#broiler processing plant

Text

Insects are eaten in 128 countries, according to a study published this year in the journal Scientific Reports, which found 2,205 species are eaten worldwide. Most of these species are in Asian countries, followed by Mexico, and African countries.

In Thailand, India, the Democratic Republic of Congo and China hundreds of species of insect are consumed, with Brazil, Japan and Cameroon each eating 100 or more species.

Singaporean chefs will be able to import many creative insect recipes from around the world, where they are served deep fried, on sticks, in noodles, in margaritas, in arancini, tinned, or confit. Insect products are sold round the world in restaurants, markets, supermarkets and from vending machines.

The EU is in the process of approving more insects as what it calls a “novel food source”, but to date it has approved only four. Australiahas only approved three species – a cricket and two kinds of mealworm – so far as “non-novel, non-traditional” food sources.

[...]

Why does the UN want us to eat insects?

Because it is crunch time climate-wise, and insects are a much more sustainable source of protein than livestock.

They have a high “conversion rate”, which means they are efficient at turning plant energy into protein, or in other words, turning what they eat into their own bodies. “Crickets need six times less feed than cattle, four times less than sheep, and twice less than pigs and broiler chickens to produce the same amount of protein,” according to the FAO.

They can also be farmed indoors, use less space and water, and produce lower emissions. Because they can be farmed in rural and urban areas in relatively small rooms, they can also be a source of income for people who have less access to land or the training needed to farm livestock.

10 July 2024

53 notes

·

View notes

Text

How Delaware’s Agriculture Sector Boosts the State’s Economy

Despite being one of the smallest states in the U.S., Delaware's agriculture sector stands tall in bolstering its economy. Famed for its fertile soils, strategic location, and farming legacy, Delaware boasts a robust agriculture industry that sustains jobs and food production and fuels economic growth. From poultry farming to crop production, Delaware's agriculture is a fundamental part of the state's identity and a robust economic engine, showcasing its resilience and stability.

Let's look into the importance of Delaware's agriculture sector and how it contributes to the state's economic success.

1. The Poultry Industry: A Cornerstone of Delaware Agriculture

The poultry industry is one of the most significant contributors to Delaware's agriculture sector. The state is one of the top producers of broiler chickens in the U.S., and the poultry industry accounts for a significant portion of the state's agricultural revenue.

The poultry industry supports thousands of jobs, from farmworkers to processing plant employees. Additionally, it stimulates demand for feed grains and other supporting industries such as transportation and packaging. Delaware's poultry industry's success has ripple effects throughout the state's economy, bolstering local businesses and contributing to community development.

2. Crop Production: Supporting Food and Livestock

Alongside poultry, Delaware hosts a robust crop production sector encompassing corn, soybeans, wheat, and vegetables. Corn and soybeans are significant because they are used as feed for the poultry industry, underscoring the deep interconnection between crop and livestock production that fortifies Delaware's comprehensive agricultural ecosystem.

Delaware's crop production contributes to the state's economy by providing raw materials for human consumption and livestock feed. The sale of these crops generates income for farmers, and processing facilities create additional employment opportunities. Farmers in Delaware also play a vital role in national food production, ensuring that grocery shelves and restaurants remain stocked with locally grown goods.

3. Dairy and Livestock: Smaller but Significant Players

While Delaware is primarily known for poultry and crop farming, dairy farming and other livestock operations contribute to the state's agricultural output. Delaware dairy farms produce milk, cheese, and other dairy products sold locally and regionally. Additionally, beef and pork production is on a smaller scale than poultry.

The dairy and livestock sectors add diversity to Delaware's agriculture, making the industry more resilient to market fluctuations. These farms support local economies by providing jobs and contributing to Delaware's food supply chain. Although smaller than poultry, the dairy and livestock sectors provide essential goods to consumers in and out of the state.

4. Employment Opportunities: Agriculture as a Job Creator

The agriculture sector is a significant employer in Delaware, providing thousands of jobs across various fields. Agriculture supports employment at every level, from farmworkers and equipment operators to scientists and agribusiness professionals. The industry also offers opportunities for seasonal workers and young people through farm internships and training programs.

Agriculture's contribution to Delaware's employment is critical for rural areas where job opportunities may be limited. In addition to direct employment, agriculture creates jobs in related industries, including transportation, logistics, manufacturing, and retail. This ripple effect ensures that agriculture's economic impact extends beyond the farm.

5. Local and Sustainable Agriculture: Supporting Delaware's Communities

Delaware is witnessing a burgeoning movement towards local and sustainable agriculture. The popularity of farmers' markets, community-supported agriculture (CSA) programs, and organic farming practices is not just a trend but a testament to the shared values of many Delaware residents. This demand for locally grown food is economic and a way to support small and mid-sized farms, fostering a sense of community and shared values.

The rise of local agriculture allows Delaware farmers to sell directly to consumers, keeping money within the community. This form of agriculture also promotes sustainable farming practices that reduce environmental impact, conserve water, and preserve soil health. As a result, Delaware's local agriculture contributes to economic stability and long-term sustainability.

6. The Role of Technology in Delaware's Agriculture

Modern technology is vital in increasing productivity and efficiency in Delaware's agriculture sector. Technological advancements have transformed agriculture, from precision farming techniques that optimize crop yields to automation in poultry processing plants. Delaware farmers increasingly adopt intelligent farming technologies, such as drones, GPS-guided equipment, and data analytics, to improve decision-making.

Technology enables Delaware's agriculture industry to stay competitive globally. By increasing efficiency and reducing waste, technology helps farmers save on labor and resources while improving output. This increases profitability for farmers and ensures that Delaware can meet the growing demand for food locally and nationally.

7. Export Markets: Extending Delaware Agriculture's Reach

Delaware's strategic location along the East Coast gives it easy access to major transportation routes, ports, and international markets. The state exports a significant portion of its agricultural products, particularly poultry and grains, to other states and countries. This access to global markets is critical for the long-term success of Delaware's agriculture industry.

Exporting agricultural products brings additional revenue to Delaware's economy. It allows farmers to tap into international demand and diversify their income streams. This global reach strengthens Delaware's agriculture sector and positions the state as a critical global food supply chain player.

Agriculture's Crucial Role in Delaware's Economy

Delaware's agriculture sector is a cornerstone of the state's economy, contributing billions of dollars in economic output and supporting thousands of jobs. From the thriving poultry industry to the diverse crop production and increasing focus on local agriculture, Delaware's farmers play a vital role in feeding the nation and driving economic growth.

For Delaware residents, supporting local agriculture by purchasing from farmers' markets, participating in CSA programs, and choosing locally grown products is a way to contribute to the success of the state's agriculture industry. Additionally, continued investment in technology and sustainable practices will ensure that Delaware's agriculture remains competitive and resilient in the future. As the state evolves, agriculture will remain a key pillar of the Delaware economy.

0 notes

Text

Present Scenario of Poultry in India

The fowl industry in India has witnessed tremendous growth in last few decades. India is now the 3rd largest egg producer and 5th largest broiler meat producer in the world. The per capita consumption of eggs has risen from just 23 eggs in 1990 to 62 eggs in 2019. Similarly, broiler meat consumption has increased from 1 kg per person to 4 kg per person in last 20 years. The growth has been fuelled by multiple factors like rising disposable incomes, urbanization, health awareness and aggressive marketing by fowl players.

Role of contract farming and Integrators

Indian Poultry industry is primarily organized through a contract farming model where integrators provide inputs like chicks, feed and veterinary services to farmers while procuring the produce at a pre-determined rate. Major players like Venky's, Godrej Agrovet, CP Group etc. have established strong backward integration through hatcheries and feed mills while maintaining a large outgrower base. This model has led to standardization of operations and assured market access for small farmers. It has played a pivotal role in the overall development of the sector.

Government Support through policies and schemes

Successive governments have recognized the growth potential of fowl and implemented several schemes to boost production and investment in the sector. Introduction of National Fowl Development Board and National Poultry Mission are notable initiatives. State governments also provide subsidies on inputs and set up infrastructure development schemes. Focus on rural development and employment generation along with food security has kept fowl high on the policy agenda.

Opportunities in Processed Products and Export

With overall production rising, there is large untapped potential in processed value added products like frozen ready-to-cook items, cut parts and deboned meat. Major players are setting up dedicated processing plants to cater to urban consumers looking for convenient dining solutions. Export markets offer huge scope given India's competitive advantage of low cost production. China Plus One policy can boost shipments to non-Chinese markets in future. Strict implementation of quality and safety standards will open more global opportunities.

Challenges on the Environmental and Disease Front

Rapid intensification especially in broiler sector in some states poses risks to environmental sustainability due to issues like excessive ground water use, disposal of litter and manure etc. Recurrence of avian diseases like bird flu and Ranikhet also affects profitability and expansion plans periodically. Players will have to focus on biosecurity protocols and integrate sustainable practices to balance growth and environment protection responsibilities. Adoption of preventive vaccines and improved surveillance systems is the need of the hour.

To summarize, Indian Poultry industry has come a long way and is poised for further growth driven by domestic consumption as well as export potential. However, managing environmental fallouts and animal health challenges in evolving scenario will determine its sustainability and scope for the future. Continuous policy support coupled with private sector initiatives can help realize its full potential.

Get More Insights On, Poultry

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Poultry#Chicken#Geese#Poultry Farming#Organic Poultry#Poultry Nutrition#Poultry Processing#Poultry Equipment

0 notes

Text

The Cruel Reality of Broiler Chicken Farming

Broiler chickens, also known as meat chickens, are a common sight in grocery stores and restaurants all over the world. These chickens are specifically bred for their meat production, resulting in a bird that grows at an alarmingly fast rate. While this may seem like a profitable business for farmers, the reality is that broiler chickens crueltyand suffering.

From the moment broiler chicks are born, they are subjected to a life of confinement and mistreatment. As soon as they hatch, the chicks are transported to large industrial farms where they are crowded into tight, overcrowded sheds. These sheds are often dark, dirty, and poorly ventilated, creating an environment that is conducive to disease and suffering.

Due to the genetic manipulation of broiler chickens, they are bred to grow at an accelerated rate. This rapid growth puts a significant strain on their bodies, leading to painful leg deformities, heart problems, and respiratory issues. In fact, some broiler chickens grow so quickly that their legs are unable to support their weight, causing them to collapse under their own bodies.

To make matters worse, broiler chickens are often deprived of food and water in an effort to limit their growth. This practice, known as feed restriction, leaves the birds in a constant state of hunger and thirst, leading to malnutrition and dehydration. As a result, many broiler chickens suffer from weakened immune systems and are more susceptible to disease and infection.

In addition to physical suffering, broiler chickens also endure significant emotional distress. The overcrowded conditions in which they are kept prevent them from engaging in natural behaviors, such as foraging and socializing. As a result, many birds exhibit abnormal behaviors, such as pecking at each other and self-mutilation.

The cruelty of broiler chicken farming extends beyond the confines of the farm. Once the birds reach slaughter weight, they are transported to processing plants where they are killed in large numbers. The process of catching, loading, and transporting broiler chickens is extremely stressful for the birds, often resulting in injuries and even death.

Despite these glaring issues, broiler chicken farming continues to be a profitable industry. The demand for cheap, readily available meat has driven the expansion of industrial chicken farms, leading to the widespread suffering of millions of birds each year. Consumers are often unaware of the conditions in which broiler chickens are raised, allowing this cruelty to persist unchecked.

It is important for consumers to educate themselves about the realities of broiler chicken farming and make informed choices about the meat products they purchase. By supporting companies that prioritize animal welfare and sustainability, consumers can help drive positive change in the industry.

In conclusion, broiler chicken farming is a cruel and inhumane practice that subjects millions of birds to unnecessary suffering. From the moment they are born to the moment they are slaughtered, broiler chickens are denied the most basic rights to food, water, and space. It is time for us to acknowledge the cruelty of this industry and demand better treatment for these animals. Only then can we truly claim to be responsible stewards of the planet and its inhabitants.

0 notes

Text

The Cruelty of Factory Farming: A Call for Change

Factory farming, the industrialized process of raising large numbers of animals for food production, has become a cornerstone of modern agriculture. However, this system is fraught with ethical, environmental, and health concerns, largely stemming from the inherent cruelty involved. This article delves into the various aspects of factory farming's cruelty, highlighting the urgent need for more humane and sustainable practices in animal agriculture.

At the heart of factory farming’s cruelty is the inhumane treatment of animals. Chickens, pigs, and cows are typically confined in overcrowded and unsanitary conditions, where they have little room to move and are deprived of natural behaviors. For example, egg-laying hens are often kept in battery cages so small they cannot spread their wings, while pigs are housed in gestation crates barely larger than their bodies. These restrictive environments cause severe physical and psychological distress. Chickens may develop crippling leg disorders from being bred to grow unnaturally fast, and pigs frequently resort to biting the bars of their cages out of frustration and boredom.

The cruelty extends beyond confinement. Animals in factory farms are routinely subjected to painful procedures without anesthesia, such as debeaking, tail docking, and castration. These practices are performed to prevent injuries from aggressive behaviors that arise in such stressful conditions. Additionally, the rapid growth rates enforced by selective breeding and the use of growth hormones lead to severe health problems. Broiler chickens, bred to grow quickly for meat, often suffer from heart failure and skeletal deformities due to their unnatural body weight.

The environmental impact of factory farming adds another layer of cruelty, affecting not only animals but also the planet and human populations. Factory farms generate massive amounts of waste, which often contaminates air and water supplies, leading to health problems in nearby communities. The overuse of antibiotics to promote growth and prevent disease in these crowded conditions contributes to the rise of antibiotic-resistant bacteria, posing a significant public health threat. Furthermore, the industrial farming of animals is a major driver of deforestation, greenhouse gas emissions, and biodiversity loss, exacerbating climate change and environmental degradation.

Ethical concerns also arise from the deceptive practices employed by the factory farming industry. Many consumers are unaware of the conditions in which their food is produced, as the industry often promotes a sanitized image of farming that belies the reality. Labels such as “free-range” or “organic” can be misleading, as they may not necessarily guarantee humane treatment of animals. This lack of transparency prevents consumers from making informed choices about the food they eat and its ethical implications.

Addressing the cruelty of factory farming requires a multifaceted approach. Regulatory reforms are essential to ensure better living conditions for animals, including larger spaces, access to the outdoors, and the elimination of painful procedures. There is also a growing movement towards plant-based diets and lab-grown meat, which offer cruelty-free alternatives to traditional animal products. Educating consumers about the realities of factory farming and promoting transparent labeling practices can empower people to make ethical food choices.

In conclusion, the f factory farming’s cruelty encompasses the inhumane treatment of animals, significant environmental damage, and ethical deceptions. Transitioning to more humane and sustainable agricultural practices is not only a moral imperative but also a necessity for the health of our planet and its inhabitants. By advocating for animal welfare, supporting alternative food sources, and demanding transparency, we can work towards a future where farming is synonymous with compassion and sustainability rather than cruelty.

0 notes

Text

The Clucking Truth: Addressing the Mistreatment of Chickens

In the world of animal agriculture, chickens often occupy a peculiar place. They are one of the most populous and economically significant livestock animals on the planet, yet their treatment is frequently overlooked or misunderstood. Behind the idyllic images of free-roaming hens pecking in the grass lies a stark reality of widespread mistreatment and exploitation.

From cramped cages to inhumane slaughter practices, the mistreatment of chickens is a pervasive issue that demands urgent attention. Here, we delve into some of the key areas where chickens suffer and explore potential avenues for change.

1. Confinement in Factory Farms:

The vast majority of chickens raised for meat and eggs are confined to industrial-scale factory farms. These facilities prioritize efficiency and profit margins over animal welfare, resulting in overcrowded and unsanitary conditions. Chickens are often packed into small cages or overcrowded barns, unable to engage in natural behaviors such as dust-bathing, perching, or foraging.

2. Cruelty in Egg Production:

For egg-laying hens, life is especially grim. Many are confined to battery cages, which are so small that the birds can barely move. These cages often house multiple hens, leading to aggression, stress, and injuries. Even in cage-free or free-range systems, hens may still face crowded conditions and lack of access to the outdoors.

3. Suffering in Slaughterhouses:

The journey for chickens doesn’t end with the farm. Slaughterhouses are notorious for their high-speed processing lines, where birds are subjected to rapid and often botched killing methods. Improper stunning and slaughter techniques can result in chickens being scalded alive or conscious during the slaughter process, causing immense suffering.

4. Genetic Manipulation:

Selective breeding has led to the genetic manipulation of chickens for increased productivity, but at great cost to their welfare. Broiler chickens, bred for rapid growth, often suffer from skeletal problems, heart issues, and organ failure due to their unnaturally fast growth rates. Similarly, egg-laying hens are bred to lay an unnatural number of eggs, which can lead to reproductive disorders and osteoporosis.

5. Lack of Legal Protections:

Despite mounting evidence of their suffering, chickens have historically received little legal protection. Many countries have minimal regulations governing their treatment, and even those that do exist are often poorly enforced. The result is a system where cruelty and exploitation are rampant, with few consequences for those responsible.

Addressing the Issue:

Efforts to improve the welfare of chickens must involve a multi-faceted approach. Consumer awareness and demand for ethically produced chicken products can drive change within the industry. Supporting companies that prioritize animal welfare standards, such as pasture-raised or certified humane producers, sends a clear message that cruelty will not be tolerated.

Legislative action is also crucial in holding the industry accountable for its treatment of chickens. Stronger animal welfare regulations, enforced through rigorous inspections and penalties for non-compliance, can help raise the bar for humane treatment standards.

Furthermore, investing in alternative protein sources, such as plant-based or lab-grown meat, offers a sustainable and cruelty-free solution to the demand for chicken products. By reducing reliance on animal agriculture, we can alleviate the suffering of billions of chickens worldwide. In conclusion, the mistreatment of chickens is a pressing ethical issue that requires immediate attention. From factory farms to slaughterhouses, these animals endure unimaginable suffering in the name of profit and convenience. It is incumbent upon us as consumers, activists, and policymakers to advocate for a more compassionate and sustainable approach to chicken production. Only then can we truly address the clucking truth behind their mistreatment.

0 notes

Text

3-4T/H Chicken Feed Mill Plant for Our United Arab Emirates Customer

The poultry industry in the United Arab Emirates (UAE) holds significant importance within the country's livestock sector, primarily aimed at meeting the domestic demand for chicken meat and eggs. Poultry farming is typically categorized into two main types: broiler farming and egg-laying chicken farming.

In terms of broiler farming, chicken meat production in the UAE heavily relies on poultry farms equipped with modern facilities and management systems to ensure the growth and health of chickens. These farms vary in scale, ranging from small to large operations, and utilize various farming methods, including free-range and cage systems.

Regarding egg-laying chicken farming, the UAE also boasts a considerable number of egg production farms. These farms are dedicated to producing high-quality eggs to meet the domestic demand for egg products. Similar to chicken meat production, these farms often employ modern farming equipment and management techniques to enhance both yield and quality.

youtube

It's worth noting that the poultry industry in the UAE faces challenges due to the country's climate conditions and limited water resources. Challenges include the impact of high temperatures and arid environments on chicken growth, as well as issues related to feed and water supply. Therefore, the government and poultry industry stakeholders typically implement measures such as providing technical support, improving feed formulations, and enhancing water resource management to promote the sustainable development of the poultry industry.

Firstly, we opted for a high-performance feed grinder. This equipment efficiently grinds raw material particles into the desired powdered form, ensuring uniformity and digestibility of the feed. Subsequently, we introduced an advanced feed mixer capable of thoroughly blending different types and proportions of raw materials, ensuring nutritional balance and consistency in the feed. Additionally, we selected an efficient feed pelletizer capable of compressing the blended feed materials into uniform, visually appealing pellets, thereby enhancing the quality and stability of the feed.

To safeguard the quality of the feed pellets, we specifically chose an integrated feed cooling and sieving device. This equipment effectively cools and sifts the feed pellets during the production process, ensuring that they meet standardized appearance and texture requirements. Furthermore, to facilitate the client's sales and storage processes, we equipped the production line with an efficient feed packaging machine capable of packaging the feed pellets according to customer specifications, enhancing the overall efficiency of the production line.

In addition to the primary equipment, we provided the client with a range of auxiliary equipment, including electrical control panels, boilers, air compressors, and storage silos, to ensure the smooth operation of the entire production process. During the shipping phase, we implemented stringent quality control measures to ensure that all equipment was dispatched in optimal condition. To maximize cargo protection, we custom-designed packaging and protection measures suitable for container shipping, minimizing the risk of damage or loss during transit.

We are delighted to learn that the client has successfully received all goods and has expressed exceptionally high praise for the quality, performance, and reliability of our equipment. Their endorsement has earned our factory immense trust and acclaim. We remain committed to maintaining a close partnership with the client, continually optimizing our products and services, and making a greater contribution to the development of the feed production industry.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Whatsapp: 0086 18037508651

0 notes

Text

Clean Coal? Myth or Reality

Clean coal has been touted as a newer and safer nonrenewable resource. However, when one looks at the evidence provided by authoritative sources on the issue of whether clean coal is really clean or not, the answer is clear. Clean coal is not as clean as it reports itself to be. What clean coal really is something that could be a future possibility. However, we do not have it due to the perceived cost of the technology that industry and government leaders are currently not investing in. As well as the technology itself not helping to completely eliminate polluting emissions.

The term clean coal first started to crop out around 2008. During this time, congress had started talks in introducing new legislation regarding climate change. Made nervous for their bottom line by these potential new laws. The coal industry in turn brought out the concept of “clean coal”. However, they made sure to keep what exactly made this particular coal clean as vague. However, it was agreed upon that this meant that the plants that were working with the coal were preventing carbon dioxide from the smokestacks from entering the atmosphere. Instead of ending up in the atmosphere, it would instead be buried underground. Thus helping to prevent further global warming.

Now while this technology admittedly does have promise, it is still incredibly young and expensive. The Southern Company attempted to construct a plant with similar carbon capture technology, however by the end of the project it ran over budget by some four billion dollars. Due to this enormous cost, no other carbon-capture coal plants have been constructed since then. This is the case not just in the coal industry, but in similar areas of processing and manufacturing like steel and cement manufacturers. Even the title of “Clean Coal” is very misleading in the first place. That is because the techniques and technology do not reduce a hundred percent of emissions. Techniques like carbon capture, as well as washing coal help reduce the amount of ash content. While these techniques do lower emissions, they do not entirely fix the problem.

Other developed and industrialized countries have also tried to take a crack at cleaning up coal as well. Many developed economies have made a commitment to completely end coal use within the country within the next seven years. However, Japan has gone in the opposite direction. Claiming instead that they can clean up coal production within the country. The company Jera is the owner of the nation’s largest coal firing plant. The plant is spread out over a whopping forty soccer fields. Jera wants to demolish this plant in order to create a new plant. This future coal plant plans to mix ammonia with its coal broilers in an effort to clean its coal. This is due to the fact that ammonia does not produce any carbon dioxide when burned. As the article explains it “The company says the ammonia method can reduce dangerous emissions in the fight against global warming. In an effort initially conceived — and heavily subsidized — by Japan’s government, it is one of several power companies planning to use ammonia in a process marketed as “clean coal.” (Rich and Hida 1). Companies hope to use this tactic to help clean coal from pre-existing plants instead of having to build entirely new ones. They have a good reason for hoping that this will be a success as nearly a third of the nation's energy comes from coal. Critics of this proposed strategy say that this only acts as a crutch for Japan to extend the nation's reliance on fossil fuels instead of directly addressing the problem directly. Disasters like the 2011 Fukushima Daichi power plant meltdown have led to the rise of anxieties surrounding energy concerns. The disaster led to thirty percent of Japan’s supply of energy being whipped out from the event. This then leads the country to produce more coal power plants. This is very concerning due to Japan's inability to be self-reliant on its energy needs, as well as its being the third largest economy in the world. This means a Japan not able to support its energy concerns will impact the world economy, as well as its own. This then explains why Japan has said it will follow its own timetable for cutting its carbon emissions.

All and all, the technology for lowering the emissions caused by coal plants is possible. However, the methods proposed do not completely clean coal, more so giving it a light dusting. These methods are also too expensive for companies to want to implement and invest in. Or only help to try and extend the lifespan of coal plants, instead of tackling the problem directly.

Sources Cited

Plumer, Brad. “What “Clean Coal” Is — and Isn’t.” The New York Times, 23 Aug. 2017, www.nytimes.com/2017/08/23/climate/what-clean-coal-is-and-isnt.html.

Rich, Motoko, and Hikari Hida. “Japan Says It Can Make Coal Cleaner. Critics Say Its Plan Is ‘Almost Impossible.’” The New York Times, The New York Times, 22 July 2023, www.nytimes.com/2023/07/22/world/asia/japan-coal-renewable-energy-ammonia.html?searchResultPosition=4.

1 note

·

View note

Text

Growth Strategies Adopted by Major Players in the Carotenoids Market

The carotenoids market is projected to grow from USD 1.5 billion in 2019 to USD 2.0 billion by 2026, recording a CAGR of 4.2% during the forecast period. This is attributed to the increasing awareness regarding the potential benefits of caortenoids in preventing heart diesaes, cancer, and treating eye disorders, parkinson’s disease, alzhmier’s disease and macular denegraton. Moreover, carotenoids has high antioxidant properties and helps in slowing the ageing process. These factors have made carotenoids a popular preference among consumera and players in food industry.

Furthermore, consumers across the world are demanding clean-label products due to increasing concnern over use of synthetic ingredients in food. This has driven the demand fornatural colorants in food industry and carotenoids being a red pigment is now being widely applied in meat industry to impart color to products such salmon, trout, and other meat and seafood products.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=158421566

The lutein segment is projected to grow at the highest rate during the forecast period

The lutein segment, on the basis of type, is projected to grow at the highest CAGR, in terms of value, during the forecast period. Lutein is synthesized by plants and found in some of the major food items, such as egg yolks, carrot, spinach, kale, squash, grapes, and pepper. It is used in both, human nutrition and animal nutrition products. Its wide acceptability due to its ability to treat age-related eye disorders, including cataracts and macular degeneration, is a key factor driving its demand.

By application, the feed segment is estimated to account for the largest market share in 2019 in the carotenoids market

Carotenoids are extensively used in animal nutrition products due to their coloring properties and are incorporated in feed to pigment the egg yolks, broiler skin, fishes, and crustaceans. These also help in increasing the immunity and improving the health of livestock by enhancing the quality of nutrition. The fertility of cattle, swine, and horses can be improved by feeding beta-carotene, whereas astaxanthin and canthaxanthin help in improving the growth of salmons and larval fishes.

Request for Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=158421566

Europe is projected to account for the largest share in the carotenoids market during the forecast period

The European market accounted for the largest share in 2018 due to the presence of leading manufacturers, such as Koninklijke DSM (Netherlands), BASF (Germany), Chr. Hansen (Denmark), and Dohler Group (Germany). Further, the increase in the aging population in the region has led to a surge in demand for lutein, lycopene, and beta-carotene to treat cataract and reduce the risk of diabetes, cancer, and other heart-related issues. Although synthetic carotenoids account for a high share in the market, consumers prefer opting for natural and clean label products, which is projected to drive the growth of the naturally-sourced carotenoids market in this region.

0 notes

Text

CHEF ILONA: Tornado Shrimp!

Whether you call it kataifi, knafeh, kanafe, kenafeh or kunafeh, this filament-like dough, popular throughout the Middle East and the Mediterranean, signifies a singular gastronomic textural experience is guaranteed.

Kataifi dough is essentially phyllo dough that has been shredded into delicate tendrils which can be used in the preparation of both sweet and savoury preparations. Kataifi is almost exclusively sold in a frozen format here in Canada, so be sure to include defrosting time in your required prep time.

When you first open a package of shredded phyllo, the papery threads hardly seem edible. They tend to resemble the grass you might find used as packing material, rather than something you might want to eat, but please trust in the process.

The shredded phyllo is handled very similarly to its sibling, phyllo sheets. The dough is lean, which lends to rapid moisture loss, so be sure to keep the dough covered with a damp cloth while preparing the tornado shrimp.

Tornado shrimp make for a moreish appetizer or can be a light lunch when served with a salad. This impressive-looking snack sees marinated shrimp wrapped in buttered kataifi dough, which then gets baked in a very hot oven.

The dish is called tornado because the dough when twisted and twirled around a shrimp resembles a tornado’s funnel cloud.

The shrimp can be substituted with thin strips of chicken breast, white fish or plant-based mini sausages.

It is best to eat the tornado shrimp as close to getting them out of the oven as possible. If aioli is not your thing, these crunchy treats work well dipped in sweet chilli sauce.

Torpedo Shrimp

By Chef Ilona Daniel

Serves four to six as an appetizer

Ingredients

20 jumbo raw shrimp, peeled, deveined and tails on

Juice and zest of one lime

1 garlic clove, finely minced

1 Tbsp whole grain Dijon mustard

3 tablespoons olive oil

½ teaspoon smoked paprika, optional

Salt, freshly ground black pepper to taste

½ pound/1package kataifi dough

3 Tbsp butter, melted

Instructions

Rinse and drain the shrimp. Set aside.

In a large bowl, mix lime juice and zest, garlic, olive oil, mustard, smoked paprika, salt and pepper.

Add the shrimp and coat with the marinade. Marinate for 30 minutes.

Meanwhile, make the dipping sauces by combining the ingredients for each sauce in two separate, small serving bowls.

Preheat the oven to 400 F.

Unroll the kataifi dough and separate a small bundle of strands about 1.5 inches wide. Using scissors, cut kataifi strands about nine inches long. For each shrimp, spread a kataifi bundle on your work surface and wrap dough around each marinated shrimp, leaving the tail uncovered.

Arrange them on a baking sheet lined with parchment paper. Brush with melted butter using a pastry brush.

Bake for 10-15 minutes or until kataifi is golden brown. If needed, turn on a broiler for 30-60 seconds (keep your eye on it so it doesn't burn) to brown kataifi.

Serve immediately with sambal olek aioli.

#recipeoftheday#sustainable seafood#chefilona#eater#tornadoshrimp#canadianfoodwriter#foodstylist#canadianchef#shrimprecipes#smabalolek#discovercharlottetown#explorepei#explorecanada#meetinpei#welcomepei#mypei#cbcpei#cbcmainstreet#radiopersonality#kataifi#nom nom nom#chefsofinstagram

0 notes

Text

Biscuits Production line

Kiron Food Processing Technologies bread rolls makers with proficient, solid, and clean creation frameworks. On our cutting edge, high-volume creation line, you can make hard bread rolls, delicate rolls, treats with different shapes and flavors. We support clients by giving adaptable, effective arrangements that will keep them serious in the food market.

Our bread rolls creation line can be associated with the mixture broiler, hot-air course electrical baking stove, and hot-air flow gas baking broiler. The stove has separately movable temperature zones constrained by PLC, which gives rolls an even and pleasant baking impact. The baking broiler is finished with stove driven, enter-stove machine, out-broiler machine, and stripping machine.

• S-formed cutting edge assists with setting up the mixture in ideal circumstances.

• Guarantee the mixture can be definitively and constantly cut. Scrap batter can be released and once again directed to the mixture dealing with framework for reuse.

• Can be outfitted with enlivening machine to deliver imaginative rolls.

• Creation of delicate bread rolls of different shapes, sizes, surface examples, and flavors.

• Simple activity, little impression with high monetary productivity.

• Can be outfitted with different transport lines and tweaked creation lines as indicated by processing plant designs.

• Coordinated expulsion and cutting activity with free servo engine drive. Outfitted with PLC control.

• Uniform administering. The cutting blade is made of solid treated steel.

• Can be furnished with various molds that are not difficult to dismantle.

1 note

·

View note

Text

How to make cannabis tincture

What is a cannabis tincture?

A tincture in the most essential sense is a cannabis separate, in which a fluid is mixed with cannabis, implied for sublingual utilization, not vaporization or smoking. The cannabis plant absorbs a base fluid, for example, food-grade liquor, glycerin, or even oil, and following quite a while of soaking, the plant matter is stressed out and — presto! The cannabinoids, terpenes, and different mixtures have merged with the base fluid, prepared to portion and consume.

In fact, the expression "tincture" explicitly alludes to liquor based item and one made with oil or glycerin is an "implantation," however we're involving it as an umbrella term here.

In the grown-up use market, tinctures ordinarily come in 1 fl oz (30mL) glass bottles with droppers to manage low and predictable dosages. Since they are not viewed as a food thing, they can surpass the 100 mg THC cap on edibles in many business sectors.

Tinctures may not appear to be essentially as tomfoolery or inventive as a sticky or a spot, however they have a large number of medical advantages while as yet offering a happy with, inebriating experience.

Come figure out how to make your own custom made cannabis tincture utilizing a straightforward cold liquor (ethanol) extraction strategy with our bit by bit guide. I've included a lot of photographs to make the interaction as understood and simple to follow as could really be expected. There is likewise a printable rundown toward the end - however I would think you'll prefer not to miss the additional tips in the body of the post.

Tinctures are a helpful, circumspect, and simple method for partaking in your plant medication. It's kinder to your lungs than smoking or disintegrating, and offers more controlled and steady dosing contrasted with smoking or custom made edibles. (I love that I can take only a couple of drops if necessary.) You can utilize this hand crafted cannabis tincture recipe with any of your #1 cannabis strains, with CBD hemp just, or as we do - with local spice!

What sort of liquor to make natively constructed cannabis tincture?

It is ideal to utilize either 200-proof food grade ethanol (otherwise known as ethyl liquor) or 190-proof Everclear liquor for this cannabis tincture recipe. Both are solid regular solvents that will successfully strip and separate the ideal cannabinoids from the plant material. We use USDA natural ethanol from Culinary Solvents. It is unadulterated food-grade grain liquor, and contains no added substances or water. Use code "deannacat" to save 10% off pints, quarts, and gallons of ordinary and natural ethanol from Culinary Solvents!

Lower-proof liquor (for example 80 proof vodka) is a more fragile dissolvable and furthermore has a higher water content than ethanol, which can disrupt the extraction and tincture-production process. You actually can make hand crafted cannabis tincture with vodka or other lower proof alcohol, however it requires extra advances that we won't cover in this article.

Supplies Expected to Make a Natively constructed Cannabis Tincture

8 grams of decarbed cannabis

6 ounces of 200-proof food grade ethyl liquor (ethanol) or 190 proof Everclear

Cooler safe glass compartments, for example, wide-mouth half quart artisan containers or half-16 ounces containers with tops.

Little unbleached espresso channels, similar to these ones

Cheesecloth

Advanced Scale

Dropper jugs to store your completed tincture. We like these 2-ounce golden jugs; the droppers have mL markers on them for precise dosing.

Yields: 2 ounces of hand crafted cannabis tincture

Kindly note that this is a two-day process, however fixings are simply sitting in the cooler for 97% of that time.

Directions

Stage 1: Decarb your cannabis

To decarb cannabis, fire by destroying the buds into tiny pieces. Then, at that point, spread it out equitably on a baking sheet. For THC-predominant strains, heat the cannabis in the broiler at 250°F for 25 to 30 minutes. For high-CBD strains, heat it for 40 to 50 minutes at a similar temperature. (It takes somewhat longer for CBDA to switch over completely to CBD than THCA to THC does.) In the event that you're utilizing an even THC:CBD strain, compromise at 30 to 35 minutes. See this article for a more top to bottom gander at decarbing cannabis.

Try not to need to smell up the house? Consider involving a Passionate Nova gadget for a simple, almost scent free decarboxylation experience. We just got one as of late and love it!

Note that your cannabis will diminish in weight somewhat during the decarb cycle (as it gets drier). Thus, begin with a couple of additional grams so you'll wind up with the 8 grams required for this cannabis tincture recipe. Or then again, prepare bounty so you have sufficient extra to make hand crafted cannabis oil or effective ointment!

Stage 2: Freeze Cannabis and Liquor (independently)

Utilize a scale to weigh out 8 grams of decarbed cannabis. Add the cannabis to a cooler safe glass holder with a cover. We like to utilize a wide-mouth half quart glass container. (Despite the fact that it appears to be more than huge enough, the additional room in the container makes it simpler to shake contrasted with a half-16 ounces container.) Next add 6 ounces of ethanol to a different cooler safe holder. Try not to blend the liquor and cannabis yet. Put the two compartments in the cooler for no less than 24 hours. Stage 2: Freeze Cannabis and Liquor (independently)

Utilize a scale to weigh out 8 grams of decarbed cannabis. Add the cannabis to a cooler safe glass holder with a cover. We like to utilize a wide-mouth half quart glass container. (Despite the fact that it appears to be more than huge enough, the additional room in the container makes it simpler to shake contrasted with a half-16 ounces container.) Next add 6 ounces of ethanol to a different cooler safe holder. Try not to blend the liquor and cannabis yet. Put the two compartments in the cooler for no less than 24 hours.

Stage 3: Join Cannabis and Liquor (First Wash)

After the underlying 24 hours (or longer) is up, eliminate the cannabis and liquor from the cooler. Pour Just 50% of the cool liquor (3 ounces) into the compartment of frozen cannabis. Add a cover and shake overwhelmingly for 5 minutes. Enclose the container by a kitchen towel in the event that it's excessively cold to hold serenely.

This interaction extricates the cannabinoids and terpenes from the plant material, and is viewed as the "primary wash". We'll complete two rounds all out.

Presently return the cannabis-liquor combination as well as the different leftover 3 ounces of plain liquor to the cooler for 2 extra hours.

Stage 4: Shake and Strain

When the two hours are up, it's the ideal opportunity for another shake - and afterward we strain! Eliminate the container of blended cannabis and liquor from the cooler, and shake it again for 5 extra minutes. (We needn't bother with the container of plain liquor right now.)

Next we will strain the tincture through two mediums: cheesecloth first to channel the bigger plant material, and afterward a better espresso channel to additional eliminate undesirable lipids and other buildup.

First set up the espresso channel stressing station. We find it most straightforward to set a little espresso channel in the highest point of a different clean 16 ounces glass container, crease it over the edge of the container, and afterward screw on a top ring to hold it set up. The cannabis tincture requires a significant stretch of time to leak through the channel, so holding it by hand isn't entertaining.

Then, put cheesecloth over the container that contains the cannabis-liquor blend (we utilize the ring stunt once more) and gradually pour it through the cheesecloth and into the espresso channel container. See the photographs underneath.

Presently return the container of outstanding cannabis to the cooler while the main wash fluid is stressing through the espresso channel (around 10 minutes).

Stage 5: Second Wash and Strain

Presently it's the ideal opportunity for the second and last wash. This step helps extricate any last leftover cannabinoids from the plant material into your natively constructed cannabis tincture.

Get the container of cannabis that was in the cooler while the principal wash stressed (for around 10 minutes) and afterward rehash the washing/stressing process from stages 3 and 4. Once more add the excess 3 ounces of cold plain liquor to the cannabis container, add a top, shake vivaciously for 5 minutes, and strain through the cheesecloth and espresso channel - emptying it into a similar channel and container as the main wash.

Stage 6: Diminish

After all the fluid has stressed through the espresso channel into the container, now is the right time to decrease it by about around 50% of the volume. Overabundance liquor will handily dissipate off, and the outcome is a more focused and viable custom made cannabis surface.

Do this by essentially permitting the container to sit out at room temperature with the cover off for a few hours. We place the container before a fan to assist with facilitating the cycle. Note the volume of fluid in the holder when you start (utilize an elastic band around the container, or a glass checking pen). Watch out for it! When it diminishes significantly, add a top to stop further dissipation - or feel free to bottle your last custom made cannabis tincture.

Stage 7: Container and Store

Whenever it's decreased considerably, move the stressed cannabis concentrate to a last stockpiling bottle -, for example, these golden glass dropper bottles. Golden jugs are ideal since they lessen light openness, which debases cannabinoids. Store the jug in the fridge for the best dependable quality. Congrats, you just made a natively constructed cannabis tincture! Continue perusing for use and dosing data.

The most effective method to Utilize or Take a Cannabis Tincture

You can consume your cannabis tincture either under your tongue (sublingually) or blended in with a drink (oral ingestion). Sublingual utilization will bring about additional quick impacts, while oral ingestion will have a more slow beginning however longer-enduring outcomes. See the realistic underneath.

In any case, continue with some mindfulness! 200 proof ethanol is serious areas of strength for exceptionally, I find it creates a consuming uproar when applied straight under my tongue. To keep away from that, I put a tiny measure of water in my mouth first, spurt in the tincture, hold the weakened combination in my mouth for a couple of moments, and afterward swallow. Subsequently my admission is generally sublingual, however with a little oral ingestion as well.

0 notes

Text

Broiler Farming Market by Current Industry Status, Growth Opportunities, Top Key Players, and Forecast to 2028

This Broiler Farming study offers global and regional market estimates and forecasts, as well as significant product development trends and a typical downstream segment condition, all against a backdrop of market drivers and inhibitors. Gross margin, sales, revenue, production, market share, CAGR, and market size by region are all covered in the Broiler Farming market research. This study examines the current global market in terms of supply and demand, as well as pricing trends in current and future years.

This study looks at the supply chain from the industry's perspective, including an introduction to the process chart, upstream major raw material and cost analysis, a distributor and downstream buyer analysis, and a distributor and downstream buyer analysis over the forecast period 2022-2028. Revenue, market share, profit margin, primary product portfolio, and SWOT analysis are all covered for the world's leading corporations. This Broiler Farming market study covers forecasting output and production value, forecasting significant producers, and forecasting output and production value by type.

Get Sample Copy of Report @ https://www.intelligencemarketreport.com/report-sample/580600

The research study includes profiles of leading companies operating in the global Broiler Farming industry:

Wayne Farm

Sunner Development

Shandong Minhe Animal Husbandry

New Hope Liuhe

Lihua Animal Husbandry

Hubbard

Cobb Europe

Aviagen

Market Segmentation

After determining the overall Broiler Farming market size, the market was divided into numerous categories and sub-segments, which were then validated through primary research, which included extensive interviews with industry experts such as CEOs, VPs, directors, and executives. To complete the overall market engineering process and arrive at specific numbers for all segments and sub-segments, data triangulation and market breakdown approaches were used.

Research Methodology

The revenue and market share of the key competitors is documented as part of the research technique used to analyze and forecast this market. This information was used to compute the overall market size. To locate and compile information for this detailed commercial investigation of the Broiler Farming market, major sources such as press releases, yearly reports, non-profit organizations, industry groups, governmental agencies, and customs data were used.

The Broiler Farming Market Major Segments and Subsegments Listed Below:

Broiler Farming Market Segmentation, By Type

Male

Female

Broiler Farming Market Segmentation, By Application

Retail

Catering Services

Food Processing Plants

Agricultural Market

Others

For More Information or Query, Visit @ https://www.intelligencemarketreport.com/send-an-enquiry/580600

Covid-19 Impact Analysis

This Broiler Farming market research looks into the effects of COVID-19 on the upstream, midstream, and downstream industries. Finally, this report includes a thorough examination of the period following COIVD-19, as well as professional advice. This study offers a comprehensive market analysis by highlighting data on a wide range of topics, including market dynamics, obstacles, opportunities, threats, and industry news and trends over the forecast period 2022-2028.

Competitive Scenario

The study compares vendors in terms of revenue and client base. Knowing the Broiler Farming market share in the base year gives you an idea of the supplier's size and competitiveness. The market share analysis considers each vendor's contribution to the overall market. It demonstrates how much money it makes in comparison to other industry providers.

Key features of the Broiler Farming report.

The report includes an in-depth analysis of the market size, market share, growth, market trends, latest technology analysis, driving factors, demand, sales, revenue, consumption etc.

The forecast period from 2022 to 2028 provides the evaluation of the market and the current trends.

Table of Content

1 Scope of the Report

2 Executive Summary

3 Broiler Farming Market Size by Player

4 Broiler Farming by Regions

5 Americas

6 APAC

7 Europe

8 Middle East & Africa

9 Market Drivers, Challenges and Trends

10 Global Broiler Farming Market Forecast

11 Key Players Analysis

12 Research Findings and Conclusion

Direct Purchase Report@ https://www.intelligencemarketreport.com/checkout/580600

Contact Us:

Akash Anand

Head of Business Development & Strategy

[email protected]

Phone: +44 20 8144 2758

0 notes

Note

Ma’am why do you know so much about eggs

Anon, where do I even begin...

When I was 5 and running for my life from one of my grandpa’s roosters? Probably not because that just made me deathly afraid of chickens 😂

Believe it or not I was on a poultry judging team in high school that was in a national competition? And yes, it’s as bizarre as it sounds! We ranked laying hens and broilers, graded eggs, looked for defects in products, graded carcasses, and took a general knowledge test.

I went on to get my BS in food science and now I work at a poultry processing plant, so I know more about poultry than I could ever want to know! And now I just won’t shut up about it 😊

#asks#this question made me laugh hysterically#it made my night so thank you#i am just as weird as this makes me sound i can assure you

6 notes

·

View notes

Text

Go Big With Your Burgers

Photo courtesy of America’s Test Kitchen/ Keller + Keller

Memorial Day Weekend is around the corner. Just the other day, I was thinking, the gas grill needs to be brought out from winter’s hibernation and the propane tank filled so it is ready for dad’s arrival from Florida. For three months a year, he enjoys grilling, especially those juicy burgers he makes by hand.

A couple of years ago, I found the the perfect Father’s Day gift for him, “The Ultimate Burger: Plus DIY Condiments, Sides, and Boozy Milkshakes,” by America’s Test Kitchen (2019, America’s Test Kitchen, $26.99).

Whether you want a beef burger or a cauliflower burger, are cooking on the grill or stovetop, or want to try making homemade buns and condiments, all the inspiration is in the book to achieve burger perfection.

In the “Anatomy of an Ultimate Burger,” it says, “no one element makes a burger ultimate, it’s the result of a combination of flavors and textures coming together.”

In this section, buns, sauce, toppings, cheese and the patty are discussed. I found the Dos and Don’ts of Store-Bought Ground Beef helpful. “Go Beyond Beef” introduces other burger options.

For those who want to really want to get into the “meat” of it, “Be Your Own Butcher” gives the knowledge in choosing the right cuts to create your signature blend and how to grind your meat without intimidation.

“Get Ready to Cook” ensures that every burger you make is tender and flavorful. You’ll learn how to properly grill (on a gas or charcoal grill) , shape a burger, and how to test the level of doneness. America’s Test Kitchen spent the time, often days and months, testing the recipes, the best equipment to use for burger making and the best store-bought burger fixings.

The book’s recipes don’t stop with burgers. Included are recipes for all of the trimmings; sauces, fries, potato and macaroni salads, buns, and milkshakes.

From the recipes here to pretzel buns, beer-battered onion rings, buttermilk cole slaw and ultimate cookies and Irish cream milkshakes to grilled Portobello burgers with goat cheese and arugula, and Connecticut steamed cheeseburgers (the latter two can be found at https://bit.ly/2VTJGpt, America’s Test Kitchen’s “The Ultimate Burger” will make your barbecues varied and delicious.

If you look around, burgers are everywhere. You can find local, regional and national restaurants dedicated to burgers. Some think of the hamburger as the “cuisine” of the country. Chefs have come up with creative signature craft burgers, plant-based patties and home cooks are getting into grinding their own meat.

As many know, the hamburger has roots in New Haven. Louis’ Lunch claims to be the inventor of the hamburger. Today, they are still cooked in the original vertical broilers as they were in 1900. And remember, no ketchup allowed!

Grilled turkey burgers with spinach and feta

The headnote says, “Why This Recipe Works: Ground turkey is a great neutral canvas, making it an ideal choice as the base for a burger with lots of mix-ins. We wanted super flavorful turkey burgers that take full advantage of this fact, but first we had to start by addressing the problems that plague ground turkey. Despite their popularity, turkey burgers are notorious for being bland and/or dry. This is because turkey has a mild flavor, and its leanness means it can easily dry out during cooking. We wanted to reinstate the turkey burger’s good reputation with an easy way to crank up the flavor and add some much needed moisture. We boosted the flavor of our patties by stirring some melted butter and feta cheese into the ground meat; these simple additions provided plenty of richness and flavor while preventing the burgers from drying out. For textural interest, we added fresh baby spinach to the meat mixture. Chopped dill lent a hit of freshness, and minced garlic rounded out the flavors. Be sure to use 93 percent lean ground turkey, not 99 percent fat-free ground turkey breast, or the burgers will be tough.”

1 1/4 pounds ground turkey

2 ounces (2 cups) baby spinach, chopped

2 ounces feta cheese, crumbled (1/2 cup)

2 tablespoons unsalted butter, melted and cooled

2 teaspoons minced fresh dill

1 garlic clove, minced

1/4 teaspoon pepper

1/2 teaspoon table salt

4 hamburger buns, toasted if desired

Break ground turkey into small pieces in large bowl. Add spinach, feta, melted butter, dill, garlic, and pepper and gently knead with hands until well combined. Divide turkey mixture into 4 equal portions, then gently shape each portion into 3/4-inch-thick patty. Using your fingertips, press center of each patty down until about 1/2-inch thick, creating slight divot.

For a charcoal grill:Open bottom vent completely. Light large chimney starter filled with charcoal briquettes (6 quarts). When top coals are partially covered with ash, pour evenly over grill. Set cooking grate in place, cover, and open lid vent completely. Heat grill until hot, about 5 minutes.

For a gas grill: Turn all burners to high, cover, and heat grill until hot, about 15 minutes. Turn all burners to medium.

Clean and oil cooking grate. Season patties with salt. Place patties on grill, divot side up, and cook (covered if using gas) until well browned on first side and meat easily releases from grill, 4 to 6 minutes. Flip patties and continue to cook until browned on second side and meat registers 160 degrees, 5 to 7 minutes. Transfer burgers to platter and let rest for 5 minutes. Serve burgers on buns. Serves 4

Variations

Grilled turkey burgers with miso and ginger: Omit spinach, feta, salt, and pepper. Whisk 2 tablespoons miso paste and 1 tablespoon water together in bowl until combined. Add miso mixture to turkey with melted butter. Substitute 1 teaspoon grated fresh ginger for dill and 2 minced scallions for garlic.

Grilled turkey burgers with herbs and goat cheese: Omit spinach and garlic. Substitute 3/4 cup crumbled goat cheese for feta. Add 1 large minced shallot and 2 tablespoons minced fresh parsley to turkey with melted butter.

Smoky grilled potato salad

The headnote says, “Why This Recipe Works: Creamy potato salad may be the classic, but we wanted a modern, summery option that could cook on the grill from start to finish right alongside some of our delectably charred burgers. For smoky potatoes with tender insides and crispy, grilled outsides, we started with halved, unpeeled red potatoes. Leaving the skins on helped the potatoes stay intact, as their firm, waxy texture stood up to the heat of the grill. Crumbled bacon was an obvious choice to add smokiness, and we found that we could infuse our salad with even more savory bacon flavor by reserving some of the fat and coating the potatoes with it before grilling. Grilling our onions with the potatoes gave them a beautiful char that heightened their flavor. Instead of a thick dressing that would hide the spectacular grill marks on our potatoes, we opted for a bold vinaigrette with a kick of chipotle to add even more smoky depth. Halving our potatoes after they cooled exposed their creamy center and allowed them to soak up the spicy, tangy flavors of the dressing. Use small red potatoes 11/2-2 inches in diameter. If you don’t have 2 tablespoons of fat in the skillet after frying the bacon, add olive oil to make up the difference.”

4 slices bacon

2 tablespoons red wine vinegar

11/2 tablespoons mayonnaise

11/2 teaspoons minced canned chipotle chile in adobo sauce

1/2 teaspoon table salt, divided

1/4 teaspoon pepper

2 tablespoons extra-virgin olive oil, plus extra for brushing

2 pounds small red potatoes, unpeeled, halved

1 onion, sliced into 1/2-inch-thick rounds

3 scallions, sliced thin

Cook bacon in 12-inch skillet over medium heat until crisp, 7 to 9 minutes. Using slotted spoon, transfer bacon to paper towel-lined plate. When cool enough to handle, crumble bacon and set aside. Reserve 2 tablespoons bacon fat. (If necessary, add olive oil to equal 2 tablespoons.) Whisk vinegar, mayonnaise, chipotle, 1/4 teaspoon salt, and pepper together in large bowl. Slowly whisk in oil until combined; set aside.

For a charcoal grill: Open bottom vent completely. Light large chimney starter three-quarters filled with charcoal briquettes (41/2 quarts). When top coals are partially covered with ash, pour evenly over grill. Set cooking grate in place, cover, and open lid vent completely. Heat grill until hot, about 5 minutes.

For a gas grill: Turn all burners to high, cover, and heat grill until hot, about 15 minutes. Turn all burners to medium.

Clean and oil cooking grate. Toss potatoes with reserved bacon fat and remaining 1/4 teaspoon salt in bowl. Push toothpick horizontally through each onion round to keep rings intact while grilling. Brush onion rounds lightly with oil and season with salt and pepper. Place potatoes, cut side down, and onion rounds on grill and cook, covered, until charred on first side, 10 to 14 minutes.

Flip potatoes and onion rounds and continue to cook, covered, until well browned all over and potatoes are tender, 10 to 16 minutes. Transfer potatoes and onion rounds to rimmed baking sheet and let cool slightly.

When cool enough to handle, halve potatoes. Remove toothpicks and coarsely chop onion rounds.

Add potatoes, onion, scallions, and bacon to dressing and toss to combine. Season with salt and pepper to taste. Serve warm or at room temperature. Serves 4-6

Grilled bacon burgers with caramelized onions and blue cheese

The headnote says, “Why This Recipe Works: Smoky, salty bacon can take any burger to the next level, but burgers with just a few strips on top failed to deliver bold bacon flavor. Our version nixes the strips and mixes bacon directly into the burger for bacony bliss in every bite. Mixing raw bacon with raw ground beef overworked and compressed the patties so that they cooked up tough and dry, and cooked crumbled bacon — though it mixed in better — was too crunchy. For the perfect balance of bacon flavor and juicy texture, we processed raw bacon in the food processor and then cooked it briefly in a skillet. The par cooked pieces incorporated easily into the ground beef and dispersed bacon flavor more evenly throughout while the burgers stayed moist and juicy. Instead of tossing the leftover bacon fat we used it to sauté some onions, which provided salty balance to their sweet flavor. To turn these burgers into a savory showstopper, we topped them with rich and creamy crumbled blue cheese.”

8 slices bacon

1 large onion, halved and sliced thin

1/4 teaspoon table salt

11/2 pounds 85 percent lean ground beef

1/4 teaspoon pepper

4 ounces blue cheese, crumbled and chilled (1 cup) (optional)

4 hamburger buns, toasted if desired

Process bacon in food processor to smooth paste, about 1 minute, scraping down sides of bowl as needed. Cook bacon in 12-inch nonstick skillet over medium heat, breaking up pieces with wooden spoon, until lightly browned in spots but still pink (do not cook until crisp), about 5 minutes. Drain bacon in fine-mesh strainer set over bowl. Transfer bacon to paper towel-lined plate and let cool completely. Reserve bacon fat.

Add 2 tablespoons reserved fat to now-empty skillet and heat over medium heat until shimmering. Add onion and salt and cook until well browned, about 20 minutes. Transfer to bowl and set aside.

Break ground beef into small pieces and spread into even layer on rimmed baking sheet. Sprinkle with bacon and gently toss to combine using 2 forks. Divide beef mixture into 4 equal portions, then gently shape each portion into 3/4-inch-thick patty. Using your fingertips, press center of each patty down until about 1/2-inch thick, creating slight divot.

For a charcoal grill: Open bottom vent completely. Light large chimney starter filled with charcoal briquettes (6 quarts). When top coals are partially covered with ash, pour evenly over grill. Set cooking grate in place, cover, and open lid vent completely. Heat grill until hot, about 5 minutes.

For a gas grill: Turn all burners to high, cover, and heat grill until hot, about 15 minutes. Leave all burners on high.

Clean and oil cooking grate. Season patties with pepper. Place patties on grill, divot side up, and cook until well browned on first side, 2 to 4 minutes. Flip patties, top with blue cheese, if using, and continue to cook until well browned on second side and meat registers 120 to 125 degrees (for medium-rare) or 130 to 135 degrees (for medium), 3 to 5 minutes. Transfer burgers to platter and let rest for 5 minutes. Serve burgers on buns, topped with onions. Serves 4.

Recipes courtesy of ....

3 notes

·

View notes

Text

Worldbuilding - Food and Recipes

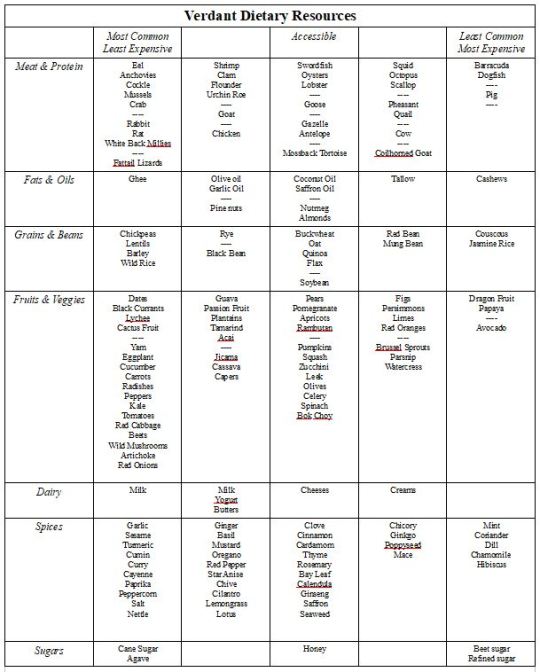

*The chart above illustrated the dietary resources available to the majority of the nation.

Culture of Food

Food is a huge part of what makes a culture and Verdant is no exception to this. They pride themselves as a nation in which no one goes hungry. In a country where most of the land is desert, this is much more difficult to achieve than one might think. But thought centuries of trial and error they have not only learned to take advantage of the county which the land provided, but to cultivate their own food by utilizing the unique seasons to their advantage.

Verdant food is colorful, packed with flavor, and prepared with passion. The hearth is the center of the household and as such the kitchen and living area are usually inseparable in all but the most wealthy estates. Something is always cooking, and as such it is considered polite to offer an unexpected guest food and drink, and considered very impolite to refuse! If invited over, it is an absolute scandal not to bring something along, even if it's just goat cheese rolled in garlic and chives or a bottle of homemade wine.

Accessibility

When one looks at the scope of what the people of Verdant eat, it is important to remember the wide range of territory in which their nation covers. For instance in the capitol city which straddles the coastline, the bounty of the sea is plentiful. This means that people in the capitol can obtain fresh fish, seaweed and such for next to nothing. However in the further reaches, such as the Speckled Pond Oasis, their ability to serve food like swordfish or lobster is severely limited.

As in all countries, the wealthy always have access to more than those in lower classes. The more processed or refined something is the more likely you have to be wealthy in order to afford it. The more elaborate and time consuming it is to obtain and cook, the more likely you must have thralls or servants available in order to ensure it gets accomplished. Domestic pigs, for instance, do not do well in the Verdant heat and are difficult to keep content. So much so that pigs are considered to be a status symbol and kept like very spoiled pets by the super wealthy and socially elite. Goats and chickens on the other hand are a much more common source of sustenance and can be obtained by all but the most impoverished folk. Even then, foraging and trapping is a common chore given to children. Verdant has only a few laws regarding hunting practices, allowing for easier access to food sources.

Preservation

Food must be properly preserved to last as long as possible. With a flooding season and a sandstorm season to factor into the equation, Verdant folk must ensure their larder will hold for as long as possible. Most meat is cured in salt or smoked to prolong it's shelf life. Jerked meats are fairly common, especially among the working class. Packing in animal fat and storing it in a cool, dry place is an excellent method for ensuring the meat remains tender for months. Herbs are air dried and ground into powders,or drowned in oil or vinegar. Fruits and vegetables are often pickled or soaked in a sweet brine which is often then turned into alcohol. Waste is the enemy, and if anything can be used it will be used. Bone broths are immensely popular as a method for stripping the most nutrition out of an animal.

Household Staples

Some things are just a ubiquitous part of the culture, and Verdant is no exception. There are staples served on every table from rich to poor, though the amount and embellishments may differ. As a part of their initiative to ensure everyone is fed, monthly stipends of grain and rice are provided to the poorer districts, the amount depending upon the size of the family. These come from the silos kept by the Queen's government, which are filled through yearly taxes collected at harvest time. Each meal has rice with herbs, pickled vegetables, and flatbread lightly fried in oil. The most popular dish through out all the nation being a saffron crispy-rice cakes. They keep well and can be stored in cloth and reheated for meals or handed off to a worker to take with them for mid-day meals.

Saffron Crispy-rice Cake

Ingredients

2 cups basmati rice

3 ½ cups water

2 tablespoons kosher salt

¼ teaspoon crushed saffron threads

1 cup plain yogurt

3 eggs

2 tablespoons unsalted butter, melted

½ cup olive oil

1 cup vegetable oil

Instructions

Put your rice in a bowl with enough water to cover and let soak for about 30 mins. Rinse thoroughly until the water runs clear.

Place 3 ½ cups water into a large pot and add a generous sprinkle of kosher salt. Bring to a boil and add the drained basmati rice. Bring to a boil and give it a stir. Reduce heat and let cook till tender.

Sprinkle small amount of salt and saffron threads in mortar and crunch until powdered. Add 2 tbsp hot water and stir lightly. Let steep for about ten mins until deep reddish-orange color.

Mix 3 egg yolks, yogurt, ½ cup olive oil, and 2 tbsp salt into large bowl. Add saffron mix when steeping is done.

Pour 1 cup vegetable oil into skillet and heat.

Fluff basmati rice mixture and test to see if fully cooked. Slowly integrate it into the saffron mixture until every grain is thoroughly coated. Don't skimp! You want it to be saturated with this mixture.

Once your oil is hot, put in a small bit of rice to test and see if it is ready. If it begins to bubble immediately, you are ready to proceed! Form the saffron and rice mixture into patties with you hands and carefully place in skillet, frying on each side until golden brown.

Remove from skillet and place on rack to drain. Serve with choice of topping.

Note: I have personally made this recipe and let me tell you it packs a LOT of flavor. I've put a fried egg on top, mixed it with sweet coleslaw, tossed it with chicken and even put a thick slice of mozzarella on top and stuck it under a broiler until bubbling! It's addictive and it keeps in the fridge forever! The saffron threads are a little bit pricy, $7.99 for 1 tblsp where I got them. But since it made like five meals it was worth it.

Another staple of the Verdant meal is flatbread with garlic oil drizzled over it. The garlic oil is easy enough to make by chopping and frying large amounts of garlic in copious amounts of oil, then straining. The oil is useful for just about every dish in Verdant and is used liberally. The chips are kept and dried out, then ground as a topping or crusting for meals.

Garlic Flatbread

Ingredients

½ cup warm water

1 teaspoon sugar

1 package dry active yeast (2 1/4th tsp)

¼ cup plain yogurt

2 cups bread flour

¼cup garlic oil

2 tbsp crushed garlic chips

1 teaspoon kosher salt

fresh parsley

Instructions