#Precast Concrete Market Trends

Explore tagged Tumblr posts

Text

Precast Concrete Market Size To Reach $156.13 Billion By 2030

Precast Concrete Market Growth & Trends

The global precast concrete market size is expected to reach USD 156.13 billion by 2030, registering a CAGR of 5.8% over the forecast period, according to a new report by Grand View Research, Inc. This growth can be attributed to the increasing construction activities in the residential, commercial, and industrial sectors. Precast concrete is used in the production of various products used in construction, such as wall panels, underground vaults, pipes, tanks, slabs, and barriers. Construction end-users prefer precast structures due to their superior strength and durability. Precast concrete also helps in the faster completion of construction projects, leading to increased adoption. Offsite construction is gaining prominence in the construction industry as the method helps in saving time and avoiding material wastage.

The process can be carried out irrespective of the weather conditions. The growth in offsite construction is anticipated to be a key driver for the industry over the forecast period. Although precast concrete has several advantages over conventional concrete, its use in developing countries is limited due to the high investment involved. The cost of machinery and molds needed for the manufacturing of these products is high and requires advanced technology with highly skilled labor to handle the same. Thus, the high initial investments are projected to hamper the growth over the forecast period. The Asia Pacific construction industry has been developing rapidly in recent years. The industry has witnessed numerous technological advancements and the proliferation of unique architectural designs that promote the usage of precast concrete in commercial, residential, and industrial applications.

Rapid industrialization in emerging economies, such as China and India, has led to a rise in the construction of factories and office spaces. In addition, industrialization has led to migration, resulting in increased urbanization and the growth of residential construction activities. Developed regions, such as North America, have also seen a rise in residential construction activities due to an increased consumer expendable income. The construction industry in Central & South America is also expected to witness substantial growth on account of the rising investments in various infrastructure projects by foreign and domestic private players in the region. The construction of single-family houses in the region contributed majorly to the residential construction market.

This is attributed to the increasing number of people living separately in the majority of the countries in the region. The industry consists of several global players providing high-quality products focusing on price differentiation, thus leading to high competition in the industry. Strategies followed by key players include long-term contracts with end-users and intensive R&D activities. The prominent industry players have signed agreements with raw material suppliers and construction companies to maintain their market position. In addition, most of the key players collaborate with local end-users and suppliers to minimize operational costs and improve their localized market share.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/precast-concrete-market

Precast Concrete Market Report Highlights

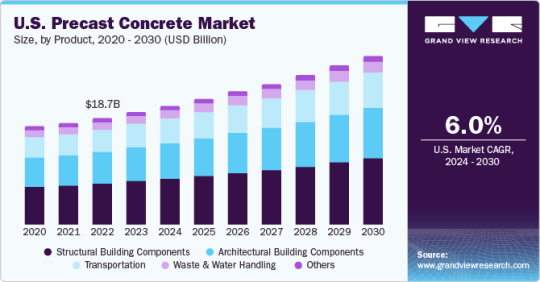

Structural building components segment is expected to register the fastest CAGR of 6.2% from 2024 to 2030 due to their superior characteristics like high strength, increased durability, and faster installation

The infrastructure application segment dominated the industry in 2023 owing to high investments in infrastructure development by emerging as well as developed economies

Asia Pacific is estimated to witness the fastest growth rate during the forecast period owing to the high economic growth in the region and rising industrial & commercial investments by private players and local governments

The construction industry in MEA is expected to face setbacks due to uncertainty in government spending on infrastructure development. However, increasing the consumer base in the region will likely boost the market growth in the coming years

The global demand was hampered due to the COVID-19 pandemic in 2020. Government regulations resulted in delays and cancellation of planned construction projects, negatively impacting the industry growth

Precast Concrete Market Segmentation

Grand View Research has segmented the global precast concrete market report on the basis of element, construction type, product, application, end-use, and region:

Precast Concrete Element Outlook (Revenue, USD Billion; 2018 - 2030)

Girders

Columns & Beams

Walls & Barriers

Floors & Roofs

Utility Vaults

Pipes

Paving Slabs

Others

Precast Concrete Construction Type Outlook (Revenue, USD Billion; 2018 - 2030)

Elemental Construction

Permanent Modular Buildings

Relocatable Construction

Precast Concrete Product Outlook (Revenue, USD Billion; 2018 - 2030)

Wet Concrete

Dry/Semi-dry Concrete

Precast Concrete Application Outlook (Revenue, USD Billion; 2018 - 2030)

Structural Building Components

Architectural Building Components

Transportation

Waste & Water Handling

Others

Precast Concrete End-Use Outlook (Revenue, USD Billion; 2018 - 2030)

Residential

Commercial

Infrastructure

Tunnels

Bridges

Wind Towers

Industrial

Precast Concrete Regional Outlook (Revenue, USD Billion; 2018 - 2030)

North America

S.

Canada

Mexico

Europe

Germany

UK

France

Spain

Italy

Poland

Czech Republic

Croatia

Asia Pacific

China

India

Japan

South Korea

Singapore

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

Israel

List of Key Players of Precast Concrete Market

Boral Ltd.

LafargeHolcim

Gulf Precast Concrete Co. LLC

Olson Precast Company

CEMEX S.A.B. de C.V

Forterra Pipe and Precast LLC

Tindall Corporation

Spancrete

Elementbau Osthessen GmbH & Co., ELO KG

GÜlermak A.S.

STECS

LAING O’Rourke

Larsen & Toubro Ltd.

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/precast-concrete-market

#Precast Concrete Market#Precast Concrete Market Size#Precast Concrete Market Trends#Precast Concrete Market Share#Precast Concrete Market Forecast

0 notes

Text

0 notes

Text

Global Precast Concrete Market Size and Growth Trends: Forecast 2024-2032

The global precast concrete market size was valued at USD 133.84 billion in 2023 and is projected to grow from USD 141.01 billion in 2024 to USD 232.93 billion by 2032, at a CAGR of 6.5% during 2024-2032. Precast concretes mean mold in the reusable form which can be used to provide a superior level of resistance to insects and mold, or natural disasters, or in case of fires. Unlike other building material, precast concrete is resistant to termites, requires low maintenance, and meager insurance costs. As per a report by Fortune Business Insights, titled, “Precast Concrete Market Size, Share & Industry Analysis, By Product Type (Building Components, Transportation, Water & Waste Handling, and Others), By End-Use (Residential, and Non-Residential), and Regional Forecast, 2024-2032,” the market value was USD 115.98 billion in 2019.

The Report Answers the Following Queries:

What is the nature of the market?

Who are the key players of the market for precast concrete, and what is their strategy?

How will urbanization contribute to the growth of the market?

What are the recent industry developments in this market?

Drivers & Restraints-

Increasing Demand for Commercial and Residential Spaces to Propel Growth

Increasing population, growing industries and businesses, and the rising need for residential and commercial spaces are the key factors promoting the precast concrete market growth. In addition to this, rapid urbanization and industrialization have propelled the demand for construction activities. This has led to a rise in the expenditure for construction activities, thereby augmenting growth.

On the contrary, certain drawbacks may pull down this market in the future. These include the environmental and health concerns concerning cement manufacturing. It is believed that cement production releases many gases such as sulfur dioxide, carbon monoxide, and nitrogen oxide into the atmosphere. This may result in numerous environmental impacts such as global warming, depletion in the quality of water, and acid rain, among others. Besides this, there are several health issues such as visual impairment, asthma, and various cardiovascular diseases that may cause hindrance to the overall market in the coming years.

Segment:

Building Components Segment Earned Major Share Attributed to Utilization in Construction Projects

Based on segmentation by product type, the building components segment gained the largest precast concrete market share. Growth of this segment is attributable to the increasing demand for cost-efficient quality houses at affordable prices that propelled a rise in the number of construction projects.

Regional Analysis-

Asia Pacific to Emerge Dominant on Account of Rising Investments in Infrastructural Development

Geographically, Asia Pacific earned a revenue of USD 46.97 billion in the year 2019 and received the largest precast concrete market share. This is attributable to the increasing investments on infrastructural development by emerging nations such as India, China, and Japan in the forecast duration that will propel the demand for precast concrete in the regional market. Europe ranks second on account of the increasing use of precast concrete products for commercial and industrial construction projects.

Competitive Landscape-

Players Focusing on Geographical Expansion for Gaining Significant Position in Market

The global market for precast concrete is fragmented as the number of players is many. Some of them are investing heavily on material supply and other partnership strategies to gain a competitive edge in the market. Others are planning on expanding their brand presence geographically to draw significant revenues to the market.

Get More Information: https://www.fortunebusinessinsights.com/precast-concrete-market-103301

Major Industry Developments of the Market for Precast Concrete Include:

January 2019 – Alfons Greten Betonwerk was acquired by Lafarge Holcim for operating collaboratively on one ready-mix and one precast concrete plant located in Germany. This effort is expected to help increase its brand presence in the nation.

April 2017 – The Caissons of maritime infrastructure by Bouygues Construction was pre-casted for the Monaco offshore extension project located in Marseille. This will help to serve as the new base for offshore extensions.

Some of the Key Players of the Market for Precast Concrete include:

Oldcastle Precast (U.S.)

Balfour Beatty(U.K.)

Bouygues Construction(France)

Elementbau Osthessen GmbH & Co., ELO KG (Germany)

Spancrete (U.S.)

Tindall Corporation (U.S.)

Forterra (U.S.)

CEMEX (Mexico)

Larson & Turbo Limited (India)

Olson Precast Company (U.S.)

Gulf Precast (UAE)

LafargeHolcim (Switzerland)

Boral (Australia)

Other players

0 notes

Text

Precast Boundary Walls: A Reliable and Cost-Effective Perimeter Solution

Precast Boundary Walls: A Reliable and Cost-Effective Perimeter Solution

Let’s discuss the advantages of precast boundary walls over other comparable solutions in the market. When it comes to fencing around residential, commercial or industrial structures, precast boundary walls are by far the most secure, durable and beautiful structures one can ever imagine. These structures are made of high quality Concrete casted in molds at the factory and then transported to the appropriate sites. Precast boundary walls have very strong benefits over traditional bricks or masonry walls, and hence these walls are growing in trend due to their performance, quick installation, and durable usage.

Resilience and Endurance: Exploring structure walls for boundaries, precast concrete is exceptional because of its ability to withstand extreme and changing weather. Precast walls, as opposed to fencing made of bricks or timber, do not corrode, wear away or break, allowing for safe and secure containment over time.

Reduction of Time During Dry Construction: Remember that prefabricated walls do not require dry installation at the building site. Thanks to the hope of work on245545476 installation, the wall can be assembled within days which cuts down labor expenses and time of construction with respect to ex54ist construction systems like bricks and stones.

Economical: Precast concrete requires low upkeep and hence is a solution that is viable in the long run. Wood and steel may need frequent repair or anti-rust treatment which is impractical with inexpensive building fences such as precast concrete.

Aesthetic Options: Owners of building structures have a wide choice in the designs, colors and textures of precast panels so that they select the most appropriate one which complements the surroundings.

Security and Privacy: A precast boundary wall is high offering a solid fence that affords the user utmost secured and private enclosure making it perfect for withstanding residential constructions, industries and commercial places.

Conclusion

Precast boundary walls offer a smart, efficient, and low-maintenance solution for property owners seeking a reliable way to define and secure their spaces. With their durability, quick installation, and aesthetic options, precast walls are the perfect choice for modern boundary solutions.

1 note

·

View note

Text

AAC Block Making Machines in India

As India continues to experience rapid urbanization and infrastructural growth, the demand for innovative building materials has surged. Among these, Autoclaved Aerated Concrete (AAC) blocks have emerged as a preferred choice due to their lightweight, energy-efficient, and eco-friendly properties. Central to the production of these versatile blocks are AAC block making machines, which play a crucial role in enhancing the construction landscape in India. This article explores the significance of AAC block making machines, their features, and their impact on the Indian construction industry.

Understanding AAC Blocks

AAC blocks are precast building materials made from a mixture of cement, lime, water, and an expanding agent, usually aluminum powder. The mixture is poured into molds and then subjected to a curing process under high-pressure steam in an autoclave. This process gives AAC blocks their distinctive properties, including excellent thermal insulation, soundproofing, and fire resistance. These attributes make AAC blocks an attractive option for residential, commercial, and industrial construction.

The Role of AAC Block Making Machines

The production of AAC blocks requires specialized machinery designed to ensure efficiency, consistency, and quality. AAC block making machines automate the entire manufacturing process, from mixing raw materials to curing and packaging the finished products. Here are some key features and components of these machines:

Mixing UnitThe mixing unit combines cement, lime, water, and the expanding agent in precise ratios to create a uniform slurry. This step is critical for ensuring the quality of the AAC blocks.

Molding SystemOnce mixed, the slurry is poured into molds that shape the blocks. Advanced machines feature automated systems that streamline this process, reducing labor costs and increasing output.

Cutting and ShapingAfter the blocks are formed, they are cut to the desired dimensions using specialized cutting equipment. This ensures uniformity in size and shape, which is essential for construction standards.

Curing ChamberThe cured blocks undergo a steaming process in an autoclave, where they are subjected to high pressure and temperature. This step is crucial for achieving the strength and durability of the blocks.

Packaging and HandlingOnce cured, the blocks are automatically packaged for transportation. Efficient handling systems minimize damage and ensure that the blocks reach construction sites in optimal condition.

Advantages of AAC Block Making Machines

High Production CapacityModern AAC block making machines are designed for high output, enabling manufacturers to meet the increasing demand for AAC blocks in the construction industry.

Consistency and QualityAutomated processes reduce human error, ensuring that each block meets stringent quality standards. This consistency is vital for large-scale construction projects.

Labor EfficiencyBy automating many aspects of production, AAC block making machines reduce the need for manual labor, resulting in lower labor costs and improved safety on the manufacturing floor.

Eco-Friendly ProductionThe production of AAC blocks involves minimal waste, and the use of recycled materials, such as fly ash, can further enhance their sustainability. Advanced machines can optimize resource utilization, contributing to eco-friendly practices.

Customization OptionsMany AAC block making machines allow for the customization of block sizes and shapes, catering to the specific needs of builders and architects. This flexibility can enhance market competitiveness.

The Growing Market in India

The market for AAC block making machines in India is rapidly expanding. As the country focuses on sustainable construction practices, the adoption of AAC blocks is on the rise. Government initiatives promoting green building technologies and energy-efficient construction further drive this trend.

Additionally, the increasing number of infrastructure projects, including residential complexes, commercial buildings, and industrial facilities, has created a significant demand for AAC blocks. Consequently, manufacturers are investing in advanced AAC block making machines to scale production and meet market needs.

Conclusion

AAC block making machines are at the forefront of India’s construction revolution, enabling the efficient production of sustainable and high-quality building materials. As the country grapples with urbanization and the pressing need for eco-friendly construction solutions, these machines will play a pivotal role in shaping the future of the industry. With their numerous advantages, including high production capacity, consistency, and eco-friendliness, AAC block making machines are set to transform the Indian construction landscape, paving the way for a more sustainable future.

0 notes

Text

Concrete Superplasticizers Market Innovations in High-Performance Concrete Solutions

Concrete Superplasticizers Market Growth Strategic Market Overview and Growth Projections

The global concrete superplasticizers market size was valued at USD 4.8 billion in 2022 and is projected to reach a value of USD 7.8 billion by 2031, registering a CAGR of 5.6% during the forecast period (2023-2031).

The latest Global Concrete Superplasticizers Market by straits research provides an in-depth analysis of the Concrete Superplasticizers Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Concrete Superplasticizers Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Concrete Superplasticizers Market are

Arkema

Sika AG

BASF SE

GCP Applied Technologies Inc.

MAPEI S.p.A.

Kao Corporation

M&I Materials Limited

Dupont

SOLVAY

R. Grace & Co.-Conn.

Setral Chemie GmbH

Enaspol a.s

CAC Admixtures

CHRYSO GROUP

Ashland Inc

Rhein-Chemotechnik GMBH

Get Free Request Sample Report @ https://straitsresearch.com/report/concrete-superplasticizers-market/request-sample

The Concrete Superplasticizers Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Concrete Superplasticizers Market: Segmentation

The Concrete Superplasticizers Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Type

PC Derivatives

Sulfonated Naphthalene Formaldehyde (SNF)

Sulfonated Melamine Formaldehyde (SMF)

Modified Lignosulfonates (MLS)

By Form

Ready-Mix Concrete (RMC)

Precast Concrete

High-Performance Concrete

Others

By Application

Ready-Mix Concrete (RMC)

Precast Concrete

High-Performance Concrete

Others

By End-Use Sector

Residential

Commercial

Infrastructure

Other End-use Sectors

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/concrete-superplasticizers-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Concrete Superplasticizers Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Concrete Superplasticizers Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Concrete Superplasticizers Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Concrete Superplasticizers Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Concrete Superplasticizers Market Market#Concrete Superplasticizers Market Market Share#Concrete Superplasticizers Market Market Size#Concrete Superplasticizers Market Market Research#Concrete Superplasticizers Market Industry#What is Concrete Superplasticizers Market?

0 notes

Text

Concrete Admixtures Market Analysis of Growth, Trends and Forecast to 2030

The rising demand for concrete admixture in the constructions industry is a significant driver for market growth. concrete admixture plays a crucial role in the construction industry. The high demand for precast concrete's excellent strength, adaptability, and durability makes it ideal for use in pre-fabricating buildings and modern construction units. Precast concrete demand is rising as a result of the increased demand for green buildings. Precast construction is made up of a variety of precast elements, including walls, beams, slabs, columns, staircases, landings, and some bespoke ones that are standardized and created to ensure the building's stability, toughness, and structural integrity.

According to the UnivDatos Market Insights Analysis, the rising awareness for concrete admixtures market will drive the global scenario of the concrete admixtures market and as per their “Concrete Admixtures Market” report, the global market was valued at USD 500 million in 2021, growing at a CAGR of 8.2% during the forecast period from 2023 - 2030.

Request Free Sample Pages with Graphs and Figures Here - https://univdatos.com/get-a-free-sample-form-php/?product_id=48659

Employing concrete admixture, the infrastructure industries are expected to benefit from the rising demand for precast concrete is growing rapidly in the construction sector, which will support the growth of the superplasticizer market over the forecast period. This growth is being driven by the expansion of the construction industry in some emerging nations, the growth of commercial and residential construction projects, as well as the hotel industry, and the demand for quick installations and results.

Moreover, cement, water, sand, and aggregates are components of ready-mix concrete (RMC). When laying concrete in tiny batches or on an irregular schedule, ready-mix concrete is especially useful. The best uses for ready-mixed concrete include huge projects where there is not much capacity for an aggregate stockpile or a mixing facility. It is modified in accordance with the applications in the industrial, infrastructure, residential, and commercial sectors. Roadways, factories, and residential areas in general and industrial structures employ ready-mixed concrete. Ready-mix concrete is extensively utilized in the construction industry.

Moreover, ready-mix concrete that offers greater quality is expanding due to the expanding construction industry and rising demand for new homes and businesses. Due to its higher convenience, simplicity of use, and superior quality, ready-mix concrete is frequently employed in place of conventional concrete. The simplicity of installation and labor shortage at construction sites are the two main factors influencing demand for RMC. RMC are also much easier to transport than traditional concrete, which increases demand for RMC and superplasticizer because to their increased durability and other desirable qualities. Precast concrete and ready mix concrete are therefore likely to be used more frequently, which will increase the market's revenue.

Related Reports-

Middle East Building Information Modelling Market: Current Analysis and Forecast (2023-2030)

Indian Aluminium Formworks Market: Current Analysis and Forecast (2023-2030)

Construction Industry to Extensively Utilize Concrete Admixture in Future over the Forecast Period

The disruption in the construction industry due to government restrictions implemented during the COVID-19 pandemic had a significant influence on the adoption of concrete admixtures. This pandemic had generated uncertainty and unprecedented delays on construction projects. Also, due to machinery closures, the severe shortage of trained and skilled labor, and a scarcity of raw materials, the building construction processing remained closed. According to the United Nations Environment Program (UNEP) organization, in 2020, the impact of COVID-19 on the global construction industry has been severe, and construction activities have decreased by 10–25% when compared with the previous year 2019. Furthermore, the pandemic had negatively disrupted the economy and has simultaneously affected businesses, households, industrial establishments, and financial institutions. However, various governments are coming up with supportive policies and seeking to re-establish their economy back on track. As a result, the construction industry is likely to stabilize over the next couple of years.

Secondly, demand for concrete admixture would increase due to growing interest in carbon-free materials and the demand for carbon-free steel. Increasing use of carbon-free steel in a variety of industries, including cars, electronics, freight, and construction projects.

Additionally, the rising awareness about carbon-free materials, demand for carbon-free steel is anticipated to boost the need for concrete admixture in the upcoming decade.

For more information about this report visit- https://univdatos.com/report/concrete-admixtures-market/

Conclusion:

The concrete admixture market conclusion market is poised for significant growth in the coming years, particularly in the construction industry. The increasing demand for infrastructure, including impurities, counterions, and APIs, is driving the adoption of concrete admixtures market conclusion as a preferred analytical technique.

The versatility of concrete admixtures are artificial or natural additives that are included in the concrete mixture or added beforehand. The major goal of adding these admixtures is to give the buildings features like corrosion resistance, workability, durability, compressive strength, and finish ability. The use of concrete will be accelerated by the quickly expanding building sector, which raises the need for admixtures. Additionally, the product's capacity to reduce the amount of time that hardened concrete has to cure combined with quick infrastructure development will further fuel market expansion during the anticipated time range.

Furthermore, the regulatory landscape in the construction industry places a strong emphasis on compliance and quality assurance. Concrete admixtures provide the necessary capabilities to meet these regulatory requirements, contributing to its growing adoption in the infrastructure sector.

Overall, the concrete admixtures market is set to experience rapid expansion, driven by the construction industry's need for accurate analysis, regulatory compliance, and quality assurance. The future looks promising concrete admixtures market, as it continues to play a vital role in ensuring the safety and efficacy of construction industry.

0 notes

Text

Smart Solutions: IoT and AI Integration in Precast Concrete Manufacturing

Precast Concrete market size was valued at USD 146.3 Billion and is supposed to reach a valuation of USD 258.2 Billion by 2032. Between 2023 and 2032, this market is estimated to register the highest CAGR of 6.0%.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/precast-concrete-market/#requestSample

Precast concrete refers to concrete elements that are cast in a reusable mold and cured in a controlled environment before being transported to the construction site. This method offers several advantages over traditional onsite casting, including better quality control, enhanced safety, and increased efficiency. The ability to reuse molds multiple times before replacement adds to the cost-effectiveness of precast concrete, making it an attractive option for many construction projects.

The precast concrete market is experiencing significant growth due to the rising trend towards sustainable and cost-effective construction methods. As urbanization and construction activities increase, especially in developing nations, the demand for modern infrastructure is driving the market forward. Precast concrete is not only eco-friendly but also aligns with the industry's shift towards more efficient building techniques.

The growth of this market is expected to continue as more construction projects adopt precast concrete to meet the demands of urban development and infrastructure modernization. This trend highlights the importance of precast concrete in the future of construction, offering a blend of quality, safety, and sustainability.

Market Key Segments

Product Type

Foundations

Structural Beams

Slabs

Walls

Other Product Types

Application

Structural Building Components

Architectural Building Components

Transportation Products

Waste & Water Handling Products

Other Applications

End-user

Residential

Non-Residential

In the precast concrete market, structural beams and building components are experiencing high demand, driven by urbanization and infrastructure development worldwide. Non-residential sectors, such as commercial spaces, educational institutions, and healthcare facilities, dominate the market due to increased public and private investments. Residential segments are also growing, supported by global population growth and government initiatives aimed at affordable housing. This dual growth trajectory underscores the versatility and durability of precast concrete in meeting diverse construction needs across both urban and industrial landscapes.

Market Key Players

Boral

LafargeHolcim

Gulf Precast

Olson Precast Company

Larsen & Toubro Limited

CEMEX

Forterra

Tindall Corporation

Spancrete

Elementbau Osthessen GmbH & Co., ELO KG

Bouygues Construction

Balfour Beatty

Oldcastle Precast

Other Key Players

Driver:

The advantages of precast concrete, including superior quality, faster construction times, and durability, are major drivers in the market. These benefits attract construction projects seeking efficiency and reliability, particularly in urban and infrastructure developments where time and quality are crucial.

Restraint:

High initial costs and the requirement for skilled labor pose significant challenges to the precast concrete market. The investment in molds and specialized equipment, coupled with the need for trained personnel, limits widespread adoption, especially in developing regions where cost sensitivity is higher.

Opportunity:

The growth of offsite construction, facilitated by precast concrete's suitability for prefabrication, presents a significant opportunity. This method offers advantages like reduced construction time and weather-independent assembly, appealing to industries aiming for faster project completion and enhanced efficiency.

Challenge:

Environmental regulations and sustainability concerns pose challenges to the precast concrete market. Meeting stringent environmental standards while maintaining cost-effectiveness and operational efficiency remains a balancing act for manufacturers and developers alike. Adapting to evolving regulatory landscapes and enhancing sustainable practices will be crucial for long-term growth and market acceptance.

0 notes

Text

Precast Concrete Construction Market - Forecast(2024 - 2030)

Precast Concrete Construction Market Overview

Precast concrete construction market size is forecast to reach US$156.5 billion by 2027, after growing at a CAGR of 4.5% during the year 2022-2027. Precast concrete is a type of construction product that is made by��concrete mixing, casting concrete in a reusable mold, and then curing it in a controlled environment before transporting it to the construction site and lifting it into place. Precast concrete containing expanded polystyrene is beneficial for construction activities as they are lightweight and thermally insulated. The precast concrete market is majorly driven by the surging commercial construction activities across various regions. For instance, in March 2022, commercial construction projects such as the Paris Olympics facilities construction 2024, the CIBC Square office building in Canada, 2024, and more such commercial projects are under construction. Additionally, the increasing infrastructure development projects including bridges, airports, and more are expected to fuel the demand for precast concrete, thereby, propelling the precast concrete construction industry growth over the forecast period.

Download Sample

COVID-19 Impact

The Covid-19 pandemic hampered the precast concrete construction market growth in the year 2020. Governments all across the world imposed stringent lockdown regulations, which resulted in a temporary halt on commercial, residential, and other types of construction activities. For instance, in March 2020, the Mayor of Boston restricted the construction activities in Boston, U.S related to commercial, residential, and other types. Likewise, such temporary halts related to construction activities in other regions negatively impacted the precast concrete demand because it is utilized in the floor, beams, and other such applications. This resulted in revenue losses for the precast concrete construction market. However, in 2021, the surge in construction activities due to increased safety measures facilitated the precast concrete construction market growth. Moreover, it is predicted during the upcoming years the impact of the Covid-19 pandemic will be restrictive, which will lead to a precast concrete construction industry growth trend similar to the pre-Covid time.

Report Coverage

The "Precast Concrete Construction Market Report –Forecast (2022-2027)”, by IndustryARC, covers an in-depth analysis of the following segments of the Precast Concrete Construction Industry.

By Type: Beam (Internal and External), Floor (Internal and External), Walls (Infill and Cantilever), Stairs, Column (Edge column, Inner Column, and Corner column), Roof, Paving Slabs, and Others

By Construction Type: New Construction and Remodeling/Renovation Construction

By End-Use Industry: Residential (Independent Houses, Row Houses, and Apartments), Commercial (Office Buildings, Healthcare Facilities, Retail Stores, Banks, Hotels and Restaurants, Concert Halls and Museums, Sports Arena, Educational Institutes, and Others), Industrial (Warehouse, Manufacturing Facilities, and Others), and Infrastructure (Dams, Tunnels, Airports, Parking Spaces, Railways, Flyovers and Bridges, Roads, Pavements, and Others)

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East (Saudi Arabia, UAE, Israel, and Rest of Middle East), and Africa (South Africa, Nigeria, and Rest of Africa))

Key Takeaways

Asia-Pacific region dominated the precast concrete construction market, owing to the increasing commercial construction activities in the region. For instance, in August 2021, Hotel Okura Co., Ltd based in Japan announced the construction of the Hotel Okura Shanghai Sheshan, which will be completed in 2024.

Building Information Modeling (BIM) is increasingly being used in precast concrete projects because it allows for more efficient design, manufacture, and construction by generating and managing virtual models that include both physical properties and functional behavior. The implementation of contemporary systems is benefiting the market growth.

Moreover, modern precast concrete sandwich systems utilizing expanded polystyrene (EPS) are gradually replacing traditional blockwork systems due to their lightweight, improved insulating features, and quick construction, this is creating an opportunity for the precast concrete market.

However, the availability of many substitutes in the market such as reinforced concrete, prefabrication concrete, and more is restricting the precast concrete construction market. Asia-PacificPrecast Concrete Construction MarketRevenue, 2021-2027 (US$ Billion)

#Precast concrete construction market price#Precast concrete construction market size#Precast concrete construction market share

0 notes

Text

0 notes

Text

https://www.intellectualmarketinsights.com/report/precast-concrete-market-size-and-trends/imi-001816

0 notes

Text

Geopolymers Market Regional Analysis, Key Players, Future Projection, Comprehensive Study, and Forecasts

The Insight Partners stands out as a reliable ally in the syndicated market research and consultation through its steadfast commitment to the market research industry. With extensive experience and proven dedication, we have been delivering outstanding outcomes. With a team of researchers catering to distinct business requirements, we can emerge as a trusted research partner in the past decade.

By prioritizing precision and trust ahead, we are proud to announce the addition of the latest offering titled “Geopolymers Market Growth Outlook to 2031”. This report ensures spotless coverage of recent updates and a range of business environment factors impacting the Geopolymers market growth. The meticulous approach opted by our researchers can assist companies in transforming business space into the Geopolymers market.

Geopolymers market report offers a comprehensive analysis of regional and global scenarios. The scope of the market report extends to the competitive landscape, cost analysis, key players, specific market regions, profit margin, and market situation. A glance at wide-ranging factors restricting Geopolymers market growth is deliberately included in this study.

Objectives of Geopolymers Market Report

To deliver a detailed market overview by integrating quantitative and qualitative analysis

To unveil growth strategies by evaluating the competitive landscape and examining key companies against their position and strategic advantage

To offer estimates on sales volume, market share, size, and CAGR for the projected period.

To offer segment wise insights

This detailed report on Geopolymers market size is heavily based on verified information and authoritative sources. The study intended to offer market players an overview of market opportunities in the coming period. This report helps clients as a first-hand source of knowledge on the market while providing a full-fledged analysis of each segment.

The study contains details on frontrunners in the market along with their recent collaborations, segments, revenues, product launches, and Geopolymers market trends. It projects the competition in the Geopolymers market for an estimated duration. This research further looks at industry channels and the performance of key market players to help businesses stay ahead in the market.

Our Report Sample May Brief On:

Scope of Geopolymers market report

Brief introduction of Geopolymers market and Industry Overview

Table of Contents

Top market players covered in this report

Report Structure

Research Methodologies by The Insight Partners

Regional Insights:

This section includes insights on different regions and key players present in the region. This section attempts to analyze the growth of a specific regional market based on economic, technological, and environmental factors. Readers may expect revenue-based data and sales insights gathered by our team after comprehensive research. This informative chapter remains an absolute perk for investors, as it will help them to understand potential investment value and expected returns in specific regions.

Report Attributes

Details

Segmental Coverage

Product Type

Cement and Concrete

Precast Panel

Grout and Binder

Other Product Types

Application

Building

Road and Pavement

Runway

Pipe and Concrete Repair

Bridge

Tunnel Lining

Railroad Sleeper

Coating Application

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Ask Chemicals India Pvt. Ltd.

eske Lupkove Zavody, A.S.

Ecocem Ireland Ltd.

Fengyuan Chemical

Inomat Gmbh

Milliken Infrastructure Solutions, Llc.

Pci Augsburg Gmbh

Schlumberger Limited

Wagner Global

Zeobond

Other key companies

Why The Insight Partners?

Proven Expertise: The Insight Partners comprises expert market research analysts who have extensive industry-specific knowledge. Through this report, our team is bringing years of experience to the table while safeguarding the accuracy of insights.

Actionable Insights: TIP relies on a combination of primary and secondary research methodologies that drive tangible results. We are committed to keeping our offerings clear, accessible, and concise to guide businesses in the decision-making process.

Integration of Technology: We embrace technology in all its forms as the core of our research tactics. We use various tools and platforms to analyze and interpret the data. This allows timely results.

Summary:

Current and Future Market Estimates- Geopolymers Market Share, and Size | 2031

Market Dynamics – Drivers, Challenges, Regional Trends, and Market Opportunities

Market Segmentation – Product, Application, End-use Industries, and Regional Growth Prospects.

Competition Matrix – Key Market Players and Strategies

Recent Developments and Innovation contributing Market Growth

Author’s Bio:

Shashikant Ligade

Senior Analyst The Insight Partners

0 notes

Text

Concrete Bonding Agents Market: Revolutionizing Construction Adhesion

The concrete bonding agents market provides strong adhesive properties to bond fresh concrete to old, cured concrete surfaces. These agents are available as cementitious agents or epoxy-based adhesives and are formulated to offer excellent binding strength along with moisture and weather resistance. The products primarily find usage for repairs and construction of industrial floors, overlays, parking structures, and precast elements. The market demand is driven by infrastructure development activities and growth of commercial real estate.

The Global Concrete Bonding Agents Market is estimated to be valued at US$ 2,773.5 Mn in 2024 and is expected to exhibit a CAGR of 8.2% over the forecast period 2023 to 2030. Key players operating in the concrete bonding agents market are Sika AG, Fosroc International Ltd., BASF SE, Saint-Gobain Weber S.A., Mapei S.p.A., Dow Construction Chemicals, Lafarge Holcim, The Euclid Chemical Company, GCP Applied Technologies Inc, Dow Corning Corporation, and The Quikrete Companies, Inc. Rising infrastructure development activities across developing nations and increasing renovations and repairs in developed regions are fueling the demand for concrete bonding agents. Furthermore, the growth of the real estate sector particularly in Asia Pacific is also contributing to the market growth. Concrete bonding agents find widespread application in bonding freshly placed concrete to existing concrete surfaces and repairing cracks or joints in concrete structures. They facilitate quick repairs while ensuring high bond strength even under harsh weather conditions or moisture exposure. The products enhance the lifespan of structures by preventing loose concrete pieces from falling off. They aid in reducing noise levels from impact as well as preventing corrosion of reinforcing steel. With advances in concrete technology, manufacturers are offering eco-friendly, low VOC products along with enhanced workability and early strength gain features. The key trends in the concrete bonding agents market include the development of crystalline admixtures and shotscrete bonding agents. Crystalline admixtures help seal hairline cracks and pores in concrete enabling long-term protection against water and chloride ion ingress. Shotscrete bonding agents are specifically formulated for sprayed concrete applications ensuring uniform bonding to both horizontal and vertical surfaces. Their rapid strength gain facilitates quick turnaround of construction projects.

Porter’s Analysis

Threat of new entrants: The concrete bonding agents market requires large capital investment in production facilities and R&D which makes the threat of new market entrants low.

Bargaining power of buyers: Numerous concrete bonding agent manufacturers globally makes buyers' bargaining power moderate.

Bargaining power of suppliers: Raw materials used in concrete bonding agents such as cement and resins are commoditized, making suppliers' bargaining power moderate.

Threat of new substitutes: Few product substitutes available makes the threat of substitutes low.

Competitive rivalry: The market dominated by few international players intensifies competitive rivalry. Geographical Regions

North America currently holds the largest share of the global concrete bonding agents market in terms of value owing to rising industrial and infrastructure development activities in the region. Growth of the construction industry in developing economies of Asia Pacific is anticipated to drive fastest growth in demand for concrete bonding agents during the forecast period. Countries such as China and India are concentrating significant manufacturing and construction activities in this region, making it an important geographical region for concrete bonding agents market.

#Concrete Bonding Agents Market Growth#Concrete Bonding Agents Market Size#Concrete Bonding Agents Market Share

0 notes

Text

Exploring the Future of Construction. The Rise of AAC Block Plants

In the evolving landscape of global construction, Autoclaved Aerated Concrete (AAC) blocks are emerging as a cornerstone of eco-friendly and efficient building practices. This article delves into the world of AAC block plants, exploring their significance, manufacturing process, benefits, and the impact they are set to have on future construction trends.

What are AAC Blocks?

AAC blocks are lightweight, precast concrete building materials that offer superior insulation, durability, and fire and mold resistance compared to traditional concrete and clay bricks. Made from sand, cement, lime, water, and an expanding agent like aluminum powder, these blocks are autoclaved under heat and pressure to create a cellular structure. This unique composition delivers a material that is about one-fifth the weight of normal concrete.

The Manufacturing Process at an AAC Block Plant

The production of AAC blocks is a fascinating blend of chemistry and precision engineering, and it begins with the mixing of finely ground raw materials (sand, or fly ash), cement, lime, and a small quantity of aluminum powder. This mixture is then poured into molds where it reacts to form hydrogen gas bubbles, causing it to expand. Once the desired aeration is achieved, the material is precut into blocks or panels and then autoclaved under high pressure and temperature to give it structural strength. The end product is a lightweight, robust block with excellent thermal and acoustic properties.

Key Benefits of AAC Blocks

Sustainability: AAC blocks are an environmentally friendly choice. The materials used are abundant and often sourced from industrial waste (fly ash), and the finished blocks are recyclable. Moreover, their lightweight nature reduces transportation costs and emissions.

Thermal Efficiency: These blocks provide superior thermal insulation, reducing the need for additional insulation and the overall energy required for heating and cooling, leading to significant cost savings over the building’s lifetime.

Fire Resistance: AAC blocks are fire-resistant, capable of withstanding up to 1200 degrees Celsius, and can provide fire protection for up to four hours, significantly enhancing building safety.

Pest and Mold Resistance: The inorganic material of AAC blocks does not promote mold or mildew growth and is resistant to pests, contributing to healthier indoor environments.

Ease of Installation: AAC blocks are easy to work with and can be cut to size with standard tools, speeding up the construction process and reducing labor costs.

Challenges and Considerations

While AAC blocks offer numerous advantages, there are challenges to consider:

Initial Investment: Setting up an AAC block plant requires significant initial investment in terms of machinery and technology.

Technical Skill: Producing AAC blocks requires precise control over the material mixture and autoclaving process, necessitating skilled operators.

Market Acceptance: In regions where AAC is not well-known, market penetration can be slow, requiring extensive outreach and education about its benefits.

Future Outlook

The demand for AAC blocks is projected to rise as more builders and architects become aware of their benefits. With increasing regulatory focus on sustainable construction practices, AAC block plants are poised for significant growth. Innovations in manufacturing technology and enhanced supply chains will likely further reduce costs and improve the accessibility of these materials.

In conclusion, AAC block plants represent a transformative advancement in the construction sector, offering a blend of sustainability, efficiency, and performance. As the industry continues to evolve towards greener and more cost-effective building solutions, AAC blocks are undoubtedly set to play a pivotal role in shaping the future of construction.

0 notes