#advantages of laser deep welding

Explore tagged Tumblr posts

Text

Laser Deep Welding: Principles, Advantages, and More

Laser Welding: An In-Depth Look at Deep Welding Techniques

Laser welding is an essential and versatile technique widely used across industries such as manufacturing, automotive, aerospace, and electronics. This method has two primary types: continuous and pulsed, further classified into heat-conductive welding and laser deep melting welding. This article will delve into laser deep welding, discussing its principles, key factors, and advantages and disadvantages.

Principles of Laser Deep Welding

Laser deep welding employs a continuous laser beam to join materials, sharing similarities with electron beam welding in its metallurgical process. A critical aspect of this technique is the formation of a "keyhole" structure, essential for energy conversion. Here are the main stages of the laser deep welding process:

Energy Absorption: The material’s ability to absorb laser energy varies based on its properties, including absorption rate, reflectivity, and thermal conductivity. Non-metallic materials like ceramics and plastics absorb laser energy well at room temperature, while metals exhibit low absorption rates until they melt or vaporize.

High Energy Concentration: When exposed to a high-power laser, a small, vapor-filled hole form, absorbing nearly all incident energy. The temperature within this cavity reaches around 2500°C.

Molten Metal Formation: Heat transfer from the high-temperature cavity’s outer walls causes the surrounding metal to melt. As the wall material evaporates, vapor fills the hole, creating a molten metal layer around it.

Continuous Flow: The molten metal flows outward, and surface tension maintains a dynamic balance with the cavity's vapor pressure. As the laser moves, this molten "keyhole" structure follows, enabling high-speed welding at rates of several meters per minute.

Key Parameters Affecting Laser Deep Welding

Several factors influence the effectiveness of laser deep welding, including:

Laser Power: Higher laser power density enhances melting depth and welding speed.

Beam Focal Spot Size: A smaller focal spot increases power density, affecting weld penetration.

Material Absorption Rate: The absorption rate and surface condition impact laser energy absorption.

Welding Speed: Adjusting the speed can control melt depth. Optimal speed varies by material, power, and thickness.

Protective Gas: Inert gases like helium, argon, and nitrogen protect the molten pool, prevent oxidation, and disperse plasma.

Lens Focal Length: The lens focal length affects power density and spot size, with shorter focal lengths producing smaller spots.

Focus Position: The focal point’s position relative to the workpiece surface impacts weld width and depth.

Laser Beam Position: Precise control of the laser beam’s position is crucial, particularly in butt joint welding.

Gradual Power Control: Gradual power adjustments at the start and end of welding help avoid defects like pits and excessive melting.

Advantages and Disadvantages of Laser Deep Welding

Laser deep welding provides multiple benefits:

High Depth-to-Width Ratio: Produces narrow, deep welds.

Minimal Heat Input: Reduces thermal distortion and heat-affected zones.

High Weld Density: Results in strong, high-quality welds with low impurities.

Precise Control: Allows accurate beam positioning and is suitable for automation.

Non-Contact Process: Welding occurs without physical contact, protecting the workpiece.

Cost-Efficiency: High welding speeds and low operating costs improve overall efficiency.

However, laser deep welding also has some limitations:

Limited Welding Depth: The technique has constraints on maximum weld depth.

High Assembly Requirements: Accurate alignment and assembly of workpieces are necessary.

High Initial Investment: Laser welding systems require a significant initial cost.

Conclusion

Laser deep welding is a powerful and adaptable welding technique valued for its ability to produce deep, high-quality welds with minimal heat input and precise control. Although initial costs and depth limitations exist, its benefits often outweigh these drawbacks, making laser deep welding a valuable tool in modern manufacturing and fabrication.

#advantages of laser deep welding#laser deep welding#laser deep welding machine#laser welding#laser welding machine#laser welding machines in India#principles of laser deep welding

0 notes

Text

Industrial Laser Systems Market Report, Market Size, Share, Trends, Analysis By Forecast Period

Global Industrial Laser Systems Market Report

The Industrial Laser Systems Market research report offers an in-depth analysis of market dynamics, competitive landscapes, and regional growth patterns. This comprehensive report provides businesses with the strategic insights necessary to identify growth opportunities, manage risks, and develop effective competitive strategies in an ever-evolving market.

According to Straits Research, the global Industrial Laser Systems Market size was valued at USD 21.23 billion in 2023. It is projected to reach from USD 22.78 billion in 2024 to USD 40.09 billion by 2032, growing at a CAGR of 7.32% during the forecast period (2024–2032).

Request a Sample Report Today @ https://straitsresearch.com/report/industrial-laser-systems-market/request-sample

Global Industrial Laser Systems Market Segmental Analysis

As a result of the Industrial Laser Systems market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Type

Macro Processing

Micro Processing

By Power

Less than 1 kW

More than 1.1 kW

By Applications

Cutting

Welding

Non-Metal Processing

Additive manufacturing

Others

You can check In-depth Segmentation from here: https://straitsresearch.com/report/industrial-laser-systems-market/segmentation

Why Invest in this Report?

Leverage Data for Strategic Decision-Making: Utilize detailed market data to make informed business decisions and uncover new opportunities for growth and innovation.

Craft Expansion Strategies for Diverse Markets: Develop effective expansion strategies tailored to various market segments, ensuring comprehensive coverage and targeted growth.

Conduct Comprehensive Competitor Analysis: Perform in-depth analyses of competitors to understand their market positioning, strategies, and operational strengths and weaknesses.

Gain Insight into Competitors' Financial Metrics: Acquire detailed insights into competitors' financial performance, including sales, revenue, and profitability metrics.

Benchmark Against Key Competitors: Use benchmarking to compare your business's performance against leading competitors, identifying areas for improvement and potential competitive advantages.

Formulate Region-Specific Growth Strategies: Develop geographically tailored strategies to capitalize on local market conditions and consumer preferences, driving targeted business growth in key regions.

List of Top Leading Players of the Industrial Laser Systems Market -

Amonics Ltd.

Apollo Instruments Inc.

Coherent Inc.

IPG Photonics Corporation

Jenoptik Laser GmbH

CY Laser SRL

NKT Photonics A/S

Quantel Group

TRUMPF

Toptica Photonics AG.

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

Regional Analysis Industrial Laser Systems Market

The regional analysis section of the report offers a thorough examination of the global Industrial Laser Systems markets, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Industrial Laser Systems markets in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

Buy Now @ https://straitsresearch.com/buy-now/industrial-laser-systems-market

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Industrial Laser Systems Market#Industrial Laser Systems Market Share#Industrial Laser Systems Market Size#Industrial Laser Systems Market Research#Industrial Laser Systems Industry

0 notes

Text

Medical Sheet Metal Fabrication

In the modern medical industry, sheet metal products are an indispensable part. Medical device sheet metal product processing is an important manufacturing process that can provide high-quality medical equipment and appliances for hospitals and medical institutions, and provide better healthcare services for patients.

The application of medical device sheet metal processing is very wide, mainly involving medical equipment, medical devices, medical appliances and other fields. Sheet metal processing technology can manufacture medical devices of various shapes and sizes, such as operating tables, surgical lamps, surgical instrument racks, etc. These devices can help doctors perform surgeries and treatments more effectively. Medical sheet metal products can also be used to manufacture medical equipment, such as stretchers, wheelchairs, beds, etc. These tools can provide a more comfortable nursing environment and help patients recover.

Medical Metal Parts Manufacturing Capabilities

The advantage of medical sheet metal product processing is its precision and reliability. As an experienced sheet metal factory in China, we follow the strict quality control system, use well trained engineers and workers, use state of the art equipment to ensure our sheet metal parts have the best precision and accuracy.

We have decades of experience in manufacturing sheet metal parts for medical industry. Because of its complexity in design and aesthetics in appearance, medical device has high requirements on factories, and almost all processes will be involved, such as laser cutting, CNC bending, precision stamping, deep drawing, welding, surface treatment, etc. We already have a deep understanding of medical devices and can meet our customers' quality requirements.

How Yixing Technology Produce Medical Metal Parts

How to make medical device can be mainly divided into below four parts:

Part 1: Cutting Materials

Laser cutting is one of the most common cutting methods in sheet metal processing. Firstly, according to the size specifications of the finished sheet metal parts, stainless steel and other sheets are laser cut into the required dimensions for backup. This process is collectively referred to as cutting.

Part 2: Bending

Bending is the process of CNC bending the finished material according to the size specifications of the sheet metal workpiece. It will be prepared for the next step of sheet metal welding. Take patient transfer device as example, the main parts are square tubes. We use press brake or pipe bending machine to do the precise bending.

Part 3: Welding

Welding can be divided into two methods: manual welding or robot automatic welding. It is a process of welding finished materials based on the cut, bent or formed sheet metal parts. It is combining two or more types of the same or different types of sheets. Shanghai Yixing Technology can do TIG and MIG welding. Material selection and welding quality is the most important because it will influence the load bearing capacity and whether the machine can do straight line rolling. We pay attention on every detail.

Part 4: Surface Treatment

There are many surface treatment we can do such as sandblasting, anodization, polishing, powder coating, electrophoretic paint, hot-dip galvanizing, electroplating or others. For the patient transfer device, the main surface treatment is powder coating. The minimum coating thickness is more than 60um and we do 100 grid test and salt spray test to check the adhesion and corrosion resistance.

Patient transfer device is a complicated design and more process will be involved which is not listed above like riveting, threading, printing, heat treatment, assembly with motors and other plastic parts and hammock.

0 notes

Text

Mastering Sheet Metal Fabrication: Techniques, Tools, and Applications

Sheet metal fabrication, SMF, is a centuries-old craft that has evolved into a sophisticated process, vital across industries. From aerospace to automotive, construction to manufacturing, sheet metal fabrication plays a pivotal role in creating durable, functional, and intricate structures and components.

Understanding Sheet Metal Fabrication

At its core, sheet metal fabrication involves transforming flat sheets of metal into specific shapes and forms through cutting, bending, and assembling techniques. Materials commonly used include stainless steel, aluminum, brass, copper, and various alloys. The process begins with the selection of the raw material, followed by precise measurements and design considerations.

Tools of the Trade

1. Shears and Cutting Tools: Shears, laser cutters, or water jets are used to cut the metal into desired shapes and sizes. Laser cutting, in particular, offers precision and versatility, enabling intricate designs and complex cuts.

2. Press Brakes: These machines bend the metal to create angles, curves, and shapes according to design specifications. They are pivotal for forming the metal accurately.

3. Roll Forming Equipment: Utilized for shaping long strips of metal into curved or cylindrical shapes, roll forming machines are essential for producing components like pipes, tubes, and curved panels.

5. Finishing Tools: Grinding, sanding, and polishing equipment gives the fabricated metal its final surface finish, enhancing aesthetics and removing imperfections.

Techniques in Sheet Metal Fabrication

1. Cutting: Precision cutting is fundamental. Laser cutting and plasma cutting offer accuracy and speed, ensuring clean and smooth edges without material deformation.

2. Bending: This involves using press brakes to shape the metal. Accurate bending angles are crucial for the functionality and aesthetics of the final product.

3. Forming: Techniques like roll forming, stretching, and deep drawing shape the metal into complex geometries, catering to diverse industrial needs.

4. Joining: Welding, soldering, and fastening methods are employed to join metal pieces securely, maintaining structural integrity.

Applications Across Industries

1. Automotive: From chassis components to body panels, SMF is integral to automotive manufacturing, ensuring both safety and aesthetics.

2. Aerospace: In the aerospace industry, precision and lightweight materials are crucial. SMF creates components for aircraft, satellites, and spacecraft.

3. Construction: Architectural structures, HVAC systems, and decorative elements rely on SMF for durability and customized designs.

4. Manufacturing: Machinery, appliances, and consumer goods often incorporate fabricated sheet metal parts for their strength, durability, and cost-effectiveness.

Innovations and Future Trends

Recent advancements in technology, such as 3D printing of metal components and the integration of AI-driven design and manufacturing processes, are revolutionizing SMF Additive manufacturing techniques offer increased design flexibility and reduced material waste, while AI optimization enhances precision and efficiency in production.

Challenges and Sustainability

The sheet metal fabrication industry faces challenges in reducing material waste, energy consumption, and environmental impact. However, efforts are underway to adopt sustainable practices, including recycling scrap metal, using eco-friendly coatings, and optimizing manufacturing processes for reduced energy consumption.

Specialized Techniques

2. Piercing and Perforating: Used to create holes or patterns in the metal, these techniques are crucial for ventilation, drainage, or aesthetic purposes.

3. Hydroforming: This method uses high-pressure fluid to shape metal sheets into complex forms, offering advantages in producing lightweight yet durable components.

Quality Control and Precision

Ensuring quality throughout the fabrication process is essential. Metrology tools like coordinate measuring machines (CMMs) and optical inspection systems verify dimensions and tolerances, maintaining high standards in the produced parts.

Design Considerations

SMF heavily relies on meticulous design. Factors such as material selection, thickness, bend radii, and nesting techniques are crucial for optimizing efficiency and minimizing material waste.

Customization and Prototyping

The flexibility of sheet metal fabrication allows for customization, enabling rapid prototyping and iterative design improvements. This agility is invaluable in product development and innovation.

Importance of Skilled Labor

Skilled artisans and technicians play a critical role in sheet metal fabrication. Their expertise in interpreting blueprints, operating machinery, and problem-solving contributes significantly to the quality of the final product.

Global Impact and Market Trends

The global SMF market continues to expand, driven by demand across industries. Emerging economies, technological advancements, and the adoption of automation are influencing market growth and innovation in fabrication processes.

Collaboration and Integration

Collaboration between designers, engineers, and fabricators is essential for a seamless and efficient fabrication process. Integration of CAD/CAM software allows for streamlined communication and data transfer, reducing errors and improving overall productivity.

Future Challenges and Opportunities

As technology evolves, the industry faces challenges in adapting to automation and upskilling the workforce. However, these challenges also present opportunities for innovation, efficiency improvements, and the development of new materials and processes.

Global Sustainability Efforts

The sheet metal fabrication industry is increasingly embracing sustainable practices. Initiatives like using recycled materials, adopting energy-efficient machinery, and exploring alternative materials contribute to reducing the environmental footprint of fabrication processes.

Conclusion

Sheet metal fabrication stands at the intersection of craftsmanship, technology, and innovation. As industries continue to evolve and demand for intricate, durable, and sustainable components grows, the art of SMF will undoubtedly continue to play a pivotal role in shaping our technological landscape. Through a blend of traditional expertise and cutting-edge advancements, this field remains integral in transforming raw metal into functional works of art that power various sectors worldwide.

Also Read: The Art of Metal Fabrication and the Versatility of a Metal Fabricator

#SheetMetal#Fabrication#InnovationInMetal#ManufacturingTech#MetalDesign#IndustryInsights#TechEvolution

0 notes

Text

Laser Cutting and Welding Technologies: Illuminating the Future of Metal Fabrication with Sarda Metals

Metal fabrication has witnessed a revolutionary transformation with the advent of laser cutting and welding technologies. These cutting-edge processes have not only streamlined production but have also elevated precision and efficiency in the metalworking industry. Let's delve into the latest developments in laser-based cutting and welding, exploring their applications, benefits, challenges, and the promising future they hold.

Evolution of Laser Cutting

In the genesis of laser cutting, the technology was a mere concept, slowly evolving into the powerhouse it is today. The journey from the first laser cut to the sophisticated processes we have now is a testament to relentless innovation and engineering prowess. The advancements in laser cutting have significantly impacted metal manufacturers worldwide, with companies like Sarda Metals leading the way as prominent metal manufacturers in India.

Laser Cutting Processes

The contemporary metal fabricator can choose from various laser cutting processes, each with its unique advantages. CO2 laser cutting and fiber laser cutting, in particular, have gained prominence. The choice between them often hinges on factors like material type, thickness, and desired cutting speed. This decision-making process is crucial for metal manufacturers in India, including industry leaders like Sarda Metals, who strive to adopt the most effective and efficient laser cutting techniques in their operations.

CO2 Laser Cutting

The venerable CO2 laser cutting technology utilizes a gas mixture to generate a laser beam. This process, tried and true, is renowned for its versatility across different materials, including metals, plastics, and woods.

Fiber Laser Cutting

On the other hand, fiber laser cutting employs a solid-state laser source, enhancing speed and precision. This method has gained favor for its remarkable efficiency and ability to tackle thin to thick metal sheets with ease.

Advancements in Laser Cutting

Recent years have witnessed substantial advancements in laser cutting technologies, pushing the boundaries of what was once considered possible. Precision levels have reached new heights, enabling intricate designs and minimizing material waste.

Laser Welding Techniques

In parallel to laser cutting, laser welding has emerged as a pivotal technique in metal fabrication. Unlike traditional welding methods, laser welding is a non-contact process that utilizes a focused laser beam to join metals seamlessly.

Types of Laser Welding Processes

Various laser welding techniques cater to different applications. From conduction welding suitable for thin materials to keyhole welding ideal for deep welds, the versatility of laser welding makes it a preferred choice across industries. This adaptability is particularly crucial for metal manufacturers in India, such as Sarda Metals, who leverage the diverse applications of laser welding to meet the specific requirements of their varied clientele.

Applications in Metal Fabrication

The marriage of laser cutting and welding has found widespread application in diverse industries. The automotive sector benefits from precise laser-cut components, while aerospace relies on the integrity of laser welding for critical structures. General manufacturing, too, has embraced these technologies for their efficiency and accuracy.

Benefits of Laser Cutting and Welding

The adoption of laser cutting and welding brings forth a multitude of advantages, reshaping the landscape of metal fabrication.

Efficiency and Speed

Laser technologies significantly reduce production times. The non-contact nature of laser cutting and welding translates to swift processing, allowing manufacturers to meet tight deadlines with ease.

Minimal Heat-Affected Zones

Traditional welding processes often introduce excessive heat, leading to deformations in the welded area. Laser welding minimizes heat-affected zones, preserving the structural integrity of the metal.

Enhanced Precision

The precision achievable with laser technologies is unparalleled. Intricate designs and fine details are executed with utmost accuracy, catering to the increasing demand for intricate metal components. This level of precision is particularly vital for metal manufacturers in India, exemplified by industry leaders like Sarda Metals, who prioritize delivering top-notch quality in their metal products.

Challenges in Laser Technology

While laser cutting and welding offer transformative benefits, certain challenges accompany their implementation.

Initial Setup Costs

The acquisition of laser systems involves initial investments that might pose challenges for smaller businesses. However, the long-term gains often outweigh these initial costs.

Maintenance Considerations

Regular maintenance is crucial to ensure the continued optimal performance of laser systems. Understanding and addressing maintenance requirements are imperative for sustained productivity.

Skill Requirements

Operating laser cutting and welding systems demands a certain skill set. Adequate training and expertise are essential to harness the full potential of these technologies.

Recent Technological Innovations

The integration of artificial intelligence (AI) in laser systems marks a significant leap forward. AI optimizes cutting and welding parameters in real-time, adapting to variations in materials and environmental conditions. Additionally, 3D laser cutting has opened new avenues, allowing for the creation of intricate three-dimensional structures with precision.

Environmental Impact

The environmental implications of manufacturing processes are increasingly under scrutiny. Laser cutting and welding contribute to sustainability efforts by being energy-efficient and minimizing material waste, aligning with the growing emphasis on eco-friendly practices in the industry.

Market Trends in Laser-Based Metal Fabrication

The demand for laser-based metal fabrication is on the rise. As industries recognize the advantages these technologies offer, market trends indicate a continuous upward trajectory. Key players in the field are investing in research and development to stay at the forefront of innovation.

Future Prospects

The future of laser cutting and welding technologies looks promising. Anticipated developments include enhanced automation, further integration of AI for predictive maintenance, and the exploration of new materials for laser processing.

Case Studies

Examining real-world applications provides insight into the success stories of industries that have embraced laser cutting and welding. From increased production efficiency to improved product quality, case studies highlight the tangible benefits.

Best Practices for Laser Cutting and Welding

Achieving optimal results with laser technologies requires adherence to best practices.

Safety Measures

Prioritizing safety is paramount. Protective gear, proper training, and adherence to safety guidelines ensure a secure working environment.

#sarda#ferro alloys producer in india#silico manganese#metals manufacturer in india#ferro manganese#metal suppliers in india#ferro alloys suppliers in india#sarda metals and alloys ltd#sardametals

0 notes

Text

Metal fabrication unveiled: tips and types of sheet metal fabrication processes.

Metal fabrication is a crucial aspect of the manufacturing industry, involving the shaping, cutting, and assembling of metal structures. Sheet metal fabrication focuses on transforming thin metal sheets into usable components and products. This article explores the various types of sheet metal fabrication processes, provides useful tips for successful fabrication, and delves into the market data within the UK, with specific reference to the metal fabrication industry in Falkirk.

Types of Sheet Metal Fabrication Processes

Cutting: Cutting is the initial step in the sheet metal fabrication process. It involves separating the metal sheet into desired shapes and sizes. Common cutting methods include shearing, laser cutting, plasma cutting, and waterjet cutting. Each method offers distinct advantages in terms of precision, speed, and cost-effectiveness.

Bending: Bending is used to create three-dimensional shapes from flat metal sheets. The process involves using specialized machinery such as press brakes to apply force and form the metal into the desired angle or curve. Bending can be done manually or through automated CNC machines, ensuring accuracy and repeatability.

Forming: Forming involves manipulating the metal sheet to achieve specific shapes or contours. It includes processes like deep drawing, roll forming, and stamping. Deep drawing creates hollow parts by stretching the metal sheet into a die cavity. Roll forming gradually bends the sheet into a desired profile, while stamping uses a die to cut or shape the metal.

Joining: Joining methods are employed to connect different metal components. Welding, a commonly used joining technique, fuses metals together using heat. Other methods include riveting, fastening with screws or bolts, and adhesive bonding. Each joining technique has its advantages based on the application requirements.

Tips for Successful Sheet Metal Fabrication

Material Selection: Choose the right metal material based on the desired characteristics of the final product. Factors to consider include strength, corrosion resistance, thermal conductivity, and cost. Commonly used metals in sheet metal fabrication include steel, aluminum, stainless steel, and copper.

Design Considerations: Design components with fabrication in mind. Minimize the need for complex shapes or excessive bends to reduce manufacturing costs. Optimize designs for efficient material usage and ease of assembly. Consult with an experienced metal fabricator during the design phase to ensure manufacturability.

Precision Measurements: Accurate measurements are crucial for successful sheet metal fabrication. Utilize advanced measuring tools and techniques, such as digital calipers or coordinate measuring machines (CMM), to ensure precise dimensions. Invest in quality control processes to minimize errors and ensure consistency.

Collaboration with a Skilled Metal Fabricator: Partnering with a reputable metal fabricator is essential for achieving high-quality results. Look for a fabricator with experience in your specific industry or product requirements. A skilled fabricator will provide valuable insights, suggest process optimizations, and ensure efficient production.

An Overview: Metal Fabrication in Falkirk

The metal fabrication industry in the UK is a thriving sector, contributing significantly to the country's economy. In Falkirk, a town located in Central Scotland, metal fabrication plays a crucial role in supporting various industries such as construction, automotive, aerospace, and manufacturing.

Falkirk is home to several metal fabricators specializing in steel fabrication and other metalworking processes. These fabricators offer a wide range of services, including welding, cutting, bending, and assembly. They cater to both small-scale projects and large-scale industrial requirements.

The market demand for metal fabrication in Falkirk is driven by the construction industry's growth, infrastructure projects, and the need for customized metal components in various sectors. The availability of skilled labor, technological advancements, and a supportive business environment further contribute to the sector's growth.

In conclusion, sheet metal fabrication encompasses various processes that transform metal sheets into functional components. By following the tips mentioned above, manufacturers can ensure successful fabrication. Within the UK market, Falkirk is a hub for metal fabricators, particularly specializing in steel fabrication. With the continued growth of the construction industry and demand for customized metal components, the metal fabrication sector in Falkirk is poised for further expansion and success.

1 note

·

View note

Text

Laser welding as a high-energy beam precision welding technology, with its low thermal input, small welding deformation, welding speed, high degree of automation, a series of advantages, more and more widely used in the industrial field.

However, in Dotslaser welding, if the arc section and the arc collection section do not carry out special process treatment, then due to the machine tool or robot and other moving body of the acceleration process, at the beginning of the weld is prone to appear "match head" appearance, the end of the weld is prone to arc pit depression, the overall uniformity of the weld appearance has a greater impact, and the arc at the end of the arc will reduce the strength of the weld, easy to produce arc cracks. And the greater the laser power density, the more obvious this phenomenon.

Therefore, in the actual production process, the weld arcing and arcing process needs to be special treatment. If the weld position and conditions allow, can be avoided by adding an introduction arc plate, but in the actual mass production, this scheme is not applicable, and part of the weld trajectory is closed graphics, weld start and end segments are in the weld, so it is necessary to optimize the weld process parameters to adjust the shape of the weld arc closing segment.

The weld shape can be adjusted by the laser power control and PWM control of the starting arc segment, and during the arcing phase, the power can gradually change from low to high as the moving mechanism accelerates from stationary to normal welding speed, and the power can be changed gradually from low to high, low power in the low-speed stage and high power in the high-speed stage, which can be avoided. At the arc "match head" shape, in the arcing stage, the laser power is gradually reduced, can reduce the energy density of the welding line, the weld melt width gradually narrows, the welding process deep melting hole gradually becomes shallow, thus improving the arc pit shape at the weld arc.

Therefore, by controlling the laser power slowly rising and falling, the weld can be smoothed too smoothly at the start and end of the arc, significantly reducing the height of the weld starting arc point and the size of the arc pit at the end of the arc and depression. On this basis, in order to further control the heat input volume of the starting and ending segments, the dubing ratio or modulation frequency can be optimized again with the change of welding speed.

DOTSLASER uses continuous optical lasers for continuous welding and modulation mode welding, and laser power can be adjusted in real time. With Jept's continuous laser monitoring software, not only can the laser's working status be monitored in real time, but also the line energy density can be precisely controlled, thus avoiding the "matchhead" shape at the arc. Fiber Laser Marking Machine Manufacturer China, CO2 Laser Marking Machine Manufacturer China

#Fiber Laser Marking Machine Manufacturer China#CO2 Laser Marking Machine Manufacturer China#Fiber Laser Engraving Machine Manufacturer China#Laser Marking Marking Manufacturer China#Laser Marking Marking Supplier China

1 note

·

View note

Text

Build A 12V 280Ah LiFePO4 For A Golf Cart! Full Process Of Battery Cell Assembly!

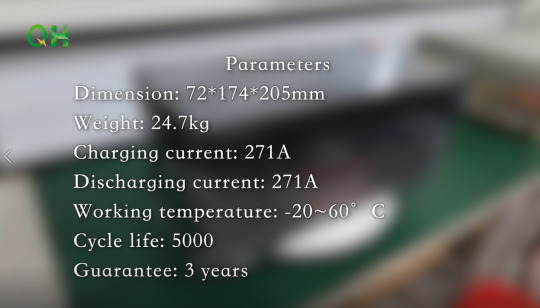

LiFePO4 batteries have lots of advantages and are becoming quite in demand in the market of trolling motors. When referring to the LiFePO4 batteries, you may compare them with the GEL batteries. For a long time, GEL batteries have played a role in our lives. Nowadays, we prefer LiFePO4 batteries.

As opposed to boats that use GEL batteries, electrical ships equipped with the 12.8Volt 280Ah lithium batteries are more economical, less polluting, and clearly better for the environment. The LiFePO4 battery has a longer life span and deep cycle times(even more than 5,000 times).

Are you a Lithium battery amateur and interested in li-ion battery pack assembly? Now we’d like to share the whole assembly process for beginners, which takes the 12.8V 280Ah LiFePO4 battery as an example.

*Note: It is recommended that you learn some basic knowledge about LiFePO4 batteries before assembling the battery pack. Keep safe when you are assembling the battery pack.

youtube

Material Used

3.2V 280Ah LiFePO4 battery cells (4 pieces)

There are currently three common shapes of LiFePO4 batteries: cylindrical, prismatic, and pouch. Different shapes of batteries will have a certain impact on performance. At present, the most suitable battery DIY enthusiasts are the prismatic LiFePO4 batteries, which are very suitable for both performance and operational difficulty.

We recommend you purchase the Grade A battery with a high quality and reliable warranty.

BMS (Battery Manage System, 1 piece)

Connectors (About 4pieces)

Others: EVA cotton, screws, ribbon cable, plastic pipes, etc.

Tool Used:

Spot Welder

Spot Welding Pen

Soldering Iron

Wire Cutter

Wire Stripper

Multimeter

Assembly Methods: 4 Series And 1 Parallel

Series(S): The way of connecting the positive and negative electrodes of two different cells is called a series connection. As a result, the voltage of the battery pack will increase while the capacity remains the same.

Parallel(P): where the positive and positive electrodes of two different cells are connected in parallel. The result is that the capacity of the battery pack increases while the voltage remains the same.

Assembly Process

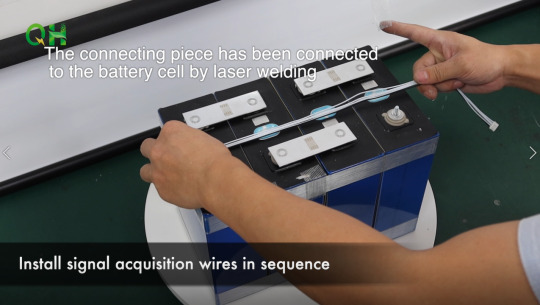

1. Install Signal Acquisition Wires In Sequence

The connecting piece has been connected to the battery cell by laser welding. Before installing the signal acquisition, we checked the consistency of the battery and fixed them with fiber tape.

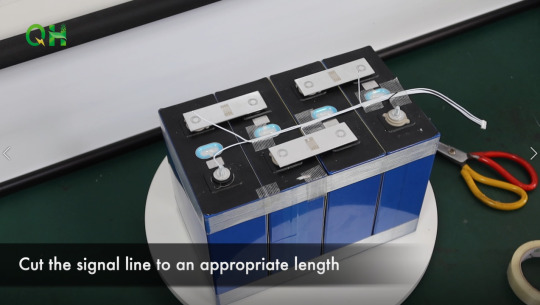

2. Cut The Signal Lines To An Appropriate Length

Tidy up the signal lines and tape them with fiber tape, then cut the signal lines to an appropriate length.

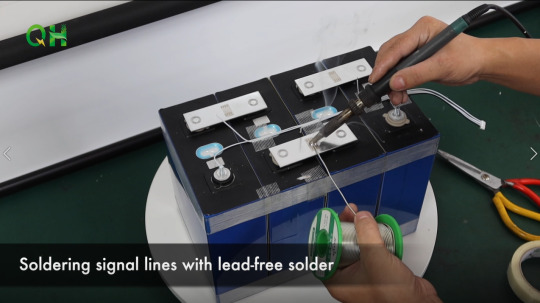

3. Soldering Signal Lines With Lead-Free Solder

Generally, leaded solder is composed of tin and lead. The advantages of using leaded solder include: being easier to bring to working temperature, being shock resistant, and having fewer internal flaws in the structure after being cooled. However, lead material is harmful to the body as it’s readily absorbed. We’d better choose lead-free solder to protect our health and environment.

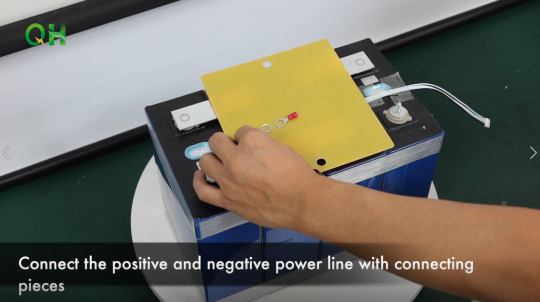

4. Connect The Positive And Negative Power Line With Connecting Pieces

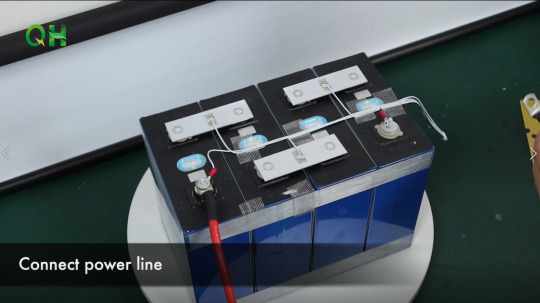

5. Connect The Power Line

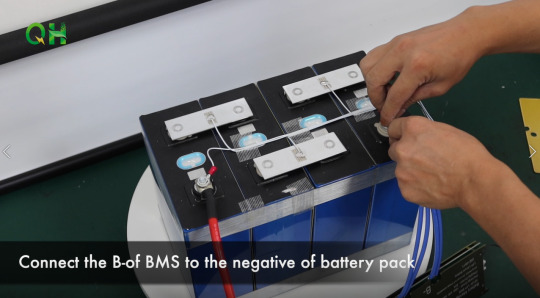

6. Connect The B- Of BMS To The Negative Of Battery Pack

A BMS is one of the most important elements in a LiFePO4 battery, like the brain of the battery pack. It calculates the State of Charge (the amount of energy remaining in the battery) by tracking how much energy goes in and out of the battery pack and by monitoring cell voltages, which can prevent the battery pack from overcharging, over-discharging, and balancing all the cells voltage equally.

There are two main sets of wires we need to install, the thick wires and the thin wires. The thick wires are your charging/discharging wires and the thin wires are your balance wires. Not every BMS is the same, but most are similar. Your BMS will likely have 3 thick wires or 3 pads to solder on your own heavy gauge wires. These are the B-, P-, and C- wires (or pads for adding wires). We usually start with the B- wire. We can connect the B- of BMS to the negative pole of the battery pack.

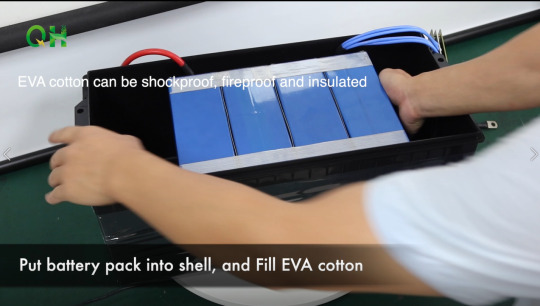

7. Put The Battery Pack Into Shell, And Fill The EVA Cotton

EVA cotton can be shockproof, fireproof, and insulated.

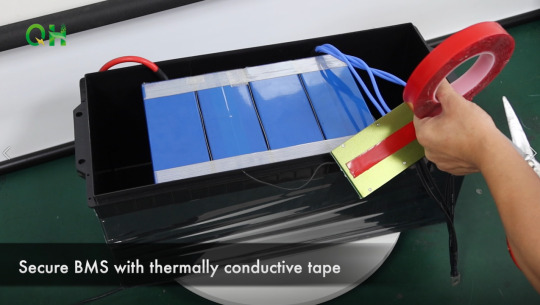

8. Secure BMS With Thermally Conductive Tape

The thermally conductive tape for battery packs keeps the BMS in place and protects them from the shock of extreme temperature changes.

Besides, these tapes provide electrical insulation, which prevents short circuits and provides a barrier to BMS.

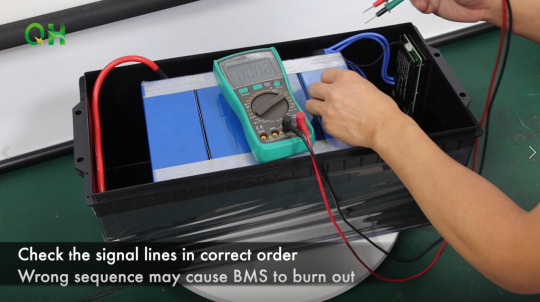

9. Check The Signal Lines In Correct Order

Pay attention, the wrong sequence may cause BMS to burn out!

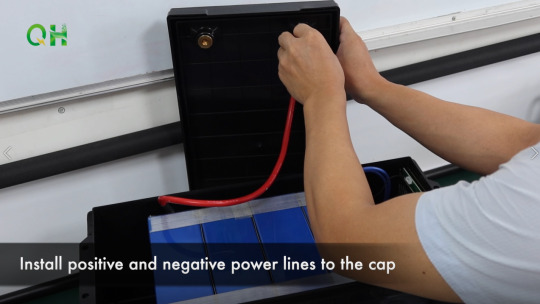

10. Install Positive And Negative Power Lines To The Cap

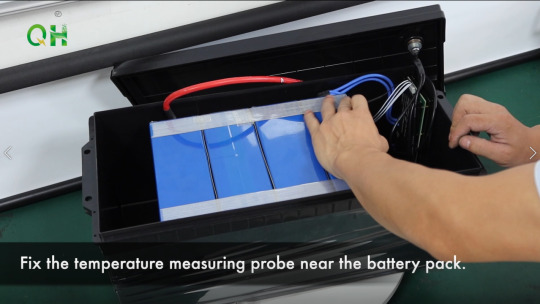

11. Plug Signal Acquisition Wires’ Port Into Interface

12. Fill EVA Cotton

EVA cotton can be shockproof, fireproof, and insulated.

Battery Tests

13. Test Voltage Of The Battery Pack

In these steps, we can use a multimeter to check the voltage of the whole battery pack. Attach the multimeter probes to the positive and negative battery terminals. Then we can check the voltage on the screen. The multimeter’s red probe must be connected to the positive terminal, while the black probe must be connected to the negative one.

A fully-charged battery must indicate a slightly higher voltage than the voltage listed on the battery. For instance, a 12 volts battery will indicate about 12.8 volts when it is fully charged.

14. Charging Test

The battery capacity, or the amount of energy a battery can hold, can be measured with a battery analyzer. If you’re doing a capacity test, be sure to charge the battery until the battery reaches 100%. Then discharge the device until the battery is fully depleted. The charge and discharge rates of a battery are governed by C rates. The capacity of a battery is commonly rated at 1C, meaning that a fully charged battery rated at 280Ah should provide 280A for one hour.

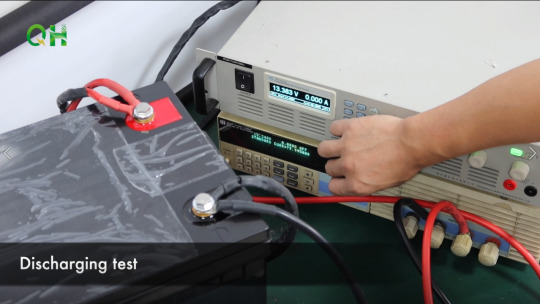

15. Discharging Test

The discharging test of the battery is very helpful to the battery cycle life and discharge performance evaluation. We can use a professional device(Such as a Programmable DC Electronic Load) to check whether the battery works well or not during the discharging process, which can protect our battery and devices for further daily using.

When testing, there are three factors we need to pay attention to the port voltage of the battery, the resistance of the wire between the battery and the electronic load, and the temperature of the battery.

Summary

After assembling and testing the batteries step by step successfully, you will get your new 12.8V 280Ah LiFePO4 battery pack! It is suitable for your golf cart or other applications(such as household solar energy storage, Recreational Vehicle, Yacht, etc.)

Thanks for reading the full tutorial on assembling the 12.8V 280Ah LiFePO4 battery! It is not hard for us to build a LiFePO4 battery. Which voltage and capacity of the LiFePO4 battery do you need?

0 notes

Text

Fanart for @dana-chan-the-control-brain ‘s fanfic tech support: chapter 4 weasel words

The Computer was broken from his thoughts at the sound of high pitched shrieking. His cameras and processors devoted his attention to the distressed little irken in the experiment room. Who was being attacked by the very same weasels he was experimenting with. Apparently, Weasels did not take kindly to having sleep hypnosis parasites planted in their brains.

Zim ran and shrieked and flailed his arms as the little furry creatures crawled all over him, slathering him with bites, claw marks and laser eyes. A quick scan confirmed that these weasels did not have rabies, they were just angry. VERY angry. And aside from Zim’s panicking and mild bleeding from the bites he appeared unharmed. He was just freaking himself out, making the weasels angrier. He was going to seriously hurt himself if this kept up. Even if it was, admittedly, hilarious to watch.

The Computer wordlessly opened up the weasel containment unit without a verbal command.

“Master, contain the weasels in here.”

Zim then slammed the glass door to the containment unit shut. Panting heavily.

Zim peeled one of the weasels off his face, and threw it in the containment unit. He did the same for the one biting underneath his leggings and two others that were chomping down on his antenna and leg respectively.

“Wheeeeeeeeew… ha… that was a close onnnnAUGHHHH!!!”

Zim reached a new octave as he realized he didn’t notice the weasel clinging to his PAK, that had begun clawing the shell, causing a port to open up and began nibbling on wires to it’s heart’s content.

“AHH! NO NONONONONONONONONO!!! GET OUT OF THEREEEE!”

Zim tried to reach behind his back but instead he squeaked and convulsed as his eyes rolled back and his antenna twitched. He spun around in a circle and fell to the floor, before leaning back upright with his bodyweight only. Jerking and moving in an unnatural way. As if he didn’t have control of his own limbs. His arms and legs behaved like noodles as if the weasel was hosting the world’s worst grotesque puppet show. Zim’s tongue rolled out his mouth as his PAK began flashing red as a warning.

Now this was something the Computer WOULD intervene with. A robotic arm descended from the ceiling and snatched the weasel off Zim’s back, and threw it in the containment unit unceremoniously, crashing it into all it’s other bite-happy brethren before sealing them up again.

Zim fell to the ground, moaning and twitching.

Was he alright?

The Computer ran a scan of Zim’s current state. Specifically his PAK. He cross-compared reference to the scan he took on the first day Zim arrived to Earth. He didn’t have time to go over Zim’s PAK data in depth yet. Between GIR’s food experiments and Zim’s animal experiments, he had a feeling he'd be in pretty high demand over the weekends.

“Master,” The Computer began, speaking in an authoritative neutral voice. “Some nerve ending wiring for your arm control nerve is frayed along with your limb systems and several other nerve wirings. I'll plug in and begin an automatic PAK repair as soo-”

“NO!” Zim shrieked, far more panicked then the Computer ever heard him, and that was saying a lot judging by how jumpy he was.

“N-No.” Zim stammered, shakily getting to his feet, swaying where he stood. “There’s no need for an automatic PAK repair… I can do it myself.”

“......I… what? Are you sure? You can barely stand right now.. And your arms are very limp and...shaking....” The Computer couldn’t help but say aloud.

“Ah, Don’t worry, it’s just a little scratch and some loose wires, it’s fine!” Zim extended his PAK legs to walk to the PAK repair work station, as opposed to walking on his little organic legs that were trembling like jelly. Thankfully, that part of his PAK was undamaged as he was able to extend and use his PAKlegs no problem.

“...With all due respect, Master…” the Computer began as Zim leaned his body against the console, trying to figure out how to word what he would say next. “I don’t believe in your current condition that you would be able to repair your PAK manually.”

For a moment, Zim said nothing. He didn’t snap at him immediately like he normally did. Which worried him. He just leaned his head against the console, closing his eyes for a few moments.

“....Master?”

“EH!?” Zim’s antenna shot upwards and he looked confused. As if he wasn’t talking to him a few seconds ago.

That was very worrisome.

“Let me repair your PAK.” The Computer said in the most soft and stern voice he could muster.

Zim’s antenna twitched, as he realized what the Computer was asking.

“Eh.. Ah, no, don’t worry about it! I’m FINE!”

Before the Computer could argue his reasoning some more, Zim turned around so he could face the workbench and detached his PAK onto the work station. The PAK extended a few extra port wires and crawled onto the bench obediently, apparently used to this type of repair from its host. The lifeclock in the Computer’s systems activated, displaying the ten minute time limit in the center screen of every single camera in the home. A normal precaution so Invader Computers were currently aware when the PAK was attached to their Master and if they were at any risk of dying.

Zim arched his back and gave a long stretch that cracked his spine. He took a deep breath as he flexed his arms and claws, and began blinking each eye separately at a time and flexing his antenna individually from each other. The Computer observed him for a few moments. He consulted his database to see if such behavior was common for irkens who performed manual PAK repair. Oddly, there weren’t many instances of manual PAK repair operated by the irken host itself. PAK maintenance drones would repair other irkens typically, but not themselves. Invaders were trained in basic first aid, due to the nature of their job. They had to spend long quantities of time alone, and basic wear and tear maintenance was expected in their line of work.

A few chewed off wires however, that’s a different story.

“...Are you sure you know what you’re doing?” The Computer began hesitantly, suspecting that Zim had no clue what he was tampering with. He can never know with him.

Zim flexed his claws a few more times before he seemed satisfied, and he grabbed the wielding tool from overhead.

“Huh-hmm.” Zim said plainly. “This kinda thing happens all the time.”

“...You…. your wires get chewed out by weasels all the time?” The Computer asked.

“Yes! Well, no. Well.. I just mean… ya know… trainee combat and all that.”

Invader training combat?.... Zim had his wires yanked out of him before? The Computer suspected that was highly unlikely. Due to the nature of an irken’s PAK, and how they held most of an irken’s consciousness and served as a secondary brain to work alongside their primary one, PAKs were strictly off limits from attacking. Especially during training and simulations. In fair duels one of the main rules is to not mess with a fellow irken’s PAK. Everything else is fair game. Punch them in the eye, yank their antenna or grind the heel of their boot into the spooch. Attacking or tampering with an Irken’s PAK is strictly forbidden and would cause low marks and demerits, and in extreme cases, re-encoding.

“...How does that happen?” The Computer couldn’t stop himself from asking.

“Ah, oh ya know how training is..” Zim said distractedly as he began welding and repairing the loose wires. “Stomping or yanking of the PAK to see how long I can last, throwing it back and forth amongst the Elites, hitting it a bit with the brunt of the electro spears a bit too hard…that’s just how it goes. All normal endurance training for only the most elite of the elite.”

…….He was kidding? Right?

"Like this one time during training, my PAK was yanked off and my fellow soilders wanted to see how long I could last, and that skilled Invaders are able to survive past the ten minute mark. Well, my record is about three minutes till. So we waited. They kept it away from me a little bit past my record, one minute was cutting it a little close, but we all had a good laugh about it."

He wasn’t kidding.

“They are just testing to make sure I have the right endurance! They obviously were testing my durability and enguitity! I had to learn a few things about PAK repair if I wanted to complete my Invader training! A few dents and dings like this is nothing.”

.....

The Computer immediately pulled up any information he had based on Zim’s training days as an Elite. He couldn’t find any documented evidence that his fellow elites had bullied him like this, but he did notice the peers he was typically stationed with at the time.

ELITE RED:

SKILLED TACTICIAN AND IMPRESSIVE COMBAT SKILLS

HIGHLY FAVORED BY FORMER ALL MIGHTY TALLEST MIYUKI

CURRENT STATUS: ALL MIGHTY TALLEST RED

ELITE PURPLE

RUTHLESS NO MERCY APPROACH TO COMBAT.

TOP SCORES IN STEALTH

CURRENT STATUS: ALL MIGHTY TALLEST PURPLE

That….

That can’t be right.

That would be impossible.

Logical evidence would suggest that these two were the ones that would purposely mess with Zim’s PAK to give him clear and unfair advantages. However, the Tallest are all powerful and all knowing in their judgements. They wouldn’t have become the Tallest if they were breaking the rules as elites. Even then, while Zim was the runt of his squad, he didn’t deserve such treatment. Either Zim did not know of the protocols or he thought that it was a standard part of training.

But… Zim had to be lying? Right? I mean he’s defective, who knows what crazy thinks?

That’s what the Computer wanted to think. But watching Zim calmly and accurately repair his PAK as if it was normal routine for him suggested otherwise. He’s been at it for about a minute now.

“...Master.” The Computer said lowly and softly, lowering the probability of startling him.

“Hmmm?” Zim responded, laser-focused on his task.

“How are your hands so steady…. You were flailing around with limp arms not to long ago… and your PAK is still damaged.”

Zim blinked up from his work, pausing for a moment before he gave a soft chuckle. It was unlike when Zim laughed loudly to assert his dominance. It was squeaky and soft.

“Silly Computer!” Zim chuckled and he got back to work.

“...Uhhhhh..”

Zim snickered to himself. “You’re a machine, so I don’t expect you to get it.”

What? What was so funny?

“My PAK has been damaged.” Zim then pointed towards his temple. “Not my ORGANIC brain.”

“....I …..”

“Once the PAK is detached, my biological shell draws resources from the organic brain. The nerve endings in those are FINE. It’s the PAK that’s the problem.”

The Computer considered this. While what Zim was saying was true, most irkens didn’t tend to view themselves as a disconnect to their PAK. It was a level of heightened awareness not many had achieved. If an iken’s PAK was damaged, it was common they would still experience pain once it was detached. There were many reports of a PAK being damaged, the PAK thinking that it’s host has broken a leg, and once the PAK was removed, the irken biological shell would still feel as if their leg is broken. Only PAK technicians had this level of understanding on how the PAK brain and organic brain co-exist together.

“You know, for an Irken super Computer, you’re not that smart if you forgot how PAKs work.” Zim snickered.

Oh that little…

“I have not!” The Computer huffed. “Just seeing this level of competence from you is shocking.”

“I know, I know. I am truly amazing!” Zim beamed. Apparently not absorbing the Computer’s insult. Probably for the best.

“Now silence! I need to concentrate.”

The Computer remained silent as he watched Zim work. Zim's hands worked efficiently at a pace that showed he was comfortable making these types of repairs.

Even so, an automatic repair would be faster and more efficient. The Computer took into consideration the stress patterns in his voice and heart rate when he thought he needed an automatic repair. In addition to his reluctance to being scanned or his PAK being scanned.

…...So, he knew he was defective then?

That had to be the logical conclusion. Only Defectives tended to get nervous about PAK fiddling or PAK repair. Although, observing his Master's hands, Zim had no qualms with repairing himself. Due to his intense focus and efficiency, it could almost be described as therapeutic for him.

Then was it the Computer himself he was afraid of?

There was still too much insufficient data for him to make a logical conclusion at the moment. But he will take Zim's comfort in mind when he eventually needs to consult him about PAK and biological repair in the future. Because let's face it, Zim will hurt himself again.

/////////////////////////////

this part made me very emotional, and also made me hate the tallest even more

34 notes

·

View notes

Link

Metal Fabrication Melbourne is one of the biggest providers of specialized metal fabrication services across the nation. It is renowned for its expert metal fabrication capabilities and is considered as a leader in the industry. This company is dedicated to providing customers with the best quality services at an affordable price. The company strives to maintain high standards of consistency, innovation, quality and value. They also provide services at an economical cost that is friendly on your pocket.

The Metal Fabrication Melbourne Company has a wide range of Metal Fabrication products to offer its customers. The highest quality sheet metal fabrication is used by this company. The highest quality steel and alloy fabrication is used by the company. The company uses the latest techniques and methods to ensure that you get a product that is made to your exact specifications.

Stainless steel fabricators are located in Australia's manufacturing hub. They are world-class professional metal fabricators and offer a wide variety of services. They also offer the perfect solution for customizing products. They provide the highest quality products to their customers at competitive prices. The company offers an extensive range of stainless steel and alloy fabrication, hot dip galvanized finish, precision edge drilling and many other services. They have a very strong and deep understanding of metal fabrication and know how to make every project a success.

This is a very reputable company that provides services like handrails, stainless steel, precision edge drilling and a variety of other requirements. They are very much experienced and committed to making sure that they create a perfect product for any upcoming project. They have designed and created a handrail system to suit not only the Victorian building market but any other high-rise building. They are fully dedicated to creating the most superior quality construction and finishing products that are made from sheet metal. They use the latest laser and computer technology to ensure that the client gets the best value for their money.

They have the most advanced machinery and tools, and use them constantly to make sure that their customers are satisfied. This includes all types of stainless steel construction, handrails, stair cases, balconies and a lot more. They also have a huge selection of accessories and fixtures, stainless steel balusters and handrails to name just a few. They manufacture all of their own products right here in the united state so you don't have to worry about having to wait on the supplier to get parts or materials. They will get you finished in no time.

Metal Fabrication Melbourne can offer you everything you need for a beautiful new office building including custom doors, balustrades and even sky lights. Using the latest metal fabrication services in Melbourne means that your company will have the ability to serve its clients in style. Whether it is a hotel that needs a face lift or an executive office complex with multiple levels the experts at Metal Fabrication Melbourne will be able to address all of their needs.

Some of the custom metal fabrication services that are offered in melbourne include: metal balustrade systems, handrails and girders, stainless steel fittings, guttering and roofing, stairway handrails, and more. These custom made products make your clients feel like they are in a posh, luxurious residence when in fact they are in a warehouse. They also come in a variety of sizes and colors to match the architecture of whatever you may be constructing.

Metal Fabrication Melbourne has grown into a nationally- renowned metalworking and finishing company that produces custom and unique metalworking components for industrial, residential and even commercial applications. They have many years of experience in creating and designing a variety of handrailings, balustrades and girders. If you need some help or are looking for a great product to use as part of your current or future projects simply contact Metal Fabrication Melbourne. They will be more than happy to assist you with any questions or requirements that you may have. You can take advantage of their custom stainless steel detailing, custom stainless steel balustrade and stainless steel handrail systems, and the benefits of a well-designed and built wooden or steel girders or handrails.

#Commercial Building Maintenance#Engineering Maintenance Solutions#Steel Welding Melbourne#Steel Fabrication Services

1 note

·

View note

Text

Heres a wip of a sequel.

Dmviolence, by jade

Hello, if youre hearing this, it probably means im dead. Either that, or im alive and just got tired of keeping this hidden. You might remember my voice from a previous recording about a takeover in sector ⬽:➻, in which id helped prevent total annihilation of the sector. At the time i was unnamed, however now you may call me Kalton. After the takeover i resigned and moved to a job at a dmv. This planet was, for some reason, in one of the most tactically advantageous locations in the galaxy. And for some reason the higher ups dedicated the whole damn planet to dmvs. Dont ask why. Now, onto the story.

I woke up, and i put on my emerald green contact lenses. Just like any other day. I put on a basic white t-shirt and a leather bomber jacket along with a pair of jean shorts. If you cant tell by now, im gay.

I live in a small apartment. By small apartment i mean a bedroom, a bathroom and a kitchen all crammed into 2 rooms. I hopped out the bedroom window onto my motorcycle. It was a diamond white motorcycle with deep red stripes along the sides and the handlebars. My pride and joy. I put on my jet black helmet and took off towards my job at the, you guessed it, dmv.

Chapter 2

I pulled up in the parking lot and took off my helmet, my blue hair a total rats nest. The doors were push doors, yet i somehow ALWAYS pulled first. I entered the dmv and went to my station. A few hours passed by and no one had come in yet, which was unusual. So naturally i decided to sit down on the floor, put in my earbuds, and enjoyed some heavy metal. A few more hours passed by, and usually by now i wouldve been yelled at by my boss. This struck me as odd so i stood up. I really wish i hadnt stood up. The place had been completely destroyed. There were drop pods crashed in through the roof and they all had the ERGON logo on them. Ergon was a multi trillion dollar pencil manufacturing company with its own military. They had previously tried to take over sector ⬽:➻ when i had been working there. I was not looking forwards to what was about to happen.

Quickly, i ducked back onto the floor before anyone saw me. There were 4 riot soldiers holding this building. This was gonna be fun. The riot soldiers are your stereotypical riot gear and police baton soldiers. But these guys had laser batons and the riot gear gave them heightened strength and speed. They also had some, dare I say, shitty energy pistols. I crawled over to one of the soldiers who wasnt being watched and broke their neck. Carefully I took the baton and the pistol. Slowly crawled my way back to my station and checked the shot count in the pistol. I had 6 shots, just enough to take care of the remaining three soldiers. I stood up quickly and shot each soldier twice in the head. First shot to open the riot helmet, second shot to kill. I vaulted over the counter and grabbed the three pistols. These things were so stupid. You couldnt even remove the clips. Once you ran out of shots, the pistol was useless. Nonetheless, i didnt have any choice. I had a laser baton and 18 total shots in 3 pistols.

Upon leaving the building, my motorcycle was one of the few things to survive. It had alot of scratches and damage, but it still worked. The helmet was shattered however. I mounted the motorcycle and took off towards the next closest dmv. Maybe id find some better gear there.

Chapter 3

Pulling up next to the second dmv i immediately noticed 3 things. 1: there was blood everywhere. 2: there were 25 soldiers here. And 3: they all had energy weapons. The reason these things are relevant is because energy weapons dont cause bloodshed. This was the result of something else. Something new i hadnt dealt with yet.

I drove up and ran over 5 of the soldiers. This was probably an incredibly bad idea, seeing as i had 18 shots, enough for 9 kills, and there were 20 soldiers left. Every single soldier turned to me and i, being the absolute genius that i am, welded the front of one of the pistols shut with the laser baton, shot it off, and threw it into thei crowd of soldiers. It exploded, releasing a shockwave of energy and disabling the soldiers. I then used the baton to cut through the riot gear and kill the soldiers. I felt like a badass. That is until a mechanical looking wolf jumped at me and started trying to rip my face off.

The wolf was a frostwolf, except it had been placed into a mechanical frame and its teeth and claws had been replaced with lasers. I tried to bash it off of me with the baton but it just bit it in two. This gave me just enough time to grab an energy pistol and shoot the wolf. It kept trying to kill me amd i wasted a whole clip on it until suddenly, the dog started to levitate in the air and got thrown aside into a wall. I got up and was instantly frozen in place. Thats when.. she walked up.

Chapter 4

The she i am reffering to is ebony. A goth/punk wannabe with light blue tear shaped eyes and black hair with purple streaks. Shes a bitch whos mind got too powerful and now she can move things without touching them. Shes been chasing me for months. Not in a murderous way. Shes just obsessed with me. Ive tried to tell her im gay but she wont listen. And now im at her mercy.

She walked up to me and kissed me on the cheek. I hated it. She looked as if she was contemplating whether or not to free me when a pod came down from the sky and crushed her. Thank god. But i honestly wouldve rathered suffered at her hand than deal with what i had to deal with next...

Out of the pod came the warden. The goddamn warden from sector ⬽:➻. Last id seen him hed been in the same situation as ebony. Crushed to death under a pod. But this time, instead of being on my side, he was here to kill me. He was huge. Like seriously huge. He was at least 8 feet tall and shaped like gaston. Whos gaston? Nobody knows these days. But its basically a way to say "extremely buff and wide". Back to the story. The warden wasnt looking very good, considering the rotten skin, obviously quickly patched together face, and muscles hanging loose out of his skin. His rotting ruined body was held together by an exoskeleton of chromium-tungsten alloy. Nothing i had was gonna cut through that. I was gonna have to get creative here..

The warden had 2 weapons, both of them were his fists. Huge gauntlets that were each about the size of a cow. Definitely bigger than his previous set. They were a golden green metal i couldnt identify. But i didnt want to get hit with one to try and find out. I ran. I ran as fast i could run into the dmv and hid. I could hear the wardens footsteps. It was as if a small earthquake happened each time he took a step.

I peeked over the desk i was hiding behind and saw him punch through the 2 desks opposite to me. It took no effort and i couldve sworn i saw him smile. Obviously i didnt. Cause he didnt have a mouth anymore. But if he did, he definitely wouldve smiled. I took a shot to get his attention and ran off towards the wall. The warden was definitely faster than i expected.

Luckily i managed to dodge the blow by a centimeter. The metal smelled of decaying flesh and popcorn. The wardens blow punched a huge hole in the wall. I hope you see where im going with this.

I ran off to another wall and we repeated this same process a number of times until the building was barely still up. I ran out the doors and threw the baton at the last of the supports, cutting through it and causing the building to collapse in on the warden. He wasnt getting out of that. I decided to search the rubble to see if i could find anything worth taking. I found a new baton, a flame rifle and a few more energy pistols.

The flame rifle was a very interesting design. The sides were painted jet black with flame decals scattered about. You could feel the heat on the inside and it made the gun warm to the touch. Comfortable to hold. Other than that though, it looked like an old fashioned 8.59mm sniper rifle. It had 4 shots remaining, so id have to use it sparingly.

I grabbed some scrap materials out of the rubble to make a holster for it and put it on my back.

The energy pistols just dangled from a keychain. The baton was simply turned off and placed through a hole in the back pockets of my shorts. I ran to my motorcycle and drove off, i needed to find out more. I had questions, and i had a sneaking suspicion that i knew where to find the answers.

I drove off again, i was dirty and there was blood on me and my bike. I probably looked like a serial killer. But i knew that if anyone was still alive, itd be jayden. They were.. well. They were a vampire. They lived in a swampland area and wore sparkly rainbow shirts and a huge sunhat. The sunhat allowed them to go outside in the sun, and they only drank coconut water. They also had a crazy amount of weaponry and used to work at ergon, before being fired for stealing weaponry. By the way, if you havent noticed by now, im using they/them to refer to jayden. Jayden doesnt have a gender. Jayden.. is kind of my crush. It probably has something to do with the fact that theyre the only person on this planet who talks to me. Other than ebony.. but ebony is... not my type i guess. Anyways, back to jayden. Jayden was on the roof of their swamp shack drinking coconut water out of a wine glass. I yelled up at them and they fell off the roof onto my back. I guess i cushioned their fall. Jayden immediately said "What do you need dear" without waiting for me to stand up, and shattered the wine glass. I informed them of the situation and asked the questions i had. Things like "what are the ergon soldiers defences like on their ships" and "how did they reanimate the warden" they had answers.

Jayden told me about the new security measures that had been put in place since id last been on an ergon ship. There was now a code for each teleportation pod and the gaurds had doubled. As for the warden, it turns out jayden was actually the first test run in reanimation sciences, and couldnt answer me because they had been unconcious in a lab when the warden was reanimated. That explained the vampire undead thing. Jayden invited me into the shack where they pulled a nail out of the floorboards and it turned into a ramp to the basement. Down in the basement? Thats where jayden kept their weapons they stole. And boy oh boy were there some interesting ones.

One that immediately caught my attention was the big rocket launcher. It had 3 barrels and each was a different colour, indicating a different effect. One was red, one was yellow, and one was green. The red barrel fired a normal explosive rocket, the yellow barrel fired an electromagnetic pulse rocket, and the green barrel fired an acidic explosive. And the launcher shrunk down to the size of an energy pistol when a button was pressed. It gathered up dirt and dust and garbage around it from the back to quickly convert into ammo but the only downside is that it would be difficult to use more than once in an area.

Jayden picked out an old shotgun. At first i didnt understand why, but then they loaded the clip. The clip was a huge drum that loaded in the bottom of the barrel. The drum was see through and inside you could see sawblades lined up side by side. When they pumped the shotgun a blade got lifted into a slot between the 2 shotgun barrels and started glowing red. When the trigger was pulled, the blade spun at high speeds and fired out of the slot, spinning along the ground like a wheel. It could cut through anything a baton could cut through and seemed to almost follow its target. The gun itself looked like an DP-12, except behind the pump, a large clear drum full of sawblades was in place. The blade sat between the barrels in place of the iron sights and got heated up by an electrical circut.

I also took a laser sword instead of my baton, it was just like the one that [3825968] had, except this one was about an inch longer. The final weapon i took was an acid thrower. It was basically just a watergun with acid in it. Ive always been partial to acidic weapons. If youve heard my other story, youd know why..

Jayden also took a submachine gun that fired freezing rounds. The rounds were essentially glorified waterballoons with liquid nitrogen in them. Though the rounds were bullet sized, enough shots from it would certainly freeze you in place. The freeze gun was about the size of the average human head, and was painted navy blue with blue saphire stripes placed along it. We both left the shack, me with my sword and jayden with a wine glass. We were ready to kick ass and put a stop to this.

We left and immediately both got flung into some trees. Guess who it was. It was ebony. Her body had been found and reanimated. I was starting to see a pattern. And now we had to fight the telekinetic who could kill us with a wave of her hand.

She was levitating. Her eyes were glowing red and her hair was floating in the air. She had a smile of someone about to rip your arms off and beat you with them. I tried to take a shot at her but my hand got knocked aside by an invisible force. So i tried the next best thing. Seduction. Fake seduction. Hopefully the whole dying and coming back from the dead thing didnt make her stop being weirdly obsessed with me.

While i faked surrender and complimented ebony and attempted to seduce her, jayden took aim of their ice gun and shot a burst at ebonys right arm. The arm froze in place and shattered. Hopefully that would lower the strength of her telekinetic abilities. It did. But only by about half. Which meant jayden got thrown into the air as i tried to discreetly unholster my acid gun. It wasnt discreet enough and the gun was knocked from my hand.

The gun flew forwards and the impact of hitting the ground set it off for a second, just enough to spray an acidic burn through her arm. Incapacitating her. Jayden ended up sneaking up behind her and impaling her through the skull with the shattered end of their wine glass. Finally ebony was dead for good.

The acid gun was busted, so we had to leave it behind. We got onto my motorcycle and took off towards my apartment building. We would need food if we were going to be traveling. An apartment complex would probably be full of foods, and alot of dead people who wouldnt care if we took some stuff.

1 note

·

View note

Text

Application of high power semiconductor lasers welding

With the development of laser processing technology, high power semiconductor lasers have gradually emerged, and are regarded as a new generation of laser light sources together with fiber lasers, ultrafast lasers, disk lasers, etc., making many important applications possible. Listen to High power semiconductor lasers exporter Dershine to explain the application of high power semiconductor lasers welding for you.

Compared with other lasers, high power semiconductor lasers have incomparable advantages, such as small occupied space, simple structure, stable system, and long service life; uniform energy distribution, high photoelectric conversion efficiency, and high light absorption rate of metal materials It realizes the characteristics of automation and is widely used in metal material processing.

High power semiconductor lasers have been widely used in metal material welding due to their excellent performance. Because of its large light spot, uniform beam quality distribution, and high absorption rate of metal materials, the molten pool is stable, with no spatter, and the weld surface is smooth and beautiful during the welding process. welding.

1. Laser spot welding, seam welding

The semiconductor laser spot welding process is thermal conduction welding, which is achieved by adjusting the laser power and radiation time to melt the metal material. Due to the uniform distribution of the spot energy, the laser energy can be slowly decreased and the gradient can be realized, thereby solving the problem of porous porosity caused by the collapse of the pseudo-keyhole at the end of the spot welding seam.

2. Laser continuous welding

The semiconductor laser can form a keyhole effect in the continuous welding process and has a strong penetrating ability. In continuous thermal conduction welding, the welding process is stable, the surface is smooth, the shape is beautiful, and the welding seam section is semi-circular, which can realize the welding of metal sheet structural parts (butt welding, lap welding, fillet welding, etc.), and the welding seam width can reach 3.5mm; during continuous deep penetration welding, the welding process is stable, spatter-free, and the weld section is Y-shaped. The strength after welding can meet the requirements of the workpiece.

3. Double beam laser welding