#Rotating paddle level switch

Explore tagged Tumblr posts

Text

Rotating Paddle Level Switch – The Ultimate Solution for Bulk Material Monitoring

In industries that handle bulk solids, powders, and granules, maintaining precise inventory control is crucial. A Rotating Paddle Level Switch is a trusted solution for reliable level detection in storage tanks, hoppers, and silos.

Levtron, a leading manufacturer of rotating paddle level switches, provides high-performance devices designed to deliver accurate, maintenance-free material monitoring across various industries.

How Does a Rotating Paddle Level Switch Work?

A Rotating Paddle Level Switch operates on a mechanical principle where a motor-driven paddle continuously rotates. When bulk material reaches the paddle, it resists movement, triggering a signal that detects the level of the material.

Key Benefits of Rotating Paddle Level Switches:

✔ Highly reliable – Works with a wide range of bulk materials ✔ Maintenance-free operation – No electronic components prone to failure ✔ Adjustable sensitivity – Detects even lightweight powders ✔ Versatile applications – Compatible with different material densities

Features of Levtron’s Rotating Paddle Level Switch

✅ Durable Construction – Designed for long-lasting performance in harsh industrial conditions ✅ High Sensitivity Adjustment – Detects fine powders, grains, and bulk solids ✅ Dust & Moisture Resistant – Ideal for use in food, cement, and chemical industries ✅ Fail-Safe Mechanism – Ensures process safety with reliable detection ✅ Easy Installation & Integration – Compatible with industrial automation systems

Applications of Rotating Paddle Level Switch

1. Cement & Construction Industry

Detects levels of cement, sand, and fly ash in silos

Prevents material overflow and wastage

2. Food & Beverage Industry

Monitors grain, flour, and sugar levels in hoppers

Ensures smooth production processes

3. Chemical & Pharmaceutical Industry

Ideal for detecting chemical powders, resins, and granules

Enhances storage efficiency and reduces spillage

4. Agriculture & Plastics Industry

Used for animal feed, plastic pellets, and other granular materials

Ensures effective bulk handling operations

Why Choose Levtron for Rotating Paddle Level Switches?

Levtron offers industry-leading solutions for bulk material level detection. Our Rotating Paddle Level Switches provide high-accuracy, durability, and easy integration, ensuring seamless industrial operations.

What Sets Levtron Apart?

✔ Cutting-edge technology for bulk material sensing ✔ Custom solutions tailored to specific industry needs ✔ Long-lasting and maintenance-free performance ✔ Seamless automation integration for process efficiency

Conclusion

A Rotating Paddle Level Switch is a reliable and cost-effective solution for bulk material monitoring across industries. Levtron’s advanced technology ensures high precision, durability, and efficiency, making it an essential tool for inventory management.

🔹 Looking for a premium Rotating Paddle Level Switch? Explore Levtron’s trusted solutions today!

0 notes

Text

Rotating Paddle Level Switch – The Reliable Solution for Level Monitoring

In industries where the storage and movement of bulk solids are essential, having an efficient level detection system is critical to ensure operational accuracy and safety. Among the advanced level measurement devices available today, the Rotating Paddle Level Switch stands out as a highly reliable and versatile solution. Levtron Instruments Pvt. Ltd., a leading manufacturer of level switches, specializes in designing and delivering high-quality rotating paddle level switches for various industrial applications.

What Is a Rotating Paddle Level Switch?

A Rotating Paddle Level Switch is a mechanical device used to detect the presence or absence of bulk solids, such as grains, powders, or granules, in storage silos, hoppers, and tanks. The device features a motor-driven paddle that rotates freely when the material is not present. When the material comes into contact with the paddle, the rotation stops, triggering a signal to alert the operator or control system.

Levtron Instruments Pvt. Ltd. offers robust and reliable rotating paddle level switches designed for long-lasting performance in demanding industrial environments.

Why Choose a Rotating Paddle Level Switch?

High Reliability in Solid MaterialsA Rotating Paddle Level Switch is perfect for monitoring solids like sand, grain, cement, or plastic pellets. Its reliable mechanism ensures precise detection without interruptions.

Cost-Effective SolutionThese switches are budget-friendly and require minimal maintenance, making them an economical choice for level measurement.

Versatile ApplicationsFrom food processing plants to cement factories, rotating paddle level switches are adaptable to various industries.

Durable and Sturdy DesignLevtron Instruments Pvt. Ltd. ensures its rotating paddle level switches are built with high-quality materials, guaranteeing durability in harsh operating conditions.

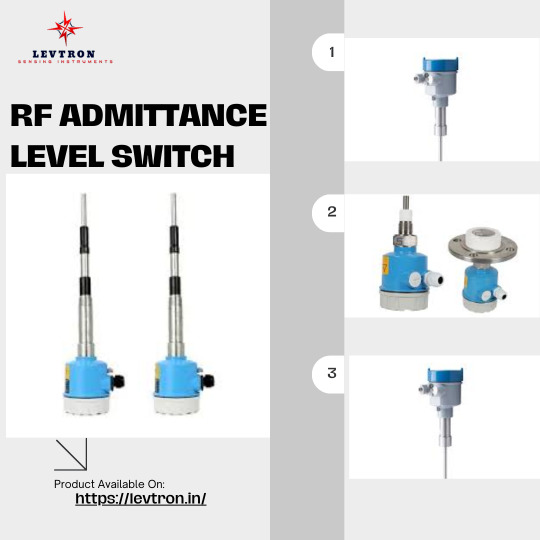

Rotating Paddle Level Switch vs. RF Admittance Level Switch

While the Rotating Paddle Level Switch is highly effective for bulk solids, the RF Admittance level switch is an advanced solution for liquid and slurry level measurement. RF Admittance level switches work on capacitance-based technology and are ideal for applications where temperature and pressure conditions are extreme.

Levtron Instruments Pvt. Ltd. manufactures both Rotating Paddle Level Switches and RF Admittance level switches, helping industries find the right solution for their specific needs.

Key Features of Rotating Paddle Level Switches by Levtron Instruments Pvt. Ltd.

Adjustable Sensitivity These devices allow easy adjustments to suit the density of the material being monitored.

Compact and Simple Design Installation and operation are straightforward, making them suitable for diverse industrial setups.

Long Service Life Levtron Instruments Pvt. Ltd.’s rotating paddle level switches are designed for longevity, reducing replacement costs and downtime.

Fail-Safe Mechanism Equipped with fail-safe features, these devices provide accurate alerts, even in power failure scenarios.

Applications of Rotating Paddle Level Switches

Grain Storage FacilitiesAccurate level monitoring of grains like wheat, rice, or corn.

Chemical IndustryReliable detection of powdered chemicals and granules.

Cement PlantsMonitoring cement or other construction materials in hoppers and silos.

Levtron Instruments Pvt. Ltd. has extensive experience in delivering rotating paddle-level switches to industries with diverse needs, ensuring efficiency and reliability in every application.

Why Levtron Instruments Pvt. Ltd.?

Levtron Instruments Pvt. Ltd. is a trusted name in the level measurement industry. As a prominent manufacturer of Rotating Paddle Level Switches, the company provides:

Tailor-made solutions for specific industry needs.

High-quality products designed for challenging environments.

Expert support and consultation for level measurement devices.

A comprehensive range of solutions, including RF Admittance level switches.

With Levtron Instruments Pvt. Ltd., industries can achieve better operational efficiency, safety, and reliability in level monitoring systems.

Conclusion

The Rotating Paddle Level Switch is an excellent solution for industries handling bulk solids. With its robust design and dependable performance, this device ensures accurate level monitoring and prevents material overflows or shortages. Levtron Instruments Pvt. Ltd. takes pride in offering superior rotating paddle level switches and advanced RF Admittance level switches, catering to industries worldwide.

Choose Levtron Instruments Pvt. Ltd. as your trusted partner for level measurement solutions. Contact them today to explore their comprehensive range of products, including the highly reliable Rotating Paddle Level Switch!

0 notes

Text

Rotating Paddle Level Switch supplier, Manufacturer, Exporter, Dealer in Philippines, Cambodia, Bangladesh, manmar, Africa, Egypt, Ethiopia, Iran, Iraq, Kenai, Tanzania, Nigeria, shrilanka, Thailand, south America, Argentina, Bolivia, Brazil, Colombia, Peru

Jaycee tech is the best Rotating Paddle Level Switch supplier, Manufacturer, Exporter, Dealer in Philippines, Cambodia, Bangladesh, manmar, Africa, Egypt, Ethiopia, Iran, Iraq, Kenai, Tanzania, Nigeria, shrilanka, Thailand, south America, Argentina, Bolivia, Brazil, Colombia, Peru

#Rotating paddle level switch#Rotating paddle level switch supplier#Rotating paddle level switch Manufacturer#Rotating paddle level switch Exporter#Rotating paddle level switch Dealer#Philippines#Cambodia#Bangladesh#manmar#Africa#Egypt#Ethiopia#Iran#Iraq#Kenai#Tanzania#Nigeria#shrilanka#Thailand#south America#Argentina#Bolivia#Brazil#Colombia#Peru

0 notes

Text

#Rotating paddle level switch#rotating paddle level switch supplier#rotating paddle level switch manufacturer#rotating paddle level switch exporter#rotating paddle level switch dealer#Rotating paddle level switch in pune#Rotating paddle level switch in india#rotating paddle level switch supplier in pune#rotating paddle level switch supplier in india#rotating paddle level switch manufacturer in pune#rotating paddle level switch manufacturer india

0 notes

Text

Trumen is a technocrat driven organization aimed at providing top-of-the-range and high quality level measurement and process control instruments. Formed by the pioneers who devoted their respective lives in development, design and delivery of solution to the problems faced in the field of level sensing and process measurements. Trumen has a fixed point agenda about “sensing matters”, and each device created at Trumen is thoroughly tested to pass the quality norms set in-house, in order to give the best performance in all operating conditions.

The products designed and manufactured by Trumen confirm to various international quality standards. Instruments having best in class IP-68 certified enclosures, Ex-proof enclosures suitable for hazardous area and gas group IIA, IIB and IIC and PU Epoxy coated enclosures suitable for harsh environment. Trumen also produces instruments with SS enclosures suitable for food and pharma industries and PU enclosures suitable for chemical industries.

Address: 39, Mangal Nagar, Behind Sai Ram Plaza, Near Rajeev Gandhi Circle, AB Road, Indore, Madhya Pradesh 452001

Web: https://trumen.in/

Contact: 0731 497 2065

#Point Level Switches#Level Transmitter#Indicator Controller Transmitter#Level Switch#Level Sensor#Level Indicator#Vibrating Fork Level Sensor#Vibrating Fork Level Switch#Vibrating Rod Point Level Switch#Tuning Fork Point Level Switch#Admittance Point Level Switch#Rotating Paddle Level Switch#Radar Level Transmitter

0 notes

Text

0 notes

Text

0 notes

Text

Take Control of the Race with the Ant Esports GW190 Crosa Racing Wheel (Black): An Immersive Experience for Budget-Conscious Racers

Strap yourself in and experience the thrill of the race track with the Ant Esports GW190 Crosa Racing Wheel. This versatile and affordable racing wheel offers a realistic driving experience for casual and serious sim racers alike. Here's a closer look at what the GW190 Crosa has to offer:

Get in the Driver's Seat:

Realistic Driving Experience: Feel the natural turning radius of a real car with the 270-degree lock-to-lock rotation. This allows for precise control and a more immersive driving experience.

Sturdy Pedals with Heel Rest and Anti-Slip Pad: Maintain precise control over acceleration and braking with the included gas and brake pedals. The built-in heel rest and anti-slip pad provide a comfortable and stable driving position.

Customizable Sensitivity Levels: Tailor the wheel's sensitivity to your driving style and preferred feel. Choose from three levels: Arcade, Pro, and Expert, for a personalized racing experience.

Versatility and Compatibility:

Universal Compatibility: The GW190 Crosa connects seamlessly to your PC, Xbox One, Xbox Series X/S, PS4, PS3, Nintendo Switch, and even Android TV using a wired USB connection. Enjoy racing on a variety of platforms without needing additional adapters.

Compact Design: The compact size of the GW190 Crosa makes it ideal for smaller desks or setups where space is limited.

Additional Features:

Ergonomic Design: The comfortable and well-gripped wheel ensures you can race for extended periods without fatigue.

Shift Paddles: Integrated shift paddles allow for quick and easy gear changes, adding another layer of realism to your racing experience.

Easy Setup: The GW190 Crosa is simple to set up and use, allowing you to jump into the race quickly.

Who is the Ant Esports GW190 Crosa For?

The GW190 Crosa is ideal for:

Gamers on a budget: This racing wheel offers a great balance of affordability and features.

Casual and beginner sim racers: The user-friendly design and customizable sensitivity make it perfect for those new to racing games.

Gamers with limited space: The compact design makes it a great option for smaller desks or setups.

Things to Consider:

Limited Force Feedback: This racing wheel does not feature force feedback, which provides a more immersive feel by simulating bumps, vibrations, and resistance from the road.

No Clutch Pedal: The GW190 Crosa only includes gas and brake pedals. While some racing games might not require a clutch, it's a feature missing for more serious sim racers.

Durability: Given its budget-friendly price point, the long-term durability might not be on par with high-end racing wheels.

Overall, the Ant Esports GW190 Crosa Racing Wheel is a compelling choice for budget-conscious gamers looking to enhance their racing experience. Its comfortable design, customizable controls, and wide compatibility make it a great entry point into the world of sim racing.

0 notes

Text

Point Level indicator

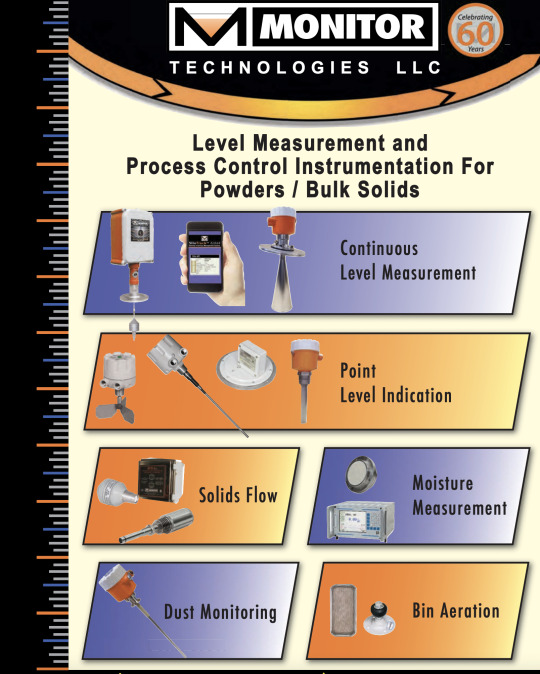

Understanding Point Level Indicators: Applications, Types, and Benefits

In industrial processes where precise measurement and control are paramount, point level indicators play a crucial role. These instruments provide essential information about the level of liquids, solids, or powders in tanks, silos, or vessels. Whether it's monitoring inventory levels, preventing overfilling or emptying, or ensuring efficient operation, point level indicators offer reliable solutions across various industries.

1. What is a Point Level Indicator?

A point level indicator is a device used to detect the presence or absence of material at a specific point within a container. Unlike continuous level sensors, which provide continuous measurement, point level indicators simply indicate whether the material level has reached a predetermined point. This simplicity makes them ideal for applications where precise level control at specific thresholds is required.

2. Types of Point Level Indicators

a. Mechanical Level Switches: These switches use mechanical mechanisms, such as floats, to detect material levels. When the material reaches the designated level, the switch is activated, signaling the presence of material.

b. Capacitance Probes: Capacitance probes utilize changes in capacitance to detect material presence. When the material comes into contact with the probe, it alters the capacitance, triggering a signal.

c. Vibrating Forks: Vibrating fork point level indicators consist of two prongs that vibrate at their natural frequency. When material covers the forks, the vibration frequency changes, indicating material presence.

d. Optical Level Sensors: These sensors use light to detect material presence. When material obstructs the optical beam, the sensor triggers a signal.

e. Conductivity Probes: Conductivity probes measure the electrical conductivity of the material. When the material reaches the probe, completing an electrical circuit, it triggers a signal.

f. Rotary Paddle Switches: Rotary paddle switches employ a rotating paddle that is stopped or impeded when material reaches a certain level, signaling its presence.

3. Applications of Point Level Indicators

a. Inventory Management: Point level indicators are commonly used in inventory management systems to monitor material levels in storage tanks or silos. By providing timely alerts when material levels reach predetermined thresholds, they help prevent stockouts or overfilling.

b. Process Control: In industrial processes, maintaining precise material levels is essential for ensuring optimal operation and product quality. Point level indicators help control material flow, preventing equipment damage or production bottlenecks.

c. Safety Monitoring: Point level indicators play a crucial role in safety systems by detecting high or low material levels that could lead to hazardous conditions, such as spills, leaks, or equipment failures.

d. Pump Protection: In pump systems, point level indicators prevent dry running by signaling when the liquid level is too low, protecting pumps from damage and extending their lifespan.

e. Overfill Prevention: In storage tanks, overfilling can result in environmental hazards, regulatory violations, and costly cleanup efforts. Point level indicators help prevent overfilling by signaling when the tank reaches its maximum capacity.

4. Benefits of Point Level Indicators

a. Reliability: Point level indicators offer reliable performance in detecting material presence or absence, ensuring accurate monitoring and control.

b. Versatility: With various types and configurations available, point level indicators can be adapted to suit different applications and materials, from liquids to solids.

c. Cost-Effectiveness: Compared to continuous level sensors, point level indicators are often more cost-effective, making them an economical choice for many industrial applications.

d. Easy Installation and Maintenance: Most point level indicators are straightforward to install and require minimal maintenance, reducing downtime and operational costs.

e. Safety: By providing timely alerts and preventing overfilling or emptying, point level indicators contribute to a safer working environment and help mitigate risks associated with material handling. Point level indicators are indispensable tools in industries where precise level measurement and control are essential. From inventory management to process control and safety monitoring, these devices offer reliable solutions for a wide range of applications. With their versatility, reliability, and cost-effectiveness, point level indicators continue to play a vital role in optimizing operations, enhancing safety, and ensuring efficient resource management across industries. As technology advances, we can expect further innovations in point level indicator design and functionality, continuing to meet the evolving needs of modern industrial processes.

1 note

·

View note

Text

Level Switches Market Growth, Challenges & Opportunities for Future Development 2022 to 2032

The level switch or sensor monitors the level of the liquid and sends a signal to the monitoring station if the specified level or marked point falls below or rises over the designated point. This enables the system to respond and function properly as soon as something is detected. The global market for level switches is expected to reach US$ 4,133.7 million by 2032, expanding at a 3.7% CAGR between 2022 and 2032.

They are installed in a tank or container, and the switches include a vertically mounted level switch, a side mounted level switch, and a stem mounted level switch that is linked to an electrical contact output. For example, level switches are used in various equipment in power plants. For example, in steam boilers, the proper amount of water is necessary to generate steam at the right moment, and level switches are installed within the closed tank to do this.

Download a PDF Sample Copy of this Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-4816

Regional Outlook

The regional coverage of level switches market includes North America, Latin America, Europe, APAC and MEA. Level switches market witnesses a high demand and production in Europe and North America. APAC holds major market share in the global level switches market due to intensifying demand for automation, increasing manufacturing industries and also increasing energy sectors where level switches are highly used.

North America & Europe hold the second highest share in the global level switches market. Adoption of automation and implementing automation-related infrastructure in all industries are going to boost the global level switches market. The evolution of the automation and energy sector in North America, where sensors are highly used in measuring the liquid, solid, dirty liquid, are the growth factors for the market in North America. Followed by Latin America & MEA.

Global Level Switches Market: Drivers

Level switches, which detect the specified level and send signal to the monitoring station, help the system to operate effectively without any liability.

In closed and heavy tanks, such as steam boilers and oil tankers where manual operation is difficult, these level switches or sensors are fixed, making it one of the key driving factors for the global level switches market. Industries such as wood and chemical, where the chemicals used are dangerous, hazardous to inhale, level switches are used.

Global Level Switches Market: Trends

The increasing demand for automation in end-use sectors, such as power plants, chemical plants and manufacturing industries, are going to upsurge the growth of the level switch where switches are highly used for various operations. Wide variety of level switches are available, each one is used in specific application and specific function. Capacitive switches are used in non-metallic materials, which are used in ceramic, plastic and glass industries.

Optical level switches or level sensors are used in air-conditioning systems, hydraulic reservoir, etc. Tilt switches are used in trippers, hoppers, etc. they have a probe which is designed to sense bulk material. Paddle switch is a rotating sensor used in powder, material level check. Tuning fork switches are used in chemical processing, they control the level of powder, grains etc. Floating level switches are used to detect the level of the liquid tank.

By Market Participants

Examples of some of the market participants identified across the value chain include Water Level, Murphy, Pricol Ltd, Electronet Equipment’s Pvt Ltd, AMETEK , BinMaster, Endress+Hauser AG, GEMS, GHM Group, elobau sensors technology, EGE,IMB Industrielle Messtechnik, Soway.

The research report presents a comprehensive assessment of the market and containsthoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

In December 2020, Rockwell Automation Indonesia launched a new safety switch (Allen-Bradley Guardmaster 440G-EZ) which can help to protect people, process and equipment. The new electromagnetic safety switch uses a power-to-lock magnetic locking function to improve the overall process.

In October 2021, OMRON launched the D41 series safety door switch that can effectively reduce the risk of interlock devices being deactivated to ensure a safe and worry-free production site.

For More Information on this Report @ https://www.futuremarketinsights.com/reports/level-switches-market

Global Level Switches Market: Segmentation

By switch type, the global level switches market is segmented into:

Capacitive

Conductivity

Diaphragm

Displacer

Float

Optical

Paddle

Tilt

Tuning fork

Rod

By application, the global level switches market is segmented into:

Closed vessels

Reservoirs

Temperature requirements

Mining

Hooper’s

Grain silos

Liquid holding tank

By end-use, the global level switches market is segmented into:

Plastic industry

Chemical industry

Power plant

Pharmaceutical

Wood industry

Ceramic industry

0 notes

Link

Jayceetech is best Rotating Paddle Level Switch supplier, Manufacturer Company in Pune, Maharashtra, India. We provide Rotating Paddle Level Switch at best cost. For more information contact +91-8554982251

0 notes

Text

High-Performance 4-Vane Rotating Paddle Level Switch | Levtron

Ensure precise level measurement with Levtron’s 4-vane rotating paddle level switch. Designed for bulk solid applications, it prevents overflow and material wastage in industrial processes. Levtron’s 4-vane rotating paddle level switch provides reliable level sensing for bulk solids and powders. Ideal for silos, bins, and hoppers, ensuring smooth and efficient operations.

0 notes

Photo

Rotating Paddle Level Switch is basically a spring-loaded, eccentrically driven rotating vanes or blades which rotate at a very slow rotation of one revolution per minute, using an ac synchronous motor.

#Rotating Paddle Level Switch#level switch#rotary paddle type level switch#rotary paddle level switch manufacturers#rotary paddle level switch price

0 notes

Text

Flow Meter, Level Switch for Solids, Liquids, Level Controller, Vibrating Rod Level Switch, Rotating Paddle Level Switch, RF Admittance, RF Capacitance supplier, Manufacturer, Exporter, Dealer

Jaycee tech is the best Flow Meter, Level Switch for Solids, Level Controller, Vibrating Rod Level Switch, Rotating Paddle Level Switch, RF Admittance, RF Capacitance supplier, Manufacturer, Exporter, Dealer in Pune, Philippines, Cambodia, Bangladesh, manmar, Africa, Egypt, Ethiopia, Iran, Iraq, Kenai, Tanzania, Nigeria, shrilanka, Thailand, south America, Argentina, Bolivia, Brazil, Colombia, Peru

#Flow Meter#Level Switch for Solids#Level Controller#Vibrating Rod Level Switch#Rotating Paddle Level Switch#RF Admittance#RF Capacitance#supplier#Manufacturer#Exporter#dealer in Pune#Philippines#Cambodia#Bangladesh#manmar#Africa#Egypt#Ethiopia#Iran#Iraq#Kenai#Tanzania#Nigeria#shrilanka#Thailand#south America#Argentina#Bolivia#Brazil#Colombia

0 notes

Text

#Flow Meter#Level Switch for Solids#Level Controller#Vibrating Rod Level Switch#Rotating Paddle Level Switch#RF Admittance#RF Capacitance#supplier#Manufacturer#Exporter#Dealer#Philippines#Cambodia#Bangladesh#manmar#Africa#Egypt#Ethiopia#Iran#Iraq#Kenai#Tanzania#Nigeria#shrilanka#Thailand#south America#Argentina#Bolivia#Brazil#Colombia

0 notes

Text

Trumen came into existence in 2009 and initially started with manufacturing of Tuning Fork Level Switches for liquid and solid applications. With time, the manufacturing range increased with addition of Capacitance Level Transmitter & Capacitance Level Switches, RF Admittance Level Switches, Rotating Paddle Level Switches, Conductivity Type Level Switches, Vibrating Rod Level Switches, Hydrostatic Level Transmitter, Radar Level Transmitter & Ultrasonic Level Transmitter. Trumen is a technocrat driven organization aimed at providing top-of-the-range and high quality level measurement and process control instruments. Formed by the pioneers who devoted their respective lives in development, design and delivery of solution to the problems faced in the field of level sensing and process measurements. Trumen has a fixed point agenda about "sensing matters", and each device created at Trumen is thoroughly tested to pass the quality norms set in-house, in order to give the best performance in all operating conditions.

Address: 39, Mangal Nagar, Behind Sai Ram Plaza, Near Rajeev Gandhi Circle, AB Road, Indore, Madhya Pradesh 452001

Web: https://trumen.in/

#Rotating Paddle Level Switch#Radar Level Transmitter#Point Level Switches#Level Transmitter#Indicator Controller Transmitter#Level Switch#Level Sensor#Level Indicator#Vibrating Fork Level Sensor#Vibrating Fork Level Switch#Vibrating Rod Point Level Switch#Tuning Fork Point Level Switch#Admittance Point Level Switch#Level Switch in India#level switch manufacturer in india#level sensor manufacturers in india#radarleveltransmitter#vibratingforklevelswitch#vibratingforklevelsensor#rotatingpaddlelevelswitch#levelindicator

0 notes