estimated at USD 39.80 billion in 2024 and is projected to grow at a CAGR of 4.2% from 2025 to 2030.

Composites Market Segmentation

Grand View Research has segmented the collated screws market on the basis of product, manufacturing process, end-use, and region:

Composites Product Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Carbon Fiber

Glass Fiber

Others

Composites Manufacturing Process Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Layup Process

Filament Winding Process

Injection Molding Process

Pultrusion Process

Compression Molding Process

Resin Transfer Molding Process

Others

Composites End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

Automotive & Transportation

Wind Energy

Electrical & Electronics

Construction and Infrastructure

Pipes & Tanks

Marine

Others

Composites Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Order a free sample PDF of the Composites Market Intelligence Study, published by Grand View Research.

0 notes

Text

Casing Centralizer Market Analysis: Growth Trends and Forecast Through 2031

The Casing Centralizer Market size was valued at USD 420.20 million in 2023 and is expected to grow to USD 738.33 million by 2031 and grow at a CAGR of 7.3% over the forecast period of 2024–2031.

Market Overview

Casing centralizers are essential drilling tools that maintain the position of casing pipes within boreholes, which is crucial for ensuring uniform cement distribution. This helps prevent gas migration and formation breakdown, making centralizers a vital component in the successful completion of drilling operations.

With the expansion of both onshore and offshore drilling projects, as well as investments in advanced drilling technologies, the demand for effective casing centralizers is expected to grow steadily over the forecast period.

Request Sample Report@ https://www.snsinsider.com/sample-request/2999

Key Market Drivers

Increasing Drilling Activities: Growing demand for oil and gas resources, especially in developing regions, is fueling the need for extensive drilling operations, thereby driving the casing centralizer market.

Advancements in Casing Centralizer Technology: Technological innovations are leading to the development of advanced centralizers that enhance efficiency and reduce operational risks.

Focus on Enhanced Well Integrity: Casing centralizers contribute to improved wellbore stability and uniform cementing, which are critical for well integrity and safety.

Offshore Exploration Growth: Expanding offshore drilling projects, particularly in deep-water and ultra-deep-water regions, are creating a demand for robust casing centralizers.

Environmental and Safety Regulations: Regulatory requirements for well safety and environmental protection are prompting companies to adopt high-quality centralizers that ensure safe and efficient drilling.

Market Segmentation

The casing centralizer market can be segmented by type, material, application, and region.

By Type

Bow Spring Casing Centralizers: Known for their flexibility, these centralizers are used in a range of wellbore applications due to their ability to maintain centralization under challenging conditions.

Solid Rigid Centralizers: Offering strength and durability, solid rigid centralizers are ideal for highly deviated or horizontal wells.

Semi-Rigid Centralizers: These provide a balance between rigidity and flexibility, suitable for moderate wellbore conditions.

Mold On Centralizers: Molded directly onto the casing, these centralizers are beneficial in low-clearance situations.

By Material

Steel: Commonly used in high-strength applications, steel centralizers offer durability and resistance in extreme conditions.

Aluminum: Known for its lightweight properties, aluminum centralizers are used in less demanding applications where lower weight is an advantage.

Zinc: Zinc centralizers provide corrosion resistance, making them suitable for certain offshore and corrosive onshore environments.

By Application

Onshore: Onshore drilling remains a significant segment, especially in areas with abundant shale reserves and established oil fields.

Offshore: Offshore applications, including deep-sea exploration, require specialized centralizers that can withstand high pressures and corrosive conditions.

Regional Analysis

North America: The U.S. and Canada are leading regions for casing centralizer demand, driven by extensive shale drilling activities and advancements in drilling technologies.

Europe: Europe’s growing offshore exploration activities, particularly in the North Sea, are contributing to market growth in this region.

Asia-Pacific: Countries like China and India are experiencing increased drilling activities to meet domestic energy demand, fueling demand for casing centralizers.

Latin America: The region, led by Brazil, is investing in offshore exploration, making it a key market for casing centralizers.

Middle East & Africa: Known for its vast oil reserves, this region is a significant market for centralizers due to ongoing onshore and offshore drilling projects.

Current Market Trends

Innovation in Materials and Design: Manufacturers are focusing on developing lighter and more durable materials that can withstand extreme environments and improve performance.

Increased Focus on Offshore Exploration: The demand for offshore casing centralizers is growing, especially as countries explore new reserves in deep-sea and ultra-deep-sea areas.

Customization of Centralizers: To meet the unique requirements of each wellbore, companies are providing customized centralizer solutions that offer enhanced performance.

Investment in Sustainable Practices: The industry is investing in environmentally sustainable practices, with centralizers being designed to reduce waste and improve efficiency.

R&D for Enhanced Efficiency: Research and development efforts are focused on creating centralizers that reduce friction, minimize drag, and provide optimal centralization in complex wellbores.

Buy a Complete Report of Casing Centralizer Market 2024–2031@ https://www.snsinsider.com/checkout/2999

Conclusion

The global casing centralizer market is poised for strong growth as drilling activities continue to expand globally. With technological advancements, the need for efficient wellbore centralization, and rising offshore exploration projects, the demand for high-quality casing centralizers will only increase. As the market advances, manufacturers are expected to invest in innovative materials and customized solutions to meet the evolving needs of the oil and gas industry.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions. Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Thermoplastic Elastomer Market Size, Share and Growth Report, 2031

Global thermoplastic elastomers market is projected to witness a CAGR of 3.9% during the forecast period 2024-2031, growing from 6.25 million tons in 2023 to 8.49 million tons in 2031. The flourishing footwear industry is augmenting the demand for thermoplastic elastomers market growth. This growth is attributed to footwear sales through e-commerce sites and increasing sports events. The increasing deployment of thermoplastic elastomers in transport parts bolstered market growth. For instance, according to the Alliance for Automotive Manufacturers, in 2022, investments in automotive parts manufacturing reached USD 43 billion.

The robust growth of the transportation sector is ascribed to various factors, including the production expansion of aircraft, multiple government initiatives to develop electric vehicle manufacturing hubs, and the ongoing manufacturing activities associated with the new marine vessels. The increasing consumer demand for a new range of footwear, shifting consumer preferences, and advancements in manufacturing technologies are some of the prime attributes influencing the growth of the footwear industry at the global level. Thus, the robust growth of the transportation and footwear sectors at the global level is boosting the demand for thermoplastic elastomers to ensure superior chemical resistance, which, in turn, is supplementing the market growth.

In addition, the recent opening of new facilities for thermoplastic elastomer development will boost the supply of products in the global market, thereby creating a lucrative opportunity for market growth in the long run. For instance, in October 2022, Audia Elastomers launched a new manufacturing plant in Changshu, China. The new manufacturing facility of Audia Elastomers is manufacturing a range of elastomers, including thermoplastic elastomers (TPEs). However, thermoplastic elastomers have several performance limitations, restraining the market’s growth.

The Booming Transportation Industry at the Global Level is Augmenting the Market Traction

In the transportation industry, deploying thermoplastic elastomers is vital as the material ensures superior benefits, such as being lightweight, cost-effective, and highly durable, as opposed to thermoset materials in the total system cost, thereby making it increasingly desirable for transport product manufacturers. Thermoplastic elastomers are employed in transportation products such as commercial aircraft, passenger vehicles, cruise ships, and others. The development of new transport manufacturing facilities, rising commercial flight activities, increasing aircraft production, and surging innovations in the upgraded transport vehicle models are some of the prominent variables fostering the transportation sector’s growth at the global level.

For instance, according to Airbus, a global aircraft manufacturer, the production of A330 aircraft reached 3 per month in 2022. Moreover, Airbus is focusing on increasing the production of A330 aircraft by 4 in 2024. Furthermore, Airbus delivered 611 commercial aircraft units, and in 2022, it was 661 units, an annual growth rate of 8%. Hence, the booming transportation industry is fueling the adoption of thermoplastic elastomers for manufacturing bumpers, air ducts, and high & low-pressure pipes, which forms a major aspect accelerating the market growth.

Download free Sample Report- https://www.marketsandata.com/industry-reports/thermoplastic-elastomers-market/sample-request

The Bolstering Footwear Sector is Supplementing the Growth of the Market

Thermoplastic elastomers are ideal for manufacturing footwear midsoles as TPEs serve significantly higher levels of flexibility than traditional materials such as ethylene-vinyl acetate (EVA) foams. Additionally, thermoplastic elastomers can be molded into complex shapes for enhanced cushioning, shock absorbency, and support. The footwear sector is experiencing significant demand growth due to several key factors, including the growing sales facilitated by e-commerce, extensive spending on advertising by footwear brands, rising demand for athletic, trendy, and comfortable footwear, and rapid urbanization.

According to the recent statistics published by the World Footwear Yearbook 2023, 2022 global footwear production was 23.9 billion pairs, representing a year-on-year growth rate of 7.6%. Likewise, according to the Sports & Fitness Industry Association (SFIA), the sporting goods industry experienced record-breaking sales in 2021, with a 15.8% increase in revenue from 2020 and a 16.4% increase since 2019 pre-pandemic numbers. Henceforth, the bolstering footwear sector is spurring the demand for thermoplastic elastomers to ensure superior damping properties, propelling the market growth.

Superior Technical Properties of Thermoplastic Elastomers are Amplifying the Market Growth

The thermoplastic elastomers are equipped with beneficial technical properties such as specific gravity at 0.89-1.0, shore hardness of 60A-75D, low-temperature limit at -60°C, high-temperature limit at 120°C, compression set resistance at 100 °C, and resistance to hydrocarbon fluids. Thus, due to the above technical properties, thermoplastic elastomers are often deployed in various applications such as transport parts, construction extruded seals, and electrical and electronic components.

For instance, according to the recent data published by Invest India, in 2022, the production of electronic components in India was valued at USD 11 billion and is projected to reach USD 18 billion by 2026. Therefore, the superior technical properties associated with thermoplastic elastomers augment the adoption of TPEs across various applications, thereby proliferating the market growth.

Asia-Pacific Held a Significant Share in the Thermoplastic Elastomers Market

The regional economic growth of the Asia-Pacific is driven by the expansion of the various end-use industries such as medical equipment, transportation, building & construction, and industrial. Prominent variables, such as increasing spending power of people, flexible trade regulations, easy availability of raw materials, and ease of import-export policies, are some of the favorable aspects fostering the growth of the transportation sector in the Asia Pacific region.

According to the recent report published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2022, the Asia Pacific region held the highest manufacturing share in the global automotive share, which was 58.8% of the global automotive share. Moreover, in 2021, the production of automobiles in the Asia-Pacific region was 46,768,800 units, whereas in 2022, it was 50,020,793, representing a year-on-year growth rate of 7%. Thus, the booming transportation sector in the Asia-Pacific region is boosting the adoption of thermoplastic elastomers to ensure superior durability, thereby supplementing the market growth in the region.

Impact of COVID-19

The COVID-19 pandemic in 2020 restrained the supply of raw materials, labor movement, and halt in the production of non-essential industrial products. As a result, the demand for thermoplastic elastomers declined. Furthermore, the demand revenue losses incurred by various end-use industries, such as transportation, industrial, and building and construction, resulted in the decline in the growth of the thermoplastic elastomers industry.

For instance, according to the statistics published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2019, the global production of automotive was 92,175,805 units and in 2020, it was 77,621,582, a decline of 15.8%. However, the sudden surge in the need for medical equipment boosted the demand for thermoplastic elastomers. Additionally, favorable government measures across various countries efficiently promoted the resurgence of various end-use industries, including thermoplastic elastomers, thereby accelerating the market growth in the years 2021 and 2022.

Impact of Russia Ukraine War

The Russia and Ukraine war had a strong impact on respective economies. Since Russia is among the major trade partners of Europe, the supply chain disruption strongly impacted the production activities in the region. As a result, there was a shortage of automotive components in the European countries during 2022, ultimately resulting in a decline in automotive production in the region.

For instance, according to the recent data published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2021, the automotive production in Netherlands was 107,021 units and in 2022, it was 101,670 units, an annual decline of 5% as compared to 2021. However, the procurement of materials from local sources and other prominent markets such as China and India aided the growth of the thermoplastic elastomers market despite the impact of the Russia-Ukraine war in the first half of 2022.

Report Scope

“Thermoplastic Elastomers Market Assessment, Opportunities and Forecast, 2017-2031F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of the global thermoplastic elastomers market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities, and forecast between 2024 and 2031. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/thermoplastic-elastomers-market

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

#Thermoplastic Elastomer Market#Thermoplastic Elastomer Market Size#Thermoplastic Elastomer Market Share

0 notes

Text

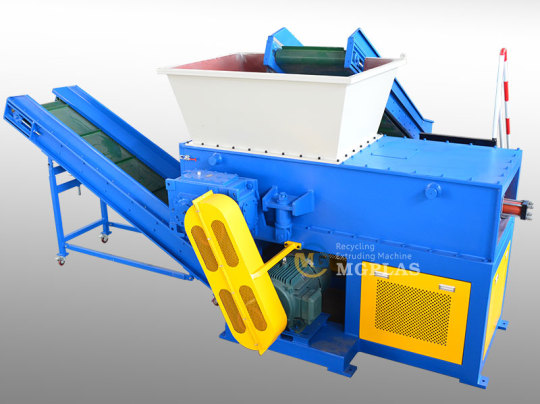

China Good Quality Rigid Plastic Shredder Machine for Sale: A Comprehensive Guide

In the modern era of industrial production, the demand for efficient and reliable plastic waste management solutions has never been higher. Among the leading solutions is the rigid plastic shredder machine, a critical asset for recycling and waste management facilities. For businesses seeking top-notch quality at competitive prices, machinemg.com offers exceptional rigid plastic shredder machines made in China. This article delves into the features, benefits, and reasons why investing in these machines can be a game-changer for your operations.

What is a Rigid Plastic Shredder Machine?

A rigid plastic shredder machine is specifically designed to process tough, durable plastic materials that are commonly used in a variety of industries. These machines can handle various plastic products, including pipes, drums, containers, and large molded parts, breaking them down into smaller, manageable pieces for recycling or disposal.

Key Features of Rigid Plastic Shredder Machines

High Durability:

Constructed with robust materials, these machines can withstand heavy-duty use, ensuring longevity and consistent performance.

Powerful Shredding Capability:

Equipped with strong, sharp blades, the shredder efficiently cuts through rigid plastics, significantly reducing their volume.

User-Friendly Design:

Designed for ease of use, these machines come with intuitive controls and safety features to protect operators.

Energy Efficiency:

Advanced engineering ensures that the machines use energy efficiently, reducing operational costs while maintaining high productivity.

Versatility:

Suitable for a wide range of plastic materials, making them an ideal choice for various industries.

Benefits of Using Rigid Plastic Shredder Machines

Environmental Impact:

By converting large plastic waste into smaller pieces, these machines facilitate recycling, reducing landfill waste and promoting a circular economy.

Cost Savings:

Recycling plastic waste on-site can significantly lower disposal costs and create a new revenue stream through the sale of shredded materials.

Space Efficiency:

Shredding reduces the volume of plastic waste, saving valuable space in storage and transportation.

Compliance:

Helps businesses comply with environmental regulations by managing waste responsibly and sustainably.

Why Choose machinemg.com?

Quality Assurance:

Machines from machinemg.com are manufactured to the highest standards, ensuring reliability and excellent performance.

Competitive Pricing:

Offering top-quality machines at competitive prices, making it a cost-effective solution for businesses of all sizes.

Expert Support:

The company provides comprehensive support, from choosing the right machine to installation and maintenance, ensuring a seamless experience.

Proven Track Record:

With a history of satisfied customers and successful installations, machinemg.com is a trusted name in the industry.

Conclusion

Investing in a high-quality rigid plastic shredder machine from machinemg.com is a smart move for businesses looking to enhance their waste management practices, improve efficiency, and contribute to environmental sustainability. With robust features, significant benefits, and the backing of a reputable supplier, these machines are a valuable addition to any industrial setup. Visit machinemg.com today to explore their range of shredder machines and take the first step towards a more efficient and eco-friendly operation.

#wpc production line#wpc machine#Plastic crusher machine#Waste shredder machine#Plastic shredder machine

0 notes

Text

Non-metallic Gasket Material

Non-metallic Gaskets

Non Metallic Gasket Material refers to a broad category of different gasket materials that do not contain metal. These materials, which include rubber, silicone, graphite, and PTFE, are known for their flexibility, adaptability, and excellent sealing capabilities. They can be easily cut and shaped to fit a wide range of applications, from automotive and plumbing to industrial machinery. Some non-metallic gasket materials can withstand high temperatures and resist a variety of chemicals, making them a versatile choice for many sealing needs. The lifespan and environmental impact of these gaskets can vary depending on the specific material and application.

What Are the Advantages of Non-metallic Custom Gasket Material?

Non metallic seal gasket materials offer several advantages. They are highly flexible and adaptable, allowing them to be easily cut and shaped to fit a wide range of applications. This makes them ideal for complex or custom sealing needs. Many non-metallic materials, such as rubber, silicone, and PTFE, have excellent sealing properties and can effectively seal under low bolt load. They also have good resistance to a variety of chemicals and can withstand different temperature ranges, enhancing their versatility. Additionally, non-metallic gaskets are often more cost-effective than their metallic counterparts. Lastly, many non-metallic materials are recyclable or biodegradable, making them a more environmentally friendly option.

What Are the Applications of Non-metallic Gasket Material?

Non-metallic gasket materials are used in a wide range of applications due to their versatility and adaptability. In the automotive industry, they are used for sealing engines, transmissions, and fuel systems. In plumbing, they are used to create watertight seals in pipes and fittings. In industrial machinery, they are used to prevent leaks and maintain pressure in various systems. They are also used in the electronics industry for insulation and protection. Non-metallic gaskets can be found in appliances, HVAC systems, and even in the food and beverage industry, where they are used to seal containers and machinery to ensure hygiene and prevent contamination.

FAQS

FAQs of Non-metallic Gasket Material

How is Non-metallic Gasket Material made?

The manufacturing process varies depending on the specific material. For example, rubber gaskets can be molded, while PTFE gaskets are often cut from sheets.

Can Non-metallic Gasket Material withstand high temperatures?

How long does Non-metallic Gasket Material last?

Is Non-metallic Gasket Material environmentally friendly?

0 notes

Text

Iron Casting: Navigating Opportunities and Challenges in the Sector

The global iron casting market size is expected to reach USD 172.66 billion by 2030, according to a new report by Grand View Research, Inc., expanding at a CAGR of 6.1% over the forecast period. The increasing investments in the infrastructure & renewable energy industry are expected to propel the demand for the product. Iron castings are produced by pouring melted cast iron into casts or molds to make products of desired shape and size, via various methods such as sand and investment casting. Different product types available in the market include gray, ductile, and malleable, which are used according to their application requirements.

Iron Casting Market Report Highlights

Based on the product, ductile cast iron is anticipated to register the fastest CAGR of 6.4%, in terms of revenue, from 2022 to 2030. The product is preferable in various end-use industries such as automotive, water system & sanitization, and renewables as it offers higher toughness and strength than gray cast iron.

Based on application, the railway is expected to grow at a CAGR of 7.4%, in terms of revenue, across the forecast period. This growth is attributable to increasing investments by countries to develop their rail infrastructure to promote transportation of goods via rail and improve connectivity.

Based on region, North America is expected to register a CAGR of 5.5%, in terms of revenue, over the forecast period. Rising emphasis on shifting towards renewables, investment in railways, up-gradation & development of water system & sanitization, and advancement of machines & tools is expected to drive the market growth in the region.

For More Details or Sample Copy please visit link @: Iron Casting Market Report

Based on product, gray cast iron held the largest revenue share of the global market in 2021, and this trend is expected to continue across the forecast period. It is preferred owing to the benefits it offers such as abrasive resistance, vibration damping capacity, and better castability than other types. The product is used for making machine tool bases, soil pipes, automobile engine blocks, and internal combustion engine head manifolds.

Based on region, Asia Pacific held the largest revenue share of the global market in 2021. In the region, China was the key market in 2021 but India is expected to register the fastest growth rate across the forecast period. The increasing demand for the product from various industries such as railways, renewables, machines & tools, and infrastructure is propelling competition in the region.

In February 2022, Bharat Forge announced the acquisition of JS Autocast Foundry India, a manufacturer of ductile iron castings for hydraulics, wind energy, automotive, and off highways. The acquisition is anticipated to help Bharat Forge expand its product portfolio as well as manufacturing presence.

The global market is highly competitive in nature. Key players in the industry are carrying out mergers & acquisitions for the development of their business. For instance, In November 2021, Wisconsin-based Charter Manufacturing acquired Aarrowcast Inc., a gray and ductile iron casting manufacturer. Aarrowcast Inc. has a production capacity of 42,000 tons per year. This acquisition is expected to help Charter Manufacturing to expand the manufacturing of its metal offerings and diversify its customer base.

#IronCasting#FoundryIndustry#MetalCasting#IndustrialManufacturing#Metallurgy#GlobalMarket#FoundryTechnology#CastingProcesses#IronFoundry#Metalworking#FoundryEquipment#CastingIndustry#MarketAnalysis#IronProduction#FoundryTrends

0 notes

Text

dual mold sewer sealing fitting

China bi mold maker, offer multi material plumbing drainage fitting, two shot bath drainage pipe, bicolor toilet connection sewage pipe, dual mold sewer sealing fitting

#china mold#2 component mold#bi material mold#two color plumbing drainage fitting mold#2k bathroom drainage pipe mold#multi shot toilet connection sewage pipe mold#double sewer sealing fitting mold

0 notes

Text

UNLEASH YOUR CREATIVITY: FEEKE-TPPYONY 600 PCS PIPE CLEANERS CRAFT SET

Feeke products are popular among consumers for their durability and performance.They aims to provide high-quality and reliable products.

Hot Product

Feeke-tppyony 600 Pcs Pipe Cleaners Craft Set Including 200Pcs Chenille Stems

Pipe Cleaners: 100 x fiber pipe cleaners, 100 x metallic pipe cleaner chenille stems.10 Random Colors each set. Size: 6 mm x 12 Inch. Easy to bend and mold to create designs. Colorful, soft and ideal for all craft projects.

Pom Poms Craft: Contains 250 pcs pom poms craft in different sizes.

Wiggle Eyes: 150 x self-sticking wiggle eyes,meet your different needs for making crafts, size: 5/ 8/ 12 mm.

Multi-Purpose Cleaners: Use it to create handmade small articles such as roses, more animals, vegetables and so on by your idea.

Guarantee: Your satisfaction with our product and service is our priority. Unconditional return rights are reserved by all customers.

A Review Of Feeke

Haven’t worked with the eyes yet but the wire cleaners are excellent for rainy day fun or lately during the quarantine. We were able to do some projects that kept him entertained and gave him something to do while I was teleworking. You will need to YouTube some videos on what to make because this doesn’t come with any instructions on how to create art projects.

Customer Q&As

Q: Where are these manufactured from?

A: They were made from China.

Q: How is this packaged? Does it come with a storage case?

A: No case, it comes in packaged cellophane that is resealable.

Convenient Storage: Keep your crafting supplies organized and easily accessible with the convenient storage container included in the set. With separate compartments for pipe cleaners and accessories, you can neatly store and transport your crafting materials wherever inspiration strikes.

Unleash Your Creativity: Discover the joy of crafting with the Feeke-tppyony 600 Pcs Pipe Cleaners Craft Set. With its abundance of pipe cleaners and colorful accessories, this comprehensive set provides endless opportunities for imaginative expression and creative exploration, allowing you to unleash your creativity and make your crafting dreams a reality.

0 notes

Text

https://www.advancemarketanalytics.com/reports/104979-global-drum-melter-market

Drum Melter Market May See a Big Move

Advance Market Analytics released a new market study on Global Drum Melter Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Drum Melter Forecast till 20279*.

Drum Melter is called band heater, which mostly is used to reduce the viscosity of liquids and gels by heating in order to fill, pump, or bottle with to respective liquid or to prevent liquids from freezing inside the drum. Drum Melter is mostly used for cooling tubes for liquid cooling. Drum Melter mostly used in automotive & transportation, non-woven industries (diapers, adult incontinence products, sanitary napkins, and other one-time use products), paper & packaging. Geographically, North America is the leading region in terms of consumption in various automotive, manufacturing as well as transportation industries. Hence this is a key factor and application which is dominating the market in a positive manner

Key Players included in the Research Coverage of Drum Melter Market are:

Tempco Electric Heater Corporation (United States), The Cary Company (United States), Ulane (United States), Cast Aluminum Solutions , AirPac, Inc (United States), Backer Marathon (United States), BriskHeat (United States), Creative Assemblies,Inc (United Kingdom), Dalton Electric Heating Co, Inc (United States), DBK Designs,Inc (United States), Delta T (United States), Hampton Controls.Inc (United States), Hazloc Heaters (Canada), Marathon (United States), Others

What's Trending in Market: It has huge opportunities for PVC pipe bending

Challenges: An excessive amount of heating may damage the quality of the product

Market Growth Drivers: It is a chip solution for high maintenance energy without paying its cost Barrel heater allows for slow, controlled heating without the danger of scorching product

The Global Drum Melter Market segments and Market Data Break Down by Type (Cast-In Band Heaters, Ceramic Band Heaters, Tubular Band Heaters, Others), Application (Autoclaves & sterilizers, Blow molding machines, Blow film Dies, Others), Shape (Cone, Cylindrical, Hexagon, Others), Distribution Channel (Wholesaler, Distributor, Retailer, Others)

Get inside Scoop of the report, request for free sample @: https://www.advancemarketanalytics.com/sample-report/104979-global-drum-melter-market

To comprehend Global Drum Melter market dynamics in the world mainly, the worldwide Drum Melter market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

0 notes

Text

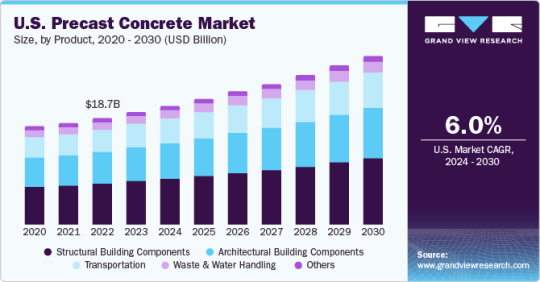

Precast Concrete Market Size To Reach $156.13 Billion By 2030

Precast Concrete Market Growth & Trends

The global precast concrete market size is expected to reach USD 156.13 billion by 2030, registering a CAGR of 5.8% over the forecast period, according to a new report by Grand View Research, Inc. This growth can be attributed to the increasing construction activities in the residential, commercial, and industrial sectors. Precast concrete is used in the production of various products used in construction, such as wall panels, underground vaults, pipes, tanks, slabs, and barriers. Construction end-users prefer precast structures due to their superior strength and durability. Precast concrete also helps in the faster completion of construction projects, leading to increased adoption. Offsite construction is gaining prominence in the construction industry as the method helps in saving time and avoiding material wastage.

The process can be carried out irrespective of the weather conditions. The growth in offsite construction is anticipated to be a key driver for the industry over the forecast period. Although precast concrete has several advantages over conventional concrete, its use in developing countries is limited due to the high investment involved. The cost of machinery and molds needed for the manufacturing of these products is high and requires advanced technology with highly skilled labor to handle the same. Thus, the high initial investments are projected to hamper the growth over the forecast period. The Asia Pacific construction industry has been developing rapidly in recent years. The industry has witnessed numerous technological advancements and the proliferation of unique architectural designs that promote the usage of precast concrete in commercial, residential, and industrial applications.

Rapid industrialization in emerging economies, such as China and India, has led to a rise in the construction of factories and office spaces. In addition, industrialization has led to migration, resulting in increased urbanization and the growth of residential construction activities. Developed regions, such as North America, have also seen a rise in residential construction activities due to an increased consumer expendable income. The construction industry in Central & South America is also expected to witness substantial growth on account of the rising investments in various infrastructure projects by foreign and domestic private players in the region. The construction of single-family houses in the region contributed majorly to the residential construction market.

This is attributed to the increasing number of people living separately in the majority of the countries in the region. The industry consists of several global players providing high-quality products focusing on price differentiation, thus leading to high competition in the industry. Strategies followed by key players include long-term contracts with end-users and intensive R&D activities. The prominent industry players have signed agreements with raw material suppliers and construction companies to maintain their market position. In addition, most of the key players collaborate with local end-users and suppliers to minimize operational costs and improve their localized market share.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/precast-concrete-market

Precast Concrete Market Report Highlights

Structural building components segment is expected to register the fastest CAGR of 6.2% from 2024 to 2030 due to their superior characteristics like high strength, increased durability, and faster installation

The infrastructure application segment dominated the industry in 2023 owing to high investments in infrastructure development by emerging as well as developed economies

Asia Pacific is estimated to witness the fastest growth rate during the forecast period owing to the high economic growth in the region and rising industrial & commercial investments by private players and local governments

The construction industry in MEA is expected to face setbacks due to uncertainty in government spending on infrastructure development. However, increasing the consumer base in the region will likely boost the market growth in the coming years

The global demand was hampered due to the COVID-19 pandemic in 2020. Government regulations resulted in delays and cancellation of planned construction projects, negatively impacting the industry growth

Precast Concrete Market Segmentation

Grand View Research has segmented the global precast concrete market report on the basis of element, construction type, product, application, end-use, and region:

Precast Concrete Element Outlook (Revenue, USD Billion; 2018 - 2030)

Girders

Columns & Beams

Walls & Barriers

Floors & Roofs

Utility Vaults

Pipes

Paving Slabs

Others

Precast Concrete Construction Type Outlook (Revenue, USD Billion; 2018 - 2030)

Elemental Construction

Permanent Modular Buildings

Relocatable Construction

Precast Concrete Product Outlook (Revenue, USD Billion; 2018 - 2030)

Wet Concrete

Dry/Semi-dry Concrete

Precast Concrete Application Outlook (Revenue, USD Billion; 2018 - 2030)

Structural Building Components

Architectural Building Components

Transportation

Waste & Water Handling

Others

Precast Concrete End-Use Outlook (Revenue, USD Billion; 2018 - 2030)

Residential

Commercial

Infrastructure

Tunnels

Bridges

Wind Towers

Industrial

Precast Concrete Regional Outlook (Revenue, USD Billion; 2018 - 2030)

North America

S.

Canada

Mexico

Europe

Germany

UK

France

Spain

Italy

Poland

Czech Republic

Croatia

Asia Pacific

China

India

Japan

South Korea

Singapore

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

Israel

List of Key Players of Precast Concrete Market

Boral Ltd.

LafargeHolcim

Gulf Precast Concrete Co. LLC

Olson Precast Company

CEMEX S.A.B. de C.V

Forterra Pipe and Precast LLC

Tindall Corporation

Spancrete

Elementbau Osthessen GmbH & Co., ELO KG

GÜlermak A.S.

STECS

LAING O’Rourke

Larsen & Toubro Ltd.

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/precast-concrete-market

#Precast Concrete Market#Precast Concrete Market Size#Precast Concrete Market Trends#Precast Concrete Market Share#Precast Concrete Market Forecast

0 notes

Text

Masterbatch Market 2030 Driving Factors, Future Trends, Size & Key Vendors

In 2023, the global masterbatch market reached a valuation of USD 6.24 billion and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2024 to 2030. Masterbatch is used to add color to polymers and enhance their properties, making it highly suitable for applications across diverse industries, such as automotive, transportation, building and construction, consumer goods, and packaging. A key factor driving this market growth is the shift from metal to plastic components in various end-use sectors due to plastics’ lighter weight, cost-effectiveness, and versatile properties.

Masterbatch products are available in solid and liquid forms, and they enhance polymers with properties such as antistatic, antifog, antilocking, UV stabilization, and flame retardation. These enhancements are achieved by combining masterbatch with various carrier polymers like polypropylene, polyethylene, polyvinyl chloride, and polyethylene terephthalate. These materials can then be used in key manufacturing processes, including injection molding and extrusion, which are crucial for producing plastic components across many industries.

Gather more insights about the market drivers, restrains and growth of the Masterbatch Market

In the United States, growing demand from the packaging sector is expected to be a significant driver of masterbatch market growth. This demand surge is linked to the rapid expansion of the e-commerce industry, which has increased the need for durable, attractive packaging solutions. The U.S. hosts over 16,800 plastic manufacturing facilities nationwide, highlighting the scale of plastic usage in consumer goods, construction, automotive, and other industries. Manufacturers are increasingly focusing on visually appealing packaging to attract consumers, particularly in competitive markets. Masterbatch is used to create vibrant, diverse packaging designs that enhance consumer appeal, which is expected to further boost demand.

Moreover, masterbatch applications are expanding into new areas within the packaging industry. For instance, in July 2023, Gerdau Graphene and Brazilian film manufacturer Packseven developed a graphene-enhanced stretch film using masterbatch technology. This advanced film, produced with graphene masterbatch, allows for a 25% reduction in plastic usage while maintaining film strength and durability. This example highlights how innovation in masterbatch technology can lead to material savings and increased efficiency in packaging.

End-use Segmentation Insights:

In 2023, the packaging sector led the masterbatch market, capturing a revenue share of 26.91%. The strong demand for packaging spans across retail, industrial, and consumer segments, including both flexible and rigid packaging options. The rising urban population, particularly in metropolitan areas, has intensified the demand for packaged goods, which, in turn, drives the need for masterbatch in the packaging industry. Consumers are increasingly looking for packaging that is convenient, sustainable, flexible, protective, and traceable. Since plastic packaging can meet all these criteria, its demand is expected to rise, thereby boosting the demand for masterbatch.

The packaging industry is also witnessing strong growth potential in emerging markets, particularly in countries like India and China, where rapid urbanization and economic growth are fueling demand. These countries are investing heavily in infrastructure, leading to an increase in building and construction activities. This growth in construction fuels demand for masterbatch, as the construction industry uses plastics for applications such as insulation, piping, and coatings. Government initiatives, such as India’s "Make in India" and the Smart Cities Mission, are expected to stimulate construction projects further, thus driving the demand for masterbatch products in these regions.

In summary, the masterbatch market is expanding due to its ability to enhance the functionality and aesthetics of plastics in numerous applications. With increasing demand from the packaging industry, coupled with innovative new applications like graphene-enhanced films, the masterbatch market is poised for steady growth. Additionally, emerging economies and large-scale construction activities are anticipated to contribute significantly to the demand for masterbatch, making it a crucial material for the future of diverse industries globally.

Order a free sample PDF of the Masterbatch Market Intelligence Study, published by Grand View Research.

0 notes