#car door panel injection mold

Explore tagged Tumblr posts

Text

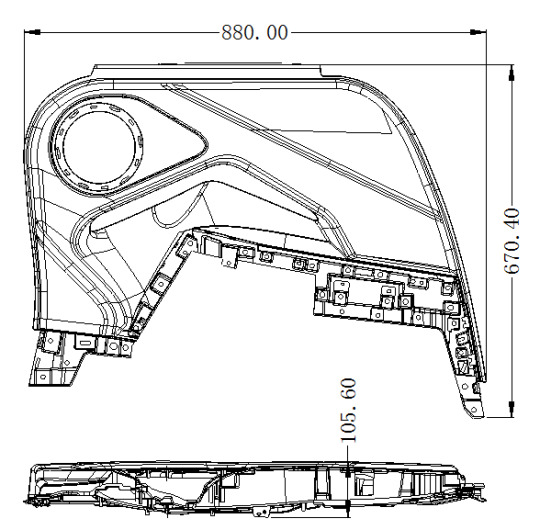

Design of large injection mold for left rear door panel of automobile

Automobile door panels are an important part of automobile interior parts. They are located on the inside of car door and are divided into front, back, left and right. They vary according to car series, usually two doors and four doors. These parts are collectively referred to as door panel series. Below, editor takes left rear door panel of car as an example to explain design points and…

View On WordPress

#automobile door panel injection mold#automobile door panel injection molds#automobile injection molds#automobile molds#automobile plastic part mold#automobile plastic parts#Automotive mold design#automotive plastic parts#car door panel injection mold#Design of demoulding system#Design of lateral core pulling mechanism#door panel injection mold#door panel molds#injection mold#injection mold for left rear door panel#injection mold for left rear door panel of automobile#mold design#mold designers#Mold exhaust system design#mold structure design#Mold working process#molding part design#plastic mold#plastic part#Structural analysis of plastic parts

0 notes

Text

1958 chevrolet bel air impala convertible

History, The Impala name was first used for the full-sized 1956 General Motors Motorama show car that bore Corvette-like design cues, especially the grille. It was named Impala after the graceful African antelope, and this animal became the car's logo. Painted emerald green metallic, with a white interior, the Impala concept car featured hardtop styling. Clare MacKichan's design team, along with designers from Pontiac, started to establish basic packaging and dimensions for their shared 1958 General Motors "A" body in June. The first styling sketch that would directly influence the finished Chevrolet automobile was seen by General Motors Styling vice president Harley Earlin October. Seven months later, the basic design was developed.

For its debut in 1958, the Impala was distinguished from other models by its symmetrical triple taillights. The Chevrolet Caprice was introduced as a top-line Impala Sport Sedan for model year 1965, later becoming a separate series positioned above the Impala in 1966, which, in turn, remained above the Chevrolet Bel Air and the Chevrolet Biscayne. The Impala continued as Chevrolet's most popular full-size model through the mid-1980s. Between 1994 and 1996, the Impala was revised as a 5.7-liter V8–powered version of the Chevrolet Caprice Classicsedan.

First generation (1958)

1For 1958, GM was promoting their fiftieth year of production, and introduced anniversary models for each brand; Cadillac, Buick, Oldsmobile, Pontiac, and Chevrolet. The 1958 models shared a common appearance on the top models for each brand; Cadillac Eldorado Seville, Buick Roadmaster Riviera, Oldsmobile Super 88 Holiday, Pontiac Bonneville Catalina, and the #Chevrolet Bel-Air #Impala.

The Impala was introduced for the 1958 model year as top of the line Bel Air hardtops and convertibles. From the windshield pillar rearward, the 1958 Bel Air Impala differed structurally from the lower-priced Chevrolet models. Hardtops had a slightly shorter greenhouse and longer rear deck. The wheelbase of the Impala was longer than the lower priced models, although the overall length was identical. Interiors held a two-spoke steering wheel and color-keyed door panels with brushed aluminum trim. No other series included a convertible.

The 1958 Chevrolet models were longer, lower, and wider than its predecessors.The 1958 model year was the first with dual headlamps. The tailfins of the 1957 were replaced by deeply sculptured rear fenders. Impalas had three taillights each side, while lesser models had two and wagons just one. The Impalas included crossed-flag insignias above the side moldings, as well as bright rocker moldings and dummy rear-fender scoops.

The standard perimeter-type frame was abandoned, replaced by a unit with rails laid out in the form of an elongated "X." Chevrolet claimed that the new frame offered increased torsional rigidity and allowed for a lower placement of the passenger compartment. This was a transitional step between traditional construction and the later fully unitized body/chassis, the body structure was strengthened in the rocker panels and firewall.However, this frame was not as effective in protecting the interior structure in a side impact crash, as a traditional perimeter frame.

A coil spring suspension replaced the previous year's rear leaf springs, and an air ride system was optional. A 283 cu in (4,640 cc) engine was the standard V8, with ratings that ranged from 185 to 290 horsepower. A "W" block (not to be confused with the big-block) 348 cu in (5,700 cc) Turbo-Thrust V8 was optional, producing 250 hp (190 kW), 280 hp (210 kW), or 315 hp (235 kW). The Ramjet fuel injection was available as an option for the Turbo-Fire 283 V8, not popular in 1958.

A total of 55,989 Impala convertibles and 125,480 coupes were built representing 15 percent of Chevrolet production. The 1958 Chevrolet Bel Air Impala helped Chevrolet regain the number one production spot in this recession year.

3 notes

·

View notes

Text

Mitsubishi Debonair V AMG version.

AMG is a tuning manufacturer in West Germany that specializes in German luxury cars. Its technical capabilities are widely recognized and highly evaluated by the general public. 3000 Royal AMG is a full-fledged European sporty sedan forged by this prestigious tuner.

■AMG aero parts consist of front bumper spoiler, front grille, side step panel, door protection panel, rear spoiler, rear bumper spoiler, rear end panel, and wheel cut molding.

A form that further refines the aerodynamics of the original body. The impression of its styling can be said to be a splendid fusion of personality and sporty image. Equipped with low-profile tires and aluminum wheels and electronically controlled suspension to support fast and safe driving. From the day you own this car, highway dominance will be yours. The interior also features an AMG-designed steering wheel. The Debonair V3000 Royal AMG is full of Senmou's European spirit in both its exterior and interior.

Body Color: Sarajevo White

■ Seat color: Gray (optional leather seats are beige)

■ Interior base color: Gray

Pictured from left: AMG design steering wheel, AMG design aluminum wheels & 205/60R15-89H tires, dual exhaust pipes.

Debonair V3000 Royal AMG Cyclone V6 3000 engine ELC 4-speed full automatic with OD Main equipment Air conditioning & audio remote control switch Cruise control Auto lighting control 205/60R15-89H tires

Front 5-layer laminated glass (bronze) Electric retractable door mirror Soft touch heater control AMG aero parts Driver's seat power seat Rear power seat AMG Steering wheel ELR seat belt with electric tension reducer Dual auto air conditioner (microcomputer)

MITSUBISHI DEBONAIR V 3000 ROYAL AMG

The Debonair V3000 Royal AMG, which gives the image of driving on the European autobahn. The exterior, suspension, and equipment all feature high-quality specifications unique to this car.

ENGINE BOX

Unprecedented responsiveness and quietness. Advanced driving with Cyclone V6 engine.

What the times demand from engines is not just high power or low-speed torque. It is the response performance that can pick up the power you want when you need it, and the quietness that makes you feel the high quality. In other words, it can be said that it is a high-performance car that truly values the sensibilities of the rider. Mitsubishi's cyclone engine was born by refining everything to meet such demands. And the Cyclone V6 3000 engine of the Debonair V3000 Royal AMG is a proud power unit that stands at the top of them. Achieved new performance and excellent quietness in the entire range from low speed to high speed while achieving compactness and weight reduction. In addition, ECI-MULTI (Multi-Point Injection), which always supplies the best air-fuel mixture and controls accurate fuel injection timing and appropriate ignition timing for each of the six cylinders, is also adopted. Also, in each process of intake, combustion and exhaust, advanced technologies such as manifolds with optimal shape and diameter, dual exhaust system and compact combustion chamber are incorporated.

BOTTOM INFO SECTIONS FROM LEFT

door-linked high-tilt steering,

Light operability created by ELC4A/T with OD.

A driver's seat that secures a wide field of vision and enhances safety. The electronically controlled power steering employs door-linked high-tilt steering that hops up when the driver's side door is opened to facilitate boarding and exiting. Equipped with a cruise control that automatically maintains the set vehicle speed, an ELC 4-speed full automatic transmission with OD that electronically controls for smooth shifting, and a steering audio remote control switch that allows remote control of audio from the steering wheel. As an option, a hands-free car telephone is also available, which allows you to talk without having to use both hands.

The spaciousness of the interior of the FF and its excellent quietness make it a truly relaxing place to live.

Debonair V achieves top-class spaciousness in the interior and trunk room with the FF (front wheel drive) system. Beneran instrument panel pads with a leather touch and urethane-injected floor mats that create a soft feel further enhance the quality of living. The driver's seat and rear seats are equipped with electric power seats that can be adjusted steplessly. In addition, the adoption of a flush body and triple weatherstripping achieves excellent quietness, and is equipped with a high-power audio system with Diatone ASS that adds value to a quiet space.

Optional leather seats are also available.

Safety and reliability brought by electronically controlled suspension and 4-wheel ventilated disc brakes.

Equipped with an electronically controlled suspension that automatically controls suspension characteristics and vehicle height to provide stable driving with consistently high marginal performance. The braking system is equipped with 4-wheel ventilated disc brakes with excellent heat dissipation. The body uses high-quality paint to improve durability and rigidity, integrally molded doors, and new anti-corrosion steel plates. In addition, the front five-layer laminated glass that reduces the impact on the driver in the event of an accident, and ETACS, which electronically controls various timers and alarms, protects irreplaceable safety from all angles.

Door-linked high-tilt steering (with memory) Auto door lock High-power audio with Diatone ASS (B speaker Audio steering remote control switch Electric suspension AMG aluminum wheels Electronic control power steering 4-wheel pentillated disc brakes

36 notes

·

View notes

Text

The newly introduced Car Parts Injection Mold is engineered with a focus on precision, ensuring that each car component produced meets exacting standards. This precision in molding allows for the creation of intricate and complex designs with unparalleled accuracy. From door panels to interior trims, the mold elevates the quality of automotive components, contributing to the overall performance and aesthetic appeal of vehicles.

0 notes

Text

PP Products

PP products are made from polypropylene, a thermoplastic polymer material known for its high chemical and corrosion resistance, low density, and excellent fatigue resistance. PP products have various applications in industries such as packaging, textiles, automotive, and construction for things like sheets, rods, and tubes. PP products are a popular choice due to their durability and versatility.

Types of PP Products

PP Sheet

A PP sheet refers to a flat, solid component made from polypropylene (PP), a thermoplastic polymer. PP sheets are known for their excellent chemical resistance, high impact strength, and lightweight nature. They are commonly used in various industries for applications such as packaging, automotive parts, signage, and construction materials.

PP Rod/Bar

A PP rod/bar refers to a cylindrical component made from polypropylene (PP), a thermoplastic polymer. PP rods/bars are known for their excellent chemical resistance, high impact strength, and lightweight nature. They are commonly used in various industries for applications such as machining, fabrication, and structural support.

Other PP Products

PP products refer to a wide range of items made from polypropylene (PP), a versatile thermoplastic polymer. PP is known for its excellent chemical resistance, high impact strength, and lightweight nature.

Why Choose Xinrui's PP Products

High-Quality Material – Xinrui uses high-quality polypropylene plastic (PP) materials, ensuring that their products are robust, durable, and long-lasting. The material also has high impact resistance, which means that it can withstand wear and tear during usage.

Customizable – Xinrui offers customizable PP products that can be tailored to the specific needs of a customer. They can be modified to fit the desired design, size, and color.

Comprehensive Product Line – Xinrui has an extensive range of PP products to choose from, including corrugated sheets, boxes, bins, crates, and trays, making it a one-stop shop for all PP product needs.

Eco-Friendly – Since PP is a recyclable material, Xinrui's products are considered environmentally friendly. As a result, customers can be assured that they are contributing to the sustainable management of plastic by using these products.

Exceptional Service – Xinrui is known for providing exceptional customer service and support. They focus on listening to the customer's needs and providing them with tailored services and solutions that meet specific demands.

Polypropylene Plastic Uses & Applications

Polypropylene (PP) plastic is a versatile material that has a wide range of applications in various industries. Here are some common uses and applications of PP plastic:

Packaging - PP plastic is widely used in packaging applications, such as food packaging, beverage containers, and shipping boxes. PP plastic offers high strength and barrier properties to protect and preserve the contents from external factors like moisture, light, and temperature.

Automotive Industry - PP plastic materials are used in automotive components such as car battery cases, under-the-hood components, door panels, and interior trims for their strength and durability.

Textile Industry - PP is used to produce a range of textiles used for medical and personal hygiene products like diapers, sanitary napkins, and medical gowns, and industrial materials like geotextiles.

Injection Molding - PP plastic is an excellent material for injection molding because it can retain its shape well after hardening, allowing for complex shapes and designs for a wide range of products like toys, caps, containers, and kitchenware.

Medical Devices - PP plastic is suitable for manufacturing medical devices due to its hygienic nature and chemical resistance. It is often used in applications like disposable syringes, surgical trays, and medical implants.

Stationery Products - PP plastic is a popular material for making stationery items such as sheet protectors, file folders, storage bins, labels, and wallets.

Construction Industry - PP is used to produce many components and materials for the building and construction industry, such as pipes, insulation, roofing, cladding, and flooring.

0 notes

Text

Exploring the Vital Role of Automotive Fasteners and Their Production Materials.

Auto part manufacturers rely on various joining mechanisms! They often need to join and connect other components to panels. From dowels and clevis pins; to screws, bolts, and nuts Many fasteners can be used in this scenario! Automotive fasteners are essential components that keep parts together. A range of panel fasteners are engineered to meet manufacturing requirements in automotive industries and other industries such as electronics, construction, aerospace, HVAC, and more.

The Importance of Automotive Fasteners

The images of diverse engine parts, hefty doors, or wheels come to mind when we think of automotive parts. The truth is that the typical vehicle consists of over 30,000 tiny pieces! The majority of them are classified under the automotive fastener category. The term "fasteners" is a collective noun that refers to all small parts like bolts, nuts, screws, spacers, or springs. Most of them are used in almost all car components. You must choose the right one and the right material before its application.

Automotive panel fasteners are available in a variety of sizes and designs, are adaptable, and may be replaced. They firmly arrange car parts by mechanically holding them together. Except for rivets, all automotive fasteners are typically temporary. It suggests that it should be possible to separate the parts from one another without causing any damage after removing the fastener. Additionally, the purpose of automotive fasteners need not be confused with that of glues and adhesives. Because they use tensional force to affix automotive parts, they are distinct from one another. As a result, a vehicle is unharmed under adverse circumstances (such as an accident) or after speed bumps.

The Materials Used in Automotive Fasteners?

Two fastener types are mainly employed in automobile projects. These are:

1. Metal Fasteners: The most frequent materials used in automotive projects are iron or aluminum alloy. The majority of bolts are covered in zinc to prevent rust and increase longevity because it is typically the most resilient and reusable material. Produced from wire and bar stock, bolts, screws, nuts, and spring fasteners are used to secure large objects, engine parts, and suspension components.

2. Plastic Fasteners: Plastic fasteners are frequently used to make connections, pins, washers, and spacers. Plastic fasteners are produced by injection molding and are made of vinyl. The materials are less expensive and don't conduct heat or electricity or rust.

The most important factors to consider while shopping for car panel fasteners are dependability, security, and time efficiency.

Trusted automotive panel fastener solution providers like Car Clip Supplier ensure you have a reliable product irrespective of your need. You can use their products for better fastening and reduce your cost of repairing & maintenance! If you have questions about automotive panel fastening solutions, reach out to Car Clip Supplier at 0499001004 today.

0 notes

Text

Importance of Mitsubishi Clips

Automotive makers are searching for more and more ways to lightweight a vehicle as the demand for Electric Vehicles rises and fuel-efficiency rules tighten. They've done this, by substituting injection-molded snaps and fasteners for conventional metal clamps. Unfortunately, it is not always easy to do this type of work.

They are crucial to maintaining the polished appearance of your car. Automobile parts that are only partially attached result from vehicle panel clips that pop out due to regular wear and tear or break-in collisions and incidents. You can securely fix broken clips, door trim panels, inserts, and more with our wide variety of mitsubishi clips and metal fasteners! The Mitsubishi clip is a useful item.Design, material, tooling, injection molding, and validation testing knowledge are all necessary when designing a plastic part to replace a metal component.

Mitsubishi clipsFastening Strategies

Automotive manufacturers have access to a huge library of various fastening clip designs that they can use and improve. The tree, hand-grip, and rib-cage patterns are just a few examples of the small, delicate details included in many of these designs, all of which are susceptible to flashing and packaging concerns. These problems may result in performance failures if not handled properly with precise tooling.Design is what matters most in the end. Parts that work poorly or cannot be created result from improper feature spacing, a lack of material, an excess of material in some places, etc.

There isa library of clip and fastening designs that have been tested and are in use by significant automotive OEMs below. To surpass performance requirements, these design components can be merged and adjusted.It is frequently used for the rear center brake lights, dashboards, engine covers, air cleaner boxes, and pipes. Some vehicles' interior trimmings are made by Mitsubishi. Some variants have Suzuki motorbike fairings & interior trim.

0 notes

Text

CNC auto Parts factory in China - JTC Machining

Enhancing Automotive Production

As the automotive industry continues to evolve, customers are demanding more control, precision, and personalization. JTC Machining is partnering with value-driven automotive companies and part manufacturers to make high-quality components for lighter and faster cars. Our production and digital manufacturing services include CNC machining services, 3D printing, and plastic injection molding. All of our services can be leveraged to meet industry trends like autonomous driving, hybrid drive trains, and high-end, user-specific customizations.

With size, speed, weight, and fuel consumption remaining crucial to market success, JTC Machining has worked with many high-end brands to explore the frontiers of electric vehicle production, spare part manufacturing, cleaner fuel combustion, and just-in-time inventory management. Through our quote and design for manufacturability feedback, we can collaborate with designers and engineers to mitigate process failure, improve test qualities, shorten product development cycles, and deliver flexibility to automotive supply chains.

CNC auto Parts factory in China - JTC Machining

Why does the Vehicle and Automobile Industry Trust Us?

Shorter Product Development Cycles

JTC Machining has an on-demand manufacturing process that accelerates automotive product development. Through 3D printing and CNC machining services, automotive designers and engineers can drive product development from idea to rapid prototypes in a matter of hours and arrive at final parts in as quick as 72 hours.

Rapid Prototyping

Manufacture high-quality prototypes of replacement parts, fixtures, tooling, and OEM components tailored towards faster product development and functional testing. Our rapid prototypings are suitable for pilot testing and marketing showpieces, helping you mitigate design risks before moving to mass production.

Classic/Obsolete Part

JTC Machining can help you make OEM, aftermarket parts, and components for older vehicles, custom automobiles, and vintage fleets no longer available on the market.

User-specific Customization

Our digital manufacturing solutions, like 3D printing and CNC machining services, have been optimized to meet your end-users' demands. This allows an array of finishing techniques for high customization and personalization to the taste of each driver.

Cost-savings

Save cost on production by using our rapid tooling and digital manufacturing to eliminate expensive tooling costs and make your parts on demand. Our design-for-manufacturability analysis from our production experts will also highlight multiple design areas that can be optimized for cost-effectiveness.

Quality Guaranteed

At JTC Machining, ours is a guarantee of quality. Our one-stop-shop services mean that your parts are made in-house from start to finish. Our stringent quality control system and robust process control also mean that automotive designers and engineers can be guaranteed part consistency and excellent finish, all made to specifications.

What can we make for you?

Our general manufacturing techniques for the automotive industry can be used for any of the following:

Interior parts

Dashboard

Dashboard components

Panels and finishes

Ergonomic seats

Knobs and dials for electronic components

Exterior parts

Fenders

Bumpers

Doors

Hoods

Stylings

Side skirts

Frames

Front lips

Grilles

Headlights, tail lights, and lamps

Mechanical components

Shafts

Cylinders

Engine components

Bearings

Radiators

Suspension parts

Shock absorbers

Struts

Springs

Coils

Bushings

Linkages

Stabilizers

Axles

Obsolete parts

Customized/Aftermarket parts

Aftermarket upgrade kits

Exotic bumpers

Bespoke accessories

Emblems, customized branding

Custom head and tail lights

Lightweight, high-strength components

Rapid tooling

Custom tools suited for specific/one-off repair tasks.

OEM-substitute parts to prevent costly downtimes.

Quick auto components to augment just-in-time manufacturing

Complex parts

Vehicle components with complex and intricate geometries.

The Clients We Serve

The automotive industry is vast, consisting of many players serving various purposes. At Premium part, our range of automotive manufacturing services can serve and meet the needs of these players. Through high-quality CNC machining service, plastic injection molding, 3D prototyping service, pressure die casting, Sheet metal fabrication, and polyurethane vacuum casting, we can serve:

Automobile manufacturers

OEM part manufacturers

Automobile design studios

Aftermarket part suppliers

Vehicle servicing outlets

Spare part wholesalers and manufacturers

Industrial and agriculture equipment suppliers

Repair hubs and mechanic workshops

Vehicle customization outlets

Automotive Manufacturing Materials

Nylon

Nylon 6 and 66 are the most widely used engineered thermoplastics in the automotive industry. They can be 3D printed to make rapid prototyping, and maybe mineral or glass-filled when higher strength is required. It is coveted for its high strength, low cost, high dimensional stability, and excellent resistance. It is applied in making crankcases, timing belts, cylinder head covers, cams, bushes, gears, bearings, oil containers, wire harness connectors, and fuse boxes.

Thermoplastics

Explore an array of thermoplastic resins to make functional, attractive end-use automotive components for any function. We stock the most popular thermoplastic for automotive production, including Acetal, PEEK, Polypropylene, PVC, ABS, Polystyrene, Polycarbonate, and more.

Thermoplastics can deliver high strength, design flexibility, no-corrosion, and UV resistance for applications in vehicle design.

Elastomers

LSR is used for custom O-rings, gaskets, seals, self-lubricating components, harnesses, and damper components. Because of their mechanical properties, elastomeric materials are suitable for flexibility, self-lubricating, and high-performance applications within vehicles.

Aluminum

Aluminum is widely sought in the automotive industry for its excellent strength and lightweight. Aluminum parts are corrosion-free. They are also easily CNC machined, 3D printed, and formed into intricate geometries.

Aluminum is affordable and readily available for use in making a wide array of parts. It can also be finished in a variety of ways to boost appearance and functionality.

Our Automotive Manufacturing Services

CNC Machining Services

CNC milling and turning operations for making automotive components with intricate geometries, cylindrical shapes, and high precision. CNC machining services are capable of producing parts with tight tolerances. It is also excellent for finishing and adding details to your part.

Sheet Metal Fabrication Services

Our sheet metal fabrication can help you fabricate parts with high strength-to-weight ratios from light layers of metal alloys. Automotive components can be formed through bending, pressing, punching, and more.

Plastic Injection Molding

Plastic Injection molding is used to make plastic parts in significantly high volumes. At JTC Machining, we can create high-quality plastic parts with several resins. This allows you to choose the best materials based on the mechanical and cosmetic needs of your part. Our injection-molded parts can also be finished in multiple ways.

3D Printing

3D printing can be used for rapid prototyping and rapid tooling. Through SLA, SLS, FDM, and more, JTC Machining can make functional prototypes and end-use parts with the most complex shapes and geometries from your CAD files.

Vacuum casting

At Premium part, our vacuum casting has been widely used for making low-volume copies of a piece with excellent cosmetic finishes. With the use of a 3D printed master pattern, our vacuum casting operation will use elastomers to make your final part without the need for any capital tooling cost.

Pressure Die Casting

Pressure die casting is suitable for making large volumes of metal parts with a high level of detail and dimensional stability. Our pressure die casting service is cost-effective and affordable, lowering the unit cost per part. Castings can also be finished in a range of options.

Compliment Your Part With Our Finishing Options

Our range of production techniques can be further enhanced with our finishing services. We understand the need to compliment part quality with cosmetic excellence. This is why we offer several finishing options for augmenting the surface finish of your part. Our finishes are decorative, aesthetic, and in some instances, functional. See below the list of finishing options we offer for your automotive parts:

Texturing

Anodizing

Polishing

Blasting

Painting

Electroplating

Passivation

Heat treatment

Powder coating

Custom

Ready. Set. Push to Start

Ready to begin on your next project? Upload your files through our website and receive a free quote and design-for-manufacturability analysis. Our expert engineers will send you suggestions on how best your design can be optimized for cost-effectiveness and ease of production. At JTC Machining, we understand the automotive industry's peculiarities, and the ever-evolving needs to meet future agility and performance. Please work with us and take advantage of our high quality, shorter product development cycles, and production volume flexibility. Upload your CAD prototype design and receive your free quote now!

0 notes

Text

How It’s Made Index(S01~S10)

How It’s Made是由 Discovery Channel 制作一款王牌节目,又被翻译为制造的原理或造物小百科, 本片从2001年推出至今,涵盖了几乎所有的制造技术 ,非常适合机械专业和对此感兴趣的同学。希望大家享受这趟制造的艺术之旅!

第一季推出时间为2001-01-06至2001-03-31

S01E01 Aluminum foil, Snow Boards, Contact lenses, Bread. 铝箔,雪橇板,隐形眼镜,面包

本集看点:铝锭是如何一步步用轧制工艺压制成像纸一样薄的铝箔的;

S01E02 Compact Discs; Mozzarella Cheese; Pantyhose; Fluorescent Tubes. 光碟,奶酪,女式连袜裤,荧光灯管

本集看点:CD光盘是怎么从模具注塑出来的;玻璃管的热弯,以及荧光灯复杂的自动化制程;

S01E03 Toothpicks; Acrylic Bathtubs; Helicopters; Beer. 牙签,玻璃纤维增强塑料浴缸 ,直升机,啤酒

本集看点:牙签的制作,是类似于螺钉,是先用木材做成木板再切割而成;塑料的吸塑制程,玻璃纤维+树脂强化制程;碳纤维制作的飞机支架;

S01E04 Hearing Aids; 3-D Puzzles; Rubber Mats; Toilets 助听器,三维拼图,胶垫,抽水马桶

本集看点:用模具制作陶瓷的加工制程;

S01E05 Copy Paper; Jeans; Computers; Plate Glass 复印纸,牛仔裤,电脑,平板玻璃

本集看点: 浮法平板玻璃的制作过程;

S01E06 Nails and Staples; Safety Glasses; Fabrics; Bicycles 钉子,护目镜,布匹,自行车

本集看点:一卷钢丝的艺术之旅;透明塑胶模具的高亮抛光;线全自动编制成布;自行车架的焊接与喷涂工艺;

S01E07 Kayaks; Safety Boots; Electronic Signs; Cereals 皮划艇,安全靴,电子招牌,麦片粥

本集看点: 热塑性塑料的成型方法加工,不需要压力,只需要加热和摇晃即可;LED制成的大型广告或体育比赛显示屏

S01E08 Trucks; Adhesive Bandages; Computer Circuit Boards; Liquors 卡车,创口贴,计算机电路(PCB),酿酒(威士忌)

本集看点:SMT和波峰焊制程(单面器件),目前手机等产品已经主要使用回流焊制程;

S01E09 Steel; Apple Juice; Aircraft Landing Gear; Cosmetics 钢铁,苹果汁,起落架,化妆品

本集看点:钢铁是怎样练成的;车削和铣削加工,喷砂工艺,外观电镀处理;

S01E10 Holograms; Package Printing; Skin Culture; Canned Corn 全息摄影,包装盒,皮肤培植,罐装玉米

本集看点:还是不懂的全息摄影和底片冲洗;

S01E11 Plastic Bags; Solar Panels; Plastic Gasoline Containers; Hockey Sticks 塑料袋,太阳能电池板,塑料汽油桶,曲棍球棍

本集看点:塑料袋通过聚乙烯吹膜制程制作;吹塑制作塑料桶;

S01E12 Aluminum Screw Caps; Chocolate; Pills; Pasta 铝瓶盖,巧克力,药丸,面食

本集看点:铝合金的拉伸制程;

S01E13 Bicycle Helmets; Aluminum; Car Brakes; Lithium Batteries 自行车头盔,铝,汽车刹车,锂电池

本集看点:聚苯乙烯发泡注塑;电解铝制程,制作成铝锭;电池是怎么卷出来的;

本季资源链接:

magnet:?xt=urn:btih:e1ec692441019f65979f29e09bc9f84b3bdf563e&dn

第二季推出时间为2002-09-07至2002-12-07

S02E01 Eyeglass Lenses; Granite; Potato Chips; Microprocessors 眼睛镜片,花岗石板,薯片,微处理器

本集看点:塑胶镜片的抛光和AR镀膜;芯片的封装制程;

S02E02 Honey; Fiber-Optics; Bricks; Pipe Organs 蜂蜜,光纤,砖块,管风琴

本集看点:玻璃管拉丝成为光纤;

S02E03 Personal Watercraft; Wine; Office Furniture; Ice Skates 水上摩托,葡萄酒,办公家具,溜冰鞋

S02E04 Winter Jackets; Animation; Mushrooms; Gold Rings 冬季夹克衫,动画片,蘑菇,金戒指

本集看点:用 熔模铸造工艺制作魔戒;

S02E05 Hydroponic Lettuce; Construction Wood; Recycling; Fishing Flies 水培莴苣,建筑木材,垃圾回收,假蝇饵

本集看点:完全工业化种菜;

S02E06 Diamond Cuttings; Wood Doors; Paintballs; Newspapers 切割钻石,木门,彩色球,报纸

S02E07 Carpets; Drinking Water; Laser Eye Surgery; Acoustic Guitars 地毯,饮用水,激光眼科手术,吉他

S02E08 Fiberglass Boats; Clothes Dryers; Bubble Gum; Fireworks 玻璃纤维艇,干衣机,泡泡糖,焰火

本集看点:玻璃纤维+树脂制作的船体上盖;钢板制作圆筒;

S02E09 Steel Safes; False Teeth; Airplanes; Maple Syrup 保险箱,假牙,轻型飞机,枫糖浆

本集看点:来了,玻璃纤维+树脂制作的飞机机身;

S02E10 Gummies; Aluminum Cans; Fish Farming; Bronze Sculptures 花色软糖,易拉罐,养鱼,青铜雕塑

本集看点:可口可乐,来一罐!

S02E11 Aluminum Pots and Pans; Artificial Limbs; Peanut Butter; High Intensity Light Bulbs 旋压铝制品,假肢,花生酱,高光灯泡

本集看点:用旋压而非拉伸制作的铝合金罐子和盖子,两种方式各有优势;

S02E12 Cars; Grocery Carts; Rapid Tooling and Prototyping; Collectible Coins 小汽车,购物车,快速模具成型,纪念币

本集看点:钣金的加工制程,电阻焊;3D打印树脂零件,浇铸工艺及其模具制作;银币复杂的图案转移过程;

S02E13 Ball Bearings; Electrical Wires; Lost Wax Process Casting; Automated Machines 轴承,电线,熔模铸造,自动化机器

本集看点:钢球的制造过程(冲压+研磨); 熔模铸造的金属铸造件, 熔模本身也是通过模具制造的;极其舒适的全自动化制造过程合集;

本季资源链接:

magnet:?xt=urn:btih:543050ad51e44c744d235680efec5db2693724f7&dn

第三季推出时间为2003-10-01至2003-12-30

S03E01 Pre-inked Stamps; Cranberries; Cotton Yarn; Road Signs 原子章,酸果,棉纱,交通标志

本集看点:丝印网板的制作过程;

S03E02 Combination Locks; Pottery; Recreational Vehicles; Erasers 字码锁,陶器,休闲拖车,橡皮擦

本集看点:如何用模具制作陶罐;

S03E03 Wheel Loaders; Vegetable Oil; Hand Tools; Cotton Swabs 轮式装运机,植物油,手动工具,棉签

S03E04 Temporary Metal Fences; Asphalt Shingles; Polystyrene Products; Hard Candies 金属栅栏,沥青屋面板,泡沫板,花式硬糖

本集看点:泡沫发泡制程;

S03E05 Horse-drawn Carriages; Artificial Eyes; Dog and Cat Food; Mirrors 老式马车,假眼,猫粮和狗粮,镜子

S03E06 Yogurt; Candles; Neon Signs; Bookbindings 酸奶,蜡烛,霓虹灯,装订

S03E07 Prepared Mustard; Violins; Nuts and Bolts; Toilet Paper 芥末,小提琴,螺母螺帽,卫生纸

本集看点:螺杆的滚丝螺纹制程,螺母是钢丝在高温下压制而成的,螺母的螺纹后加工CNC制成;

S03E08 Fresh Cut Flowers; Adhesive Tape; Tofu; Lottery Tickets 鲜花,胶带,豆腐,彩票

S03E09 Inflatable Watercraft; Couscous; Modelling Dough; Wicker Products 充气筏,蒸粗麦粉,玩具胶泥,柳条编织

S03E10 Wind Generators; PVC Gloves; Thermo-Formed Glass; Fire Trucks 风力发电机,塑胶手套,热塑玻璃,消防车

本集看点:手工让平板玻璃热成型成精美盘子;

S03E11 Radiators; Hatchery Chicks; Filo Pastry; Cross-Country Skis 汽车散热器,孵蛋机,薄生面片,滑雪撬

S03E12 Electric Baseboard Heaters; Moulded Pulp Containers; Chicken; Video Games 电加热器,纸浆(鸡蛋)托盘,鸡肉,电脑游戏

本集看点:钣金连续冲压过程;

S03E13 Fire Fighter Boots; Garden Tools; Automated Machines; Gypsum Board 防火靴,园艺工具,自动化机械,石膏板

本集看点:新一期极其舒适的自动化流水线;

本季资源链接:

magnet:?xt=urn:btih:724f7b0bbf3278e4eec84db6c0373551017fb874&dn

第四季推出时间为2005-01-04至2005-03-29

S04E01 Plastic Bottles & Jars; Mail; Eggs; Handcrafted Wooden Pens 塑料瓶,邮件分拣,鸡蛋,木柄定制钢笔

本集看点:塑料瓶的吹塑制程(舒适);鸡蛋是怎么生产的;

S04E02 Plastic Injection Moulds; Automotive Oil Filters; Filing Cabinets; Blown Glass 塑料注塑模具,汽车滤油器,档案柜,吹塑玻璃

本集看点:塑料注塑模具的加工制程:CNC加工、EDM电极加工,以及双色注塑过程;钣金柜子的加工制程;美女是如何吹玻璃的;

S04E03 High-Precision Cutting Tools; Stained Glass; Semi-Trailers; Recorders 钻头,拼花玻璃,拖车,木直笛

本集看点: 涡流加热,通过热处理后软化或硬化金属;

S04E04 Conga Drums; Metal Plating; Buttons; 康茄鼓,金属电镀,纽扣

本集看点: 金属电镀制程;

S04E05 Grinding Wheels; Compost; Window Blinds; Milk 砂轮,堆���,百叶窗,��奶

S04E06 Brushes & Push Brooms; Blackboards; Smoked Salmon; Zippers 木刷子,黑板,熏鲑鱼片,拉链

本集看点: 毛刷组装时的金属U型倒扣固定住刷毛;

S04E07 3D Commercial Signs; Hardwood Floors; Corrugated Polyethylene Pipe; Mattresses 立体标牌,硬木地板,聚乙烯管,床垫

本集看点: 大型塑胶型材的成型过程;弹簧的制作过程;

S04E08 Ceramic Tiles; Nuts; Steel Forgings; Skateboards 瓷砖,果仁,炼钢,滑板

本集看点: 炼钢和轧钢;

S04E09 Car Engines; Flour; Recliners; Envelopes 轿车引擎,面粉,活动躺椅,信封

S04E10 Plastic Cups & Cutlery; Special Effects Makeup; Gold; Harps 塑料杯和餐具,特技化妆,黄金,竖琴

本集看点: 热成型一次性塑料杯;简单一些的塑料管型材制作过程;金锭的制作过程;

S04E11 Countertop Laminate; Frozen Treats; Children's Building Blocks; Detergents 表面压片,雪糕,儿童积木,清洁剂

S04E12 Architectural Moldings; Pulleys; Industrial Rubber Hose; Sheet Vinyl Flooring 装饰嵌条,滑轮,橡皮管,树脂地板

S04E13 Putty Knives; Garage Doors; Electric Motors; Wool 油灰刀,车库活动门,电动机,毛料衣物

本季资源链接:

magnet:?xt=urn:btih:0e69c6104b7c64173fa6ef64df6d7a801dd95f6f&dn

第五季推出时间为2005-09-07至2005-11-29

S05E01 Paving Asphalt; Marshmallow Cookies; Loudspeakers; Electronic Door Locks 沥青石料,葵糖饼干,高音喇叭,电子门锁

S05E02 Wood Burning Stoves; Orthoses; Ballet Slippers; Buses 木炭火炉,矫正鞋具,芭蕾舞鞋,公共汽车

S05E03 Robotic Arms; Tattoos; Sanitary Napkins; Concrete Pipes 机械手,纹身,卫生巾,水泥管

S05E04 Hockey Gloves; Snack Cakes; Remoulded Tires; Wastewater Treatment 曲棍球手套,点心蛋糕,轮胎翻新,污水处理

S05E05 Ambulances; Dining Room Tables; Diatonic Accordians; Acrylic Awards 救护车,餐桌,手风琴,有机玻璃工艺品

S05E06 Alkaline Batteries; Wheelchairs; Flutes; Cowboy Boots 碱性电池,轮椅,长笛,牛仔靴

本集看点: 学习一下最常见类型电池的制作原理;

S05E07 Golf Balls; Furniture Handles; Parking Meters; Room Dividers 高尔夫球,门扣,停车计时器,房间屏风

S05E08 Suits of Armour; Street Light Poles; Bent Hardwood; Membrane Switches 铁盔甲,电灯杆,弯曲硬木,薄膜开关

本集看点: 可以看到锅仔片的结构原理;

S05E09 Sulkies; Bagpipes; Yule Logs; Fishing Lures 单座两轮马车,风笛,圣诞节原木形大蛋糕,假鱼饵

S05E10 Goalie Pads; Lapel Pins; Cardboard Boxes; Crystal Wine Glasses 守门员护具,衣襟徽章,纸盒,水晶杯

S05E11 Cement; Caskets; Soft Drinks; Glider Rockers 水泥,棺材,饮料,摆动式摇椅

S05E12 Kitchen Knives; Mannequins; Socks; Hypodermic Needles 厨刀,人体模型,纱袜,针头

S05E13 Electrical Panels; Kites; Eyeglass Frames; Toothbrushes 配电板,风筝,眼镜架,牙刷

本季资源链接:

magnet:?xt=urn:btih:997cae2b195f96293de6b35858cc50fdc73431f3&dn

第六季推出时间为2006-01-04至2006-03-29

S06E01 Three-Wheeled Vehicles; Baseball Bats; Artificial Bonsais; Trombones 三轮摩托,棒球棍,盆景,长号

S06E02 Springs; Pavers; Pianos; 弹簧,路砖,钢琴

本集看点: 各种弹簧的全自动制作过程;

S06E03 Ropes; Billiard Tables; Sailboards; Cymbals 绳索,台球桌,帆板,铙钹

S06E04 Seatbelts; Windows; Wax Figurines; Hot Air Balloons 安全带,塑钢窗,小蜡像,热气球

S06E05 Air Filters; Billiard Cues; Ice Sculptures; Suits 空气过滤器,台球杆,冰雕,西服

S06E06 Escalator Handrails; Highlighters; Guitar Strings; Wigs 自动扶梯扶手,荧光记号笔,吉他弦,假发

S06E07 Traditional Bows; Coffee Machines; Mascots; Hammocks 传统的弓,咖啡机,吉祥物,吊床

S06E08 Fiberglass Insulation; Wooden Ducks; Gumball Machines; Exhaust Systems 玻璃纤维隔层,木鸭子,口香糖球售卖机,排气管

S06E09 Chains; Bagels; Vinyl Records; 链条,硬面包圈,唱片

S06E10 Windshields; English Saddles; Butter; Post Clocks 挡风玻璃,英式马鞍,黄油,柱钟

本集看点: 夹层玻璃的制作过程;

S06E11 Individual Transporters; Canoes; Electric Guitars 双轮代步车,雪松独木舟,电吉它

S06E12 Residential Water Heaters; Air Bags; Jelly Beans; Ice Resurfacers 宅用热水器,气囊,胶质软糖,冰面修整器

S06E13 Amphibious Vehicles; Putters; Model Ships; Drumheads 水陆两用车,高尔夫球杆,轮船模型,鼓面

本季资源链接:

magnet:?xt=urn:btih:2575f1794b6554ba85b38125e673a95ecb7bb668&dn

第七季推出时间为2006-09-05至2007-03-30

S07E01 Footballs; Electric Guitar Amplifiers; Marbles; Airplane Propellers 橄榄球,吉它扩音器,玻璃球,飞机螺旋桨

本集看点: 精美的艺术品玻璃球;先锻造再CNC成型的结构件;

S07E02 Engine Blocks; Jawbreakers; Drum Shells; Drums 引擎铸模,硬球糖,爵士鼓

本集看点: 引擎的模具制造和浇铸过程;

S07E03 Lighters; Fossils; Hockey Pucks; High-Pressure Cylinders 打火机,化石,冰球,高压钢瓶

本集看点: 铝合金的多次拉伸成型过程;

S07E04 Balloons; Wallpaper; Frozen French Fries; Incandescent Light Bulbs 气球,墙纸,炸薯条,白炽灯泡

S07E05 Matches; Carousel Horses; Fine Porcelain; Fuel Tanks 火柴,旋转木马,细瓷,汽油箱

S07E06 Glass Cookware; Soap Bars; Steel Drums; Firefighter Uniforms 玻璃炊具,肥皂,铁皮鼓,防火服

S07E07 Crayons; Wooden Kayaks; Lawnmowers; Gold Chains 蜡笔,木伐子,割草机,金项链

S07E08 Inflatable Safety Devices; Braille Typewriters; Carbon-Fibre Cellos 安全气囊,盲人打字机,碳纤维大提琴

S07E09 Carbon-Fibre Masts; Fortune Cookies; IMAX Projectors; Roller Chains 碳纤维桅杆,好运饼干,IMAX 放映机,滚子链

S07E10 Firefighter Helmets; Nautical Compasses; Packaging Tubes; Hand Saws 消防员头盔,罗盘,包装软管,手锯

S07E11 Halogen Bulbs; Cellulose Insulation; Aluminum Ladders; Bamboo Fly Rods 卤素灯,纤维绝缘层,铝梯,竹制飞蝇钓竿

S07E12 Drill Bits; Photo Booths; Stamps 钻头,照相亭,邮票

S07E13 Yacht Wheels; Braided Rugs; Automobile Thermostats; Chisels 游艇方向盘,编织毯,汽车调温器,凿子

本季资源链接:

magnet:?xt=urn:btih:06d33183a0f6ea98b8a64257d73ae0ce870082c6&dn

第八季推出时间为2007-01-02至2007-04-03

S08E01 Motorcycles; Clay Pipes; Drumsticks; Whistles 摩托车,水泥管,鼓槌,哨子

S08E02 Glass Bottles; Hacksaws; Goalie Masks 玻璃瓶,钢锯,守门员面具

本集看点: 极其舒适的玻璃瓶模具制造和吹制成型制程;

S08E03 Lacrosse Sticks; Frozen Fish Products; Flashlights; Paintbrushes 长柄曲棍球杆,油炸冻鱼肉,手电筒,油漆刷

S08E04 Deep Cycle Batteries; Tins; Optical Lenses 蓄电池,白铁罐,光学镜头

本集看点: 镜头的打磨抛光制程,以及多层镜片结构;

S08E05 Pistons; Paint Rollers; Parachutes; Chimneys 活塞,油漆滚筒,降落伞,烟筒

本集看点: 先锻压成型再CNC的典型结构件;由钢板卷成圆筒的典型制程,提前制作倒钩结构进行预固定,自动化制程不需要;

S08E06 Fishing Reels; Miniature Houses; Kitchen Mixers 渔线轮,���你房屋,厨房搅拌器

S08E07 Photographs; Fur Tanning; Welding Electrodes; Electric Violins 照片,毛皮制革,电焊条,电子小提琴

S08E08 Horseshoes; Dishwashers; Graphite Fly Rods; Pizza 马蹄铁,洗碗机,石墨飞蝇钓竿,比萨饼

S08E09 CO2 Cartridges; Pretzels; Scissor Lifts; Skating Rinks 二氧化碳弹药筒,椒盐卷饼,剪式提升机,滑冰场

S08E10 Pro Hockey Sticks; Bronzed Shoes; Treadmills; Computers 职业曲棍球棍,古铜色婴儿鞋,跑步机,掌上电脑

S08E11 Handcuffs; Caulking Compound; Propane Tanks; Forensics 手铐,堵缝剂,丙烷罐,法医学面部再造

本集看点: 上下焊接的冲压铝罐制程;

S08E12 Fur Coats; Hearses; Outdoor Lighting Fixtures; Golf Tees 毛皮大衣,灵车,室外照明器材,高尔夫球座

S08E13 Manhole Covers; Range Hoods; Artificial Logs; Snowmobiles 下水道井盖,抽油烟机,人造原木,雪地摩托

本集看点: 简单一些的金属铸造制程;

本季资源链接:

magnet:?xt=urn:btih:c04d9b7696663c9326761cf99038907f5db5f089&dn

第九季推出时间为2007-09-21至2008-04-06

S09E01 Solid Tires; Cheesecake; Canoe Paddles; Globes 实心轮胎,奶酪蛋糕,独木舟短桨,地球仪

S09E02 Boomerangs; Barbeques; Pinball Machines; Strobe Lights 回力镖 ,烧烤炉具,弹球机,闪光灯

S09E03 Wooden Bowls; Chainsaws; Stackable Potato Chips; Jet Compressor Blades 木圆盆,链锯,马铃薯片,喷气压缩机叶片

S09E04 Steel Wool; Ranges; Carved Candles; Slot Machines 钢丝棉,炊具系列,雕刻蜡烛,老虎机

S09E05 CCD Semiconductors; Airline Meals; Paper Cups; Trumpets CCD半导体,航空餐,纸杯,小号

本集看点: 先进制程之相机CCD感应芯片制作过程;

S09E06 Padlocks; Hair Clippers; Wooden Shoes; Synthetic Leather 挂锁,电推剪,木鞋,人造革

S09E07 Racing Shells; Stainless Steel Sinks; Leather; Pedal Steel Guitar 划艇,不锈钢水池,皮革,踏板钢铁吉他

S09E08 Swords; Pontoons; Grandfather Clocks; Fuses 剑,浮船, 落地大摆钟,保险丝

S09E09 Bumpers; Lighting Gels and Camera Filters; Steam-Powered Models; Candy Canes 保险杠,滤色片,蒸汽模型,苔杖糖

S09E10 Umbrellas; Outboard Motors; Silver Cutlery; Tape Measures 雨伞,舷外马达,银制餐具,卷尺

S09E11 Scalpels; Oil Paints; British Police Helmets; Ice Axes 手术刀,油画颜料,英国警察头盔,冰斧

S09E12 Bacon; Snowblowers; Luxury Cars 熏肉,扬雪车,豪华轿车

S09E13 Automatic Transmissions; Silver Miniatures; Hot Air Balloon Baskets; Darts 自动变速器,银制微型复制品,热气球吊篮,飞镖

本季资源链接:

magnet:?xt=urn:btih:a9aa449eda3eeaa8d9e9d91996dde5510940630f&dn

第十季推出时间为2008-06-11至2008-09-03

S10E01 Magnets; Cooked Ham; Silver Teapots; Crash Test Dummies 磁铁,火腿,银制茶壶,撞击测试人体模型

本集看点: 用线圈磁化的磁铁;对于收口的茶壶,内芯位置冲压模具应该是用可变形的橡胶;

S10E02 Curling Stones; Refrigerators; Aluminum Baseball Bats; Opalescent Glass 冰壶,冰箱,铝制棒球棍,乳白玻璃

S10E03 Levels; Hot Dogs; Abrasive Grains; Sandpaper 水平尺,热狗,抛光粉,砂纸

S10E04 Ice Cream Treats; Wooden Golf Clubs; Aircraft Wings; Car Battery 冰淇淋,木制高尔夫球杆头,飞机机翼,车用蓄电池回收

S10E05 Automotive Fuel Pumps; Cricket Bats; Change Machines; Ductile Iron Pipe 汽车燃油泵,板球,纸币找换机,球墨铸铁管

S10E06 Wooden Barrels; Fire Hydrants; Automotive Seats; Cathode Ray Tubes 木桶,消防栓,汽车座椅,阴极射线管

本集看点: 老式CRT电视是如何制作的;

S10E07 Stainless Steel; Football Helmets; Resin Figurines; Laboratory Glassware 不锈钢,橄榄球头盔,树脂小塑像,实验室玻璃器具

本集看点: 不锈钢轧制制程;玻璃管的热切割制程;

S10E08 Fire Extinguishers; Doughnuts; Shock Absorbers; Banjos 灭火器,甜甜圈,减震器,班卓琴

S10E09 Dress Forms; Boat Propellers; Duvets; Faucets 女装人体模型,小艇螺旋桨,羽绒被,水龙头

本集看点: 注塑的融模,再进行浇铸;

S10E10 Bronze Bells; Wooden Airplane Propellers; Charcoal Briquettes; Gas Log Fireplaces 铜钟, 木制螺旋桨, 木炭和煤气炉

S10E11 Ice Cream Cones; Tent Trailers; Shoe Polish; Pliers 折叠刀, 皂石, 变压器和传统雪鞋

S10E12 Steel Shipping Drums; Police Whistles; Miniature Train Wagons; Glass Blocks 油桶, 警笛, 微型车厢和玻璃垫块

S10E13 Pocket Knives; Soapstone Products; Electric Pole Transformers; Snowshoes 蛋筒, 篷式挂车, 鞋油和钳子

本季资源链接:

magnet:?xt=urn:btih:3e5cd2ae716c8363111416709f962ae68ec36a60&dn

8 notes

·

View notes

Text

Injection Molding Car Parts

Injection molding is just one of the most commonly made use of manufacturing procedures for plastics, as it provides a practical option for standardizing high quality and consistent parts from a broad series of polymers. In the auto sector, where uniformity, security and high quality are all of the utmost value, injection molding has actually become a staple. In the early days of the automotive industry, autos were made nearly entirely of steel, which indicated that they were confusing and extremely heavy. As the industry advanced and the plastics market emerged in the 1940s and 50s, vehicle producers began to check out using polymer parts for lorry manufacturing. In the 1970s, the very first cars and trucks with plastic attractive aspects were presented, while a lot more useful parts like plastic headlights, bumpers and fenders were introduced in the 1980s. In the very early 2000s, the very first plastic structural elements for cars and trucks were introduced, which had the advantage of being a lot more lightweight than their metal equivalents, opening enhanced fuel performance as well as cheaper manufacturing. Today, injection molding is still among the dominant manufacturing techniques for manufacturing plastic components in the automotive market because it is well matched to automation.

Advantages of Injection Molding for Automotive Applications

Injection molding is a well-known manufacturing procedure in which a molten plastic material is injected into a mold dental caries. The melted plastic then cools as well as sets and also the completed component is eliminated. Though the mold style process is important and tough (a badly designed mold can lead to flaws), injection molding itself is a trustworthy method for creating strong plastic get rid of a high quality finish.

Repeatability

In the auto sector, repeatability-- or the ability to regularly create identical parts-- is essential. Since injection molding generally relies on durable steel molds, the last plastic components produced utilizing the mold are almost identical. There are elements that enter have fun with injection molding, however if the mold is well developed and also made, injection molding is a highly repeatable procedure.

Scale and also cost

Though the injection mold-making process is expensive (as well as the price of the mold), injection molding is a highly scalable procedure whose total price decreases the more parts are made. For automation applications, injection molding is thus beneficial to the manufacturer. For anything less than mass production, however, injection molding tooling expenses may suppress the cost performance of the process.

Product accessibility

A substantial advantage of using injection molding for automobile manufacturing is the vast array of inflexible, versatile as well as rubber plastics the procedure works with. In the vehicle industry, a variety of various polymers are made use of for numerous applications, consisting of ABS, polypropylene, acrylic, acetal, nylon, polycarbonate and also even more.

High precision and also surface area coating

Injection molding is perfect for producing plastic get rid of fairly simple geometries and also results in parts with high surface area coating high quality. Makers have numerous finish alternatives when generating parts, consisting of various surface area textures-- such as glossy, rough or matte-- which are used straight to the mold rather than the shaped component. Different plastic products additionally influence the final surface coating.

Color choices

When plastic injection molding automobile parts, it is easy to change shades in order to fit within the color scheme of the car. Unlike other processes, injection molding permits you to blend dyes with the raw material pellets before making starts. This generates solid, consistent coloration without the need for paint or tinting after the molding is total.

Quick models with quick tooling

Injection molding is extensively utilized for mass manufacturing of car components, an automobile plastic parts manufacturer can likewise utilize it as a prototyping device. By developing fast, inexpensive light weight aluminum molds with rapid tooling-- normally by additive manufacturing or CNC machining-- suppliers can turn around short runs of model formed auto components much faster than they can with traditional (steel) tooling. Manufacturing Applications for Injection Molding in the Automotive Industry Within the automotive sector, injection molding is one of the primary techniques made use of for developing plastic parts. Considering a finished cars and truck, it would be hard to list every single element generated utilizing injection molding, so we'll take a look at some of the major ones.

Under-the-hood

For the past twenty years or so, several under the hood components that were as soon as made from metal have actually been transitioned to plastic. For these applications, durable polymers such as ABS, Nylon and PET are common. Components such as cylinder head covers as well as oil frying pans are created utilizing injection molding and also offer lower weights and expenses contrasted to steel parts.

Exterior

Injection molding is a recognized process for lots of outside automotive components, consisting of fenders, grilles, bumpers, door panels, flooring rails, light real estates and even more. Splash guards are a fine example for demonstrating the resilience of injection built components. The elements, which shield the car from roadway debris and also reduce spilling, are often made from rubber or other long lasting and flexible materials.

Inside

Many vehicle interior parts are also produced using injection molding. They consist of instrumentation components, interior surface areas, dashboard faceplates, door manages, handwear cover areas, air vents and also more. Attractive plastic aspects can additionally be produced utilizing injection molding.

1 note

·

View note

Text

"Large" injection mold design for car left rear door panel

Car door panel is an important part of car interior parts. It is located on the inside of car door. It is divided into front, rear, left and right. It varies according to car series, usually two-door and four-door. These parts are collectively called door panel series. This article takes left rear door panel of a car as an example to explain key points and experience in designing injection molds…

View On WordPress

#automobile door panel injection mold#automobile door panel injection molds#automobile injection molds#automobile left rear door panel injection mold#Automobile Mold#automobile mold design#automobile plastic parts. mold designers#Automotive mold design#design of automobile injection molds#Design of demoulding system#door panel injection mold#Door panel injection mold cooling system#Door Panel Mold Design#door panel molds#gating system design#Guidance and positioning system design#hot nozzles#hot runner control system#hot runner gate#hot runner pouring system#injection mold#injection mold design#injection mold design for car left rear door panel#injection molding#injection molds#injection molds for car door panels#large automobile molds#large automotive plastic parts molds#Mold exhaust system design#mold structure design

0 notes

Text

Automotive Mold

HanKing Mould serves for globally Automotive & Vehicle products customers, more than 10 years of experience enabling the HanKing team to provide customers the fast development time and stable quality to ensure the new project running well. HanKing engineer will analysis the filling to obtain the best gate position the best flowing regime, and design the best cooling channel to ensure the minimum wrapping deformation and we have a very good injection operator to help set the best injection parameter to avoid any development time waste and improving the molding parameter reliability.

HanKing Mould is very experienced in small and medium-sized automotive precision molds, in the past years, the types of products we involved were included fuse and fuse box, connector, switch, relay, sensors, actuators, terminal, valve, handle and other body accessories.

In the development of the automotive industry, the proportion of plastic parts in automotive parts is very large, and the demand for plastic parts is increasing day by day because plastics have the advantages of beautiful appearance, lightweight and easy processing. Most plastics have a specific gravity of 0.9 to 1.6, and the proportion of glass fiber reinforced composites will not exceed 2.0, while A3 steel is 7.6, brass is 8.4, and aluminum is 2.7. The use of plastic can reduce the weight of parts by about 40%, and the cost can be greatly reduced, which makes plastic the preferred material for automotive light-weighting. Plastic is easy to molding parts with complex shapes. According to the plastic composition of the plastic, by adding different fillers, plasticizers and hardeners to produce the desired properties of the plastic, changing the mechanical strength and processing properties of the material to meet the requirements of different parts of the car. The plastic consumption of each auto part accounts for 20% of the total vehicle materials and may reach 35% in the future. When the auto company develops a new car, it needs to use hundreds of sets of plastic injection molds, which requires the quality assurance of plastic parts in production, and the quality of plastic parts is determined by the mold.

Which parts of the car are commonly used in plastic?

Bumper, the instrument panel accessories, inlet grille, fender, radiator grille, trim panel, engine parts, Water tank accessories, air conditioning accessories, air filter accessories, various kettles, seat accessories, floor panel accessories, roof panel accessories, bar accessories, steering wheel accessories, door trims, rearview mirrors and various fastener, front and rear lamp, etc.

https://www.hanking-mould.com/products/automotive-mould/

1 note

·

View note

Text

Is It Safe to Use Plastic Parts to Change Metal Components in the Vehicle?

Are you thinking whether plastic vehicle parts are safe? There are a lot of people who believe that making use of plastic automobile components will certainly not maintain them secure. Luckily, this is a simply a myth. The Federal Corporate Average Fuel Economy j( CAFÉ) Standard has restricted using fossil fuels in order to secure the setting. This has actually led the vehicle manufacturers to lower the weight of the vehicles without having to compromise the efficiency. The most effective as well as ingenious remedy they developed was replacing metal with formed plastic. The built plastic is not only lighter yet it is stronger as well as sturdy. In this short article, we have actually talked about is it secure to replace steel with plastic in a car. Read on to recognize even more concerning it. Plastic Can Protect You Better A lot of individuals believe that light autos are more hazardous than heavy automobiles. Plastic has actually taken over the auto industry in today's world. Producers are utilizing plastic parts in cars and trucks now more than ever. Among the reason is that it a excellent method to protect lives. The side doors, airbags, safety belt, front and also rear bumpers, and also control panels, all are used plastic. According to the record by National Highway Traffic Safety Administration stated that plastic car components have actually saved 613,501 lives from 1960 to 2012. In another study, it was shown that motorist fatalities have decreased by 28 each one million over the duration from 2002 to 2011. This decline in the death toll was due to the innovative safety features. According to the Rocky Mountain Institute, a lighter car has better accident safety in contrast to the hefty car. So, this suggests that lighter vehicles are more secure than hefty vehicles. Safety From the Front The vehicle components made from plastics offer even more protection to the vehicle driver and passenger. This is since the plastic is qualified to soak up energy that may be created by an impact. It could develop a crumple zone that acts as a cushion to protect individuals inside the vehicle. In an mishap, the crumple area will certainly lower the result of the collapse on the occupant in the cars and truck. Previously, people thought about rigid autos are capable to shield the guests. In recent times, this assumption of individuals has actually transformed. The crumple zone in the front as well as back of the vehicle is the security function in new automobiles. For increasing the protection, plastics are effective and reliable materials. A Final Word In the long run, utilizing plastic for auto parts is a fantastic choice as it gives better security to the passengers. The use of plastic in safety features of a automobile is a advanced modern technology that will help keep the public secure in a accident. We, at RJC Mold, offer a wide variety of automobile components produced utilizing plastic injection mold and mildews. This makes the auto components robust as well as strong enough to offer the much-needed defense. You can securely take a trip in your vehicle without needing to stress over the security of your family members. If you need even more details or trying to find a reputable business, do not hesitate to call us.

1 note

·

View note

Text

Car Body Parts

Bearings

Body Kits

Body Shell

Body Trim

Bonnet

Bonnet Grill

Brake Fluid Bottle

Bumper Grill

Bumper Guards

Bumpers

Cabin Parts

Coolant Bottle

Dashboard

Door Parts

Fenders

Fog Lamp Grill

Fuel Lid Cable

Glass

Hood And Trunk Release Cable

Horn

Injection-Molded Parts

License Plate & Brackets

Mirror

Mud Flaps

Nuts & Bolts

Power Window Components

Quarter Panel

Seals & Beadings

Sunroof

Sunroof Glass

Windshield Washer Motor

Wiper Arm And Wiper Blade

Wiper Motor Assembly

Wiper Water Bottle

#bmw#audi#Range Rover#landroverdefender#automotive#car accessories#car parts#cars#google#yahoo#bing#facebook#instagram#tumblr#car body parts#news#blog#blogging#automobile#autoblogging#autoblog

1 note

·

View note

Text

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding can be performed with a variety of materials, including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into an automotive injection mould cavity where it cools and hardens to the configuration of the cavity. Injection molding is used in many different industries including automotive manufacturing. Injection molding is a process commonly used in the automotive industry to produce car parts. It is a manufacturing technique that involves injecting molten material into a mold to create the desired shape. Injection molding is widely used because it is efficient and can produce high-quality parts. The automotive injection molding process typically begins with creating a metal mold, which is then placed into a machine that heats the material and injects it into the mold. Once the part has cooled, it is removed from the mold and undergoes quality control testing before being shipped to the customer. Introduction: what is automotive injection molding? Injection molding is widely used in the automotive industry to create parts and components such as dashboards, door panels, and body panels. Injection molded parts are strong and have a high level of dimensional accuracy. They can also be designed with complex geometries. Injection molding is a versatile manufacturing process that can be used to create parts with different colors, textures, and properties. Automotive injection molded parts must meet stringent quality standards for durability, fit, and finish. The history of automotive injection molding The history of automotive injection molding is a long and complicated one. In the early days of the automobile, injection molding was used to create metal parts for the cars. However, as time went on and cars became more complex, injection molding was used to create plastic parts for the cars as well. In the early days of automotive manufacturing, assembly line workers would laboriously hand-fit each component onto the chassis of a car. This was a time-consuming and often repetitive process that was ripe for automation. Injection molding proved to be the perfect solution. Injection molding is a manufacturing process in which molten material is injected into a mold and allowed to harden. This can be done with metal, plastic, or other materials. The automotive industry began using injection molding in the 1950s with the mass production of plastic parts like dashboards and door panels. Injection molding quickly became the preferred method for producing car parts because it was faster and more consistent than hand-fitting components. In addition, injection molded parts are often stronger and more durable than their handmade counterparts. Today, injection molding is one of the most important methods for creating car parts. It is used to create both small and large parts, and can be used to create parts that are either simple or complex in design. Injection molding is an essential part of the modern automotive industry, and its history is a long and fascinating one. How automotive injection molding works Injection molding is a process that is used to create parts and products from thermoplastic and elastomeric materials. Injection molding is used to create parts for a wide variety of industries, including the automotive industry. Automotive injection molding is a complex process that involves injecting molten plastic into a mold to create car parts. The process begins by heating the plastic to its melting point. Once it’s in a liquid state, the plastic is injected into the mold under high pressure. The mold cavity is filled and the plastic cools and hardens to take on the desired shape. Injection

molding is used to create a variety of car parts, including dashboard components, door panels, and more. The process is relatively quick and efficient, making it a popular choice for mass-producing car parts. The benefits of automotive injection molding Injection molding has been used in the automotive industry for over 50 years. Injection molding is a process that uses molten plastic to create parts and products. The benefits of injection molding include its ability to create complex shapes, its high production rate, and its low cost. Injection molding is a versatile manufacturing process that can be used to create a wide variety of parts and products. Injection molding is particularly well suited for the automotive industry because it can be used to create complex shapes, such as car body panels, and it has a high production rate. In addition, injection molding is a relatively low-cost manufacturing process. Injection molding is faster than traditional manufacturing methods. Injection molding is a very efficient manufacturing process. Because the material is heated and forced into a mold, the process is quick and can be used to create large volumes of parts. Injection molding is more precise. Injection molding machines are very accurate, so the parts created by the process are consistent and have good fit. Injection molded parts also have superior dimensional accuracy and repeatability compared to other manufacturing processes , which results in less waste and fewer defects. Injection molding can be used to create parts with complex shapes that would be difficult or impossible to produce using other manufacturing methods. The injection molding process is versatile and can be used to create parts with a wide range of different properties, such as strength, flexibility, and durability. Injection molding is widely used in the automotive industry to produce parts such as body panels and engine components. Injection molding is a versatile manufacturing process for producing parts from thermoplastic and thermosetting plastics. Materials such as polystyrene, polycarbonate, nylon, and ABS can be molded into complex shapes with tight tolerances. Injection molding is commonly used in the automotive industry to produce interior and exterior parts, including dashboards, door panels, and bumpers. Advantages of injection molding include the ability to produce large quantities of parts quickly and efficiently. Disadvantages of injection molding include the high initial investment cost of the equipment and tooling, as well as the need for skilled operators. Injection molding is one of the most popular manufacturing processes for producing parts and components for the automotive industry. This process is cost-effective because it allows manufacturers to create large quantities of parts quickly and efficiently. The challenges of automotive injection molding Automotive injection molding is a process used to create parts and components for cars and other vehicles. The process is complex and challenging, and it requires a high level of skill and experience to execute correctly. One of the biggest challenges of automotive injection molding is achieving the correct dimensions for parts. The molds used in this process are very precise, and even small variations can result in faulty parts. In addition, the materials used in automotive injection molding must be able to withstand high temperatures and pressures, which can be difficult to achieve. Another challenge of this process is creating parts with smooth surfaces. Any imperfections in the molding process can result in visible defects on the finished product. This can be especially problematic for car parts that are exposed to the elements, as these defects can lead to rust and other damage. Conclusion

0 notes

Text

Application and characteristics of acrylic metal display

Acrylic is also known as plexiglass with special treatment.Acrylic metal display made of acrylic has good light transmission performance, pure color, beautiful and smooth.

First, the characteristics of acrylic metal display:

1. Relatively high light transmittance: Plexiglass is the most excellent fully transparent raw material for polymer materials, with a light transmittance of 92%, which is higher than that of laminated glass.

2. High impact toughness: The relative molecular mass of plexiglass is about 2 million, which is a long-chain polymer material chemical substance, and the chain that generates the molecular structure is very soft. Therefore, plexiglass has very high hardness, tensile and The impact resistance is 7-18 times higher than that of ordinary glass.

3. Lighter weight: The relative density of plexiglass is 1.18kg/dm3. The net weight of raw materials of the same size is only half of that of ordinary glass. Metal aluminum belongs to 43% of non-metallic materials.

4. Ease of production and processing: plexiglass can not only be drilled by CNC lathes, drilled by planers, but also bonded into various shapes of equipment such as toluene and ether, and can also be formed by injection molding, injection, extrusion and other plastic molding methods. It produces and processes a wide range of products ranging from airport covers to removable dentures and dental trays.

Second, the application of acrylic metal display:

1. Building uses: shop windows, soundproof doors and windows, lighting masks, telephone booths, etc.

2. Advertising applications: light boxes, signboards, signs, display stands, etc.

3. Transportation applications: doors and windows of trains, cars, etc.

4. Medical uses: baby care boxes, various surgical medical instruments, civil products: sanitary facilities, handicrafts, cosmetics, stents, aquariums, etc.

5. Industrial use: exterior, panel, cover, etc.

6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

7. Household: fruit bowls, tissue boxes, acrylic art paintings and other household products, outdoor advertising in Langfang

Dongguan Haiyi Trading specializes in creating a one-stop experience from design, manufacturing, and quality management for global customers. It is exported to overseas and has excellent after-sales service. If you are interested in customized displays, please contact our company.

0 notes