#bluewavesemi

Explore tagged Tumblr posts

Text

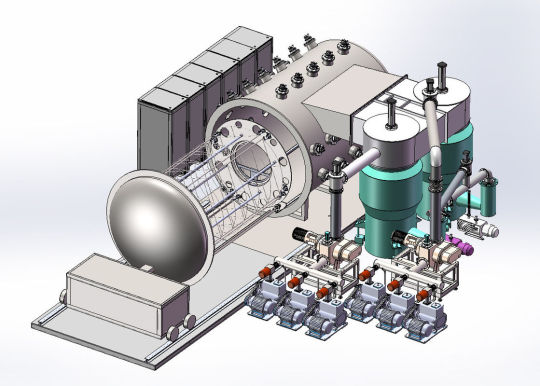

Advanced Sputtering System by Blue Wave Semi Explore the cutting-edge BWS sputtering system from Blue Wave Semi. Our advanced technology ensures precise thin film deposition for a range of applications. Transform your research and development with our reliable and innovative sputtering solutions.

0 notes

Link

0 notes

Text

All about thermal evaporator system: its features, uses and working procedure!!

Thermal evaporation is basically a very common procedure of physical vapor deposition (PVD). It is also the simplest form of PVD that uses a resistive heat source to evaporate the solid material into a vacuum environment in order to form a thin film. For more information visit: https://www.klusster.com/portfolios/bluewavesemi/contents/16114?code=bb393b2e-7f98-4e9d-9e7d-f64c144192c4

0 notes

Link

#Substrate heater for vacuum deposition#PLD System#Pulsed laser deposition system#E Beam evaporator system#Electron beam evaporator system#Thin film deposition Services#Sputtering system#Thermal Evaporator system

0 notes

Link

#Substrate Heater#Thin Film deposition and coating services#Chemical Vapor Deposition System#Metal oxide thin film coating#Multilayer coating#Reactive Sputtering#Thin Film Materials systems

0 notes

Link

0 notes

Link

Evaporation systems for making thin films can be configured by professionals using specialized software and some configuring tools. Some of the common methods are substrate pre heat stations and ion assisted deposition deepening upon ion source capability.

0 notes

Link

Pulsed Laser Deposition (PLD) system ordinarily utilize a centered Pulsed excimer or Nd:YAG laser to vaporize a little area of a strong target material in a vacuum chamber so as to deliver a thin film with an indistinguishable chemical sythesis from the first target material.

0 notes

Link

Semiconductors have really changed the way that we live our lives in numerous ways. They are found in almost every electronic and electrical device that we use throughout the day and the technology that's available is constantly changing.

0 notes

Link

The thin films and coatings are deposited using multi-purpose vacuum thin film deposition setup. The coating is usually done by coaxing the coating material from vaporous or dissolved state using various means like a chemical reaction, high heat, evaporation or any other technique.Thin Film Deposition Products & Technologies.

0 notes

Link

The term arrived from a particular form of electronic sputtering in case of multiple charged projectile ions. In this type of sputtering system, the potential energy stored in multiple charged ions is liberated as the ions recombine during impact on a solid surface.

0 notes

Link

The rate of deposition is dependent on the temperature of the material like all other thermal evaporation systems. Firms with e-beam evaporation systems are used for depositing the wide variety of materials.

0 notes

Link

The PLD system is based on the box chamber design which transfers the substrate easily and targets through the front door. The substrate or film substrate cannot fill into the turbo pump as it safely mounted on the back wall. The system has a variety of lasers and the unit can operate off a computer.

0 notes

Link

Diamonds have a scope of utilizations from the up and coming era of top quality level board presentations to coatings for mechanical pump seals and apparatuses. Where diamond truly scores is that it far beats some other material as far as its capacity to protect high voltages crosswise over thin layers of the material.

0 notes

Link

Chemical Vapor Deposition (CVD) is basically the process of coating a surface with a polymer material. It is used to obtain the desired properties such as hardness, luster or durability. Now CVD has replaced many conventional techniques of coatings as it provides significant advantages over other deposition techniques.

0 notes