Don't wanna be here? Send us removal request.

Text

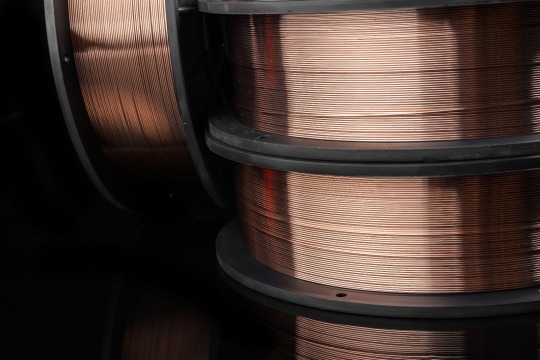

How are Silver Plated Copper Wires Made?

Silver plated copper wire is a specialized type of wire that combines the excellent conductivity of copper with the superior corrosion resistance and other beneficial properties of silver. As a result, you will find its application in various fields ranging from electronics to telecommunications. Understanding how these wires are made not only enhances your knowledge but also helps you appreciate the intricacies involved in their production.

In essence, silver plated copper wire is formed by applying a thin layer of silver onto a copper core. This process amplifies the wire's performance while ensuring that it remains cost-effective. The unique combination of these two metals results in a product that is not only durable but also highly efficient for transmitting electrical signals.

As you delve deeper into the manufacturing process, you will uncover the components, techniques, and applications of silver plated copper wires. By the end of this article, you will have a comprehensive understanding of this versatile material and its significance in modern technology.

Components: Copper Core and Silver Coating

The primary components of silver plated copper wire are the copper core and the silver coating. Each of these elements plays a crucial role in determining the wire's overall performance and applicability.

Copper Core -

Conductivity: Copper is renowned for its exceptional electrical conductivity, which is why it is often used as the core material for various types of wires. With a conductivity rating of approximately 97%, copper efficiently transmits electrical signals with minimal resistance.

Mechanical Strength: Copper is also relatively strong and flexible, making it suitable for various applications where durability is essential. This strength allows the wire to withstand mechanical stress without breaking or deforming.

Cost Effectiveness: Compared to silver, copper is much more affordable. This aspect makes it an ideal choice for the core material, as it helps keep production costs down while still delivering high-quality performance.

Silver Coating -

Corrosion Resistance: One of the primary advantages of silver is its resistance to tarnishing and corrosion. This property ensures that the wire maintains its conductivity over time, even in challenging environments.

Enhanced Conductivity: Silver has the highest electrical conductivity of all metals, surpassing even that of copper. By applying a silver coating, the overall conductivity of the wire is significantly improved, making it ideal for high-performance applications.

Solderability: Silver plating enhances solderability, allowing for easier and more reliable connections in electronic components. This quality is particularly beneficial in applications where reliable electrical connections are paramount.

Together, the copper core and silver coating create a wire that is both efficient and durable, suitable for a wide range of applications.

Silver Plating Process Explained

The silver plating process is a critical step in the production of silver plated copper wire. Several techniques exist, but the most commonly used methods include electroplating and cladding.

Electroplating: Electroplating involves immersing the copper wire in a solution containing silver ions. An electrical current is then applied, causing the silver ions to deposit onto the surface of the copper wire. This process is highly controlled, allowing manufacturers to achieve a uniform coating thickness. Here’s how it works.

Cladding: Cladding is another method that involves wrapping a layer of silver around the copper core. Both methods have their advantages and can be chosen based on the specific requirements of the application. For example, electroplating may be preferred for more delicate applications where precision is critical, while cladding may be utilized for applications requiring thicker coatings.

Why Choose Silver Plated Copper Wire?

Choosing silver plated copper wire over other conductive materials can provide a multitude of advantages. Below are some compelling reasons why you should consider using this type of wire in your projects.

Exceptional Conductivity: With silver being the best conductor of electricity, you can expect superior performance from silver plated copper wires. This enhanced conductivity means that your electrical systems will operate more efficiently, reducing energy loss and improving overall performance.

Durability: Silver plated copper wire is designed to withstand harsh environments. The silver coating provides an additional layer of protection against oxidation and corrosion, extending the lifespan of the wire. This durability makes it an ideal choice for long-term applications, especially in industries like telecommunications and aerospace.

Applications of Silver Plated Copper Wires

Silver plated copper wires are utilized across a range of industries, each benefiting from the unique properties of this material. Understanding these applications can help you appreciate the wire's significance in modern technology.

Electronics: In the electronics industry, silver plated copper wire is often used in circuit boards, connectors, and other components where high conductivity and reliability are essential. The combination of copper's mechanical strength and silver's electrical properties ensures that devices operate efficiently without signal degradation.

Aerospace: The aerospace sector frequently employs silver plated copper wire in avionics and communication systems. Given the extreme conditions faced by aircraft, the durability and corrosion resistance of the wire become critical factors. Moreover, its lightweight nature contributes to overall aircraft efficiency.

Telecommunications: High-frequency transmission lines benefit from the low-loss characteristics of silver plated copper wire. In telecommunications, where signal integrity is paramount, this wire type ensures that data is transmitted with minimal interference and loss, making it a preferred choice in fiber optic systems and telecommunications equipment.

Medical Equipment: In the medical field, reliability is crucial. Silver plated copper wires are used in various medical devices, ensuring that they function correctly in critical situations. Their corrosion resistance makes them particularly well-suited for applications in challenging environments, such as those involving bodily fluids.

Future Innovations in Silver Plated Copper Wire Technology

As technology continues to evolve, so too does the manufacturing of silver plated copper wire. Several innovations are on the horizon that could further enhance its performance and applicability.

Advanced Coating Techniques: New methods for applying silver coatings are being developed that could improve adhesion and durability. These techniques may allow for thinner coatings without sacrificing performance, leading to lighter and more efficient wires.

Smart Materials: The integration of smart materials into silver plated copper wires could enable them to adapt to changing environmental conditions. This innovation could lead to wires that automatically adjust their conductivity based on temperature or load, enhancing efficiency in applications like electric vehicles.

Sustainability Initiatives: The push for sustainable manufacturing practices is leading to advancements in recycling and resource management. Innovations in circular economy practices could significantly reduce waste and improve the environmental footprint of silver plated copper wire production.

Conclusion

Silver plated copper wire stands out as a high-performance material that combines the strengths of both copper and silver. From its manufacturing processes, including electroplating and cladding, to its wide-ranging applications in electronics, telecommunications, and aerospace, this wire is a preferred choice for many industries.

Understanding the components, benefits, and manufacturing techniques will empower you to make informed decisions for your projects. As technology continues to advance, keeping an eye on future innovations will ensure you remain at the forefront of developments in this versatile material.

If you are considering silver plated copper wire for your next project, it's time to explore your options. Whether you're in the electronics sector, aerospace, or telecommunications, the advantages of using silver plated copper wire can significantly enhance your applications.

#copper wire#stranded copper wire#braided copper wire manufacturer#electricalcontractor#electricianlife#structuredcabling

0 notes

Text

Stranded wire is a type of electrical wire that consists of multiple thin, flexible copper strands twisted together, while solid wire is a single, solid copper conductor. These two wire types have distinct characteristics and applications, and understanding their differences can help you make an informed choice for your electrical projects.

0 notes

Text

Earthing Copper Wire Wholesalers

Ganpati Engineering trusted Earthing Copper Wire Wholesalers, offers high-quality wires ensuring superior conductivity and safety. Ideal for electrical grounding and industrial needs. Contact us today for reliable solutions at competitive prices!

0 notes

Text

What Are the Various Types of Copper Pipes?

Ganpati Engineering is the industry leader in providing high-grade copper and copper products. Copper pipes are an important ingredient for the effective and flawless movement of several commodities as well as in interior design and solar applications. Copper, with high electrical conductivity and thermal conductivity, is the chosen metal for electrical, Manufacturing, and mechanical industries. Explore more @ https://www.ganpatiengineering.com/copper-pipes.html

0 notes

Text

What Advantages Does Stranded Copper Wire Provide?

Ganpati Engineering is the industry leader in producing high-quality copper and copper products. Stranded copper wire is an essential component for the efficient and easy movement of various commodities, as well as for interior design and solar applications. Copper, with its excellent electrical and thermal conductivity, is the preferred metal for the electrical, manufacturing, and engineering fields. @ https://www.ganpatiengineering.com/stranded-copper-wire.html

0 notes

Text

Understanding Stranded Flexible Copper Connectors: Key Features and Advantages

In the field of electronics and electrical engineering, the efficiency and reliability of your systems can be heavily affected by the connector you use. Among the several choices at hand, stranded flexible copper connections stand out for their adaptability and better electrical features. With an eye on silver-plated and Nickel Plated Copper Wire, this blog explores the salient characteristics and benefits of Stranded Flexible Copper Connectors.

What Are Stranded Flexible Copper Connectors?

Made to provide more flexibility and conductivity than their solid counterparts, Stranded Flexible Copper Connectors Many tiny copper wires braided together to create a single conductor from these connectors. This design offers many advantages, especially in uses needing constant movement or adaptability.

Key Features of Stranded Flexible Copper Connectors

Enhanced Flexibility: Stranded copper connectors have mostly one benefit: their flexibility. Stranded connectors stretch and flex without losing their conducting qualities, unlike inflexible, breakable solid copper wires under stress. For uses where the cables must constantly move or where the connectors must negotiate confined areas, their adaptability makes them perfect.

Improved Durability: By more fairly spreading mechanical stress over the wire, the stranded architecture lowers the chance of damage and wear over time. This produces more robust connectors able to tolerate physical strain, vibration, and bending without sacrificing performance.

Superior Electrical Conductivity: Excellent electrical conductivity abounds from stranded copper cables. More surface area for electrical flow given by the many threads helps to reduce resistance as compared to solid wires. This increased conductivity guarantees effective power transfer and lowers the heat-generating risk resulting from electrical resistance.

Reduced Signal Loss Stranded copper connectors reduce signal loss in high-frequency uses. By lowering impedance and preserving constant electrical characteristics across the wire's length, the design makes higher signal integrity possible. In data transfer and telecommunications applications especially, this is crucial.

Silver Plated Copper Wire: Advantages

Because of its specific plating, Silver Plated Copper Wire is a speciality kind of stranded copper wire with further advantages. Using copper wire with silver plating offers the following benefits for your connections.

Enhanced Conductivity: Silver among all the metals has the best electrical conductivity. Silver arranging of the copper wire will significantly boost the general conductivity of the connection. Improved conductivity adds to better performance in high-speed and high-frequency applications.

Corrosion Resistance: A protective coating created by Silver Plated Copper Wire aids to stop corrosion and oxidation. In settings where the connectors come into contact with moisture or hostile circumstances, this especially helps to guarantee long-term performance and dependability.

Improved Solderability: Excellent solderability of copper wire with Silver Plated Copper Wire makes building dependable and robust connections simpler. Ensuring constant performance and reducing the possibility of connection failure depend on this function.

Nickel Plated Copper Wire: Advantages

Another choice for stranded connectors, Nickel Plated Copper Wire offers several advantages:

Increased Mechanical Strength: Copper wire gains mechanical strength via Nickel Plated Copper Wire, so increasing its resistance to wear and abrasion. In applications where the connectors experience mechanical stress or regular movement, this is especially important.

Superior Corrosion Resistance: Silver among all the metals has the best electrical conductivity. Silver plating of the copper wire will significantly boost the general conductivity of the connector. From this enhanced conductivity, better performance in high-speed and high-frequency uses follows.

High-Temperature Performance: Nickel Plated Copper Wire resists higher temperatures than unplated copper wire. This qualifies for uses including automotive or industrial environments when heat is a consideration.

Choosing the Right Connector for Your Application

Selecting Stranded Flexible Copper Connectors for your projects requires careful consideration of the particular needs of your application. Here are some things to bear in mind:

Flexibility Needs: If your application calls for constant movement or bending, you really should use a very flexible stranded copper connector. Choose one that fits your needs since both silver plated and nickel plated choices provide different degrees of flexibility.

Environmental Conditions: Think about the surroundings where the connectors will be used. While Nickel Plated Connections provide great mechanical strength and high-temperature performance, silver-plated connectors are best for settings likely to be corrosive.

Performance Requirements: Silver Plated Copper Wire offers the best conductivity and signal integrity for high-frequency or high-speed uses. Conversely, nickel plated wire shines in conditions calling for strong mechanical qualities and thermal resistance.

Conclusion

Whether silver plated or nickel plated, Stranded Flexible Copper Connectors provide many advantages that could improve the dependability and performance of your electrical systems. Knowing the main characteristics and benefits of different connectors helps you to decide which kind of connector best fits your particular use. Stranded Flexible Copper Connectors offer a flexible and efficient answer for a variety of electrical and electronic needs, regardless of your priorities—flexibility, conductivity, or durability.

See Ganpati Engineering for further details on premium Stranded Flexible Copper Connectors, including nickel-plated and Silver Plated Copper Wire choices. Search our selection of items to identify the ideal fit for your project.

#copper wire#stranded copper wire#stranded flexibility tin copper wire rope#braided copper wire manufacturer#bare braided copper wire

0 notes

Text

Why Choose Silver Plated Copper Wire for Your Next Project?

The materials you use in your next electrical or electronic project will greatly affect the performance, lifetime, and general success of the effort. Among the several choices at hand, Silver Plated Copper Wire, services are a great one for a variety of uses. When working on high-frequency electronics, aerospace projects, or complex audio systems, this material provides a special mix of qualities that appeal to experts.

What are Silver Plated Copper Wires?

Silver-plated copper wire is one type of wire that combines the strong resistance to corrosion and conductivity of silver with the conductivity of copper. Although the silver coating improves the copper core's conductivity, which certifies the wire for high-performance applications where reliability and integrity of signals are of great importance,

Superior Conductivity and Low Resistance

The great conductivity of Silver Plated Copper Wire was one of the main factors influencing your decision. Although copper is already well-known for its great electrical conductivity, this quality is further improved when covered in silver. With the best electrical conductivity among all the metals, silver lowers the resistance of the wire considerably more when used on a copper core. Silver Plated Copper Wire is therefore perfect for uses like delicate electronic circuits or high-frequency signals when low energy loss is very vital.

Silver Plated Copper Wire guarantees that signals are transmitted with minimum loss, so preserving the integrity and dependability of the system, in the aerospace sector, where exact signal transmissions are vital. In high-end audio systems, likewise, by lowering the loss of audio signals, Silver Plated Copper Wire can improve the clarity and purity of sound.

Durability and Corrosion Resistance

Silver Plated Copper Wire's endurance and corrosion resistance are yet more major benefits. Although copper is a great conductor, over time it can oxidize and reduce performance. However, the silver plating serves as a protective covering, slowing oxidation and extending the lifetime of the wire. Silver Plated Copper Wire is therefore especially fit for usage in demanding surroundings or in applications requiring long-term dependability.

For example, silver plating offers an additional layer of protection in maritime or industrial environments where wires might be subjected to moisture, chemicals, or severe temperatures, therefore ensuring that the wire stays functional and trustworthy over time.

Versatility Across Various Applications

Extremely flexible and used in a broad spectrum of applications, silver-plated copper wire is This material can satisfy your project needs whether your job is on a complex aerospace project, building high-frequency electronic gadgets, or manufacturing premium audio equipment.

Braided Speaker Tinsel Lead Wire is frequently used in the audio sector for Silver Plated Copper Wire. Often used in speakers and other audio components, this kind of wire guarantees a flexible, low-resistance connection that guarantees excellent sound reproduction. Popular among audiophiles and audio engineers for both conductivity and longevity, the silver plating improves both.

In conclusion

Excellent for a range of tasks, Silver Plated Copper Wire's great conductivity, durability, and adaptability make it The advantages of selecting Silver Plated Copper Wire are obvious whether you're comparing it with Nickel Plated Copper Wire services or thinking about using it in Braided Speaker Tinsel Lead Wire. This material provides unparalleled value for projects where dependability and performance are of great importance, so it is the best choice for your next one.

0 notes

Text

Exploring the Versatility of Stranded Flexible Copper Jumpers and Silver-Plated Copper Wire

Introduction

Today's low-pressure technology relies heavily on electroplating materials. From the gadgets we use every day to the electricity infrastructure supplying electricity to cities, dependable electrical supplies are critical. Among these items, soft wires brass jumpers in silver-plated brass wires stand out for their adaptability and effectiveness.

What are Stranded Flexible Copper Jumpers?

Definition and Structure

Simple brass jumps are made from several small twisted copper wires, forming a simple single type. This design offers greater flexibility compared to rigid copper tubing, making it ideal for applications requiring movement or bending.

Applications and Uses

Stranded Flexible Tin Coated Copper Wire Rope jumps in wires are commonly used in electrical equipment, grounding systems, and bonding applications. Their flexibility makes them suitable for dynamic environments with vibration or frequent movement.

Advantages of Stranded Flexible Copper Jumpers

Flexibility and Durability

The main advantage of flexible copper jumpers is their flexibility. This quality reduces the risk of breakage when the lines are bent or twisted, and increases their durability.

Conductivity and Efficiency

Copper is known for its excellent conductivity, and stranded flexible copper jumpers maintain this characteristic while adding the benefit of flexibility. This provides a smooth flow of electricity with minimal energy loss.

Installation and Maintenance Easy

Easy Installation Process

Installation of stranded flexible copper jumpers is straightforward due to their flexibility. It can easily be moved around tight surfaces and around obstacles, making installation easy.

Maintenance Tips

Regular inspection is essential to ensure the longevity of the flexible brass jumpers. Check for evidence of wear and tear, and replace all damaged parts as quickly as you can to ensure peak performance.

What is Silver Plated Copper Wire?

Definition and Structure

Silver-plated copper wire is made of copper covered with a small amount of silver. This combination mixes copper's powerful durability and silver's above conductivity and oxidation resistance.

Applications and Uses

Silver-plated copper wire is used in repetitive and high-temperature applications, such as aerospace, telecommunications, and military equipment. The silver coating increases performance in these harsh environments.

Benefits of Silver-Plated Copper Wire

Enhanced Conductivity

Silver is the most conductive metal, and coating copper wire with silver increases the overall conductivity of water. This makes silver-plated copper wire ideal for repetitive applications where efficient signal transmission is critical.

Corrosion resistance

The silver coating protects the wire prevent corrosion and oxidation, enhancing its life in all kinds of events.

Stranded, flexible copper jumpers & silver-plated copper wire.

Key Comparison of Differences

While both types of wire are highly conductive, stranded flexible a copper jumpers offer greater flexibility, making them ideal for frequent flight applications. Silver-plated copper wire, on the other hand, performs well at elevated frequencies and temperatures because of its excellent conductivity & corrosion resistance.

When to Use Each

Use Stranded Flexible Copper Connectors jumpers in sticky areas where flexibility is required, such as mechanical or electrical outlets. Choose silver-plated copper wire in multi-use applications such as telecommunications and aerospace, where high conductivity and durability are required.

Typical Applications of This Material

Telecommunications

Flexible copper jumpers with both wires and silver-plated copper wire are important in the telecommunications industry. They ensure reliable signal transmission and power distribution, supporting the larger network.

Automotive Industry

Flexible horizontal copper leaps are used in cars electrical systems due to their flexibility & durability. Silver-plated wire made from copper is utilized in applications requiring strong conductivity and resilience in harsh conditions.

Aerospace Industries

Silver-plated copper wires have become commonplace in the aerospace sector due to their superior performance for high-frequency and high-temperature settings. This guarantees the safety & reliability of vital space systems.

Recycling Copper Jumpers and Silver-Plated Copper Wires

Emerging Technologies

Emerging technologies, such as electric cars and renewable energy sources, are increasingly dependent upon high-performance electrical components. Both smooth copper jumpers and silver-plated copper wire are crucial in these new applications.

Future Trends

As technology advances, the demand for efficient and durable electrical products will continue to grow. The versatility and reliability of the smooth copper jumpers and silver-plated copper wire position them well for future developments.

Environment and Sustainability

Recycling and Recycling

Copper and silver all highly recyclable materials. Recycling this metal reduces its environmental impact & conserves natural resources, pushing the business to adopt more sustainable methods.

Environmentally friendly practices

Manufacturers are using ecologically friendly processes to manufacture elastic copper jumpers & silver-plated copper wire. This includes removing waste, avoiding energy, and utilizing environmentally friendly products and procedures.

Choosing the Right Supplier

What to Look for in a Supplier

When choosing a supplier of smooth brass jumpers and silver-plated brass wire, consider factors such as product quality, reliability, and customer service. Ensure that the supplier has a good reputation and delivers products that meet industry standards.

Questions to Ask Potential Suppliers

What certifications do you have for your products?

Can you provide references from interested customers?

What is your quality management system?

How do you handle product verification and returns?

Cost Considerations

Price and Performance

While cost is an important factor, it is important to balance price and performance. Investing in a simple smooth brass jumper and silver-plated brass wire can provide long-term savings by reducing maintenance and replacement costs.

Long-Term Financing Investment

Think about the long-term advantages of using excellent in quality electrical equipment. High-quality items may cost more at first, but they boost performance, durability, and confidence, resulting in expense advantages.

Case Studies

Successful Applications

Several manufacturers have successfully used flexible copper jumpers and silver-plated copper tubing in their systems. This case study highlights the value of high-quality electrical components for a variety of applications.

Lessons Learned

Learning from the experiences of others can provide valuable insights into the best practices for flexible copper jumpers and silver-plated copper wire. This knowledge can help improve performance and efficiency in your applications.

Conclusion

Flexible copper jumpers with silver-plated wire made of copper are critical components of current electrical systems. Their flexibility, durability, and efficiency render them great for an array of applications across industries.

0 notes

Text

A Detailed Guide to Stranded Flexible Copper Connectors, Jumpers, and Silver and Nickel Plated Copper Wire

Introduction

Stranded flexible copper connectors & specialized copper wires are crucial for ensuring an accurate electrical connection. These parts are essential for a lot of things, such industrial machinery and home wiring. We will look at those links in detail in this book, covering their various forms, advantages, and uses. We will additionally address the special qualities of copper wire that have been plated using silver and nickel.

What Are Stranded Flexible Copper Connectors?

Stranded flexible copper Connectors are made out of copper wire wrapped together. This setup improves both adaptability and durability over single-strand wires.

Definition and Features

These connectors are well-known for being able to tolerate repeated bending & flexing with breaking, making them suitable for applications that involve a lot of movement and vibration.

Common Uses

Stranded flexible copper connections are used in a wide range of applications, including distribution systems for electricity, automotive electrical wiring, and machinery that has to move often.

Types of Stranded Flexible Copper Connectors

Understanding the many types or stranded flexible copper connectors can assist you select the best one for your application.

Tinned Copper Connectors

Tinned copper connections feature a small layer of tin on the copper strands. This tinning procedure minimizes corrosion and increases the connector's lifespan.

Bare Copper Connectors

These connections are made completely of copper, with no extra coatings. They are extremely conductive and are frequently used in situations where corrosion doesn't pose a major problem.

Silver-plated connectors.

High-performance applications benefit significantly by the high electrical conductivity and resistant to corrosion for silver-plated interactions.

Benefits of Using Stranded Flexible Copper Connectors

Flexibility

The stranded construction allows the connections to bend and flex without breaking, which can be critical in areas with frequent movement.

Durability

Stranded flexible copper relationships have the ability to survive, even in tough environments, thanks to their strong structure.

Electrical Conductivity

Copper is known for its high electrical conductivity, which ensures minimum power loss throughout transmission.

Applications of Stranded Flexible Copper Connectors

Industrial Use

These connectors are utilized in industrial environments where machinery and equipment demand robust yet adaptable electrical connections.

Residential use.

Stranded flexible copper connections are frequently employed in home wiring systems because they are reliable and easy to install.

Automotive Use

The automobile sector relies on such connections for wire systems that must resist frequent vibrations and movement.

Understanding Copper Jumpers

Copper jumpers are small pieces from copper wire used to link various components in a wiring system.

Definition and Purpose

These jumpers bridge connections instantly and effectively, maintaining circuit continuity.

Types of Copper Jumpers

Copper jumpers are available in a number of styles, such solid, stranded, and braided, each tailored to a specific use.

Advantages of Copper Jumpers

High conductivity

Copper jumpers provide good electrical conductivity, which ensures efficient power transmission.

Simple Installation

These jumpers are easy to install, making them popular among both professional electricians & DIY enthusiasts.

Versatility

Copper jumpers may be used for a variety of applications, including tiny electronics and big industrial systems.

Applications of Copper Jumpers

Electrical panels

Copper jumpers link various components in electrical panels, ensuring correct power distribution.

Circuit Boards

On circuit boards, jumpers serve to connect different areas of the board.

Grounding Systems

Copper jumpers are commonly used for grounding systems to offer a stable channel for electrical grounding.

Silver Plated Copper Wire

High-performance applications benefit greatly by the high electrical conductivity and resistant to corrosion for silver-plated interactions.

What is Silver Plated Copper Wire?

This wire is made of a copper core with a light layer of silver plating, which improves its performance for high-frequency & high-temperature applications.

Advantages of Silver Plating

Silver plating enhances electrical conductivity and is very durable to oxidation and corrosion.

Applications of Silver Plated Copper Wire

Aerospace Industry

Silver-plated copper wire is often used in the aircraft industry for critical circuits that require to perform using great reliability and effectiveness.

Medical Devices

This wire is widely used for medical equipment because of its good conductivity and biocompatibility.

High-Frequency Applications

Silver-plated copper wire works well for high-frequency applications that it has low resistance and good signal transmission attributes.

Nickel Plated Copper Wire

A unique combination of conductivity, durability against high temperatures, & against corrosion is offered through nickel-plated copper wire.

What is Nickel Plated Copper Wire?

This wire's nickel-coated copper core enhances overall ability to endure within difficult situations.

Advantages of Nickel Plating

Nickel plating is very resistant for oxidation, high temperatures, & corrosive conditions.

Applications of Nickel Plated Copper Wire

High-Temperature Environments

Nickel-plated wire made from copper is used for applications involving high temperatures, such as heating components and industrial furnaces.

Corrosive Environments

This wire is more durable and trustworthy in corrosive situations.

Military Applications

Nickel-plated copper wire is employed by the military because it is durable and operates well in severe situations.

Choosing the Right Connector or Wire

When choosing the right relationship or wire, many factors should be taken into account, including the unique application, ambient situations, and the required performance.

Factors to Consider

When deciding on a product, consider electrical conductivity, mobility, durability, and environmental resistance.

Application-Specific Recommendations

Choose the connector and wire that is most suited to the specific demands and conditions of the area.

Installation and Maintenance Tips

Proper setup and upkeep are critical to the longevity and efficiency of copper connections and cables.

Best Practices for Installation

Follow the installation directions and advised procedures given by the manufacturer to ensure a reliable and safe connection.

Maintenance and Longevity

Regular maintenance and inspection can help avoid issues and improve the life of the connections and cables.

Conclusion

Stranded Flexible Tin Coated Copper Wire Rope, jumpers, & silver and nickel-plated copper wires are critical components in a variety of applications. Their distinct qualities and advantages render them indispensable for both standard and customized electrical systems. Understanding their features, advantages, and applications allows you to make educated decisions that assure the optimum performance and dependability in your projects.

#Silver Plated Copper Wire#Nickel Plated Copper Wire#Braided Speaker Tinsel Lead Wire#Super Enameled Coated Copper Strip#Stranded Flexible Copper Jumpers#Stranded Flexible Tin Coated Copper Wire Rope

0 notes

Text

Explore Stranded Flexibility Tin Coated Copper Wire Rope and The Connectors: A Detailed Overview delves into the versatile and durable nature of tin-coated copper wire rope, highlighting its superior flexibility and applications. This comprehensive guide also covers the various types of connectors that ensure optimal performance and reliability in diverse electrical and mechanical projects.

0 notes

Text

Explore Stranded Flexibility Tin Coated Copper Wire Rope and The connectors: A Detailed Overview

Stranded flexible Copper Connectors made of copper wire, coated with tin, are a resilient and adaptable type of wire rope utilized in various industries. These wire ropes are known for their outstanding flexibility, resistance to corrosion, and ability to conduct electricity, making them crucial elements in different uses.

Flexibility and Durability

One of the most notable characteristics of stranded elasticity in tin-coated copper wire ropes is its increased flexibility. The wire ropes are made of numerous strands of twisted copper wire, which allows for a wider range of motion & the capacity to negotiate small areas and intricate arrangements. This flexibility is especially critical in situations where the metallic rope must bend, flex, or move frequently while maintaining structural integrity.

These wire ropes not only are flexible but also show great durability. Applying tin coating to the copper wires increases the durability of the rope against corrosion, allowing it to be used in challenging environments such as moisture, chemicals, or external elements. The longer lifespan of the wire rope is due to its improved adaptability, resulting in less frequent replacement and servicing required.

Electrical Conductivity

Stranded flexibility tin-coated copper wire rope are known for their high electrical conductivity. The copper center of the wire rope provides an effective channel for the transfer of electrical signals or authority, making it an attractive option in applications requiring dependable electrical connectivity.

This conductivity of electricity is especially significant in industries like telecommunications, automation in industry, and electric grounding systems, where wire ropes are used to convey data, signals, and provide a safe conduit for electrical currents to move.

Applications

Flexible tin-coated copper wiring strands featuring stranded elasticity are adaptable and may be used in a variety of industries.

Telecommunications:In the field of telecommunications, wire ropes are utilized to connect equipment, support cable bundles, and protect delicate electronic components.

Industrial Automation: Wire ropes are used in industrial control and automation systems to carry control signals, give power to various components, and offer adaptability between moving elements.

Electrical Grounding: Stranded copper wire ropes coated using tin are extensively used in electrical grounding systems to provide a safe path for the discharge for currents while preventing static electricity buildup.

Automotive and Aerospace: Because of their flexibility, longevity, and conductivity, these wire ropes are used in a range of applications in the aerospace and automotive sectors, including systems for control, landing devices, and wiring harnesses.

Marine and Offshore: Tin coated copper wire ropes with stranded flexibility are perfect for marine and offshore environments because they resist corrosion, making them great for mooring systems, crane operations, and underwater cabling.

The Connectors: A Detailed Overview

Connectors are essential for ensuring the dependable and effective operation of stranded, flexible tin-coated copper wire ropes. These connectors are created to offer a reliable and long-lasting link between the wire rope and other parts or systems.

Types of Connectors

There are various connectors available to be utilized with stranded flexibility tin coated copper wire ropes, each having its own set of properties and uses. Some of the often used connections are:

Crimp Connectors: Crimp connectors were a common way to make secure and lasting connections. To install these connections, use a crimping tool and press to compress the connector into the wire rope, resulting in a tight, low resistance connection.

Compression Connectors: Compression Connectors use a threaded and swaged fitting that presses down on the wire rope, resulting in a strong and stable connection. These connectors are commonly utilized in situations where the connection must be detachable or changeable.

Swage Connectors: Swage connections are placed by using a specialized tool to compress the connector onto the wire rope, providing a permanent & seamless connection.

Splice Connectors: Splice connectors are used to join multiple wire ropes, allowing for continuous lengths or the repair of broken pieces.

Connector Selection Considerations

When choosing the proper connection for the stranded flexibility tin coated copper wire rope usage, numerous things should be addressed, including:

Wire Rope Diameter: Connectors are intended to handle certain wire rope diameters, therefore select a connection that matches the size of the wire rope that is being used.

Tensile Strength: In order to ensure a secure and reliable link, the connector's tensile strength rating needs to exceed the expected weight or strain on the wire rope.

Environmental Conditions: In situations where the cord and connection will be exposed to hostile environments such as dampness, chemicals, or dangerous temperatures, it is critical to use connectors that can endure these circumstances while maintaining performance.

Ease of Installation: The ease for installation and availability of specialist tools or equipment necessary to install the connection should also be evaluated, since these factors might influence the entire installation procedure and cost.

Conclusion

Stranded flexibility tin copper wire rope serves as a flexible and necessary component in a variety of industries, providing outstanding flexibility, durability, and electrical conductivity. The connectors used for these wire ropes play an important part in creating a secure and stable connection, and choosing the right connector is key to the general efficiency & lifespan of the wire rope system.

Users can optimize the performance and reliability of their wire rope systems by understanding the primary characteristics and applications for stranded flexibility tin coated copper wire ropes, in addition to the various types of connectors that are accessible and the factors to consider when selecting them.

0 notes

Text

Premium Stranded Flexible Tin Coated Copper Wire Rope, Connectors, Jumpers, and Silver Plated Copper Wire

Introduction

Understanding Stranded Flexible Tin Coated Copper Wire Rope — What is It?

Stranded flexibility tin coated copper wire rope is a kind of wire rope made of many strands of copper wire, each coated with tin. This structure not only increases flexibility, but it also improves both oxidation and corrosion resistance

Key Features:

Flexibility: Ideal for tasks that need movement and bending.

Durability: Tin coating increases the longevity of copper wires.

Conductivity: Maintains good electrical conductivity, which is necessary for optimal performance.

Common Applications

This type of wire rope is widely utilized in the electronics, telecommunications, and automobile sectors, where dependability and performance are critical.

The Manufacturing Process

How It is Made

The manufacturing method consists of multiple phases, including pulling copper into fine strands, covering each one with tin, and twisting them together to make a flexible rope.

Quality Control Measures

Benefits of Tin Coating

Enhanced Durability

The tin coating forms a protective layer over the copper, shielding it from surroundings and considerably increasing its longevity.

Immune to corrosion

Tin-coated copper wire is especially corrosion resistant, making it ideal for usage in severe situations.

Improved electrical conductivity

The tin coating helps to retain great electrical conductivity, resulting in efficient power transfer and signal clarity.

Connectors: The Essential Components

Types of Connectors

Connectors are classified into three types: crimp connectors, screw connectors, & solder connections, each with its own application.

Selecting the Right Connector

Selecting the suitable connector is influenced by the type of wire, the environment where it will be employed, and the application’s specific requirements.

Copper connectors have various industrial applications.

Copper connections are commonly utilized in industrial applications such as equipment, distribution of power, and control systems.

Household Applications

Copper connectors are commonly used in residential wiring, appliances, and automation systems for homes.

Jumpers: Bridging Connections

What Are Jumpers?

Jumpers are small lengths of wire that link two separate locations in a wiring system. They are vital for establishing dependable and adaptable relationships.

Different Types of Jumpers

Jumpers come in a variety of forms, including solid wire jumpers, wire with strands jumpers, and insulated jumpers, all suited for a particular use.

Relevance of Quality Jumpers

Ensure Reliable Connections

High-quality jumpers provide stable and trustworthy connections, which are critical for the operation of electronic systems and devices.

Reducing Signal Loss

Using quality jumpers reduces signal loss and disruption, which is especially critical in high-frequency applications.

A closer look at silver-plated copper wire.

Why the silver plating?

Silver plating copper wire improves its conductivity and durability against tarnishing, making it excellent for high-performance applications.

Key Benefits

Superior Conductivity: Silver is an outstanding conductor of electricity.

Tarnish Resistance: Silver coating prevents the wire against tarnishing & ensures long-term performance.

High-Temperature Performance: Silver-plated copper wire can endure higher temperatures than traditional coatings.

Applications for silver-plated copper wire includes aerospace and defense.

Silver-plated copper wire is employed in the defense and aerospace sectors due to its dependability and performance in extreme conditions.

Silver plated copper wire is an ideal alternative for medical devices due to its accurate and stable connections.

High-frequency electronics

In high-frequency circuits, silver plated copper wire’s enhanced conductivity assures little signal loss and optimum efficiency.

Comparing Tin Coated and Silver Plated Copper Wires

Key Differences

While both types of stranded flexible copper connectors wires are highly conductive and long-lasting, silver-plated copper wire excels in extremely energetic and high-temperature applications.

Best Use Cases for Each

tin-coated copper wire: Excellent for general-purpose applications involving flexibility and resistance to corrosion.

Silver-plated copper wire works well for high-performance applications that require superior conductivity and tarnish resistance.

Choosing the Proper Option for Your Needs

Factors to Consider.

When choosing copper goods, consider electrical requirements, ambient circumstances, and your application’s special needs.

Industry-specific recommendations

Electronics: Silver-plated copper wire for high-energy applications.

Automotive: Tin-coated copper wire provides flexible and long-lasting connections.

Aerospace: Silver-plated copper wire for exceptional reliability.

Maintaining and Handling Copper Wires and Connectors

Best Practices

Copper wires and connectors should be stored dry and cool to avoid corrosion.

Regular Inspection: Keep an eye out for indicators of wear or damage.

Correct Installation: For optimal efficiency, follow the manufacturer’s installation requirements.

Common Mistakes to Avoid:

Overbending Avoiding: overbending the wires since it might break the strands lowering conductivity.

Improper Soldering: Use proper soldering procedures to ensure strong connections.

Future Trends in Copper Wire Technology.

Future innovations in material research and production will improve the performance and endurance of copper cables and connectors.

Potential Impact on Different Industries

These advancements could result in more efficient and dependable electronic equipment, enhanced systems for power distribution, and enhanced performance in key applications such as aerospace and medical equipment.

Conclusion

To summarize, premium stranded flexible tin-coated copper wire rope, connectors, jumpers, and silver-plated copper wire are critical components in numerous sectors. Their unique qualities and advantages make them ideal for applications that require dependability, durability, and high performance.

0 notes

Text

Developing Your Copper Wire Size Calculation Skills: A Complete Guide

To guarantee a secure and effective flow of electrical current in electrical installations, the size of the size of the copper wire must be done correctly. The ability to determine the appropriate wire size is crucial, regardless of whether you work as a professional electrician or are a do-it-yourself enthusiast. Oversized wires can be wasteful and needlessly costly, while undersized wires can lead to overheating, voltage drops, and possible fire hazards. I’ll take you step-by-step through the process of estimating copper wire size in this extensive guide, accounting for several rules and regulations.

0 notes

Text

How to Sell Your Used Copper Wire for the Best Price: Optimizing Profits

Getting the best price for your scrap copper wire is essential in the current dynamic market. Optimizing returns on your scrap materials can have a big impact on your bottom line, regardless of how big or small your company is. We’ll go into the methods and techniques that can help you get the most money for your copper wire in this in-depth article.

0 notes

Text

What Are the Many Different Kinds of Copper Tape?

Ganpati Engineering Industries manufactures excellent in quality copper tape is used to conduct current from one area of the circuit to the next. There are several circuit designs that may be used for activities like this, but copper tape is an excellent addition and is suitable for conducting modest levels of electricity around the circuit.

0 notes

Text

What is the Best Different Types of Copper Sheets?

Copper sheet is commonly used in the construction and electrical appliance industries. If you want to acquire these copper sheets, one of the finest places to go is Ganpati engineering industries, which has a large selection of cooper sheets at wholesale costs.

0 notes

Text

Tin coated copper wire has become increasingly popular in modern industries due to its unique properties and advantages over other wire coatings. This type of wire is made by coating copper wire with a layer of tin, which provides enhanced conductivity, corrosion resistance, and solderability.

0 notes