#Cylinder Heads and Cylinder Blocks Manufacturers

Explore tagged Tumblr posts

Link

Due to heat generated, it is not possible to repair cracks and damage to cylinder heads, cylinder liners, and components made of aluminium or cast iron using the welding procedure. Generally, metal locking and metal stitching surgery may fix any heavy components made of aluminium casting. For more information on aluminium crack repair, repair of aluminium cast pistons, and cast iron or steel casting components call +91 9810012383 and email [email protected].

#aluminium crack repair#metal locking and metal stitching#metal locking#metal stitching surgery#cylinder liners#aluminium or cast iron repair#Cast Iron Crack Repair#Aluminium Piston Crack Repair#aluminium crack repair by metal stitching#metal surgery process#Cracked Aluminium Cylinder Head Repair#aluminium casting#damage of cylinder head#manufactured of aluminium or cast iron#repair of damage aluminium casting#Metal Locking process#Fix cracked engine block#Turbine casing crack repair on site

0 notes

Photo

TVR Tuscan 2S

First released in 1999 and manufactured up until 2006 the TVR Tuscan was available in various specifications with varying performance. Being a 2S the car is fitted with the 4 liter Speed-Six TVR engine and revised suspension for increased handling performance. A full engine rebuild was completed resulting in a reliable smooth engine that produces just north of 400BHP. The completed work includes -Syvecs engine management system -Aluminium radiator -FFF EVO2 cylinder head -Billet crankshaft -H section conrods -Up-rated cylinder block -Simplex timing sprockets and chain -Modified half time bearing -New piston rings and bearings -Lightened flywheel -New clutch -Race proven clutch slave cylinder -De-cat exhaust -SC engine mounts -AST suspension -Suspension poly bush kit -Silicone hoses This work completed ensures that this TVR is not only fabulous to drive but most importantly reliable.

200 notes

·

View notes

Text

The W-43 Saga: Oldsmobile’s Experimental 32-Valve 455 V8

Oldsmobile’s experimental W-43 engine is surrounded in myth, legend, and a tall tale or two. Let’s see if we can sort it all out.

Here at Mac’s Motor City Garage, we’re grateful to the World Wide Web for rediscovering so many wonderful stories in automotive history and bringing them to public attention. Still, we have to note that that often, the info isn’t always totally accurate—which is only natural, we suppose. After all, the internet could be described as the biggest and longest game of Telephone in history.

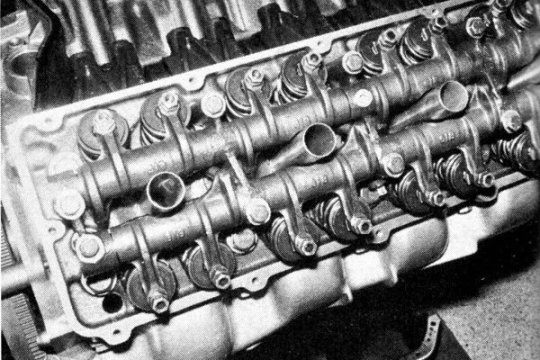

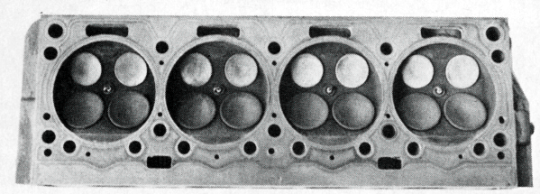

Take this fascinating engine, for instance: the Oldsmobile W-43, an experimental V8 developed in 1967-69. Various sources have described this engine as a hemi (it isn’t) or a Can-Am engine (that was never its purpose) or a double overhead-cam design (nope). In truth, the W-43 was a conventional overhead-valve, pushrod V8, in the classic Motor City style, but with special cylinder heads and valvetrain that provided four valves per cylinder.

To the average car enthusiast, a four-valve head with pushrod operation—that is, each rocker arm and pushrod operating a pair of valves—may seem like an outlandish setup, but in the diesel truck world it’s fairly commonplace (Cummins and Detroit, to name two). It looks cumbersome but it works just fine, especially where high engine speeds are not required.

The W-43 was indeed based on a standard 455 CID production block, but with some key modifications, including four-bolt main caps and special valve follower retainers that bolted into the lifter valley. The spark plugs were buried in tubes in the center of the valve covers, which no doubt fed the stories that the engine was a hemi. Bore, stroke, and other significant specs were identical to the production 455 CID V8. There was also an aluminum-block variant of the W-43 designated the OW-43, and the program eventually produced an experimental four-cam, 32-valve V8 based on the production engine’s architecture.

With four valves per cylinder, the combustion chambers of the W-43 were not hemispherical but rather a classic pentroof layout, utilizing shallow valve angles in the Cosworth style. Intake valves were 1.75 inches in diameter and 1.375 inches on the exhaust, providing 43 percent more intake valve area than the production 455 two-valve heads. According to a feature in the May 1971 issue of Hot Rod magazine, the W-43 was good for 440 horsepower at 4600 rpm in a relatively mild state of tune. And given the improved volumetric efficiency enabled by the far greater valve area, that figure seems downright conservative.

Reportedly, the W-43 V8 was at one point considered as an across the board replacement for the standard two-valve 455 CID V8, but as we know, that never happened. Various theories have been proposed to explain why, including stricter emissions regulations and corporate infighting with the far more powerful Chevrolet division at General Motors. But as we see it, the four-valve version’s considerably greater size, weight, and manufacturing cost would have been more than sufficient to kill the program. At least two W-43 prototype engines still exist, one of them incomplete, but their current whereabouts are unclear.

43 notes

·

View notes

Text

MTV Era Motorcity Masterpost (+ NEVER BEFORE SEEN INFORMATION)

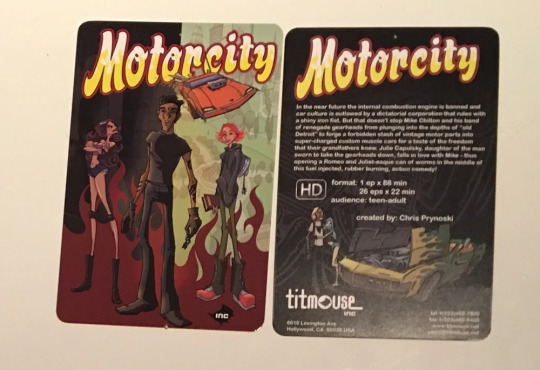

In 2000, Chris Prynoski pitched a cartoon called Motorcity.

He made a card and a website promoting the show, which wouldn't see the light of day until the Walt Disney Company got their hands on it.

THE SETUP

"MotorCity is The Dukes of Hazzard meets Akira. It's American Graffiti and Big Daddy Roth rumbling with 8 cylinders into the world of Sci-Fi. It's the heart of American car culture driven to the next level."

"Sex, cars, Rock & Roll, and the freedom to wrap your ride around a tree trunk goin' 160."

"In the near future, concerns over global warming, pollution, and the ever-worsening problem of gridlock in America’s major cities brings about the Anti-Combustion Acts of 2009." "These laws banned the use of any vehicle powered by an internal combustion engine. At first there was a lot of vocal opposition. But the so-called "Digital Revolution" as well as the advent of amazing new transportation technologies neatly filled the void, and the benefits of an improved environment along with a safer, faster and more efficient means of getting from point A to B managed to win even the staunchest opponents over. The oil companies and car manufacturers were forced to shut down under the political and economic pressures." "And a new era was born. Cleaner, faster and safer. America’s cities became modern utopias where its citizens could travel without fear or hazard in comfortable flying boxes affectionately known as "living rooms", and Detroit (The Renaissance City), became the finest example of this new policy. But with all of this wondrous innovation, something was lost. Something inherent in the soul of old America, something called freedom. The freedom to go anywhere. Anyhow. As fast, or as slow as you want. The freedom to speed. And the freedom to die." "This is where our characters come in. A few radicals realized that although you might never die in the "living rooms" , you’ll never really live in them either. So in the "Live fast and die young" mind-set, they fight the law. Scavenging parts and gas from Detroit’s massive underground, Mike Chilton and his gang, as well as a few others are trying to recapture some of what it meant to risk all for the freedom of speed."

THE CHARACTERS

Mike Chilton: A young talent on the illegal race circuit. Mike's right leg is always twitching and itching to jam a gas pedal to the floorboards, and his foot is as lead as they come. He's got gasoline surging through his veins and a 450 horsepower soul. His heart burns to drive and it's all he can do to keep moving faster and faster so that the flames don't consume him. He might be a gangly 19-year-old kid, but his ride has as much muscle as he'll ever need and he knows how to use it.

Vehicle of choice: Retrofitted '77 Trans Am

Julie Capulsky: An Anthropology student with a quick mind and a quicker pulse. She's a city girl with a passion for adventure who's secretly writing a paper on the underground "Burner" culture. As she gets to know Mike and his crew, she feels the freedom of the road and learns the power of a rumbling big block at her command. She is torn between the high performance life of a Gearhead and the love of her father who has sworn to take them down.

Vehicle of Choice: Any Hot Rod that'll give her a ride.

Lt. Capulsky: Julie's Dad and head of Detroit's Anti-Combustion Enforcement Division. He's old enough to remember when the highways were the arteries of America and the drivers were its blood. He rode with Fast Eddy in his youth and understands the joy of inhaling the fumes of burning rubber as the hot road turns his tires to black jelly. He's forced to deal with enforcing a law he's not sure he believes in. But that doesn't stop him from holding the record for the most illegal auto busts in the state of Michigan.

Vehicle of choice: Police "Living Room"

Ed Pirelli: (Fast Eddy) The old-timer who serves as Mike and the crew's link to the past, as well as their guide for the future. A wrecked hulk of a man, Eddy lived in a time when America was the land of wide-open spaces, and you had the liberty to go where, when and how you wanted to travel. You had the freedom to live, and the freedom to die. None of those damn boxes.

Vehicle of choice: Retrofitted '58 Chevy Roadster

Greg Raden: This young cop looks up to Lt. Capulsky as his ultimate hero. Born after the Anti-Combustion Act, He doesn't understand the rush of a vibrating steering wheel responding to every reflex of your sweaty palms. He wants nothing more than to grind the gears of the "Burners" to a halt.

Vehicle of choice: Police "Living Room"

Dave Earnhardt: Mike's worthy rival on the race circuit. He's a speed demon who stops at nothing to win. He might be Mike's worst enemy on the tar, but he'd take a speeding bullet for him off the track.

Vehicle of choice: Retrofitted '69 Camaro RS

Holly Biscayne: A fellow "Burner" who has a thing for Mike. She's jealous and suspicious of Julie's big city motives. She wants to make sure that when the checkered flag waves, she'll be on top.

Vehicle of choice: Retrofitted '05 Jaguar convertible

Brute Conklin: The bastard child of internal combustion and computer technology. This crafty gearhead beats "The Man" at his own game with a never-ending digital assault on the computers that control the Global Satellite System.

Vehicle of choice: Chopped 98' Harley Pan-head

Claire Constance: This ice queen might look like a hot number, but she's really a wet blanket who tries to smother her best friend Julie's fire. She can't understand what's with risking your life in the "sewers" when you can be shopping in style in the safety and comfort of your own clean home.

Vehicle of choice: None if she can help it

Promo card released in 2000

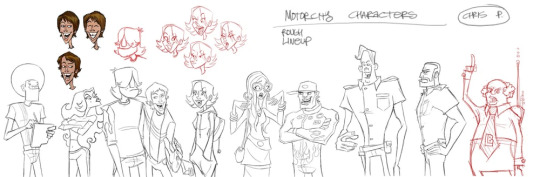

Concept art made shortly after the trailer (ones that closely resemble the final show)

From left to right: Luv (Dutch), Holly Biscayne, Chuck, Mike Chilton, Julie Kapulsky, Claire Constance, Texas, Greg Raden (Tooley), Lt Kapulsky (Abraham Kane), and The Mayor of Detroit

youtube

Pitch Trailer

#motorcity#mike chilton#waksworldrebooted#chuck motorcity#dutch gordy#texas motorcity#julie kane#waksworldart#holly motorcity#Youtube

46 notes

·

View notes

Text

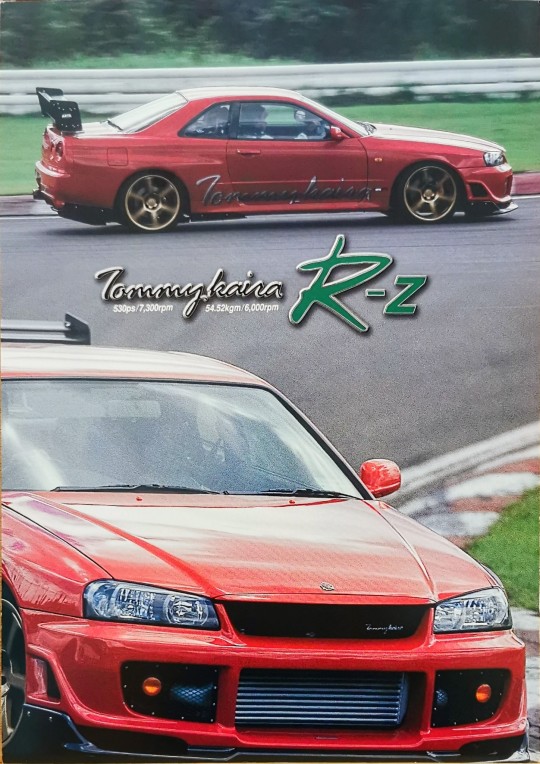

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Engine Repair Instruction Full Guide

Engines are the heart of any vehicle, powering everything from your daily commute to long road trips. Knowing how to repair an engine can be a game-changer, whether you're an enthusiast who loves getting your hands dirty or someone looking to save money on mechanic bills. This guide will walk you through the entire process of engine repair, from diagnosing problems to reassembling your engine and ensuring it runs smoothly.

Understanding the Basics of an Engine

Before diving into the repair process, it’s crucial to understand how an engine works. Most vehicles use an internal combustion engine, which combines fuel and air, ignites it, and transforms that explosion into mechanical energy.

Components of an Internal Combustion Engine

The main components include:

Cylinder Block: The engine's core where combustion occurs.

Cylinder Head: Houses the valves and spark plugs.

Pistons: Move up and down to create the force needed to turn the crankshaft.

Crankshaft: Converts the pistons' up-and-down movement into rotational motion.

Camshaft: Controls the opening and closing of the valves.

Valves: Regulate the flow of fuel and air into the engine and exhaust gases out.

How an Engine Works: A Simple Explanation

An engine works by pulling in a mixture of air and fuel, compressing it, igniting it with a spark (in gasoline engines), and then expelling the exhaust gases. This cycle—intake, compression, power, and exhaust—happens in each cylinder and repeats hundreds of times per minute.

Tools and Equipment Needed for Engine Repair

Whether you're performing a basic repair or diving into more complex work, having the right tools is essential.

Essential Tools for Basic Repairs

Socket Set: For removing and tightening bolts.

Wrenches: Different sizes for various engine parts.

Screwdrivers: Flathead and Phillips for screws and clips.

Pliers: For handling wires and small parts.

Torque Wrench: Ensures bolts are tightened to the correct specifications.

Specialized Equipment for Advanced Engine Work

Engine Hoist: For removing the engine from the vehicle.

Cylinder Hone: Prepares cylinders for new piston rings.

Compression Tester: Checks the health of each cylinder.

OBD-II Scanner: Diagnoses engine codes and issues.

Safety Gear and Precautions

Gloves: Protect your hands from cuts and chemicals.

Safety Glasses: Shield your eyes from debris.

Work Boots: Offer protection against heavy parts or tools.

Diagnosing Engine Problems

Accurately diagnosing engine problems is the first step in any repair process. Understanding the symptoms can save time and prevent unnecessary work.

Common Symptoms of Engine Issues

Check Engine Light: Indicates a problem detected by the car's computer.

Strange Noises: Knocking, tapping, or grinding sounds can signal internal damage.

Excessive Smoke: Blue smoke might mean burning oil, while white could suggest a coolant leak.

Loss of Power: Often linked to fuel or air delivery issues.

Step-by-Step Diagnostic Process

Listen and Observe: Note any unusual sounds, smells, or behaviors.

Check Engine Light Codes: Use an OBD-II scanner to retrieve error codes.

Perform Compression Test: Assesses the health of your engine’s cylinders.

Inspect Fluids: Look for contamination or leaks in oil, coolant, and other fluids.

Step-by-Step Guide to Reassembly

Prepare Your Workspace: Ensure that your workspace is clean, organized, and well-lit. Lay out all the parts and tools you'll need in the order of reassembly. Keep the engine manual handy for specific torque specs and sequences.

Install the Crankshaft: Place the crankshaft back into the engine block, ensuring it is seated correctly. Use assembly lube on the main bearings to prevent damage during the initial startup. Torque the main caps to the manufacturer's specifications.

Insert the Pistons: Install the pistons and connecting rods. Be sure to align the piston rings correctly and use a ring compressor to insert the pistons into the cylinder bore. Attach the connecting rods to the crankshaft and torque the rod bolts to spec.

Install the Camshaft and Timing Components: If your engine uses a timing chain or belt, install it according to the timing marks on the camshaft and crankshaft gears. This step is crucial for ensuring the engine's valves open and close at the correct times.

Attach the Cylinder Head: Place the cylinder head gasket on the engine block, followed by the cylinder head. Torque the head bolts in the correct sequence and to the proper specifications. This ensures a good seal and prevents head gasket failure.

Install Valves, Lifters, and Pushrods: If applicable, install the engine's valves, lifters, and pushrods. Make sure they are properly aligned and that the lifters are seated correctly in their bores.

Reassemble the Valve Train: Install the rocker arms and adjust the valve lash according to the engine manual. Proper valve lash is critical for engine performance and longevity.

Reattach External Components: Begin reattaching external components like the water pump, oil pump, timing cover, oil pan, and intake manifold. Replace any gaskets and seals during this process to prevent leaks.

Reconnect the Fuel and Ignition Systems: Reinstall the fuel injectors, spark plugs, and ignition wires. Ensure all electrical connections are secure and properly routed to avoid short circuits or malfunctions.

Final Checks: Before moving on, double-check all connections, bolts, and components. Make sure nothing is left loose or unconnected.

Applying Proper Torques and Specifications

Every engine has specific torque settings for each bolt. Over-tightening can strip threads or warp components, while under-tightening can lead to leaks or parts coming loose. Use a torque wrench and follow the manufacturer's specifications closely.

Double-Checking Work for Mistakes

It's easy to miss a step or make a mistake during reassembly. Double-check your work:

Ensure all components are installed in the correct order.

Verify all bolts are torqued to spec.

Check for any leftover parts or tools in the engine bay.

Testing the Repaired Engine

With the engine reassembled, the next step is testing it to ensure everything is functioning properly.

Preparing for Initial Startup

Before starting the engine, perform a few preparatory checks:

Prime the oil system: This can be done by cranking the engine with the fuel system disabled until oil pressure is achieved.

Fill the engine with fresh oil and coolant.

Double-check all electrical connections and fuel lines.

Checking for Leaks and Unusual Noises

Once you start the engine, pay close attention to any unusual noises or leaks:

Oil Leaks: Check around the oil pan, valve covers, and front and rear seals.

Coolant Leaks: Inspect the radiator, hoses, and water pump area.

Unusual Noises: Listen for knocking, tapping, or whining sounds, which could indicate an issue with the timing components or internal parts.

Fine-Tuning and Adjusting the Engine

After the initial startup, the engine may require some adjustments:

Timing Adjustments: Use a timing light to set the ignition timing.

Idle Speed: Adjust the idle speed according to the manufacturer’s specifications.

Fuel Mixture: On carbureted engines, you may need to adjust the air-fuel mixture for optimal performance.

Common Engine Repair Mistakes to Avoid

Engine repair is complex, and mistakes can be costly. Here are some common errors to watch out for:

Misalignments and Incorrect Torques

Misaligned timing components can lead to poor engine performance or damage.

Incorrectly torqued bolts can cause leaks, parts failure, or engine damage.

Overlooking Small Parts and Connections

Small parts like washers, clips, or gaskets are easy to overlook but crucial for preventing leaks and ensuring proper function.

Electrical connections: Double-check that all sensors and connectors are properly seated.

Skipping Diagnostic Steps

Skipping steps in the diagnostic process can lead to unnecessary repairs or missed issues. Always perform thorough diagnostics before and after repairs.

Maintaining Your Engine After Repair

Proper maintenance is key to ensuring the longevity of your newly repaired engine.

Importance of Regular Maintenance

Regular maintenance, such as oil changes, air filter replacements, and coolant checks, is essential to keep your engine running smoothly and prevent future problems.

Tips for Extending Engine Life

Use high-quality oil and filters.

Avoid hard driving until the engine is fully warmed up.

Regularly check and maintain fluid levels.

When to Seek Professional Help

While DIY repairs can save money, some issues are best left to professionals, especially if you encounter complex problems or lack the necessary tools and expertise.

Dealing with Advanced Engine Repairs

Some engine repairs are too complex for the average DIYer. Here's when to consider professional help:

Understanding When It’s Beyond DIY

Extensive internal damage: Cracked blocks or severely worn bearings usually require professional expertise.

Advanced electrical issues: Problems with engine management systems often need specialized diagnostic tools and knowledge.

Overview of Complex Repairs: Timing Belt, Engine Rebuilds

Timing Belt Replacement: Involves precise alignment of engine components and is critical for preventing engine damage.

Engine Rebuilds: This is a time-consuming and complex task that often requires professional machining and specialized tools.

Working with a Professional Mechanic

When the repair is beyond your capabilities, working with a professional mechanic ensures that the job is done correctly and safely. They have the tools, experience, and resources to handle complex engine repairs.

Cost Considerations in Engine Repair

Engine repair costs can vary widely depending on the scope of work, parts required, and whether you do it yourself or hire a professional.

Estimating Costs for DIY vs Professional Repair

DIY Repairs: Typically cost less but require an investment in tools and time.

Professional Repairs: Can be expensive but come with the assurance of experience and often a warranty.

Budgeting for Tools, Parts, and Time

Consider the cost of any special tools or equipment you might need, as well as the cost of replacement parts. Factor in the time required, especially if the vehicle is your daily driver.

Understanding the Cost of Mistakes

Mistakes can be costly. Stripping a bolt, breaking a part, or incorrect assembly can lead to additional expenses. Always weigh the risks before starting a major repair.

Conclusion

Recap of Key Points

Engine repair is a rewarding but challenging task that requires careful planning, the right tools, and attention to detail. Whether you’re fixing a minor issue or performing a complete rebuild, following the correct procedures is crucial for success.

Encouragement for DIY Enthusiasts

For those who love working on their vehicles, engine repair can be a satisfying and cost-effective way to maintain your car. With patience and persistence, even complex repairs can be tackled with confidence.

Final Thoughts on Engine Repair

Always approach engine repair with a clear plan and the right resources. Don’t hesitate to seek professional help when needed, and remember that regular maintenance is the best way to avoid major repairs.

FAQs

How do I know if my engine needs repair?

Common signs include unusual noises, excessive smoke, loss of power, and a check engine light. Regular diagnostics can help catch issues early.

Can I repair my engine without professional help?

Basic repairs like replacing gaskets or sensors can often be done at home with the right tools. However, more complex tasks like engine rebuilds may require professional expertise.

What are the signs of a failing engine?

Signs include knocking noises, excessive oil consumption, smoke from the exhaust, and persistent overheating.

How long does it take to repair an engine?

The time required varies greatly depending on the complexity of the repair. Simple repairs might take a few hours, while a full rebuild could take several days or longer.

2 notes

·

View notes

Photo

Back in a former life, I had an addiction that I loved beyond sanity. Here’s the story of it. 2002 2003 2004 2005 2006 2007 2008 2009 pt1 2009 pt2 2009 Redux

This is the final spec list for my glorious, insane Brutal Truth.

Nissan Skyline BCNR33 GT-R (Type 2) manufactured in April 1996. JDM non V-Spec vehicle retailed through Osaka Nissan Prince in May/June 1996. Imported to the UK in June 1997. Remained in original JDM spec without speedometer conversion until August 2002. Only the steering wheel & white dial sets were fitted in Japan.

Nismo RB26N1 bare engine: [N1 water pump (improved flow & less cavitation)/Reinforced cylinder block head bolt boss/Increased sump capacity (6L 20w60)/1.2mm oil restrictor]

N1 head with 0.5mm overbore (2598cc)

Cryogenically hardened N1 crankshaft

Wossner forged & cryogenically hardened pistons

Abbey Motorsport reinforced & cryogenically hardened con-rods

ACL Race Series conrod & crankshaft bearings

Tomei sump baffle kit

Tomei high flow (larger drive gears) oil pump

HKS 1.2mm metal head gasket

Tomei Procam Spec 2 cam kit (270 degree inlet & outlet with 10.25mm lift)

HKS V-Cam System Step 1 Type B (variable 248-278 degree inlet; replaces Procam inlet camshaft)

HKS vernier cam pulleys

HKS kevlar reinforced timing belt

Trust metal intake & throttle gaskets

HKS front pipe & decat gaskets

GReddy Iridium 08 Racing sparkplugs

Mocal 19-row oil cooler & Abbey Motorsport remote oil filter assembly

Abbey Motorsport catch tank & washer reservoir with SFS breather hoses

Abbey Motorsport Pro Alloy large radiator

Tomei fuel pump, fuel regulator & 600cc injectors

A’PEXi Power Intake induction kit

A’PEXi GT Spec intercooler (237x610x136mm) & hard pipe kit

HKS GT-SS turbos

HKS twin AFM delete kit

Tomei turbo elbows

HKS downpipes

HKS Silent Hi-Power exhaust

Abbey Motorsport 80mm decat pipe

Mine’s VX-ROM

HKS F-Con V Pro

HKS EVC 6 boost controller (1.6 bar)

AEM wideband lambda sensor

Splitfire DI Super Direct Ignition System

HKS Circle Earth kit

HKS GD Max twin-plate clutch (with lightened flywheel)

Abbey Motorsport rebuilt transfer box

Abbey Motorsport rebuilt gearbox with cryogenically hardened gear set, modified Nissan synchromesh upgrade and OS Giken strengthening plate

Abbey Motorsport rebuilt rear diff

Nismo gearbox mounts

Nismo Solid Shift gear stick (10% short shift)

Omex Shift Light Sequential

Sunsei SE-135 solar panel trickle charger mounted on a custom aluminium riser between the rear parcel shelf speaker enclosures.

Team Dynamics Equinox alloys 19x9.5, ET+15 in silver with polished stainless steel rim.

Falken FK452 265/30/19 Y-rated tyres

Cusco brake master cylinder brace

Cusco rear steering delete kit

Cusco front & rear upper suspension links

AST Sport Line 1 full suspension kit with UK spring setup

Nismo stainless steel braided brake hoses

StopTech 355mm rotor 4 pot caliper front brake kit

StopTech 355mm rotor 2 pot caliper rear brake kit with Abbey Motorsport modified pad retainers

Ferodo DS2500 brake pads front & rear

Bomex AD-390 front splitter

Nismo R34 smoked front indicators in custom aluminium mounting plates finished in crackle black

Nissan Xenon headlamp units

Border Racing Aero Fenders (vented front wings) with silver GT emblems from a R32 Skyline

Nismo smoked side repeaters

Top Mix one-off FRP twin blade rear spoiler on custom aluminium mounting plates

Entire exterior resprayed in BMW black (code 086) base and lacquer

Nissan Motorsport International carbon fibre B-pillar plates

PIAA carbon effect silicon wipers, front pair with spoilers, rear without

Nismo white face dial sets (dashboard & centre console) in carbon fibre panels

AEM AFR gauge mount replaces the lighter socket

HKS EVC display mounted on custom carbon fibre plate replacing the ashtray

Lighter socket relocated to the fog light switch panel

Nissan Momo steering wheel (with airbag)

Dressycar Nismo harness pads

Redline Automotive leather gearstick & handbrake gaiters

Abbey Motorsport carbon fibre door sill trims

Carbon fibre boot sill trim

Inlet plenum and sundry induction pipework finished in powder grey

Trust clear cam pulley cover

HKS Kansai Service carbon fibre spark plug cover

Right hand cam cover finished in crackle black

Nismo radiator & washer reservoir caps

HKS Kansai Service front strut brace finished in high gloss black

GReddy aluminium slam panel finished in crackle black

Tein bonnet dampers with black sleeves

Custom made one-off Cobra Misano Lux front seats: [Alcantara (colour code 9189) outers/Alcantara (colour code 9182) centre panels/One-piece carbon fibre backs/Sidewinder bases on custom subframes adapted by Abbey Motorsport/Cobra logo in silver thread on the headpads/GT-R logo beneath the grommets on seat backs]

JVC KD-AVX2 multi-media DVD/CD receiver with built-in 3.5” widescreen monitor

2x JL Audio Evolution VR600-CXi 6” speakers (front)

2x JL Audio Evolution TR650-CXi 6.5” speakers (rear)

Multiple and interlaced Thatcham rated security systems.

500 bhp. 520 ft/lb.

Ludicrously, hilariously, unbelievably fast.

Hope you enjoyed this little trip down memory lane with me. Cheers! JM.

(Photo by N. Liassides.)

#r33#bcnr33#skyline#gt-r#nissan skyline#Abbey Motorsport#HKS#Bomex#Tomei#A'PEXi#GReddy#Nismo#RB26N1#Mocal#Team Dynamics

13 notes

·

View notes

Text

youtube

Unlock Superior Surface Finishes with Vapor Blasting: The Ultimate Cleaning and Restoration Solution

When it comes to precision cleaning, restoration, and surface preparation, vapor blasting has become the gold standard. Also known as vapor honing, this process offers unmatched benefits for a wide range of applications, from automotive parts to industrial components. In this blog post, we’ll explore what vapor blasting is, its benefits, and why it’s the preferred choice for professionals and enthusiasts alike.

What is Vapor Blasting?

Vapor blasting, or vapor honing, is an advanced surface finishing process that combines water, abrasive media, and compressed air to clean and refine surfaces. Unlike traditional dry blasting methods, vapor blasting uses water to cushion the abrasive particles, creating a gentler yet highly effective cleaning action.

This process is ideal for removing dirt, corrosion, grease, and old coatings while leaving the underlying surface intact and smooth. It’s widely used for cleaning engine parts, restoring delicate components, and preparing surfaces for further treatment.

Benefits of Vapor Blasting

Gentle on Surfaces Vapor blasting is less abrasive than traditional sandblasting, making it ideal for delicate components such as aluminum engine parts, carburetors, and gear housings. The water cushion prevents material erosion, preserving the original dimensions and integrity of parts.

Enhanced Surface Finish The combination of water and fine abrasive media produces a smooth, satin-like finish that not only looks great but also enhances the performance of the part. It’s perfect for restoring automotive parts to like-new condition.

Environmentally Friendly Vapor blasting reduces dust and airborne contaminants, making it a safer and cleaner process for operators and the environment.

Versatility This process is suitable for a wide range of materials, including aluminum, steel, brass, and plastic. It can be used for cleaning, polishing, deburring, and surface preparation.

Reduced Heat and Friction The water used in vapor blasting cools the surface during the process, preventing warping or other heat-related damage.

Applications of Vapor Blasting

Vapor blasting is widely used in industries such as automotive, aerospace, and manufacturing. Common applications include:

Engine Restoration: Cleaning and refinishing cylinder heads, engine blocks, and other components without damaging mating surfaces.

Motorcycle and Automotive Parts: Restoring carburetors, intake manifolds, and vintage parts to their original appearance.

Surface Preparation: Prepping parts for painting, powder coating, or anodizing.

Delicate Components: Cleaning intricate or sensitive parts where traditional methods might cause damage.

Vapor Blasting Services at LN Engineering

LN Engineering offers professional vapor blasting services through RND Engines, providing high-quality surface restoration and cleaning for automotive and industrial components. Their state-of-the-art vapor honing technology ensures precision results, whether you’re restoring vintage parts or prepping components for assembly.

Before:

After:

Key Features of LN Engineering’s Vapor Blasting Services:

Restores surfaces to like-new condition.

Removes oxidation, grease, and grime effectively.

Gentle on intricate and delicate parts.

Perfect for Porsche and other high-performance engine components.

Why Choose Vapor Blasting Over Traditional Methods?

Compared to traditional sandblasting or bead blasting, vapor blasting is superior in maintaining the integrity of parts while achieving a high-quality finish. It’s the best choice for enthusiasts and professionals looking for precision cleaning and restoration without compromising on quality.

Before:

After:

Conclusion

Whether you’re restoring a classic engine, prepping parts for a rebuild, or cleaning delicate components, vapor blasting is the ultimate solution. Its ability to clean, polish, and protect surfaces makes it an indispensable tool for achieving superior results. For top-notch vapor blasting services, trust LN Engineering to deliver unparalleled quality and care for your parts.

0 notes

Text

How Brass Shim Sheets Enhance Performance in the Automotive Industry | Ultimate Guide

This article helps in understanding brass shim sheets as, they are thin, flat pieces of brass used to fill gaps, adjust alignment, or provide support between components. Shims are essential in ensuring that automotive parts are securely fixed, precisely aligned, and can withstand long-term use.

Brass is chosen for shims due to its excellent combination of strength, corrosion resistance, and malleability. This makes it the ideal material for the automotive industry where high-stress, high-precision parts are crucial.

This article helps in the use of brass shim sheets spans across multiple areas of automotive manufacturing. Here are some of the most common applications:

Engine Assemblies: Brass shim sheets are used in engine blocks, cylinder heads, and other critical engine components to ensure that parts are properly aligned and gaps are filled. This leads to smoother engine operation and reduced wear and tear.

Suspension Systems: In suspension systems, shim washers help adjust the clearance between various parts, such as shock absorbers and coil springs. This ensures that the suspension is working at peak performance, offering better control and comfort.

Transmission Systems: Brass shim sheets are often used in the assembly of transmissions to ensure smooth gear operation and prevent wear in high-stress areas.

Brake Systems: Brass shims are also used in brake components, where they help reduce vibrations, enhance performance, and reduce noise.

Exhaust Systems: In exhaust systems, brass shim plates are used to ensure a tight seal and reduce the possibility of leaks in high-temperature environments.

When sourcing brass shim sheets, it’s important to find reliable shim washer manufacturers that specialize in high-quality materials. Here are some places to look:

Shim Manufacturers in India: India has a thriving manufacturing sector, with many companies specializing in producing high-quality brass shims, such as stainless steel shims and brass shim sheets.

Online Suppliers: Many online platforms offer brass shim sheets in various sizes and thicknesses. Look for verified suppliers with good customer reviews.

Local Manufacturers: If you prefer to purchase locally, check with suppliers and manufacturers in your region who provide precut shims and shim washers tailored to automotive applications.

Brass shim sheets are essential components in the automotive industry. They provide unmatched precision, durability, and performance, ensuring that automotive parts operate smoothly and efficiently. Whether you’re involved in engine assembly, suspension systems, or brake systems, the use of brass shim sheets can significantly enhance the overall performance and longevity of the vehicle.

By choosing the right shim washer manufacturers, using best practices, and understanding the role of brass shim sheets, you can ensure that your automotive parts are optimized for the best performance possible.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

How Brass Shim Sheets Enhance Performance in the Automotive Industry | Ultimate Guide

#BrassShimSheets#AutomotivePerformance#MaterialInnovation#ShimSheetTechnology#AutomotiveIndustry#PrecisionEngineering#PerformanceMaterials

0 notes

Text

Why Barium and Calcium Inoculants Are Crucial for Superior Metal Production!

In the world of metallurgy, achieving superior metal quality is an ongoing challenge. Foundries and metal production facilities rely on advanced technologies and materials to optimize the characteristics of metals. Among these materials, barium inoculant and calcium inoculant stand out as crucial agents for improving the microstructure and mechanical properties of metals. These inoculants play a significant role in enhancing casting performance, reducing defects, and ensuring high-quality production. Let’s delve deeper into why these inoculants are indispensable in metal production.

The Role of Inoculants in Metallurgy

Inoculants are substances added to molten metal to influence its solidification process. Their primary function is to refine the grain structure, promote uniformity, and reduce casting defects such as porosity and shrinkage. This ensures that the final product meets stringent quality standards required in various industries, including automotive, aerospace, and construction.

Among the wide range of inoculants available, barium and calcium-based inoculants have gained prominence due to their unique properties and effectiveness in enhancing metal quality.

Barium Inoculant: Key Benefits

Barium inoculant is widely used in the production of gray iron and ductile iron. Its addition to molten metal provides several benefits:

Refined Grain Structure: This inoculant promotes the formation of fine, evenly distributed graphite flakes in gray iron and nodules in ductile iron. This leads to improved mechanical properties, including strength and durability.

Reduction of Chill Formation: In iron casting, chill is the formation of hard carbides, which can compromise machinability and toughness. Its minimizes chill, ensuring a smoother and more consistent casting surface.

Improved Fluidity: Barium enhances the fluidity of molten metal, making it easier to fill molds completely. This reduces the likelihood of defects and ensures intricate designs can be cast effectively.

Stabilization of Graphite Formation: Barium inoculant ensures consistent graphite precipitation during solidification, preventing the formation of irregular structures.

Calcium Inoculant: Key Benefits

Calcium inoculants are another essential component in high-quality metal production. They are particularly effective in cast iron and steel manufacturing processes. Here are the key points on how they contribute to superior metal quality:

Nucleation Sites for Graphite: these inoculants provide nucleation sites for graphite precipitation, resulting in a refined and uniform microstructure. This enhances the mechanical and thermal properties of the metal.

Reduction of Sulfur Content: Calcium reacts with sulfur in molten metal to form calcium sulfide, which prevents the formation of harmful sulfides that can weaken the metal’s structure. This makes These type of inoculants particularly useful in applications requiring high ductility and toughness.

Prevention of Carbide Formation: Like Ba, Ca inoculants inhibit the formation of carbides, which can negatively impact machinability and overall metal performance.

Improved Surface Finish: (Ca) inoculants help achieve a smoother casting surface by promoting uniform solidification, which is critical in industries requiring precise and aesthetic components.

Applications of Barium and Calcium Inoculants

The versatility of (Ba and Ca) inoculants makes them valuable in various applications. Here are some of the common uses:

Automotive Industry: Inoculants are crucial in the production of engine blocks, cylinder heads, and brake components, where strength, durability, and machinability are paramount.

Aerospace Industry: High-performance materials with refined microstructures are essential in aerospace applications. (Ba and Ca) inoculants ensure the reliability of critical components.

Construction Equipment: Heavy machinery and construction tools require robust and defect-free components. These inoculants help achieve the necessary quality standards.

Piping and Fittings: Cast iron pipes and fittings benefit from the enhanced properties imparted by these inoculants, including resistance to pressure and corrosion.

Choosing the Right Inoculant

The choice between inoculants depends on the specific requirements of the metal production process. Factors such as the type of alloy, desired mechanical properties, and casting conditions play a role in determining the most suitable inoculant.

Barium inoculant is often preferred for applications where the elimination of chill and improved graphite morphology are critical.

Calcium inoculants are ideal for reducing sulfur content and preventing carbide formation, making them indispensable in processes requiring high ductility and machinability.

Conclusion

In the quest for superior metal production, the importance of barium and calcium inoculants cannot be overstated. These materials not only enhance the physical and mechanical properties of metals but also ensure consistency and reliability in casting processes. By refining microstructures, reducing defects, and improving overall performance, (Ba and Ca) inoculants contribute significantly to the advancement of the metallurgy industry.

For foundries and metal production facilities aiming to achieve excellence, investing in high-quality inoculants is a strategic decision. Whether Ba inoculant can prevent chill formation or Ca inoculant’s sulfur-reducing properties, these agents are indispensable tools for producing metals that meet the highest standards of quality and performance.

#inouclant #bariuminouclant #calciuminoculant

0 notes

Text

USD 110,203.8 Million in Milling Machine Market by 2033

By 2023, the worldwide milling machine market is anticipated to be valued at $68,303.3 million. Between 2023 and 2033, the market is expected to grow at a sluggish but consistent CAGR of 4.9%. The market value is expected to rise to US$ 110,203.8 million by 2033.

Milling machines are the workhorses of metalworking, capable of carving, drilling, and shaping various metals with precise control. From crafting intricate parts for aerospace components to machining engine blocks for automobiles, milling machines play a vital role in numerous industries. Let's delve into the diverse applications of milling machines and explore the trends propelling this important market forward.

Applications of Milling Machines

Milling machines offer a range of functionalities across various metalworking applications:

Machining Complex Parts: With their ability to move a cutting tool along multiple axes, milling machines can create intricate three-dimensional shapes in metal components. This is crucial for industries like aerospace, where lightweight and high-precision parts are needed.

Die and Mold Making: The ability to create precise and polished surfaces makes milling machines ideal for manufacturing dies and molds used in various forming and casting processes.

Engine Component Production: From machining cylinder heads and engine blocks to creating intricate channels for oil and coolant flow, milling machines are essential for engine manufacturing.

Job Shops and Contract Manufacturing: Milling machines offer versatility for small-batch production or one-off projects. Job shops and contract manufacturers rely on them to fulfill diverse customer requirements.

Maintenance and Repair: Machine shops and repair facilities utilize milling machines for machining replacement parts, modifying components, or repairing damaged metal parts.

Get Exclusive Sample Copy of the Report: https://www.fmisamplereport.com/sample/rep-gb-16589

A Market Fueled by Progress: Growth Factors Shaping the Future

The milling machine market is driven by several key trends:

Growth in Automotive and Aerospace Industries: The increasing demand for lightweight, high-performance vehicles and complex aerospace components necessitates the use of advanced milling machines for precise part creation.

Rise of Automation and CNC Technology: The integration of Computer Numerical Control (CNC) technology into milling machines allows for automated and highly precise machining processes, improving efficiency and productivity.

Demand for Shorter Production Cycles: Manufacturers are constantly striving to reduce time-to-market for new products. Milling machines, with their ability to produce complex parts quickly and accurately, contribute to achieving this goal.

Growing Focus on Advanced Materials: The increasing use of hard-to-machine materials like titanium alloys and composites in various industries necessitates the development of more powerful and versatile milling machines.

Skilled Labor Shortage: The growing demand for skilled machinists is a challenge. Milling machines with user-friendly interfaces and automation capabilities can help address this gap to some extent.

The global milling machine market is poised to reach a significant valuation of USD 68,303.3 million by 2023, with an expected CAGR of 4.9% from 2023 to 2033. By the end of the forecast period, the market is anticipated to surge to USD 110,203.8 million.

Challenges and Considerations

While offering significant advantages, the milling machine market faces some challenges:

High Initial Investment: CNC milling machines, particularly those with advanced features, can involve a significant upfront investment. This can be a barrier for smaller workshops or businesses with limited budgets.

Skilled Workforce Requirements: Operating and programming CNC milling machines effectively requires a skilled workforce with a strong understanding of machining principles and CNC programming languages.

Rapid Technological Advancements: The milling machine market is constantly evolving with new technologies and features. Keeping pace with these advancements can be challenging for manufacturers and machining professionals.

0 notes

Photo

Abarth 1300OT Periscopica Coupé

In 1958, the American Chrysler Corporation pursued an entry into the European motor manufacturing market by buying 15 per cent of the French Simca company's stock from Ford. At that time, however, the dominant shareholder remained Fiat of Turin, and their influence remained distinctively apparent in the engineering and design of Simca cars for several years into the early 1960s. However, in 1963 Chrysler increased its Simca stake to a controlling 64 per cent by purchasing stock from Fiat, subsequently extending that holding to 77 per cent.

Chrysler had no interest in any continuation of the previously successful Simca Abarth and Abarth Simca high-performance car collaboration, which came to a juddering halt. In Turin Carlo Abarth found himself left more or less high and dry, but the supply of basically Simca 1000 chassis floor pans, upon which the sleek and superfast Abarth Simca 1600s and 2000s had been based, left quite a number in stock, as yet unused. The popular legend is that it was upon these unused Simca platforms that Abarth then founded his 1300cc class Gran Turismo design for 1965 – the OT 1300. Abarth's technical team under Mario Colucci had developed a boxed pressed-steel chassis structure on the modified Simca 1000 floor pan to which allindependent suspension was attached with componentry drawn from the Fiat 850 shelves. The Abarth OT 1300 then emerged, to race for the first time as a prototype in the September, 1965, Nurburgring 500-Kilometre classic.

Driver Klaus Steinmetz hammered the new Coupé home to a fine third-place finish overall and the OT 1300 was up and running into the record books, becoming one of the most successful – and also one of the most distinctive – models that Abarth & C ever produced. The OT 1300's rear-mounted all-Abarth engine was overhung – in best Carlo Abarth-approved style. It was a 4-cylinder unit with twin overhead camshaft cylinder head, using a block with cylinder bore and stroke dimensions of 86mm x 55.5mm to displace 1289cc.

With two valves per cylinder and a 10.5:1 compression ratio, the engine breathed through two twin-choke Weber 45DCOE9 carburettors. Ignition was by two plugs per cylinder, fired by single distributor. Dry-sump lubrication was adopted and the power unit produced a reliable 147bhp at 8,800rpm. This lusty engine, perfected by Abarth's power-unit specialist Luciano Fochi with five main-bearing crankshaft, drove via a five-speed and reverse Abarth transaxle.

Wheelbase length of the OT 1300 was nominally 2015mm, front track 1296mm and rear track 1340mm. It featured moulded glassfibre clamshell-style opening front and rear body sections moulded by Sibona & Basano in Turin, and this pert-nosed Coupé became a familiar sight dominating its class for three consecutive years. Production of the OT 1300 began on May 15 1966 and ended on March 30, 1966, by which time the minimum production number of 50 required by the FIA for homologation as a Gran Turismo model had (allegedly) been achieved. The most distinctive single characteristic of the OT 1300 Coupé, apart from its huge International success within its class, was its adoption of the Periscopica air-cooling intake on the rear of the cabin roof. Casual onlookers would assume that the periscopelike intake fed intake air into the rear-mounted engine, but this is absolutely not the case. Instead, the water and oil-cooling pipe runs through the cockpit area heated-up the cabin to what was generally considered to be an unacceptable level for endurance racing, and the periscope intake merely blasted cold air down into the cabin to cool the driver himself...

From the OT 1300 Mario Colucci developed the OT 2000 Coupé using the 1946cc 4-cylinder power unit perfected by his colleague Luciano Fochi and with some 215bhp at 7,600rpm that largerengined model was capable of exceeding 165mph in a straight line. In fact all these Abarths with their sleek aerodynamic bodies and light weight really were exceedingly rapid by the standards of the time and within their respective capacity classes.

98 notes

·

View notes

Text

WIDMA: A Leader in Precision Machining Solutions

In the world of advanced manufacturing, precision and reliability are key. WIDMA, a division of Kennametal, has established itself as a trusted name in the machining industry, delivering innovative solutions for complex requirements. From deep hole drilling machine manufacturers to state-of-the-art grinding and boring machines, WIDMA offers a diverse range of products that cater to the evolving needs of industries like automotive, aerospace and energy.

Excellence in Deep Hole Drilling Machines

When it comes to precision drilling, WIDMA stands out as one of the top deep-hole drilling machine manufacturers. Their machines are engineered to handle operations like gundrilling, BTA drilling, counter boring, skiving and roller burnishing with unmatched accuracy. These machines are ideal for industries requiring high precision in manufacturing components such as crankshafts, fuel injectors and hydraulic cylinders. With a focus on efficiency, WIDMA ensures that their machines are built for durability and optimal performance, making them a preferred choice for global manufacturers.

Advanced Tool Grinding Machines

In today’s competitive market, high-quality tools are essential for achieving superior machining results. WIDMA’s tool grinding machine solutions are designed to manufacture and regrind complex geometry tools such as shaper cutters, hobs and round tools. These machines use advanced software and automation technology to deliver precision and consistency, ensuring that manufacturers meet their production goals with ease. Whether it’s creating new tools or reconditioning existing ones, WIDMA’s grinding machines provide unparalleled performance and reliability.

Precision with Fine Boring Machines

WIDMA also excels in delivering fine boring machines for applications that demand high accuracy. These machines are perfect for machining components like engine blocks, cylinder heads and gear housings. Built to achieve tight tolerances, WIDMA’s boring machines are equipped with advanced controls and tooling options that make them a valuable asset for manufacturers. Their fine boring solutions not only enhance productivity but also ensure superior surface finish and dimensional accuracy.

Why Choose WIDMA?

WIDMA’s reputation as a leader in precision machining solutions is built on decades of expertise, state-of-the-art manufacturing facilities and a customer-centric approach. Based in Bengaluru, India, their 75,000-square-foot facility is equipped with the latest technology to design, develop and deliver customized solutions. Their products are trusted globally and their commitment to innovation has made them a pioneer in the industry.

Industries Served

WIDMA caters to a wide range of industries, including:

Automotive: Solutions for machining engine components, gear systems and more.

Aerospace: High-precision machines for critical aerospace parts.

Energy: Custom solutions for turbines, oil & gas equipment and wind energy components.

General Engineering: Versatile machines for diverse engineering applications.

Conclusion

WIDMA continues to set benchmarks in the machining industry with its advanced solutions. Whether you’re looking for a reliable deep hole drilling machine manufacturer, a high-performance tool grinding machine, or a precision fine boring machine, WIDMA has the expertise and technology to deliver. With a legacy of innovation and quality, WIDMA remains a trusted partner for industries worldwide, driving efficiency and excellence in modern manufacturing.

0 notes

Text

SuperonTechnik: Your Reliable Source for High-Quality Cast Iron Electrodes

In the realm of welding, choosing the right electrode is crucial for achieving strong and durable welds, especially when dealing with cast iron materials. SuperonTechnik is a leading supplier of high-quality cast iron electrodes, offering products designed to meet the demands of various industrial applications. With a commitment to excellence and innovation, SuperonTechnik ensures that your welding projects achieve optimal performance and reliability. Discover how our cast iron electrodes can elevate your welding processes and deliver superior results.

Why Choose SuperonTechnik for Cast Iron Electrodes?

1. Exceptional Quality

SuperonTechnik is dedicated to providing cast iron electrodes that meet the highest standards of quality. Our electrodes are manufactured using premium materials and undergo stringent quality control processes to ensure consistent and reliable performance.

2. Versatile Applications

Our cast iron electrodes are suitable for a wide range of applications, including repair and maintenance of cast iron components, joining cast iron to steel, and surfacing operations. Whether you're working on automotive parts, machinery, or structural components, SuperonTechnik has the right solution for you.

3. Excellent Weldability

SuperonTechnik's cast iron electrodes are engineered for excellent weldability, producing smooth and strong welds with minimal spatter. Our electrodes are compatible with various welding processes, ensuring versatility and ease of use in different welding environments.

4. High Crack Resistance

One of the key advantages of our cast iron electrodes is their high crack resistance. This makes them ideal for welding cast iron, which is prone to cracking due to its brittle nature. SuperonTechnik's electrodes provide strong and durable welds, minimizing the risk of cracks and ensuring the longevity of your projects.

4. High Crack Resistance

One of the key advantages of our cast iron electrodes is their high crack resistance. This makes them ideal for welding cast iron, which is prone to cracking due to its brittle nature. SuperonTechnik's electrodes provide strong and durable welds, minimizing the risk of cracks and ensuring the longevity of your projects.

5. Comprehensive Technical Support

At SuperonTechnik, we believe in providing comprehensive support to our customers. Our team of experts is available to offer technical advice and guidance, helping you select the right cast iron electrodes for your specific needs. We are committed to ensuring your satisfaction and success.

Applications of Cast Iron Electrodes

Automotive Industry: Our cast iron electrodes are used in the repair and maintenance of automotive components, such as engine blocks, cylinder heads, and manifolds, ensuring strong and durable welds.

Machinery Repair: Enhance the performance and lifespan of machinery with our high-quality cast iron electrodes. They are ideal for repairing cast iron machine parts and equipment.

Structural Components: Our electrodes provide reliable solutions for welding structural cast iron components, ensuring the integrity and stability of construction projects.

Industrial Equipment: SuperonTechnik's cast iron electrodes are suitable for welding and surfacing industrial equipment exposed to high wear and tear, improving their durability and performance.

Pipe and Fitting Repairs: Our versatile electrodes are perfect for repairing cast iron pipes and fittings, providing strong and leak-proof welds.

How to Get Started with SuperonTechnik

Visit Our Website: Explore our extensive range of cast iron electrodes on the SuperonTechnik website.

Contact Us: Reach out to our team for personalized assistance and expert advice.

Place Your Order: Select your desired cast iron electrodes and place your order with confidence.

Experience Superior Performance: Receive your high-quality electrodes and experience the exceptional performance and durability that SuperonTechnik is known for.

Get Started with SuperonTechnik

Trust SuperonTechnik to be your reliable partner in welding and fabrication. Visit our website today to discover our premium cast iron electrodes and elevate the quality of your projects. How to choose the right cast iron electrode With our commitment to excellence, we provide you with the best solutions to meet your welding needs. Choose SuperonTechnik for unmatched quality and performance in every weld.

0 notes

Text

How Rubber Seals and O-Rings Drive Reliability in the Automotive Industry

In automotive engineering, even the smallest components play critical roles in vehicle performance and safety. Among these are rubber O-rings and other sealing components, which, despite their size, are vital to the proper functioning of many automotive systems. This guide delves into the significance of rubber O-rings, their applications, and how sealing components produced by leading manufacturers keep vehicles running smoothly and reliably.

The Vital Role of Rubber O-Rings in Automotive Sealing

Rubber O-rings, small donut-shaped elastomer rings, are essential for preventing fluid and gas leaks in automotive systems. Used widely across vehicles, they are crucial in engine and fuel systems. In engines, O-rings prevent oil leaks by creating seals between parts, thus ensuring that oil is contained within the system, supporting efficient performance and preventing potential breakdowns. In fuel systems, these O-rings provide secure seals that prevent dangerous and costly fuel leaks.

Leading rubber parts manufacturing companies produce O-rings designed to withstand high temperatures, pressures, and exposure to harsh chemicals. Such durability ensures they perform reliably even in the challenging conditions typical of automotive environments.

High-Performance Features of Rubber O-Rings

Not all O-rings are suitable for automotive use. High-performance O-rings must be crafted from durable materials such as nitrile, EPDM, silicone, or fluorocarbon rubber, each with specific properties that suit different applications. Nitrile, for example, resists oil and fuel, while silicone performs well in high-temperature environments.

Top rubber parts manufacturers adhere to strict standards, often following ISO certifications, to ensure quality and durability. This commitment is crucial for developing O-rings that withstand the wear and tear of dynamic automotive environments, such as engines with constantly moving parts. Without these high-quality seals, automotive systems would be prone to leaks, resulting in breakdowns and expensive repairs.

Other Key Sealing Components in Automobiles

O-rings are not the only essential sealing components in vehicles. Gaskets and oil seals are equally important for preventing fluid leaks and maintaining system integrity.

Gaskets: Gaskets are commonly found in engines, creating secure seals between engine parts to prevent fluid leaks. Located in areas like the engine block, cylinder heads, and exhaust systems, gaskets withstand high temperatures and pressures without degrading, ensuring the vehicle operates smoothly.

Oil Seals: These seals are designed to prevent oil leaks in key areas, such as axles, crankshafts, and gearboxes. Oil seals contain lubricants while keeping out dust and debris, helping to maintain the performance and longevity of components.

Manufacturers like GB Rubber utilize advanced techniques to produce these components, enhancing the reliability, efficiency, and lifespan of vehicles.

Advancements in Sealing Technology by Leading Rubber Parts Manufacturers

In addition to producing high-quality parts, top rubber parts manufacturers are at the forefront of sealing technology innovation. These companies heavily invest in research and development, constantly developing new materials and production processes that improve the performance and durability of automotive components.

As sustainability becomes a focus, leading manufacturers are exploring eco-friendly alternatives such as thermoplastic elastomers, which offer similar performance to traditional rubber but are more recyclable. Companies like GB Rubber are driving this shift, creating sealing solutions that balance high performance with environmental responsibility.

Choosing a Reliable Rubber Parts Manufacturer for Your Needs

Rubber O-rings and other sealing components are small parts with a big impact on vehicle safety and functionality. Manufacturers of these components play a crucial role, ensuring that vehicles stay on the road safely and efficiently. As the automotive industry advances, especially with electric and hybrid vehicles, rubber parts manufacturers are evolving to meet new demands, developing the next generation of sealing technology.

0 notes

Text

Bharat Engineering: Leading the Charge as Premier Automotive Casting Manufacturers

In the world of automotive manufacturing, the need for precision, quality, and reliability is paramount. Whether it's engine components, transmission parts, or chassis elements, every part needs to be expertly crafted to ensure performance and safety. Bharat Engineering, a leading name in the automotive casting industry, has established itself as a trusted manufacturer of high-quality automotive castings that meet the demands of the global automotive market.

Who is Bharat Engineering?

Bharat Engineering is a pioneering company specializing in the design, development, and manufacturing of a wide range of automotive casting products. With decades of experience in the field, Bharat Engineering has positioned itself as one of the top automotive casting manufacturers in the industry, serving a broad spectrum of clients from original equipment manufacturers (OEMs) to suppliers in the aftermarket sector.

The company operates with a strong emphasis on quality, precision, and innovation. They understand the critical role of casting in automotive production, ensuring that every part they manufacture is engineered to withstand the rigorous demands of modern vehicles.

The Importance of Automotive Castings

Automotive castings are essential to a vehicle’s performance, durability, and safety. These castings, typically made from metals like aluminum, steel, and iron, are used in various components such as engine blocks, cylinder heads, transmission housings, and brake components. High-quality castings provide strength, heat resistance, and long-lasting durability, all of which are essential for the efficient and safe operation of a vehicle.

Automotive casting manufacturers like Bharat Engineering play a crucial role in ensuring that these parts meet the highest standards of quality and precision. By using advanced manufacturing techniques and state-of-the-art technology, Bharat Engineering ensures that each automotive casting product meets strict tolerances and is free from defects, ensuring optimal performance.

Why Choose Bharat Engineering for Automotive Castings?

State-of-the-Art Manufacturing FacilitiesBharat Engineering invests heavily in its manufacturing capabilities. The company utilizes advanced casting technologies such as sand casting, die casting, and investment casting, enabling them to produce parts with exceptional accuracy and strength. Their manufacturing facilities are equipped with the latest machinery, ensuring that all castings meet international standards and industry requirements.

Customization and VersatilityOne of the key strengths of Bharat Engineering is its ability to provide customized solutions. Whether it’s a highly complex casting or a mass-produced component, Bharat Engineering can design and manufacture castings tailored to the specific needs of their clients. This flexibility allows them to serve a wide range of automotive sectors, from small car manufacturers to large commercial vehicle producers.

Quality AssuranceAt Bharat Engineering, quality is not just a buzzword; it is embedded in every stage of production. The company follows a stringent quality control process, with multiple checks throughout the manufacturing cycle. Each product undergoes rigorous testing to ensure it meets the highest standards for dimensional accuracy, strength, and durability. This commitment to quality ensures that their customers receive automotive castings that perform optimally, even under the most challenging conditions.

Cost-EffectivenessBharat Engineering’s experience and scale allow them to offer competitive pricing without compromising on quality. The company’s efficient manufacturing processes help reduce wastage and production time, enabling them to pass on cost savings to their clients. This makes Bharat Engineering an attractive partner for OEMs and suppliers looking for high-quality castings at a reasonable price.

Sustainability and Environmental ResponsibilityAs environmental concerns continue to grow, Bharat Engineering is committed to sustainability. The company employs eco-friendly casting processes and practices waste reduction techniques to minimize its environmental footprint. They also use recycled materials whenever possible, helping reduce the demand for raw resources and lowering the overall environmental impact of their operations.

Key Automotive Components Manufactured by Bharat Engineering

Bharat Engineering specializes in a wide array of automotive castings, including:

Engine BlocksEngine blocks are at the heart of every vehicle’s performance. Bharat Engineering manufactures robust and high-strength engine blocks using advanced casting techniques. These blocks are designed for optimal thermal efficiency and strength, ensuring a long lifespan and superior performance.

Transmission PartsTransmission systems require components that can withstand immense torque and stress. Bharat Engineering produces transmission housings, gearboxes, and other transmission parts that are engineered for precision and durability.

Brake ComponentsAutomotive brake systems are critical to vehicle safety. Bharat Engineering’s castings for brake rotors, calipers, and other braking system components are designed to deliver high performance and reliability, even under extreme conditions.

Suspension and Chassis ComponentsBharat Engineering produces a variety of suspension and chassis components such as control arms, knuckles, and crossmembers. These parts are designed to provide strength, durability, and weight reduction, improving overall vehicle handling and safety.

Exhaust and Emission Control PartsWith the automotive industry’s growing focus on sustainability, Bharat Engineering manufactures components for exhaust systems and emission control, including catalytic converter housings and muffler parts, using materials designed to withstand high temperatures and corrosive environments.

Innovation and Future of Automotive Castings

As the automotive industry evolves with advancements in electric vehicles (EVs), autonomous technology, and lightweight materials, Bharat Engineering continues to innovate. The company is actively working on developing new casting techniques to produce lighter, stronger, and more cost-effective components, particularly for the emerging electric vehicle market.

With the shift towards EVs, castings for electric motor housings, battery enclosures, and power electronics have become increasingly important. Bharat Engineering is at the forefront of this shift, exploring new materials and casting methods that meet the unique requirements of the electric vehicle industry.

Conclusion

Bharat Engineering has established itself as a leader in the automotive casting industry, offering a comprehensive range of high-quality components that meet the demands of modern vehicles. With a focus on precision, innovation, and sustainability, Bharat Engineering continues to push the boundaries of what’s possible in automotive casting manufacturing. Whether you are an OEM, a Tier 1 supplier, or a manufacturer in the aftermarket sector, Bharat Engineering is a trusted partner in delivering reliable, high-performance casting solutions.

For businesses looking for reliable automotive casting manufacturers, Bharat Engineering offers the expertise, technology, and commitment to quality needed to drive success in the competitive automotive market.

0 notes