#electron beam evaporator

Explore tagged Tumblr posts

Text

Efficient precision with the electron beam evaporator system

The electron beam evaporator system offers unmatched precision and control for advanced material deposition, delivering high-quality, uniform thin films. With optimized electron beam technology, this system enables efficient evaporation of metals and dielectrics, meeting the stringent demands of semiconductor manufacturing and research. Designed for durability and reliability, it supports a broad range of applications, from microelectronics to optoelectronics, ensuring consistent results across processes. The electron beam evaporator system stands out for its precision, making it an essential tool for professionals seeking top-tier performance in material science and semiconductor industries.

0 notes

Text

Electron-Beam Technology

Electron beam (e-beam) sources are used for the evaporation of materials which have melting points above 1800C or which react with evaporation boats or filaments. Sources typically have a turret which can accommodate 4 to 8 crucibles which can be selected for multi-layer films.

0 notes

Text

oc intro (tua)

“I’m the poison, literally”

Vorax Hargreeves “The poison” {Number 8}

→she/they →aroace →works as a pharmacist →professional at medicine and chemicals →smokes →tired and snarky

Voice claims:

Raiden Shogun{genshin impact} https://m.youtube.com/watch?v=_SUX0sKxTS4&t=164s

looks

childhood

teenage

adult

personality

Vorax is a very very very tired woman, mostly because of her job and her family’s dumbass energy. She looks at herself as the poison and the one who ruins everything. she is very damaged inside but cover it up with a no muss no fuss face, where her work and her family are important more important than herself she often make jokes about her trauma which is why she gets dismissed by her siblings a lot as they take their trauma seriously she tries to leave her past trauma behind but flashbacks still come whenever something triggers it. in her childhood reggie tried to subdue her powers but she only grew more unhinged from the chemicals in the pills, so to stop her fits of rage and chaos he allowed her to train with her siblings but she’s only sent on missions if it’s necessary. she gets along with klaus really well as they were also locked in rooms with traumatic stuff like she was snakes and toxic gas and Klaus was ghosts!

Powers

Radioactive shockwave: Vorax can self-generate vast amounts of radiation to crush, repel, or destroy objects or entire areas, and possibly kill or paralyze their targets and cause various radiation-based effects on the affected area

Radiation manipulation: Vorax can manipulate radiation; energy in the form of photons, electrons, positrons, protons, neutrons, or unidentified forces produced from thermal emissions, electromagnetism, nuclear fission chain reactions, or radioactive decay.

Poison manipulation: Vorax can create, shape and manipulate poisons and poisonous substances. For the sake of clarity: poison, toxin, and venom are terms for any substance that injures or destroys the health of living beings when absorbed into the system

Poison immunity: Vorax is immune to all forms of poisons/toxins/venom

chemical Capacitor: Vorax could absorb sound and store it for later use. she could use it however they see fit, channeling it for any purpose she can formulate.

poison Attacks: Vaxor is able to release and use poison/toxins to attacks of various shapes and/or intensities.

Poison/toxin Blast: Vaxor could release toxic waves over a target area of her choosing causing great damage and/or delivering shock waves of strong toxins

nutrition/toxin Drain: Vaxor could drain energy from individuals or objects. she can drain energy from targets, making the affected weaker. with chemical beams draining the needed nutrition and changing the biochemical structure of the body

poison/toxin Absorption: Vaxor could absorb toxins into her body and use it to, gain advantage.

poison/toxin Conversion: Vaxor could absorb toxins and convert it into various forms of attacks, essentially converting toxins she absorb into any other form of powers she has

projection through toxins: from toxicated blasts to waves of toxins. The nature of the energy varies on how much toxins she has

Telekinesis: Through manipulating mini radioactive waves, Vaxor was able to move and control objects, as well as generate force. Offensively, she is able to immobilize and repel others with her radioactive waves

radioactive Emission: Vaxor could emit beams of toxins that are capable of decaying/evaporating anything within her path, waves spreading from the base center of her body

8 notes

·

View notes

Text

Laser Deep Welding: Principles, Advantages, and More

Laser Welding: An In-Depth Look at Deep Welding Techniques

Laser welding is an essential and versatile technique widely used across industries such as manufacturing, automotive, aerospace, and electronics. This method has two primary types: continuous and pulsed, further classified into heat-conductive welding and laser deep melting welding. This article will delve into laser deep welding, discussing its principles, key factors, and advantages and disadvantages.

Principles of Laser Deep Welding

Laser deep welding employs a continuous laser beam to join materials, sharing similarities with electron beam welding in its metallurgical process. A critical aspect of this technique is the formation of a "keyhole" structure, essential for energy conversion. Here are the main stages of the laser deep welding process:

Energy Absorption: The material’s ability to absorb laser energy varies based on its properties, including absorption rate, reflectivity, and thermal conductivity. Non-metallic materials like ceramics and plastics absorb laser energy well at room temperature, while metals exhibit low absorption rates until they melt or vaporize.

High Energy Concentration: When exposed to a high-power laser, a small, vapor-filled hole form, absorbing nearly all incident energy. The temperature within this cavity reaches around 2500°C.

Molten Metal Formation: Heat transfer from the high-temperature cavity’s outer walls causes the surrounding metal to melt. As the wall material evaporates, vapor fills the hole, creating a molten metal layer around it.

Continuous Flow: The molten metal flows outward, and surface tension maintains a dynamic balance with the cavity's vapor pressure. As the laser moves, this molten "keyhole" structure follows, enabling high-speed welding at rates of several meters per minute.

Key Parameters Affecting Laser Deep Welding

Several factors influence the effectiveness of laser deep welding, including:

Laser Power: Higher laser power density enhances melting depth and welding speed.

Beam Focal Spot Size: A smaller focal spot increases power density, affecting weld penetration.

Material Absorption Rate: The absorption rate and surface condition impact laser energy absorption.

Welding Speed: Adjusting the speed can control melt depth. Optimal speed varies by material, power, and thickness.

Protective Gas: Inert gases like helium, argon, and nitrogen protect the molten pool, prevent oxidation, and disperse plasma.

Lens Focal Length: The lens focal length affects power density and spot size, with shorter focal lengths producing smaller spots.

Focus Position: The focal point’s position relative to the workpiece surface impacts weld width and depth.

Laser Beam Position: Precise control of the laser beam’s position is crucial, particularly in butt joint welding.

Gradual Power Control: Gradual power adjustments at the start and end of welding help avoid defects like pits and excessive melting.

Advantages and Disadvantages of Laser Deep Welding

Laser deep welding provides multiple benefits:

High Depth-to-Width Ratio: Produces narrow, deep welds.

Minimal Heat Input: Reduces thermal distortion and heat-affected zones.

High Weld Density: Results in strong, high-quality welds with low impurities.

Precise Control: Allows accurate beam positioning and is suitable for automation.

Non-Contact Process: Welding occurs without physical contact, protecting the workpiece.

Cost-Efficiency: High welding speeds and low operating costs improve overall efficiency.

However, laser deep welding also has some limitations:

Limited Welding Depth: The technique has constraints on maximum weld depth.

High Assembly Requirements: Accurate alignment and assembly of workpieces are necessary.

High Initial Investment: Laser welding systems require a significant initial cost.

Conclusion

Laser deep welding is a powerful and adaptable welding technique valued for its ability to produce deep, high-quality welds with minimal heat input and precise control. Although initial costs and depth limitations exist, its benefits often outweigh these drawbacks, making laser deep welding a valuable tool in modern manufacturing and fabrication.

#advantages of laser deep welding#laser deep welding#laser deep welding machine#laser welding#laser welding machine#laser welding machines in India#principles of laser deep welding

0 notes

Text

Help, I'm stuck thinking about neutron stars!

I may need a physicist!

A few years ago I looked up how photons pop into existence, because years before that I read one (1) article about quantum physics and since then I've had no idea how fire works

Anyway

Supposedly photons pop up when an electron gets excited and jumps to a higher orbit, but that's unstable so it drops back down to its stable orbit releasing the excess energy as it's own little package of energy - a particle called Photon. There's a bell inside my brain that rings out that photons have the same mass as electrons, meaning the mass of the electron has doubled, but that's another bucket of worms

A neutron star (and pulsars are just a type of neutron star) is the remnant of a supernova, which matter is squished to tight that the electrons fell into the protons and merged into neutrons. So there is no electron to excite enough to jump around different orbits.

SO WHY DO NEUTRON STARS EVEN GLOW?

Where do these photons come from? Are they only from the surface? And pulsars emit powerful beams from their poles, but what pushes all that energy out?

All I know about neutron stars is that they're made of neutrons, have strong magnetic fields and spin super fast. No word on what goes on inside them

So my brain is currently stuck in a loop about what could possibly make a neutron star glow if there are no fuel consumption processes going on inside them, and how do they emit strong X-rays or radio waves or whatever it is when nothing is exploding or imploding in the centre

Do they just kind of evaporate until they're too weak to stay alight and spit out beams? Floating around, slowly cooling down, and being recycled until the heat death of the universe? We'll probably be too dead to care at that point, but for now I'm stuck in this loop - and I wanted to go to the cinema today because it's Half-Price day, aww…

1 note

·

View note

Text

The Application of Silicon Powder

Silicon is a chemical element with the symbol Si and atomic number 14. It is from the same group with carbon, germanium and tin. They all have similar properties, and are all tetravalent metalloid and semiconductor.

Silicon powder is made from silicon lump by breaking & milling. Depending on the purity & particle size of the silicon powder, it can be used for many purposes.

Semiconductor manufacturing

Due to the high melting point, thermal stability, rich resources and higher purity of silicon powder, silicon integrated circuits and large-scale integrated circuits have been applied to various areas. Silicon powder is an important raw materials of electronics and semiconductor industry

Coating Industry

-High purity Silicon Powder with suitable grain sizes for use in preparation of pressed and bonded sputtering targets and in CVD, PVD processes including Thermal and Electron Beam (E-Beam) Evaporation, Low Temperature Organic Evaporation, ALD, MOCVD.

-Silicon powder with narrow particle size distribution is used for thermal spaying, this makes the coating dense and uniform.

Silicone industry

Silicon powder is the basic raw material of synthetic materials. It is used in the production of silicone rubber, silicone resin, silicone oil, etc. The materials are high temperature tolerant, electrical insulation, corrosion-resistant, waterproof etc.

Refractory industry

Silicon powder is an antioxidant additive in iron groove and iron ditch of Iron smelting, mud water cannon, and containing silicon carbide mixes to raise the temperature, resistant to wear and oxidation resistance.

Metallurgical and foundry industry

Silicon powder is used as non-iron-based additives, silicon steel alloy agent to enhance the harden ability of steel. Silicon powder can also be applied to certain metal reducing agent, such as a new type of ceramic alloy.

Edgetech Industries specializes in producing high purity silicon powder with customized particle size. Our standard silicon powder particle sizes: - 325 mesh, -200mes, - 100 mesh, or any size between 20-500mesh. Nanoparticles & Submicron particles are also available on request. One of our most remarkable technologies is to provide silicon powder with a narrow particle size distribution. We will talk about the manufacturing process of silicon powder, which explain the reason we can provide narrow PSD for Si powder.

1 note

·

View note

Text

Physical Vapor Deposition Coating: Methods for the Future

What are the Physical Vapor Deposition coating approaches for the future? Ever wonder how the elegant, robust finishes on luxury timepieces, vehicle parts, and modern equipment are accomplished? Top Pvd coating Kerala is the novel solution. With unmatched benefits in terms of durability, appearance, and environmental impact, this revolutionary technology is changing the field of surface engineering.

Describe PVD Coating

A luxury living room furniture in Bangalore, Karnataka method known as physical vapor deposition (PVD) forms a thin film by vaporising solid components in a vacuum atmosphere and then laying them onto a substrate. Three primary steps—vaporization, transit, and condensation—form part of this process. High-energy sources evaporate the coating material, such as an electron beam, resistive heating, or arc discharge in a vacuum chamber.

Transportation: Maintaining its gaseous condition, the vaporized substance passes via the vacuum chamber.

Condensation: A thin, homogeneous coating results from the vapor condensing on the substrate.

Uses of PVD Coating

Industry of Automobile Equipment

PVD coatings spectrum Bangalore improves engine components, gear, and other important parts performance and longevity in the automotive industry. Better fuel economy and lower maintenance costs are achieved in part by PVD coatings' reduced friction and enhanced wear resistance.

Medical Objects

PVD coatings greatly help medical tools and implants since they are biocompatible and resistant to wear and corrosion. PVD-coated surgical instruments remain sharp and sterile for extended periods, guaranteeing accuracy and safety during medical treatments.

Watch Video: Click Here

Tool for Cutting

Custom-designed luxury furniture is essentially used in the machining sector as cutting tools. PVD-coated tools' reduced friction and enhanced hardness lead to higher cutting speeds, longer tool life, and better precision. For manufacturers, this lowers expenses and increases output.

Technology

Using protection, PVD coatings are applied in the electronics sector to improve the performance of parts, including semiconductors, sensors, and displays. PVD techniques' thin, homogeneous coatings guarantee great dependability and performance in electrical equipment.

The Prospect of PVD Coating

As long as research and development continue to stretch the boundaries of this technology, PVD coating looks bright. Innovations in coating materials development, deposition technique improvement, and PVD coating application expansion center on these areas.

Fresh Materials

Researchers are investigating novel materials to improve PVD coatings' qualities even more. Diamond-like carbon (DLC) coatings are under development for greater hardness and wear resistance. Such developments create fresh opportunities in sectors needing extremely durable surfaces.

Enhanced Techniques for Deposition

The development of deposition methods seeks to increase PVD process efficiency and cost-effectiveness. High-power impulse magnetron sputtering (HiPIMS) and other innovations enhance the quality and homogeneity of PVD coatings, increasing their availability for a greater spectrum of uses.

Broad Uses

As PVD coating technology develops, its uses should expand into new sectors. For example, PVD coatings on solar panels and wind turbine components would improve their efficiency and durability, benefiting the renewable energy sector.

Conclusion

With its unparalleled durability, cosmetic appeal, and environmental advantages, PVD coating transforms the surface engineering discipline. PVD coating will be very important as businesses seek creative ideas to enhance sustainability and product performance. PVD coating finds wide and always expanding uses in automotive, medical, electronics, and fashion. Accepting this new technology will surely result in a time when goods are more attractive and durable and better for our world.

Full Audio: Listen Here

Direction: Get Here

#pvd coating service bangalore#luxury sofa set for living room#luxury dining chairs#pvd coating bangalore#luxury sofa set#spectrum pvd coating#pvd decorative coatings#pvd coating price in bangalore#luxury leather sofa set

0 notes

Text

Optical Coating Market Size To Reach $37.58 Billion By 2030

The global optical coating market size is expected to reach USD 37.58 billion by 2030, registering a CAGR of 9.2% from 2024 to 2030, according to a new report by Grand View Research, Inc. The market is estimated to be driven by the growing smart consumer electronics industry across the globe. The rising focus on electricity generation through clean sources is also expected to drive product demand. Consumer electronic devices include smartphones, tablets, phablets, smartwatches, and smart televisions. Rapid urbanization resulting in changes in consumer lifestyles is expected to create lucrative opportunities for smart consumer electronic devices. This is projected to lead to an increase in the utilization of optical coatings as they have a superior optical display and impact resistance properties.

The Asia Pacific is a major market for consumer electronics owing to the presence of a large number of key players. The demand in the region has shifted toward Southeast Asian countries, a trend that is likely to continue over the forecast period. However, the outbreak of highly contagious COVID-19 across the globe is severely affecting manufacturing industries, which, in turn, is anticipated to negatively impact the growth of the global optical coatings in various applications such as consumer electronics, automotive, and aerospace and defense, solar, and architecture. As COVID-19 continues to spread across the world, order cancellations and shipping complications are surging throughout the optical coatings industry.

The reflective coating segment is anticipated to progress at a substantial growth rate over the forecast period. A rise in the use of this product for roofing applications in the construction industry owing to factors such as prevention of direct exposure to sunlight on the roof and reduction in cooling cost is anticipated to propel the demand for reflective coating over the forecast period. There has been a rising demand for both commercial and passenger automobiles in emerging economies like South Africa, Mexico, Brazil, India, and China in light of improving standards of living and population growth. This is projected to benefit the automotive coatings industry, which in turn, is expected to propel the demand for optical coatings.

Furthermore, the increasing requirement for protection against dust, dirt, UV radiation, and harsh climate is anticipated to drive market growth in the coming years. Companies in the market experience fluctuating prices of raw materials, which are driven by factors such as changes in supplier feedstock costs, inventories, demand and supply factors, and government regulations. Therefore, manufacturers have been focusing on developing technologies for efficient coating at a low cost. In addition, key players are continuously engaged in the diversification of their existing product portfolio in order to cater to a large customer base, which ultimately enables a strong foothold in the global market.

Request a free sample copy or view report summary: Optical Coating Market Report

Optical Coating Market Report Highlights

North America dominated the market and accounted for a revenue share of more than 37.0% in 2023

The anti-reflective coatings segment is the largest product segment and accounted for a revenue share of more than 29.0% in 2023. The growing demand for anti-reflective coatings from the solar industry is likely to fuel the market over the forecast period

In 2023, The consumer electronics application segment led the market and accounted for a revenue share of more than 31.0%

Optical Coating Market Segmentation

Grand View Research has segmented the global optical coating market based on technology, product, application, and region:

Optical Coating Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Vacuum Deposition Technology

E-Beam Evaporation Technology

Sputtering Process

Ion-Assisted Deposition (IAD) Technology

Optical Coating Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Anti-Reflective Coating

Reflective Coating

Filter Coating

Conductive Coating

Electrochromic Coating

Others

Optical Coating Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Consumer Electronics

Solar

Medical

Architecture

Aerospace & Defense

Automotive

Telecommunication

Others

Optical Coating Regional Outlook (Volume, Kilotons; Revenue, USD Billion, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

France

Italy

Spain

U.K.

Netherlands

Poland

Norway

Asia Pacific

China

Japan

South Korea

India

Singapore

Malaysia

Australia

Thailand

New Zealand

Central & South America

Brazil

Argentina

Columbia

Middle East & Africa

Saudi Arabia

South Africa

UAE

Qatar

Egypt

List of Key Players in Optical Coating Market

Alluxa, Inc.

Cascade Optical Corporation

Chroma Technology Corp.

Inrad Optics

Optical Coatings Japan

PPG Industries Inc.

Viavi Solutions

Schott AG

Abrisa Technologies

Berliner Glas

0 notes

Text

Recrystallized Silicon Carbide

Recrystallized silicon carbide boasts exceptional mechanical strength and erosion resistance. Furthermore, it boasts excellent oxidation resistance as well as low thermal expansion coefficient.

RSiC can be found in many applications due to its versatile combination of properties. R-SiC typically is used in furniture for kilns and rollers for roller presses as well as shed boards and shed boards - it even makes excellent insulation materials!

Excellent mechanical properties

Silicon carbide boasts exceptional mechanical properties, making it an excellent material choice for industrial use in various fields. Its Mohs hardness scale 13 hardness rating and strength characteristics help components endure even harsh environments while its chemical inertness make it suitable for environments susceptible to corrosion from acids, bases or liquid metals.

Recrystallized silicon carbide is manufactured through evaporation-coagulation and fired at temperatures reaching 2400 degC, yielding a porous network structure with open porosities between 11-15% and an open grain size of 100 pm, distinguished from reaction sintered and pressureless sintered materials that feature higher densities but poorer mechanical stress performance.

Due to its dimensional stability and high-temperature bearing capacity, steel is well suited to use as kiln furniture and kiln accessories, including rollers, shed boards and hollow beams. Furthermore, its use can also assist in the manufacturing of refractories, electric ceramics and semiconductor industry equipment.

R-SiC's superior corrosion resistance has contributed to its wide adoption across high-tech industries. Coating it onto the shaft of a turbine impeller can increase wear resistance by over one time, thus prolonging maintenance period. Applying boronized R-SiC to 45degsteel harvester blades significantly increase their hardness allowing them to resist erosion from molten metals and chemicals more effectively.

Excellent electrical properties

Recrystallized silicon carbide is an engineered ceramic material with exceptional thermal, chemical, and mechanical properties. It can be formed into flat and elongated shapes such as plates, tubes or beams by sublimation and condensation processes at temperatures exceeding 2000 degC; then solidified at high temperatures by sublimating and condensation processes of fine silicon carbide particles consolidated at these elevated temperatures. Recrystallized silicon carbide has outstanding inherent thermochemical and mechanical properties.

SiC's popularity can be attributed to its crystalline formation, with silicon and carbon atoms arranged in a tetrahedral lattice structure. Furthermore, its outstanding thermal stability, strength, durability, abrasion resistance and thermal conductivity make it highly suitable for applications. Furthermore, doping it with aluminium or boron impurities results in p-type semiconductors while nitrogen or phosphorus impurities produce N-type semiconductors; additionally controlled doping may even result in superconducing material properties if this material meets specific conditions - all very promising features indeed!

SiC's high atomic density makes it an outstanding electrical conductor with low dissipation and parasitic losses, making it suitable for use in various electronic devices such as diodes, MOSFETs and IGBTs that offer favorable electrical characteristics such as high breakdown voltages, low turn-on resistances and fast operating times.

This report offers a comprehensive view of key players operating in the Recrystallized Silicon Carbide Material (RSiC) Market as well as their business strategies. In particular, its competitive landscape section gives an in-depth view into company profiles, product offerings, financial details, and recent developments of key market participants.

Excellent thermal properties

Recrystallized silicon carbide's excellent thermal properties make it an excellent material for high-performance refractories, such as fireclay refractories. It has an exceptional thermal conductivity ten times greater than fireclay materials, along with superior resistance to cooling shock and corrosion as well as low thermal expansion coefficient and strength and hardness, all characteristics which have made RSiC an outstanding choice in applications across metallurgy, ceramics and electrical engineering industries.

RSiC stands out from other porous ceramics by not shrinking during the firing process and its open porosity does not diminish material strength. Furthermore, no additional additives or porogen are necessary to combat oxidation and erosion as its voids are filled with silica particles that act as solid insulators material.

RSiC is an advanced engineered material capable of being cast into flat or elongated forms such as plates, tubes, or beams. Created through sublimation and condensation of fine silicon carbide particles, it comes in several grades including granular and crystalline varieties with maximum dimensions up to 3.5 meters (11 feet). As such it can be used as a mirror alternative in large space telescopes like Herschel and Gaia observatories as well as for filtering of diesel vehicle exhaust emissions and metal smelting applications.

Excellent corrosion resistance

Recrystallized silicon carbide is well known for its outstanding corrosion resistance, making it the ideal material for applications where other materials would quickly degrade. Due to its durability, recrystallized silicon carbide is used in ceramic products like construction and sanitary ware, industrial furnaces that need to withstand high-voltage electric discharges, as well as pump bearings, valves and sandblasting injectors.

Recrystallized silicon carbide offers exceptional corrosion resistance due to its crystalline structure, which contains a passive oxide layer that provides protection from acids, alkalis, and solvents - an asset in industries like oil refining and chemical processing that regularly encounter these substances. This makes recrystallized silicon carbide an excellent material choice.

Recrystallized silicon carbide not only offers superior mechanical properties, but its thermal conductivity is outstanding as well. Thanks to its low coefficient of expansion and high melting point, recrystallized silicon carbide can withstand temperatures that would melt or damage other materials such as glass, plastics or metals; its excellent thermal conductivity also makes it an attractive choice for electrical components such as resistors and semiconductors.

Gelcasting is an ideal method for fabricating complex-shaped refractory components with uniform density and strong flexural strength, according to this paper. A concentrated suspension of coarse SiC powders was created specifically for gelcasting; with its rheological properties helping produce green bodies with consistent densities and great flexural strengths.

0 notes

Text

Physical Vapor Deposition Market Advancements: Unveiling Innovations

Physical Vapor Deposition: The Advanced Thin Film Deposition Technique

Introduction to PVD

Physical Vapor Deposition (PVD) is an advanced thin film deposition technique that is used to deposit thin films with a thickness ranging from a few nanometers to several micrometers. In PVD, the material to be deposited is initially heated to a gaseous form and then allowed to react or condense on the substrate or object that needs to be coated. The key processes involved in PVD include evaporation, sputtering, and cathodic arc deposition.

PVD vs CVD

PVD is different from Chemical Vapor Deposition (CVD) in the sense that in CVD, the deposition of thin films involves both chemical and physical reactions between the gaseous reactants whereas in PVD only physical processes like evaporation or sputtering are involved. CVD usually allows forming compound thin films by the reaction of two or more gases on a heated substrate. In contrast, PVD deposits thin film by directly transferring material from a solid target to the substrate.

Applications of PVD

PVD finds a wide range of applications due to its ability to deposit thin, hard, corrosion-resistant coatings with excellent adhesion to the substrate. Some common applications of PVD coating include: - Cutting tools: PVD is used to deposit wear-resistant coatings like titanium nitride, chromium nitride on cutting tools to improve performance. - Medical implants: PVD coatings of titanium, titanium nitride, etc. improves biocompatibility and corrosion resistance of implants. - Data storage: Films like titanium, aluminium, niobium are used in magnetic hard disks for better interface properties. - Decorative coatings: PVD process can deposit thin films of various colors on objects to make them look shiny and aesthetically appealing. - Solar panels: Anti-reflective coatings of silicon oxide, titanium dioxide improve light absorption in panels. - Consumer goods: PVD coatings provide scratch resistance and durability to products like watches, jewelry, eyeglasses. Working Principle of Physical Vapor Deposition

The basic working principle involved in PVD includes the following steps:

- Feedstock Material: The pure material that needs to be deposited in thin film form is taken as the feedstock. It is usually in the form of a solid metal target. - Vacuum Chamber: The substrate on which the coating is to be deposited and the target material are placed inside a vacuum chamber which is then evacuated to produce a high or ultra-high vacuum. - Target Sputtering/Evaporation: The target material is either physically sputtered/ejected by bombardment of energized gas ions or evaporated by heating it to a very high temperature depending on the PVD technique used. - Film Deposition: The ejected atoms from the target travel through the vacuum and deposit as a thin film on all surfaces including the desired substrate, present in the path of the vapor flux. - Film Growth: With continuous bombardment/ejection of atoms from the target, the deposited film starts growing uniformly on the substrate forming a thin even coating of thickness up to a few microns. - Process Variables: Variables like vacuum level, substrate temperature, discharge power/voltage determine properties of the growing film. Process is usually computer controlled.

Main PVD Techniques

Some major PVD techniques that are used for thin film deposition include: - Sputter Deposition: One of the most widely used methods which involves sputtering/ejection of target material atoms by bombarding it with energized gas ions inside a vacuum chamber. Can be used to deposit conductive as well as nonconductive films. - Evaporation Deposition: Involves heating the source material in vacuum either by electron beam, resistance or inductive heating so that it undergoes thermal evaporation/sublimation and gets deposited on nearby surfaces. Commonly used for depositing metals. - Cathodic Arc Deposition: High power electrical arc discharge vaporizes small amounts of target material which is then deposited. Offers higher deposition rates for producing thick coatings but involves macro-particle issues. - Pulsed Laser Deposition: A high power laser beam is used to vaporize material from a solid target which then deposits as a thin film. Used for producing complex oxide, superconducting thin films with stoichiometry matching with the target.

Advantages and Limitations

PVD offers several advantages over traditional metal coating techniques like plating due to its ability to precisely engineer thin films down to the nanometer level. However, it also has certain limitations some of which are: Advantages:

- Uniform and very thin coatings - Excellent adhesion to the substrate - Precise control over film properties and composition - Environment-friendly and suitable for reactive metals - Applicable for both conductive and non-conductive materials Limitations:

- Initial setup and equipment costs are higher - Throughput is comparatively less for large volume applications - Often requires post-deposition annealing/processing for many materials - Film properties dependent on process parameters - Industry 4.0 and automation scope remains to be fully realized In conclusion, Physical Vapor Deposition has emerged as an advanced thin film deposition technique for high-performance, functional and decorative coatings which is gaining widespread applications across industries owing to its ability to engineer material properties with precision at the micro and nanometer levels. Further developments in PVD technology and integration with Industry 4.0 are expected to enhance its utilization potential for newer applications.

#Physical Vapor Deposition Market Share#Physical Vapor Deposition Market Growth#Physical Vapor Deposition Market Trend

0 notes

Text

Cutting-Edge Electron Beam Evaporator System by Blue Wave Semiconductors

Explore Blue Wave Semiconductors' advanced electron beam evaporator system for precise thin film deposition. Our innovative technology ensures superior performance for various applications. Trust us to enhance your research and development with our reliable and state-of-the-art electron beam evaporator solutions.

0 notes

Text

The Future of Electron-Beam Technology: Trends & Innovations Shaping the Industry

Electron-beam (e-beam) technology has become an essential tool in various industries, including materials science, electronics, and optics, due to its precision and versatility. As technology continues to evolve, so does the role of electron-beam technology in shaping advancements across multiple fields. The future of electron-beam technology is promising, driven by key trends and innovations that are enhancing its capabilities and applications.

A major trend in Electron-Beam Technology is the development of more efficient electron beam sources. These sources are crucial for material evaporation, especially for materials with high melting points above 1800°C, or those that react with traditional evaporation boats or filaments. The ability of electron beam sources to handle such demanding materials makes them indispensable for industries where precision and durability are essential. In particular, electron-beam technology is increasingly being used in large deposition tools, particularly in optics and ophthalmics, where it is paired with ion-beam processes to achieve higher levels of material deposition and precision.

One of the key innovations in this field is the development of electron beam sources with higher power outputs, ranging from 3kW to over 20kW. This expanded power range allows for more efficient processing of a broader spectrum of materials, including those used in advanced semiconductor manufacturing and high-performance coatings. As industries such as optics and aerospace continue to demand more advanced and durable materials, electron-beam technology is playing a pivotal role in meeting these needs.

Moreover, electron-beam technology is becoming increasingly integrated into smaller systems, such as the Auto306, which allows for precise material deposition even in compact setups. This flexibility in system size and capability opens up new opportunities for industries that require both high-quality results and space efficiency. Electron-beam technology is thus adapting to the needs of various industries, allowing for both large-scale and smaller-scale applications with the same level of precision.

As electron-beam technology continues to evolve, companies like HHV Ltd are leading the charge in innovation. By continuously improving their electron beam sources and deposition tools, HHV Ltd is providing cutting-edge solutions that meet the growing demands of industries worldwide. Their focus on high-quality, efficient, and versatile electron-beam technology positions them as leaders in the field, ensuring that future advancements in electron-beam technology will continue to shape the industry.

The future of electron-beam technology is not only about improving existing processes but also about enabling new applications and innovations. With ongoing advancements in Electron Beam Sources and deposition systems, this technology will remain a critical enabler of progress across multiple sectors, driving improvements in manufacturing, optics, and beyond.

For more insights, visit https://hhvltd.com/

0 notes

Text

Roll to Roll Vacuum Coating System, Global Market Size Forecast, Top 13 Players Market Share

Roll to Roll Vacuum Coating System Market Summary

Roll-to-roll vacuum coating systems are designed to deposit films or coatings onto substrates such as plastics or metal foils in a continuous roll-to-roll process. The system typically consists of several key components, including:

Unwind system: This allows a roll of substrate material to be continuously fed into the coating process. Cleaning and Pretreatment Unit: This unit prepares the substrate surface by removing all contaminants and applying a pretreatment process to enhance coating adhesion. Coating chamber: This is the main part of the system where the actual vacuum coating process takes place. It houses one or more coating sources, such as electron beam evaporation, sputtering, or thermal evaporation, which evaporate or ionize the coating material and deposit it onto the moving substrate. Vacuum system: maintains the required vacuum conditions in the coating chamber. It includes a vacuum pump, pressure control system and gas inlet/outlet mechanism. Cooling System: Since the coating process generates heat, a cooling system is required to regulate the temperature and prevent any damage to the substrate or coating material. Winding system: After the coated substrate passes through the coating chamber, it is wound onto a reel to achieve continuous production.

Roll-to-roll vacuum coating systems have the advantages of high production throughput, uniform coating deposition, and the ability to coat large areas of flexible materials. They are widely used in applications such as thin-film solar cells, flexible electronics, barrier coatings for packaging materials, and anti-reflective coatings for displays.

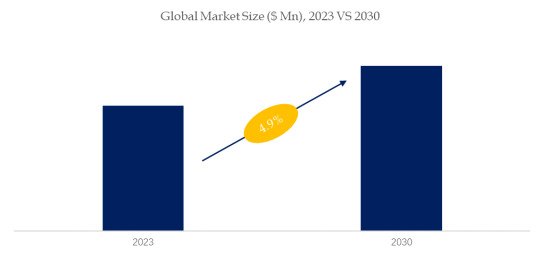

According to the new market research report "Global Roll to Roll Vacuum Coating System Market Report 2024-2030", published by QYResearch, the global Roll to Roll Vacuum Coating System market size is expected to reach USD 1444 million by 2030, at a CAGR of 4.9% during the forecast period.

Figure. Global Roll to Roll Vacuum Coating System Market Size (US$ Million), 2023-2030

Above data is based on report from QYResearch: Global Roll to Roll Vacuum Coating System Market Report 2024-2030 (published in 2023). If you need the latest data, plaese contact QYResearch.

Market Drivers:

The demand for high-quality thin film coatings in electronic products, solar cells, flexible displays and other fields continues to grow, driving the development of the roll-to-roll vacuum coating market. Roll-to-roll vacuum coating systems have important applications in sustainable energy industries such as solar cells. With the continuous development of the renewable energy market, this will further promote the demand for roll-to-roll vacuum coating systems.

Restraint:

Achieving high-quality, consistent and efficient thin film coatings requires solving many technical challenges such as coating uniformity, material loss and processing speed. Solving these problems may require further R&D and innovation, and manufacturers will need to invest significant R&D costs to develop high-quality equipment to meet market demand.

Opportunity:

Roll-to-roll vacuum coating systems are widely used in fields such as electronic products, solar cells, and flexible displays. With the emergence of emerging applications, such as flexible electronic technology and new smart devices, this will provide more development opportunities for the industry.

Figure. Global Roll to Roll Vacuum Coating System Top 13 Players

Above data is based on report from QYResearch: Global Roll to Roll Vacuum Coating System Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

This report profiles key players of Roll to Roll Vacuum Coating System such as Applied Materials, Bühler, ULVAC, Hitachi, Intellivation, Mustang Vacuum Systems, FHR Anlagenbau, Angstrom Engineering, NAURA, Guangdong Huicheng, Ziwoo Co, SCREEN Finetech Solutions, Yasui Seiki.

In 2023, the global top three Roll to Roll Vacuum Coating System players account for 60% of market share in terms of revenue.

About The Authors

Tingyue Chen

Email: [email protected]

QYResearch Guangzhou Branch Analyst, as a member of the QYResearch Machinery Manufacturing Department, her main research directions are engineering machinery, electrical machinery, industrial robots and other fields. Some subdivided research topics include industrial heat treatment equipment, farm robots, X-ray fluoroscopy systems, etc. She is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

How is Manufacturing Sectors Driving Demand for Hard Coatings?

The dependence on machineries in industries has been growing since a while now. Manual labor is increasingly being replaced by advanced machines in the manufacturing sector for increasing productivity and efficiency. It is obvious then that such machines need to operate smoothly, which is why, hard coatings are used for protecting them against wear and tear.

These coatings further provide increased lifetime, greater functionality, enhanced energy efficiency, which, in turn, decrease lubricant requirements and fuel consumption. Therefore, the growth of the manufacturing industry is predicted to result in the expansion of the global hard coatings market.

One of the key applications of these coatings is lenses, where they are used for making lenses scratch resistant. Other than that, hard coatings also find applications in decorative coatings, gears, cutting tools, optics, cylinders, bearings, firearms, cylinders, hydraulic and pneumatic components, implants, and injection moulding dies. The two hard coatings processes are chemical vapor deposition (CVD) and physical vapor deposition (PVD). The CVD coating technique is atmosphere-controlled, where the solid state precursor is coated in a gaseous form in a CVD reactor. This is technique is utilized for surface coating process for producing fine grained, high purity, and impervious bulk materials which are utilized in several industries.

Coatings produced through this process are utilized in semiconductors, nanomachines, and optical fiber industry. Under the PVD technique, the base material is utilized for forming a thin coating layer on an object by condensing and evaporating the used material. The technologies used under this process are sputter deposition, electron beam, physical vapor deposition, evaporative deposition, cathodic arc deposition, and pulsed laser deposition. Due to its wear resistance and hardness, enhanced oxidation resistance, and decreased friction, the PVD technique is being demanded by a number of industries, including cutting tools, aerospace, and automotive.

Geographically, the Asia-Pacific (APAC) region is expected to emerge as a major hard coatings market in the years to come, which can be attributed to the surging demand for cutting tools and decorative coatings in the region. The requirement for cutting tool especially, in countries including Malaysia, China, and India, is creating high demand for hard coatings in APAC. In addition to this, the durability, steady application, and less time taking properties of the PVD technology is used in the cutting tools industry, and is leading to the replacement of traditional deposition technology.

In conclusion, the demand for hard coatings is growing due to the expansion of the manufacturing industry and rising demand for cutting tools.

#Hard Coatings Market#Size of Hard Coatings Market#Demand for Hard Coatings Market#Trends in Hard Coatings Market#Growth

0 notes

Text

Pyrolytic Graphite Coated PBN Crucible for Electron Beam Evaporation

Pyrolytic graphite coated PBN (pyrolytic boron nitride) crucible refers to a crucible made of PBN material with a coating of pyrolytic graphite on its surface. The purity of Pyrolytic Graphite Coated Crucible is over 99.99% and the air tightness is good, which has high-temperature resistance, chemical stability, good thermal shock resistance, good thermal conductivity, low coefficient of thermal expansion, resistance to acid, alkali, salt, and organic reagent corrosion. In addition, it has a long service life.

By coating a PBN crucible with a layer of pyrolytic graphite, several advantages can be achieved: 1.Enhanced thermal conductivity: The pyrolytic graphite coating improves the thermal conductivity of the PBN crucible, allowing for efficient heat transfer during high-temperature processes. 2.Chemical resistance: The PBN material already exhibits exceptional chemical inertness, and the additional pyrolytic graphite coating further enhances its resistance to corrosive substances, ensuring greater durability and lifespan of the crucible. 3.Non-wetting properties: Pyrolytic graphite has a non-wetting surface, meaning it repels and does not absorb liquids. This property prevents molten materials from sticking to the crucible, facilitating easy removal and preventing contamination. 4.Electrically insulating: PBN itself is an excellent electrical insulator, and the pyrolytic graphite coating maintains the insulating properties of the crucible. This trait is valuable in electrical and electronic applications, where electrical isolation is necessary. 5.Reduced thermal stress: The combination of PBN and pyrolytic graphite helps reduce thermal stress caused by temperature variations, extending the crucible's lifespan. Pyrolytic graphite coated PBN crucibles are commonly used in high-temperature applications, such as semiconductor manufacturing, crystal growth, metallurgical processes, and materials research, where both high thermal stability and chemical resistance are critical. Read the full article

#PBNCrucible#PBNCrucibles#PyrolyticBoronNitrideCrucible#PyrolyticBoronNitrideCrucibles#Pyrolytic Graphite Coated Crucible

0 notes

Text

Butterfly-inspired films create vibrant colors while passively cooling objects

The new films, which don’t absorb any light, could be used on the outside of buildings, vehicles and equipment to reduce the energy needed for cooling while preserving vivid color properties. “In buildings, large amounts of energy are used for cooling and ventilation, and running the air conditioner in electric cars can reduce the driving range by more than half,” said research team leader Wanlin Wang from Shenzhen University in China. “Our cooling films could help advance energy sustainability and carbon neutrality.” In Optica, Optica Publishing Group’s journal for high-impact research, the researchers show that the films they developed lower the temperature of colorful objects to about 2 °C below the ambient temperature. They also found that when left outside all day, the blue version of the films was approximately 26°C cooler than traditional blue car paint. This represents an annual energy savings of approximately 1377 MJ/m2 per year. “With our new films, excellent cooling performance can be achieved, no matter the desired color, saturation or brightness,” said Wang. “They could even be used on textiles to create clothes of any color that are comfortable in hot temperatures.” Inspired by nature A car with blue paint appears blue because it absorbs yellow light and reflects blue light. The large amount of light that is absorbed heats the car. Morpho butterflies, however, produce their highly saturated blue color based on the nanostructure of their wings. The design of the cooling nanofilm mimics these structures to produce vibrant colors that don’t absorb light like traditional paint. advertisement To create their Morpho-inspired nanofilms, the researchers placed a disordered material (rough frosted glass) under a multilayer material made of titanium dioxide and aluminum dioxide. They then placed this structure on a silver layer that reflects all light, thus preventing the absorption of solar radiation and the heating associated with that absorption. The film’s color is determined by how components within its multilayered structure reflect light. To create blue, for example, the multilayer material is designed to reflect yellow light in a very narrow range of angles while the disordered structure diffuses the blue light across a broad area. Although this type of passive photonic thermal management has been accomplished before, it has only been used with white or clear objects because it is difficult to maintain a wide viewing angle and high color saturation. Passive cooling of colorful objects “Thanks to the layered structure we developed, we were able to extend the passive cooling method from colorless objects to colorful ones while preserving color performance,” said Wang. “In other words, our blue film looks blue across a large range of viewing angles and doesn’t heat up because it reflects all the light. In addition, high saturation and brightness can be achieved by optimizing the structure.” To test the new technology, the researchers created blue, yellow and colorless films, which they placed outdoors at Shenzhen University, on surfaces such as roofs, cars, cloth and cell phones, from 9 a.m. to 4 p.m. in both winter and summer. Using thermocouple sensors and infrared cameras to measure temperature, they found that the cooling films were more than about 15 ? cooler than the surfaces they were placed on in the winter and about 35 ? cooler in the summer. The researchers point out that replacing the silver film with an aluminum film would make the films less expensive and manufacturable by a scalable fabrication method such as electron beam evaporation and magnetron sputtering. Now that they have demonstrated the cooling and color performance of the films, the researchers plan to study and optimize other properties such as mechanical and chemical robustness.

0 notes