#braided copper wire manufacturer

Explore tagged Tumblr posts

Text

How are Silver Plated Copper Wires Made?

Silver plated copper wire is a specialized type of wire that combines the excellent conductivity of copper with the superior corrosion resistance and other beneficial properties of silver. As a result, you will find its application in various fields ranging from electronics to telecommunications. Understanding how these wires are made not only enhances your knowledge but also helps you appreciate the intricacies involved in their production.

In essence, silver plated copper wire is formed by applying a thin layer of silver onto a copper core. This process amplifies the wire's performance while ensuring that it remains cost-effective. The unique combination of these two metals results in a product that is not only durable but also highly efficient for transmitting electrical signals.

As you delve deeper into the manufacturing process, you will uncover the components, techniques, and applications of silver plated copper wires. By the end of this article, you will have a comprehensive understanding of this versatile material and its significance in modern technology.

Components: Copper Core and Silver Coating

The primary components of silver plated copper wire are the copper core and the silver coating. Each of these elements plays a crucial role in determining the wire's overall performance and applicability.

Copper Core -

Conductivity: Copper is renowned for its exceptional electrical conductivity, which is why it is often used as the core material for various types of wires. With a conductivity rating of approximately 97%, copper efficiently transmits electrical signals with minimal resistance.

Mechanical Strength: Copper is also relatively strong and flexible, making it suitable for various applications where durability is essential. This strength allows the wire to withstand mechanical stress without breaking or deforming.

Cost Effectiveness: Compared to silver, copper is much more affordable. This aspect makes it an ideal choice for the core material, as it helps keep production costs down while still delivering high-quality performance.

Silver Coating -

Corrosion Resistance: One of the primary advantages of silver is its resistance to tarnishing and corrosion. This property ensures that the wire maintains its conductivity over time, even in challenging environments.

Enhanced Conductivity: Silver has the highest electrical conductivity of all metals, surpassing even that of copper. By applying a silver coating, the overall conductivity of the wire is significantly improved, making it ideal for high-performance applications.

Solderability: Silver plating enhances solderability, allowing for easier and more reliable connections in electronic components. This quality is particularly beneficial in applications where reliable electrical connections are paramount.

Together, the copper core and silver coating create a wire that is both efficient and durable, suitable for a wide range of applications.

Silver Plating Process Explained

The silver plating process is a critical step in the production of silver plated copper wire. Several techniques exist, but the most commonly used methods include electroplating and cladding.

Electroplating: Electroplating involves immersing the copper wire in a solution containing silver ions. An electrical current is then applied, causing the silver ions to deposit onto the surface of the copper wire. This process is highly controlled, allowing manufacturers to achieve a uniform coating thickness. Here’s how it works.

Cladding: Cladding is another method that involves wrapping a layer of silver around the copper core. Both methods have their advantages and can be chosen based on the specific requirements of the application. For example, electroplating may be preferred for more delicate applications where precision is critical, while cladding may be utilized for applications requiring thicker coatings.

Why Choose Silver Plated Copper Wire?

Choosing silver plated copper wire over other conductive materials can provide a multitude of advantages. Below are some compelling reasons why you should consider using this type of wire in your projects.

Exceptional Conductivity: With silver being the best conductor of electricity, you can expect superior performance from silver plated copper wires. This enhanced conductivity means that your electrical systems will operate more efficiently, reducing energy loss and improving overall performance.

Durability: Silver plated copper wire is designed to withstand harsh environments. The silver coating provides an additional layer of protection against oxidation and corrosion, extending the lifespan of the wire. This durability makes it an ideal choice for long-term applications, especially in industries like telecommunications and aerospace.

Applications of Silver Plated Copper Wires

Silver plated copper wires are utilized across a range of industries, each benefiting from the unique properties of this material. Understanding these applications can help you appreciate the wire's significance in modern technology.

Electronics: In the electronics industry, silver plated copper wire is often used in circuit boards, connectors, and other components where high conductivity and reliability are essential. The combination of copper's mechanical strength and silver's electrical properties ensures that devices operate efficiently without signal degradation.

Aerospace: The aerospace sector frequently employs silver plated copper wire in avionics and communication systems. Given the extreme conditions faced by aircraft, the durability and corrosion resistance of the wire become critical factors. Moreover, its lightweight nature contributes to overall aircraft efficiency.

Telecommunications: High-frequency transmission lines benefit from the low-loss characteristics of silver plated copper wire. In telecommunications, where signal integrity is paramount, this wire type ensures that data is transmitted with minimal interference and loss, making it a preferred choice in fiber optic systems and telecommunications equipment.

Medical Equipment: In the medical field, reliability is crucial. Silver plated copper wires are used in various medical devices, ensuring that they function correctly in critical situations. Their corrosion resistance makes them particularly well-suited for applications in challenging environments, such as those involving bodily fluids.

Future Innovations in Silver Plated Copper Wire Technology

As technology continues to evolve, so too does the manufacturing of silver plated copper wire. Several innovations are on the horizon that could further enhance its performance and applicability.

Advanced Coating Techniques: New methods for applying silver coatings are being developed that could improve adhesion and durability. These techniques may allow for thinner coatings without sacrificing performance, leading to lighter and more efficient wires.

Smart Materials: The integration of smart materials into silver plated copper wires could enable them to adapt to changing environmental conditions. This innovation could lead to wires that automatically adjust their conductivity based on temperature or load, enhancing efficiency in applications like electric vehicles.

Sustainability Initiatives: The push for sustainable manufacturing practices is leading to advancements in recycling and resource management. Innovations in circular economy practices could significantly reduce waste and improve the environmental footprint of silver plated copper wire production.

Conclusion

Silver plated copper wire stands out as a high-performance material that combines the strengths of both copper and silver. From its manufacturing processes, including electroplating and cladding, to its wide-ranging applications in electronics, telecommunications, and aerospace, this wire is a preferred choice for many industries.

Understanding the components, benefits, and manufacturing techniques will empower you to make informed decisions for your projects. As technology continues to advance, keeping an eye on future innovations will ensure you remain at the forefront of developments in this versatile material.

If you are considering silver plated copper wire for your next project, it's time to explore your options. Whether you're in the electronics sector, aerospace, or telecommunications, the advantages of using silver plated copper wire can significantly enhance your applications.

#copper wire#stranded copper wire#braided copper wire manufacturer#electricalcontractor#electricianlife#structuredcabling

0 notes

Text

0 notes

Text

#Hydraulic Hoses#PTFE Hoses#PTFE Tubes#Convoluted PTFE Hose Manufacturers#Convoluted Hoses#High Pressure PTFE Hose#Threaded Pipe Connector#Threaded Connector#SS Wire Braided Convoluted Hoses#PTFE Hoses Aerospace#PTFE Plain Hoses#Two Axis Pipe Connector#Fixed Flange Connector#Copper Ended Connector#Dash 2 PTFE Hoses

1 note

·

View note

Text

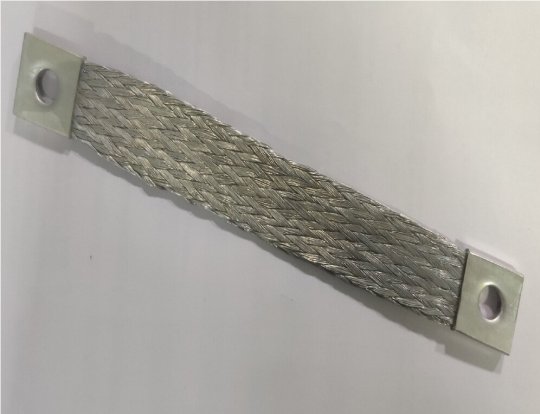

BAJERIA - Copper Braided Flexible Shunts | Jumpers | Connectors | Fuse | WIRE , STRANDED COPPER WIRE

Bajeria Industries is a leading manufacturer specializing in the production of a wide range of copper-based products. Their offerings include Copper Stranded Shunts, Copper Shunts, Copper Stranded Flexible Shunts, Copper Braided Flexible Shunts, Copper Flexible Wires, Copper Braided Wires, and Stranded Copper Wires. As a renowned braided wire manufacturer, Bajeria Industries excels in delivering top-quality products. Their expertise in producing braided copper wires and stranded copper wires ensures reliable and efficient electrical solutions for various applications.

https://www.bajeria.com/copper-braided-flexible-shunts.html

#COPPER STRANDED SHUNT#COPPER SHUNT#COPPER STRANDED FLEXIBLE SHUNT#COPPER BRAIDED FLEXIBLE SHUNT#COPPER FLEXIBLE#COPPER BRAIDED WIRE#BRAIDED WIRE MANUFACTURER#BRAIDED COPPER WIRE#STRANDED COPPER#STRANDED COPPER WIRE

0 notes

Text

Cable Wire Manufacturing Demystified: Everything You Need to Know

In today’s interconnected world, cable wires are essential for powering homes, industries, and communication networks. From electrical cables to telecommunications wires, these products are used daily in virtually every aspect of life. However, few people truly understand how cable wires are manufactured. This blog will take you through the cable wire manufacturing process and provide a deeper look into the materials, steps, and technologies involved in creating these critical components.

Cable Machinery Manufacturers

1. The Basics of Cable Wire Manufacturing

Cable wire manufacturing is a detailed and systematic process that involves several key stages. Each stage ensures that the cables are durable, efficient, and meet international standards for safety and functionality. The primary materials involved in cable manufacturing include copper, aluminum, plastics, and various insulating compounds.

2. Materials Used in Cable Wire Manufacturing

Copper: Copper is a popular choice for conductors because it is an excellent conductor of electricity. It’s also highly durable, corrosion-resistant, and offers high tensile strength. Copper cables are found in everything from power distribution to telecommunications.

Aluminum: Aluminum is used as an alternative to copper in some cables, especially for low-voltage applications. It is lighter and more cost-effective than copper but not as efficient in conducting electricity. However, aluminum cables are still reliable and widely used in power distribution.

Insulation: The insulation around a wire is crucial to prevent accidental electric shocks and short circuits. Various types of insulation materials are used, including PVC (polyvinyl chloride), rubber, and Teflon. The type of insulation depends on the wire's intended use, the environment it will be exposed to, and specific electrical requirements.

Other Materials: Steel and other metals might be used for reinforcement in certain types of cables, such as those used for high-tension power lines or cables exposed to mechanical stress.

3. The Cable Manufacturing Process

The process of manufacturing a cable wire can be broken down into several key stages:

Stage 1: Drawing the Wire The manufacturing process begins with drawing the raw material (usually copper or aluminum) into thin wires. The material is fed into a drawing machine, which gradually pulls and stretches the metal through progressively smaller dies until it reaches the desired gauge or thickness. This process is essential for producing the thin strands needed for cables.

Stage 2: Stranding Stranding is the process of grouping multiple wires together to form a single cable. In this stage, individual wires are twisted together to form strands that are then bundled to create a thicker conductor. The more strands in a wire, the more flexible the cable becomes. Some cables require a single strand, while others may have up to 7, 19, or even 37 strands, depending on the application.

Wire Machinery Manufacturers

Stage 3: Insulation and Jacketing Once the wire is stranded, it’s time to apply insulation. This is typically done by extruding a plastic material, such as PVC or polyethylene, around the wire to prevent electrical interference and ensure safety. For certain cables, multiple layers of insulation may be used, such as a primary insulation layer followed by a secondary protective jacket.

Stage 4: Shielding Some cables, especially those used in high-frequency telecommunications or power distribution, require shielding to prevent signal interference or to protect the cable from external electromagnetic interference (EMI). Shielding can be made from a variety of materials, including copper, aluminum foil, or braided metal wires. This step helps maintain the integrity of signals and reduces the risk of power loss or interference.

Stage 5: Final Assembly and Testing In the final stages of production, cables undergo additional processes like the addition of protective coatings or armoring (for cables used in harsh environments). Once complete, cables are rigorously tested for quality, strength, and electrical properties. Tests include checking for continuity, insulation resistance, and the ability to withstand heat or extreme conditions.

4. Types of Cable Wires

There are many different types of cables, each designed for specific uses. Here are a few common categories:

Power Cables: These are designed for transmitting electricity and are commonly found in electrical grids, factories, and homes. They may carry high-voltage or low-voltage power and can be either underground or overhead.

Communication Cables: These cables, including coaxial cables and fiber optics, are used for transmitting data, television signals, and internet connectivity. They must be able to handle high frequencies with minimal loss of signal.

Control Cables: Typically used in machinery and industrial equipment, control cables are designed to control signals, not necessarily to conduct large amounts of power.

Submarine Cables: These specialized cables are designed for undersea use, such as communication or power cables connecting continents. They must be durable enough to withstand harsh underwater environments.

5. Technological Advancements in Cable Manufacturing

The cable wire manufacturing industry has seen significant technological advancements over the years. Automation and robotics have streamlined production, increasing efficiency and consistency. Innovations in materials have led to more flexible, durable, and environmentally-friendly cables. For example, cables are now being made with recyclable materials and have reduced environmental impact.

Fiber optic technology has also transformed the cable industry, allowing for ultra-fast communication and data transfer over long distances. The development of stronger, lighter materials, like carbon fiber and advanced polymers, has also made cables more reliable and capable of handling heavier workloads.

Cable Machinery Manufacturers

6. Quality Control and Standards

To ensure that cables meet safety and performance standards, manufacturers must adhere to international guidelines and certifications. Some of the key standards for cable manufacturing include:

IEC (International Electrotechnical Commission): Specifies the design, safety, and testing requirements for a wide range of cables.

UL (Underwriters Laboratories): A certification mark that verifies a cable meets safety standards in the United States.

RoHS (Restriction of Hazardous Substances): Regulations that limit the use of harmful materials like lead and mercury in cables to protect the environment.

These standards ensure that cables are safe to use, perform as expected, and can withstand the challenges they will face in real-world applications.

7. The Future of Cable Wire Manufacturing

As technology continues to advance, the cable manufacturing industry will keep evolving. The growing demand for renewable energy, faster internet speeds, and smarter infrastructure will drive innovation in cable design and manufacturing. We are likely to see the rise of cables that are not only more efficient but also more sustainable and adaptable to emerging technologies like 5G, smart cities, and autonomous vehicles.

Wire Machinery Manufacturers

Conclusion

Cable wire manufacturing is an intricate process that requires precision, expertise, and an understanding of materials science. From the selection of the right materials to the final testing, each stage ensures that cables are durable, safe, and capable of performing under a wide variety of conditions. Understanding how these essential components are made helps us appreciate the vital role cables play in our daily lives and the technologies we rely on.

By staying up to date on the latest developments in the cable industry, manufacturers, engineers, and consumers can make better-informed decisions and ensure they’re using the best possible cables for their needs.

#Wire Machine Manufacturers#Wire Machinery Manufacturers#Cable Machinery Manufacturers#Cable Making Machine Manufacturers#Wire Making Machine Manufacturers

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer Power On-The-Go ABCC-60 ensures your Type-C devices are always charged, wherever you are. Its simple plug-and-play design makes it the perfect companion for busy days. 60W Fast Charging ABCC-60's 60W fast charging with Power Delivery technology ensures speedy device power-up, perfect for your busy life on the go. Type-C Compatibility ABCC-60 is designed exclusively for Type-C port enabled devices, ensuring seamless compatibility and efficient charging for all your gadgets. Swift Charging ABCC-60 offers 60W fast charging with Power Delivery technology, ensuring your devices are powered up in no time. Ideal for those on the move, its rapid charging capabilities keep up with your busy lifestyle. High-Quality Copper Wire With its high-quality copper wire core, ABCC-60 ensures fast and stable power transmission, maximising charging speed and reliability. Durable Connectors Equipped with durable connectors, ABCC-60 withstands daily wear and tear, providing a secure and stable connection for uninterrupted charging. Tough Nylon Braided Material Wrapped in tough nylon braided material, ABCC-60 offers superior durability and tangle-free convenience, ideal for on-the-go charging. Charge Type-C Laptops Not just for smartphones, ABCC-60 supports charging for Type-C laptops, offering versatile charging solutions for all your devices. 12000+ Bends Lifespan With a lifespan of over 12000 bends, ABCC-60 is built to last, ensuring long-term durability and reliability even with frequent use. Diverse Shades Choose from a range of diverse shades to express your personal style while staying connected with ABCC-60, adding a touch of flair to your charging routine. 60W Charging: Experience fast and efficient charging with the ABCC-60, capable of delivering up to 60W of power to your devices. 12000+ Bending Lifecycle: Built to last, this cable boasts a bending lifecycle of over 12000 cycles, ensuring long-term durability and reliability.

3A Fast Charging Speed: Enjoy rapid charging with a 3A fast charging speed, allowing you to power up your devices quickly and efficiently. Power Delivery Technology: Equipped with Power Delivery (PD) technology, the ABCC-60 optimizes power output for safe and efficient charging. Compatible with Type-C enabled Devices: Whether it's a smartphone, tablet, laptop, or any other Type-C device, the ABCC-60 is compatible with them all, offering universal convenience. Charge Type-C Laptops: Need to charge your laptop on the go? The ABCC-60 has you covered, supporting charging for laptops equipped with Type-C ports. 1.2m Tangle-Free: Crafted with a 1.2-meter tangle-free cable, the ABCC-60 ensures hassle-free charging experiences wherever you go. 480 mbps Data Transfer: Transfer data with ease and speed thanks to the ABCC-60's support for data transfer rates of up to 480 mbps. 180 Days Warranty: This product comes with a 180-day warranty against any manufacturing defects. [ad_2]

0 notes

Text

Multicore Flexible Cables Manufacturers: A Complete Guide

In the world of electrical wiring and cabling solutions, Multicore Flexible Cables Manufacturers play a crucial role in delivering high-quality cables designed for a variety of industrial, commercial, and residential applications. Whether you're looking to connect multiple electrical devices or ensure optimal performance in a range of environments, multicore flexible cables are the ideal choice. In this blog, we will explore everything you need to know about Multicore Flexible Cables Manufacturers, including their offerings, benefits, and how to select the best one for your needs.

What Are Multicore Flexible Cables?

Multicore Flexible Cables are cables that consist of multiple conductors, all housed within a single outer sheath. These conductors can carry different signals or electrical currents and are often used for complex electrical installations that require the distribution of power and data. The term "flexible" indicates that the cables are designed to be pliable and durable, able to withstand bending and twisting without damage.

These cables are commonly used in a variety of industries, including manufacturing, automotive, telecommunications, and control systems. The flexible nature of these cables makes them perfect for dynamic environments where movement is essential, and durability is a top priority.

Why Choose Multicore Flexible Cables?

There are several reasons why Multicore Flexible Cables are preferred in various applications:

Durability: Designed to withstand mechanical stress, these cables offer long-term reliability.

Flexibility: The flexibility of these cables allows for easy installation and movement without compromising performance.

Versatility: Suitable for a wide range of environments, including outdoor, indoor, and hazardous locations.

Space-saving: Multiple cores within a single cable reduce the need for multiple cables, helping to save space in cable trays and conduits.

Key Applications of Multicore Flexible Cables

Power Supply Systems: They are widely used to distribute power in industrial setups and control systems.

Automation and Robotics: These cables are essential in robotic arms and automated manufacturing units due to their flexibility and durability.

Telecommunication: Multicore flexible cables are often used for data transmission in telecommunication networks.

Control Panels: They provide power and signals to various components in control panels and machinery.

Frequently Asked Questions (FAQs) About Multicore Flexible Cables Manufacturers

1. What Should I Look for in Multicore Flexible Cables Manufacturers?

When choosing Multicore Flexible Cables Manufacturers, consider the following factors:

Quality Assurance: Ensure that the manufacturer offers high-quality cables that comply with industry standards.

Product Range: A good manufacturer should provide a wide range of cables for different applications.

Customization: Look for manufacturers who offer custom solutions based on your specific requirements.

Technical Support: Strong customer support and technical assistance can be critical when selecting the right cables for your project.

2. How Do Multicore Flexible Cables Differ From Other Cables?

Compared to single-core cables or multi-pair cables, Multicore Flexible Cables are designed for higher flexibility and strength. The main difference is that they have multiple cores inside one outer sheath, which allows for the transmission of several signals or power channels in one cable. This design makes them ideal for situations where space and flexibility are critical.

3. What Are the Common Materials Used by Multicore Flexible Cables Manufacturers?

The materials used in the construction of Multicore Flexible Cables typically include:

Copper or Aluminum Conductors: For effective electrical conductivity.

PVC or Thermoplastic Elastomers: For the outer insulation to ensure durability and flexibility.

Screening Materials: Such as foil or braid, to protect against electromagnetic interference.

4. Are Multicore Flexible Cables Suitable for Outdoor Use?

Yes, Multicore Flexible Cables can be designed for both indoor and outdoor applications. Manufacturers offer cables with various protective sheaths, including weather-resistant materials, making them suitable for harsh environmental conditions. Always ensure that the cables you select are rated for the intended environment, whether it's high humidity, UV exposure, or extreme temperatures.

5. How Do I Choose the Right Multicore Flexible Cable for My Project?

When selecting a Multicore Flexible Cable, consider the following factors:

Voltage Rating: Ensure the cable’s voltage rating matches the requirements of your application.

Temperature Range: Choose a cable that can withstand the temperature conditions of your project.

Number of Cores: Depending on the complexity of your wiring system, choose a cable with an adequate number of cores.

Flexibility Requirements: Ensure the cable’s flexibility meets the demands of your application, especially if the cable will be subjected to frequent movement.

6. What Are the Benefits of Working with Reputable Multicore Flexible Cables Manufacturers?

Working with experienced Multicore Flexible Cables Manufacturers ensures that you receive:

High-quality products that meet international standards.

Expertise to help you choose the right cable for your needs.

Reliable after-sales support to assist with any issues that arise during installation or operation.

7. Can Multicore Flexible Cables Be Used in Heavy Duty Applications?

Yes, Multicore Flexible Cables are available in versions designed for heavy-duty applications. Manufacturers offer cables with enhanced durability and resistance to extreme mechanical stresses, making them suitable for industrial machinery, automation systems, and more.

Conclusion

Multicore Flexible Cables Manufacturers offer essential solutions for a wide range of industries, providing cables that ensure safe, reliable, and efficient electrical installations. By understanding the benefits, applications, and technical specifications of these cables, you can make informed decisions for your projects. Whether you're working on a large-scale industrial system or a simple home setup, choosing the right multicore flexible cables will guarantee optimal performance.If you're ready to invest in Multicore Flexible Cables, make sure to partner with a reputable manufacturer that can meet your specific requirements and offer quality products that will last.

1 note

·

View note

Text

copper wire manufacturers in Mumbai call us- 8010336422

Looking for reliable copper wire manufacturers in Mumbai Get high-quality copper wires crafted to meet diverse industrial and commercial needs. Renowned for durability and precision, our manufacturers ensure premium-grade materials and timely delivery. Whether for electrical, construction, or specialized applications, trust Mumbai's best for superior performance and efficiency. Contact us today!

visit here

0 notes

Text

Understanding Stranded Flexible Copper Connectors: Key Features and Advantages

In the field of electronics and electrical engineering, the efficiency and reliability of your systems can be heavily affected by the connector you use. Among the several choices at hand, stranded flexible copper connections stand out for their adaptability and better electrical features. With an eye on silver-plated and Nickel Plated Copper Wire, this blog explores the salient characteristics and benefits of Stranded Flexible Copper Connectors.

What Are Stranded Flexible Copper Connectors?

Made to provide more flexibility and conductivity than their solid counterparts, Stranded Flexible Copper Connectors Many tiny copper wires braided together to create a single conductor from these connectors. This design offers many advantages, especially in uses needing constant movement or adaptability.

Key Features of Stranded Flexible Copper Connectors

Enhanced Flexibility: Stranded copper connectors have mostly one benefit: their flexibility. Stranded connectors stretch and flex without losing their conducting qualities, unlike inflexible, breakable solid copper wires under stress. For uses where the cables must constantly move or where the connectors must negotiate confined areas, their adaptability makes them perfect.

Improved Durability: By more fairly spreading mechanical stress over the wire, the stranded architecture lowers the chance of damage and wear over time. This produces more robust connectors able to tolerate physical strain, vibration, and bending without sacrificing performance.

Superior Electrical Conductivity: Excellent electrical conductivity abounds from stranded copper cables. More surface area for electrical flow given by the many threads helps to reduce resistance as compared to solid wires. This increased conductivity guarantees effective power transfer and lowers the heat-generating risk resulting from electrical resistance.

Reduced Signal Loss Stranded copper connectors reduce signal loss in high-frequency uses. By lowering impedance and preserving constant electrical characteristics across the wire's length, the design makes higher signal integrity possible. In data transfer and telecommunications applications especially, this is crucial.

Silver Plated Copper Wire: Advantages

Because of its specific plating, Silver Plated Copper Wire is a speciality kind of stranded copper wire with further advantages. Using copper wire with silver plating offers the following benefits for your connections.

Enhanced Conductivity: Silver among all the metals has the best electrical conductivity. Silver arranging of the copper wire will significantly boost the general conductivity of the connection. Improved conductivity adds to better performance in high-speed and high-frequency applications.

Corrosion Resistance: A protective coating created by Silver Plated Copper Wire aids to stop corrosion and oxidation. In settings where the connectors come into contact with moisture or hostile circumstances, this especially helps to guarantee long-term performance and dependability.

Improved Solderability: Excellent solderability of copper wire with Silver Plated Copper Wire makes building dependable and robust connections simpler. Ensuring constant performance and reducing the possibility of connection failure depend on this function.

Nickel Plated Copper Wire: Advantages

Another choice for stranded connectors, Nickel Plated Copper Wire offers several advantages:

Increased Mechanical Strength: Copper wire gains mechanical strength via Nickel Plated Copper Wire, so increasing its resistance to wear and abrasion. In applications where the connectors experience mechanical stress or regular movement, this is especially important.

Superior Corrosion Resistance: Silver among all the metals has the best electrical conductivity. Silver plating of the copper wire will significantly boost the general conductivity of the connector. From this enhanced conductivity, better performance in high-speed and high-frequency uses follows.

High-Temperature Performance: Nickel Plated Copper Wire resists higher temperatures than unplated copper wire. This qualifies for uses including automotive or industrial environments when heat is a consideration.

Choosing the Right Connector for Your Application

Selecting Stranded Flexible Copper Connectors for your projects requires careful consideration of the particular needs of your application. Here are some things to bear in mind:

Flexibility Needs: If your application calls for constant movement or bending, you really should use a very flexible stranded copper connector. Choose one that fits your needs since both silver plated and nickel plated choices provide different degrees of flexibility.

Environmental Conditions: Think about the surroundings where the connectors will be used. While Nickel Plated Connections provide great mechanical strength and high-temperature performance, silver-plated connectors are best for settings likely to be corrosive.

Performance Requirements: Silver Plated Copper Wire offers the best conductivity and signal integrity for high-frequency or high-speed uses. Conversely, nickel plated wire shines in conditions calling for strong mechanical qualities and thermal resistance.

Conclusion

Whether silver plated or nickel plated, Stranded Flexible Copper Connectors provide many advantages that could improve the dependability and performance of your electrical systems. Knowing the main characteristics and benefits of different connectors helps you to decide which kind of connector best fits your particular use. Stranded Flexible Copper Connectors offer a flexible and efficient answer for a variety of electrical and electronic needs, regardless of your priorities—flexibility, conductivity, or durability.

See Ganpati Engineering for further details on premium Stranded Flexible Copper Connectors, including nickel-plated and Silver Plated Copper Wire choices. Search our selection of items to identify the ideal fit for your project.

#copper wire#stranded copper wire#stranded flexibility tin copper wire rope#braided copper wire manufacturer#bare braided copper wire

0 notes

Text

What Materials are Used in Auto Wiring Harnesses

The automotive industry has undergone significant changes over the past few decades, and with each advancement, the complexity of automotive wiring harnesses has increased. These harnesses are essential for transmitting power and signals throughout the vehicle to ensure optimal operation of electrical and electronic components. As a professional automotive wiring harness manufacturer, we understand the importance of using high-quality materials to ensure safety, reliability, and durability. In this article, we will discuss the materials commonly used in automotive wiring harness manufacturing.

Conductive Materials: Copper and Aluminum

At the heart of any wiring harness is the conductive material that carries the current. Copper is the most commonly used conductive material in automotive wiring harnesses because of its excellent conductivity, flexibility, and tensile strength. It can carry high current loads without significant voltage drop, which is critical in automotive applications where performance and safety are critical.

Insulation Materials: PVC, XLPE, and TPE

Insulation materials are critical in automotive wiring harnesses because they protect wires from environmental factors and prevent electrical leakage. Polyvinyl chloride(PVC)is a common insulation material favoured for its flexibility, durability, and resistance to abrasion, chemicals, and temperature changes. It is suitable for both low- and high-voltage applications and can be easily colour-coded for wire identification.

Cross-linked polyethene (XLPE)is another popular insulation material used in automotive wiring harnesses. It has superior thermal, chemical, and physical properties to PVC and has enhanced abrasion resistance, making it ideal for harsh automotive environments.

Thermoplastic elastomers(TPE)are a blend of plastic and rubber, so they have the properties of both materials.TPEs are used in applications that require flexibility and durability, such as areas that experience frequent movement or vibration.

Protective Coverings: Corrugated Tubing, Braided Sleeving, and Foil Tape

To further protect wires from environmental hazards such as moisture, heat, abrasion, and chemical leaks, additional protective coverings are required. Corrugated tubing made from nylon or polypropylene offers an excellent balance between flexibility and strength and is commonly used to wrap automotive wiring harnesses.

Braided tubing made from materials such as polyester or nylon provides physical protection while maintaining flexibility. They can also reduce noise by minimizing vibration and rattle of cables within the harness.

Foil tape is made from aluminium or copper and can be wrapped around the harness to shield electromagnetic interference(EMI), which can disrupt the operation of sensitive electronic components in modern vehicles.

Connectors and Terminals: Brass, Copper, and Plastics

Connectors and terminals play a key role in connecting wires and ensuring reliable electrical connections. Brass and copper are widely used to manufacture terminals due to their excellent conductivity and corrosion resistance. Terminals can also be plated with materials such as tin or gold to further improve performance and lifespan.

Committed to Quality and Innovation

As a professional automotive wiring harness manufacturer, we are constantly exploring and adopting new materials and technologies to ensure that our products meet the highest standards of quality and reliability. Our commitment to innovation is matched by our dedication to sustainability, which compels us to seek environmentally friendly materials and manufacturing processes.

In summary, there are a variety of materials used in automotive wiring harnesses, which are selected for their ability to withstand the harsh conditions in which automobiles operate. Copper and aluminium remain the conductors of choice, while insulation and protective jacketing materials such as PVC, XLPE, and TPE ensure the integrity of the wiring harness. Connectors and terminals made of brass, copper, and durable plastics ensure a solid electrical connection. As a manufacturer, we are committed to providing the automotive industry with wiring harnesses that are superior in performance, safety, and quality.

0 notes

Text

Asia Pacific and Japan Wire Cable Market Future Trends to Look at | BIS Research

A wire cable is a strong, flexible assembly made of multiple strands of metal wire twisted or braided together. Wire cables are typically used for lifting, pulling, tensioning, or transmitting mechanical force. They are commonly made from steel, stainless steel, or other durable metals and are used in a variety of applications such as construction, cranes, elevators, bridges, and heavy machinery

The Asia-Pacific and Japan wire and cable market was valued at $88.26 billion in 2022, and it is expected to grow at a CAGR of 8.03% and reach $199.71 billion by 2032

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data, blockchain technology, Asia Pacific and Japan Wire Cable Material , advanced materials and chemicals, agriculture and FoodTech, mobility, robotics, and aerospace and defense, among others.

Asia Pacific and Japan Wire Cable Overview

Wire and cable are essential components used in electrical and mechanical systems for conducting electricity, transmitting signals, and supporting structural loads. While often used interchangeably, "wire" generally refers to a single conductor made of metal, such as copper or aluminum, whereas "cable" consists of two or more wires bundled or braided together, often with insulation or protective sheathing.

Types of Wire and Cable

Electrical Wire - Used to carry electrical current within buildings, appliances, or equipment. These wires are often insulated to prevent short circuits and protect users from electric shocks.

Communication Cable - Includes fiber optic and coaxial cables used for transmitting data, phone, or internet signals over distances.

Mechanical Wire Cables - Comprising twisted or braided metal strands, these are designed to bear loads and are commonly used in cranes, bridges, elevators, and other heavy-duty applications.

Key Features

Conductivity - Electrical wires and cables use materials like copper or aluminum for efficient electrical conduction.

Insulation - Protective layers, such as plastic, rubber, or PVC, are used to prevent electrical leakage and ensure safe handling.

Durability - Cables, especially mechanical wire cables, are designed to be strong, flexible, and resistant to wear, corrosion, and environmental factors.

Applications of Asia Pacific Japan Wire Cable Market

Electrical Wiring in Buildings

Data Transmission

Heavy Industries

Demand - Drivers and Limitations

Following are the demand drivers for the Asia-Pacific and Japan wire and cable market:

• Increase of Investments in the Telecommunications Industry • Increase in Demand for Sustainable Wire and Cable Products • Rise of Industrial Revolution 4.0 • Increase in Sales of Electric Vehicles • Rise in the Demand for Energy Produced from Renewable Sources

Following are the limitations of the Asia-Pacific and Japan wire and cable market:

• Fluctuations in Raw Material Prices • Ban by the Government on Materials Used in Wire and Cable Production • Limited Availability of Sustainable Materials and its Related Standardization Challenges • Challenges Faced by Wire and Cable Manufacturers Due to Plastic Disposal

Key Companies

Dow

Wacker Chemie AG

Momentive Performance Materials

Shin-Etsu Chemical Co., Ltd.

China National Bluestar (Group) Co., Ltd.

Rogers Corporation

Cabot Corporation

Reiss Manufacturing Inc.

MESGO S.p.A.

CHT Germany GmbH

Bellofram Elastomers

Grab a look at the report page click here !

Market Segmentation for Asia Pacific and Japan Wire Cable

Segmentation 1: by Application

Based on application, in the Asia-Pacific and Japan wire and cable market, the infrastructure application is poised to lead, indicating a strong demand for wiring and cabling solutions in construction and development projects.

Segmentation 2: by Product

Segmentation 3: by Voltage Type

Based on product, low voltage energy cables (<1kV) are leading the Asia-Pacific and Japan wire and cable market due to their widespread applications and compatibility with diverse electrical systems.

Segmentation 4: by Country

Based on the country, China is poised to lead the Asia-Pacific and Japan wire and cable market, holding the largest share due to robust industrialization, extensive infrastructure development, and growing demand for power solutions. Its role in manufacturing and technology adoption strengthens its market position, influencing trends and competitiveness in the region.

Visit our Next Generation Fuel/ Energy Storage Solutions

Recent Developments in the Asia-Pacific and Japan Wire and Cable Market

• In August 2023, LS Cable & System Ltd. invested an additional $118.5 million (KRW 155.5 billion) for its business establishment in Donghae City, Gangwon Province, South Korea, for the expansion of its submarine cable production facilities. • In April 2023, Finolex Cables allocated $24.3 million (INR 200 crore) for its production center in Pune, India, to expand its production capabilities across several industries, including fiber optic cables, auto cables, and photovoltaic cables sector.

Have a look at the free sample click here !

Conclusion

In conclusion, the Asia Pacific and Japan Wire Cable market serves as the backbone of global communication, addressing the need for rapid and reliable data transmission. The growth of this market is fueled by technological advancements, the expanding telecommunications landscape, emerging 6G sector and the ongoing digital transformation.

The increasing adoption of 5G networks, the rise of cloud computing, and the growth of data centers are key factors propelling the demand for both Asia Pacific and Japan Wire Cable s.

Asia Pacific and Japan Wire Cable are integral to the functioning of the digital economy, enabling seamless communication, connectivity, and data sharing across industries, homes, and businesses.

0 notes

Text

#high temperature cable manufacturers in india#flexible link and jumper manufacturers in kolkata#rubber trailing cable manufacturers in kolkata

0 notes

Text

314 Redraw Wire - Properties and Applications

314 Redraw Wire, often made from high-purity copper, is prized for its exceptional conductivity, ductility, and corrosion resistance. With a fine, smooth surface, it's commonly used in electrical applications, including winding, braiding, and weaving in the manufacturing of cables, wires, and connectors. Its high thermal conductivity makes it ideal for heat exchangers and other applications requiring efficient heat dissipation.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer Apple MFi (Made for iPhone, iPad, and iPod) certification ensures complete charge and sync compatibility with your Apple device. Simply connect the Lightning adapter to your Apple device and the USB end to a wall adapter or USB hub to charge or to a computer to sync data. Complete charge and sync compatibility Works with Apple devices with Lightning connection Apple MFi Certified Lightning adapter on one end, USB on the other Copper wires with added Kevlar promote maximum signal quality and strength Durable nylon fiber cloth for protection, strength, and flexibility AmazonBasics Double Nylon Braided USB A Cable with Lightning Connector, Premium Collection Charge and Sync with Confidence A step-up from the original AmazonBasics Lightning to USB A Cable, this enhanced version is rated to withstand 20,000 bends at 95 degrees, which gives it a 5X longer life expectancy compared to the original cable (rated 4,000 bends). The premium cable also offers a nicer-looking overall appearance. Laser-welded connectors allow for more precise results, compared to typical welding done by a torch or other heat source. Rated to 20,000 bends Enhanced appearance Small Head Works With Most Cases 0.4" x 0.245", the narrow Lightning Adapter is small enough to fit most cases but strong enough to withstand repeated unplugging and storage. Copper Wire High-quality copper wire maximizes signal quality and increases durability. Insulation Wound tightly around the cord, the high-tensile nylon fiber cloth offers superior strength with a bit of flexibility. The braided nylon can handle daily stress, ensuring long-lasting performance. Shielding Wire, aluminum foil, and mylar shielding reduces interference and provides additional layers of protection to prevent wear.

Outer Jacket Wound tightly around the cord, the high-tensile nylon fiber cloth offers superior strength with a bit of flexibility. The braided nylon can handle daily stress, ensuring long-lasting performance. Compatible Devices For complete charging and syncing, this cable works with Apple devices that have a Lightning port, including the XS / XS Max / XR / X / 8 Plus / 8 / 7 Plus / 7 / 6s Plus / 6s / 6 Plus / 6 / 5s / 5c / 5 / iPad Pro / iPad Air / Air 2 / iPad mini / mini 2 / mini 4 / iPad 4th gen / iPod Touch 5th gen / iPod nano 7th gen and Beats Pill+ Note: The cable is rated for 5V, 2.4A. AmazonBasics Nylon Braided Lightning to USB A Cable AmazonBasics Double Braided Lightning to USB A Cable, Advanced Collection AmazonBasics Double Braided Lightning to USB A Cable, Premium Customer Reviews — — — Price — — —

Color Selection Golden, Silver, Dark Grey, Rose Gold Golden, Silver, Dark Grey, Rose Gold Black, Red, Golden, Silver, Dark Grey, Rose Gold MFi Certified ✓ ✓ ✓ Compatibility iPhone, iPad, iPod iPhone, iPad, iPod iPhone, iPad, iPod Bend Lifespan 4,000 6,000 20,000 Connector Strength relief that extends product life Strength relief that extends product life Strength relief that extends product life MFi-certified charging cable for securely charging Apple devices Compatible with iPhone 13, 12, 11; 13, 12, 11 Pro; 13, 12, 11 Pro Max;13 and 12 mini; XS, XS Max, XR, X; 8 Plus, 8; 7 Plus, 7; 6s Plus, 6s, 6 Plus, 6; 5s, 5c, 5; iPad Pro, iPad Air, Air 2, iPad mini, mini 2, mini 4, iPad 4th gen; iPod touch 5th gen, iPod nano 7th gen and Beats Pill+ Nylon-braided cable. Can bend upto 90 degrees Wire width & reduced cord resistance deliver high speed charging (up to 2.4 amps charging current) Uses Apple's original C89 smart chip that recognises and instantly connects to Apple devices to provides safe, stable charging solution Damage-resistant connectors fit securely An additional protective layer added to the lightning and USB ends for enhanced durability and reduced fraying Length: 1.2 metres; Colour: Grey [ad_2]

0 notes

Text

Tinned Copper Flexible Braided Connectors & Manufacturer

Terowell manufactures, exports and supplies Flexible Flat Copper Braid Bond made of numerous copper wires are likewise now and again utilized for adaptable electrical associations between large components. The various littler wires involving the twist are a great deal more impervious to breaking under repeated motion and vibration than is a cable of larger wires.

#Gunmetal Clamps manufacturer#solid copper earth rod manufacturer#Copper Bonded Earth Rod manufacturer in mumbai#u bolt clamp suppliers in mumbai#PVC Covered Copper Tape

1 note

·

View note