#cargo ballast tank

Explore tagged Tumblr posts

Text

0 notes

Text

types of freight cars

made a whole post to help ppl design stex ocs as the resident freight enthusiast :) while this isn't every freight car in existence, it's definitely a good chunk of them!

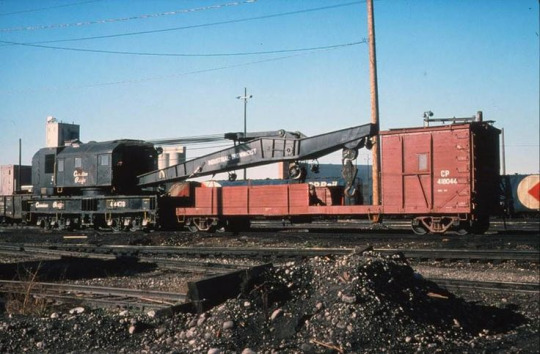

FLATCARS

The most basic type of freight car. They’re…well…flat! Designed for carrying bulky loads.

Autorack: Transport automobiles. Can have single, double, or triple levels.

Boom/Idler: Placed in front of a breakdown crane to protect the boom or in front of/behind oversized loads to protect the overhang.

Bulkhead: Have walls (bulkheads) on the end. Used to transport pipe, poles, slabs, and lumber. Prone to derailing when traveling empty and put speed restrictions on the freight train.

Centerbeam: Carry lumber. Another type is the opera (round) window style. Have to be loaded/unloaded evenly to avoid the car tipping over.

Depressed Center: Used to carry extremely heavy loads such as generators. Have a lowered (depressed) middle section.

Intermodal/Well: Carry semi-truck trailers and containers. Have a lowered bottom (well).

Skeleton/Spine: Very narrow car used to transport lumber. Has stakes on the sides. Spine cars do not have stakes and are often used for intermodal transport.

GONDOLAS

Open-topped cars that generally transport loose goods. Can also be covered. Differ from hoppers in that they have flat bottoms and have to be manually unloaded or put through a rotary dumper.

Bathtub: Transport coal. Have rounded bottoms for extra space.

Coil: Carry coils of metal. Can be open or have specialized covers to protect the cargo. Typically considered a subtype of gondola, but can also be a subtype of flatcar as well.

Side-dump: Cars tip sideways to dump loads. Often carry ballast or rocks for railbeds.

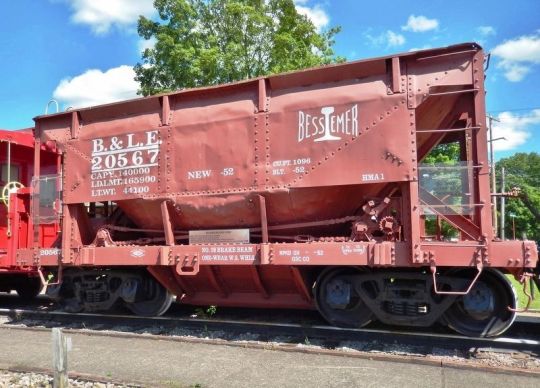

HOPPERS

Evolved from gondolas but differ in that they have sloped bottoms and discharge doors. Can be covered or uncovered, and have between two to five chutes. Open cars transport bulk goods such as coal, while covered ones carry food items.

Ore Jenny: A small, specialized hopper designed to carry large loads of iron ore from mines.

BOXCAR

Enclosed cars with side or end doors. Used for bulk commodities and for goods that need to be protected from the weather.

Stock: Used to transport livestock such as cattle, horses, sheep, and poultry. Have ventilated sides for airflow. A variant used to carry fish was attached to passenger trains and was more luxurious.

Refrigerator: Insulated and cooled cars used to transport frozen goods.

TANKERS

Used to transport liquids or gases. Can be specialized to carry hazardous materials.

Milk: Specialized tank car variant (as opposed to the boxcar variant) that carries milk. Attached to passenger trains to prevent spoilage.

Pickle: There's pickles in there! The vats were filled with vinegar.

Torpedo: Carry molten iron. Designed to withstand very high temperatures.

Whale Belly: Large tank car with a lowered midsection for additional carrying capacity.

SCHNABEL

These cars are a type all of their own. Used to transport extremely large loads by pinching it between the arms of the car.

94 notes

·

View notes

Text

A lot more stories that Grant can make up with his model trains when he rebuilds his model railway layout.

Paxton’s package. Paxton the diesel engine received a special package at the harbor. Sir Topham Hatt said it’s a gift for Salty to celebrate the anniversary of when he first came to the island. And the gift was an antique anchor from one of the very first cargo ships to ever come to Sodor. Will Paxton be able to keep it hidden from Salty before his party at the docks?

Ulli and Oliver. Oliver the great western engine was going to work with Ulli, one of the diesel shunters from the mainland. He really hopes the diesel can handle Dulcie & Isabel the way he does.

Samantha’s Santa special. Samantha the purple saddle tank engine is very excited. She was going to pull the presents train, as well as pick a coach for Santa to ride in so he can go to his grotto and give out presents for the children.

Rosie and Hector. Rosie was requested to collect an extra large load of stone from the blue mountain quarry. Paxton would normally do it, but he was feeling sick. But Rosie was nervous because she had to carry the crushed stone in Hector. Rosie was still a little bit nervous about Hector because she still remembered that he frightened her on his first day on Sodor. Will Rosie be able to forgive Hector for scaring her?

Double Timothy trouble. It was almost Halloween, and Timothy the oil burning engine heard a story from Thomas that there’s a ghost engine who shares the same name as him. The oil burning engine was rather nervous, but he had to do something because there can be only one Timothy on Sodor.

Amanda’s ghost hunt. Amanda was requested to take some passengers to go trick or treating from station to station when she heard a story from Fizzy. It’s a story about another E2 tank engine. He’s not as scary as Timothy aka engine number zero. He is known as engine 17.

Engines in space. Jupiter and 119 were visiting Sodor from their American railroad because they were to help Thomas with a brand new place on the railway. It’s a long tunnel with cardboard models of the planets. It was to make them feel like they were in outer space.

Mixed traffic trains. Sir Topham Hatt is trying out a new railway experiment, mixed traffic trains, which are trains that have coaches and freight cars together. Gordon thought the idea was ridiculous because he says passengers and freight don’t mix. He wouldn’t want smelly freight too close to his passengers.

Fizzy fizzles out. Fizzy the red tank engine was shunting freight cars when the ballast trucks began making him very upset. He gave them such a bump that he and the trucks came off the rails. To make matters worse, his fire bars collapsed. So he couldn’t deliver Coca-Cola to the stations. So he was sent to be repaired and Poy had to deliver his freight cars for him.

Robin’s race. The engines on the Island of Sodor were being visited by some of the famous engines from the mainland. Jimmy the Jinty and some of his friends, Simon, Robin and Terry. Sir Topham Hatt had requested Shedmaster Jimmy to bring them to visit and lend a wheel or three for the summer holidays on Sodor. Robin explained he’s as quick as the robins that nested on him years ago and Thomas challenged him to a race after telling him that he can go faster than the wind. Who will win the race from the quarry and back to Knapford station?

Engine ten thousand. Gordon was feeling very excited because a very grand looking engine is coming to visit from the mainland. It was a class W1 engine who has the number 10000 on his cab. He was known as Hush-Hush. He had come to fill in for Rebecca when she was sent to the works to be fitted with new boiler tubes.

Stephen’s great race. Stephen was feeling very excited because it was the anniversary of when he won the Rainhill Trials many years ago. He wanted to find a way to celebrate his anniversary. So, the engines decided that Stephen should race a horse pulling a single wagon from Ulfstead Castle to Brendam Docks. Will Stephen show everyone, especially Diesel that he’s more than just an antique, but a reliable engine with the heart of a champion?

Tiger’s roaring whistle. One day, an old fashioned steam locomotive named Tiger was visiting the Island of Sodor. Although he looks exactly like the one who used to work on the Liverpool and Manchester railway, he’s in fact a replica. After his long journey, he was given a new whistle that sounded a bit like a tiger roaring. Will he be able to put it to good use?

Henry and the holograms. Henry the green engine saw Ronnie the Amtrak engine was given a gift from Kenji in Japan. It was a hologram projector that will be fitted to the computer in his cab. A hologram is a three dimensional reproduction of an image. That way, Ronnie can download pictures from the web and make them look real. But Henry was a little bit worried that Ronnie might have trouble getting the hang of his new hologram projector.

Flash dashes in. A new high speed train has come to visit the Island of Sodor. His name is Flash. He’s 4 years old and he is eager to impress the other engines. But will he be able to fit in with Thomas and the other engines?

Diesels and Daleks. The engines were having an anniversary party for the show known as Dr. Who. Diesel, Timmy, Splatter and Dodge teased Percy and Poy about the Daleks coming to send the steam engines to the scrap heap by blasting their boilers to bits. The two little green engines felt rather nervous. But then Thomas had a naughty idea on how to teach Diesel and his pals a lesson. He spoke to Ruth the inventor, who had created remote control replicas of the Daleks for the party to help prank the diesel engines. And that night, just before the party began, they used them to scare the four diesels into thinking they were going to exterminate them.

3 notes

·

View notes

Text

Ballast

The Space Administration were clueless, in Sunita's general experience. Not the brightest stars in the constellation. A few planets short of a solar system. Sure, they knew how to build these modules, how to get them in the air and then out of it, but they had no queching idea when it came to the practicalities - like how to go about to actually staffing them.

The cabins were tight. They had to be, to conserve space, and weight, to make this whole spaceflight miracle work. The corridors were uncomfortably cramped; the connecting hatches more so. The Nakari required crew who were small, agile, and able to stay out of each other's way. People like Sunita. Like Pavindeep. Like Emyr. That shouldn't have been hard to understand. It was hardly rocket science.

What they didn't need was some hulking brute from the Administration's military, a fourth point on their perfectly efficient triumvirate, using up all the air and the food and the square footage. Lt. Daniel Masterson simply didn't fit on the Nakari, and they all felt it when he crammed himself into a room. Even on the edges of the solar system, Sunita was starting to feel like they were running out of space.

He was supposed to be their military escort, assigned to ensure that their cargo made it safely back to base, but with no care for the comfort of the crew. The Administration's focus was always the mission: in this case, to collect tisjan specimens, the first live aliens to ever make it back to base. They would be the Nakari's gifts to science, the public, and ultimately some esoteric collector.

Concerned about the unique challenges this posed, the Administration had sent Masterson as two-hundred pounds of animal handling, all of it unnecessary. The tisjan were predators, but in the same way as a polecat or mink, and weighed only a few pounds themselves. They could only be a danger if they all attacked at once: and even if they did try eating Masterson, they'd be occupied for a week on his torso alone. Sunita had actually done those calculations, one night keeping watch. The man snored.

Yet here he was: neither wanted nor needed, but the Administration's solution to a non-existent risk. They'd opted not to send a xenozoologist, not a veterinarian, but some jarhead with a body to match - barrel-chested, pot-bellied and with hands the size of pitchers. Claustrophobia in a tank top and jeans. Sunita knew that the Administration's first launches had sent animals up into space for observation, but she hadn't expected them to send a primate up here with her.

"What's happening?" Masterson manoeuvred his bulk into the cockpit, not without some difficulty.

"You see that amber light?" Sunita pointed to her display, where a whole array of the things were flickering orange and red.

"Sure." Standing in front of the entry hatch, the glow behind was eclipsed by his hulking, gorillian frame. "What does it mean?"

"That should only be a white LED. It means the computer behind the console is on fire."

"Quech." He took a step backwards, for which Sunita was grateful. If she'd known it only took a little bit of fire, she might have turned to arson long ago. "Are we going to die?"

"I've turned off all of the power, so it should burn itself out soon, but we're drifting through space at the moment. I sent an SOS signal first, so relief should be on its way. We're just stranded in the meantime."

"Stranded?" He started taking deep breaths, which gave the impression of a children's bouncy castle being pumped up by one of those box machines. Sunita could feel the oxygen level of the cabin drop with every inhalation.

"With relief on its way." The search for intelligent life really should have begun at home. "We'll just have to float for a week or so. It's no big deal."

"We were supposed to be back at base tomorrow. Do we have enough food to last another week?"

"If you stop trying to bulk up, yes. They plan for this when sorting our supplies. There is always a bit of a buffer in the number of days' rations, just in case of something like this."

"What about the tesjin?"

"The tisjin will be fine," she corrected. "They have their own food."

They'd collected that themselves, from their distant homeworld, to buy some time whilst they worked out what else they liked to eat. So far it had been yes to fried chicken, lamb curry, and even the awful fake cheese they got out of a can, but no to a slice of Emyr's birthday cake.

"I don't think we factored in the extra week, thought," Masterson said, finding himself in an unexpected area of expertise. They'd made him carry most of the food back onto the ship. He had to be good for something. "Do you think they'll be able to last?"

"That's a good point," Sunita told him, although it hurt her to concede it. "Why don't you bring them a few cans of cheese, just to tide them over?"

"Sure." He seemed grateful to have something to do, and squeezed his way back out through the hatch, like get cheese from a tin. With one last assessment of that torso, Sunita locked the hatch behind her, and hoped that Pavindeep and Emyr, wherever they were on the ship, were doing the same. At least until it died down.

She'd been honest with Masterson about the fire. What she'd neglected to tell him was that the doors in the tisjin room, being electronic, would all have opened. It was tragic what could happen in an accident like this. She hoped that the Administration, for all their faults, would appreciate that - as long as the mission was a success. Delay or not, the priority had to be getting the tisjin home alive.

Sunita had bought them a week, give or take, until relief arrived. She hoped they liked the taste of gorilla.

19 notes

·

View notes

Text

Brisen

Tanker Brisen aground off Sandhamn #maritime #tanker #sweden

On November 30, the 67 meter long, 2103 dwt tanker Brisen (IMO: 9970595) ran aground in the Baltic Sea near Sandhamn, Sweden. The Brisen was en route to Stockholm from Karlskrona with a cargo of bunker oil when it grounded and sustained hull damage. Authorities found the vessel had sustained several holes in the vessel’s ballast tanks. The tanker would be refloated the next day and proceeded to…

View On WordPress

0 notes

Text

Marine and Industrial Applications of Control Valves: A Comprehensive Guide

Control valves are integral components in both marine and industrial systems, ensuring the smooth regulation of liquids, gases, and other materials. These devices play a critical role in maintaining system performance, safety, and operational efficiency. Whether on ships or in power plants, control valves are key to preventing system failures and ensuring smooth operations. In this guide, we’ll explore their importance, common applications, and best practices for maintenance.

What Are Control Valves?

Control valves are mechanical devices designed to regulate the flow of fluids within a system. They control parameters like flow rate, pressure, and temperature in response to control signals from automated systems. Their primary function is to keep processes stable, avoiding damage to equipment, maintaining efficiency, and optimizing performance in various operational settings.

Marine Applications of Control Valves

In marine environments, control valves are vital for the safety, stability, and performance of ships, offshore platforms, and other related systems. Some of their most critical applications include:

Fuel Supply: Control valves regulate fuel flow to engines, ensuring the correct amount is delivered for optimal engine performance, efficiency, and reducing fuel waste.

Ballast Systems: Control valves are essential in managing ballast water, which maintains the stability of ships. They ensure the precise amount of water enters or exits ballast tanks to maintain balance during various loading or unloading operations.

Water Treatment: Marine vessels require reliable water treatment systems to provide potable water for the crew and maintain operational safety. Control valves manage water flow through filtration and purification systems to ensure clean water is available.

HVAC Systems: On board HVAC systems depend on control valves to regulate airflow and temperature, ensuring a comfortable environment for the crew and protecting sensitive cargo. This is vital for operational safety and crew well-being.

Industrial Applications of Control Valves

Control valves also play a critical role across various industrial sectors, including oil and gas, power generation, and chemical processing. Their functions in these sectors include:

Oil & Gas: In oil and gas operations, control valves regulate the flow of crude oil, gas, and associated products through pipelines and refinery units. This ensures that systems remain safe, efficient, and within operational limits.

Power Generation: In power plants, control valves manage the flow of steam and water in boilers and turbines. By maintaining optimal pressure and temperature levels, they ensure efficient energy production and prevent costly system failures.

Chemical Processing: Control valves are critical in chemical processing plants, where they control the flow of chemicals in reactors and mixers. Proper regulation is essential for maintaining product quality, safety, and consistency.

Water Treatment: Industrial water treatment plants rely heavily on control valves to manage processes such as filtration, chemical dosing, and wastewater treatment. Efficient valve control ensures safe, clean water supplies and the proper treatment of waste materials.

Best Practices for Maintenance

Regular maintenance is vital for ensuring the longevity and reliability of control valves in both marine and industrial settings. Here are some best practices for keeping control valves in optimal condition:

Regular Inspections: Periodically check valves for wear and tear, leaks, and any other signs of malfunction.

Calibration: Ensure that control valves are correctly calibrated to respond accurately to control signals.

Lubrication: Proper lubrication reduces friction and wear on valve parts, improving performance and extending service life.

Parts Replacement: Replace worn or damaged parts promptly to prevent system failures or operational inefficiencies.

Conclusion

Control valves are indispensable in both marine and industrial applications, ensuring safe, efficient, and reliable operations. Whether regulating fuel flow on a ship or managing steam pressure in a power plant, they help keep systems running smoothly. For optimal performance, it’s essential to choose the right valve, perform regular maintenance, and address any issues promptly.

At Dropship Automation, we provide the tools and solutions needed to automate key operational processes, ensuring reliability and safety in your systems. Start optimizing your processes today and achieve greater operational efficiency!

1 note

·

View note

Text

Simplifying Maritime Operations with Al Bahar Shipping: The UAE's Reliable Partner The foundation of international trade is the maritime sector, and accurate operations, strict safety regulations, and strong management systems are essential to its effectiveness. Al Bahar Shipping, one of the top shipping company in UAE, provides a wide range of surveying, inspection, and analytical services to guarantee the smooth functioning of both onshore and offshore activities.

Al Bahar Shipping is your go-to partner for attaining operational excellence and cost effectiveness, whether you're looking for a reputable ship management company or professional services for freight forwarding company in UAE.

Promoting Excellence in Inspection and Surveying

Our onshore and offshore surveying services at Al Bahar Shipping are intended to address problems in asset-record management, engineering, and construction. We provide cutting-edge technology and experience to each project, offering observable advantages like:

1.improved precision for important choices.

2.decreased field time and operational expenses.

3.enhanced safety regulations, reducing hazards.

4.quicker project completion, which saves important time.

We take a comprehensive approach to ship management and logistics, making sure that every facet of our offering complements the operational objectives of our customers.

Complete Ship Inspections for All Requirements

Our comprehensive ship survey services are designed to satisfy the particular requirements of the marine industry, assisting companies in streamlining their operations and cutting expenses and delivery times.

We provide bunker quantity and quality surveys as part of our ship survey services.

1.Initial Surveys

2.Surveys of Tank and Hatch Cleanliness

3.Inspections before to purchase

4.Inspections from Ship to Ship and On/Off-Hire Surveys

5.Surveys of Custody Transfers

Every service is completed with painstaking attention to detail, and you will receive unbiased, independent reports to back up your business decisions.

Inspections of Bunkers and Marine Cargo

In maritime operations, the quality of the fuel and cargo is crucial. Our staff of knowledgeable surveyors specializes in marine cargo monitoring and bunker inspections, providing precise and thorough evaluations to assist you steer clear of expensive disputes.

Bunker Detective Survey (221B) is one of our bunker services.

De-bunker Surveys: Supervision of Loss Control

Testing of Bunker Fuel

We are a vital partner for any freight forwarding company in UAE since we guarantee cargo integrity by providing supervision and monitoring services that verify both quantity and quality.

Superior Analytical Services to Improve Outcomes

We stand out as one of the top logistics company in UAE thanks to our laboratory-grade testing and reporting skills. From cylinder scrape-down oil analysis to water testing, we provide useful information that maximizes vessel performance.

Important Analytical Services:

Monitoring of Lube Oil Conditions

Testing of Ballast Water, Lubricant, and Fuel Blend Research

Analysis of Mass Flow Meter Data

These services increase asset longevity, enable our clients to make well-informed decisions, and uphold international standards.

Al Bahar Shipping is a partner for maritime excellence.

Our goal at Al Bahar Shipping is to offer our customers customized solutions that increase operational effectiveness, boost safety, and cut expenses. Being a leading shipping company in UAE, we are dedicated to going above and beyond industry norms and providing unparalleled value.

Our staff has the know-how to satisfy your needs, whether you need professional surveys, inspections, or trustworthy freight forwarding services. You can rely on Al Bahar Shipping to confidently and precisely negotiate the difficulties of marine operations.

#freight forwarding company in uae#logistics company in uae#ship management company#uae shipping company#shipping company in uae

0 notes

Text

What Are the Key Components of a Marine Automation System?

Marine automation systems have become integral to modern maritime operations, helping enhance safety, improve efficiency, reduce fuel consumption, and optimize overall ship performance. A typical marine automation system integrates various technologies, allowing ships to operate with minimal human intervention while maximizing operational accuracy and effectiveness. Below, we explore the key components that make up a marine automation system and how they contribute to seamless vessel management.

1. Engine Control and Monitoring System (ECMS)

The Engine Control and Monitoring System (ECMS) is one of the most critical components of a marine automation system. It is responsible for overseeing the main engine's operation, auxiliary engines, and other critical machinery. The system continuously monitors engine parameters such as temperature, pressure, fuel consumption, and engine speed. Real-time data is fed into the system to ensure that engines operate at optimal efficiency, preventing breakdowns and reducing fuel wastage. ECMS can also trigger alarms and automatic shutdowns in case of critical failures, thereby enhancing operational safety.

2. Power Management System (PMS)

A ship’s power management system is essential for optimizing power generation and distribution. The PMS oversees the operation of generators, managing electrical load distribution, and switching between power sources to ensure energy efficiency. It regulates the ship’s electrical supply, balancing demand from various equipment, machinery, and systems. Automation in power management helps reduce fuel consumption by optimizing generator usage and prevents overloading or blackouts that could disrupt vessel operations.

3. Navigation and Steering Automation

Automated navigation systems are a crucial element in modern marine automation. These systems integrate various tools such as GPS, radar, and automatic identification systems (AIS) to provide real-time data for safer navigation. Autopilot systems, which can automatically control the ship’s course, are a key feature of navigation automation. These systems reduce the need for constant manual input, allowing ships to maintain precise routes, avoid collisions, and improve fuel efficiency by optimizing sailing paths. Additionally, integrated bridge systems (IBS) combine data from different navigational tools into a single interface for easier monitoring and control by the crew.

4. Ballast Water Management System (BWMS)

A Ballast Water Management System is designed to automate the process of controlling the amount of ballast water on board, ensuring the vessel maintains proper stability and meets regulatory requirements. Marine automation helps in monitoring the ballast tanks, controlling pumps, and adjusting the ballast levels based on the ship's loading condition and sea conditions. Moreover, automated BWMS systems are increasingly being integrated with water treatment technologies to ensure compliance with environmental regulations regarding ballast water discharge.

5. Cargo Management System

For vessels carrying bulk cargo, automation in cargo management is vital for efficient loading, unloading, and monitoring. This system includes automation of pumps, valves, and cargo tank monitoring to ensure that the loading process is safe and efficient. Automation ensures the cargo is distributed evenly, maintaining ship stability while minimizing the risk of human error, which could lead to dangerous conditions, especially in liquid cargo handling such as oil or chemicals.

6. Alarm and Monitoring Systems

Alarm and monitoring systems play a pivotal role in marine automation by continuously tracking various shipboard parameters such as temperature, pressure, vibration, and liquid levels. These systems are equipped with sensors distributed throughout the ship to detect anomalies and potential faults in machinery, power systems, and other operational areas. Should a system exceed safety thresholds, the alarm system triggers alerts, providing the crew with the information needed to take corrective action or, in some cases, initiate automatic responses, such as engine shutdown or power redistribution.

7. Communication Systems

Modern ships are equipped with sophisticated communication systems that are integrated with automation technologies. These systems allow the vessel to stay connected with shore-based operations centers and receive remote support. Additionally, automated communication systems are used to transmit critical data related to engine performance, fuel consumption, and route planning to shore facilities for real-time analysis and decision-making.

8. Cybersecurity Systems

As marine automation becomes more advanced, the importance of cybersecurity within these systems has grown. Cybersecurity systems are now an integral component, ensuring that the automation systems are protected from external cyber threats, which could compromise the safety of the vessel or lead to operational disruptions.

Conclusion

Marine automation systems are composed of several key components, each playing a vital role in enhancing the operational efficiency, safety, and reliability of modern ships. From engine control and power management to navigation, cargo handling, and cybersecurity, each subsystem integrates seamlessly to provide a comprehensive solution that reduces human intervention while improving precision and safety. As technology continues to advance, marine automation systems are likely to evolve further, playing an even more prominent role in the future of maritime operations.

0 notes

Text

design notes: I was trying to figure out where to fit nitrogen tanks, and how that would diminish the capacity of the cargo hull which I didn't like too much, in fact not at all

also looking at it in terms of structure and of what fits where, keeping in mind that we are way below auxiliary tanks which are almost right beneath the skin of the ship on top

that's when I realized that we are looking at them… right there within the hexagonal mesh structure of the ship instead of high density helium foam

and the whole ship suddenly looked more alien than anything else and based repeatedly, a repeat, of hexagonal structures

extra tanks for the ones on the sides of the wings, because they should be the most used, if those don't cut it then there is something wrong with the course

the ones in midsection are used mostly for adjusting landings

and capacious tanks for the ones in front which control the tilt of the nose, also during landings

done, with 100% of the initial cargo hull volume and width

ionic thrusters wise I could now fit them inside the hull and not sweat it, it's lower in that portion anyways because the compression core is right above it

who said you can't have your own space agency, it took us 8 years to get there, quite an achievement considering available resources, basically there's no budget aside from residential WiFi

so these are the tanks the gas expansion chambers tutti quanti, sometimes the height of the tanks is less such as for the wing tips,

sometimes the tank is more extensive such as in front where it takes place within the height of the nose

it's a lot of nitrogen for an exploration ship that isn't meant to tank nitrogen light years away where there are no support infrastructures, yet

design notes continued: we ended up fitting the outlet pipes and expansion chambers so this would be the full set up

I have also come to consider the ionic propulsion module as a lifesaver together with a full height nitrogen tank that takes place in the cargo hull

the gas expansion chambers sit on top of the tanks, or below, this view is a bit of both, and they are not huge in fact they could be pretty flat

likewise for the ballasts of the Cuba Libre 3D modeling should allow us to fine tune these designs in terms of height and volumes

which we don't have right now 3D tools, they look complex and even cumbersome to be honest, I got used to modelling under paint its fast and straightforward

plus I do not see the use of dwelling into 3D modelling only to be told by engineering graduates that this or that, or many of them are not it, ie the whole model needs to be scrapped because it would take longer to fix even

rather I am clear minded about where my skills end and where actual 3D modelling for building these things starts, achieve what you can to the best of your abilities, try different things, see what works pursue it to the greatest extent, see what doesn't try to fail fast and move on, don't waste time doing other people's work or specialties

on the last view we have RCS modules that we haven't seen so far and that take place on the sides of the nose, so in fact vs the nitrogen tank in front we have 3 different gas expansion chambers that take place, on top for the topdeck RCS module, in the middle for these on the sides of the nose, and below for the keel RCS module

how do they operate, we said those outlets can function on an individual basis, using valves simply put, that let us action one outlet or several in particular and not the rest, the goal of course being to conserve the nitrogen supply as long as possible

essentially an AI that assists in navigating this ship, that helps in determining how much nitrogen should be released in these gas expansion chambers vs the course that the ship has to take so that the waste is minimal

yes but you are filling the whole gas expansion chamber in order to action the valve of one outlet, I don't care since that gas stays there, in fact it's a plus because the chambers are not running on empty when RCS modules are called

the only thing you don't want aboard a spaceship is an empty tank, and what I am saying is that this makes RCS modules more reactive, plus by the looks of it the chambers are already filled when the ship takes off

that means the system can hold more capacity by tapping into the volumes of these gas expansion chambers vs having them on empty, ie I am going to fill those chambers, and refill the nitrogen tanks

space is the most highly demanding environment, you can only make it by making use of every last square cubic centimeter that you have on board

0 notes

Text

Ballast water convention

Context : The Tamil Nadu Water Resources Department (WRD) has informed the National Green Tribunal that it has sought ₹160 crore from the Kamarajar Port in Ennore, Tamil Nadu, to facilitate the removing of invasive Mytella strigata, or charru mussel. What is Ballast water and how does it introduce invasive species? Ballast water is fresh, or saltwater held in the ballast tanks and cargo holds…

0 notes

Photo

Calibration Cargo Tank Monitoring

1 note

·

View note

Text

Marine Coatings Market Analysis: Global Overview

Antifouling Coatings One of the most important coatings used in marine applications is antifouling coatings. These coatings are applied to the hulls of ships and boats to prevent biofouling, which is the unwanted accumulation of microorganisms, algae, plants, and animals on wet surfaces. Biofouling can have significant detrimental effects if left untreated as it increases drag, decreases fuel efficiency, and affects maneuverability. Traditional antifouling coatings contained biocides like tributyltin (TBT) which leached from the coating into the surrounding seawater to deter biological growth. While very effective, these TBT-based antifoulings posed environmental and health risks. As a result, the International Maritime Organization banned the use of TBT-based antifoulings worldwide in 2008. Modern antifouling coatings now rely on alternative biocides or biocide-free mechanisms to prevent slime and organism accumulation. Copper-based antifoulings are now one of the most common alternatives as copper is a naturally occurring element that marine life encounters. The copper leaches slowly from the coating and acts as a biocide at low concentrations safely. Other non-biocide mechanisms involve foul-release and fouling-release coatings, which create very slick surfaces that marine organisms struggle to adhere to. The coating periodically "sloughs off" any organisms that start to attach. Overall, the goal of modern antifouling coatings is to provide effective hull protection while minimizing environmental impact. Anticorrosion Coatings In addition to preventing biofouling, marine coatings play a critical role in protecting a ship's steel hull and other metal components from corrosion due to seawater exposure. Left uncoated, steel readily corrodes when submerged in seawater which contains dissolved oxygen, carbon dioxide, and chloride salts. The main types of marine anticorrosion coatings are anticorrosive primers and topcoats. Epoxy and polyurethane coatings are commonly used anticorrosive primers that form a protective barrier on the metal surface, disrupting the corrosion process. Topcoats are then applied over primers to provide additional physical, mechanical, and aesthetic protection. Popular topcoats include further epoxy coats, chlorinated rubber, and acrylic coatings. Specialized Coatings Beyond generic hull and anticorrosion coatings, specialized marine coatings serve various other functions. Tank coatings applied to cargo oil tanks, ballast tanks, and fuel tanks assist in corrosion protection and help prevent contamination. Due to cargo compatibility concerns, different tank coating chemistries may be selected depending on the types of fluids being stored or transported. Additionally, many vessels require scrubber coatings. These physically robust coatings line exhaust gas desulfurization (EGD or "scrubber") systems that remove sulfur oxides from engine exhaust to comply with emissions regulations. Scrubber coatings must withstand the corrosiveness of seawater and chemical cleaning agents used in the scrubbing process. Epoxy and silicon-based coatings tend to work well in these highly demanding environments. Successful coatings receive certification from classification societies like Lloyd's Register verifying they meet procurement specifications. Examples are Lloyd's Register Certificates for fitness of antifouling coatings or NORSOK M-501 for offshore structures. With thorough R&D testing and certifications, marine coatings manufacturers can provide assurance their products will maintain maximum performance and lifetime when used for their intended purpose.

0 notes

Text

The Role of Ballast and Bilge Eductors in Maritime Operations Ensuring Efficiency and Safety

In maritime operations, effective water management is critical for maintaining ship stability, safety, and compliance with environmental regulations. Ballast Eductors play a pivotal role in achieving these objectives. This article explores the function of ballast and bilge eductors, their benefits, and how they contribute to optimal maritime operations. Understanding Ballast and Bilge Eductors : Ballast and bilge eductors are devices designed to move fluids, primarily water, by creating a vacuum. This technology is widely used in maritime applications to manage ballast water and remove excess bilge water from ships. Ballast Eductors control the distribution and balance of water in ballast tanks, while bilge eductors remove water that accumulates in the ship's bilge.

The Importance of Ballast Management : Ballast water is used to stabilize ships, particularly when cargo loads vary or during rough seas. Proper ballast management ensures that ships remain balanced and meet stability requirements. Bilge Eductors help move ballast water between tanks, allowing ships to adjust their trim and draft efficiently. This flexibility is crucial for maintaining safe navigation and reducing fuel consumption.

The Role of Bilge Eductors: Bilge water accumulates in the lower parts of a ship due to condensation, leaks, or other sources. It's essential to remove this water to prevent corrosion, maintain ship safety, and comply with environmental regulations. Bilge Eductors provide a reliable solution for quickly extracting water from the bilge, minimizing the risk of flooding and structural damage.

Environmental Considerations : Ballast and bilge eductors play a role in environmental protection by ensuring that ships manage ballast and bilge water responsibly. Proper ballast management helps prevent the transfer of invasive species, while efficient bilge water removal reduces the risk of oil and other contaminants being discharged into the ocean. Compliance with environmental regulations is critical for ship operators, and eductors help achieve this compliance.

Versatile Applications : Ballast and bilge eductors are used across a wide range of maritime applications, from cargo ships and tankers to passenger vessels and offshore platforms. Their versatility makes them suitable for various ship types and sizes, providing a reliable solution for water management.

Choosing the Right Eductors : When selecting ballast and bilge eductors, consider the following factors to ensure they meet your specific needs. Visit: https://www.crystaltcs.com/ballast-eductor.php Contact: +91 0253 2941600

0 notes

Text

[For Sale - CS00192] 2,600 DWT DOUBLE HULL CHEMICAL TANKER

Built: 1982, TurkeyDimensions: 85 x 13,32 meter – depth 6 mClass: BV – SS due May 20242681 dwt on about 4,65 m draft GT: abt 1756Tanks: 12 cargo tanks coated interline 994 (also ballast and slop tanks) – 1608 cbm (60%)3 screw pumps 350 m3-hr.Stainless steel manifolds – steam coils 80 C.2 ballast centrifugal pumps 400 cbm hr.Main Engine: Deutz KHD SBV 8M 628 – 900 rpm – 1800 hpAux:2 dsl 608…

View On WordPress

0 notes

Text

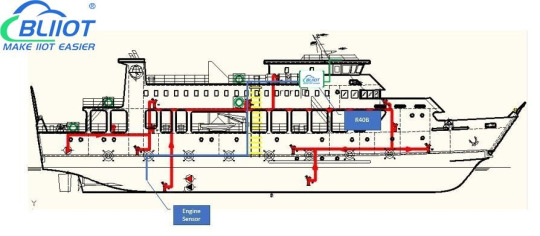

BLIIoT Industrial Edge Router R40B for Marine Automation

Introduction

In the current era of booming industrial Internet of Things, the shipping industry has an increasing demand for automation and intelligence. With its excellent performance and rich functions, the R40B industrial 4G edge computing router has shown broad application prospects in Marine Automation.

Marine Automation

Marine Automation ranges from main propulsion monitoring and alarm systems to highly integrated automation systems, including process control, ballast control, tank measurement monitoring, pump/valve control, bilge control, cargo load control and stability calculation, information management, fault The diagnostic and power management system adopts a modular design, which allows the system to be flexibly configured to meet the different requirements of users. It allows users to quickly and conveniently monitor the operation of related equipment through a graphical human-machine interface, optimize operation management, and thereby improve the automation level of the entire ship.

Application scenarios

Remote ship monitoring system

Real-time monitoring of ship engine status to improve real-time understanding of engine performance.

Remote tracking of ship position enhances precise monitoring of ship position.

Remote maintenance and fault diagnosis of shipboard equipment can reduce ship maintenance time and improve operational efficiency.

Marine Power Management System

Generator unit status is monitored in real time to ensure the stability of power supply.

Collect and analyze energy efficiency data to achieve optimal management of energy consumption.

Real-time reporting and forecasting of energy consumption provides more accurate energy planning for ships.

Marine Environmental Monitoring and Safety System

Monitoring of ship's internal environmental parameters ensures the safety and comfort of the crew's working environment.

Real-time monitoring of dangerous events such as fires and leaks to improve rapid response to dangerous situations.

Crew safety alarm system to ensure the safety of crew members.

Ship logistics and cargo tracking system

Real-time location tracking of goods improves real-time management and control of goods.

Monitor the status of ship cargo holds to ensure that cargo is transported in good conditions.

The temperature and humidity of ship cargo are remotely controlled to provide a precise transportation environment for special cargo.

In Conclusion

The wide application of R40B industrial 4G edge computing router in ship automation not only improves the operational efficiency and safety of ships, but also brings new opportunities for the shipping industry to embrace the digital era. In the future, with the continuous innovation of technology, R40B will play a more important role in the field of Marine automation and promote the progress of the entire shipping industry.

More information about BLIIoT Industrial Edge Router R40B: https://www.bliiot.com/edge-iot-router-p00307p1.html

#iot#marineindustry#automation#remotemonitoring#remotecontrol#4g#wifi#ethernet#sms#modbus#mqtt#cloud#scada#bliiot

0 notes

Text

BLIIoT Industrial Edge Router R40B for Marine Automation

Introduction

In the current era of booming industrial Internet of Things, the shipping industry has an increasing demand for automation and intelligence. With its excellent performance and rich functions, the R40B industrial 4G edge computing router has shown broad application prospects in Marine Automation.

Marine Automation

Marine Automation ranges from main propulsion monitoring and alarm systems to highly integrated automation systems, including process control, ballast control, tank measurement monitoring, pump/valve control, bilge control, cargo load control and stability calculation, information management, fault The diagnostic and power management system adopts a modular design, which allows the system to be flexibly configured to meet the different requirements of users. It allows users to quickly and conveniently monitor the operation of related equipment through a graphical human-machine interface, optimize operation management, and thereby improve the automation level of the entire ship.

Application scenarios

Remote ship monitoring system

Real-time monitoring of ship engine status to improve real-time understanding of engine performance.

Remote tracking of ship position enhances precise monitoring of ship position.

Remote maintenance and fault diagnosis of shipboard equipment can reduce ship maintenance time and improve operational efficiency.

Marine Power Management System

Generator unit status is monitored in real time to ensure the stability of power supply.

Collect and analyze energy efficiency data to achieve optimal management of energy consumption.

Real-time reporting and forecasting of energy consumption provides more accurate energy planning for ships.

Marine Environmental Monitoring and Safety System

Monitoring of ship's internal environmental parameters ensures the safety and comfort of the crew's working environment.

Real-time monitoring of dangerous events such as fires and leaks to improve rapid response to dangerous situations.

Crew safety alarm system to ensure the safety of crew members.

Ship logistics and cargo tracking system

Real-time location tracking of goods improves real-time management and control of goods.

Monitor the status of ship cargo holds to ensure that cargo is transported in good conditions.

The temperature and humidity of ship cargo are remotely controlled to provide a precise transportation environment for special cargo.

In Conclusion

The wide application of R40B industrial 4G edge computing router in ship automation not only improves the operational efficiency and safety of ships, but also brings new opportunities for the shipping industry to embrace the digital era. In the future, with the continuous innovation of technology, R40B will play a more important role in the field of Marine automation and promote the progress of the entire shipping industry.

More information about BLIIoT Industrial Edge Router R40B: https://www.bliiot.com/edge-iot-router-p00307p1.html

#iot devices#iot solutions#datacollection#industrial automation#awscloud#thingsboard#smartcities#Marine Automation

0 notes