#chiller cooling pump

Explore tagged Tumblr posts

Text

Differences Between Split and Integrated Laser Chillers | Cooling Circulation Pump Selection Suggestions

In the application of laser equipment, laser chillers are key components to ensure the stable operation of laser devices. By providing precise and stable temperature control, they ensure the efficient, safe, and long-lasting operation of laser equipment. With the continuous development of technology, both split and integrated laser chillers have occupied a place in the market due to their respective characteristics and advantages. This article will discuss the differences between these two types of chillers and the differences in cooling circulation pump selection for them.

Differences Between Split and Integrated Laser Chillers

Split and integrated laser chillers differ in terms of structure, installation, and application scenarios. When choosing a laser chiller, it is essential to select the appropriate type based on actual needs and application scenarios to ensure the normal operation and stability of the chiller.

1. Structure and Design

Split Laser Chiller: Its design feature is that the indoor unit and outdoor unit are installed separately and connected through pipelines and wiring. The indoor unit mainly includes the evaporator, water tank, water pump, and other components, while the outdoor unit contains core refrigeration components such as the compressor and condenser.

Integrated Laser Chiller: All components, including the compressor, condenser, evaporator, water tank, and water pump, are integrated into one cabinet, making the structure compact and easy to install and move.

2. Installation and Maintenance

Split Laser Chiller: Since the indoor and outdoor units are installed separately, it requires a larger installation space, and the installation process is relatively complex, requiring professional personnel. In terms of maintenance, both the indoor and outdoor units need to be maintained separately.

Integrated Laser Chiller: The installation process is simple; just place the whole unit in the designated position and connect the power and water sources. Maintenance is also relatively convenient because all components are concentrated in one cabinet, making inspection and repair easier.

3. Application Scenarios

Split Laser Chiller: Suitable for large industrial facilities, high heat-generating environments, places with strict noise control, and areas with high ambient temperatures. Its design advantages in heat management and noise control enable it to meet more complex and high-demand cooling needs.

Integrated Laser Chiller: Suitable for small working environments, places requiring high mobility and quick deployment, and small to medium-sized laser equipment. Its compact and easy-to-install and maintain characteristics make it an ideal choice for small and flexible application scenarios.

Differences in Water Pump Selection for Split and Integrated Laser Chillers

Regardless of whether it is a split or integrated laser chiller, cooling circulation pump plays a crucial role. It is responsible for driving the operation of the water circulation system, ensuring that the cooling water can efficiently and stably provide a cooling effect for the laser equipment. The different designs of split and integrated laser chillers result in different demands and considerations for pump selection.

1. Split Laser Chiller

Flow and Head Requirements: The flow needs to consider the distance between the indoor and outdoor units, pipe length, pipe diameter, and hydraulic loss of the system. Since split chillers usually need to deliver coolant to more distant equipment, the pump head needs to be higher to overcome pipe resistance and height differences.

Power and Efficiency Requirements: Power is determined based on the required drive power of the pump, and it is necessary to choose pumps with as high efficiency as possible to improve energy utilization and reduce energy costs.

Installation Requirements: Since the indoor and outdoor units of the split chiller are relatively independent, the pump can be installed near the chiller or separately. The installation location of the pump should be chosen based on the actual situation.

Selection Considerations: Consider the connection method and material of the pipes between the indoor and outdoor units to ensure compatibility between the pump and the pipes. Additionally, consider the ease of maintenance and repair of the pump.

2. Integrated Laser Chiller

Flow and Head Requirements: The flow is determined based on the internal heat exchange efficiency and cooling requirements of the chiller. The length and complexity of the pipes are lower. The head is relatively low because the cooling water circulates inside the chiller and does not need to be lifted to a high position.

Power and Efficiency Requirements: Due to the compact structure, more attention is paid to the energy-saving and high efficiency of the pump to ensure the overall performance of the chiller.

Installation Requirements: Since all components are integrated into one cabinet, the pump needs to be small in size and highly integrated to achieve efficient cooling in limited space.

Selection Considerations: Consider the compatibility and matching of the pump with other internal components of the chiller to ensure the overall stability and reliability of the chiller.

Advantages of TOPSFLO Laser Chiller Water Pumps

TOPSFLO has provided cooling pump solutions for many high-end integrated laser chiller customers internationally. The industrial laser chiller cooling system from a well-known American chiller brand, adopts TOPSFLO high-flow DC circulation pumps with intelligent speed control functions, helping their chillers achieve precise flow control according to actual needs and meet different cooling capacity requirements.

TOPSFLO laser chiller cooling pumps have high-precision structural design, precise flow control, low noise and energy-saving, long life and durability, and safety without leaks. They have successfully replaced pumps from many well-known imported brands.

1. High-Precision Structural Design

TOPSFLO micro brushless DC water pumps are small in size, making them an ideal choice for integration into integrated laser chiller units. Their compact size ensures that the entire cooler remains lightweight and easy to move, promoting mobility and versatility.

2. Precise Flow Control

Using imported electronic components, they can be seamlessly integrated with control systems. This function can more accurately control the flow, reduce energy consumption, and meet the long-term working cooling effects of the equipment.

3. Low Noise and Energy-Saving

The core component, the rotor, is molded in a Sino-Japanese joint venture, with high initial mold costs ensuring industry-leading low noise levels and superior batch consistency.

4. Long Life and Durability

Using the most advanced ECM brushless DC motor, they are maintenance-free with a lifespan of up to 30,000 hours, ensuring continuous and stable water flow, contributing to the optimal performance of the chiller system.

5. Safety Without Leaks

Integrated advanced magnetic drive technology ensures sealing and leak-proof systems, eliminating the risk of water leakage and improving the safety and efficiency of the chiller unit. The magnetic drive mechanism also allows the pump to withstand high temperatures, ensuring reliable performance even in harsh environments.

Conclusion

TOPSFLO is one of the earliest manufacturers in China specializing in R&D and manufacturing micro pumps, and it is the only company focusing on high-end products, with 90% of its products exported to the European and American markets. The company has long-term stable cooperation with many world-renowned brands in Europe and America. The core components are mainly sourced from joint ventures and wholly foreign-owned enterprises in the industry, and the manufacturing equipment is mainly imported equipment to ensure the stability of the manufacturing process and craftsmanship. The precision and reliability of product components remain at the leading level among domestic peers. If you want to learn more about cooling circulation pumps for integrated laser chillers, please feel free to contact our sales engineers.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

youtube

#dcwaterpump#waterpump#micropump#coolingwaterpump#liquid cooling#coolingpump#water chiller#lasercoolingpump#laser chiller pump#chiller cooling pump#chillerpump#watercoolingpump

0 notes

Photo

(via United States Central Air Conditioning Systems Market 2024-2030) Rebounding in 2024, with a growth of 8.1% to reach 7.8 million units, U.S. unit shipments of Central Air Conditioning (CAC) Systems are projected to reach 11 million units valued at $27.6 billion by 2030, registering a compound annual growth rate (CAGR) of 6% during this period. This growth will be primarily driven by heightened sales of Variable Refrigerant Flow (VRF) systems and heat pumps, reflecting the ongoing demand for energy-efficient cooling solutions.

#united states central air conditioning systems shipments#us cac systems market#split ac systems#packaged ac systems#heat pumps#central plant cac systems#chillers#cooling towers#air handling units#fan coil units

0 notes

Text

A Guide to Data Center Cooling Systems: Ensuring Optimal Performance

Data centres are the beating heart of our digital world, powering everything from online shopping to critical infrastructure. However, this relentless operation generates immense heat, posing a significant challenge to maintaining optimal performance and efficiency.

A well-cooled data center cooling system is not just a luxury; it's a necessity. Inadequate cooling can lead to system failures, data loss, and increased operational costs. In fact, studies show that cooling can account for up to 40% of a data centre's total energy consumption, according to a report by McKinsey & Company.

In this article, we delve into the critical role of data center cooling systems and explore the various options available, including data center chillers,to ensure optimal performance, energy efficiency, and sustainability.

Why do Data Center Cooling Systems Matter?

First things first, why should we care about keeping our data centres cool? Well, there are a few compelling reasons:

1. Performance is King

Ever noticed how your laptop slows down when it gets too hot? The same principle applies to data centres but on a much larger scale. By maintaining optimal temperatures with optimal data center cooling systems, we keep those servers humming along at peak performance.

2. Reliability is Non-Negotiable

In our always-on world, downtime is a dirty word. Overheating can lead to system failures and unplanned outages. Effective cooling, with proper data center chillers for instance, helps ensure that critical IT services stay up and running 24/7.

3. Longevity Saves Money

Let's discuss money. Keeping components cool with effective data center cooling systems extends their lifespan, which means less frequent replacements and lower costs in the long run.

Energy Efficiency is Good for Everyone: Here's a sobering thought - cooling can eat up to 40% of a data centre's total energy use. By implementing efficient data center cooling systems and optimized data center chillers, we can significantly cut energy consumption, which is good for both the bottom line and the environment.

Best Practices for Data Center Cooling Systems

Now that we know why cooling matters, let's dive into how we do it right. The key is to think holistically about your data centre ecosystem, which includes your data center cooling systems and data center chillers. And we, at Climaveneta, experiment with that in our products.

See the Big Picture: Your data center cooling system doesn't exist in isolation. It interacts with the building structure, IT equipment, and power distribution systems. By considering these interactions, you can optimize your overall efficiency.

Master Airflow Management: One of the most effective strategies while creating data center cooling systems is to implement hot and cold aisle containment. This approach separates hot exhaust air from cold intake air, minimizing mixing and maximizing cooling efficiency. It's like keeping your hot coffee and iced tea separate - they both stay at their ideal temperature longer.

Mind the Gaps: Even small openings in your cooling infrastructure can lead to hot air recirculating into cold aisles. Be vigilant about sealing these gaps to maintain the integrity of your data center cooling system.

Tame the Cable Jungle: We've all seen it - the tangled mess of cables that seems to multiply when you're not looking. Beyond being an eyesore, poorly managed cables can obstruct airflow and create hotspots. Invest time in organizing your cables to ensure smooth airflow throughout your data centre.

Strategic Equipment Placement: How you arrange your servers and other equipment, like the data center chiller, can make a big difference in cooling effectiveness. Think of it like arranging furniture in your living room - you want to create pathways for air to flow freely.

Cooling Technologies

When it comes to data center cooling systems, there's no one-size-fits-all solution. Let's explore some of the most common methods:

Air-based Cooling

Computer Room Air Conditioning (CRAC): These units are the workhorses of many data centres. They cool air directly and often include humidifiers to maintain optimal moisture levels. They're reliable but can be energy-intensive components of a data center cooling system.

Computer Room Air Handlers (CRAH): These systems use chilled water to cool air from the data center chiller. While they require more infrastructure, they generally offer better energy efficiency than CRAC units.

Liquid-based Cooling

Chilled Water Systems: These data center cooling systems circulate chilled water to absorb heat from servers, then transfer it to the data center chillers for cooling. They're highly efficient but require careful planning to implement.

Direct Liquid Cooling: This method delivers coolant directly to heat-generating components. It provides precise temperature control and can handle high-density computing environments, but it's more complex to set up and maintain.

Hybrid Technologies

Some data centres are finding success with hybrid approaches that combine air and liquid cooling methods. These data center cooling systems can offer the best of both worlds, optimizing performance and efficiency.

Each of these cooling methods has its pros and cons. Air-based systems are generally simpler to implement and maintain but may struggle with high-density environments. Liquid-based systems offer superior cooling capacity and efficiency, especially for high-performance computing, but they're more complex and can be costlier to install.

The choice of cooling technology depends on various factors, including your data centre's size, density, location, and budget. It's not unlike choosing between central air conditioning and a swamp cooler for your home - what works best depends on your specific situation and the capabilities of your data center cooling system.

Looking to the Future

As data centres continue to evolve, so too will data center cooling systems. We're seeing exciting developments in areas like artificial intelligence for predictive maintenance, advanced heat recovery systems, and even underwater and underground data centres that leverage natural cooling.

The push for greater energy efficiency is also driving innovation. Many data centres are exploring free cooling techniques that use outside air or water sources to reduce reliance on mechanical cooling. Others are experimenting with raising operating temperatures to reduce cooling needs without compromising performance.

Wrapping It Up

In the end, an effective data centre cooling system is all about balance. It's a delicate dance between maintaining optimal performance, ensuring reliability, maximizing energy efficiency, and managing costs. By implementing best practices and choosing the right cooling technologies for your specific needs, you can keep your data centre running cool, calm, and collected.

Remember, a well-cooled data centre isn't just about avoiding problems - it's about creating opportunities. With the right data center cooling system, you can push the boundaries of performance, reliability, and efficiency, setting the stage for innovation and growth in our increasingly digital world.

0 notes

Text

The Ultimate Guide to High Capacity Water Chillers for Industrial Use

Introduction to High Capacity Water Chillers

High capacity water chillers play a crucial role in industrial processes. They ensure optimal temperatures, improve efficiency, and enhance product quality. This guide explores the benefits, types, and maintenance of these essential machines.

Benefits of High Capacity Water Chillers

Industrial water chillers offer numerous advantages. Firstly, they maintain precise temperature control, which is vital for sensitive processes. Secondly, they improve operational efficiency by reducing downtime. Additionally, they can lower energy costs through advanced cooling technologies. Finally, these chillers enhance the longevity of industrial equipment by preventing overheating.

Types of High Capacity Water Chillers

Understanding the different types of water chillers is essential. The three main categories are:

1. Air-Cooled Chillers

Air-cooled chillers are ideal for environments with limited water supply. They use ambient air to dissipate heat, making them cost-effective and easy to install. However, they can be less efficient in hot climates.

2. Water-Cooled Chillers

Water-cooled chillers are more efficient than their air-cooled counterparts. They use water from cooling towers to remove heat, making them suitable for larger industrial applications. These chillers are known for their reliability and energy efficiency.

3. Absorption Chillers

Absorption chillers utilize heat sources such as steam or hot water instead of electricity. They are eco-friendly and can be a good option for industries with excess waste heat. However, their initial setup can be more expensive.

Key Features of High Capacity Water Chillers

When selecting a high capacity water chiller, consider these key features:

1. Cooling Capacity

Ensure the chiller meets your specific cooling needs. Assess the required cooling load to choose an appropriately sized unit.

2. Energy Efficiency

Look for chillers with high COP (Coefficient of Performance) ratings. Energy-efficient models reduce operating costs and environmental impact.

3. Reliability and Durability

Invest in chillers from reputable manufacturers known for reliability. Durable units minimize maintenance needs and ensure long-term performance.

4. Control Systems

Advanced control systems enhance chiller performance. Features such as remote monitoring and automated adjustments optimize efficiency and reduce manual intervention.

Maintenance Tips for High Capacity Water Chillers

Proper maintenance extends the lifespan and efficiency of water chillers. Follow these maintenance tips:

1. Regular Inspections

Conduct routine inspections to identify potential issues early. Check for leaks, corrosion, and abnormal noises.

2. Clean Heat Exchangers

Clean heat exchangers regularly to maintain optimal heat transfer. Accumulated dirt and debris can hinder efficiency.

3. Monitor Refrigerant Levels

Ensure refrigerant levels are within the recommended range. Low refrigerant levels can impair cooling performance.

4. Lubricate Moving Parts

Lubricate components such as compressors and fans to reduce friction and wear. Proper lubrication extends the lifespan of these parts.

High capacity water chillers are indispensable in industrial settings. They provide precise temperature control, improve efficiency, and protect equipment. By understanding the types, features, and maintenance of these chillers, you can make informed decisions for your industrial cooling needs. Prioritize energy efficiency and reliability to maximize benefits and minimize costs.

For More Details Visit Us…

Water Chiller UAE

0 notes

Text

Boilers And Chillers Erection Services In India

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

For more details please visit our website-

https://avengineersefp.com/service/boilers-and-chillers-erection/

0 notes

Text

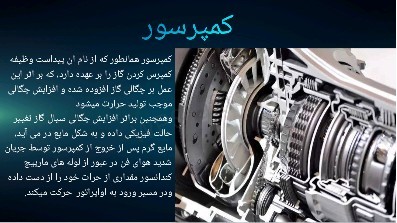

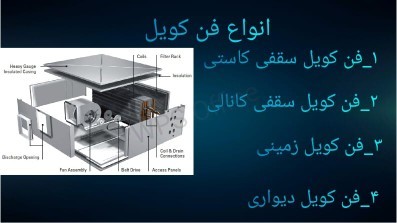

#تهویه#تهویه مطبوع#چیلرتراکمی#فن_کویل#تعمیرات#سرویس#داکت اسپلیت#کولرگازی#موتورخانه#chiller#fan coil#air conditioning#heating#cooling#ventilation#plumber#plumbing#pumps#services#technical#refrigeration#industrial air compressors

0 notes

Text

Glikol etylenowy Factory - Klucz do sukcesu Twojego przedsiębiorstwa.🔝💯

Zdumiewający i nowoczesny płyn niezamarzający Factory mający temperaturę krzepnięcia na poziomie -10oC w pojemniku 1000L. Glikol etylenowy Factory posiada niższe opory toczenia, co za tym idzie zwiększa żywotność elementów mechanicznych m.in. pomp obiegowych.🛠️✔️

Skuteczny odbiór i przenoszenie ciepła płynu niezamarzającego Factory oddziałuje na znakomite chłodzenie i szybką stabilizację temperatury medium.❄️💣

Skontaktuj się z nami już dzisiaj i otrzymaj spersonalizowaną wycenę❗

📞 +48 530 805 705

🌐 www.sklepinternetowypl.com

#ChillerTech#glikolpropylenowy#biznes#poland#polska#business#glikol#glikole#antifreezetechnology#antifreeze#klimatyzacja#chłodnictwo#chłodzenie#cooling#cooling equipment#chiller#refrigeration#refrigeration equpment#pompy ciepła#heat pump

0 notes

Text

Carrier Chiller Technology: A Beacon of Efficiency and Reliability in Malaysia

In the dynamic sphere of commercial cooling, Carrier stands as a paragon of excellence, especially when it comes to chiller technology. Recognized for its innovative approach, Carrier continually pioneers chiller solutions engineered to cater to a vast array of large commercial applications, seamlessly blending efficiency with reliability.

Healthcare Facilities

In the healthcare sector, the importance of maintaining a consistent, cool temperature cannot be understated. Carrier’s chillers play a vital role in ensuring that medical facilities have the reliable cooling systems necessary to keep equipment and environments at optimal temperatures, thereby aiding in the provision of high-quality healthcare services.

Industrial Settings

Industrial setups, known for their extensive cooling requirements, greatly benefit from Carrier's adept chiller solutions. With a focus on energy efficiency, these chillers facilitate smooth operations in industrial environments, helping to maintain the necessary climate conditions while minimizing operational costs.

Educational Institutions

In educational establishments, Carrier’s chillers create conducive atmospheres for learning and growth. Their solutions are designed to maintain comfortable temperatures, fostering environments that enhance focus and productivity, which is crucial for both learners and educators.

Data Centers

In the data center realm, where enormous amounts of heat are generated, Carrier’s chiller technology stands as a sentinel guarding against overheating. These chillers ensure that data centers remain at ideal temperatures, thus averting potential heat-related damages and downtimes, and securing data integrity and server longevity.

Innovative and Sustainable Solutions

Carrier's commitment to innovation is further underscored by their drive to develop sustainable solutions. Their chillers are not only potent in their cooling capabilities but also adhere to environmental-friendly standards, reflecting a responsible approach towards the planet.

Conclusion

In Malaysia, where the commercial sector is burgeoning, Carrier’s chiller solutions come as a breath of fresh air, bringing reliable, efficient, and sustainable cooling solutions to the fore. As the country marches towards a future characterized by technological advancements and urban growth, Carrier stands as a dependable ally, equipped with the technology to foster comfort and efficiency across various commercial spheres.

#hvac#air conditioning#air quality#commercial chillers#air cooled chillers#chillers#air conditioner#cooling solutions#chiller#chiller plant#heat pump#chillers and heat pump

0 notes

Text

30 weeks,

and I still do not have a firm understanding of what projects I’m going to be working on.

In other news it looks like the project in San Antonio is turning into a clusterfuck of horseshit. The HVAC & plumbing contractor cannot seem to provide simple information and follow simple directions. If they can’t do that, why trust them to install (2) new 300 ton chillers, pumps, and new cooling towers?

Sometimes people shoot themselves in their own foot. So maybe this will not be a project after all?

Finally, I got a haircut today, so I can look sharp for my trip to Houston early next week. Less hair on my head, means less hair for me to stress induced rip out of my head.

Less and less as the weeks go by.

11 notes

·

View notes

Note

I love thinking that even kevin even if hes annoyed with pump he be somewhat a good father- Like yeah its the kid who causes so many issues but he sees how marco is so happy with pump and susie and after how marco explained how their parents arent that good he woulddd be like "fuckkkkk they gotta deal with shitty parents-" and hes more chiller with them even if pump a crazy gremlin on purpose/silly i like to think kevin gets along with susie more while marco gets along with pump- i like to think kevin was sortaaaa a art kid when he was younger so he enjoys alot of susies stuff while marco who was a little shit to begin with likes hanging out with pump more but marco spends alot of time with susie too!! Like to think kevin worries a fuck ton about marco though since she is taking care of pump- like every time her and pump are out he calls marco every now and then to make sure nothing bad happens fdhnjfvnjdf ill add more later lol

IN THE END HE JUST WANTS TJEM SAFE AND HAPPY... KEVIN MY BELOVED :C

No it's actually because they both got the autism connection, she infodumps about demons and him about space/j /silly BUT FR HE WOULD BE SO CHILL WITH HERRRR, I CAN SEE HIM JUST SO CALM WHILE SEEING HER DRAWINGS AND FIND IT GENUINELY SO COOL!!

Marco and Pump literally just eating ice cream and meanwhile there's Kevin on the phone

" Are you sure you okay. You sure. No demons. Eldritch Monsters. Ghosts?? Killers??? GODS???? "

4 notes

·

View notes

Text

So the funny thing last night:

Scheduled Shutdown namin dahil meron maintenance sa Turbine, and yep, going smooth lahat. Papatay na talaga ang planta, tapos BIGLA NAGBLACKOUT! Anak ng…. Bali imbis na smooth down na e nagloko yung feedback power sa labas (bali kumukuha na kami ng power sa NGCP since hindi na nakakapagproduce ng kuryente)

Tapos ayun na nga, nung nagkaroon ng power, paranf nag-startup lang din kami uli. Binuksan lahat ng operating machines na need para sa pagpatay ng tama ng planta (from Cooling water pumps, Air compressor, Air dryer, Bottom Ash Removal System, Start-up Diesel Burner, Chillers, Makeup-Condenser-&Boiler Feed pump) grabe ang lala. Imbis na agad makakapg-pahinga e nawalan ng pahinga buong duty 🫡🥲💀💀💀💀

Yeah masaya sa Powerplant. Masaya…. 😊😊😊😊💀💀💀💀at pagod

Pero ang ganda ng view na total blackout sa planta.

9 notes

·

View notes

Text

The Future of Data Center Cooling: Pioneering Sustainable Solutions

The rapid expansion of digital infrastructure is driving an unprecedented surge in energy consumption by data centers. Projections indicate that by 2026, global data centers will require a staggering 1000 terawatt-hours (TWh) of electricity for cooling alone, nearly doubling the 460 TWh consumed in 2022. This increase represents a significant 2% of global electricity use, underscoring the urgent need for sustainable cooling solutions to mitigate the environmental impact of our expanding digital world.

In this blog post, we will explore the evolution of data center cooling systems, highlight current trends in sustainable technologies, analyze real-world case studies, and discuss how AI and automation are transforming cooling efficiency. Join us as we examine the critical steps necessary to ensure a greener future for data centers.

The Evolution of Data Center Cooling

The evolution of data center cooling is a story of adaptation and innovation. Early data centers relied on basic air conditioning units to manage the heat generated by mainframe computers. As computing power and data center density increased, these rudimentary systems proved inadequate.

The late 20th century saw the rise of Computer Room Air Conditioning (CRAC) units and chilled water systems. CRAC units used refrigerants to cool the air, which was then circulated under raised floors to maintain server temperatures. Chilled water systems, conversely, circulated cold water to cool the data center. Although effective, these traditional methods were energy-intensive and had a significant environmental impact.

In response to growing climate concerns, the industry began to explore more sustainable cooling solutions. Innovations such as free cooling—utilizing ambient air or water to reduce energy consumption—emerged as viable alternatives to conventional methods. Additionally, integrating renewable energy sources like solar and wind power has become a critical strategy for reducing the carbon footprint of data center operations.

Current Trends in Sustainable Cooling Systems

Today's data center cooling solutions focus on reducing energy consumption and environmental impact. Free cooling remains a leading trend, leveraging natural resources to minimize reliance on traditional refrigerants. Free air cooling systems use economizers to bring in cool outside air when conditions permit, significantly cutting down on compressor usage. Similarly, free water cooling systems use cold water from natural sources such as rivers or oceans to provide cooling.

The adoption of renewable energy is another key trend. Data centers are increasingly incorporating solar panels and wind turbines to generate clean electricity on-site or purchase renewable energy credits. This shift not only helps offset the carbon emissions associated with cooling systems but also supports a broader move toward sustainable energy practices.

The Role of AI and Automation

Artificial intelligence (AI) and automation are revolutionizing data center cooling by enhancing efficiency and reducing energy consumption. AI-driven systems enable real-time optimization of cooling operations, adjusting to varying conditions to minimize waste.

Predictive maintenance is one of the most impactful applications of AI in data center cooling. Leveraging the Internet of Things (IoT) and machine learning, AI systems analyze performance data from sensors to foresee potential issues before they occur. This proactive approach enables timely maintenance, reduces downtime, and extends equipment lifespan.

The convergence of 5G, edge computing, and IoT is creating a network of interconnected devices and sensors within data centers. This network generates vast amounts of data, which AI systems can use to continuously optimize cooling performance, driving further energy efficiency.

Real-World Case Studies

To illustrate the impact of sustainable cooling innovations, consider the following case studies:

Microsoft's Data Centers: Microsoft has implemented free cooling technologies and uses renewable energy to power its data centers. Its advanced cooling solutions, including submerged cooling and AI-driven systems, have significantly reduced energy consumption and carbon emissions.

Google's Data Centers: Google has pioneered the use of AI to optimize its cooling systems. By analyzing real-time data from thousands of sensors, Google's AI algorithms have achieved substantial energy savings, making its data centers some of the most energy-efficient in the world.

Equinix's Sustainable Initiatives: Equinix, a global data center provider, has invested in renewable energy and advanced cooling technologies. Its commitment to sustainability includes using free cooling systems and implementing energy-efficient practices across its facilities.

Looking Ahead

The future of data center cooling is anchored in the pursuit of sustainability and innovation. As data demand continues to rise, the industry must adopt cutting-edge technologies, integrate renewable energy sources, and leverage AI-driven optimization to mitigate environmental impact.

Climaveneta is at the forefront of this transformation, offering state-of-the-art, eco-friendly cooling systems designed to address the unique challenges of modern data centers. As we face a warming climate and increasing data needs, the role of sustainable cooling solutions becomes ever more critical. Join us in advancing energy-efficient and environmentally responsible digital infrastructure, paving the way for a greener future.

0 notes

Text

The Ultimate Guide to Ice Bath Chillers and Recovery Baths

Cold therapy has gained immense popularity among athletes, fitness enthusiasts, and wellness seekers for its recovery benefits and muscle relaxation. Whether you’re looking for a water chiller for ice bath with a pump, the best water chiller for ice baths, a metal tub for ice baths, a portable ice bath with chillers, or a recovery bath, the right setup can make all the difference in optimizing your cold therapy experience.

At Renest, we specialize in providing high-quality ice bath chillers and recovery solutions to ensure that your body gets the best post-workout treatment.

Why Choose an Ice Bath for Recovery?

Ice baths are widely used for muscle recovery, inflammation reduction, and enhanced performance. By exposing the body to cold temperatures, ice baths can help:

✔ Reduce muscle soreness — Cold therapy reduces inflammation and speeds up recovery. ✔ Improve circulation — Alternating between cold and warm therapy improves blood flow. ✔ Boost mental resilience — Cold exposure strengthens the nervous system and enhances endurance. ✔ Enhance post-workout recovery — Athletes use ice baths to recover faster after intense workouts.

Water Chiller for Ice Bath with Pump: A Game-Changer

A water chiller for ice bath with a pump eliminates the need for manually adding ice to your bath. These chillers provide continuous cooling, ensuring your bath maintains the ideal temperature for recovery.

Benefits of a Water Chiller with a Pump

✔ Consistent Cooling — No need to keep refilling ice; the chiller maintains your preferred temperature. ✔ Cost-Effective — Saves money over time by eliminating the need for purchasing ice. ✔ Convenient Setup — Simply connect it to your metal tub or portable ice bath, and you’re ready to go. ✔ Adjustable Temperature — Most chillers allow you to set the water temperature to your desired level.

A high-quality water chiller from Renest ensures that your ice bath is always ready for use without the inconvenience of melting ice.

Best Water Chiller for Ice Baths

Choosing the best water chiller for ice baths depends on factors such as cooling capacity, efficiency, and durability.

What to Look for in an Ice Bath Chiller?

Cooling Power — A chiller should be capable of maintaining water temperatures as low as 39–50°F (4–10°C).

Flow Rate — A powerful pump ensures even cooling throughout the tub.

Energy Efficiency — Choose a low-energy consumption model to save on electricity bills.

Durability — A rust-resistant and high-quality unit will last longer.

Ease of Use — A plug-and-play system makes installation and maintenance easy.

Metal Tub for Ice Baths: Durable and Reliable

A metal tub for ice baths is a popular choice due to its durability, excellent cooling properties, and aesthetic appeal.

Advantages of Metal Tubs for Ice Baths

✔ Better Insulation — Retains cold temperatures longer than plastic tubs. ✔ Durable and Long-Lasting — Made from stainless steel or galvanized steel. ✔ Easy to Clean — Resists bacterial growth and odors. ✔ Ideal for Indoor and Outdoor Use — Can be placed in a gym, backyard, or wellness space.

When paired with a water chiller from Renest, a metal tub transforms into a high-performance ice bath.

Portable Ice Bath with Chillers: Perfect for On-the-Go Recovery

A portable ice bath with chillers is ideal for athletes, travelers, and fitness enthusiasts who need a flexible recovery solution.

Why Choose a Portable Ice Bath?

✔ Easy to Transport — Lightweight and compact, making it convenient for travel. ✔ Quick Setup — Can be inflated or unfolded in minutes. ✔ Works with a Chiller — Compatible with Renest’s water chillers for continuous cooling. ✔ Perfect for Small Spaces — Ideal for homes, apartments, and gyms with limited space.

If you need cold therapy on the go, a portable ice bath with chillers is an excellent choice.

Recovery Baths: Enhancing Muscle Recovery

A recovery bath is designed to provide maximum benefits for muscle healing and relaxation. These baths use cold therapy to reduce inflammation, flush out toxins, and speed up muscle repair.

Key Benefits of a Recovery Bath

✔ Relieves Muscle Fatigue — Cold water helps soothe sore muscles. ✔ Reduces Swelling — Ideal for athletes recovering from injuries. ✔ Improves Sleep Quality — Cold therapy promotes relaxation and better sleep. ✔ Boosts Mental Clarity — Ice baths stimulate alertness and focus.

How does a water chiller for an ice bath work?

A water chiller cools the water by circulating it through a refrigeration system, maintaining a consistent low temperature without the need for ice.

What is the ideal temperature for an ice bath?

The recommended temperature range is between 39–50°F (4–10°C) for optimal recovery benefits.

How long should I stay in an ice bath?

A session of 5 to 15 minutes is typically enough to gain the benefits of cold therapy.

Is a metal tub better than a plastic tub for ice baths?

Yes, a metal tub retains cold better, is more durable, and is easier to clean compared to plastic tubs.

What is the best water chiller for ice baths?

The best water chiller should have strong cooling power, a reliable pump, and energy-efficient operation. Renest offers premium-quality ice bath chillers designed for maximum efficiency.

Can I use a portable ice bath with a chiller?

Yes, many portable ice baths are compatible with chillers, allowing for an on-the-go recovery experience.

Are ice baths safe for everyone?

While ice baths are generally safe, individuals with heart conditions, high blood pressure, or cold sensitivities should consult a doctor before use.

Conclusion

Whether you’re a professional athlete, a fitness enthusiast, or someone looking for the benefits of cold therapy, having the right setup is crucial. Investing in a water chiller for ice bath with a pump, the best water chiller for ice baths, a metal tub for ice baths, a portable ice bath with chillers, or a recovery bath can elevate your recovery experience.

At Renest, we provide top-quality ice bath chillers and recovery solutions designed for maximum performance. Explore our range of chillers, tubs, and recovery baths to experience the ultimate cold therapy benefits today!

0 notes

Text

Boilers and chillers Erection manufacturer and supplier

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

For more details please visit our website -

#boiler#chiller#erection#manufacturer#supplier#fabrication#hot water boiler#chiller boiler#system pumps#cooling tower

0 notes

Text

The Smart Trick of heizung pool That No One is Discussing

My ultimate recommendation for how to warmth your pool would be to Prepare well. You gained’t do oneself any favors by placing your swimming pool in total shade. Even on the very hot working day, your pool h2o will be Significantly cooler if it doesn't get some daylight during the day. The Solar is your greatest free heating resource, so utilize it!

Although this solar blanket poses no basic safety threats, is easy to use, will never Use a detrimental impact on the pool filtration system and is also affordable, it will also feel to carry the bottom amount of effectiveness. These liquid photo voltaic blanket’s efficiency are impacted by wind pace for the floor from the pool as well as h2o features that crack the surface area from the pool generating pool surface area agitation.

Coiled copper pipe is put on an elevated rack inside the stove, and also the Wooden fire heats it up. As copper melts at 2000°File, and wood stoves range between one hundred ten° to 250°File, you’ll don't have any troubles When you've got problems concerning the coil melting.

Heat pumps remain perceived as a fresh principle to a lot of homeowners in the US and Canada and since they've improved noticeably in general performance over the years there are lots of…

If you want to warmth your pool as swiftly as feasible, you need to investigate setting up a propane or organic fuel heater. A fuel pool heater warms the pool drinking water as being the water is pumped in the filter.

With eleven+ a long time of encounter inside the pool marketplace, Rick is a specialist in fixing even probably the most sophisticated pool and scorching tub problems. He is aware a point or two about all aspects of pool maintenance but his superpower is drinking water chemistry.

Gasoline heaters tend to be the swiftest choice to warmth your pool, but they may have higher ongoing charges and so are not eco-welcoming.

But Thankfully, with the help of technological innovation, Now you can heat your pool h2o, so you're able to consider issues into your own hands in place of solely counting on the elements.

Working with gas heaters frequently will increase your energy bill exponentially. Based upon your region, all-natural fuel may be on the list of costlier utilities, so working it for hrs at a time will bring about a significant Invoice.

All Arctic Spa & Pool Heat Pumps are both heater together with chillers. On automated manner, the warmth heizung pool pump will preserve The best temperature by switching from heating to cooling as required. Great for scorching summertime climates where a refreshing pool is welcomed in the warmth waves.

A titanium heat exchanger making sure a protracted Functioning lifestyle. Arctic Spa Warmth Pumps use titanium to stand up to the severe natural environment of a spa or a pool which can consist of superior levels of chlorine, bromine, or salt.

A solar include or blanket is actually a big sheet of slim plastic you area with your pool drinking water when not in use, usually resembling bubble wrap. In addition they come in various shapes, dimensions, thickness, and colours.

We have been thoroughly amazed Along with the GeoBubble EnergyGuard photo voltaic pool cover. It surpassed our anticipations and it has garnered fairly the fascination via the pool company that helped us install it and our heater, along with the pool support human being. Given that putting in it about per month in the past, our pool temps have not dropped greatly overnight and the pool has needed less routine maintenance Over-all.

Numerous who may have thought of or used both of the above described blankets also take into account them being Ugly, challenging and/or pricey to use - and as we reported, encompassing ourselves with vinyl just isn't an excellent decision of material so polyethylene may be a better option (see right here). The last kind of blanket readily available out there is definitely the Liquid blanket, so we must always examine that.

0 notes

Text

Helping The Others Realize The Advantages Of pool pumpe

Hayward has the marketplace’s broadest line-up of pool pumps engineered to deliver ultra-superior effectiveness with powerful and dependable functionality.

Publication Stay informed with our slicing-edge insights and stay forward inside your industry with our expertly curated newsletter.

Area keep price ranges may possibly differ from those exhibited. Items proven as readily available are Usually stocked but inventory ranges cannot be assured.

The market standard will be to flow into all h2o inside an 8-hour interval. Though changing a pump "like for like" might sound reasonable, In case your pump unsuccessful prematurely, it could indicate an incorrect pump option.

A swimming pool pump features as the center of your respective pool, circulating water through the entire technique to forestall it from turning out to be stagnant and improperly sanitised.

Her finder du et stort udvalg af filterpumper til din swimmingpool.Vi har altid et bredt udvalg af de mest anvendte og gense pumper til pools i forskellige motorstørrelser og med enten en eller tre faser. Hvis du er i tvivl om, hvilken pumpe der passer til din pool, er du altid velkommen til at kontakte os.

Because the name implies, this cable can be a multiconductor cable that connects a submersible pump controller towards the motor with the pump, often located in a deep very well. Cables are in good shape to face up to wet and hostile conditions and can be employed in each refreshing and saltwater.

With no useful swimming pool pump, pools can swiftly turn murky and most likely dangerous. Swimming pool pumps Manage the circulation method, impacting the pool’s cleansing, filtration, and also distribution of heat and chemicals.

A titanium warmth exchanger making sure an extended Operating life. Arctic Spa Warmth Pumps use titanium to face up for the severe environment of the spa or even a pool which might include superior levels of chlorine, bromine, or salt.

Arctic Pool Warmth Pumps are the very best rated heat pumps in North The united states for lower ambient temperatures as tested with the CEC. With DC inverter technological innovation the pool warmth pump is 50% far more efficient that normal single or two-stage AC pool warmth pumps and nearly 60% quieter.

Pump Basket: Collects particles, guarding the pump motor from strain and early burnout. All our pumps include things like removable filter baskets and inspection covers for straightforward upkeep.

The included chilly temperature structure allows the Arctic Pool Heat pump to operate in temperatures under freezing. Now you could prolong you pool season in both of those the spring and the fall! This is very essential for northern regions that have already got a short pool year.

All Arctic Spa & Pool Heat Pumps are both heater in addition to chillers. On computerized manner, the warmth pump will retain the ideal temperature by switching from heating to cooling as necessary. Great for scorching summertime climates where by a refreshing pool is welcomed in pool pumpe the warmth waves.

Den tekniske lagring eller adgang er strengt nødvendig for det legitime varietyål at muliggøre brugen af en specifik tjeneste, som abonnenten eller brugeren udtrykkeligt har anmodet om, eller med det ene typeål at udføre transmissionen af en kommunikation around et elektronisk kommunikationsnetværk. Choices Choices

Regardless how you end up picking to make use of your pool warmth pump technique – another thing is certain. It’s economical layout and incredible listing of features are positive to save you approximately 75% in comparison to common poo heating procedure.

0 notes