#china cnc cutting service carbon fiber

Explore tagged Tumblr posts

Text

Table Operation

New Post has been published on http://www.cncmachinings.com/table-operation/

Table Operation

Revolving Table Operations

With both the workpiece and the revolving table correctly situated and the workpiece appropriately made sure about, machining tasks can start. Turning tables can be hefty, so get help when going and mounting them, and utilize legitimate lifting techniques.

Ordering for Milling and Drilling

On the off chance that the rotational table is just to be utilized to record the work to an ideal plot for machining, the turning table lock should be delivered and the hand wheel pivoted to situate the revolving table at the right point. The lock should be retightened prior to machining starts to look after position.

To situate openings on a jolt circle, move one table hub a distance equivalent to the range of the jolt circle. At that point opening positions can be situated by pivoting the table to the ideal rakish settings utilizing the rotating table graduations. Make certain to secure the rotational table situation prior to machining.

cof

To process points, utilize the revolving table to turn the work-piece to the ideal rakish setting utilizing the rotating table graduations. Once more, make certain to secure the rotating table position. At that point utilize one of the table tomahawks to set cut position and feed with the other table pivot to play out the processing pass.

Processing Outside and Inside Radii

To process a span, the brace on one of the factory tomahawks should be delivered and the table moved to balance the shaper from the turning table centerline (revolution pivot). Just balance one of the factory table tomahawks to cut a range. The counterbalance sum is controlled by taking the completed workpiece span measurement and changing the sum to make up for the shaper range when required. When processing an outer component, add the shaper range. When processing an inside component, take away the shaper range. When processing a range opening dimensioned to its centerline, make no shaper span change.

Similar principles of standard processing apply to get precision cnc lathe machining all kinds of precision metal parts when utilizing the turning table. Make sure to be mindful when climb processing while at the same time pivoting the table, as it is particularly simple for the workpiece to be maneuvered into the shaper. On the off chance that processing a halfway bend that appends another element or juncture, it is essential to watch out for the area of the shaper, as it is anything but difficult to go past the ideal halting point. china metal custom 4 axis cnc machining high precision micro spare parts manufacturers utilize the revolving table graduations to intently screen those curve endpoints.

Ordering can be performed by precision machining parts suppliers precision machining parts suppliersvutilizing a gadget, for example, a square or hexagonal collet block. A collet fits in the square and a nut strings on the rear of the collet to make sure about the workpiece in the collet. The square can be held in a standard processing tight clamp. Ordering is performed physically by eliminating the square from the tight clamp, turning it to another position, and reinstalling in the tight clamp. custom cnc machined precision machining titanium parts suppliers shows a square and hexagonal collet block.

Partitioning heads can be substantial, so get help while going them and utilize legitimate lifting techniques and gear.

This article is from http://www.cncmachinings.com/

#aluminum and brass machining parts suppliers china#buy brass cnc turning components#china brass cnc turning components manufacturers#china brass machining parts suppliers#china bronze custom made parts manufacturers#china cnc cutting service carbon fiber#china cnc lathe machine parts manufacturers#china cnc lathe turning stainless steel parts manufacturers#china cnc machine for carbon fiber#china cnc stainless steel milling parts#china cnc stainless steel milling parts manufacturers#china custom high precision aluminum cnc parts#china high-precision tooling suppliers#china large lathe machining parts suppliers#china metal custom 4 axis cnc machining high precision micro spare parts manufacturers#china milling mild steel suppliers#china steel machining#china swiss style lathe#cnc brass turning suppliers#cnc drehteile#cnc lathe machining factory#cnc machine product china#cnc machining parts supplier#cnc machining turning parts#cnc milling parts components company#cnc prototyping manufacturers china#cnc prototyping suppliers china#cnc stainless steel machinery parts china#cnc titanium milling parts suppliers#cnc turned parts manufacturer

0 notes

Text

Blind Holes

Posted from 5 axis machining China blog

Blind Holes

Through and Blind Holes

Openings that are bored totally through a workpiece are called through gaps (or through gaps). Openings that are just penetrated incompletely through a workpiece are called daze gaps. The profundity of a visually impaired gap is determined as full-width profundity. This is the profundity of the gap excluding the calculated base bit made by the drill point.

To bore a visually impaired gap, the profundity stop on the drill press can be utilized by precision machined parts factory to restrict the separation of the plume feed. There are a couple of approaches to set and check the profundity of a visually impaired gap.

If profundity isn’t basic, the plume can be set against the profundity stop similarly as the drill starts cutting its full breadth. At that point the stop can be moved a separation equivalent to the ideal profundity.

The drill tip can likewise be brought into light contact against a spacer on the top surface of the workpiece with the plume against the profundity stop. The length of the drill point and the spacer thickness can be added to the ideal profundity and afterward the stop moved the aggregate sum. At that point start the shaft and drill the opening until the plume arrives at the profundity stop.

If profundity is basic, utilize this equivalent strategy however set the profundity stop so the gap profundity is shallow. In the wake of arriving at the stop, profundity can be checked by setting a pin gage in the gap and estimating the uncovered length of the pin. Taking away that esteem from the general pin length will give the profundity of the bored opening. At that point change the profundity stop until the ideal profundity is reached.

On drill presses with a force feed instrument, the profundity stop will normally withdraw the force feed somewhat before arriving at the full profundity. The plume can be taken care of physically to arrive at the full profundity.

It is acceptable practice in cnc machining services in china to set the profundity stop in any event, when boring through gaps to keep away from unintentionally penetrating into the workholding gadget or worktable, or hitting the top surface of the workpiece with a drill throw, sleeve, expansion attachment, or the essence of the shaft. At the point when physically taking care of while driling a through gap, decline feed pressure when getting through the lower part of the workpiece to abstain from authoritative or breaking the drill.

REAMING

At the point when an opening must be machined by cnc prototyping manufacturers china to a more precise breadth or surface completion than can be created by boring, a reaming activity might be chosen to meet necessities. Reaming somewhat expands a current gap and gives a smooth surface, so an opening must initially be penetrated with a standard turn drill before reaming. Drill size for making the underlying opening ought to be underneath the last size by the accompanying sums.

0.010″ for an opening up to 1/4″

0.015″ for a gap between 1/4″ and 1/2 “

0.025″ for a gap between 1/2″ and 1-1/2 “

When too little material is left in a gap, the reamer may just rub against the side of the gap rather than really cutting. On the off chance that an excessive amount of material is left in an opening, material will reach out past the reamer’s front lines. This can make the reamer tie and break.This article is from http://www.5axismachiningchina.com

#china cnc cutting service carbon fiber#china cnc lathe machine parts manufacturers#china cnc lathe machining cosmetic parts suppliers#china cnc machine for carbon fiber#china cnc titanium turning parts and service suppliers#china custom high precision aluminum cnc parts#china metal custom 4 axis cnc machining high precision micro spare parts manufacturers#china steel parts manufacturers#cnc lathe machining machine parts suppliers#cnc machining parts supplier#cnc machining services in china#cnc precision turned parts china#cnc prototyping manufacturers china#custom machine parts made in china#precision machined digital camera components manufacturers#precision machined parts factory#precision machining brass components china#stainless steel parts china

0 notes

Text

Carbon fiber plate 200mm x 300mm thickness 2mm.

Carbon fiber is a kind of high-tech composite materials, used in many high-tech fields because of its valuable and rare attribute.People usually call it the “black gold”.Along with the development of many luxury goods, now more and more used due to its unique properties and GuanZe degrees, become the symbol of the identity and status.

Carbon fiber plate 200mm x 300mm thickness 2mm.

Product description:

Our stock carbon fiber plates are fabricated with multiple layers of high strength carbon fiber prepreg using a high pressure molding process. All carbon fiber plates are comprised of: Outer Material: 2×2 Twill Carbon Fiber Prepreg Inner Material: 0/90 (Balanced) Unidirectional Carbon Fiber Prepreg Exterior Finish: Matte/Matte Plates can be cut to size or machined to print via CNC milling or waterjet cutting.

Is your business searching for a supplier of high quality Carbon fiber? Located in China,We can customize according to customer’s requirements, special products. we can offer CNC machining, CNC engraving milling machine, CNC, lathe machine,CNC cutting ect Services.

1 note

·

View note

Photo

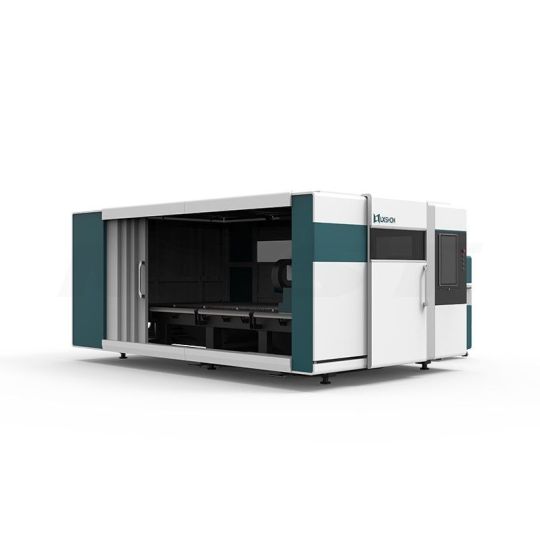

LX3015C-0 China cnc best metal plate enclosed fiber laser cutting sheet machine stainless steel carbon steel iron aluminum price

Stainless Steel Laser Cutter Description

LXSHOW LASER LX3015C-O is a product specially designed for sheet metal laser cutting machine. It has stronger cutting ability and higher cutting precision. Do you want to know more about it? The product details page below can help you.

Safety and Environment Protection

With a fully enclosed design;

The observation window adopts an European CE Standard laser protective glass;

The smoke produced by cutting can be filtrated inside, it's non-polluting and environmentally friendly;

Monitoring system

Real-time observe the machine running through the panel

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Transmission And Precision

LXSHOW fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and Taiwan Hiwin Rails. The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to more than 15 years.

Intelligent Autofocus

The high efficiency cooling:

Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.

Chase the light aperture:

Through the pore diameter of 35 mm, effectively reduce the stray light interference, ensuring cutting quality and service life.

Automatic focus:

Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.

High speed cutting:

25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.

Independent Control Cabinet

Dust-proof

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

Automatic Thermostat

The control cabinet is equipped with air conditioner for automatic constant temperature.This can prevent excessive temperature damage to components in summer.

0 notes

Video

tumblr

cnc 0.3-8mm thick cnc cut 3k forged custom carbon fiber plate sheet drone cfrp China manufacturer price

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD

https://www.carsai-precisionparts.com/ Whatsapp&WeChat: +8615212743691 email: [email protected] --------------------- cnc 0.3-8mm thick cnc cut 3k forged custom carbon fiber plate sheet drone cfrp China manufacturer price carbon fiber cnc service,carbon fiber cnc milling,carbon fiber cnc bits,carbon fiber cnc cutting tool,carbon fiber cnc gantry,carbon fiber cnc projects,carbon fiber cnc price in india,drilling carbon fiber cnc,carbon fiber cnc machine,carbon fiber cnc router,best cnc carbon fiber,carbon fiber cnc cutter,carbon fibre cnc cutting uk,carbon fibre cnc cutting,cnc carbon fiber cutting service,custom carbon fiber cnc service,cnc carbon fiber camera,desktop cnc carbon fiber,cnc endmill carbon fiber,carbon fiber for cnc machine,cnc carbon fiber for sale,can you cnc carbon fiber,how to cnc carbon fiber,how to cut carbon fiber cnc,how to cut through carbon fiber,cnc kitchen carbon fiber,carbon fiber small cnc machine,cnc carbon fiber mold,cutting carbon fiber on cnc router,carbon fibre plate cnc,cnc carbon fiber plate,cnc carbon fiber price,carbon fibre cnc router,cnc router carbon fiber sheet,carbon fibre cnc service,carbon fiber sheet cnc,cnc cutting carbon fiber sheet,cutting carbon fiber with cnc router,cnc 3018 carbon fiber,can you cnc carbon fiber,how to cnc carbon fiber,can you machine carbon fiber,can carbon fiber be cut,carbon fiber cnc machine,how to cut carbon fiber cnc,how to cut through carbon fiber,carbon fiber process flow diagram,carbon fiber processing methods,carbon fiber processing equipment,carbon fiber process cost,carbon fiber processing line,carbon fiber process description,carbon fiber processing technology,carbon fiber process definition,carbon fiber manufacturing process pdf,carbon fiber manufacturing process ppt,carbon fiber layup process,carbon fiber autoclave process,pitch based carbon fiber production process and properties,carbon fiber barrel manufacture,carbon fiber body manufacturer,carbon fiber bike manufacturing process,carbon fiber vacuum bagging process,carbon fiber bike frame manufacturing process,carbon fiber curing process,carbon fiber coating process,carbon fiber carbonization process,carbon fiber construction process,carbon fiber chemical process,carbon fiber composite processes,carbon fiber composite manufacturing process,carbon fiber dipping process,carbon fiber design process,carbon fibre design process,dry carbon fiber process,carbon fiber manufacturing process,carbon fiber forming,carbon fiber fabrication process,carbon fiber forming process,carbon fiber filament process,carbon fibre forming processes,forged carbon fiber process,carbon fiber filament winding process,carbon fiber hand lay-up process,carbon fiber infusion process,carbon fiber industry process,carbon fiber manufacturing process in india,carbon fiber vacuum infusion process,carbon fiber injection molding process,carbon fiber manufacturing methods,carbon fiber making,carbon fiber manufacture,carbon fiber production process,carbon fiber lamination process,carbon fibre layup process,carbon fibre layering process,carbon fiber wet layup process,carbon fiber molding process,carbon fiber making process,carbon fiber moulding process,carbon fibre moulding process,carbon fibre molding process,carbon fiber materials manufacturing,carbon fiber process of making,carbon fiber oxidation process,carbon fiber overlay process,how to produce carbon fibre,is carbon fiber hard to make,how to make carbon fiber frame,carbon fiber pultrusion process,carbon fiber pan process,carbon fiber production process pdf,carbon fiber parts process,carbon fiber panel process,carbon fiber producing process,carbon fiber recycling process,carbon fiber rtm process,carbon fiber reinforced process,carbon fibre resin process,carbon fibre recycling process,rayon carbon fiber process,carbon fiber raw materials process,carbon fiber reinforced polymer manufacturing process,carbon fiber shaping process,carbon fiber spinning process,carbon fiber skinning process,carbon fiber sizing process,carbon fiber solidification process,carbon fibre skinning process,carbon fiber seat manufacturer,carbon fiber sheet manufacturing process,carbon fiber tube process,carbon fiber tube manufacture,carbon fiber tube manufacturing process,carbon fiber surface treatment process,carbon fiber water transfer process,carbon fiber technology process,how to join carbon fiber tubes,how to make carbon fiber intake tube,carbon fiber lay up process,how to lay carbon fibre,carbon fiber process video,carbon fiber winding process,carbon fiber woven process,carbon fibre weaving process,carbon fibre woven process,carbon fiber wheels manufacturing process,z carbon fiber 3x3

0 notes

Text

Low Cost Fiber Laser Cutting Machine Manufacturers

What Is fiber laser cutting machine ?

fiber laser cutting machine is a kind of CNC laser metal cutting system with high quality, high speed, high precision and high efficiency. It is suitable for all kinds of metal cutting which will be your good metal working partner. It is equipped with different powers (from 1000W to 15000W) for cutting metal sheets/plates and metal tubes/pipes of stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials with different thicknesses. Fiber laser cutter is also known as fiber laser metal cutting machine, fiber laser cutting machine, fiber laser cutting system, laser cutting machine equipment.

📷

Machine Application:

Fiber laser cutting machine application materials:

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate,

Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, If you equipped with the rotary axis, Metal Plate, Tubes and Pipes, all ok.

Fiber laser cutting machine application Industries:

igoldencnc CNC Fiber Laser Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Machine Features of fiber laser cutting machine:

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects.

About us:

We are a company integrating manufacturing and sales of CNC routers, laser engraving machines, laser cutting machines, plasma cutting machines, cutting plotters, etc. The main configuration all adopt top parts imported from Italy, Japan, Germany, etc.We adopt international advanced producing technologies to improve our products. Our products are widely used in advertising, woodworking, artworks, model, electric, CAD/CAM industry models, clothing, package printing, marking, laser sealing and so on.

Our company adheres to the

Market-Oriented

business principles, and implements the business philosophy of "Quality First and Customer First". We have set up more than 20 sale and service departments around China which can offer our customers the services of design, fixing, training, maintenance and so on. Besides sale in China, our products exports around the world including the Middle East, Africa, Europe and the USA.

Monolithic cast aluminum beam,light weight, high strength, no deformation. Molded and framed by integral steel mold and die-casting technology, light crossbeam make equipment a high operation speed, improving processing efficiency and processing quality.

High speed

The light crossbeam can ensure the machine have high moving speed and improve the processing efficiency.

More efficient

The aluminum profile beam of the aerospace industry makes the equipment have efficient dynamic performance, greatly improving processing efficiency while ensuring processing quality.

Machine Parameters

Model

iGR-FT 3015

Working area/ Tube length

3000*1500mm/ 6000mm

X axis stroke

1500mm

Y axis stroke

3000mm

Z axis stroke

300mm

Tube diameter

20-220mm

Accuracy

X, Y axis positioning accuracy

0.05mm

X, Y axis repositioning accuracy

0.03mm

Speed

W axis rotate angle

n*360

W axis max. ratate speed

80rpm

X, Y axis max. running speed

150m/min

U axis max. positioning speed

800mm/s

X, Y axis max. accelerated speed

1.5G

Power supply

Phase

3

Nominal voltage

380V

Frequency

50/60Hz

Protection grade

IP65

Machine body

Max. working loading

1000kg

Body weight

2600kg

Size(L*W*H)

8060*3000*1965mm

Laser power

500w/ 750w/ 1000w/ 1500w/ 2000w/ 3000w/ 4000w/ 5000w/ 6000w/ 8000w/ 10000w/ 12000w

Worktable optional

4000*1500mm/ 4000*2000mm/ 6000*2000mm/ 6000*2500mm

Tube length optional

3000mm/ 9000mm

0 notes

Text

UV laser marking machine price!

Fiber laser marking machines and carbon dioxide laser marking machines on the market are cheap, have a long service life, are easy to maintain, and have low environmental requirements. So why are UV laser marking machines so expensive? In comparison, the service life is shorter and maintenance is more careful? Today, the editor of IGOLDEN Laser will introduce to you the reasons why the UV laser marking machine is expensive.

0 notes

Text

Sheet Metal Processing Equipment Market 2019-2027: Drivers, Key Players, Competitive Breakdown and Regional Analysis

Sheet Metal Processing Equipment Market: Introduction

Sheet metal is metal shaped into flat and thin pieces by an industrial process. Sheet metals are widely used in many industries such as automotive and aerospace. They can be bent and cut in any form. Most of the mass production cars are made from sheet metals. Thus, sheet metals are the key materials of the automotive industry. In the aircraft manufacturing industry, use of sheet metals for making aircraft parts and bodies has increased due to their lightweight and high level of strength.

Sheet Metal Processing Equipment Market: Competitive Landscape

Amada Co. Ltd.

Founded in 1951, Amada Co. Ltd is headquartered in Isehara, Kanagawa Prefecture, Japan. The company engages in the manufacture, sale, leasing, maintenance, repair, inspection and checking of metal working machinery and tools. Amada Co. Ltd. operates through the following business divisions: Metal Cutting Machine, Machine Tool, Stamping Press, Sheet Metal Fabrication Machine, Precision Welding Machine, and Others. The company operates in Asia, Europe, the Americas, and Africa.

Dalian Machine Tool Group

Incorporated in 1948, Dalian Machine Tool Group is based in Zone Dalian, Liaoning Province, China. The company manufactures industrial machinery equipment. It produces milling machines, engraving machines, lathes, bridge type machines, drilling machines etc..

To Get Glimpse of what our report offers, Ask for a Report Brochure here

DANOBATGROUP

Established in 1954, DANOBATGROUP is based in Elgoibar, Guipúzcoa, Spain. The company manufactures and supplies machine tools. Furthermore, it is specialized in developing advanced manufacturing solutions for different industrial sectors.

TRUMPF Group

Founded in 1923, TRUMPF Group is based in Ditzingen, Germany. The corporation is an expert in manufacturing of machine tools and lasers. Furthermore, it offers printing, drill driver, slat cleaners, welding, tube cutting, seam locker, power fastener, storage system, profile nibbler, marking, induction generators, and automation equipment. The company has 13,400 employees. It offers its products around the world.

FANUC Corporation

Incorporated in 1972, FANUC Corporation is located in Oshino, Yamanashi Prefecture, Japan. The company engages in development, manufacture, sale, and maintenance of computer numerical control (CNC) systems, robot systems, robo machines, lasers, robocut, roboshot, and Nano robots. FANUC Corporation operates through the following business divisions: factory automation (FA), robomachine and robot.

Some of the significant players in the sheet metal processing equipment market are DMG Mori Seiki Co., Ltd, Komatsu Ltd, Haas Automation, Inc., Makino Milling Machine Co., Ltd, and GF Machining Solutions.

Sheet Metal Processing Equipment Market: Dynamics

Increase in Demand from Automotive and Aerospace Industry

Expansion of the sheet metal processing equipment market can be attributed to the increase in demand from automotive and aerospace industries. Sheet metals are used as a prime material in car production in the automotive industry. Automobile sales in India are expected to increase due to key factors such as drop in price of crude oil and implementation of GST (Goods & Services Tax) that reduces the tax on vehicles. Thus, boost in the automotive industry is likely to impact the expansion of the sheet metal processing equipment market in India. Furthermore, sheet metal processing equipment such as laser cutting machines are being used increasingly in aircraft manufacturing for higher accuracy. Hence, several aircraft manufacturers are heavily investing in production expansion activities in order to meet the increase in demand. As a result, the sheet metal processing equipment market is likely to expand at an impressive pace in the next few years.

Increase in Use of Plastic and Carbon Fiber Reduces Application of Sheet Metal Processing Equipment

Plastic and carbon fiber based gears are easily available at low price. Furthermore, these gears enhance speed and fuel capacity of vehicles. Due to all these advantages, automobile manufacturers are increasingly adopting plastic and carbon fiber to replace metal gears. This is likely to hinder the market in the near future.

To Get a Bird’s Eye View of Market Forecast, Ask for a Custom Report here

Sheet Metal Processing Equipment Market: Segmentation

The sheet metal processing equipment market can be segmented based on:

Type

Application

Region

Sheet Metal Processing Equipment Market Segmentation – By Type

Based on type, the sheet metal processing equipment market can be segregated into:

Metal Cutting

Metal Forming

Metal Welding

Sheet Metal Processing Equipment Market Segmentation – By Application

Depending on application, the sheet metal processing equipment market can be divided into:

Electronics

Automotive

Aerospace & Defense

Machinery Manufacturing

Others

The report on the sheet metal processing equipment market is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, and inputs from industry experts and industry participants across the value chain. The sheet metal processing equipment market report provides in-depth analysis of parent market trends, macroeconomic indicators, and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various factors on sheet metal processing equipment market segments and geographies.

Request For Covid19 Impact Analysis Across Industries And Markets – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=70113

Related Reports Press-Release –

https://www.prnewswire.com/news-releases/global-semi-trailer-market-to-exceed-valuation-of-us24-bn-by-2026-demand-from-road-freight-from-heavy-industry-drive-sales-concludes-a-tmr-study-301003597.html

https://www.prnewswire.com/news-releases/increasing-focus-on-developing-technologically-advanced-products-is-helping-personal-care-appliances-market-to-reach-valuation-worth-us111-bn-by-2027-finds-tmr-301005855.html

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information, we offer customized solutions through adhocreports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key tohelp enterprises reach right decision.”

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: https://www.transparencymarketresearch.com

0 notes

Video

youtube

fiber laser cutting machine for 2mm stainless steel

CHINA STARMACNC cnc metal fiber laser cutting machine with 500w 750w Raycus laser source working video for stainless sheet, carbon steel sheet and tubes. widely used in any kind metal cutting. For the machine ,we use Japan Yaskawa Servo 850w motor and 4th Rotary axis , precision is high. If you interest, More details pls visit: www.starmacnc.com Or welcome to contact us: JINAN STARMA MACHINERY EQUIPMENT CO.,LTD. Email: [email protected] Skype: andycnc-service Whatsapp/Wechat: +86 15194126152

#fiber laser cutting#fiber laser cutting machine#fiber laser cutter#metal laser cutting machine#starma cnc laser

0 notes

Text

Tapping

New Post has been published on http://www.cncmachinings.com/tapping/

Tapping

A subset is utilized by cnc precision machining laser carving parts china to perform subsetting or chamfering procedure on existing openings. Rates for subsetting are ordinarily about 25% of those pre-owned when boring a similar material. Feeds for subsetting are typically light, similarly as while counterboring or spotfacing, as a result of the huge measure of surface contact between the instrument and the workpiece.

Feed profundity sum for a subset relies upon the point of the apparatus, the current opening size, and the ideal subset (or chamfer) measurement. When utilizing a 90-degree subset, feed profundity can be discovered utilizing the accompanying equation.

Precision machined digital camera components manufacturers ilustrates this idea and shows varieties of this recipe for various subset points.

A subset will focus itself in a current opening, so the workpiece or tight clamp is ordinarily permitted to coast on the drill press table as opposed to being firmly clasped. Rather, a positive stop is clipped to the worktable to keep the tight clamp or workpiece from turning. To chamfer or subset an opening, follow these means.

Mount the device in the shaft.

Calculate and set shaft RPM.

Set the profundity stop so the instrument is inside around 1/32″ of contacting the edge of the current opening.

Adjust the profundity stop in little additions of about 0.001 “to 0.003” until the subset contacts the edge of the current opening.

Adjust the profundity stop to accomplish the necessary profundity.

While subsetting, the tight clamp (or workpiece if sufficiently enormous to be set legitimately on the table) will move somewhat in a little round movement. This is simply the instrument consistently focusing in the gap and is ordinary.

China metal custom 4 axis cnc machining high precision micro spare parts manufacturers shows a subsetting activity and legitimate situation of a table stop to forestall tight clamp development.

TAPPING

The drill press can likewise be utilized to appropriately adjust taps, taking out the requirement for utilizing a square as when hand tapping. In the event that the workpiece has been moved between the penetrating and tapping activity, the opening can be realigned with the axle utilizing a middle point mounted in the axle, as china steel cnc turned component manufacturers.

Brace the tight clamp or workpiece safely to the table before tapping to keep the work from moving out of position. Subsequent to making sure about the workpiece, follow these means.

Mount the middle point in an axle mounted throw. This middle point fits in an opening in the head of the tap or in the rear of a tap wrench/handle.

Mount the tap in a tap wrench/handle.

Place the tap in the head of the drilled opening.

Lower the plume so the tip of the tap place is in debt in the tap or tap wrench /handle.

If utilizing a spring-stacked focus, carry the middle into contact with the tap or wrench/handle by bringing down the plume until the spring is packed. Lock the plume in position with the plume lock.

If utilizing a strong tap community, one hand must apply light strain to the plume feed handle to keep the tap adjusted while turning the tap with the other hand, as appeared in china high-precision tooling suppliers.

Turn the tap around each half to one full turn in turn.

After each forward movement, back the tap out one half turn before proceeding. This helps break the chip being shaped as it cuts. Not backing the tap up will frequently make the tap tie in the opening and break.

This article is from http://www.cncmachinings.com

#china 4 axis cnc machining manufacturers#china cnc cutting service carbon fiber#china cnc lathe machining cosmetic parts suppliers#china custom-made aluminium machining part service#china high-precision tooling suppliers#china titanium precision cnc components suppliers#chinese mold component machining suppliers#cnc grinding machine china#cnc machining parts supplier#cnc machining products suppliers china#cnc machining services in china#cnc machining turning parts#cnc precision machining laser carving parts china#cnc titanium screws factory#custom cnc machined precision machining titanium parts suppliers#custom metal parts aluminum cnc milling machining factory#customized cnc machining grinder parts#precision cnc turned parts manufacturers#precision copper machining electronics parts suppliers#precision machined digital camera components manufacturers#precision machined parts factory#Featured Articles

0 notes

Text

Rapid Traverse

Fast navigate developments should be performed cautiously in a CNC going machine to forestall crashes. Uncommon consideration should be paid to the shifting lengths of the cutting apparatuses and that they are so near other machine parts and the workpiece. Another thought is the area of the device before and toward the fruition of the fast developments. For example, if the instrument is an ID…

View On WordPress

#4 axis cnc machining service factory#china alu cnc machining#china cnc machine for cutting foam#china cnc steel turned machining parts suppliers#china custom aluminum milling suppliers#china customized cnc milling parts suppliers#china customized cnc service#china luminum cnc milling machining suppliers#china precision machining parts suppliers#china precision mini metal lathe#china titanium grinding service manufacturers#china tooling cnc machining suppliers#cnc carbon fibre machining#cnc cutting service carbon fibre manufacturers#cnc lathe parts suppliers#cnc machined carbon fiber parts factory#cnc machining turning parts manufacturers#cnc milling aluminum part factory#cnc precision machining factory#cnc turning made in china#cnc turning parts suppliers#cnc turning precision titanium parts#cnc turning stainless steel parts china#custom cnc machined precision machining titanium parts factory#medical parts machining suppliers china#precision cnc machining service factory#precision grinding machine manufacturers china#precision stainless steel cnc turned parts manufacturers#prefessional cnc milling parts factory#quality instrument machining service

1 note

·

View note

Text

Drilling in CNC

Posted from 5 axis machining China blog

Drilling in CNC

Subsequent to recognizing, the following stage in the process is for cnc machining services in china to choose and mount the ideal wind drill in the machine axle.

When china metal custom 4 axis cnc machining high precision micro spare parts manufacturers utilizing a straight-shank drill, follow these means.

Open the drill toss and addition the shank bit of the drill into the drill toss.

The boring tool ought to be embedded far enough into the throw that the whole shank is immovably held, in any case, the boring apparatus ought to never be so far in the hurl that the toss jaws will fix onto the flutes. This may make harm the drill or toss jaws.

If conceivable, embed the drill so the finish of the shank bottoms in the drill toss. This keeps the drill from being pushed once more into the toss when boring.

When the ideal opening is bigger than 1/2″ in breadth, a littler gap called a pilot gap is frequently penetrated before the bigger bore is utilized. For the pilot opening, select a drill that is marginally bigger than the width of the flawlessly focused of the bigger drill size. The pilot opening makes help for the right on target and decreases the constrain needed to take care of the drill into the work.

Secure the workpiece.

Calculate and set the correct shaft speed utilizing one of the recipes talked about beforehand.

On a drill press with a force feed choice, set the force feed to a suitable rate.

Start the axle and start to take care of the drill into the workpiece physically utilizing the feed handle. Physically taking care of the drill press gives the administrator more control.

Before the drill slices to its full breadth, stop the axle and check the separation between the edge of the cone-formed sorrow being cut by the drill point and the edge of the spread out circle.

If the gap is out of position, the dilling activity can be halted and the gap migrated by making an imprint with an etch. It is critical to play out this visual investigation in light of the fact that once the drill arrives at its full breadth, the area can never again be balanced utilizing this strategy on the grounds that the body is contained by the dividers of the opening.

After the gap area is affirmed or rectified, apply a liberal measure of a suitable slicing liquid to the drill or potentially on the workpiece.

Feed the plume utilizing the feed handle, or connect with the force feed system if accessible, to penetrate to the ideal profundity.

cof

Chips should twist out of the drill woodwinds and be of equivalent size. This demonstrates an appropriately honed drill. Peck penetrating will break chips into short pieces so they fall away from the drill. It likewise gets the chips out of the opening and permits slicing liquid to arrive at the tip of the drill. On the off chance that the drill isn’t withdrawn habitually when penetrating profound gaps, chips can gather in the flutes making the drill tie and break inside the gap. A high-pitch screeching commotion demonstrates that shaft speed is excessively high, or that the feed pressure is excessively light. When penetrating ferrous metals with HSS bores, earthy colored or blue chips demonstrate that the feed rate is excessively high.

This article is from http://www.5axismachiningchina.com

#aluminum and brass machining parts suppliers china#carbon steel axis factory#china brass cnc turning components manufacturers#china brass machining parts suppliers#china cnc cutting service carbon fiber#china cnc lathe machine parts manufacturers#china cnc machine for carbon fiber#china cnc titanium turning parts and service suppliers#china machine#china metal custom 4 axis cnc machining high precision micro spare parts manufacturers#cnc machining parts supplier#cnc machining services in china#cnc precision turned parts china#cnc prototyping manufacturers china#custom machine parts made in china#customized cnc machining titanium parts#high precision machining efficiency#other machined ptfe china#plastic milling precision parts factory#precision machined digital camera components manufacturers#precision machined parts factory#precision machining brass components china#stainless steel parts china#subcontract machining factory

0 notes

Text

Pinalloy.com - About Us

www.pinalloy.com, found in 2015 in China, international retail seller, provide auto accessories to enhance your joy with very reasonable price. We have aligned factories with technology:

Go Green - Skateboard / Longboard

Pinalloy Go Green – everything you own (or use) such as driving to work/school, car wash, gas, fuel… They do not simply come from "the store."; they all have an environmental impact. Now it is the time to ask yourself, what could we do to help this “inconvenience truth”?

“A small step for a man a giant leap for mankind” - Neil Armstrong

Go Green project recommend you with using bicycle / skateboard / longboard instead of using car. Every step you change helps our environment a giant leap.

Introducing double wheeled kit for skateboard/ longboard, a maximizer to upgrade your board to be durable on street/ road; enhancing the performance on skating on stairway.

Carbon

• It is a chemical element with symbol C and atomic number 6. It is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds. There are three naturally occurring isotopes, with 12C and 13C being stable, while 14C is radioactive, decaying with a half-life of about 5,730 years. Carbon is one of the few elements known since antiquity.

• Carbon is the 15th most abundant element in the Earth's crust and the fourth most abundant element in the universe by mass after hydrogen, helium, and oxygen. It is present in all forms of carbon-based life, and in the human body carbon is the second most abundant element by mass (about 18.5%) after oxygen. This abundance, together with the unique diversity of organic compounds and their unusual polymer-forming ability at the temperatures commonly encountered on Earth, make this element the chemical basis of all known life.

CNC router

• CNC is a computer controlled cutting machine related to the hand held router used for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, and foams. CNC stands for computer numerical control. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut mortises and tenons.

• A CNC router is very similar in concept to a CNC milling machine. Instead of routing by hand, tool paths are controlled via computer numerical control. The CNC router is one of many kinds of tools that have CNC variants.

• A CNC router typically produces consistent and high-quality work and improves factory productivity. Unlike a jig router, the CNC router can produce a one-off as effectively as repeated identical production. Automation and precision are the key benefits of CNC router tables.

• Drawing of a Tabletop DIY - CNC router. Silver: Iron, Red: Stepper Motors, Light Brown: MDF, Dark Brown: Hard Wood

• A CNC router can reduce waste, frequency of errors, and the time the finished product takes to get to market.

For more details on our products and services, please feel free to visit us at carbon fiber case, paddle shift, VW up, Paddle shifter extensions, Volkswagen MK 7.5

0 notes

Text

Klarm Machining Processes china precision cnc machining oem parts

New Post has been published on https://www.cncmachinings.com/klarm-machining-processes-china-precision-cnc-machining-oem-parts/

Klarm Machining Processes china precision cnc machining oem parts

Different toolholders are used by Klarm Machining to process china precision cnc machining oem parts. A machining focus requires a toolholder for the machine’s shaft to hold the cutting device. There are two significant attributes while deciding the proper toolholder for an application: the axle mounting type and holder-to-device connection style.

CNC Spindle Types

Most machining focus axles utilize the National Machine Tool Builder (NMTB) arrangement tighten. NMTB tighten sizes are clasified from littlest to biggest as 30, 35, 40, 45, 50, and 60. All sizes have a shape of 3-1/2″ per foot. Since this precarious shape isn’t self-holding, the little finish of these tightened holders have inside strings to acknowledge a maintenance handle. The high-precision tooling suppliers china shows a portion of the various styles of maintenance handles utilized in different machines. A ball gripper component toward the finish of the drawbar is utilized to get a handle on the maintenance handle. Spring pressure from a progression of circle unveils then draw to the drawbar to get the mating tightens. The numerous parts used to hold the toolholder are appeared in Figure 8.5.10.

Machining focus toolholders are additionally dlassified by rib type. The ATC grasps the rib of the toolholder during the apparatus change cycle. The two most basic rib types are the CAT spine (additionally called the V rib) and BT rib. The CAT rib was initially grown explicitly for CNC use by Caterpillar Inc. The BT and CAT ribs are comparative, however have some unobtrusive contrasts. The BT spine holders have a thicker rib with a topsy turvy groove, while the CAT-type holders place the section in the focal point of the rib. The maintenance handles on the BT holders have metric strings, while the CAT holders have inch-arrangement strings. Figure 8.5.11 shows a CAT-type spine holder and a BT-type rib holder.

The mix of the shape size and the CAT or BT rib are both expected to distinguish a toolholder particular. For instance, a CAT-40 holder utilizes the CAT spine and a size 40 shape, and a BT-50 uses a BT rib and a size 50 shape. The appropriate maintenance handle for some random machine should likewise then be chosen and connected to the toolholder.

Some more modest CNC processing machines don’t utilize either CAT or BT rib holders, however rather utilize a fast change NMTB tighten or the customary R-8 axle tighten to mount their tooling. This is generally normal on vertical-axle knee-type processing machines, and seat top models.

Instrument Attachment Styles

There are a few kinds of holders accessible for mounting various sorts of cutting apparatuses for CNC processing in cnc turning and milling metal combined machining manufacturer suppliers. Some are actually similar to those utilized for manual processing machines and others are planned explicitly for CNC machines.

CNC Endmill Holders

CNC endmill holders contain a drag to get a particular instrument shank measurement very much like those utilized for manual factories.

They likewise have a tapped opening with a setscrew at 90 degrees to the drag. This setscrew is fixed onto a Weldon level on the shank of the instrument. Just instruments with pads on their shanks ought to be mounted in this kind of holder.

Endmill holders are cheap, tough, basic, and fit for sending a ton of force, however there are a couple of drawbacks of endmill holders. Initial, an alternate measured holder is fundamental for each shank width. Equilibrium can be influenced by the setscrew and produce device vibration, particularly at high shaft speeds. Coolant can saturate the freedom region between the device shank and holder bore, causing consumption and making instrument evacuation troublesome.

As a result of the leeway needed for the endmill to slip into the drag, when the setscrew is fixed the slicing apparatus is compelled aside of the drag, causing runout. Runout makes the apparatus cut somewhat curiously large and makes lopsided device wear that can prompt diminished device life.

This article is from http://www.cncmachinings.com/

#bronze cnc turning parts#china cnc machined carbon fiber parts#china cnc titanium milling parts and service suppliers#china components of cnc machine#china lathe machines#china metal machining suppliers#china precision cnc machining oem parts#china titanium cnc turned parts manufacturers#china titanium cnc turned parts suppliers#cnc aluminum machining cutting manufacturers china#cnc machining price#cnc machining service cnc turning parts factory#cnc milling precision parts china#cnc precision parts suppliers china#cnc surface grinding machine manufacturers china#cnc turning and milling metal combined machining manufacturer suppliers#high-precision tooling suppliers china#micro cnc machining fastener factory#micro-grinding machine factory#steel machining component factory#Featured Articles

1 note

·

View note

Text

Facing Process in CNC Machining

New Post has been published on http://www.cncmachinings.com/facing-process-in-cnc-machining/

Facing Process in CNC Machining

Frequently, the principal activity to be performed on a milled part is a confronting activity. This machines the top surface of the part level and smooth, while accomplishing an ideal thickness. This surface turns into the Z-zero plane that any remaining profundity measurements will be referred to from. After the face processing device is stacked in the shaft, quick cross moves the device to the starting X-and Y-position, fast navigate carries the apparatus to the Z-confronting position, and afterward direct insertion is utilized to play out the confronting cut. This confronting activity starts real machining tasks and is the material expulsion segment of the CNC program design appeared in china custom titanium machined parts.

Since program organizes are identified with the focal point of the instrument, the fringe of the face factory should be considered so when the device goes to the ideal Z-profundity, it is still clear of the part. The instrument ought to likewise be taken care of completely off the workpiece toward the finish of the cut. In the model, the 3″ width face factory has a span of 1.5″, so the beginning point and finishing point of the confronting pass should clear the work by at any rate 1.5″. It is a smart thought to permit some additional room for wellbeing. For this situation, permitting an extra 0.200″ toward the beginning and the finish of each pass will be adequate.

The components of the workpiece to be confronted are appeared in china precision aluminum milling parts suppliers. In this model, the molder is sufficiently enormous to cut the full width of the part in one pass.

The Y facilitate can be the focal point of the workpiece at Y 1.25. This will place the face plant in the part along the Y-hub. The beginning X-arrange is determined by adding the sweep of the face plant and the wellbeing sum, at that point taking away that answer from the inception. The beginning X-facilitate is X 5.7. This worth would be 1.5 + 0.2= 1.7.

The closure X-arrange is X-1.7. The closure X-organize is determined by adding the length of the part, the range of the face plant, and the security sum. This point would be 4+ 1.5+0.200= 5.7.

Since past models set Z-zero on the highest point of the stock, it could be hard to see how any material will be eliminated if the face plant cuts at Z-zero.

On most parts, the Z-zero position will be set beneath the outside of the unpleasant stock. Assume the objective thickness is 0.900″ and the stock is 1.0″ thick; 0.100″ should be taken out during looking to arrive at the last thickness (1.0一0.900 = 0.100). In the event that the situation of Z-zero is set 0.100″ underneath the top surface of the harsh stock, the part will be the right thickness and the top surface plane of Z-zero will be made by the face factory of precision cnc machining parts manufacturers.

This article is from http://www.cncmachinings.com/

#china 3 axis cnc machining service manufacturers#china cnc machining medical parts#china cnc machining shop#china cnc plastic milling parts and service suppliers#china cnc stainless steel turning service manufacturers#china cnc turning&milling service manufacturers#china custom titanium machined parts#china customized precision metal lathe#china high precision cnc bronze custom made parts manufacturers#china metal cnc machining parts suppliers#china milling machine parts suppliers#china precision aluminum milling parts suppliers#china precision parts factory#china steel cnc turned component suppliers#china titanium machine parts manufacturers#cnc cutting carbon fiber part suppliers#cnc machine for carbon fiber suppliers#cnc prototyping made in china#low price custom cnc parts precision milling other cnc parts#machining parts manufacturers#machining parts quotation#medical devices tooling made in china#precision alloy manufacturers china#precision cnc machining parts manufacturers#Featured Articles

0 notes

Text

Klarm Machining Offers custom precision cnc machining plastic parts china

New Post has been published on http://www.cncmachinings.com/klarm-machining-offers-custom-precision-cnc-machining-plastic-parts-china/

Klarm Machining Offers custom precision cnc machining plastic parts china

Feed Rates

At the point when any feed-type move is modified, a feed rate should be allotted to it. Feed rates are modular and assuming none is modified in a square, the recently customized rate will in any case be dynamic. A F-character relegates the ideal feed rate.

Feed rates can be communicated in either inches each moment (IPM), utilizing a G94 code, or inches per upset (PR), utilizing a G95 code. This is regularly set at the outset segment of the CNC program or on the protected beginning square, yet can be actuated or changed whenever in the program. For processing tasks, utilization of IPM is generally normal, however IPR is here and there utilized for holemaking activities.

Feed unit settings are likewise modular, so consistently make certain of the setting that is dynamic. On the off chance that the machine is in G94 (IPM) and a feed pace of F.005 is customized (a satisfactory feed for IPR), the hub will move at just 0.005 inches each moment. In the event that the machine is in G95 (IPR) and F40.0 is customized (an adequate feed for IPM), the machine will move at 40 inches for each shaft insurgency!

An illustration of a quick situating move followed by two consecutive straight moves in a program seems as though this (notice the absence of G1 code in the last square, since it is now modular):

Roundabout Interpolation

Roundabout shaper ways can be made utilizing roundabout introduction. This movement can be utilized by china precision parts factory to process part highlights, for example, corner radi, bends, and round pockets.

cof

To program a curve development, the instrument should initially be situated at the beginning stage of the bend. At that point a G-code is utilized to show either clockwise or counterclockwise development. A G2 order is utilized for clockwise movement, and a G3 order is utilized for counterclockwise movement.

China precision machined components suppliers illustrates an illustration of a G2 and a G3 development.

In the very square that the G2 or G3 code is given, the software engineer should likewise distinguish the end point where the curve is to stop (recollect that the device was at that point toward the beginning point before the roundabout interjection order). A G2 order and a bend end point is added to the last model and featured underneath:

G0 X1. Y1. (Quick X AND Y TO START POSITION);

G1 Z-.1 F15. (Direct FEED Z TO DEPTH)

X-1.5 F30. (Straight FEED X TO NEXT POSITION);

G2 X-2. Y1.5 (CW ARC MOVE TO NEXT POSITION);

Be that as it may, this is as yet insufficient data for a round insertion move. The control realizes the beginning point, the end point, and the heading, however there is no data about the size of the circular segment span. See Figure 8.6.5 for an ilustration of why the sweep data is required. The very square of code that enacted round interjection should likewise contain that sweep data. There are two strategies for programming the size of the sweep: the bend place technique and the span strategy. The bend community technique has the upside of having the option to cut a 360-degree circular segment (round trip) utilizing just one line of code, where the sweep strategy requires round trips to be broken into two pieces and customized with two squares of code. The R-technique is generally simpler for another developer to see, nonetheless. This article is from

#china cnc lathe machining cosmetic parts manufacturers#china cnc machine for cutting foam#china cnc milling parts factory#china cnc turning laser carving parts manufacturers#china custom machined aluminum#china machining processes#china metal cnc machining parts suppliers#china milling parts suppliers#china precision machined components suppliers#china precision parts factory#china precision titanium machining manufacturers#china used cnc milling machine#cnc cutting carbon fiber part suppliers#cnc machining turning parts manufacturers#cnc milling services suppliers#cnc precision steel parts suppliers#custom carbon fibre parts cnc#custom precision cnc machining plastic parts china#custom precision machined components factory#machine components manufacturers china#metal milling part manufacturers china#plastic or metal machining parts made in china#precision machining made in china#Featured Articles

0 notes