#AdhesiveTechnology

Explore tagged Tumblr posts

Text

Pressure Sensitive Adhesives Market-Industry Forecast, 2024–2030.

Pressure Sensitive Adhesives Market Overview

Request Sample:

The increasing usage of resins such as silicone polymers, polyisobutene, and elastomers, generally synthetic rubber as the base polymer owing to its functionality and durability, in various end-use sectors will also substantially drive the demand for PSAs. Nitrocellulose adhesive, hydrogenated hydrocarbon resins, and ethylene-vinyl acetate are the thermoplastic resins generally employed in pressure-sensitive adhesives. Moreover, the increasing usage of bio-based pressure-sensitive adhesives and advancements in pressure-sensitive adhesive tapes is expected to offer enormous market expansion opportunities and boost the pressure-sensitive adhesives (PSA) industry in the projected time frame.

Impact of Covid-19

The COVID-19 pandemic and its disruption to several manufacturing activities declined the growth of the pressure sensitive adhesives market in the year 2020. Due to the supply chain disruption and insufficient labor, the manufacturing activities of the packaging, automotive, and electrical and electronic industries were set at a pause which affected the market growth. Furthermore, considering the new government norms and reopening of several industries, it is presumed that the market for pressure sensitive adhesives will return to normal conditions.

Inquiry before Buying :

Report Coverage

The: “Pressure Sensitive Adhesives Market Report — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the pressure sensitive adhesives Market.

By Formulation: Water-based, Solvent-based, Hot Melt, Others

By Resin Type: Elastomer (Natural and Synthetic), Acrylic, Silicone, Ethylene-Vinyl Acetate, Polyvinyl Ether, Polyisobutene, Polybutadiene, and Others

By Application: Tapes, Labels, Graphics, and Others

By End Use Industry: Construction, Automotive, Electronics, Medical and Healthcare, Paper, Furniture, Renewable Energy, Wood Working, and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia and New Zealand, Taiwan, Indonesia, Malaysia, and Rest of Asia Pacific),South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Schedule A Call :

Key Takeaways

Asia-pacific region dominated the pressure sensitive adhesives Market due to the rising government investments in the healthcare, electronics, and construction and infrastructure segments in countries such as China, India, South Korea, and Australia.

Current product innovations to improve modulus of elasticity and rigidity are expected to broaden the application range of pressure sensitive adhesives in structural applications and drive the growth of the market in the projected period.

Rising demand for silicone polymers based pressure sensitive adhesive (PSA) in the electronic and medical industry will further drive the growth of the pressure sensitive adhesives market.

Low adhesive strength provided by the pressure-sensitive adhesives (PSA) would further affect the growth of the market over the forecast period.

For More Details on This Report — Request for Sample

Pressure Sensitive Adhesives Market Segment Analysis- By Resin Type

Acrylic resin held the largest share in the pressure sensitive adhesives market in 2020. Acrylic PSAs are widely employed in a variety of applications due to the saturated nature of the polymer and its subsequent oxidation resistance. Also, the acrylic PSAs have good physical properties in general for a wide range of long-term exterior applications. Owing to its attractive properties such as non-flammable, easy to handle, low level of contamination, little tendency to migrate, good resistance to sunlight, oxygen and heat, and offer adhesion, cohesion and tack, the demand for acrylic resins is anticipated to rise. With the increasing demand for acrylic resin, the market for pressure sensitive adhesives will also increase, which will further drive the market growth in the forecast period.

Pressure Sensitive Adhesives Market Segment Analysis- By Application

Tapes held the largest share in the pressure sensitive adhesives market in 2020. Rising demand for tapes owing to its low cost and ease of use when compared to traditional methods is estimated to uplift the growth of the market. Due to the advantageous properties of pressure sensitive adhesives tapes such as reduced assembly time, vibration dampening and noise reduction eliminates the need for surface refinishing, and others has raised the demand for these tapes in various end use industries. Moreover, pressure sensitive adhesive tapes do not require the use of a water, solvent, or heat to activate. The amount of pressure used to apply the adhesive to the surface has a direct impact on the bond. Rising demand for polypropylene tapes owing to its flexibility and strength, and good low temperature characteristics will further drive the market growth. Thus, rising demand and production for pressure sensitive adhesives tapes is estimated to drive the pressure sensitive adhesives market growth over the forecast period.

Pressure Sensitive Adhesives Market Segment Analysis- By End Use Industry

The packaging sector held the largest share in the pressure sensitive adhesives market in 2020 and is projected to grow at a CAGR of 6% during the forecast period 2021–2026. There are two types of packaging namely flexible and rigid, pressure sensitive adhesives (PSAs) are used in these packaging depending on the application’s suitability. These adhesives are used in the packaging of electronics and electrical devices, hygiene and medical packaging, drug delivery packaging, construction sector transit packaging, automotive-related logistics packaging, and consumer and industrial goods packaging, among others. Furthermore, the increasing use of packaging tapes such as polypropylene tapes in a variety of applications including packaging transport, cartons, goods, warehousing, and logistics is estimated to uplift the market growth. PSAs are used in packaging sectors to improve consumer appeal through graphics. Therefore, the pressure sensitive adhesives market is estimated to see an upsurge over the forecast period with the growing packaging industry.

Pressure Sensitive Adhesives Market Segment Analysis– By Geography

The Asia Pacific region held the largest share of more than 39% in the pressure sensitive adhesives market in 2020. Globally, the region’s growth in the market is mainly due to strong economic growth and heavy investments in the packaging, construction, automotive, and electronic industries. Also, the rising adoption of various resins such as polyisobutene, silicone polymers, and elastomers in emerging economies has uplifted the market growth. APAC is increasing in importance as a worldwide trade and business hub. The market for pressure sensitive adhesives is expected to rise as government investments in many medical and electronic projects increase in countries such as China, India, Japan, and South Korea. The Union Cabinet authorized the production-linked incentive (PLI) plan in ten critical industries (including electronics and white products) on November 11, 2020, in order to strengthen India’s manufacturing capabilities, increase exports, and promote the “Atmanirbhar Bharat” program as per the India Brand Equity Foundation. Thus, such initiatives taken by the government for new projects will raise the demand for pressure sensitive adhesives market in the forecast period.

Pressure Sensitive Adhesives Market Drivers

Increasing Demand for Bio-based Pressure Sensitive Adhesives

Plant-derived resources are used as a raw material in bio-based PSAs. The biomass content of a bio-based material used in an adhesive product is expressed as a percentage (dry weight basis). Also, the bio-based PSAs are considered “carbon neutral” because their plant-derived raw materials absorb the same amount of CO2 during production as they emit when incinerated at the end of product life. Additionally, there is no overall increase in greenhouse gases that can cause global warming, resulting in significantly lower CO2 emissions when compared to traditional, purely petroleum-based formulations. Furthermore, most of the raw materials used for conventional PSAs are derived from fossil fuels, which are limited in supply. Bio-based PSAs can help reduce the demand for petroleum sources by replacing them with renewable plant-based materials. Thus, due to the above mentioned factors the demand for bio-based PSAs is predicted to rise, which would further drive the growth of the pressure sensitive adhesives in the projected period.

Rising Demand from the Electronics Industry will Lead Towards the Growth of the Market

For shock absorption, thermal and electrical conductivity, electromagnetic shielding, and optical characteristics, among other factors, pressure-sensitive adhesives (PSA) are increasingly being utilized in the electronics industry. Because of its high transparency, weather resilience, heat resistance, and adhesion strength, acrylic and synthetic rubber PSA composed of hydrogenated hydrocarbon resin is widely used in the display, mobile phones, and automotive applications. PSA also provides higher processability than liquid-type adhesives since it can stick to three-dimensional substrates without the need for a hardening process. With the development of new innovative products the market for pressure sensitive adhesives is estimated to rise. For instance, in 2020 DELO has developed adhesives that has similar properties to (double-sided) adhesive tapes but is applied in liquid form and that can be extensively used in the electronic applications such as smartphone speakers or display frames. Growing demand of pressure sensitive adhesives in the electronics industry is therefore expected to drive market growth during the forecast era.

Buy Now :

Pressure Sensitive Adhesives Market Challenges

Low Adhesive Strength will Hamper the Market Growth

The main challenges faced by the pressure sensitive adhesives (PSAs) are that the adhesive strength (shear and peel) is low and that it is generally sensitive to high temperatures and solvents. As a result, most pressure sensitive adhesives are unsuitable for high strength or structural applications. They are frequently used with substrates that are relatively weak, such as paper or film. Pressure sensitive adhesives are also unsuitable for rough surfaces and are relatively costly in terms of cost per bond area. Thus, due to the above mentioned properties the market growth for pressure sensitive adhesives (PSAs) is estimated to face challenges in the upcoming years.

Pressure Sensitive Adhesives Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the pressure sensitive adhesives market. Major players in the pressure sensitive adhesives market are Henkel AG & Company KGAA, Arkema Group, The Dow Chemical Company, H.B. Fuller, Avery Dennison Corporation, Sika AG, 3M Company, Scapa Group, and Ashland Inc., among others.

Acquisitions/Technology Launches

In May 2021, with the planned acquisition of Edge Adhesives Texas, a complementary asset in pressure sensitive adhesives and hot-melt adhesive tapes for residential construction, Arkema Group increased its Bostik offering of high performance adhesives in the United States.

Key Market Players:

The Top 5 companies in the Pressure Sensitive Adhesives Market are:

Henkel AG & Co., KGaA.

Arkema Group

Dow Chemical Company

H.B. Fuller

Sika AG

For more Chemicals and Materials Market reports — Please click here

0 notes

Text

Pressure Sensitive Adhesives Market size is forecast to reach US$ 9.5 billion by 2026, after growing at a CAGR of 6.5% during 2021-2026.

🔗 𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕 @ https://www.industryarc.com/Report/11719/pressure-sensitive-adhesives-market.html?utm_source=TumblrPost&utm_medium=social&utm_campaign=vikassagar

#PressureSensitiveAdhesives#AdhesiveTechnology#PSA#AdhesiveSolutions#IndustrialAdhesives#AdhesiveApplications

0 notes

Text

Cross Linking Agents Market projected to reach $13.6 billion by 2028

The report "Cross Linking Agents Market by Chemistry (Amino, Amine, Amide, Aziridine, Isocyanate, Carbodiimide), Application (Decorative, Industrial (Transportation Coatings, Industrial, Protective Coatings, Marine Coatings), & Region - Global Forecast to 2028", is projected to reach USD 13.6 billion by 2028, at a CAGR of 6.5% from USD 9.9 billion in 2023.

The Cross Linking Agent market is mainly driven by the factors including the demand for high-performance materials, increasing applications across industries, emphasis on sustainability, and advancements in technology and research.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=266941939

“Amine chemistry segment is projected to grow at third fastest CAGR, in terms of value, during the forecast period.”

Amines offer excellent cross-linking capabilities and compatibility with a wide range of polymers, making them ideal for various applications. Their strong bonding properties and ability to improve mechanical and thermal properties of materials drive their demand. Additionally, the rising focus on sustainability and the development of eco-friendly formulations using amines as cross-linking agents further contributes to the growth of this segment in the market.

“Industrial application segment is expected to lead the Cross Linking Agent market during the forecast period, in terms of value.”

The growth of the Industrial application segment in the cross-linking agents market is attributed to several key factors. Industries such as automotive, construction, electronics, and packaging demand cross-linked materials to enhance product performance and durability. Cross-linking agents provide improved mechanical properties, resistance to chemicals and weathering, and increased lifespan of industrial products. Stringent regulations and standards regarding product quality and reliability in industrial applications further drive the demand for cross-linking agents. Additionally, the growing focus on sustainable and eco-friendly solutions in the industrial sector fuels the adoption of cross-linking agents that offer reduced environmental impact. These factors collectively contribute to the rapid growth of the Industrial application segment in the cross-linking agents market.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=266941939

“Asia Pacific is expected to be the fastest growing market for Cross Linking Agents during the forecast period, in terms of value.”

The region's robust industrial and manufacturing sectors, particularly in countries like China, India, and Japan, drive the demand for cross-linking agents across various industries such as automotive, construction, electronics, and packaging. Moreover, rapid urbanization, infrastructure development, and increasing disposable incomes in the region contribute to the rising demand for high-performance materials that utilize cross-linking agents. Additionally, favorable government initiatives, investments in research and development, and a shift towards eco-friendly and sustainable solutions further stimulate the market's growth in the Asia Pacific region, solidifying its position as the largest and fastest-growing market for cross-linking agents.

New product launches, acquisitions, investments, and expansions are the major growth strategies adopted by the key players in the market. The key global players in the Cross Linking Agents market include BASF SE (Germany), Covestro AG (Germany), Allnex Group (Germany), Evonik Industries (Germany), Hunstman Corporation (US), Aditya Birla Corporation (India), Wanhua Chemicals Group Co. Ltd (China), The Dow Chemical Company (US), DSM Coatings Resins (China), and Ineos (UK).

#CrossLinkingAgents#ChemicalIndustry#PolymerScience#MaterialScience#IndustrialChemicals#AdhesiveTechnology#CoatingIndustry#Manufacturing#MarketTrends#InnovativeMaterials#ChemicalEngineering#ResinTechnology#AdvancedMaterials#ChemicalMarket#PolymerChemistry

0 notes

Text

Understanding the Importance of Industrial Adhesives in Modern Manufacturing

Adhesives, also known as glues or cements, are polymeric materials used for bonding surfaces together. They are commonly found in construction materials, woodworking, packaging and labeling, bookbinding, and more. Adhesives can be either natural or synthetic, though synthetic adhesives are much more commonly used in industrial settings due to their superior bonding strength and versatility. Some key facts about industrial adhesives:

Types of Industrial Adhesives

There are several main types of adhesives used in manufacturing:

- Pressure-Sensitive Adhesives: These include tapes, labels and stickers that bond when pressure is applied. They require no heat, water or other agents to activate the bond. Common examples include packaging tape and post-it notes.

- Reactive Adhesives: Also known as reactive or chemical curing adhesives, these bond by undergoing a chemical reaction when mixed. Popular reactive adhesives include epoxies, acrylates and urethanes. They typically provide very strong, durable bonds.

- Hot Melt Adhesives: As the name suggests, these are applied in a melted or liquid form then cool and harden to form strong bonds. They are used extensively in packaging, woodworking and construction.

- Water-Based Adhesives: These contain water as the main solvent and include products like white glues, laminating adhesives and carpet adhesives. They are sometimes called "washable" or "cleanable."

- Solvent-Based Adhesives: Using organic solvents like acetone or toluene, these adhesives are generally more durable than water-based types but can also be more toxic. Examples include contact adhesives and gummed paper adhesive.

Properties and Performance of Industrial Adhesives

Beyond just bonding materials together, high-performance Industrial Adhesives provide key attributes like:

- Strength - The adhesive bond's ability to withstand stresses like tension, compression and shear forces. Most demanding applications require very high bond strength.

- Durability - How well the bond withstands environmental conditions like humidity, temperature cycling, chemical exposure, and usage over time. Outdoor or high-stress bonds demand maximum durability.

- Temperature Resistance - The ability of the bonded joint to withstand both high and low temperatures without bond failure. Applications like automotive and aerospace have very wide temperature requirements.

- Surface Compatibility - The adhesive's ability to properly wet-out, or make good contact with, the specific surfaces being bonded together. Achieving full coverage is important for strength.

- Cure Speed - How quickly the adhesive solidifies after application and gains strength. Manufacturing processes usually require rapid cure rates.

- Gap Filling - Some adhesives are designed to bridge gaps and fill void spaces between non-flush bonding surfaces for structural reinforcement.

- Sealing Ability - Certain adhesives provide sealing protection by filling microscopic surface irregularities that could allow corrosion-causing moisture to penetrate.

Common Industrial Applications

Given their diversity of properties, there is hardly a manufacturing sector that doesn't rely on industrial adhesives in some capacity:

- Construction: Adhesives are indispensable for assembling everything from furniture to engineered wood products like OSB, LVL and plywood. They are also used in flooring, tiles, drywall and siding installation.

- Packaging: Self-adhesive tapes and labels, carton sealing, case sealing and interlamination bonding are all adhesive-dependent processes in packaging operations.

- Automotive: Assembling vehicle interiors, bodies and other components requires sophisticated adhesives engineered for vibration, temperature extremes and crash protection.

- Electronics: Adhesives allow extremely small, lightweight electronic devices to be rapidly assembled while sealing out moisture and vibration. Applications include circuit boards, displays and assemblies.

- Footwear: shoe construction heavily leverages contact adhesives, hot melts, and reactive structural adhesives for heel/sole attachment, seam bonding and decorating.

- Woodworking: Almost every wooden product relies on carpenter’s wood glues, panel bonding adhesives, veneers and other adhesives for structural integrity during assembly and finishing.

Quality Control and Testing

With dimensional consistency, bonding reliability and durability being so important in manufacturing, adhesives are carefully evaluated. Key quality tests performed by manufacturers include:

- Lap Shear Testing - Measuring bond strength when stress is applied parallel to bonded area.

- T-Peel Testing - Bond strength under a peeling stress perpendicular to the bonded area.

- Failure Mode Analysis - Identifying if failure occurred cohesively or adhesively under stress testing conditions.

- Temperature/Chemical Resistance Testing - Ensuring adhesive integrity under specific environmental conditions.

- Surface Energy Measurement - Quantifying surface “wettability” to optimize substrate preparation.

Proper industrial adhesives selection, formulation validation and production quality control helps ensure products are engineered to exacting standards for worldwide industrial and consumer applications.

Get more insights on Industrial Adhesives

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#IndustrialAdhesives#PackagingIndustry#ConstructionIndustry#AutomotiveIndustry#Electrical&Electronics#AdhesiveTechnology#BondingMaterials

0 notes

Text

0 notes

Text

#FoamAdhesives#MattressManufacturing#AdhesiveTechnology#MattressQuality#EcoFriendlyAdhesives#SleepBetter#MattressSupport#InnovativeAdhesives#FoamTechnology#ComfortableSleep

0 notes

Text

Learn more about tapes at : https://www.pioneertapes.com/the-power-of-precision-with.../

#MaskingTape#PrecisionTools#FlawlessResults#DIY#IndustrialApplications#Perfection#ProfessionalTools#maskingtapeart#adhesivetape#AdhesiveTechnology#adhesivesolutions#maskingtapedesign#IndustrialTape#industrialuse#safeguarding#PackingPerfection#PackagingInnovation#PioneerTapes

0 notes

Text

0 notes

Text

The report "Bioadhesives Market by Type (Plant based and Animal based), by Application (Paper& Packaging, Construction, Woodworking, Personal Care, Medical), Region (APAC, North America, Europe, Middle East & Africa, South America) - Global Forecast to 2025" The global bioadhesive market size is projected to grow from USD 6.0 billion in 2020 to USD 9.7 billion by 2025, at a CAGR of 10.0%, during the forecast period.

Bioadhesives Market worth $9.7 billion by 2025

#Bioadhesives#EcoFriendlyAdhesives#GreenChemistry#SustainableMaterials#BiodegradableAdhesives#Innovation#MarketTrends#AdhesiveTechnology#Biotechnology

0 notes

Text

7 Common Mistakes While Using Tile Adhesive

Here are some common mistakes to avoid while using tile adhesive:

Not mixing the adhesive properly: It's important to mix the adhesive according to the manufacturer's instructions. Failure to mix it thoroughly can lead to weak spots in the adhesive and tiles not adhering properly.

Using too much or too little adhesive: Using too much adhesive can cause the tiles to shift or slide, while using too little adhesive can result in tiles not adhering properly. Always use the recommended amount of adhesive for the size and type of tiles you are using.

Applying adhesive unevenly: It's essential to apply the adhesive evenly across the surface, ensuring that it covers the entire area where the tile will be placed. Otherwise, the tile may not adhere properly or may become unlevel.

Not allowing enough time for the adhesive to dry: Before laying the tiles, it's important to allow the adhesive to dry properly. Failure to do so can cause the tiles to shift, leading to uneven or crooked tile work.

Applying adhesive to a dirty or uneven surface: The surface where the tiles will be placed should be clean and even to ensure proper adhesion. If the surface is dirty or uneven, the tiles may not adhere properly, resulting in gaps or loose tiles.

Using the wrong type of adhesive: Different types of tile require different types of adhesive. Using the wrong adhesive can result in tiles not adhering properly or cracking over time. Always check the manufacturer's instructions for the recommended adhesive for the type of tile you are using.

Failing to remove excess adhesive: After laying the tiles, it's important to remove any excess adhesive from the surface and grout lines. Failure to do so can result in an uneven or unsightly finish.

#Tileadhesivecompany#Tileadhesivecompanyinindia#TileAdhesive#TileBonding#TileInstallation#TileRenovation#StrongBond#TilingSolutions#AdhesiveTechnology#HomeImprovement#DIYProjects#ProfessionalTiling#FlooringInstallation#TileFixing

1 note

·

View note

Text

"Hygiene Adhesives Market Expected to Rise from $3.9 Billion in 2024 to $7.2 Billion by 2034, at a 6.2% CAGR"

Hygiene Adhesives Industry encompasses the production and distribution of adhesive products specifically designed for hygiene applications, including diapers, feminine care products, and adult incontinence solutions. This sector is driven by innovations in adhesive technologies that ensure efficiency, comfort, and reliability. Key trends include the growing demand for eco-friendly adhesives, advancements in bonding techniques, and the expansion of the personal care market globally, which collectively underscore significant growth opportunities within the industry.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10630 &utm_source=SnehaPatil&utm_medium=Article

The Hygiene Adhesives Industry is experiencing robust growth, propelled by rising demand for personal care products and innovations in adhesive technologies. The baby diapers segment leads the market, driven by increasing birth rates and improved living standards globally. Feminine hygiene products emerge as the second-highest performing sub-segment, reflecting heightened awareness and acceptance of modern hygiene solutions. Geographically, Asia-Pacific dominates the market, benefiting from a large population base and rapid urbanization. North America follows closely, with significant contributions from the United States, where consumer awareness and technological advancements drive demand. Within Europe, Germany stands out due to its strong manufacturing base and focus on sustainable product development. These regions benefit from strategic collaborations and investments in research and development, which enhance product efficacy and environmental compliance. The industry’s growth is further supported by evolving consumer preferences towards eco-friendly and skin-sensitive products, creating lucrative opportunities for market players.

Market Segmentation

Type: Hot Melt Adhesives, Water-Based Adhesives, Solvent-Based Adhesives, Pressure Sensitive Adhesives, Reactive Adhesives

Product: Baby Diapers, Adult Incontinence Products, Feminine Hygiene Products, Medical Adhesives

Application: Disposable Hygiene Products, Medical and Surgical, Packaging

Technology: Nonwoven Technology, Spray Technology, Slot Die Technology

Material Type: Polyurethane, Polypropylene, Ethylene Vinyl Acetate, Styrenic Block Copolymers

End User: Healthcare, Personal Care, Household, Industrial

Form: Liquid, Solid

Component: Base Resin, Additives

Functionality: Bonding, Sealing, Coating

Process: Extrusion, Lamination

In 2023, the Hygiene Adhesives Industry reported a market volume of 1.2 billion metric tons, with projections indicating a rise to 1.8 billion metric tons by 2033. The personal care adhesives segment commands the largest market share at 45%, followed by medical adhesives at 30%, and industrial adhesives at 25%. Growth in personal care adhesives is driven by increasing demand for hygiene products in emerging markets. Key players such as Henkel AG, 3M Company, and H.B. Fuller Company dominate the market, leveraging advancements in adhesive technology and sustainable product offerings.

Competitive dynamics are shaped by these industry leaders through strategic mergers and acquisitions, enhancing their global footprint and product portfolios. Regulatory frameworks, particularly in the EU and North America, emphasize eco-friendly and non-toxic adhesive formulations, influencing market trajectories. Future projections highlight a 10% annual increase in R&D investments, focusing on biodegradable and high-performance adhesives. The industry outlook remains robust, with technological innovations and rising consumer awareness fostering growth. Challenges include compliance with stringent regulations and the need for continuous innovation to maintain competitive advantage.

#HygieneAdhesives #PersonalCareProducts #EcoFriendlyAdhesives #AdhesiveTechnology #BabyDiapers #FeminineHygiene #SustainableProducts #NonwovenTechnology #GlobalMarketTrends #HealthcareAdhesives #InnovationInAdhesives #ConsumerAwareness #RisingDemand #EmergingMarkets #TechnologicalAdvancements

0 notes

Text

Just published my latest article diving deep into the world of HPMC adhesives! Whether you're a pro in the field or just starting out, I'd love to hear your thoughts and engage in some insightful discussions. Let's connect and explore the intricacies of HPMC together! 🔬🧠 #HPMCAdhesive #MaterialsScience #AdhesiveTechnology

0 notes

Text

"MS Polymers Market Insights: Key Developments and Growth Opportunities 2024-2033"

MS Polymers are transforming the adhesive and sealant landscape with their exceptional versatility and robust performance. These hybrid materials combine the best properties of silicone and polyurethane, offering superior adhesion, weather resistance, and flexibility. Ideal for everything from construction and automotive applications to DIY projects, MS Polymers provide a strong, long-lasting bond while maintaining excellent durability in harsh conditions. As industries demand more reliable and eco-friendly solutions, MS Polymers are leading the way with advanced formulations that cater to both performance and environmental sustainability.

#MSPolymers #HybridAdhesives #SealantInnovation #ConstructionTech #VersatileAdhesives #HighPerformanceMaterials #WeatherResistance #Flexibility #EcoFriendlySolutions #DurableBonding #AdvancedFormulations #AutomotiveApplications #DIYProjects #SustainableAdhesives #AdhesiveTechnology

0 notes

Photo

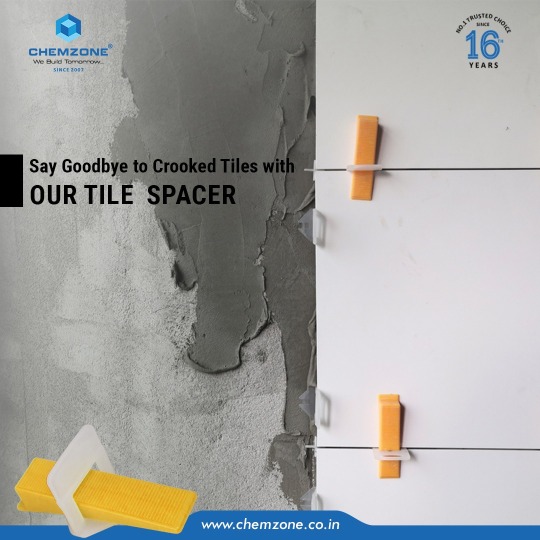

Say Goodbye to Crooked tiles with our TILE SPACER Contact us for more Details : Location :- Survey No. 123, Plot No.7, Road - D , GIDC Estate, Visnagar-384315,Gujarat, India. Website : www.chemzone.co.in | Email : [email protected] To Get More Details Fill This Form :- https://lnkd.in/eaEg8yjH

#Chemzone #ConstructionChemical #Grout #Adhesive #TileAdhesive #WaterproofingSolutions #TileInstallation #CeramicTiles #GroutSealer #TileMaintenance #WaterproofingMembrane #TileBonding #TileSealer #WaterproofingSystem #AdhesiveTechnology #TileGrout #WaterproofCoating #TileFixing #WaterproofingContractor #TileBackerBoard #WaterproofingProducts #TileDesign #WaterproofingInstallation #TileProtection

0 notes

Text

Adhesive Technology Miracle Bond 1310

Easy To Dispense, Non-Sag, Multi-Purpose Repair Epoxy

MIRACLE BOND® 1310

Features & Advantages

High strength bonding agent for materials including concrete, brick, wood, stone and block

Non-sag patching material for cracks and small spalls, great for overhead and vertical repair

Can be used as an adhesive or filler

Cured surface can be sanded and painted

Rapid initial 3 hour cure at room temperature

Used as a capping paste and injection port adhesive for crack injection process

Material Properties

Easily dispensable with most caulking guns

Moisture insensitive, can be used on damp surfaces and will cure underwater

Concrete gray color

24 month shelf life

See MIRACLE BOND® 1450 for bulk packaging

http://atcepoxy.com/wp-content/uploads/MIRACLE-BOND-1310-TDS.pdf

#epoxy#repair#easyflow#miraclebond1310#adhesivetechnology#nonsag#crackrepair#crackbondcsr#crackbond#ultrabond1#ultrabond#1300#reb#anchoring#DOT#dowelingepoxy

0 notes

Text

Putting the power of adhesive technology to work! Acrylic foam tape has been a popular choice in the automotive, construction and building, electronics, aerospace and aviation, and industrial equipment industries. Its incredible strength, flexibility, and weather-resistant properties make it the perfect solution for many of today’s tough bonding challenges. Let’s explore how acrylic foam tape can revolutionize your industry and make your projects a success!

Call 9822619307 OR Get it here- https://www.pioneertapes.com/contact-us

#AcrylicFoamTape#AdhesiveTechnology#IndustryRevolution#Ducttape#SuccessfulProjects#Pioneertapes

0 notes