#chemicalengine

Explore tagged Tumblr posts

Text

Did you know the Pharma industry hires the most Chemical Engineers? 🌍

Thinking about a career as a Chemical Engineer? 🌍 Here’s where your skills are in high demand!

Top Industries: Pharma, Petrochemicals, Manufacturing, Energy, Food. Countries in Demand: 🇺🇸 USA: 32k+ jobs 🇩🇪 Germany: 15k+ 🇨🇳 China: 50k+ 🇮🇳 India: 25k+ 🇨🇦 Canada: 5k+ 🇦🇪 UAE: 3k+

Explore how to stand out with a standout fresher resume!

2 notes

·

View notes

Text

IHF single stage single suction pump PTFE lined pump centrifugal chemical pump is working for highly corrosive mediums between -85°C~120°C (-121°F~248°F), such as arbitrary concentration of vitriol, muriatic acid, hydrofluoric acid, nitric acid, aqua regia, strong base, strong oxidant, organic solvent, reducing agent, etc.

Pump Model: IHF65-50-160

Flow rate:25m3/h

Head:32

Inlet/outlet diameter:65mm/50mm

Seal: single mechancial seal

Motor power:5.5kw/400v/3Ph/50Hz/2900rpm

Pump destination: Vietnam chemical project

#chemical#chemicalpumps#ptfe#pumps#chemicalindustry#chemicalengineering#chemicalplant#vietnam#jushipump#teflonpump#PTFELINEDPUMP#endsuctionpump#singlestagepump#IHFPUMP#centrifugalpump

If you have any inquiry or question, please feel free to contact me at [email protected] and WhatsApp +86 155 87495056.

#chemical#chemicalpumps#ptfe#pumps#chemicalindustry#chemicalengineering#chemicalplant#vietnam#jushipump#teflonpump#PTFELINEDPUMP#endsuctionpump#singlestagepump#IHFPUMP#centrifugalpump#jushi

4 notes

·

View notes

Text

Synthesis too slow? Let this robot do it

🧬 ..::Science & Tech::.. 🧬 Tiny Tides is an automated fast-flow instrument that can synthesize peptide-nucleic acids in a single shot

0 notes

Link

Changes in career aren't a divergence from a path. The common thread is you, your experience, and how you can apply what you know in a difference space.

Zaneta Mascarenhas is Member of the Australian House of Representatives for Swan. Join us as we speak about Zaneta's journey through engineering and resources, climate action, and politics -- and hear about how community and impact ties all of that together.

About Zaneta Mascarenhas MP

Zaneta Mascarenhas MP is the Federal Member for Swan and sits in the House of Representatives in the Australian Parliament. Zaneta, a chemical engineer, was elected to Parliament in 2022 and serves on the Industry, Science and Resources Standing Committee, the Climate Change, Energy, Environment and Water Standing Committee, and the Joint Statutory Committee on Corporations and Financial Services.

Prior to her election, Zaneta managed the West Australian team for Energetics, Australia’s leading carbon and energy consultancy, where she provided energy efficiency and climate change advice to the resources industry and various WA ASX200 companies, access to the Emissions Reduction Fund, and the development of emissions inventories and audits. She was selected to be trained by Al Gore to deliver Climate Reality Project presentations in 2009 and has also worked for the World Bank’s Water and Sanitation Program in Dhaka, Bangladesh on Community Led Total Sanitation as part of AusAid’s Australian Youth Ambassadors for Development Program. Zaneta has a strong track record in not-for-profit governance, having served six different boards including education institutions and a community legal centre.

As the first engineer elected as the Member for Swan and the 28th in the Parliament of Australia, Zaneta applies her planning and problem-solving skills to developing policy, including the transition to a less carbon intensive economy and developing Australia’s high tech industrial capacity.

Website: https://zanetamascarenhas.com.au/ Facebook: @ZanetaMascarenhasMP Instagram: @ZanetaMascarenhasMP

Watch or listen on your favourite platform.

Show Notes

[00:00:48] Zaneta's childhood experiences and exposure to sciences and the world around her. [00:04:00] How your environment shapes your perceptions of an industry. [00:07:27] The evolution of culture and safety in the workplace in the mining industry. [00:12:04] Observations about organisational culture in an organically culturally diverse industry. [00:14:48] The impetus and shift to climate change. [00:18:16] Working in the climate change space and perspectives of impact and timescales. [00:23:49] Policy and politics. [00:26:33] Working not just for now, but for the future. [00:31:19] Systems thinking and transferrable experience. [00:38:28] What advice would you give someone who'd like to do what you do and what advice should they ignore?

Follow STEAM Powered

YouTube Facebook Instagram Twitter Patreon

0 notes

Text

Enhancing water clarity and quality with flocculants! In water treatment, flocculants are essential for clumping contaminants, making them easier to remove. This vital process improves water safety, reduces turbidity, and supports cleaner water systems for communities.

#WaterTreatment#Flocculant#CleanWater#WaterQuality#WastewaterTreatment#SafeWater#EcoFriendlySolutions#ChemicalEngineering#WaterManagement#SustainableWater

0 notes

Text

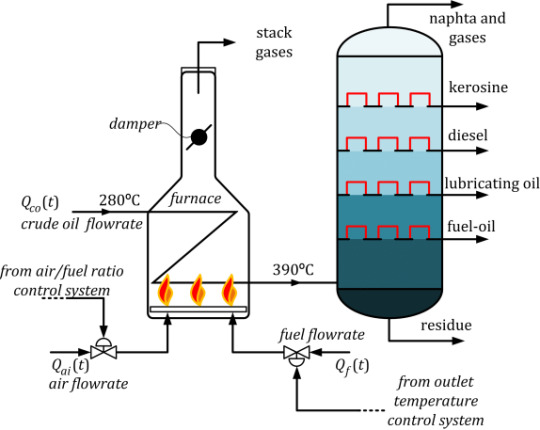

Knowledge Sharing Series#2

What is the Process that undergoes in Oil Preheating Furnace?

Crude Oil Entry: The desalted crude oil, which has already been heated and mixed with water to remove salt, enters the preheating furnace.

Heat Exchange: The furnace is typically designed with a series of tubes through which the crude oil flows. Hot flue gases, generated by burning fuel (such as natural gas or fuel oil), pass over these tubes, transferring heat to the crude oil.

Temperature Increase: As the crude oil flows through the tubes, it absorbs heat from the flue gases, gradually increasing in temperature.

Desired Temperature: The furnace is carefully controlled to ensure that the crude oil reaches the desired temperature, typically around 350°C to 360°C. This temperature is essential for effective vaporization of the lighter components in the crude oil.

Exit to Distillation Column: Once the crude oil has reached the target temperature, it exits the preheating furnace and enters the atmospheric distillation column, where the separation process begins.

#OilAndGas#Refinery#ChemicalEngineering#ProcessEngineering#Petrochemical#DownstreamProcessing#Distillation#UnitOperations#EnergyIndustry#Fuels#FossilFuels#PreheatingFurnace#CrudeOilPreheating#AtmosphericDistillation#DistillationColumn#HydrocarbonSeparation#RefiningProcess#OilAndGasEquipment#ProcessControl#HeatTransfer#Decontamination

0 notes

Text

Inorganic Salts in Chemical Products

🧪 Discover the Magic of Inorganic Salts 🌿

🔍 Dive into the world of inorganic salts used in chemical products! Learn how these compounds play a crucial role in formulations.

Inorganic Salts

#InorganicSalts#ChemicalProducts#Science#Chemistry#Innovation#IndustrialChemicals#ChemicalIndustry#InorganicChemistry#ChemicalScience#SaltsAndChemicals#ChemicalsForIndustry#InorganicCompounds#ChemicalManufacturing#LabChemicals#ChemicalEngineering#InorganicMaterials#ChemistryResearch#ChemicalSolutions

1 note

·

View note

Text

chemical

Chemistry plays a vital role in the discovery and development of new materials, processes, and technologies. From understanding the composition and properties of substances to innovating solutions for sustainable energy, healthcare, and environmental protection, the field of chemistry continuously drives scientific progress. Researchers and professionals in this domain are at the forefront of solving real-world challenges, using their expertise to improve everything from pharmaceuticals to industrial products. Advancements in chemical research contribute to a better quality of life, safety, and efficiency across various industries.

Website : sciencefather.com

Nomination: Nominate Now

Registration: Register Now

Contact Us: [email protected]

#sciencefather#researcher#Professor#Lecturer#Scientist#Scholar#BestTeacherAward#BestPaperAward#Chemistry#ChemicalScience#MaterialScience#ChemicalEngineering#SustainableChemistry#GreenChemistry#EnvironmentalChemistry#OrganicChemistry#InorganicChemistry#Biochemistry#AnalyticalChemistry#PharmaceuticalChemistry#IndustrialChemistry#ChemicalResearch#LabTech#InnovationInChemistry#MolecularScience

0 notes

Text

Chemical Engineering Careers — Opportunities in a Changing World.

Introduction

Chemical Engineering is a dynamic and versatile field that bridges the gap between science and industry. It involves the application of chemistry, physics, biology, and mathematics to solve problems related to the production and use of chemicals, materials, and energy. But What is Chemical Engineering truly about? At its core, it’s about transforming raw materials into valuable products while ensuring safety, sustainability, and efficiency.

For those considering a career in this exciting field, understanding the chemical engineering course structure, chemical engineering subjects, and the opportunities it offers is crucial. Whether you’re aiming for top-tier positions or just exploring the landscape, knowledge of the chemical engineering salary expectations and available chemical engineering jobs can guide your decisions.

India is home to some of the best educational institutions that offer world-class Chemical Engineering programs. If you’re looking to pursue this field, exploring the top chemical engineering colleges in India and identifying the best chemical engineering colleges in India is a crucial step. This blog will guide you through everything you need to know, from the top 10 chemical engineering colleges in India to the career prospects awaiting graduates.

What is Chemical Engineering?

Chemical Engineering is a multifaceted discipline that combines the principles of chemistry, physics, biology, and mathematics to design, develop, and optimize processes for large-scale manufacturing. Whether it’s producing pharmaceuticals, refining petroleum, creating new materials, or developing sustainable energy solutions, Chemical Engineering plays a vital role in transforming raw materials into valuable products that impact everyday life.

Key Chemical Engineering Subjects

A Chemical Engineering course typically covers a broad range of subjects designed to equip students with the necessary skills and knowledge to excel in the field. Core subjects often include:

Thermodynamics: Understanding the principles of energy transfer and the laws governing chemical processes.

Fluid Mechanics: Studying the behavior of fluids and their applications in industrial processes.

Heat Transfer: Exploring methods of heat exchange in various chemical processes.

Mass Transfer: Analyzing the movement of substances within different phases and its importance in separation processes.

Reaction Engineering: Designing and analyzing chemical reactors for optimal performance.

Process Control: Learning how to manage and control industrial processes to ensure safety and efficiency.

Environmental Engineering: Addressing the environmental impact of chemical processes and developing sustainable practices.

These subjects provide a strong foundation for students, enabling them to tackle complex engineering challenges and innovate within the industry.

Career Opportunities in Chemical Engineering

Chemical Engineering offers a wide array of career opportunities across various industries. Graduates can pursue roles such as:

Process Engineer: Designing and optimizing processes for large-scale chemical manufacturing.

Research and Development Engineer: Innovating new products, materials, and technologies.

Environmental Engineer: Developing sustainable practices to minimize the environmental impact of industrial processes.

Quality Control Engineer: Ensuring that products meet required standards and regulations.

Safety Engineer: Managing safety protocols in chemical plants to protect workers and the environment.

These roles are in high demand, with industries such as pharmaceuticals, petrochemicals, food processing, and energy being some of the top employers. The chemical engineering salary can vary depending on the industry, location, and level of experience, but it is generally competitive, with opportunities for growth as professionals gain experience and expertise.

The Chemical Engineering Course: What to Expect?

The chemical engineering course typically spans four years for undergraduate students, with the curriculum designed to balance theoretical knowledge and practical experience. Students engage in laboratory work, internships, and industry projects that provide hands-on learning and real-world problem-solving experience. Advanced courses may delve into specialized areas such as bioprocess engineering, nanotechnology, and renewable energy.

For those interested in further specialization, pursuing postgraduate studies or certifications in niche areas can open doors to more advanced positions and research opportunities.

Why Choose Chemical Engineering?

Chemical Engineering is not just about chemical reactions and manufacturing processes; it’s about innovation and making a positive impact on society. As the world faces challenges such as climate change, resource scarcity, and the need for sustainable practices, Chemical Engineers are at the forefront of developing solutions that can drive progress while protecting the environment.

Studying at one of the top chemical engineering colleges in India offers students the opportunity to learn from experienced faculty, engage in cutting-edge research, and connect with industry leaders. Graduates from these institutions are well-prepared to enter the workforce and contribute to a wide range of industries.

Conclusion

Choosing to pursue a degree in Chemical Engineering can lead to a rewarding and impactful career. Whether you’re drawn by the challenge of solving complex engineering problems or the opportunity to innovate in a rapidly changing world, this field offers diverse and dynamic career paths. By focusing on a comprehensive education that covers essential chemical engineering subjects and provides practical experience, students can prepare themselves for a successful career in this ever-evolving field. Whether you’re just starting your journey or looking to advance your career, understanding the scope and opportunities within Chemical Engineering is the first step toward achieving your professional goals.

1 note

·

View note

Text

Cross Linking Agents Market projected to reach $13.6 billion by 2028

The report "Cross Linking Agents Market by Chemistry (Amino, Amine, Amide, Aziridine, Isocyanate, Carbodiimide), Application (Decorative, Industrial (Transportation Coatings, Industrial, Protective Coatings, Marine Coatings), & Region - Global Forecast to 2028", is projected to reach USD 13.6 billion by 2028, at a CAGR of 6.5% from USD 9.9 billion in 2023.

The Cross Linking Agent market is mainly driven by the factors including the demand for high-performance materials, increasing applications across industries, emphasis on sustainability, and advancements in technology and research.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=266941939

“Amine chemistry segment is projected to grow at third fastest CAGR, in terms of value, during the forecast period.”

Amines offer excellent cross-linking capabilities and compatibility with a wide range of polymers, making them ideal for various applications. Their strong bonding properties and ability to improve mechanical and thermal properties of materials drive their demand. Additionally, the rising focus on sustainability and the development of eco-friendly formulations using amines as cross-linking agents further contributes to the growth of this segment in the market.

“Industrial application segment is expected to lead the Cross Linking Agent market during the forecast period, in terms of value.”

The growth of the Industrial application segment in the cross-linking agents market is attributed to several key factors. Industries such as automotive, construction, electronics, and packaging demand cross-linked materials to enhance product performance and durability. Cross-linking agents provide improved mechanical properties, resistance to chemicals and weathering, and increased lifespan of industrial products. Stringent regulations and standards regarding product quality and reliability in industrial applications further drive the demand for cross-linking agents. Additionally, the growing focus on sustainable and eco-friendly solutions in the industrial sector fuels the adoption of cross-linking agents that offer reduced environmental impact. These factors collectively contribute to the rapid growth of the Industrial application segment in the cross-linking agents market.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=266941939

“Asia Pacific is expected to be the fastest growing market for Cross Linking Agents during the forecast period, in terms of value.”

The region's robust industrial and manufacturing sectors, particularly in countries like China, India, and Japan, drive the demand for cross-linking agents across various industries such as automotive, construction, electronics, and packaging. Moreover, rapid urbanization, infrastructure development, and increasing disposable incomes in the region contribute to the rising demand for high-performance materials that utilize cross-linking agents. Additionally, favorable government initiatives, investments in research and development, and a shift towards eco-friendly and sustainable solutions further stimulate the market's growth in the Asia Pacific region, solidifying its position as the largest and fastest-growing market for cross-linking agents.

New product launches, acquisitions, investments, and expansions are the major growth strategies adopted by the key players in the market. The key global players in the Cross Linking Agents market include BASF SE (Germany), Covestro AG (Germany), Allnex Group (Germany), Evonik Industries (Germany), Hunstman Corporation (US), Aditya Birla Corporation (India), Wanhua Chemicals Group Co. Ltd (China), The Dow Chemical Company (US), DSM Coatings Resins (China), and Ineos (UK).

#CrossLinkingAgents#ChemicalIndustry#PolymerScience#MaterialScience#IndustrialChemicals#AdhesiveTechnology#CoatingIndustry#Manufacturing#MarketTrends#InnovativeMaterials#ChemicalEngineering#ResinTechnology#AdvancedMaterials#ChemicalMarket#PolymerChemistry

0 notes

Text

#ThermosetResin#ResinMarket#CompositeMaterials#IndustrialResins#PolymerScience#AdvancedMaterials#ChemicalEngineering

0 notes

Text

Cellulose Derivatives Market: Detailed Insights into Size, Share, and Growth Dynamics

The global cellulose derivatives market size is expected to reach USD 10.7 billion by 2030, registering a CAGR of 6.8% from 2023 to 2030, as per the new report by Grand View Research, Inc. The market is experiencing significant growth, driven by the increasing demand from the food and beverage industry. Cellulose derivatives are used as thickeners, stabilizers, and emulsifiers in a variety of food products, such as ice creams, yogurts, sauces, and dressings.

Cellulose Derivatives Market Report Highlights

Carboxymethyl cellulose is the fastest-growing type segment with a CAGR of 9.3 % on account of its use as a viscosifier and suspension agent to control the rheological properties of the drilling fluid

The industrial grade segment is expected to expand with a CAGR of 6.6% since it is used as raw materials in various applications such as textiles, cellulose acetate, cellulose nitrate manufacturing, papermaking, and the production of adhesives, sealants, and gels

The demand for biodegradable products is driving market growth since they are used as a key raw material in the production of biodegradable products such as biodegradable plastics, food packaging, and other disposable items

The companies are investing in R&D activities to develop new and innovative products with improved functionality and performance. CP Kelco, one of the key manufacturers, is focusing on expanding its production capacity in Asia Pacific region to meet growing demand for the cellulose derivatives

For More Details or Sample Copy please visit link @: Cellulose Derivatives Market Report

The penetration of cellulose derivatives in the global market varies based on the specific derivative and its end-use industry. Some of the products, such as cellulose acetate and ethyl cellulose, are widely used in industries such as textiles, pharmaceuticals, and food & beverage packaging, while others have more niche applications. Overall, the global market for cellulose derivatives is growing, driven by the increasing demand for environmentally friendly and sustainable materials, as well as advancements in production processes that have expanded the range of applications for these materials.

Asia Pacific is expected to witness significant growth in the product market during the coming years. This growth can be attributed to several factors such as increasing demand for the product in the food and beverage industry and the growing pharmaceutical industry, in addition to the expanding personal care industry in the region. For instance, in 2020, the Indian government announced plans to invest in the pharmaceutical sector to reduce the country's dependence on imports. This is expected to drive demand for the product as pharmaceutical excipients, binders, and disintegrants in the country.

The future of cellulose derivatives in the global market is anticipated to be positive, driven by increasing demand for the sustainable and environmentally friendly materials. The trend toward more sustainable consumption patterns and the growing awareness of the environmental impact of various materials are expected to continue to drive demand for the product. In addition, advancements in production processes and new applications for these materials are expected to further expand their market growth.

#CelluloseDerivatives#ChemicalIndustry#SustainableMaterials#IndustrialChemicals#BiodegradableMaterials#EcoFriendlyProducts#ChemicalMarket#CelluloseProducts#RenewableResources#BioBasedProducts#CelluloseMarket#ChemicalEngineering

0 notes

Text

Delving into 2-Phenoxyethanol: A Dynamic Ingredient in Contemporary Formulas

Welcome to BRM Chemicals, your trusted source for high-quality raw materials across various categories, including chemicals, herbal extracts, essential oils, colorants, butters & waxes, soap bases, fragrances, and clay powders. Today, we delve into the world of 2-phenoxyethanol, a widely used ingredient in multiple industries. This blog will explore its benefits, applications, and why it is an essential component in many chemical formulations. We’ll also discuss how BRM Chemicals can assist you with reliable chemical sourcing and distribution.

2-Phenoxyethanol is an organic compound that serves as a versatile preservative and solvent. It is a colorless, oily liquid with a faint rose-like scent, making it an ideal additive in many formulations. This ingredient is known for its efficacy in preventing the growth of bacteria, yeast, and mold, ensuring the longevity and safety of various products.

The Benefits of 2-Phenoxyethanol

Effective Preservative: 2-phenoxyethanol is highly effective in inhibiting microbial growth, making it a reliable preservative for personal care and cosmetic products.

Solubility: It is soluble in water and many organic solvents, enhancing its versatility in different formulations.

Mildness: Unlike some preservatives, 2-phenoxyethanol is gentle on the skin, reducing the risk of irritation.

Stability: It remains stable over a wide range of pH levels and temperatures, ensuring consistent performance in various products.

Broad-Spectrum Efficacy: It provides protection against a wide array of microorganisms, ensuring comprehensive preservation.

Applications of 2-Phenoxyethanol

Cosmetics: Widely used in creams, lotions, and makeup to extend shelf life and ensure product safety.

Personal Care Products: Found in shampoos, conditioners, and body washes to prevent contamination and spoilage.

Pharmaceuticals: Used as a preservative in vaccines and other injectable medications.

Industrial Applications: Employed in paints, coatings, and adhesives for its solvent properties.

Home Care: Incorporated into cleaning products to enhance preservation and efficacy.

The Role of 2-Phenoxyethanol in Chemical Formulations

2-Phenoxyethanol plays a critical role in chemical formulations, particularly in the cosmetics and personal care industries. Its ability to act as a preservative and solvent makes it invaluable for ensuring product stability and safety. Here’s how it fits into various formulations:

Preservative: It prevents the growth of harmful microorganisms, ensuring products remain safe for use over time.

Solvent: It helps dissolve other ingredients, ensuring a uniform mixture and enhancing the product’s performance.

Stabilizer: It maintains the integrity of formulations, preventing separation and degradation of active ingredients.

Sourcing Quality 2-Phenoxyethanol from BRM Chemicals

At BRM Chemicals, we understand the importance of quality and reliability in chemical sourcing. Our 2-phenoxyethanol is sourced from trusted suppliers and undergoes rigorous quality control to ensure it meets industry standards. With our extensive network, we provide efficient chemical distribution, ensuring you receive your products on time and in optimal condition. Whether you are formulating cosmetics, personal care products, or industrial applications, our high-quality 2-phenoxyethanol will meet your needs.

The Importance of Specialty Chemicals in Modern Industries

Specialty chemicals, such as 2-phenoxyethanol, are crucial for innovation and performance across various industries. They offer specific properties that enhance the functionality and stability of products, enabling manufacturers to meet stringent quality and safety standards. At BRM Chemicals, we are dedicated to providing a comprehensive range of specialty chemicals to support your formulations and drive your business forward. Our commitment to quality and reliability ensures you can trust us for all your chemical needs.

2-Phenoxyethanol is a vital ingredient in many formulations, offering preservative, solvent, and stabilizing properties that enhance product safety and performance. At BRM Chemicals, we are committed to providing high-quality 2-phenoxyethanol and other specialty chemicals to support your innovative formulations. Explore our website BRM Chemicals to learn more about our products and services. Contact us today to discover how we can assist you with reliable chemical sourcing and distribution. Elevate your formulations with premium ingredients from BRM Chemicals and ensure the success and safety of your products.

0 notes

Text

Reactors, Storage vessels, adsorptions systems, drum flakers, evaporators, dryers, distillation columns, heat exchangers, crystallization equipments.

Plot No. B-35, BHEL-AIE, Ramachandrapuram, Hyderabad

0 notes

Text

Major Equipment in Atmospheric Distillation Unit (ADU)

The Atmospheric Distillation Unit (ADU) is the primary processing unit in most oil refineries.

It separates crude oil into various fractions based on their boiling points. The following are the key pieces of equipment found in an ADU:

1. Crude Oil Preheat Furnace:

Purpose: Heats the crude oil to a temperature close to its boiling point before it enters the distillation column.

Type: Typically, a fired heater that uses fuel gas or oil to generate heat.

2. Atmospheric Distillation Column:

Purpose: Separates the heated crude oil into different fractions based on their boiling points.

Components:

Tray or Packing: Used to provide contact between the vapor and liquid phases.

Reboilers: Heat the bottoms product to generate vapor.

Condenser: Cools the vapor to condense it into liquid.

3. Fractionators:

Purpose: Further refine certain fractions (e.g., naphtha, kerosene) to meet specific product specifications.

4. Strippers:

Purpose: Remove lighter components from heavier fractions to improve product quality.

5. Heat Exchangers:

Purpose: Recover heat from the process to reduce energy consumption.

Types: Shell-and-tube, plate-and-frame, etc.

6. Pumps:

Purpose: Transfer fluids between different equipment.

7. Piping:

Purpose: Connects the various equipment in the unit.

8. Instrumentation and Controls:

Purpose: Monitor and control the process variables (temperature, pressure, flow rate, etc.).

#oilrefining #petroleum #ADU #crudeoil #fractionation #petroleumengineering #energy #fuels #petrochemicals #chemicalengineering #processengineering #Quora #Question #Answer #Discussion #KnowledgeSharing #Learn #Explore #OilRefining #Petroleum #ADU #Distillation #Engineering #ProcessEngineering #ChemicalEngineering #Energy #Fuel #Petrochemicals #Share #Follow #Like #Comment

#atmosphericdistillationunit#ADU#distillationunit#chemicalengineering#petroleumindustry#refiningprocess#industrialengineering#engineering#science#technology#fractionatingcolumn#reboiler#condenser#overheadcondenser#refluxdrum#pumparound#feedtray#strippingsection#enrichingsection#chemicalplant#oilrefinery#petroleumproducts#processcontrol#automation#engineeringstudent#engineeringlife#education#ADUcomponents#ADUprocess#majorpartsofADU

1 note

·

View note

Text

🌟 Dive deep into Chemical Engineering excellence with TuteeHub's Question Bank! 🚀🔍 Whether you're a student preparing for exams or a professional seeking to deepen your knowledge, our comprehensive guide is your key to success🌟📚. Master the concepts, ace your exams, and unlock the wisdom of Chemical Engineering with insights that flourish. 💡🌐 Chemical Engineering enthusiasts, your academic companion awaits exploration - https://bit.ly/440Xspa

#ChemicalEngineering#TuteeHubQuestionBank#AcademicExcellence#ChemicalEngineeringWisdom#MasterTheConcepts#UnlockSuccess#TuteeHUB

0 notes