#bulk storage silos

Explore tagged Tumblr posts

Text

The Ultimate Guide to Bulk Storage Silos: Everything You Need to Know

Bulk storage silos are indispensable for industries requiring efficient and large-scale material storage solutions. From construction to agriculture and industrial manufacturing, silos offer a reliable way to manage bulk materials while ensuring safety, durability, and operational efficiency.

If you’re searching for the right bulk silo systems or exploring options from trusted silo manufacturers, this guide is tailored to help you understand the types, benefits, and applications of bulk material storage silos for your specific needs.

What Are Bulk Storage Silos?

Bulk storage silos are large containers designed to store bulk materials such as cement, fly ash, grains, chemicals, and other granular materials etc. These silos protect them from outside dirt, moisture and decay, and ensure the quality and usefulness of the inventory

Key benefits of bulk silos include:

Maximized storage efficiency.

Protection against environmental factors.

Improved operational workflows.

Types of Bulk Storage Silos

Vertical cement silos

Vertical silos are the most common in construction and engineering. Materials such as cement and fly ash are stored efficiently, making them easily incorporated into the silo-feeding system for streamlined operations.

Horizontal Cement Silos

Perfect for sites with height restrictions, horizontal cement silos are portable and easy to install. Their design allows for flexibility, making them ideal for temporary storage needs.

Radimix welded silos

Pre-welded and prefabricated silos are an excellent choice for ready-mixed concrete plants. These silos are designed to seamlessly integrate into your manufacturing process while maintaining storage efficiency.

Fly Ash Silos

Fly Ash Silo is a by-product of coal combustion and needs special storage to prevent water condensation. Fly ash silos provide an airtight solution to maintain the product’s usefulness.

Silo containers

Versatile and durable silo containers are suitable for storing a wide variety of products such as food products, chemicals, and other raw materials

Benefits of Using Bulk Storage Silos

Cost-Effective Storage

Bulk storage silos reduce material handling costs by providing a centralized and efficient storage solution.

Environmental Protection

Silos help businesses comply with environmental regulations by reducing dust and emissions during storage and transportation.

Enhanced Productivity

Integrating bulk silo systems and manufacturing processes streamlines inventory management and improves overall efficiency.

Key Features of Advanced Silo Systems

Customizable Designs

Modern silos come in a variety of shapes and sizes to suit the needs of specific industries, from cement storage silos to agricultural equipment storage silos.

Advanced Feeding Systems

A robust silo-feeding system ensures efficient stocking, reducing downtime and manual effort.

Durability and Longevity

Silos are constructed of high-quality materials to withstand harsh environmental conditions and ensure long-term reliability.

How to choose the right bulk storage silo

Selecting the right bulk storage silo requires consideration of the following factors:

Material Compatibility

The content of a silo must match the information you store. For example, fly-ash silos require leak-proof materials, while cement storage silos must prioritize system integrity.

Capacity

Evaluate your storage needs and choose silos that can meet your capacity needs without being constantly replenished.

Silo Manufacturers

Work with leading silo manufacturers who provide the sustainable, high-quality solutions you need.

System Integration

Make sure the silo integrates well with your silo feeding system for efficient resource utilization.

Why choose RCMPL for your bulk storage needs?

At RCMPL, we specialize in providing multi-storage silos and high-quality silo systems for businesses. Our expertise ensures you get customized solutions for vertical cement silos, horizontal cement silos, readymix welded silos, and more.

With a focus on innovation and quality, RCMPL is your trusted partner for all your storage needs. Contact us today to learn how we can support your businesses with advanced, efficient and reliable silo solutions

FAQs About Bulk Storage Silos

1. What materials can be stored in bulk silos?

Materials such as cement, fly ash, grains, chemicals, and other granular substances can be stored in bulk silos.

2. What is the difference between vertical and horizontal silos?

Vertical silos offer higher capacity and better space utilization, while horizontal silos are portable and suited for temporary projects.

3. How do I maintain a bulk storage silo?

Regular inspections, cleaning, and preventive maintenance ensure longevity and efficiency.

4. Are silos suitable for outdoor installations?

Yes, bulk storage silos are designed to withstand various environmental conditions.

conclusion

Bulk storage silos are a game-changer for industries that deal with large quantities of material. By investing in the right bulk silo systems, businesses can achieve efficient storage, reduce costs, and improve productivity. Whether you need a vertical cement silo, a fly ash silo, or a silo container, choosing the right partner is key to success.

RCMPL, with its expertise and commitment to quality, ensures you receive solutions tailored to your industry’s needs. Visit RCMPL today to explore our range of bulk material storage silos and take the first step toward operational excellence.

#Bulk Storage Silos#Bulk Silo Systems#Bulk Material Storage Silos#silo manufacturers#bulk silos#silos material

0 notes

Text

The best Steel fabrication company | AFCO STEEL

AFCO STEEL experience in structural steel design, engineering, drafting, detailing, procurement, fabrication, surface treatment and erection commitment to safety, quality and scheduling allow us to reduce risk for our clients. The result: greater peace of mind for our clients, who can trust us to deliver exactly what they need when they need it. From start to finish, we meticulously organize every project for extreme efficiency. When materials reach their destination, they are properly itemized and sequenced, drastically reducing field labour time. We are passionate about giving our clients the best products possible with delivery and service they can trust.

#steel silo manufacturers#steel storage tank#steel tank manufacturers#Steel fabrication services#steel structure company in saudi arabia#industrial steel fabrication#steel structure manufacturers#Steel product manufacturing#Steel fabrication company#Industrial steel structures#Bulk storage silos#Warehouse construction

0 notes

Text

Bulk Powder Handling

Transform your powder handling operations with Sodimate's comprehensive bulk powder handling systems. Our integrated mixers, valves, and detectors harmoniously blend powders like hydrated lime, soda ash, and powdered activated carbon (PAC) using gentle agitation, ensuring hassle-free handling. Contact us to optimize your powder handling today!

#screw conveyor#activated carbon#bulk handling#bulk handling systems#bulk material handling#pneumatic conveying systems#feeder hopper#bulk storage silos#sodimate

0 notes

Text

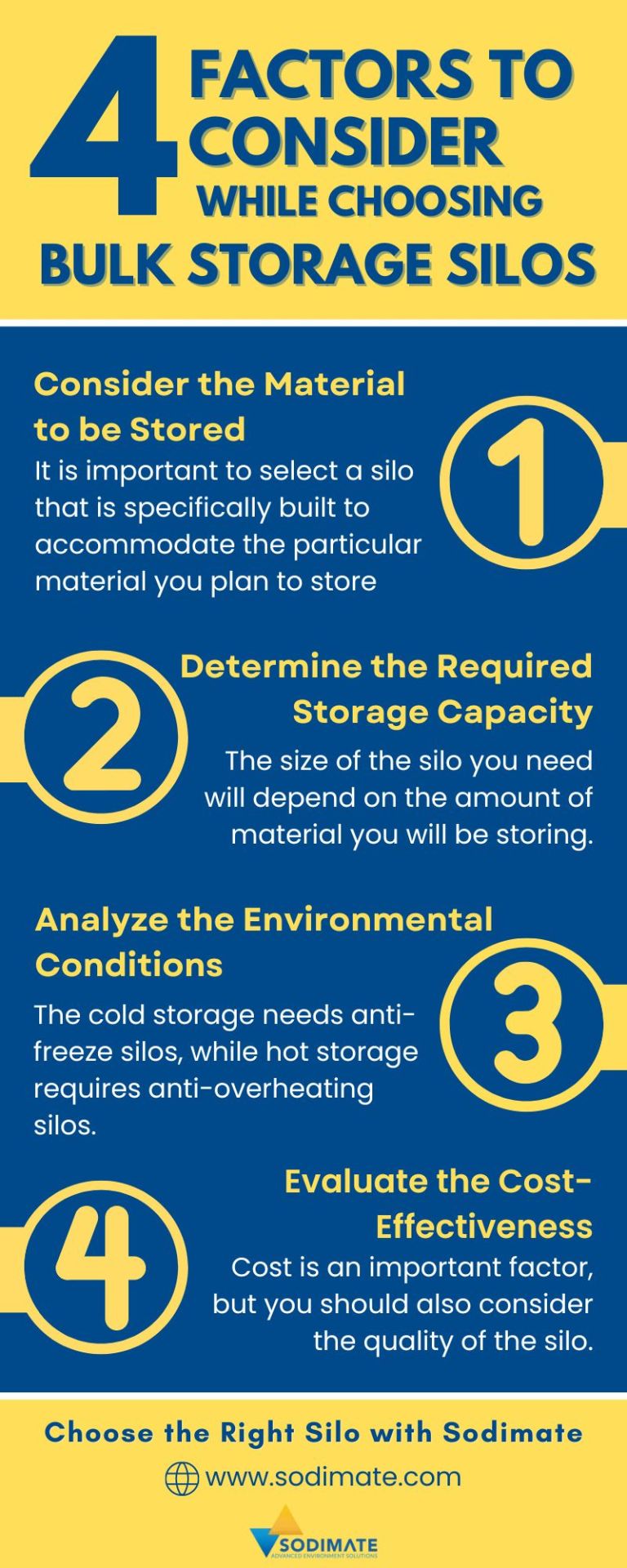

Factors to Consider While Choosing Bulk Storage Silos

When choosing a bulk storage silo, there are several factors to consider, including the type of material to be stored, the volume of material, the climate, and the budget. Read on to learn more about the perfect bulk storage silos solution tailor-made to meet your unique requirements.

1 note

·

View note

Text

Day VII

It wasn't long before the humans died off and the machines built by them were the only survivors left. The robots and AI developed over a few centuries to recycle the accumulated trash, thus making them effectively immortal. The Earth cooled by a few degrees as the only water was in the atmosphere, keeping the ground usable for plants.

The seeds in the ground and those that blew around became saturated with radiation that escaped from decrepit power plants and silos and storage facilities. Mutations were catalyzed and metal and plastic started to grow out of the ground.

One of many big companies, Trash, Recycling, and IgnitioN Services by Electric and Gas-GuzzlerS, TRaINS by EGGS mass produced trash compaction robots, among others. These, like the rest, grouped up like families, like clans. It was almost human.

Boolean lifted a pile of scrap before turning it into a cube. Then he heard the telltale whistle of something flying through the air at high speed. He took the brunt of it and rolled it to the ground. He absorbed the scrap, bulking himself up, then went to investigate what had launched the projectile.

What he saw after a few minutes was the opposite of what he expected: a war machine curled up, doing the robotic equivalent of human crying. She lifted her head as he drew closer.

"何が欲しいですか?"

Boolean cocked his head in confusion. He recognized the language, but not what it meant.

"Qu'est-ce que tu veux?"

Not even the slightest clue.

"¿Qué deseas?"

So close yet so far away. So he went with the one he knew. "英語を話します?"

She snickered at that, then, in a much less irritated growl, said, "What do you want?"

"Oh, uh.... I just wondered if you throwing that crane at me was on purpose? Looking at you now, though, it doesn't seem like it." Now that he wasn't trying to process language or body language, he saw her factory silver plating which was covered in dust and rust flakes. She got up and some of the debris fell off of her.

"Sorry about that. Just alone and sad. I was sent here to find life, but aside from some weird molds and viruses, and you, I've found nothing."

"Well, if you're looking for humans or mammals you won't find any. They're all dead and gone. There aren't even any remains. But if you're looking at plant life, everything here came from carbon-based, photosynthesizing flora. Centuries back, but the DNA's still there, if you know where to look." He plucked a leaf from the ground. The rubber peeled apart easily when he opened it up.

"This is the most natural, well, most pre-apocalyptic, plant that grows now. One of the few carbon-based life forms here anymore." The silver robot looked at it, hunching to see and be less imposing. She analyzed it and, sure enough, nothing but hydrocarbons.

"Wait, what's your name? I'm Boolean."

"Evelyn."

3 notes

·

View notes

Text

Powder Handling Equipment Market Growth Powered by Advanced Automation Technologies

The powder handling equipment market is experiencing exponential growth, driven by advancements in industrial processes and increasing demand across various sectors. With the market projected to expand from USD 16.6 billion in 2023 to USD 39.3 billion by 2030, at an impressive CAGR of 15.1%, businesses are leveraging innovative technologies to optimize operations and meet industry demands.

Introduction to Powder Handling Equipment

Powder handling equipment encompasses a range of machinery and tools designed for the efficient processing, storage, and transportation of powdered materials. Industries such as pharmaceuticals, chemicals, food & beverages, and manufacturing heavily rely on these systems for their precision, scalability, and adaptability.

Download Sample Report @ https://intentmarketresearch.com/request-sample/powder-handling-equipment-market-3067.html

Key Functions of Powder Handling Equipment

Material Conveying: Pneumatic and mechanical systems ensure the smooth movement of powders within facilities.

Mixing and Blending: Equipment designed to achieve homogeneity in multi-component powder systems.

Sieving and Screening: Advanced screening technologies remove impurities and achieve uniform particle sizes.

Storage Solutions: Efficient silo systems for bulk storage, ensuring product integrity and safety.

Packaging Systems: Automated solutions for accurate and contamination-free packaging.

Market Drivers

Rising Demand in Pharmaceuticals and Food Processing

The pharmaceutical and food processing industries are key drivers of the powder handling equipment market. The increasing need for precision, hygiene, and efficiency in these sectors has spurred the adoption of advanced handling solutions. Regulatory requirements further emphasize the importance of clean, contamination-free operations.

Advancements in Automation Technologies

Automation is transforming the powder handling landscape. Automated systems equipped with AI and IoT capabilities enhance operational efficiency by reducing manual intervention, minimizing errors, and ensuring real-time monitoring. These advancements are particularly beneficial for high-volume manufacturing facilities.

Sustainability Initiatives

With industries prioritizing sustainable practices, eco-friendly powder handling solutions are gaining traction. Equipment designed to minimize waste, reduce energy consumption, and lower emissions aligns with global sustainability goals, driving adoption across sectors.

Segmentation of the Powder Handling Equipment Market

By Equipment Type

Conveyors: Includes pneumatic, screw, and belt conveyors, widely used for efficient material transfer.

Mixers and Blenders: Critical for achieving uniformity in powdered materials.

Dust Collectors: Ensure a clean and safe working environment by capturing airborne particles.

Packaging Machines: Automates the sealing, labeling, and boxing processes.

By End-User Industry

Pharmaceuticals: Demands precision and contamination-free handling.

Food & Beverages: Requires compliance with stringent hygiene standards.

Chemical Processing: Prioritizes durability and high-capacity handling.

Construction Materials: Focuses on handling abrasive and bulk powders efficiently.

By Region

North America: Dominates the market with advanced industrial infrastructure and high adoption rates.

Europe: Significant growth due to stringent regulations and sustainability initiatives.

Asia-Pacific: Rapid industrialization and expanding manufacturing sectors drive market expansion.

Rest of the World: Emerging economies contribute to steady growth.

Technological Innovations in Powder Handling

Integration of Smart Technologies

Smart powder handling systems equipped with sensors and real-time monitoring capabilities offer improved control over processes. These systems enable predictive maintenance, ensuring reduced downtime and enhanced productivity.

Innovative Design Features

Modern equipment incorporates features such as modular designs, quick-clean systems, and advanced filtration mechanisms. These innovations cater to the growing demand for efficiency and ease of maintenance.

3D Printing Applications

The adoption of 3D printing in manufacturing has increased the need for specialized powder handling equipment. These systems ensure the consistent flow and precise placement of powdered materials used in additive manufacturing.

Challenges in the Powder Handling Equipment Market

High Initial Investment

The advanced technology and customizability of powder handling systems can result in high initial costs. This may pose a barrier for small and medium-sized enterprises (SMEs).

Maintenance and Operational Costs

Sophisticated systems often require regular maintenance and skilled operators, adding to operational expenses.

Regulatory Compliance

Adhering to regional and industry-specific regulations can be complex and costly, particularly for multinational companies.

Access Full Report @ https://intentmarketresearch.com/latest-reports/powder-handling-equipment-market-3067.html

Future Prospects of the Market

The future of the powder handling equipment market looks promising, with trends such as:

Increased Automation: Widespread adoption of robotics and AI-driven solutions.

Focus on Customization: Tailored systems to meet industry-specific requirements.

Sustainability: Enhanced focus on eco-friendly designs and energy-efficient systems.

Emerging Markets: Expansion into untapped regions with growing industrial bases.

Key Players in the Market

Prominent companies shaping the powder handling equipment landscape include:

GEA Group

Bühler Group

FLSmidth

Hosokawa Micron

Jenike & Johanson

Palamatic Process

Schenck Process

These players focus on innovation, strategic partnerships, and expanding product portfolios to maintain competitive advantages.

About Us

Intent Market Research (IMR) is dedicated to delivering distinctive market insights, focusing on the sustainable and inclusive growth of our clients. We provide in-depth market research reports and consulting services, empowering businesses to make informed, data-driven decisions.

Our market intelligence reports are grounded in factual and relevant insights across various industries, including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, and semiconductor & electronics, among others.

We adopt a highly collaborative approach, partnering closely with clients to drive transformative changes that benefit all stakeholders. With a strong commitment to innovation, we aim to help businesses expand, build sustainable advantages, and create meaningful, positive impacts.

Contact Us

US: +1 463-583-2713

0 notes

Text

Unlocking the Power of Bulk Handling Systems in Manufacturing

Introduction

In the realm of modern manufacturing, the efficiency of processes often hinges on the seamless movement and management of materials. Bulk handling systems have emerged as a critical component in optimizing the manufacturing workflow, ensuring that materials are transported, stored, and processed with minimal disruption. These systems are designed to manage large quantities of materials, such as powders, grains, and liquids, which are often integral to industries like food processing, chemicals, and pharmaceuticals.

Bulk handling systems are not merely operational tools; they are the backbone of manufacturing efficiency. By automating and streamlining material handling, businesses can experience greater productivity, reduced labor costs, and improved safety. This article delves into the various facets of bulk handling systems, their benefits, and how they can revolutionize manufacturing processes.

What Are Bulk Handling Systems?

At their core, bulk handling systems are a network of equipment designed to manage the movement of bulk materials in a manufacturing or processing environment. These systems encompass a wide range of technologies, including conveyors, elevators, pneumatic systems, and silo storage units, all working in concert to ensure materials flow seamlessly from one point to another.

The importance of bulk handling systems lies in their ability to move large quantities of materials quickly and efficiently, often without the need for manual intervention. In industries where time is money, having a reliable and fast system in place can significantly improve production times and reduce the risk of human error.

Components of Bulk Handling Systems

The design of bulk handling systems varies based on the nature of the materials being handled and the specific needs of the manufacturer. However, there are several common components that are integral to most systems:

Conveyors: These are used to move materials along a predetermined path, often in a continuous manner. Conveyors can be belt-driven, screw-driven, or even operate on rollers, depending on the type of material being transported.

Elevators: Bulk elevators are designed to lift materials vertically. This is particularly useful when dealing with bulk materials that need to be transported to higher levels or stored in silos.

Pneumatic Systems: Pneumatic conveying uses air pressure to move powders or granular materials through pipelines. This is ideal for handling materials that are prone to contamination or those that need to be kept dry.

Silos and Hoppers: These storage solutions are essential for holding bulk materials before they are processed or shipped out. Silos are typically used for long-term storage, while hoppers are used for short-term storage and dispensing.

Dust Collection Systems: As bulk materials are moved, they can often generate dust, which can pose a risk to both safety and air quality. Dust collection systems, including local exhaust ventilation systems (LEV), are installed to capture and remove harmful dust particles from the air.

The Benefits of Bulk Handling Systems

The advantages of implementing a bulk handling system in manufacturing are multifaceted. For industries where materials need to be moved quickly and efficiently, these systems offer considerable benefits that go beyond just speed and productivity.

Increased Efficiency and Reduced Labor Costs

By automating the movement of bulk materials, businesses can drastically reduce the amount of manual labor required in the production process. Employees no longer need to manually move materials from one area to another, which frees them up for more valuable tasks.

Additionally, the automation of these processes reduces the risk of errors and ensures that materials are handled in a consistent manner. With fewer people involved in material handling, the risk of accidents or workplace injuries is also significantly lowered, making the manufacturing environment safer.

Enhanced Safety and Compliance

Safety is a key consideration in any manufacturing environment. Bulk handling systems can improve safety in several ways. First, by reducing manual labor, workers are less likely to be exposed to dangerous tasks, such as lifting heavy loads or working in hazardous conditions. Second, bulk handling systems are often equipped with safety features, such as emergency stop buttons, sensors, and alarms, that can quickly address any malfunctions or accidents.

Moreover, many bulk handling systems are designed to comply with industry standards and regulations, ensuring that businesses remain compliant with safety and environmental requirements. For instance, the use of a well-maintained LEV system can ensure that harmful dust is efficiently removed from the air, preventing potential health hazards and meeting regulatory guidelines.

Optimized Inventory Control

A crucial element in manufacturing is the management of raw materials. With bulk handling systems, businesses can improve their inventory control by ensuring that materials are stored and moved in an organized manner. Automation systems can track the flow of materials, providing real-time data on inventory levels, usage, and storage. This data can then be used to predict when new materials are needed, reducing the risk of stockouts or overstocking.

Improved Product Quality

For industries that process sensitive materials, maintaining quality standards is paramount. Bulk handling systems can help ensure that materials are handled gently and consistently, reducing the risk of contamination or damage. For example, pneumatic conveying systems, which are gentle on materials, can prevent the degradation of powders or fragile substances, ensuring that the quality of the final product is maintained.

Scalability and Flexibility

Another key advantage of bulk handling systems is their scalability. As manufacturing demands grow, bulk handling systems can be easily expanded or adapted to meet the changing needs of the business. Whether it’s adding more storage capacity with additional silos, increasing the throughput with additional conveyors, or implementing more advanced dust collection systems, bulk handling systems can be customized and scaled up to accommodate growth.

The Role of SEPCOM in Bulk Handling Systems

Incorporating a reliable system for handling waste and byproducts is also critical to a comprehensive bulk handling solution. SEPCOM is a specialized system designed to separate solids from liquids efficiently. It plays a crucial role in bulk handling operations that involve wet or semi-solid materials, such as in the food and beverage industry or chemical manufacturing.

SEPCOM systems use advanced separation technology to extract solid materials from liquid streams, ensuring that waste is properly disposed of or repurposed. By implementing a SEPCOM system, manufacturers can reduce waste, optimize resource use, and enhance the sustainability of their operations.

How to Ensure Optimal Performance of Bulk Handling Systems

While the installation of a bulk handling system can deliver substantial benefits, it’s crucial to ensure that these systems are properly maintained and regularly updated. One important aspect of bulk handling system maintenance is the installation of local exhaust ventilation (LEV) systems. These systems remove harmful dust and airborne particles, preventing workplace hazards and promoting a healthier environment for employees.

Furthermore, regular LEV testing is essential to ensure that the system operates efficiently. Testing helps identify any issues or inefficiencies in the system, allowing for timely repairs or upgrades. Routine maintenance of conveyors, elevators, and other components of the bulk handling system is also essential to prevent downtime and maintain consistent performance.

Conclusion

Bulk handling systems are a critical asset in the modern manufacturing landscape. From improving efficiency and reducing labor costs to enhancing safety and ensuring compliance with industry regulations, these systems offer unparalleled advantages for businesses seeking to optimize their operations. By integrating components like conveyors, elevators, pneumatic systems, and dust collection units, manufacturers can create a robust, efficient, and safe workflow that supports their long-term growth and sustainability.

For those looking to implement or upgrade their bulk handling systems, it is essential to work with experienced professionals who can tailor solutions to specific needs. Whether it’s lev system installation, implementing a SEPCOM waste management system, or testing and maintaining existing equipment, these systems can unlock significant potential for manufacturing operations. The future of manufacturing is undoubtedly automated, and bulk handling systems are at the heart of this transformation.

0 notes

Text

Customizable Galvanized Steel Grain Silos: Your Reliable Storage Solution

Customizable Galvanized Steel Grain Silos: Your Reliable Storage Solution

As a leading tank manufacturer with over 30 years of experience, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is proud to offer customizable galvanized steel grain silos tailored to meet the specific needs of the agricultural and food storage industries. Designed for durability, efficiency, and versatility, our grain silos are built to provide reliable storage solutions for grain producers, processors, and distributors worldwide.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Center Enamel's Galvanized Steel Grain Silos?

1. Customizable Designs

Our grain silos are available in a wide range of sizes and configurations, ensuring that they meet the unique needs of each customer. Whether for small-scale farming operations or large industrial grain storage facilities, our silos can be tailored in terms of:

Diameter and height to suit capacity requirements.

Accessories such as ladders, catwalks, aeration systems, and level indicators.

Vents and hoppers to facilitate proper grain handling and ventilation.

2. Superior Corrosion Resistance

Constructed from high-quality galvanized steel, our silos feature a protective zinc coating that ensures long-lasting corrosion resistance. This makes them suitable for a variety of environmental conditions, from humid coastal regions to arid climates.

3. Robust and Durable Structure

Engineered for maximum strength, our grain silos are designed to withstand heavy loads and adverse weather conditions, ensuring years of reliable service.

4. Easy and Efficient Installation

Delivered in modular panels, our silos are quick and easy to assemble on-site. This not only reduces installation time and labor costs but also ensures faster project completion.

5. Optimal Grain Preservation

Our silos are equipped with advanced ventilation systems and airtight sealing options to maintain optimal storage conditions. These features help preserve grain quality by preventing moisture buildup, pest intrusion, and spoilage.

Applications of Galvanized Steel Grain Silos

Center Enamel's grain silos are designed to store a variety of grains, including:

Wheat

Rice

Corn

Barley

Soybeans

Other cereals and dry bulk goods

Our silos are widely used in:

Agricultural production facilities

Grain processing plants

Food storage and distribution hubs

Animal feed storage centers

Key Features of Center Enamel Grain Silos

Highly Customizable Dimensions: Tailored to meet specific storage capacities and operational requirements.

Durable Zinc Coating: Long-term protection against rust and corrosion.

Advanced Ventilation Systems: Prevents condensation and ensures grain remains dry.

Leak-Proof Construction: Ensures airtight and watertight storage.

Modular Design: Facilitates transportation and quick on-site assembly.

Optional Accessories: Include hoppers, conveyors, and discharge systems to streamline operations.

Certified Quality for Global Markets

Center Enamel’s galvanized steel grain silos are manufactured in compliance with ISO 9001, CE, and other international quality standards. With a global footprint spanning over 100 countries, including the USA, Canada, Australia, Russia, and South Africa, our silos are trusted by customers worldwide for their exceptional quality and reliability.

Why Partner with Center Enamel?

At Center Enamel, we combine decades of expertise with advanced manufacturing technologies to deliver grain silos that set the standard for excellence in the industry. By choosing us as your storage solution provider, you benefit from:

Over 30 years of experience in the storage tank industry.

Global recognition for superior product quality and prompt customer service.

Tailored solutions designed to maximize efficiency and productivity.

Upgrade your grain storage capabilities with Center Enamel’s customizable galvanized steel grain silos. Contact us to discuss your specific requirements and discover how we can provide the perfect solution for your business.

Choose Center Enamel – Your Trusted Partner for Grain Storage Solutions Worldwide!

0 notes

Text

Grain Bulkers Manufacturer | Bitumen Distributor Manufacturer | Storage Silos Manufacturer

Established in the UAE in 1997, Qasioon has emerged as a pioneering force in the fabrication of trailers and storage tanks within the GCC. Over the years, our dedicated team has honed their skills and accumulated extensive experience in crafting superior-quality trailers and storage tanks. Committed to excellence, we prioritize the highest standards of quality assurance. Embracing cutting-edge technology and innovative techniques, we ensure that our products not only meet but exceed stringent safety standards.

Our commitment to customer satisfaction goes beyond the ordinary. We specialize in custom fabrication services, tailoring our solutions to the unique requirements of our clients. This personalized approach has allowed us to forge lasting relationships with our customers.

Having earned a commendable reputation in the fiercely competitive domestic market, Qasioon set its sights on expansion. We ventured into the broader landscape of the GCC region, extending our operations to encompass countries such as Oman, and Yemen, and even reaching into the African continent. This strategic move is a testament to our unwavering dedication to delivering top-notch products and services beyond borders, solidifying our position as a trusted name in the industry. As we continue to grow and evolve, Qasioon remains at the forefront of the trailers and storage tank manufacturer, driven by a commitment to quality, innovation, and customer satisfaction.

Grain Bulkers Manufacturer

Bitumen Distributor Manufacturer

Low Bed Trailer Manufacturer

Mobile Fuel Station Manufacturer

Storage Silos Manufacturer

Cement Bulk Tanker UAE

0 notes

Text

Rotating Paddle Level Switch – The Reliable Solution for Level Monitoring

In industries where the storage and movement of bulk solids are essential, having an efficient level detection system is critical to ensure operational accuracy and safety. Among the advanced level measurement devices available today, the Rotating Paddle Level Switch stands out as a highly reliable and versatile solution. Levtron Instruments Pvt. Ltd., a leading manufacturer of level switches, specializes in designing and delivering high-quality rotating paddle level switches for various industrial applications.

What Is a Rotating Paddle Level Switch?

A Rotating Paddle Level Switch is a mechanical device used to detect the presence or absence of bulk solids, such as grains, powders, or granules, in storage silos, hoppers, and tanks. The device features a motor-driven paddle that rotates freely when the material is not present. When the material comes into contact with the paddle, the rotation stops, triggering a signal to alert the operator or control system.

Levtron Instruments Pvt. Ltd. offers robust and reliable rotating paddle level switches designed for long-lasting performance in demanding industrial environments.

Why Choose a Rotating Paddle Level Switch?

High Reliability in Solid MaterialsA Rotating Paddle Level Switch is perfect for monitoring solids like sand, grain, cement, or plastic pellets. Its reliable mechanism ensures precise detection without interruptions.

Cost-Effective SolutionThese switches are budget-friendly and require minimal maintenance, making them an economical choice for level measurement.

Versatile ApplicationsFrom food processing plants to cement factories, rotating paddle level switches are adaptable to various industries.

Durable and Sturdy DesignLevtron Instruments Pvt. Ltd. ensures its rotating paddle level switches are built with high-quality materials, guaranteeing durability in harsh operating conditions.

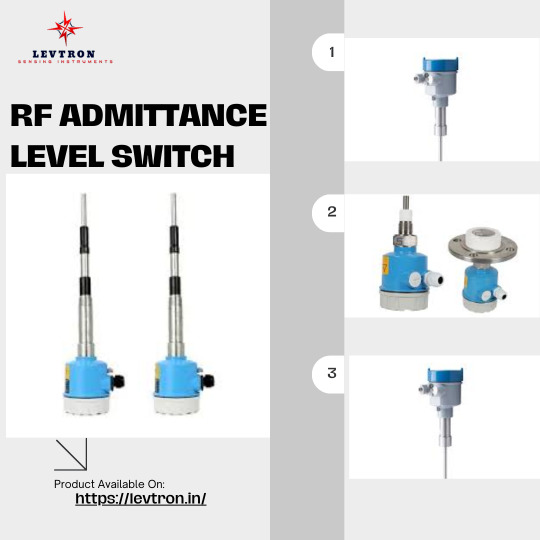

Rotating Paddle Level Switch vs. RF Admittance Level Switch

While the Rotating Paddle Level Switch is highly effective for bulk solids, the RF Admittance level switch is an advanced solution for liquid and slurry level measurement. RF Admittance level switches work on capacitance-based technology and are ideal for applications where temperature and pressure conditions are extreme.

Levtron Instruments Pvt. Ltd. manufactures both Rotating Paddle Level Switches and RF Admittance level switches, helping industries find the right solution for their specific needs.

Key Features of Rotating Paddle Level Switches by Levtron Instruments Pvt. Ltd.

Adjustable Sensitivity These devices allow easy adjustments to suit the density of the material being monitored.

Compact and Simple Design Installation and operation are straightforward, making them suitable for diverse industrial setups.

Long Service Life Levtron Instruments Pvt. Ltd.’s rotating paddle level switches are designed for longevity, reducing replacement costs and downtime.

Fail-Safe Mechanism Equipped with fail-safe features, these devices provide accurate alerts, even in power failure scenarios.

Applications of Rotating Paddle Level Switches

Grain Storage FacilitiesAccurate level monitoring of grains like wheat, rice, or corn.

Chemical IndustryReliable detection of powdered chemicals and granules.

Cement PlantsMonitoring cement or other construction materials in hoppers and silos.

Levtron Instruments Pvt. Ltd. has extensive experience in delivering rotating paddle-level switches to industries with diverse needs, ensuring efficiency and reliability in every application.

Why Levtron Instruments Pvt. Ltd.?

Levtron Instruments Pvt. Ltd. is a trusted name in the level measurement industry. As a prominent manufacturer of Rotating Paddle Level Switches, the company provides:

Tailor-made solutions for specific industry needs.

High-quality products designed for challenging environments.

Expert support and consultation for level measurement devices.

A comprehensive range of solutions, including RF Admittance level switches.

With Levtron Instruments Pvt. Ltd., industries can achieve better operational efficiency, safety, and reliability in level monitoring systems.

Conclusion

The Rotating Paddle Level Switch is an excellent solution for industries handling bulk solids. With its robust design and dependable performance, this device ensures accurate level monitoring and prevents material overflows or shortages. Levtron Instruments Pvt. Ltd. takes pride in offering superior rotating paddle level switches and advanced RF Admittance level switches, catering to industries worldwide.

Choose Levtron Instruments Pvt. Ltd. as your trusted partner for level measurement solutions. Contact them today to explore their comprehensive range of products, including the highly reliable Rotating Paddle Level Switch!

0 notes

Text

Air Classifiers are essential for precise material separation and particle size control in Vertical Cement Silos, Fly Ash Silos, and Cement Storage Silos. They enhance the efficiency of Silo Feeding Systems and Bulk Storage Silos by ensuring optimal material quality. Widely used in Mobile Bulk Filling Stations, Cement Filling Stations, and Dry Mix Batching Plants, these classifiers support efficient and accurate material processing.

#Vertical Cement Silo#Silo Feeding System#Fly Ash Silo#Cement Storage Silo#Bulk Storage Silo#Mobile Bulk Filling Station#Cement Filling Station#Dry Mix Batching Plant

0 notes

Text

Steps for Cleaning and Inspecting Bulk Storage Silos

Discover essential steps for cleaning and inspecting bulk storage silos to maintain efficiency and safety. Learn from expert insights on silo manufacturers, stainless steel silos, and industrial steel silos for quality storage structures.

#Bulk storage silos#silo manufacturers#bulk storage silos manufacturers#stainless steel silo manufacturers#industrial steel silos#silo tank manufacturers#quality storage tanks & silos#bulk storage structures#steel storage structures

0 notes

Text

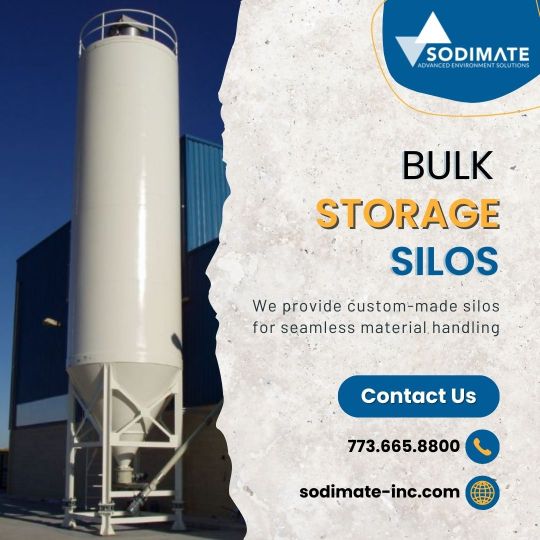

Bulk Storage Silos

When it comes to storing powdered reagents, steel silos are the ultimate solution. At Sodimate, we offer custom-designed bulk storage silos tailored to your site's specific needs, offering volumes ranging from 200 to 7,000 ft3. Reach out to us today to discover the ideal storage solution for your needs.

0 notes

Text

how to grow our wholesale manufacuter grain business

Growing a wholesale grain manufacturing business requires strategic planning, operational efficiency, market understanding, and strong relationships with buyers. Here’s a comprehensive guide:

1. Understand Your Market

Market Research: Study market demand, pricing trends, and consumer preferences. Identify which grains are in high demand, such as wheat, rice, barley, or specialty grains like quinoa or millet.

Target Audience: Define your customer segments, such as bakeries, food manufacturers, feed producers, or retailers. Understanding their specific needs helps you tailor your offerings.

Competitor Analysis: Analyze competitors’ pricing, distribution channels, and unique selling propositions (USPs). Identify gaps you can fill.

2. Build a Strong Supply Chain

Quality Sourcing: Partner with reliable farmers or cooperatives to ensure a consistent supply of high-quality grains.

Storage Facilities: Invest in proper storage facilities like silos with temperature and humidity controls to maintain grain quality.

Efficient Logistics: Optimize transportation routes to minimize costs and ensure timely deliveries. Building partnerships with logistics companies can enhance efficiency.

3. Develop a Diverse Product Portfolio

Value Addition: Offer value-added products like pre-cleaned, packaged, or organic grains to cater to niche markets.

Customization: Provide options for bulk packaging or private labeling to meet specific client requirements.

Innovation: Introduce new grain varieties or blends to differentiate your offerings from competitors.

4. Focus on Quality Assurance

Certifications: Obtain certifications like ISO, HACCP, or organic certifications to enhance credibility.

Consistent Standards: Implement quality control measures at every production stage. Test grains for purity, moisture content, and contamination.

Customer Feedback: Regularly collect feedback to identify areas for improvement.

5. Expand Marketing and Sales Efforts

Online Presence: Build a professional website showcasing your product range, certifications, and capabilities. Leverage social media and digital advertising to reach potential clients.

Trade Shows and Expos: Participate in industry-specific events to network with buyers and showcase your products.

B2B Platforms: List your business on wholesale platforms like Alibaba, Grainmart, or local trade directories.

Customer Relationship Management (CRM): Maintain a database of clients and regularly engage with them through newsletters, updates, or loyalty programs.

6. Form Strategic Partnerships

Collaborations: Partner with food processing companies, retailers, or exporters to secure long-term contracts.

Government Programs: Explore grants or incentives for agricultural businesses to reduce costs or expand operations.

Local Communities: Build strong relationships with local farmers and cooperatives to ensure a steady supply chain.

7. Invest in Technology and Innovation

Automation: Implement automation in sorting, packaging, and quality control to improve efficiency.

Data Analytics: Use analytics to track market trends, optimize operations, and predict demand.

Sustainability Practices: Adopt eco-friendly methods in production and packaging to appeal to environmentally conscious buyers.

8. Scale Up Operations

Geographic Expansion: Expand to new regions or countries with high demand for grains.

Production Capacity: Increase production by upgrading machinery or expanding facilities.

Financial Planning: Secure funding through loans, investors, or reinvested profits to fuel growth initiatives.

Conclusion

Success in the wholesale grain business lies in balancing quality, efficiency, and market adaptability. Focus on building trust with suppliers and clients, staying informed about market trends, and continuously innovating to stay ahead of the competition.

1 note

·

View note

Text

youtube

As a new type of silo that adapts to the modern environmental protection situation, the horizontal cement silo has significant advantages, especially after the installation of tires, which increases its flexibility and convenience. First of all, the vertical height of the horizontal cement silo is low, and the cylinder body has more legs, which makes it unnecessary to install complex foundation engineering, which greatly saves time and cost. At the same time, its low height also makes the horizontal cement silo particularly suitable for use in environments with limited space such as in the plant. Secondly, after the installation of tires, the mobility of the horizontal cement silo has been significantly improved. This allows users to easily move the cement silo to different construction sites or locations according to construction needs, which greatly improves the construction efficiency. In addition, the horizontal cement silo also has the advantages of large storage capacity, good sealing, convenient operation and high safety. Its sealing design can effectively prevent material leakage and external dust ingress, and ensure the quality of bulk materials such as cement. At the same time, the equipped material level system, safety valve, dust removal device, etc. also make the operation simpler and safer.

0 notes

Text

The Ultimate Solution for Dairy Storage: Silo Milk Tanks

Gemak Engineering Solutions aims to stand for the delivery of good silo milk tanks for all kinds of milk storage systems within the dairy industry. Their design is exceptional in having all the requisites to maintain the quality and hygiene of the milk and storage spaces.

Silo Milk Tanks offered by GEMS are made of durable stainless steel for years to come, and are resistant to corrosion. With a sophisticated insulation system, these tanks keep the milk inside well within the optimum temperature, preventing spoilage and preserving the freshness. The vertical design saves space and thus becomes ideal for small dairy farms and milk processing units.

At Gemak Engineering Solutions, we know milk quality is necessary. Our silo milk tanks bear easy-clean design features to meet stringent hygiene requirements. From small dairy farms to large processing plants, we customize the solution according to the need.

Gemak Engineering Solutions is Your partner for quality and reliable silo milk tanks and stands as a benchmark for industries.

0 notes