#butterfly valve supplier in India

Explore tagged Tumblr posts

Text

0 notes

Text

butterfly valve manufacturer in ahmedabad

We are leading butterfly valve manufacturer in Ahmedabad, India. A butterfly valve is used to regulate flow in a pipeline. It is made up of a butterfly-like disc-shaped closure element that spins on a spindle to regulate fluid flow. Butterfly valves are popular due to their compact design and widely used in a variety of industries including HVAC systems and water treatment.

#butterfly valve#butterfly valve manufacturer#butterfly valve supplier#butterfly valve in Ahmedabad#butterfly valve manufacturer in Ahmedabad#butterfly valve supplier in India

0 notes

Text

Gate Valve Symbols and Pipeline Instrumentation Diagrams: from Design to Manufacturing in China

In industrial pipeline systems, valves are the core components that control fluid flow, and gate valves and check valves are one of the most common types. Whether it is design engineers, procurement personnel or maintenance teams, they need to understand the symbol representation of these valves in pipeline instrumentation diagrams, as well as how to choose high-quality gate valve manufacturers and suppliers. This article will deeply analyze the gate valve symbols, check valve symbols and their meanings in PID diagrams, and explore China’s advantages as an important gate valve manufacturer in the world.

Sample of Valve Symbols in Pipeline Instrumentation Diagrams

Gate Valve Symbols and Check Valve Symbols

1. Gate valve symbol analysis

In the PID diagram, the gate valve symbol is usually composed of the following elements: - Vertical lines: Represents the main structure of the valve body. - Horizontal wedge gate: Symbolizes the opening and closing components of the gate valve, which controls the flow of fluid through lifting and lowering movements. - Handwheel or actuator symbol: Marked on the top of the valve body, indicating manual or automatic operation mode. - Flow direction arrow (optional): Indicates the allowed direction of the fluid.

Example: - Manual gate valve: A horizontal wedge is added in the middle of the vertical line, and the handwheel symbol is marked on the top. - Electric gate valve: Add a motor icon next to the wedge symbol.

2. Check valve symbol analysis

Check valve‘s symbol design emphasizes its unidirectional flow characteristics: - Triangle or arrow: Points to the direction of allowed flow. - Vertical line or spring symbol: Indicates the mechanism of automatic closing of the valve.

Example: - Swing check valve: An arc line is added next to the arrow to indicate the swing of the valve disc. - Lift check valve: vertical line with lift disc symbol.

2. Importance of Piping and Instrumentation Diagram Symbols

PID diagram is the “blueprint” of industrial process design, which clearly expresses pipelines, valves, instruments and control logic through standard symbols. The significance of using symbols correctly is:

1. Improve communication efficiency: The globally common symbol system avoids language and technical misunderstandings. 2. Ensure safety: Clearly mark valve types and functions to prevent operating errors. 3. Optimize maintenance processes: Quickly locate equipment through symbols to reduce downtime.

Common symbol standards: - ISO 10628: Internationally common flowchart symbol standard. - ANSI/ISA 5.1: Detailed symbol specifications developed by the American Instrument Association.

Global Competitiveness of Chinese Gate valve Manufacturers

As an important production base for industrial valves in the world, China’s gate valve factories and manufacturers dominate the market with the following advantages:

1. Technology and manufacturing capabilities

- Material innovation: Adopt corrosion-resistant materials such as high-strength alloy steel and stainless steel to adapt to high temperature and high pressure environments. - Precision machining: CNC machine tools and automated production lines ensure the sealing and durability of valves. - Complete certification: Meet international standards such as API 600 and ISO 9001 to meet the needs of global customers.

2. Cost advantage

- Scaled production: Reduce unit costs through mass production and provide **competitive prices**. - Supply chain integration: Localized raw material procurement and logistics networks further reduce costs.

3. Customized service

- Non-standard design: Support customers to customize valve size, pressure level and connection method. - Fast delivery: Perfect inventory management and efficient production cycle to meet urgent needs.

4. Global supply network

Chinese gate valve suppliers expand international markets through the following ways: - Cross-border e-commerce platforms: such as Alibaba International Station, directly connect with overseas customers. - Localized services: Set up warehousing and after-sales centers in North America, Europe, and the Middle East.

How to choose a high-quality Chinese Gate Valve Supplier

1. Verify qualifications and reputation - Check whether the company holds API, CE and other certifications. - Understand customer feedback through third-party platforms (such as Google Reviews).

2. Request sample testing - Test the sealing, pressure resistance and service life of the valve.

3. Pay attention to after-sales service - Ensure that the supplier provides technical support and fast repair services.

4. Compare prices and delivery dates - Avoid choosing suppliers whose quotations are far below the market level (there may be quality problems).

Application scenarios and selection recommendations for gate valves

1. Typical application areas

- Oil and gas: used for pipeline opening and closing and flow control. - Chemical industry: special gate valves that withstand corrosive media. - Water treatment system: large-diameter gate valves are used in reservoirs and water pipelines.

2. Key selection parameters

- Pressure level: such as Class 150, Class 300. - Connection method: flange, welding or threaded connection. - Operation method: manual, electric or pneumatic.

Conclusion

From the gate valve symbol in the PID diagram to the valve selection in actual application, each step directly affects the safety and efficiency of the industrial system. As the world’s leading gate valve manufacturer, China has become the first choice for international procurement with its technical strength and cost advantages. Whether you are an engineer, a purchaser or a project manager, choosing a reliable China gate valve supplier will be the key to ensuring the success of the project.

#ball valve manufacturers in india#ball valve suppliers#butterfly valve#esdv#ball valve#check valve#gate valve#gate valve manufacturers#globe valve#plug valve

0 notes

Text

Winging It: Best Butterfly Valve Manufacturers in Ahmedabad

Butterfly Valve Manufacturers in Ahmedabad – Explore Ahmedabad’s leading Butterfly Valve manufacturers & suppliers. Get quality valves for industrial applications from Gold Techno Casting.

Google Map:--> https://maps.app.goo.gl/HPDJtfx5r7s11pun7

Butterfly Valve Manufacturers in Ahmedabad, Butterfly Valve Manufacturer & Supplier in Ahmedabad, Butterfly Valves in Ahmedabad, Cast Iron Butterfly Valve Manufacturer From Ahmedabad, Butterfly Valve, Butterfly Valve Manufacturer in Ahmedabad, Top Butterfly Valve Manufacturers in Ahmedabad, Cast Iron Teflon Seated Butterfly Valve in Ahmedabad, Pneumatic Actuator Wafer Type Butterfly Valve, Butterfly Valve Manufacturer & Supplier in Ahmedabad, India, Industrial Butterfly Valves Manufacturer in Ahmedabad, India, Top Damper Butterfly Valve Manufacturers in Ahmedabad, PP Butterfly Valve Manufacturer from Ahmedabad, Cast Iron Butterfly Valve Manufacturer from Ahmedabad, Ahmedabad, Gujarat, India, www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting

#Butterfly Valve Manufacturers in Ahmedabad#Butterfly Valve Manufacturer & Supplier in Ahmedabad#Butterfly Valves in Ahmedabad#Cast Iron Butterfly Valve Manufacturer From Ahmedabad#Butterfly Valve#Butterfly Valve Manufacturer in Ahmedabad#Top Butterfly Valve Manufacturers in Ahmedabad#Cast Iron Teflon Seated Butterfly Valve in Ahmedabad#Pneumatic Actuator Wafer Type Butterfly Valve#India#Industrial Butterfly Valves Manufacturer in Ahmedabad#Top Damper Butterfly Valve Manufacturers in Ahmedabad#PP Butterfly Valve Manufacturer from Ahmedabad#Cast Iron Butterfly Valve Manufacturer from Ahmedabad#Ahmedabad#Gujarat#www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

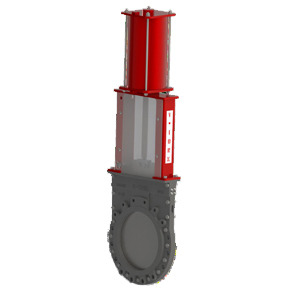

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

Pulp and Paper Industry: Efficient Fluid Control with Industrial Valves

The pulp and paper industry relies on the efficient movement and processing of water, chemicals, and pulp to produce paper products. Valves play a crucial role in controlling the flow of these materials, ensuring that processes run smoothly and efficiently.

Common Valve Types in the Pulp and Paper Industry

Knife gate valves are commonly used in the pulp and paper industry due to their ability to handle slurries and viscous fluids. These valves are designed with a sharp, knife-like gate that cuts through the material, preventing blockages and ensuring smooth flow. They are often employed in applications where pulp or other fibrous materials are transported.

Butterfly valves are another popular choice in the pulp and paper industry. These valves are ideal for controlling the flow of liquids and gases, and their compact design makes them suitable for large-diameter pipes. Butterfly valves are often used in water treatment systems, where they regulate the flow of water used in the papermaking process.

Ball valves are used in high-pressure applications, such as those involving steam or chemicals. These valves provide a tight shutoff, preventing leaks and ensuring that the system operates efficiently.

Challenges Faced in Valve Operation

The pulp and paper industry presents several challenges for valve operation. The materials used in papermaking, such as wood pulp and chemicals, can be highly abrasive, causing valves to wear down over time. This necessitates the use of durable materials, such as stainless steel or special alloys, to extend the lifespan of valves and reduce maintenance costs.

Corrosion is another issue, particularly in systems that handle chemicals such as bleach or chlorine. Valves must be made from materials that can withstand corrosive environments, ensuring long-term reliability.

Automation for Increased Efficiency

As with other industries, automation has become increasingly important in the pulp and paper industry. Automated valves allow for real-time control of flow, pressure, and temperature, ensuring that processes run efficiently and safely. By integrating automated systems, pulp and paper mills can optimize their operations, reduce downtime, and increase throughput.

Automation also plays a role in reducing waste. By controlling the flow of water and chemicals with precision, mills can minimize resource consumption and reduce environmental impact. This not only improves profitability but also helps companies meet sustainability goals.

Valves are essential in the pulp and paper industry, where they play a key role in controlling the flow of materials through complex processes. With advancements in automation and materials science, valves are becoming more efficient and durable, helping mills optimize their operations and reduce costs. By investing in high-quality valves, pulp and paper companies can ensure the smooth and efficient operation of their production lines.

#industrial valves#paper and pulp industry#ball valve#butterfly valve#bellow seal globe control valve#manufactuers#suppliers#exporter#mumbai#maharashtra#india

0 notes

Text

https://ext-6443843.livejournal.com/337.html

India's industrial landscape is diversified and rich, and the nation stands out as a key participant in the global valve sector within this robust ecosystem. AVC Valves India Pvt Ltd isfinest ball valve suppliers in India are noted for their unrelenting dedication to quality and innovation.

0 notes

Text

Top Butterfly Valve Suppliers in India

Introduction

Brief overview of butterfly valves, their industrial importance, and demand in India.

Top Butterfly Valve Suppliers

L&T Valves Ltd – Known for high-quality industrial valves.

Kirloskar Brothers Ltd – Offers durable and reliable butterfly valves.

Hawa Valves – Exporters and suppliers of industrial-grade valves.

Hyper Valves – Provides cost-effective butterfly valves.

Key Features to Look for in Butterfly Valve Suppliers

Quality Assurance

ISO Certification

After-Sales Service

Butterfly Valve Applications

Water Treatment Plants

Oil and Gas Industry

Chemical Processing

FAQs

Q: Which is the top butterfly valve brand in India? A: L&T Valves is highly trusted in the industry.

Q: How to buy butterfly valves in bulk? A: Platforms like TradeIndia and Justdial have numerous suppliers.

2 notes

·

View notes

Text

Supplier of Industrial Valve in Tamil Nadu

Meghmani Metal: Meghmani Metal is an ISO 9001:2015 certified supplier of industrial valves based in Tamil Nadu, India. The company offers a diverse range of stainless steel products, including steel flanges, SS fasteners, steel butt welding, steel pipe fittings, steel rods, wires, coils, and flats. Meghmani Metal crafts industrial valves from various material grades, including stainless steel and high nickel alloys. Their warehouse stocks a variety of valves such as ball valves, gate valves, control valves, needle valves, globe valves, butterfly valves, check valves, safety valves, and more. Specifications: Standard: ASTM A240, JIS4304-2005, ASTM A167, EN10088-2-2005, GB/T3280-2007, etc. Specifications: ASTM A240 / ASME SA240 Sizes: Ranging from 1000mm x 2000mm, 1220mm x 2440mm, 4′ x 8′, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, and 2000mm x 4000mm to 6000mm. Length: Options include 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. Thickness: Varying from 0.3mm to 100mm. Range: Extending from 5mm to 150mm. Surface Finishes: Various surface finishes are available, including hot rolled plate (HR), cold rolled sheet (CR), 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sandblast, brush, etching, SATIN (met with plastic coated), and more. Service Coverage: Meghmani Metal serves as a prominent supplier of industrial valves in Tamil Nadu, covering areas such as Arcot, Chengalpattu, Chennai, Chidambaram, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kanchipuram, Kanniyakumari, Kodaikanal, Kumbakonam, Madurai, Mamallapuram, Nagappattinam, Nagercoil, Palayamkottai, Pudukkottai, Rajapalayam, Ramanathapuram, Salem, Thanjavur, Tiruchchirappalli, Tirunelveli, Tiruppur, Thoothukudi, Udhagamandalam, and Vellore. For further inquiries and information, interested parties are encouraged to contact Meghmani Metal. Read the full article

#Arcot#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#India#IndustrialValve#Kanchipuram#Kanniyakumari#Kodaikanal#Kumbakonam#Madurai#Mamallapuram#Manufacturer#Nagappattinam#Nagercoil#Palayamkottai#Pudukkottai#Rajapalayam#Ramanathapuram#Salem#supplier#Thanjavur#Thoothukudi#Tiruchchirappalli

3 notes

·

View notes

Text

Bellows, Boots, Rubber Bellows, Manufacturer, Mumbai, India

Bellows, Boots, Rubber Bellows, Rubber Bellows Manufacturer, Anti Vibration Mounts, Rubber Anti Vibration Mounts, Anti Vibration Mounts Manufacturer, Anti Vibration Mount Supplier, Mumbai, India.

Rubber Products, Moulded Rubber Parts, Extruded Rubber Parts, Sponge Moulded Parts, Metal Bonded Parts, Manufacturers Of Rubber Components, Manufacturers Of Moulded Rubber Parts, Manufacturers Of Extruded Rubber Parts, Rubber Moulded Parts, 'O' Rings, Oilseal, U Seal, V Seal, Chevron Packing For Pumps, Hydraulics Seal, Mechanical Seal, Neoprenen Rubber, Nitrile Rubber, Epdm Rubber, Hypalon Rubber, FKM Rubber, Natural Rubber, Polymers, Flourinated Rubber, FKM Rubber, Silicone Rubber, Polyurethane Rubber, Ethylene Propylene Terpolymers, Natural Rubber, Synthetic Rubber, Chemical Resistance, O Rings, U Seals, V Seals, Lip Seals, Wiper Seals, Oil Seals, Diaphragms, Electrical Control Valves, Pneumatic Control Valves, Pressure Regulators, Valve Positioner, Ball & Butterfly Valve, Solenoid Valve With Brass, Stainless Steel Stud, Fabric, Nylon, Canvas, Rayoncord, Wiremess

2 notes

·

View notes

Text

Water Treatment Plants: Automated butterfly valve with electric actuator optimize water flow within treatment plants, ensuring efficient and reliable operation.

Oil and Gas Pipelines: Remotely operated butterfly valves with electric actuators enable safe and efficient flow control in pipelines, even in remote locations.

0 notes

Text

Flowdo Valves is a leading manufacturer of high-quality butterfly valves in India. We are offering best quality Butterfly Valve at Affordable Price.

#Butterfly Valves#Butterfly Valves in Ahmedabad -India#Butterfly Valves Manufacturer#Butterfly Valves Supplier#Butterfly Valves in India#Butterfly Valves in Ahmedabad

0 notes

Text

Top Ten Chinese Valve Brands

Top Ten Chinese Valve Brands

1. Suzhou Neway Valve Co., Ltd. (Brand: Neway)

Suzhou Neway Valve Co., Ltd. was founded in 1997. Neway has more than 200 experienced technical engineers who specialize in valve solutions. We use professional knowledge to help customers review valve specifications, customize and optimize application solutions, troubleshooting, etc.

2. China Nuclear Suval Technology Industry Co., Ltd. (Brand: China Nuclear Suval Valve)

The company was founded in 1997. It is a listed joint-stock company founded on the basis of inheriting the main business, brand, quality assurance, technology and management advantages of China National Nuclear Corporation Suzhou Valve Factory. The current registered capital is 20 million RMB 20 million. , Is the first listed company in China’s valve industry and nuclear industry system. Won the honorary title of Jiangsu Famous Brand.

3. Sanhua Holding Group Co., Ltd. (Brand: Sanhua)

Sanhua Holding Group Co., Ltd. was established in 1984 in Xinchang, a famous city in eastern Zhejiang, China. It is a large-scale private enterprise integrating scientific research, production, operation and service. The company has successively won the National Quality Award, China Famous Brand, China Well-known Brand, and many other honors and titles. Mr. Zhang Daocai, the founder of Sanhua Business, has also won many honors such as Chinese Master of Business Management and Chinese Outstanding Entrepreneur.

4. Zhejiang Chaoda Valve Co., Ltd. (Brand: Chaoda)

Chaoda was founded in 1984. The company is now a national key high-tech enterprise, a backbone enterprise of the Yongjia Pump and Valve Characteristic Industrial Base of the National Torch Program, a member unit of the supply network of Sinopec, CNPC, and CNOOC, a director unit of China General Machinery Industry Association, and China Valve Industry Association Vice-chairman unit, Zhejiang province tax credit AAA grade enterprise, Zhejiang province contract and trustworthy unit, Industrial and Commercial Bank credit AAA grade enterprise, Wenzhou key backbone enterprise, “Chaoda” won the title of Zhejiang Famous Brand and Zhejiang Famous Brand Product.

5. Wenzhou Newsway Valve Co.,Ltd. (Brand: NSW)

As one of the top ten industrial valve manufacturers and exporters in China, Wenzhou Newsway Valve Co.,Ltd. has been committed to the production and research and development of industrial valves, and takes the production of world-advanced industrial valves as its mission. Main Ball Valves, Gate Valves, globe valves, check valves and butterfly valves. Products cover almost all industrial fields, including: onshore and offshore oil extraction, oil refining, chemical industry, shipbuilding, papermaking, metallurgy, thermal power, nuclear power, etc. As China’s leading and world-renowned valve manufacturer, Newsway Valve has been committed to providing customers with a complete set of industrial valve solutions, specializing in the production, research and development, sales and service of industrial valves.

6. Shanghai Shengchang Automatic Control Valve Co., Ltd. (Brand: Shengchang)

Shanghai Shengchang Automatic Control Valve Co., Ltd. was established in Shanghai Pudong New Area in early 2002. The company has strong technical force and advanced development and design and computer management software. The products have introduced advanced German technology, and the actuators are perfectly integrated with our valves. In this industrial infrastructure On the fertile soil with a complete and complete industrial supporting system, with the strong support and assistance of the local government, after five years of continuous development, Shengchang has emerged from the industry and has become a model for the development of contemporary Chinese valve industry. The market share has been among the best in the domestic industry.

7. Sichuan Zigong High Pressure Valve Co., Ltd. (Brand: Zigong High Pressure)

Sichuan Zigong High Pressure Valve Co., Ltd. was founded in 1958. It is currently the largest long-distance pipeline valve production base in China. It specializes in manufacturing “Feiqiu brand” series of ball valves, butterfly valves, flat valves, gate valves, power station valves and other standard and non-standard valves. And special valves are the state’s key enterprises to encourage development.

The company was the first to obtain the API6D certificate of the American Petroleum Institute in 1993; it obtained the ISO9001 certificate of Norway DNV in 1994; it obtained the right to self-export in October, and was listed as an “export base” enterprise by the State Economic and Trade Commission in 1997; it was awarded in October 2003 Special equipment manufacturing license of the People’s Republic of China (pressure pipeline).

8. Qinhuangdao Special Steel Valve Co., Ltd. (Brand: Special Steel)

Qinhuangdao Special Steel Valve Co., Ltd. is located in the beautiful tourist city Qinhuangdao. It is a representative enterprise integrating development, design, OEM and sales. It specializes in the production of gate valves, globe valves, ball valves, check valves, butterfly valves, plug valves, and diaphragms. Valves, direct-buried gate valves, direct-buried butterfly valves and other high, medium and low pressure valves.

Special Steel Valve always adheres to the tenet of “Customer First, Quality First”, in line with the business philosophy of “Science and pragmatism, pursuit of innovation, and customer first”, “Forge ahead and flourish” is the desire of Special Steel to satisfy customers It is the eternal mission of Special Steel Valve.

9. Wenzhou Crane Valve Industry Co., Ltd. (Brand: Crane)

Wenzhou Crane Valve Industry Co., Ltd. is located in Yongqiang High-tech Park, Wenzhou City. It is a valve manufacturer integrating scientific research, design, manufacturing, sales and service. Its product holding standards include national GB standards, American APIs, and Japanese JIS standards. And so on, and can be designed and manufactured according to customers’ special requirements. The main products include more than 30 varieties of chip ball valves, pneumatic ball valves, gate valves, regulating valves, etc., with more than 1,000 specifications. All valve products are strictly tested before being put into storage to ensure the reliability of product quality. Over the years, we have unswervingly implemented the policy of quality first, with “committed to perfection, relentless pursuit, creating the future, and going to the world” as the business policy, constantly applying new technologies, new processes, new materials, and actively developing new varieties. Users provide better valve products and better after-sales service.

10. Beijing Detaike Valve Co., Ltd. (Brand: Detaike)

Beijing Detaike Valve Co., Ltd., headquartered in Beijing, is a valve company that sells and serves the fluid control industry. It sells imported valves, regulating valves, ball valves, needle valves, globe valves, gate valves, check valves, and butterfly valves. , Flame arresters, suction valves, etc. are in a leading position in the chemical, petrochemical, petroleum, paper, mining, electric power, liquefied gas, food, pharmaceutical, water supply and drainage fields, and its sound quality assurance system and excellent after-sales service system have won It has won unanimous praise from customers and has been rated as a “contract-honoring and credit-oriented” enterprise for many times, and has won the trust and wide praise of users.

#ball valve manufacturers in india#ball valve suppliers#gate valve manufacturers#ball valve#butterfly valve#check valve#esdv#gate valve#globe valve#plug valve

0 notes

Text

Butterfly Valve Manufacturers in Ahmedabad - Top Quality

Discover leading Butterfly Valve Manufacturers in Ahmedabad. Get high-quality products and competitive prices. Your trusted source for valve solutions.

Google Map:--> https://maps.app.goo.gl/pmF6ogWW6EPkpfYq7

Butterfly Valve Manufacturers in Ahmedabad, Butterfly Valve Manufacturer & Supplier in Ahmedabad, Butterfly Valves in Ahmedabad, Cast Iron Butterfly Valve Manufacturer From Ahmedabad, Butterfly Valve, Butterfly Valve Manufacturer in Ahmedabad, Top Butterfly Valve Manufacturers in Ahmedabad, Cast Iron Teflon Seated Butterfly Valve in Ahmedabad, Pneumatic Actuator Wafer Type Butterfly Valve, Butterfly Valve Manufacturer & Supplier in Ahmedabad, India, Industrial Butterfly Valves Manufacturer in Ahmedabad, India, Top Damper Butterfly Valve Manufacturers in Ahmedabad, PP Butterfly Valve Manufacturer from Ahmedabad, Cast Iron Butterfly Valve Manufacturer from Ahmedabad, Ahmedabad, Gujarat, India, www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php, Gold Techno Casting

#Butterfly Valve Manufacturers in Ahmedabad#Butterfly Valve Manufacturer & Supplier in Ahmedabad#Butterfly Valves in Ahmedabad#Cast Iron Butterfly Valve Manufacturer From Ahmedabad#Butterfly Valve#Butterfly Valve Manufacturer in Ahmedabad#Top Butterfly Valve Manufacturers in Ahmedabad#Cast Iron Teflon Seated Butterfly Valve in Ahmedabad#Pneumatic Actuator Wafer Type Butterfly Valve#India#Industrial Butterfly Valves Manufacturer in Ahmedabad#Top Damper Butterfly Valve Manufacturers in Ahmedabad#PP Butterfly Valve Manufacturer from Ahmedabad#Cast Iron Butterfly Valve Manufacturer from Ahmedabad#Ahmedabad#Gujarat#www.goldtechnocasting.com/butterfly-valve-manufacturers-in-ahmedabad.php#Gold Techno Casting

0 notes

Text

Discover VTORK’s bi-directional knife gate valves, engineered for reliability and efficiency in diverse industrial applications. As a leading manufacturer in India, VTORK delivers robust valves designed to handle abrasive slurries, pulp, wastewater, and power generation needs with precision and durability. Explore custom solutions tailored to your specific requirements, backed by VTORK’s commitment to quality and customer satisfaction.

#valve manufacturers in india#gate valve manufacturers#ball valve manufacturers in india#knife gate valve manufacturers in india#knife gate valve manufacturers#butterfly valve manufacturers#slurry knife gate valve manufacturers#best industrial valve manufacturers#vtork controls#ball valve suppliers#valve manufacturers in australia

0 notes

Text

The Butterfly Valve: Unveiling its Mechanism and Applications

In the realm of industrial valves, the butterfly valve stands as a significant player, providing efficient control over fluid and gas flow within a pipeline. Its design and mechanism make it a popular choice across various industries, ensuring seamless operations and enhanced productivity. This article delves into the mechanics and applications of the butterfly valve, shedding light on its importance in modern industrial setups.

Understanding the Butterfly Valve The butterfly valve is a quarter-turn rotational motion valve that employs a disk-shaped seating element for controlling flow. The valve's operation is straightforward - the disk pivots on a diametrical axis inside a pipe, allowing or obstructing the flow. When the valve is fully open, the disk is positioned parallel to the flow, minimizing resistance and enabling smooth fluid or gas passage. Conversely, closing the valve involves turning the disk to a perpendicular position, effectively blocking the flow.

The simplicity and efficiency of the butterfly valve make it a preferred choice for applications that require quick shutoff or control. The minimalistic design contributes to its cost-effectiveness and ease of operation, making it suitable for both large-scale industrial operations and smaller-scale applications.

Mechanism and Components Valve Body: The valve body is the primary structure housing all components. Typically made of materials like cast iron, steel, or even plastic, the body holds the other parts securely and withstands the pressure exerted by the flowing substances.

Disk: The disk, also known as the butterfly, controls the flow. Its positioning within the valve body determines the flow rate. When parallel to the flow, the valve is open, and when perpendicular, it's closed.

Stem and Actuator: The stem connects the disk to the actuator, allowing rotational movement. The actuator, powered by various mechanisms (manual levers, gears, pneumatic or hydraulic pressure), controls the disk's position, thereby regulating flow.

Seat: The seat forms a seal around the disk to prevent leakage when the valve is closed. It's crucial for the valve's effectiveness and longevity.

Applications HVAC Systems: In Heating, Ventilation, and Air Conditioning (HVAC) systems, butterfly valves play a vital role in controlling the flow of air, water, or steam. Their quick on-off capabilities are especially beneficial in these systems.

Water Treatment: Butterfly valves find extensive use in water treatment plants for managing water flow, particularly in large pipes where tight sealing is crucial.

Oil and Gas Industry: For applications in the oil and gas industry, especially in the transportation of oil and gas, butterfly valves are employed due to their ability to handle large flow volumes.

Chemical Processing: In the chemical industry, butterfly valves regulate the flow of chemicals through pipelines, ensuring precise control and safety in the production process.

Fire Protection Systems: Butterfly valves are utilized in fire protection systems to control the flow of water, allowing for quick response during emergencies.

Conclusion The butterfly valve's fundamental design, ease of operation, and cost-effectiveness have made it a fundamental component in modern industrial operations. Its applications range across various industries, contributing to the smooth and efficient flow of fluids and gases. Understanding the mechanics and potential of butterfly valves is crucial for industries seeking to optimize their processes and enhance overall productivity.

In the realm of industrial valves, one company stands out as a trusted manufacturer. Freture Techno Pvt. Ltd. based in Mumbai, India, leads the industry in producing high-quality butterfly valves and other industrial valves. Their commitment to quality, precision engineering, and customer satisfaction makes them a reliable partner for industries seeking efficient valve solutions. With a wide range of valve offerings, Freture Techno continues to innovate and deliver valves that meet the stringent demands of modern industrial applications.

0 notes