#brake parts supplier

Explore tagged Tumblr posts

Text

BBL Brakes: Your Trusted Partner for High-Performance Braking Solutions

Understanding the Importance of Brake Components

Your vehicle’s braking system consists of several key components that work together to ensure smooth and effective stopping power. These include:

Brake Linings – The friction material that creates resistance and slows down the vehicle.

Brake Pads – Essential for disc brakes, brake pads provide the necessary stopping force.

Brake Shoes – Used in drum brakes, brake shoes push against the drum to create friction.

Choosing the right brake pad manufacturer and brake lining exporter ensures reliability and safety in all driving conditions.

Brake Linings: The Heart of Your Braking System

What is Brake Lining?

A brake lining is a layer of friction material attached to brake shoes or brake pads. It is the component that makes direct contact with the drum or disc to create the necessary friction for braking.

Key Features of High-Quality Brake Linings

Heat Resistance: Prevents overheating and ensures consistent braking performance.

Durability: Long-lasting materials reduce wear and tear.

Smooth Performance: Minimizes vibrations and noise for a comfortable drive.

As a trusted brake lining manufacturer, BBL Brakes offers high-performance brake linings that provide excellent stopping power while ensuring minimal wear on other braking components.

Brake Pads: Essential for Disc Brakes

How Do Brake Pads Work?

Brake pads are pressed against the brake rotor to generate friction, allowing the vehicle to slow down. They are an integral part of disc brake systems found in most modern cars and commercial vehicles.

Why Choose a Reliable Brake Pad Manufacturer?

A top-tier brake pad manufacturer ensures that their products:

Provide consistent stopping power in all weather conditions.

Have a long lifespan, reducing the need for frequent replacements.

Minimize brake dust and noise, keeping the braking system clean and quiet.

BBL Brakes produces premium brake pads that deliver exceptional braking efficiency and reliability.

Brake Shoes: Reliable Stopping Power for Drum Brakes

Brake shoes are commonly used in drum brake systems, especially in commercial vehicles and heavy-duty applications. These curved metal components are lined with friction material to create the stopping force needed for safe braking.

Advantages of High-Quality Brake Shoes

Enhanced Durability: Made from strong materials that withstand heavy braking forces.

Superior Friction Material: Ensures efficient braking even under high loads.

Reduced Wear and Tear: Protects the brake drum from excessive damage.

As a top brake lining exporter, BBL Brakes supplies premium-quality brake shoes that keep commercial vehicles running safely and efficiently.

Why Choose BBL Brakes?

At BBL Brakes, we specialize in producing high-quality commercial vehicle brake parts, including brake linings, brake pads, and brake shoes. Here’s what sets us apart:

Global Reach: As a leading brake lining exporter, we supply our products to markets worldwide.

Premium Quality: We adhere to international safety standards, ensuring top-notch performance.

Advanced Technology: Our friction material supplier expertise allows us to develop durable and high-performance braking components.

Customization Options: We cater to different vehicle types, including heavy-duty trucks, buses, and passenger cars.

Tips for Maintaining Your Braking System

To maximize the lifespan and efficiency of your brakes, follow these essential maintenance tips:

Regularly Inspect Brake Components: Check brake pads, brake linings, and brake shoes for wear and replace them as needed.

Use Quality Parts: Always choose braking components from a reputable brake pad manufacturer and brake lining exporter like BBL Brakes.

Monitor Brake Fluid Levels: Low or contaminated brake fluid can affect braking performance.

Avoid Sudden Braking: Hard stops can accelerate wear and reduce the lifespan of your braking components.

Listen for Warning Signs: Squeaking, grinding, or vibrations indicate that it’s time to replace your brake parts.

0 notes

Text

Buy Akebono Disc Brake Pad Set & Auto Brake Parts & Accessories | US AutoParts Car

Buy Akebono® ACT1539 Disc Brake Pad Set Online and Auto Brake Parts & Auto Brake Accessories and Akebono Auto parts and Akebono Auto accessories online from US AutoParts Car. Also, you can shop other auto replacement parts & car accessories online and aftermarket car parts at affordable prices. Free curbside pickup is available for automotive parts.

Usautopartscar is the best retailer and distributor of auto parts and car accessories online committed to providing the best parts, pricing and customer service in the automotive aftermarket industry. Usautopartscar focuses more on customer satisfaction. Today, Usautopartscar is an American online provider of automated aftermarket components, including collision parts, engine parts, operating parts and other components.

#automotive#auto parts#car parts#automotive parts#auto accessories#car accessories#auto#car#accessories#parts#retailers#vehicle#usa#united states#aftermarket#brakes#auto parts and accessories#engine auto parts#auto parts supplier#auto parts online#auto parts store#spare parts#cars

1 note

·

View note

Text

Aftermarket Parts Supplier - Supreme Sales Agency

Supreme Sales Agency specializes in supplying top-quality automotive parts, catering to a wide range of customer needs in the industry. As a trusted aftermarket parts supplier, we offer a comprehensive selection of replacement components that meet or exceed original specifications, ensuring reliability and durability. We also pride ourselves on being a prominent OEM parts supplier, providing genuine, high-performance parts directly from the original manufacturers. Our commitment extends globally, as we are a leading automotive parts exporter, delivering premium auto parts to markets worldwide. At Supreme Sales Agency, we are dedicated to offering exceptional products and services to keep vehicles running at their best.

#Aftermarket Parts Suppliers#OEM Parts Suppliers#Auto Parts Exporter#Automotive Parts Exporter#commercial vehicle brake lining

0 notes

Text

3602S1 3602S truck brake system parts for FUWA FORD truck trailer #brakedrum 3602. B 3602. E 3602.R1 #autoparts #brakeparts #truckpartsforsale ([email protected])

Origin:China Customized--Print/logo/Mold/Weight/Drawing Factory direct sales--Yes Shipping Port--Tianjin/Guangzhou/Qingdao Package:Pallet with plastic strap and carton board Material:Brake drums :HT250 Wheel hubs :QT250 Size:Original OEM size(ISO) Warrant:1 year/8000km Production :500pc/day

We are manufacturer of barke drums for Scania Renault DAF MAN BPW WEBB Benz Volvo Isuzu Toyota Hino Iveco Hyundai HOWO .etc We support high quality and best price to our customers . Mold also can be customized . If interesting ,plz feel free to contact me anytime.Look forward to our cooperation . Whatsapp/WeChat: +(86)15830703729 Mail: [email protected]

#3602S#brake parts#truck parts#auto parts#auto parts supplier#auto parts online#autopartsstore#oemparts#auto parts and accessories

0 notes

Text

Get The Distributorship of Automobile and Transportation Distributors.

Explore lucrative opportunities in automobile and transportation distribution. Partner with us for profitable distributorship in this thriving industry today!

Visit:- Automobile and Transportation Distributors

#Automobile and Transportation Distributors#Automobile and Transportation distributorship#automobile parts distributorship#Helmets supplier#Tubes distributors#oil & lubricants distributorship#auto accessories wholesalers#car accessories distributors#Brakes manufacturers#Car parts wholesalers#Car parts manufacturers#Tyres distributorship

0 notes

Text

Best Brake Discs in Dubai | Alshiba

Brakes discs in Dubai are an essential component of a vehicle's braking system, responsible for stopping or slowing down the motion of the wheels. These discs are made from high-quality materials and are designed to withstand the harsh conditions of regular use. They are available in a variety of sizes and designs and many more. For more information, Contact us. Visit Website: https://alshiba.ae/product-category/brakes-pads-discs/

#best car air filter#brake discs and pads#Brake Discs#car air filter#car coil spring#automotive parts suppliers#coil springs#car mufflers#car coil springs#shock absorber car#catback exhaust supplier

0 notes

Text

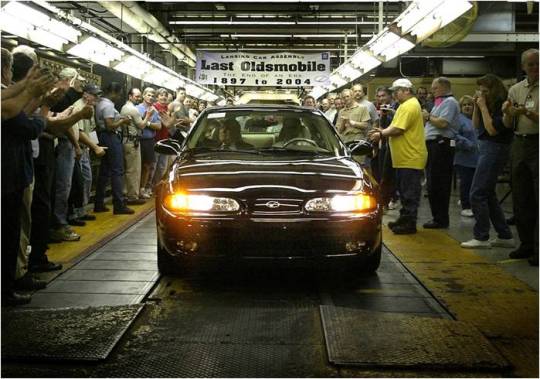

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

94 notes

·

View notes

Text

BBL Brakes: Your Trusted Partner for Brake Linings, Brake Pads, and Commercial Vehicle Brake Parts

Why BBL Brakes is the Industry Leader

At BBL Brakes, quality and innovation come together to deliver exceptional brake parts designed to withstand extreme conditions. Their wide range of products, including brake linings, brake pads, and commercial vehicle brake parts, is crafted to meet global standards while prioritizing safety and durability.

Key Advantages of BBL Brakes:

Advanced Manufacturing: Cutting-edge technology ensures consistent quality across all products.

Global Expertise: As one of the top brake lining manufacturers, BBL Brakes serves both domestic and international markets with equal dedication.

Comprehensive Product Range: From brake lining shoes to friction materials, their portfolio covers everything needed for efficient braking systems.

1. High-Performance Brake Linings

What Makes BBL Brake Linings Stand Out?

BBL Brakes specializes in manufacturing premium-quality brake linings that provide superior stopping power, even under heavy loads. These linings are designed for use in trucks, buses, and other commercial vehicles, ensuring optimal safety and performance.

Features of BBL Brake Linings:

Heat-Resistant Materials: Built to withstand high temperatures without degrading.

Long-Lasting Durability: Engineered to reduce wear and tear, even in extreme conditions.

Versatility: Suitable for a wide range of commercial and industrial vehicles.

Brake Lining Shoe Solutions

BBL Brakes also offers brake lining shoes that are crafted for precise fit and unmatched reliability. These shoes, combined with their high-quality linings, deliver unparalleled braking performance.

2. Trusted Brake Pad Manufacturers

Brake pads are critical for vehicle safety, and BBL Brakes excels in producing durable, high-performance options. As one of the most trusted brake pad manufacturers, they design pads that ensure efficient braking under all conditions.

Features of BBL Brake Pads:

Enhanced Friction Material: Made with premium materials for excellent stopping power.

Eco-Friendly Design: Manufactured with sustainable and non-toxic materials.

Durable Construction: Built to last, even in high-pressure environments like long-haul trucking.

Applications:

Commercial Vehicles: Their brake pads are designed for trucks, buses, and heavy-duty vehicles.

Passenger Vehicles: They also cater to smaller vehicles that require precision braking solutions.

3. Complete Range of Commercial Vehicle Brake Parts

Commercial vehicles often operate in demanding environments, requiring brake parts that are as tough as the job itself. BBL Brakes offers a comprehensive lineup of commercial vehicle brake parts, ensuring optimal performance and safety.

Popular Brake Parts from BBL Brakes:

Brake Linings for Trucks and Buses: Engineered for heavy-duty applications.

Brake Pads for Commercial Vehicles: Ensuring reliable braking performance.

Brake Lining Shoes: Designed to provide a perfect fit and maximum stopping efficiency.

Why Choose BBL Commercial Vehicle Brake Parts?

Custom Solutions: Tailored to meet the specific needs of different commercial vehicles.

Global Standards: All parts meet or exceed international safety and quality standards.

Reliability: Trusted by fleets and operators worldwide for consistent performance.

4. Best Supplier of Friction Materials

Friction materials are at the heart of every braking system, and BBL Brakes is proud to be the best supplier of friction materials in the industry. Their high-quality materials ensure superior performance in all braking applications.

Features of BBL Friction Materials:

Premium Composition: Designed to provide maximum friction with minimal wear.

Eco-Friendly Options: Compliant with global environmental regulations.

Versatility: Suitable for a wide range of applications, including brake linings and pads.

BBL Brakes is also recognized as a top friction material exporter, supplying premium products to clients worldwide.

5. Why BBL Brakes is a Global Leader in Brake Components

What Sets BBL Brakes Apart?

Innovation: Continuously investing in R&D to develop cutting-edge braking solutions.

Quality Assurance: Every product undergoes rigorous testing to ensure safety and reliability.

Global Reach: Trusted by clients in over 30 countries, making them a preferred brake lining manufacturer and friction material supplier.

Customer-Centric Approach: Focused on meeting the unique needs of every client, whether local or international.

6. Sustainability and Environmental Responsibility

BBL Brakes is committed to sustainability, using eco-friendly materials and energy-efficient manufacturing processes. As a responsible industry leader, they aim to reduce their carbon footprint while maintaining the highest standards of quality.

0 notes

Note

about Max and Charles having same brake issues! i noticed that yesterday but forgot to send an ask!

i just wanna yell and tell everyone that if charles didnt handle his issuse better it could most probably ended up like Max's did. that is not to say Max didnt do anything, Max's was more sever from the start and it just ..... yeah we saw what happened.

now that we have both seen what happened to Max and Charles, if one has fine eyes and or can read with proper comprehension, they would notice that Carlos' brake issue in Bahrain is not the same. nowhere near.

now, thats both races where Sainz was better than Max and Charles respectively.

regarding Charles' tyre deg yesterday on first and second stint, its all on dirty air. if Max didnt DNF i have a very nice feeling that Ferrari "boys" would have fought and the result is, we know who is very good at tyre management.

oh you cooked in this ask!

yeah, the fact that ferrari and red bull switched to the same brake supplier and both max and charles had an issue with the same part of the car within the first 3 races says a lot. max's issue was more severe because the car immediately overheated and the brakes caught on fire. charles' issue was slightly less significant because his car did not catch on fire but he also had to manage the temperature and brake imbalance.

it also shows that if charles did not manage the issue well, he could have DNFed instead of scoring that p4. his issue management was a masterclass in bahrain and i will die on this hill.

105 notes

·

View notes

Text

Can a Personal Injury Attorney Help with Mechanical Failure in Vehicle Accidents?

The aftermath of a vehicle accident can be overwhelming. Injuries, mounting medical bills, and dealing with insurance claims can make it difficult to know where to start. Understanding your rights and options becomes even more critical if you suspect mechanical failure contributed to your accident. Enlisting the help of a skilled personal injury attorney can be a pivotal step in navigating this complex situation. This article explores how an attorney can assist you in cases where mechanical failure is a key factor in a vehicle accident.

Understanding Mechanical Failure in Vehicle Accidents

Mechanical failure occurs when a vehicle's components fail to function as intended, leading to an accident. Common examples include brake malfunctions, tire blowouts, and steering issues. These failures often arise due to:

Wear and Tear: Over time, vehicle components naturally degrade. For instance, brake pads can wear down, reducing their effectiveness and increasing the risk of accidents.

Faulty Maintenance: Neglected or improper maintenance can lead to dangerous mechanical issues, such as poorly maintained tires or improperly repaired systems.

Manufacturing Defects: In some cases, a vehicle may have inherent defects due to design flaws or poor-quality materials used in its construction.

Each of these factors can significantly impact the outcome of an accident and may point to different liable parties.

How a Personal Injury Attorney Can Help

If mechanical failure is suspected, a personal injury attorney can provide invaluable assistance in several ways:

1. Conducting a Thorough Investigation

Determining whether mechanical failure played a role in your accident requires an in-depth investigation. Attorneys often collaborate with experts, such as accident reconstruction specialists and mechanical engineers, to analyze the evidence. These professionals can identify issues like defective brakes, faulty parts, or improper repairs that contributed to the incident. A comprehensive investigation forms the foundation of a strong case.

2. Identifying Liable Parties

Liability for mechanical failures can fall on various parties, including:

Vehicle Manufacturers: The manufacturer may be held responsible if a design or manufacturing defect caused the failure.

Repair Shops or Mechanics: Improper repairs or negligence during routine maintenance could implicate the service provider.

Parts Suppliers: Faulty or defective parts supplied for the vehicle may also contribute to mechanical issues.

Your attorney will identify all potentially liable parties and gather the necessary documentation to support your claim against them.

3. Handling Insurance Companies

Dealing with insurance companies can be one of the most challenging aspects of a personal injury case. Insurers may attempt to minimize their liability by attributing the accident to driver error rather than mechanical failure. A skilled attorney will navigate these negotiations, countering tactics to reduce payouts and advocating for your right to fair compensation.

4. Building a Strong Case

An attorney will collect and organize evidence to strengthen your claim, including:

Witness Statements: Testimonies from eyewitnesses can provide crucial insights into the events leading up to the accident.

Expert Opinions: Mechanical engineers and accident reconstructionists can validate claims of mechanical failure.

Maintenance Records: These documents can highlight whether proper care was given to the vehicle before the accident.

Pursuing Compensation for Your Losses

If mechanical failure is determined to be a contributing factor, your attorney will help you seek compensation for:

Medical Expenses: Covering both immediate and long-term medical needs.

Property Damage: Compensation for vehicle repairs or replacement costs.

Lost Wages: Reimbursement for income lost due to injuries.

Pain and Suffering: Acknowledgment of emotional distress and diminished quality of life.

By presenting a compelling case, your attorney will aim to secure the compensation you deserve to aid your recovery.

Navigating the complexities of personal injury claims, particularly those involving mechanical failure, can be overwhelming without professional guidance. Attorneys understand the intricacies of these cases and can manage the legal proceedings, allowing you to focus on healing. From gathering evidence to negotiating with insurers and representing you in court, a personal injury attorney ensures every aspect of your case is handled effectively.

Moving Forward with Confidence

Consulting a personal injury attorney early is crucial if you’ve been involved in an accident where mechanical failure may have been a factor. They can assess your case, guide you through the legal process, and work diligently to secure the compensation you need to move forward.

Don't hesitate to seek legal assistance—having a professional advocate on your side can make all the difference in achieving a favorable outcome.

7 notes

·

View notes

Text

Brake Lining Maintenance Tips for Long-Lasting Performance

Maintaining your vehicle's brake linings is crucial for ensuring safety and optimal performance. Proper maintenance not only extends the life of your brake linings but also enhances the overall braking efficiency. Here are some essential tips to keep your brake linings in top condition.

1. Regular Inspections

Frequent inspections are vital. Ideally, check your brake linings every 10,000 to 20,000 miles. Look for signs of wear, cracks, or glazing. Additionally, have a professional mechanic perform a thorough inspection annually to catch any potential issues early.

2.Proper Cleaning

Contaminants like oil, grease, and dirt can significantly affect brake performance. Keep your brake linings clean by using appropriate cleaning solutions and brushes. Compressed air can be used to blow out dust and particles, ensuring your brake linings remain uncontaminated.

3.Correct Installation

Ensure that brake linings are installed correctly according to manufacturer guidelines. This includes using the correct torque when tightening bolts and fittings. Proper installation prevents premature wear and ensures reliable performance.

4.Brake Fluid Maintenance

Regularly changing your brake fluid is crucial. Aim to replace it every 30,000 to 40,000 miles or as recommended by the manufacturer. Regularly inspect the system for leaks to maintain optimal brake performance.

5. Driving Habits

Your driving habits play a significant role in brake lining longevity. Avoid hard braking whenever possible and use engine braking by downshifting to reduce stress on the brake linings. Also, avoid overloading your vehicle to prevent excessive wear.

6. Environmental Factors

Be mindful of environmental factors such as temperature and humidity, which can impact brake performance. Protect your brake components from road salt and moisture to prevent corrosion.

7. Professional Servicing

Schedule regular professional maintenance to ensure your brakes are always in peak condition. Use high-quality parts from reputable manufacturers like BBL Brakes, a leading name in the industry, to replace worn-out brake linings.

8. Performance Monitoring

Continuously monitor your brake performance. Pay attention to any unusual noises or vibrations, which could indicate issues with the brake linings.

9. Proper Storage

Store brake linings in a dry, cool place, away from direct sunlight and extreme temperatures, to prevent deterioration. Choosing the Right Brake Lining Manufacturers

When it comes to selecting brake linings, quality is paramount. BBL Brakes stands out among Brake Lining Manufacturers due to their commitment to quality, innovation, and customer support. They use high-quality materials, adhere to rigorous testing standards, and provide excellent after-sales service. With a global reach and a reputation for reliability, BBL Brakes ensures that your brake linings meet the highest standards of safety and performance.

Maintaining your brake linings properly and choosing the right Brake Lining Manufacturers like BBL Brakes can significantly enhance the longevity and performance of your vehicle's braking system. Prioritize regular maintenance and quality parts to ensure safety and efficiency on the road.

Tags:-

"Brake Lining" "Brake Lining Manufacturers" "Brake Lining Supplier" "Brake Lining Exporter in India" "Brake Lining Shoe" "Brake Lining Manufacturers From India" "Commercial Vehicle Brake Lining" "commercial vehicle brake pads" "Brake Pads" "Best Brake Pad Manufacturer" "Brakes Parts Manufacturers From India" "Brake Pads Manufacturer"

#Brake Lining#Brake Lining Manufacturers#Brake Lining Supplier#Brake Lining Exporter in India#Brake Lining Shoe#Brake Lining Manufacturers From India#Commercial Vehicle Brake Lining#commercial vehicle brake pads#Brake Pads#Best Brake Pad Manufacturer#Brakes Parts Manufacturers From India#Brake Pads Manufacturer

0 notes

Photo

Aria FXE

America is due for a legitimate competitor to the likes of Ferrari, Lamborghini and McLaren, and you’ve never heard of the company that says it is the one to take on those storied brands with an all-wheel drive hybrid-electric 1,150-horsepower. It is the Aria Group, an industrial supplier best known for the high quality of the carbon fiber bodywork it provides Singer for that company’s amazing Porsche 911 builds.Aria will take on the world with the FXE, which use a supercharged 6.2-liter V8 engine from the Chevrolet Corvette ZR1. Aria claims 720 horsepower for the engine, but that may have been an early estimate, because Chevrolet announced the ZR1 at 755 horsepower. The small block will drive the rear wheels through an 8-speed sequential transaxle, surely from one of the usual suspects in the racing/supercar community such as Xtrac, Hewland, or Graziano.The FXE enjoys another 540 horsepower from the twin electric motors driving the front wheels, which also provide all-wheel drive and regenerative braking to recapture energy. This is powered by a 10 kilowatt-hour lithium-ion battery pack (about the same capacity as that in the upgraded BMW i8).

Together, they accelerate the FXE to 60 mph in 3.1 seconds and to a top speed of 220 mph.

A less expensive FE model will use a naturally aspirated version of the gas engine driving the rear wheels, with no electric motors on the front axle.

In either configuration, Aria’s cars will be a technological tour de force, employing patented new techniques for fabricating its carbon fiber chassis and 3D printing to create various titanium and aluminum parts.

86 notes

·

View notes

Text

Songshun Steel Rod Supplier: Provides Various High Quality Steel Rods

Steel rod is a common rod-shaped steel material made of metal materials, it is widely used in machinery, ships, construction, engineering, manufacturing and other fields. Steel rods are one of the indispensable materials in the steel market and are in high demand, so steel rod suppliers play a pivotal role in the steel market. Songshun Steel, as a high-quality steel rod supplier in China, can provide various high-quality steel rod materials to the world. It not only has rich varieties and sufficient inventory, but also ensures that the quality, service, price, etc. can satisfy you. This article will introduce the steel rods and advantages provided by Songshun steel rod supplier.

Steel Rod Types Songshun Steel, as a steel rod supplier with a wide range of steel materials, provides steel bar materials of various materials. Our steel rod types are as follows:

(1) Classified by process, it can be divided into hot-rolled, forged and cold-drawn steel bars; (2) Classified by material, steel rods can be divided into alloy steel rods, Ordinary carbon steel rods, stainless steel rods, tool steel rods, high-speed steel rods, aluminum alloy rods, synthetic fiber steel rods, etc.; (3)Classified by shape, it can be divided into solid steel rods, round steel rods, square steel rods, hexagonal steel rods, wire rods, etc.

Steel Rod Properties High quality steel rod supplier, offering a wide range of high performance steel rods. As a reliable steel rod supplier in China, Songshun Steel provides steel rods with the following properties:

Excellent wear resistance, corrosion resistance and high temperature resistance Better electrical and thermal conductivity High strength and rigidity Good solderability and stability Good plasticity and toughness

Uses Of Steel Rods As a professional steel rod supplier, we have an in-depth understanding of steel rods and clearly understand the purposes for which our customers purchase steel rods. Below are some of our customers’ applications for steel rods in various fields.

Construction field: Steel rods are often used to reinforce concrete structures, and are also used to support structures such as beams, columns, bridges, and columns.

Automobile manufacturing field: Steel rods are used to manufacture various engine parts, rods, brake calipers, exhaust pipes, connectors, support columns, door beams, roof frames, etc.

In the manufacturing of electronic and electrical equipment, steel rods are often used to make wires for electromagnetic coils, transformers and generators. They are also used as heat-conducting elements in air conditioners, refrigerators, and other appliances, among other things.

In the manufacturing field, it is often used to manufacture various mechanical parts, tools, cutters, drill bits, planers, etc.

In addition to the above fields, steel rods are also used in aerospace, energy and power transmission, oil and gas industry, shipbuilding, chemical and heavy industry, home furnishing and decoration, etc.

Steel Rod Supplier In addition to the above points, as a high-quality and reliable steel rod supplier, Songshun can not only provide a variety of high-performance, multi-purpose and types of steel rods, but also has advantages in quality, professionalism, service, price, etc.

We ensure the quality of steel rods, provide various testing services, provide products in strict accordance with international production standards and customer requirements, and provide steel rods with the best performance and quality to customers.

Songshun has an experienced team that studies various steel rod materials and provides customers with one-stop solutions and technical support.

Whether it is processing, pre-sales or after-sales service, we are professional and can ensure that your project is completed smoothly and perfectly.

Competitive prices, abundant inventory, and ability to deliver on time.

Understand industry policies, market demand, international trade, etc., and be able to make reasonable strategies to adjust industrial structure, optimize product quality, improve operational efficiency, and promote innovative development according to market changes in a timely manner.

Adhere to the path of sustainable development, adhere to the goal of achieving win-win development with customers, adhere to treating every customer with sincerity, adhere to customer-centeredness, and meet customer needs.

In summary, Songshun Steel can become a reliable steel rod supplier, not only providing high-quality steel rod materials, but also having other advantages. In the future, we are committed to becoming your preferred steel rod supplier, constantly moving forward, and providing you with better steel products.

2 notes

·

View notes

Text

What are the different types of automobile and transportation distributors?

The automotive and transportation industry plays a pivotal role in connecting people and goods. This industry's growth and reach have been made possible by an extensive network of distributors and dealers. These intermediaries bridge the gap between manufacturers and end-users, ensuring the smooth flow of vehicles and related products.

Read Also:- Automobile and Transportation Distributors

Visit:- Go4distributors

#Automobile and Transportation Distributors#Automobile and Transportation distributorship#automobile parts distributorship#Helmets supplier#Tubes distributors#oil & lubricants distributorship#auto accessories wholesalers#car accessories distributors#Brakes manufacturers#Car parts wholesalers#Car parts manufacturers#Tyres distributorship

0 notes

Note

Hi Hazel,

I hope you are the right person to ask about this. So the way I understand it, in formula e, formula 2 and indycar all the teams have basically the same car, but it's still very clear that some teams are better than others. What are the teams actually changing to make that difference? I know that indy has two different engines but there has to be more to it. Can you change everything except for the chassis in fe? What is up with f2/f3? Idk this really confuses me from series to series.

no worries, it is confusing tbh.

so all the series you've mentioned have a spec chassis, which means every car looks the same. it has the same parts, from the same supplier. in Formula 2 and 3 it also has the same engine, again all from a single supplier (Mechachrome).

F2 and 3 are supplied a biofuel mix by Aramco (as of this year), IndyCar is fuelled by a biofuel made by Shell and all of Formula E use the same Williams Advanced Engineering battery. so it's not like F1 teams where every garage has a different fluids supplier.

Formula 2 and 3 teams can then change the setup of the car. that's sometimes very important for maintaining a good balance; it's why having an experienced team or a driver with good setup knowledge can make a huge difference and why some ultra-rich drivers like Amaury Cordeel pay for their teammate to share setup and essentially do the work for both cars. that's stuff like front and rear wing angle, ride stiffness, etc.

in Formula E teams can then make certain parts of the car themselves (brake ducts, for instance) and there is also a range of powertrain suppliers. initially, the Porsche powertrain looked unbeatable this season because it had the best race efficiency, whereas that seems to have swung the way of the Jaguar powered cars towards this late stage. the powertrain and the teams management of it make a very big difference to the efficiency of the car. you can also make small tweaks to the physical setup of the car but in FE they're not massively major just because there's no real aero to adjust (FE cars have less downforce than a GT car) only things like tiny increments of ride height and stuff - the overall efficiency is much more important.

in IndyCar there's a common chassis and then Honda and Chevrolet are the engine suppliers. sometimes it's clear that one or the other has the upper hand in terms of outright or sustained speed (so it's pretty noticeable in some years at the Indy 500) but teams can also make substantial setup changes that will vary how quick they are or the way the car behaves. this is a good article about the aerokit options available for IndyCar teams this year.

so, in terms of mechanical or technical things they can change, there is some stuff across all the series and in Formula E or IndyCar it's quite a wide range.

then there's what I'd broadly call operational factors. this is basically how good is the team at competing in their respective series.

that can come down to how well the cars are prepared for and looked after over a race weekend - generally, bigger budget teams will have more mechanics available to work on the cars and so be able to give them more attention. no garage is slacking but if you have more resources, better analytics tools, more option to change parts, etc then you will have an advantage. drivers also pay for parts across the year, so things like crash damage and wear-and-tear might mean that they're re-using parts if they're on a budget that they're replace, if they had infinite funds.

something that's affected all the series recently is the supply chain problems that Dallara (which makes the F2/3 and IndyCar chassis) and Spark (which is a subsidiary of Dallara that makes electric racecars, in FE and XE) has had. so there has been a lack of spare parts at various points across the board and FE currently has a severe lack of Gen3 parts - not at all helped by the carnage in Rome.

then there's how well the teams work with the drivers. how much data processing power they have, how good their performance engineers (the people who translate data to the drivers, basically) are and how well the team can execute strategies. in F2 or IndyCar that can include being slick at pit stops and knowing when to call them but there's also other factors.

take qualifying in F2 and 3, for instance. F2/3 cars use the F1 pit lane, with temporary pits set up in the bays outside the garages (basically where F1 teams do a pit stop) but they can't get inside the garages. which means that they are not allowed to refuel once the car has left the support series paddock, since refuelling is only allowed in garages.

for qualifying you want to run low fuel but also give yourself enough options to get a few runs in. if the track turns out to develop super quickly towards the end but you don't have the fuel to go out again, you'll lose out on position - this happened a weird amount with Prema last year, in F2, even though they're normally one of the best teams, operationally.

and there's lots of little things like that. understanding the tyres so you can get them up to temperature the best, knowing what calls to make if it rains, having the experience and confidence to do that even in series where, since they're literally for training, the drivers don't.

in IndyCar the strategy is super complicated because there's tyres and also fuel and obviously you want to get over the line having spent the least amount of time in the pits but that's going to take being clever and as in all sports a little bit lucky. then there's also the role of the spotter, which is basically to be the opposite of the Ferrari pit wall by accurately and promptly telling the driver about everything happening around them on track. it's not an engineering role, more purely about that sporting awareness and communication - F1 could prob learn.

in FE things are slightly different because FE is slightly different (no different tyre compounds, no pit stops, etc) but basically the teams that can correlated simulator data to put together the best on-track package will be in the lead. and if the mechanics can stay up all night fixing a car from the ground up and still be on it enough to fully prepare both cars the next day then hell, they're the best in the business.

so lots of factors affect how the car performs. generally the biggest constraint for teams is budget because money can fix a lot of the other problems but experience is the next hurdle. Sacha Fenestraz was talking quite a lot about how his engineering team in Nissan is all quite new to Formula E and how much they've had to learn together during the rookie practice on Friday.

19 notes

·

View notes

Text

Fenhar Silicone Coated Fiberglass Fabric Supplier

Fenhar New Material Thermal Insulation Branch is an international enterprise focus on thermal insulation materials since 2002. Our main products are: Silicone/PVC/PU/Aluminum coated fiberglass fabric and Silica fabric,they have been widely used in aerospace, shipbuilding, wind power generation, oil development, sports equipment, fire equipment, electronic insulation products and other fields.

And mica products include: tape, paper roll, tube, parts and so on. Mica products have been widely used in fire resistant cable, braking resistors, induction furnace, general electricity, home appliance, Miscellaneous.

2 notes

·

View notes