Text

HYDRATIGHT Sweeney HTNS6 Hydraulic Nut Splitter: A Robust Solution for Marine Applications

In the demanding world of marine maintenance, efficiency and safety are paramount. The HYDRATIGHT Sweeney HTNS6 Hydraulic Nut Splitter stands out as a specialized tool designed to tackle the challenges of removing corroded or seized nuts in marine environments. Manufactured by HYDRATIGHT Sweeney, a global leader in bolting solutions, the HTNS6 is engineered for precision, durability, and safety, making it an essential asset for marine professionals.

Key Features of the HTNS6 Hydraulic Nut Splitter

The HTNS6 is a hydraulic nut splitter tailored specifically for marine use, where harsh conditions like saltwater exposure and corrosion are common. Its robust design incorporates a lightweight hydraulic cylinder that drives a precision-engineered cutting blade, capable of slicing through nuts without damaging the underlying bolt threads. This feature is critical in marine settings, where preserving the integrity of bolts is essential for maintaining structural safety.

Equipped with a spring-return cylinder for topside applications and an optional double-acting cylinder for subsea tasks, the HTNS6 offers versatility for various marine maintenance scenarios. The tool’s cutting blade, designed with three cutting edges for maximum durability, can be preset to ensure precise cuts, minimizing installation time. Additionally, an integral pressure relief valve prevents over-pressurization, enhancing operational safety.

Why Choose the HTNS6 for Marine Use?

Marine environments present unique challenges, such as rust and seized components, which traditional methods like grinding or flame cutting cannot address safely. The HTNS6 eliminates these risks by providing a fast, reliable, and non-destructive solution for nut removal. Its compact design allows it to fit into tight spaces, making it ideal for working on bolted flange joints or other confined areas commonly found on ships, offshore platforms, or marine equipment.

The tool’s ability to handle nuts up to 36 inches (as part of HYDRATIGHT’s broader nut splitter range) ensures compatibility with a wide range of ANSI flanges, catering to diverse marine applications. Its high-durability, low-maintenance design reduces downtime, enabling marine technicians to focus on critical tasks without worrying about frequent tool repairs.

Benefits for Marine Professionals

The HTNS6 delivers unmatched efficiency by reducing the time and effort required to remove stubborn nuts. Its hydraulic mechanism ensures consistent performance, even under the toughest conditions, while the interchangeable cutting heads allow for quick adjustments to suit different nut sizes. This adaptability makes it a cost-effective solution for shipyards, offshore rigs, and marine repair facilities.

By prioritizing safety, the HTNS6 eliminates the need for hazardous methods like hot cutting, protecting both workers and equipment. Its precision engineering also supports compliance with stringent marine industry standards, ensuring reliable performance in high-stakes environments.

Conclusion

The HYDRATIGHT Sweeney HTNS6 Hydraulic Nut Splitter is a game-changer for marine maintenance, offering a safe, efficient, and reliable solution for removing seized or corroded nuts. With its advanced features, durability, and tailored design for marine applications, the HTNS6 empowers professionals to maintain operational excellence in challenging conditions. For marine technicians seeking a high-performance tool, the HTNS6 is a trusted choice that delivers results.

#HYDRATIGHT#Sweeney HTNS6#Hydraulic Nut Splitter#Marine Machinery#Marine Products#Marine Solutions#Marine#Marine Hydraulics Machinery#Marine Hydraulic

0 notes

Text

The Power Behind Marine Hydraulic Pumps: A Simple Guide

Have you ever pondered how large ships navigate the ocean with ease? Hydraulic pumps, like the Brueninghaus Hydromatik AA10VS071DR/31R-PKC92KA3, are the unsung heroes powering critical marine systems. This article explains what makes these pumps vital for marine use, breaking down their role in simple terms.

Why Hydraulic Pumps Matter in Marine Applications

Hydraulic pumps are the heart of many marine systems, converting mechanical energy into hydraulic power. They drive essential functions like steering, winches, and stabilizers on ships. The Brueninghaus Hydromatik AA10VS071DR/31R-PKC92KA3, designed specifically for marine environments, ensures reliable performance under tough conditions. Without these pumps, vessels would struggle to operate efficiently.

How Marine Hydraulic Pumps Work

Think of a pump as a powerful hand exerting force by forcing water through a hose. Hydraulic pumps push special fluid through a system to generate power for moving parts. The AA10VS071DR/31R-PKC92KA3 uses advanced technology to deliver precise, high-pressure fluid flow. This makes it ideal for marine tasks requiring consistent power, like controlling heavy equipment.

Key Features of Top Marine Pumps

Marine hydraulic pumps need to be tough, efficient, and reliable. The Brueninghaus Hydromatik model stands out for its durability in harsh saltwater environments. It’s built to handle high-pressure demands while maintaining energy efficiency. These features ensure ships run smoothly, saving fuel and reducing maintenance costs.

Benefits for Marine Operations

Why choose a pump like the AA10VS071DR/31R-PKC92KA3 for marine use? It offers smooth operation, reduces wear on equipment, and handles extreme conditions like storms or high seas. For example, it can power a ship’s steering system, ensuring precise control even in rough waters. This reliability keeps crews safe and operations on schedule.

Choosing the Right Hydraulic Pump

The needs of your yacht will determine which marine hydraulic pump is best for you. Take into account elements such as climatic conditions, system compatibility, and power requirements. The AA10VS071DR/31R-PKC92KA3 is a great choice for medium to large vessels due to its robust design. Always consult with a marine engineer to ensure the pump matches your ship’s specifications.

Final Thoughts on Marine Hydraulic Pumps

Hydraulic pumps are essential for keeping ships moving safely and efficiently. A premium choice for nautical jobs, the Brueninghaus Hydromatik AA10VS071DR/31R-PKC92KA3 provides strength and dependability. If you’re involved in marine operations, understanding these pumps can help you make informed equipment choices. Curious about upgrading your vessel’s systems? Talk to a marine equipment specialist today!

0 notes

Text

Enhance Marine Operations with Double A Hydraulic Directional Valves

Marine environments require equipment that can withstand tough conditions while delivering reliable performance. The Double A QJ-3-C-10D1-V hydraulic directional valve is engineered specifically for marine applications. Manufactured by Double A, a leader in hydraulic technology, this valve ensures precise control for hydraulic systems on vessels. Its robust design makes it a top choice for marine professionals seeking durability and efficiency.

Key Features of the QJ-3-C-10D1-V Valve

This hydraulic directional control valve, also known by part number QJ-8-C-10B1-T-V, operates at 120V and 60 Hz. With a power consumption of just 27 watts, it offers energy efficiency without sacrificing performance. Built in new condition, the valve is designed to handle the rigorous demands of marine hydraulic systems. Its low power usage makes it ideal for vessels aiming to optimize energy consumption.

Why Hydraulic Valves Matter in Marine Applications

Hydraulic directional valves are essential for directing fluid to actuators and motors in marine systems. The Double A valve excels in high-pressure environments, ensuring smooth fluid flow and accurate directional control. Its compact design allows easy integration into existing setups, making it suitable for boats, ships, and offshore platforms. The valve’s corrosion-resistant construction is perfect for withstanding saltwater and harsh weather.

Boosting Efficiency and Reliability

Marine engineers prioritize equipment that enhances system efficiency. The QJ-3-C-10D1-V provides precise fluid direction, reducing energy waste and improving response times. Its 120V operation aligns with standard marine electrical systems, simplifying installation and maintenance. This valve is ideal for critical applications like steering systems, winches, and deck machinery, where consistent performance is crucial.

A Smart Investment for Marine Professionals

Choosing the right hydraulic valve can transform marine operations. Double A’s expertise ensures this valve meets strict industry standards. Its energy-efficient design lowers operational costs and supports sustainable practices. By incorporating this valve, marine professionals can enhance system longevity and reduce maintenance needs, keeping vessels operational in demanding conditions.

Conclusion

The Double A QJ-3-C-10D1-V hydraulic directional valve is a vital component for marine hydraulic systems. Its low power consumption, durable construction, and precise control make it a standout choice. By integrating this valve, marine professionals can achieve improved performance, reduced energy costs, and long-term reliability. Whether upgrading or outfitting a new vessel, this valve ensures marine systems are ready for the challenges of the open water.

0 notes

Text

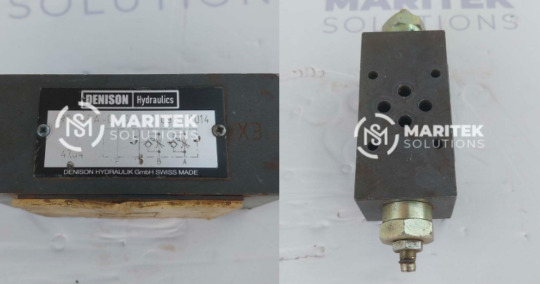

Denison ZRD-ABA-01-S0-D1 Hydraulic Throttle Check Valve: A Reliable Choice for Marine Applications

The Denison ZRD-ABA-01-S0-D1 hydraulic throttle check valve is a specialized component designed for marine applications. Known for its durability and precision, this valve plays a critical role in controlling hydraulic fluid flow in demanding environments.

Whether you’re maintaining a vessel’s hydraulic systems or upgrading marine equipment, this valve offers reliable performance. In this article, we explore its features, benefits, and why it’s a top choice for marine professionals.

What is the Denison ZRD-ABA-01-S0-D1 Valve?

The Denison ZRD-ABA-01-S0-D1 is a hydraulic throttle check valve manufactured by Denison, a trusted name in hydraulic systems. This valve regulates fluid flow, allowing precise control in one direction while permitting free flow in the opposite direction.

Its robust design ensures it can withstand the harsh conditions of marine environments, such as saltwater exposure and extreme temperatures. As a used component, it offers cost-effective performance without compromising quality.

Key Features of the ZRD-ABA-01-S0-D1 Valve

This hydraulic valve is engineered for marine applications, making it ideal for ships, offshore platforms, and other maritime systems. Its compact design allows for easy integration into existing hydraulic setups.

The valve’s throttle mechanism provides adjustable flow control, ensuring smooth operation of hydraulic systems. Additionally, its check valve function prevents backflow, enhancing system safety and efficiency.

Denison’s high manufacturing standards ensure the valve’s reliability, even in used condition. The ZRD-ABA-01-S0-D1 is built to handle high-pressure hydraulic fluids, making it suitable for heavy-duty marine tasks. Its corrosion-resistant materials further enhance its longevity in saltwater environments.

Benefits of Using the Denison ZRD-ABA-01-S0-D1 in Marine Systems

Marine hydraulic systems require components that can endure tough conditions. The Denison ZRD-ABA-01-S0-D1 excels in this regard. Its ability to regulate fluid flow with precision improves the performance of marine equipment, such as winches, cranes, and steering systems. This ensures smoother operations and reduces wear on other system components.

The valve’s check function prevents unintended fluid movement, which is critical for maintaining system stability. By choosing a used Denison valve, marine professionals can access high-quality performance at a lower cost. This makes it an excellent option for budget-conscious operators without sacrificing reliability.

Why Choose a Used Denison Valve?

Opting for a used Denison ZRD-ABA-01-S0-D1 valve offers several advantages. First, it provides access to a premium hydraulic component at a fraction of the cost of a new unit.

Denison’s reputation for quality ensures that even used valves maintain excellent performance. Each used valve undergoes rigorous inspection to ensure it meets operational standards, giving buyers confidence in their investment.

Additionally, choosing a used valve supports sustainable practices by extending the lifecycle of industrial components. For marine applications, where equipment durability is paramount, a used Denison valve delivers both reliability and environmental benefits.

Applications in the Marine Industry

The ZRD-ABA-01-S0-D1 is designed exclusively for marine hydraulic systems. It is commonly used in applications like hydraulic pumps, motors, and actuators on ships and offshore rigs.

Its ability to handle high-pressure fluids makes it ideal for controlling heavy machinery. From cargo vessels to fishing boats, this valve ensures consistent performance in critical systems.

Conclusion

The Denison ZRD-ABA-01-S0-D1 hydraulic throttle check valve is a dependable solution for marine hydraulic systems. Its robust design, precise flow control, and durability make it a valuable asset for maritime operations.

By choosing a used valve, operators can enjoy cost savings while benefiting from Denison’s trusted quality. For marine professionals seeking reliable hydraulic components, the ZRD-ABA-01-S0-D1 is a smart choice that delivers performance and value.

0 notes

Text

Top Reasons to Choose the Denison 703150 Hydraulic Pump for Marine Vessels

When it comes to marine operations, having reliable and efficient equipment is non-negotiable. The Denison Hydraulics 703150 Hydraulic Pump is a standout solution for powering marine hydraulic systems. Engineered for durability and performance, this pump is designed to tackle the toughest challenges of the sea. Whether you’re operating a fishing boat, cargo vessel, or offshore platform, the Denison 703150 ensures smooth and dependable performance. Let’s dive into why this hydraulic pump is a game-changer for marine applications.

Why the Denison 703150 Excels in Marine Environments

The Denison 703150 hydraulic pump is crafted to meet the unique demands of marine settings. Built by Denison Hydraulics, a trusted name in hydraulic engineering, this pump delivers consistent power even in harsh conditions like saltwater exposure and constant motion.

Available in both new and refurbished conditions, it offers flexibility for marine operators balancing performance and budget. Its robust design makes it ideal for critical systems like winches, steering, and propulsion, ensuring your vessel runs smoothly.

Key Features of the Denison 703150 Hydraulic Pump

What makes the Denison 703150 a top choice for marine hydraulic systems? Here are its standout features:

Corrosion Resistance: Built with high-quality materials, the pump withstands saltwater and humidity, ensuring long-term reliability in marine environments.

Energy Efficiency: Optimized fluid dynamics reduce energy loss, lowering fuel costs and boosting operational efficiency.

Durable Build: Engineered to handle vibrations, pressure changes, and heavy loads, the 703150 performs reliably under continuous use.

Precise Control: Delivers steady fluid flow for smooth operation of equipment like cranes, winches, and steering systems.

Easy Maintenance: Designed for simple servicing, the pump minimizes downtime, which is critical for marine operations.

These features make the Denison 703150 a reliable and cost-effective choice for marine vessels.

Benefits of Using the Denison 703150 in Marine Operations

Choosing the Denison 703150 hydraulic pump brings several advantages that enhance vessel performance:

Dependable in Tough Conditions: The pump’s rugged design ensures uninterrupted operation, even in extreme weather or corrosive environments.

Cost-Effective Operation: Its energy-efficient performance and durable construction reduce fuel and replacement costs, saving you money in the long run.

Improved Productivity: Consistent power delivery supports critical systems, minimizing delays and boosting vessel efficiency.

Versatile Applications: From small boats to large offshore platforms, the 703150 powers a wide range of marine equipment.

Trusted Brand: Denison Hydraulics’ reputation for quality gives operators confidence in the pump’s performance.

Marine Applications Powered by the Denison 703150

The Denison 703150 is versatile enough to support various marine systems, including:

Hydraulic Winches: Provides reliable power for anchoring, towing, and cargo handling.

Steering Systems: Ensures precise and responsive navigation for safe vessel operation.

Deck Machinery: Powers cranes and hoists for heavy lifting tasks.

Propulsion Systems: Supports efficient and dependable propulsion performance.

Offshore Platforms: Handles the demands of drilling rigs and other heavy equipment.

Why Choose a Refurbished Denison 703150?

For budget-conscious operators, a refurbished Denison 703150 offers the same high performance at a lower cost. These units are rigorously tested to meet original standards, providing:

Affordability: Significant savings without sacrificing quality.

Reliability: Thorough reconditioning ensures dependable performance.

Sustainability: Extends the life of existing components, supporting eco-friendly practices.

Suppliers like Maritek Solutions offer both new and refurbished units, ensuring you find the right pump for your needs. Contact them at [email protected] for more details.

Tips for Selecting and Maintaining Your Hydraulic Pump

To choose the right hydraulic pump, consider your system’s flow rate, pressure needs, and environmental challenges. The Denison 703150’s corrosion-resistant design makes it a great fit for marine use. For maintenance, regularly check hydraulic fluid levels, inspect for corrosion, clean filters, and follow Denison’s guidelines to keep the pump in top shape.

Conclusion

The Denison Hydraulics 703150 Hydraulic Pump is a reliable, efficient, and durable solution for marine applications. Its ability to withstand harsh conditions, deliver precise performance, and reduce costs makes it a top choice for vessel operators. Whether you opt for a new or refurbished unit, the 703150 ensures your marine systems run smoothly, boosting productivity and reliability. For a trusted hydraulic solution, the Denison 703150 is hard to beat.

0 notes

Text

Reliable Hydraulic Vane Pumps for Marine Applications

Hydraulic systems are essential in the marine industry, powering various onboard operations that demand precision, durability, and efficiency. The hydraulic vane pump is a major component underlying this performance. Designed to deliver consistent pressure and fluid flow, these pumps are ideal for the challenging conditions faced at sea.

What is a Hydraulic Vane Pump?

A hydraulic vane pump is a positive displacement pump with vanes connected to a spinning rotor. These vanes circulate fluid through the system with a smooth, consistent pressure. This type of pump is known for quiet operation, compact size, and high reliability—key qualities for marine use.

Importance of Hydraulic Vane Pumps in Marine Industry

Ships, boats, and offshore platforms rely on hydraulic systems for a wide range of essential tasks. From steering mechanisms to deck machinery, these systems must operate flawlessly under tough conditions. Hydraulic vane pumps help ensure that happens.

Key Advantages for Marine Systems

Durable in Harsh Environments Marine equipment faces constant exposure to moisture, salt, and vibration. Vane pumps are built with strong, corrosion-resistant materials that perform reliably in such conditions.

Smooth and Quiet Operation Noise control is vital on vessels, especially where crews work long hours. Vane pumps produce little noise and vibration, which improves comfort and safety on board.

Energy Efficiency at Sea Fuel efficiency is critical for marine operations. Hydraulic vane pumps reduce power waste and help vessels optimize energy use, lowering fuel costs during long journeys.

Compact Design for Tight Spaces Space is limited on marine vessels. These pumps are compact and easy to install, making them ideal for use in engine rooms, control systems, and below-deck equipment.

Easy Maintenance Simple internal components make vane pumps easy to inspect and service. Routine maintenance reduces downtime and keeps systems running without disruption.

Common Marine Applications

Hydraulic vane pumps are commonly employed in a variety of naval systems, including:

Steering Gear Systems Delivering precise and smooth movement, vane pumps support the safe and efficient steering of ships and boats.

Winches and Cranes On-deck machinery like winches, hoists, and cranes rely on hydraulic power to lift and move heavy loads during cargo handling or anchoring.

Stabilizers and Thrusters Pumps power stabilizing systems that reduce vessel roll and ensure smoother sailing, even in rough waters.

Hydraulic Power Units (HPUs) These units provide power for multiple marine operations, and vane pumps ensure steady hydraulic flow within them.

Hatch Covers and Ramps Vane pumps drive hydraulic systems that open and close heavy hatches, ramps, and doors with precision and control.

Trusted Performance in Marine Conditions

Marine environments demand equipment that performs reliably under pressure. That is why many professionals select the Continental PVX-15B30 RF-P-1SP15017-A Hydraulic Vane Pump for marine applications. It offers high efficiency, quiet performance, and long-term durability, even in the harshest sea conditions.

Conclusion

Hydraulic vane pumps are an excellent investment for marine applications. Their balance of performance, compact size, and energy efficiency makes them ideal for powering essential onboard systems. With the right pump in place, vessels can operate more smoothly, safely, and economically—no matter the sea conditions.

0 notes

Text

Boosting Motor Grader Performance with the SGP-M011720C18 Hydraulic Gear Pump

Motor graders are vital for creating smooth surfaces in construction, agriculture, and mining. The SGP-M011720C18 hydraulic gear pump, designed for the LeeBoy 785 motor grader, ensures these machines deliver top performance. This pump powers critical functions like blade control and steering, making it a key component for heavy-duty tasks.

What is a Hydraulic Gear Pump?

A hydraulic gear pump moves fluid through a system using rotating gears. It creates pressure to power hydraulic components in machinery like motor graders. For the LeeBoy 785, the SGP-M011720C18 delivers steady fluid flow, enabling precise movements and reliable operation.

Why the SGP-M011720C18 Stands Out

This pump is engineered for durability and efficiency. Its compact design fits easily into the LeeBoy 785’s hydraulic system. Made from high-quality materials, it resists wear from dust and extreme temperatures. The pump’s precise fluid control ensures smooth grading, while its low-maintenance design reduces downtime.

Benefits for Operators

The SGP-M011720C18 enhances the LeeBoy 785’s performance. It provides consistent power for tasks like road grading or land leveling. Its efficiency reduces fuel consumption, lowering costs. The pump’s reliability minimizes repairs, keeping projects on schedule. Suryansh, a trusted manufacturer, ensures this pump meets high standards.

Applications Across Industries

This pump supports multiple industries. In construction, it powers road-building tasks. In agriculture, it helps level fields for planting. In mining, it ensures stable terrain for operations. Its versatility makes it ideal for any LeeBoy 785 application.

Maintenance Tips

To keep the pump performing, install it professionally. Regularly check for leaks or debris. Use clean hydraulic fluid to prevent clogs. Follow manufacturer guidelines for maintenance. Monitoring the grader’s performance helps catch issues early.

Why Quality Matters

A reliable pump like the SGP-M011720C18 prevents breakdowns, ensuring safety and efficiency. High-quality components reduce long-term costs and improve productivity. For operators, this pump is a smart investment for consistent results.

Conclusion

The SGP-M011720C18 hydraulic gear pump is a powerhouse for the LeeBoy 785. Its durability, efficiency, and precision make it essential for construction, agriculture, and mining. With this pump, operators can tackle tough jobs with confidence, knowing their equipment will perform reliably.

#SGP-M011720C18#Hydraulic Gear Pump Marine#Marine Pumps#Marine Machinery#Marine Accessories#LeeBoy 785

0 notes

Text

Consilium Marine SAL SD2-6 Speed Log Display: Revolutionizing Maritime Navigation with Precision

Navigating the world’s oceans demands more than just experience—it requires cutting-edge tools that deliver real-time accuracy. For ship captains and crews, knowing a vessel’s exact speed and distance traveled isn’t just helpful—it’s a matter of safety, efficiency, and compliance.

Enter the Consilium Marine SAL SD2-6 Speed Log Display, a game-changing device designed to meet the rigorous demands of modern seafaring. Built by Consilium Marine & Safety, a leader in maritime innovation, this display ensures vessels stay on course, conserve fuel, and avoid hazards.

Why Accurate Speed Measurement Matters at Sea

Every ship’s bridge relies on a speed log display to track two critical metrics:

Speed Through Water (STW): Measures how fast the vessel moves relative to the surrounding water, factoring in currents or tides.

Speed Over Ground (SOG): Calculates the ship’s actual speed using GPS or seabed sensors, essential for precise navigation.

Without this data, crews risk veering off course, wasting fuel, or encountering delays. The SAL SD2-6 simplifies these challenges by providing clear, instant readings, empowering navigators to make smart decisions.

What Sets the Consilium SAL SD2-6 Apart?

This isn’t just another navigation tool—it’s a robust, multifunctional device engineered for reliability. Here’s why maritime professionals trust it:

1. Crystal-Clear Visibility in Any ConditionThe SAL SD2-6’s high-contrast screen shines even in glaring sunlight or pitch-dark nights. Its bold digits and intuitive layout let crews grasp critical data at a glance, reducing errors during high-pressure scenarios like storms or crowded waterways.

2. Dual-Speed FlexibilityWhether your ship relies on water-referenced speed (for engine performance) or ground-referenced speed (for route accuracy), this display adapts. It pairs seamlessly with Consilium’s SAL R1a (single-axis) and SAL T2 (dual-axis) systems, offering versatility for cargo ships, tankers, or luxury cruisers.

3. Built to Endure the Harshest EnvironmentsMarine equipment faces saltwater corrosion, extreme temperatures, and constant vibrations. The SAL SD2-6 tackles these challenges with a rugged, water-resistant casing and a lightweight design (just 630 grams). It’s compact enough for cramped bridges but tough enough for offshore rigs or Arctic routes.

4. Compliance Meets Cutting-Edge TechMeeting SOLAS and IMO standards is non-negotiable for safety-certified vessels. The SAL SD2-6 exceeds these requirements, supporting ships up to 50,000 GT and integrating with radar, autopilot, and AIS systems via IEC/NMEA protocols.

5. Plug-and-Play SimplicityForget complicated installations. The device runs on a standard 10–30 VDC power supply, drawing minimal energy (under 400 mA). Its streamlined setup means less downtime and faster deployment across fleets.

How It Works: Precision Beneath the Surface

The SAL SD2-6 isn’t a standalone gadget—it’s part of a sophisticated ecosystem:

Transducer: Mounted on the hull, this sensor uses acoustic correlation to measure water flow, unaffected by temperature or salinity.

Processing Unit: Converts raw data into actionable insights.

Display: Delivers real-time speed (in knots) and cumulative distance, with options to reset logs for voyage-specific tracking.

For advanced maneuvers, pairing it with Consilium’s SAL T2E system adds lateral speed detection, crucial for docking in tight ports or avoiding underwater obstacles.

Benefits Beyond Basic Navigation

Investing in the SAL SD2-6 isn’t just about compliance—it’s about transforming operations:

Boost Safety: Prevent groundings and collisions with pinpoint speed accuracy, especially in fog or narrow channels.

Slash Fuel Costs: Optimize engine performance by maintaining ideal speeds, reducing consumption by up to 10–15%.

Simplify Training: Crews master the user-friendly interface quickly, minimizing onboarding time.

Cut Maintenance: Corrosion-resistant materials and fewer moving parts mean fewer breakdowns.

Global Support: Consilium’s worldwide network offers 24/7 assistance, spare parts, and software updates.

Who Needs the SAL SD2-6?

From cargo giants to research vessels, this device serves diverse sectors:

Container Ships: Streamline schedules and fuel use on transoceanic routes.

Passenger Ferries: Ensure on-time arrivals and smooth docking for tourist hubs.

Naval Fleets: Enhance tactical navigation during missions.

Offshore Wind Farms: Monitor supply vessels in rough seas.

Finding the Right Supplier

Purchase the SAL SD2-6 through:

Certified Marine Retailers: Verify sellers via Consilium’s website.

Online Platforms: eBay or specialized maritime marketplaces.

Refurbished Options: Budget-friendly picks for older ships, backed by warranties.

Final Take: Sailing Smarter with Consilium

The Consilium Marine SAL SD2-6 Speed Log Display isn’t just a tool—it’s a lifeline for modern shipping. By blending rugged durability with unmatched accuracy, it helps crews navigate confidently, comply with regulations, and protect both profits and the planet.

Ready to upgrade your vessel’s navigation? Contact Consilium Marine & Safety today or explore their catalog for tailored maritime solutions.

0 notes

Text

Discover the Autronica Pressure Transmitter for Marine Systems

When it comes to keeping marine systems running smoothly, the Autronica GT-100 Pressure Transmitter is a top pick. Built to tackle the harsh conditions of the sea, this device delivers accurate pressure readings for critical applications.

Whether you’re managing engine rooms or monitoring fluid systems on a ship, the GT-100 is a reliable tool that maritime professionals swear by.

What Makes the GT-100 Stand Out?

The Autronica GT-100, crafted by a trusted Norwegian brand, is known for its high-quality safety and monitoring gear. It measures pressures from 1.6 to 100 Bar, making it perfect for tasks like tracking fuel systems, ballast control, or hydraulic setups on vessels.

Its 4-20 mA, 2-wire setup ensures easy integration into existing systems, allowing smooth data transfer even over long distances.

The AISI 316 diaphragm resists corrosion from salty marine environments, and at just 1.2 kg, it’s both durable and easy to install—a win for engineers on tight schedules.

Precision You Can Trust

The GT-100 shines with its ±0.75% Full Range Output (F.R.O.) accuracy. This means you get dependable data for critical decisions, whether you’re ensuring safety in the engine room or optimizing a water treatment system.

For instance, in shipbuilding, the GT-100 keeps fuel and ballast systems in check, ensuring safe and efficient operations. It’s also a go-to for offshore oil and gas platforms, where precise pressure monitoring prevents costly downtime or accidents.

Built for Tough Marine Conditions

Marine environments are no joke—saltwater, vibrations, and extreme temperatures can wear down equipment fast. The GT-100 is designed to handle it all.

Its robust build ensures it performs reliably, making it a favorite for maritime professionals who need gear that won’t quit.

Plus, the 2-wire technology simplifies installation and maintenance, saving valuable time when you’re out at sea.

Where to Find the GT-100

Though the GT-100 is no longer in production (replaced by the GT300), it’s still widely available through trusted marine suppliers like Aeliya Marine Tech and Ship Automation.

These vendors often offer new or used units with fast delivery and sometimes a 30-day warranty for peace of mind. Places like Alang, India’s largest ship-breaking yard, are great spots to source cost-effective units for budget-conscious vessel operators.

Tips for Using the GT-100

To get the best out of the GT-100, make sure it’s installed and calibrated correctly for your specific needs. Regular maintenance checks can extend its lifespan, keeping your operations hassle-free.

Whether you’re a ship engineer or a procurement officer, this transmitter is a solid investment for reliable pressure monitoring.

Final Thoughts on the GT-100 The Autronica GT-100 Pressure Transmitter is a must-have for marine applications where precision and durability are key. Its ability to perform in tough conditions, combined with easy integration and trusted performance, makes it a top choice for maritime professionals.

Ready to equip your vessel with this reliable device? Reach out to reputable marine suppliers to grab a GT-100 and keep your systems running like a well-oiled machine!

0 notes

Text

How Liebherr Deck Cranes Boost Marine Efficiency

Liebherr deck cranes are a game-changer for marine operations, offering unmatched power and reliability to handle shipboard tasks. Whether lifting cargo or moving containers, these cranes make work faster and safer. This guide explains how Liebherr deck cranes enhance efficiency at sea, highlighting their key features and benefits.

With over 60 years of expertise, Liebherr builds equipment that thrives in tough ocean conditions. If you’re a ship operator or maritime professional, these insights will show why Liebherr cranes are a top choice for marine deck cranes.

Why Liebherr Deck Cranes Shine at Sea

Liebherr deck cranes are designed to improve ship performance, delivering results in challenging maritime settings. Here’s why they stand out:

Powerful Lifting: They can hoist up to 1,000 tons, perfect for heavy cargo or equipment.

Compact Build: Models like the LS-C series save deck space, allowing more room for cargo.

Green Design: Energy-efficient systems reduce fuel use and emissions, supporting eco-friendly shipping.

Liebherr reports that their cranes maintain 99.6% uptime during operations, ensuring reliability, according to a 2023 study.

Built for Rough Waters

Ship cranes face harsh conditions like salty air and high winds. Liebherr uses sturdy materials and protective coatings to resist corrosion, keeping cranes operational in stormy seas or remote routes.

Standout Features of Liebherr Deck Cranes

Liebherr equips its cranes with cutting-edge technology to ensure safety and productivity. These features make them a top pick:

Precision Control System

The Litronic system offers precise load handling, reducing risks in rough seas. It stabilizes movements to prevent cargo swings, saving time and ensuring crew safety.

Heavy Lift Strength

Liebherr’s LS series cranes excel at heavy lifts, handling up to 1,000 tons. This allows ships to move large equipment without relying on port cranes, cutting costs and delays.

Easy Maintenance

With access to over 50,000 spare parts and a global network of 450 engineers, Liebherr ensures quick repairs, minimizing downtime during voyages.

Tips for Using Liebherr Deck Cranes

To maximize your crane’s performance, follow these practical tips:

Stick to Load Limits: Respect the safe working load (e.g., 40 tons for smaller models) to avoid damage.

Train Operators: Use Liebherr’s training programs to ensure safe, efficient operation.

Check Regularly: Inspect bearings and hoses every six months to catch wear early.

Common Mistakes to Avoid

Avoid these errors to keep your crane running smoothly:

Overloading: Exceeding capacity strains the crane. Always check load charts.

Skipping Checks: Missing maintenance can cause breakdowns. Follow Liebherr’s schedule.

Untrained Crew: Poorly trained operators risk accidents. Invest in certification.

Real-World Impact

BBC Chartering, a global shipping leader, relies on Liebherr cranes for its multipurpose vessels. Their cranes’ precision and strength help BBC handle complex cargo, boosting efficiency and client trust.

Conclusion

Liebherr deck cranes elevate marine operations with power, reliability, and smart design. Their advanced features and durability make them ideal for ships, helping you save time and costs. Start by exploring Liebherr’s models and training options to optimize your vessel. Try these tips to enhance your operations! Explore deck machinery from here.

0 notes

Text

Alfa Laval Gasketed Plate and Frame Heat Exchangers: A Comprehensive Guide

Alfa Laval’s gasketed plate and frame heat exchangers (GPHEs) are industry-leading solutions designed for efficient heat transfer across diverse sectors, including HVAC, food and beverage, chemical processing, and renewable energy.

Renowned for their compact design, high thermal efficiency, and ease of maintenance, these units optimize performance while reducing energy consumption and operational costs.

What is a Gasketed Plate and Frame Heat Exchanger?

A gasketed plate and frame heat exchanger consists of corrugated metal plates assembled between a fixed frame and a movable pressure plate, secured by tightening bolts.

Elastomeric gaskets seal the channels, directing fluids into alternating paths to facilitate efficient heat transfer without mixing.

The corrugated plate design maximizes surface area and promotes turbulence, making GPHEs up to five times more efficient than traditional shell-and-tube heat exchangers.

Key Features of Alfa Laval GPHEs

Alfa Laval GPHEs incorporate innovative features that enhance efficiency and reliability:

High Thermal Efficiency: The herringbone-patterned plates create turbulent flow, enabling approach temperatures as low as 1°F for precise temperature control and energy savings.

Compact Design: GPHEs require less space than shell-and-tube units, reducing installation costs.

Flexible Configuration: Easily adjust capacity by adding or removing plates to meet changing process needs.

Advanced Gasket Technology: ClipGrip™ gaskets ensure superior sealing, easy installation, and extended lifespan, minimizing downtime.

T-Bar Roller and Compact Frame: Simplifies maintenance and maximizes plate capacity in a smaller footprint.

PowerArc™ Plate Pattern: Enhances plate rigidity, preventing elongation and reducing leak risks.

CurveFlow™ Distribution Area: Ensures even fluid distribution, minimizing fouling and optimizing performance.

These features contribute to lower energy consumption, reduced maintenance, and long-term reliability.

Benefits of Alfa Laval GPHEs

Investing in Alfa Laval GPHEs offers significant advantages:

Energy Efficiency: Up to five times more efficient than traditional designs, reducing energy costs.

Cost-Effective: Low capital investment, minimal maintenance, and reduced installation costs lower the total cost of ownership.

Sustainability: Supports heat recovery and aligns with Alfa Laval’s Concept Zero for carbon-neutral heat exchangers by 2030.

Maximum Uptime: Designs that minimize fouling and corrosion ensure reliable operation.

AHRI Certification: Models like AlfaQ™ meet AHRI 400 standards, guaranteeing verified performance for HVAC applications.

These benefits make GPHEs ideal for businesses prioritizing performance and sustainability.

Applications Across Industries

Alfa Laval GPHEs are versatile, serving a wide range of applications:

HVAC: Efficient heating and cooling in district cooling, data centers, and ice-storage systems.

Food and Beverage: Hygienic FrontLine and BaseLine models ensure gentle treatment for dairy and beverages.

Chemical Processing: Industrial ranges handle aggressive fluids, with Diabon® for corrosive media.

Renewable Energy: Supports green hydrogen production and other sustainable processes.

Refrigeration: Semi-welded GPHEs act as evaporators and condensers.

Pulp and Paper: WideGap models manage fibrous fluids without clogging.

Power Generation: Enhances efficiency through engine cooling and heat recovery.

This adaptability ensures GPHEs meet both simple and complex heat transfer needs.

Maintenance and Serviceability

Proper maintenance is key to GPHE longevity. Alfa Laval’s design simplifies servicing with features like the five-point alignment system and bearing boxes. Recommended practices include:

Gasket Replacement: Regular inspections and replacements prevent leaks.

Plate Cleaning: Use cleaning-in-place (CIP) methods to remove fouling.

Capacity Adjustments: Add or remove plates as needed.

Reconditioning: Alfa Laval’s 360° Service Portfolio provides spare parts and performance agreements.

Effective maintenance can save up to 100 GW of energy and reduce CO2 emissions by 50 million tonnes, enhancing both cost savings and sustainability.

Selecting the Right GPHE

Choosing the right GPHE involves evaluating flow rate, fluid properties, and temperature requirements. Alfa Laval offers tools like the PHE Select and HEXpert Selector for customized recommendations, alongside expert consultations to ensure optimal performance.

Conclusion

Alfa Laval gasketed plate and frame heat exchangers set the standard for efficiency, flexibility, and reliability. With advanced features like ClipGrip™ gaskets and PowerArc™ plate patterns, they deliver superior performance across industries.

By prioritizing sustainability and ease of maintenance, Alfa Laval GPHEs offer significant cost savings and environmental benefits. For more information or to select the ideal GPHE, visit Alfa Laval’s website or consult their expert engineers.

#marine#marine machinery#marine systems#marine equipments#maritime industry#Alfa Laval gasketed plate and frame heat exchangers set

0 notes

Text

Amot Control Valves: Essential for Marine Operations

In the demanding world of marine engineering, precision components are vital for vessel reliability. Amot Control Valves excel in regulating fluid flow, pressure, and temperature, ensuring seamless operation in harsh marine environments. Renowned for durability and accuracy, these valves are critical for ship systems facing saltwater corrosion, high pressures, and extreme temperatures.

What is an Amot Control Valve?

Amot Control Valves are engineered to manage the flow of liquids and gases in marine machinery with precision. Their robust design and high-quality materials make them ideal for challenging conditions. Key components include:

Valve Body: Crafted from corrosion-resistant materials like stainless steel or bronze.

Actuator: Ensures precise valve positioning for accurate flow control.

Seals & Gaskets: High-grade materials prevent leaks and enhance durability.

Trim Components: Plug, seat, and stem regulate fluid passage effectively.

The Amot 186799-1 model is particularly valued for its reliability in fuel, cooling, and hydraulic systems.

Key Features of Amot Control Valves

Corrosion Resistance: Built with stainless steel and protective coatings to withstand saltwater exposure.

High-Pressure/Temperature Performance: Operates reliably in extreme conditions, perfect for engine cooling and hydraulic systems.

Precise Flow Control: Maintains consistent pressure and flow, preventing system failures.

Low Maintenance: Durable design minimizes upkeep, reducing downtime and costs.

Marine Compliance: Meets international maritime safety standards, ensuring reliability.

Applications in Marine Systems

Amot Control Valves are integral to various marine operations:

Engine Cooling: Regulates coolant flow to prevent overheating and optimize engine performance.

Fuel Management: Controls fuel supply to engines and boilers, enhancing efficiency and reducing emissions.

Hydraulic Systems: Maintains stable pressure for cranes, winches, and steering mechanisms.

Lubrication: Manages oil distribution to reduce friction and extend machinery life.

Bilge/Ballast Systems: Ensures efficient water flow for vessel stability and safety.

Compressed Air Systems: Regulates air pressure for automation and control systems.

Benefits of Amot Control Valves

Operational Efficiency: Precise control reduces energy use and improves fuel efficiency.

Extended Equipment Life: Minimizes wear on machinery, prolonging service life.

Enhanced Safety: Leak-proof, robust designs ensure reliable performance in extreme conditions.

Cost Savings: Durable materials lower maintenance and repair costs.

Environmental Compliance: Supports efficient fuel use, helping meet strict regulations.

Maintenance Tips for Longevity

To ensure optimal performance, follow these maintenance practices:

Regular Inspections: Check for leaks, corrosion, or unusual noises; inspect seals and actuators.

Cleaning: Remove salt and debris with marine-safe cleaning agents.

Lubrication: Apply marine-grade grease to moving parts for smooth operation.

Calibration: Periodically verify pressure and flow settings.

Part Replacement: Use genuine Amot spares for worn seals or gaskets.

Selecting the Right Amot Valve

Choose the appropriate valve by considering:

System Needs: Match flow rate, pressure, and temperature requirements.

Material Compatibility: Select materials suited for the fluid type (e.g., fuel, water).

Valve Size/Connection: Ensure compatibility with existing pipelines.

Certifications: Verify compliance with standards like ISO, DNV, or ABS.

Supplier Reliability: Purchase from authorized distributors for authentic products and support.

Conclusion

Amot Control Valves, exemplified by the 186799-1 model, are vital for marine operations, offering corrosion resistance, precise control, and durability. Their ability to optimize critical systems like cooling, fuel, and hydraulics ensures efficiency, safety, and compliance. By adhering to maintenance and selection guidelines, marine engineers can rely on Amot valves for smoother voyages and long-lasting equipment performance.

0 notes

Text

Tranberg 9964230 Helideck Floodlight: A Reliable Choice for Offshore Safety

When it comes to offshore helidecks, safety is everything. The Tranberg 9964230 Helideck Floodlight stands out as a trusted solution for lighting up helicopter landing areas in tough marine environments. Designed for reliability and performance, this floodlight ensures pilots can land safely, even in low visibility or harsh weather.

What Is the Tranberg 9964230 Helideck Floodlight?

The Tranberg 9964230 is a xenon-based floodlight built for helidecks on offshore oil rigs, ships, and other marine facilities. Made by R. STAHL Tranberg, a leader in marine and hazardous area equipment, this floodlight meets strict safety standards like CAP 437 and ICAO Annex 14. Its job?

To provide bright, glare-free lighting so pilots can see the helideck clearly during takeoff, landing, or loading operations.

This model is explosion-proof (EEx de IIC T5), meaning it’s safe for use in hazardous areas where flammable gases might be present, like Zone 1 or Zone 2 environments.

With a sturdy stainless steel body and an IP66/67 rating, it’s built to handle saltwater, storms, and extreme temperatures without breaking a sweat.

Key Features of the Tranberg 9964230

Here’s what makes the Tranberg 9964230 a go-to choice for offshore operators:

Powerful Xenon Lighting The floodlight uses a 35W or 50W D2S xenon lamp, delivering intense, white light that cuts through fog, rain, or darkness. Xenon lights are known for their clarity, helping pilots spot the helideck without dazzling their eyes.

Explosion-Proof Design Certified for hazardous areas, the 9964230 is safe in places where gas or dust could ignite. Its EEx de rating ensures it won’t spark, making it ideal for oil and gas platforms.

Durable Build Made from SS316L stainless steel, this floodlight resists corrosion from seawater and harsh weather. The IP66/67 rating means it’s dust-tight and can handle powerful water jets or submersion.

Anti-Glare Optics The light is designed to spread evenly across the helideck without blinding pilots. This meets CAP 437 guidelines, which stress safe, non-dazzling illumination.

Easy Maintenance The xenon lamp is replaceable, and the floodlight’s design allows for quick servicing, even in tough conditions. Spare parts, like the 35W D2S lamp, are widely available.

Flexible Voltage Operating at 230V (50/60Hz), it’s compatible with most offshore power systems, ensuring easy installation.

Why Choose the Tranberg 9964230?

Safety is non-negotiable on helidecks, and the Tranberg 9964230 delivers. Its bright, reliable light helps pilots navigate safely, reducing the risk of accidents during critical operations. The explosion-proof design is a must for hazardous areas, giving operators peace of mind.

Plus, its rugged construction means it can handle years of rough seas and stormy weather without needing constant repairs.

Compared to LED floodlights, xenon models like the 9964230 offer a different kind of brightness that some operators prefer for its crisp, natural look. While LEDs save energy, xenon lights excel in cutting through heavy fog or rain, which is common offshore.

That said, R. STAHL Tranberg also offers LED options like the TEF 9975 for those prioritizing power efficiency.

Applications of the Tranberg 9964230

This floodlight is perfect for:

Offshore Oil and Gas Platforms: Lights up helidecks for safe helicopter landings.

Marine Vessels: Ensures clear visibility on shipboard helipads.

Industrial Facilities: Used in hazardous areas needing bright, safe lighting.

Whether it’s refueling, passenger transfers, or emergency landings, the 9964230 keeps the helideck visible and operational.

Installation and Maintenance Tips

Installing the Tranberg 9964230 is straightforward, but it’s best done by professionals familiar with hazardous area equipment. Mount it securely to avoid vibrations, and ensure it’s positioned to light the helideck evenly without creating glare.

Regular checks are key—clean the lens to remove salt buildup and replace the xenon lamp as needed to maintain brightness.

For maintenance, follow the user manual (available from Tranberg’s website) to ensure compliance with safety standards.

Always use genuine spare parts, like the Tranberg 9400074 xenon lamp, to keep performance top-notch.

Meeting Industry Standards

The Tranberg 9964230 complies with global regulations, including:

CAP 437: UK Civil Aviation Authority standards for offshore helidecks.

ICAO Annex 14: International rules for heliport lighting.

ATEX Certification: Ensures safety in explosive atmospheres.

These certifications make it a trusted choice worldwide, from the North Sea to the Gulf of Mexico.

Where to Get the Tranberg 9964230

You can find the Tranberg 9964230 through R. STAHL Tranberg’s official distributors or marine equipment suppliers like Ship Automation or Lavastica International.

Prices vary, but expect a premium for its quality and certifications. For spares or replacements, check with suppliers like Onrion LLC for xenon lamps or other parts.

Final Words!

The Tranberg 9964230 Helideck Floodlight is a solid investment for anyone prioritizing safety and reliability offshore. Its xenon light, tough build, and explosion-proof design make it a standout for helidecks in demanding environments.

Whether you’re running an oil platform or a marine vessel, this floodlight ensures your helideck is always ready for action.

#Tranberg 9964230 Helideck Floodlight#marine machinery#Marine Products#marine equipments#Marine#Flood Light

0 notes

Text

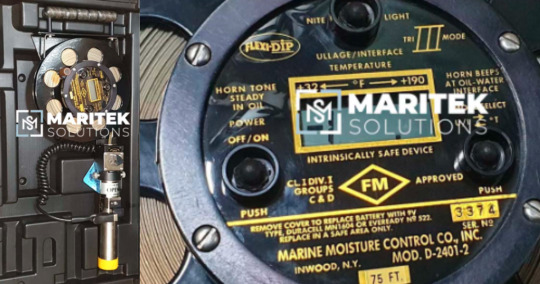

Flexi-Dip D-2401-2 Gauging Tape: A Simple Guide to Tank Measurement

The Flexi-Dip D-2401-2 Gauging Tape is a handy tool used to measure liquids in large tanks, especially in industries like oil, gas, and shipping. If you work with petroleum or chemicals, this device can make your job easier and safer. In this article, we’ll explain what the Flexi-Dip D-2401-2 is, how it works, and why it’s so popular. Let’s dive in!

What Is the Flexi-Dip D-2401-2 Gauging Tape?

The Flexi-Dip D-2401-2 gauging tape made by Marine Moisture Control (MMC), a trusted name in tank measurement tools. It’s designed to check three important things in a tank: the ullage (empty space above the liquid), the oil-water interface (where oil and water meet), and the temperature of the liquid.

This triple-function tool is perfect for people working on ships, barges, or storage tanks because it gives accurate results with just one measurement.

This gauging tape comes with a long, flexible tape—usually 15 to 30 meters (50 to 100 feet)—and a sensor at the end. The sensor is smart enough to detect liquids and tell you what’s inside the tank.

It’s also safe to use in risky environments because it’s "intrinsically safe," meaning it won’t cause sparks or explosions around flammable materials.

How Does the Flexi-Dip D-2401-2 Work?

Using the Flexi-Dip D-2401-2 is simple. You lower the tape into a tank through a special valve or opening. As the sensor moves through the liquid, it makes different sounds to let you know what it finds.

For example, it gives a steady beep when it touches oil and a broken beep when it hits water. This helps you find the oil-water interface quickly.

The tape also has a temperature sensor that shows the liquid’s temperature on a small digital display. Whether you’re measuring in Celsius or Fahrenheit, the readings are clear and easy to understand.

The tape is marked with measurements in meters or feet, so you can see exactly how much liquid is in the tank. Plus, it’s coated to resist static electricity, making it even safer.

Why Choose the Flexi-Dip D-2401-2 Gauging Tape?

There are many reasons why the Flexi-Dip D-2401-2 is a top choice for tank gauging. First, it’s fast and efficient. Instead of using separate tools for ullage, interface, and temperature, you get all three in one go. This saves time and effort, especially on busy worksites like oil tankers or chemical plants.

Second, it’s built to last. The stainless steel sensor and strong tape can handle tough conditions, like harsh chemicals or extreme temperatures. It works in cold weather as low as -40°F (-40°C) and hot conditions up to 190°F (88°C). With a 9-volt battery powering it, the device is lightweight and easy to carry in its sturdy case.

Third, it’s safe and reliable. The Flexi-Dip D-2401-2 meets strict safety standards, like those from BASEEFA and ATEX, which means it’s approved for use in hazardous areas. Whether you’re doing "closed" gauging (through a sealed valve) or "open" gauging (through a hatch), this tool keeps harmful vapors locked inside the tank.

Applications of the Flexi-Dip D-2401-2

This gauging tape is widely used in the maritime and oil industries. On ships, it helps crews measure cargo tanks to ensure they’re loaded correctly. In storage facilities, it checks how much oil or chemical is left. It’s also great for spotting water mixed with oil, which is important for quality control.

Final Words!

The Flexi-Dip D-2401-2 Gauging Tape is a must-have for anyone working with liquid tanks. Its simple design, accurate measurements, and safety features make it stand out. Whether you’re new to tank gauging or a seasoned pro, this tool is easy to use and delivers results you can trust. Next time you need to measure ullage, interface, or temperature, the Flexi-Dip D-2401-2 has you covered!

0 notes

Text

Why the NOREQ Offshore Crane Is Great for Sea Work

When it comes to offshore operations, having the right equipment can make all the difference. The NOREQ HHC 350-100/15 - 29/31 ACTA Offshore Crane is a standout choice for industries like oil and gas, wind energy, and marine construction.

Built with strength and precision, this crane proves itself as a trusted partner for tough jobs at sea. Let’s take a closer look at what makes it so special.

What Is the NOREQ HHC 350-100/15 - 29/31 Crane?

This offshore crane, designed by NOREQ—a company known for innovative maritime solutions—is a powerful tool for lifting heavy loads in challenging environments. The "HHC" stands for Hose Handling Crane, meaning it’s perfect for managing hoses and other equipment on offshore platforms. With a maximum safe working load (SWL) of 10 tons and an outreach ranging from 6 to 29 meters (approved up to 31 meters for man-riding), it’s versatile and dependable.

Whether you’re working on a wind turbine installation or an oil rig, this crane is built to handle the harsh conditions of the sea. It’s even refurbished options are available, blending reliability with sustainability—a win for both your operations and the planet!

Why Choose This Offshore Crane?

One big reason is its durability. The NOREQ HHC 350-100/15 - 29/31 is engineered to stand up to salty air, strong winds, and rough waves. Its robust design ensures it keeps working, even when the weather doesn’t cooperate. Plus, it’s easy to maintain, which saves time and money for offshore crews.

Another perk is its flexibility. With an adjustable outreach of up to 29 meters, it can lift heavy loads at various distances. Need to move equipment far from the base? No problem. Want to handle something closer? It’s got you covered. This adaptability makes it a favorite for projects that demand precision and power.

Built with Expertise and Trust

NOREQ, a Norwegian company with years of experience, teamed up with Acta, a Danish expert in offshore cranes, to create this model. Together, they bring decades of knowledge to the table. The crane even carries CE marking for offshore wind installations, a rare feature that shows its high standards. When you use this crane, you’re relying on proven engineering from a brand that cares about quality.

Perfect for Modern Offshore Needs

Today, industries are pushing for cleaner energy and smarter solutions. The NOREQ HHC 350-100/15 - 29/31 fits right in. It’s been used in wind farms like Borkum Riffgrund 1, helping install turbines that power thousands of homes. Its ability to perform in extreme conditions makes it a go-to for renewable energy projects and traditional offshore tasks alike.

Final Thoughts

If you’re looking for a crane that’s tough, flexible, and backed by expertise, the NOREQ HHC 350-100/15 - 29/31 ACTA Offshore Crane is worth considering. It’s more than just equipment—it’s a reliable helper for getting the job done at sea. Whether you’re lifting hoses, installing platforms, or supporting clean energy, this crane delivers performance you can count on.

0 notes

Text

Alming MAC 18-A-08 MS 60 Marine Air Compressor: A Reliable Choice for Maritime Needs

When it comes to keeping ships running smoothly, the right equipment makes all the difference. One piece of machinery that stands out in the maritime world is the Alming MAC 18-A-08 MS 60 Marine Air Compressor.

If you’re a ship operator or a marine engineer looking for a dependable air compressor, this model might just catch your attention. Let’s dive into what makes it special and why it’s worth considering for your vessel.

What Is the Alming MAC 18-A-08 MS 60?

The Alming MAC 18-A-08 MS 60 is a screw-type marine air compressor designed specifically for the tough conditions at sea. Ships need compressed air for all sorts of tasks—like starting engines, powering tools, or even maintaining onboard systems.

This compressor delivers that air efficiently and reliably. It’s built to handle heavy-duty operations while keeping maintenance simple, which is a big plus when you’re miles away from a service center.

What I love about this model is its compact design. Space is always tight on a ship, and the MAC 18-A-08 MS 60 fits nicely without crowding the engine room.

Plus, it’s engineered to last, cutting down on the need for frequent repairs or spare parts. For anyone who’s dealt with equipment breaking down mid-voyage, that’s a huge relief.

Key Features That Stand Out

This marine air compressor comes with some impressive features. First, it’s a screw compressor, which means it’s quieter and more efficient than older piston-style models.

That’s a win for the crew who don’t want constant noise in the background. It also runs smoothly, even in high temperatures, which is critical when you’re sailing through warm climates.

Another great thing is its durability. The Alming MAC 18-A-08 MS 60 is made to withstand the salty, humid air of the ocean—conditions that can wear out lesser machines fast. And since it’s low-maintenance, you won’t spend hours tinkering with it. Just set it up, let it run, and focus on the rest of your work.

Why Choose This Compressor?

So, why should you pick the Alming MAC 18-A-08 MS 60 over other options? For starters, it’s a practical choice for small to medium-sized vessels where space and reliability matter most.

It delivers steady compressed air for critical tasks, like starting the main engine or running pneumatic tools. Plus, its energy efficiency can help save on fuel costs—a bonus for any ship owner watching the budget.

I’ve heard from folks in the maritime community who swear by this model because it just keeps going, voyage after voyage. It’s not the flashiest piece of gear, but it gets the job done without fuss. And in the unpredictable world of sea travel, that’s what counts.

Final Thoughts

The Alming MAC 18-A-08 MS 60 Marine Air Compressor is a solid pick for anyone needing a tough, efficient, and space-saving solution at sea. It’s easy to see why it’s trusted by marine professionals. If you’re in the market for a compressor that won’t let you down, give this one a look—you might find it’s exactly what your ship needs!

0 notes

Text

What Is the Honeywell XT-XWHM-Y-NA-CS Confined Space Kit?

The Honeywell XT-XWHM-Y-NA-CS Confined Space Kit is a must-have tool for anyone working in tight, hazardous spaces like tanks or tunnels. This article breaks it down in a simple, clear way to show why it’s so useful and how it keeps people safe.

Purpose of the Kit

This kit is designed to detect dangerous gases in confined areas. It includes the GasAlertMax XT II, a multi-gas detector that monitors oxygen (O2), hydrogen sulfide (H2S), carbon monoxide (CO), and combustible gases (%LEL). These are common risks in poorly ventilated spaces, and the kit ensures they don’t go unnoticed.

Importance for Safety

Confined spaces can hide toxic fumes or low oxygen levels. The detector uses lights, sounds, and vibrations to warn users if the air turns unsafe. A built-in pump lets workers test the air before entering, adding extra protection for jobs in utilities, construction, or emergency services.

What’s Included

The kit comes with more than just the detector. There’s a sampling pump, calibration gas, a regulator, filters, a hose, a power adapter, and an IR connectivity kit for data tracking—all packed in a tough carrying case. It’s a complete solution for gas monitoring.

Ease of Use

Simple operation is a big plus. The device works with one button, and its bright screen shows all gas levels at once. The pump runs automatically, pulling air samples without extra effort. It’s lightweight, durable, and even water-resistant for real-world conditions.

Who It’s For

Workers in confined spaces—like sewer technicians or refinery crews—rely on this kit. It helps meet safety standards and prevents accidents, keeping people safe and businesses compliant. Anyone facing gas hazards on the job can benefit.

Standout Features

This kit shines with its smart pump and full accessory lineup. It’s easy to maintain with calibration tools and software included. For more details, see this confined space kit overview. It’s a step above basic detectors for serious safety needs.

Long-Term Reliability

The kit stays dependable with self-tests for sensors and battery life. Calibration every six months keeps it accurate, and its rugged build handles tough environments. With proper care, it’s a long-lasting safety tool.

This Honeywell XT-XWHM-Y-NA-CS Confined Space Kit is a practical choice for anyone working in risky, enclosed areas. It’s easy to use, packed with essentials, and built to protect—making it a smart pick for safety-focused teams.

0 notes