#bio-integrated electronics

Explore tagged Tumblr posts

Text

Unlocking the Power of RTC Batteries: Timekeeping and Beyond

In the vast landscape of electronic devices, there exists a diminutive yet essential component that quietly upholds synchronization and stability – the RTC (Real-Time Clock) battery. While its primary purpose revolves around timekeeping, these unassuming power sources play a more profound role in maintaining vital settings, preserving data integrity, and enhancing device functionality. Let’s…

View On WordPress

#BIOS settings#data integrity#device functionality#device security#electronic devices#power sources#Real-Time Clock battery#replaceable batteries#RTC batteries#timekeeping

0 notes

Photo

Dubai to London: 1985 BMW R80GS by @greasy_hands of @caferidercustom, built with one main purpose in mind: "Build a solid, reliable, good looking motorcycle that could be ridden from Dubai all the way to the UK without issue." Highlights include a rebuilt engine, custom subframe with integrated pannier rack, aluminum auxiliary fuel tank, Motogadget electronics, larger battery, upgraded regulator-rectifier, an enclosed phone holder / charger / USB port integrated into the fuel tank, and more. Photos: @sidpandey1. Full story today on BikeBound.com. ⚡️Link in Bio⚡️ https://instagr.am/p/CvM8jsSukAD/

112 notes

·

View notes

Text

Flexible, permeable and 3D integrated electronic skin combines liquid metal circuits with fibrous substrates

In recent years, research teams worldwide have been trying to develop new flexible and soft electronics. These devices could have various potential applications, for instance helping doctors to monitor their patients' health conditions or supporting rehabilitation and performance sports. To be safely and comfortably worn by users daily, these devices should be permeable (i.e., based on breathable materials that allow liquids and gases to pass through them). They should also be bio-compatible (i.e., safe to be worn on the human body for long periods of time) and strain resistant, meaning that they do not break easily when stretched or pulled in a specific direction. Researchers at the Hong Kong Polytechnic University and other institutes in China recently developed a new intrinsically permeable, 3D integrated and flexible electronic skin. This e-skin, presented in a paper in Nature Electronics, is based on high-density inorganic electronic components placed on organic stretchable fibrous substrates.

Read more.

12 notes

·

View notes

Text

DC Comics highschool AU where Bruce 18 and Harvey 18 are the golden twins (lovers) of the football team, but after an injury, Harvey is replaced with that nerd from smallville who's in the school's newspaper, and he's able to make Bruce cheer too !

Grrr

So Harvey's integrating the cheerleaders (and debate) team to stay close of the field and his mentor is the girl rumoured to be the great grandgirl of the last Chinese Emperor Talia Al-Ghul.

In this AU, there is an unofficial club of heavily mentally scarred gothamite kids, you know who i'm talking about, and they have been adopted by the Golden Twins (lovers), so better not mess with them.

Everybody knows Dick 17 , he has to settle down in Gotham when his parents died and social services were looking for a solution, Alfred Pennyworth took him in, he was there with Bruce that night. Captain of the gymnastic team, no enemy guy, the only one able to shine brighter than Harvey. Someone tried to mess with his girlfriend once, Kori Anders, apparently he also learnt muay thai on the road.

Jason Todd 16 , Stephanie Brown 15 , Duke Thomas 14, Harper 16 and Cullen Row 14 can't and won't deny coming from Park Row, sorry, crime alley, Duke is actually from Bristol, but you know, nuances are too complicated. They met each other in foster system and Dick too.

One day, when the orphanage was running very low on money, Jason appeared with multiple bags of food. The others thought he was joking when he said he stole the 4 wheels of the mayor's Bentley, when he, Jacob Kane, came with the police they weren't joking so much.

Long story short, they are Kane's wards now, it's was a package deal.

Jay and Duke are making the glorious hours of writing club, Jason would like theater and Duke chemical but Jacob made them pick a sport, Jason was kind of forced to go to the football defensive team, (Jake didn't digest the L against Metropolis in 86) and Duke for the running team. As fast as light.

Steph is Lois Lane's right hand for the school's newspaper, she's running their social medias with great sucess and is the head of gossip departement. Clark is the left hand for the investigation departement. She won against Jason, Harvey, Clark and others *wink wink* the biggest eater contest. She's now a subject for the quantum physics club.

Harper leads the electronics club, the school still remembers when her dog sized spider drone was unleashed. She's also in the kickboxing club.

Cullen is vibing in the theater and art club.

Kate Kane 18 can't stand all the dumbasses above but if she has a dream where you are glaring at them she will break your knees. Her father wanted her to do ballet, she's doing music and kickboxing. Bullying is her love langage.

Tim Drake 15 is a little genius coming in HS at 12, a unique feat until a certain someone from middle east came to school... He's driving Edward Nygma insane by solving all his riddles, photography and and electronic club. His parents are rich but always absent. 7 years ago, Alfred invited him for thanksgiving, never really left since.

Damian Al-Ghul 13 and Cassandra Wu-San 16 are cousins, they are not related but their family have known each other forever and Cass was there the day the demon spawned. Damian is Dusan's Al-Ghul son, who's 30 years older than his little sister Talia, the two are really too much well trained in martial field to be normal. Damian's is leading the escrima club.

Cass, despite being mute, is leading kickboxing club, noboby ever won a round against her. In the entire country. Except for her big sister Sandra Wu-San, also known in professional wrestling as Lady Shiva, who could give her a draw. Also she can't use technology to save her life.

The Wu-San are the adopted daughters of Dinah Drake (second cousin of Tim) and Ted Grant, a former world heavyweight boxing champion and a professional wrestler known as Wildcat. Together they have a bio daughter, Dinah Jr Laurel Drake-Grant.

A girl, Selina Kyle 18 claims she's not related to them but still has a permanent room in their house if she wants to come. Teddy met Jacob Kane in the army and were deployed in middle east together, he found his girls in some destroyed village in the Middle East and resigned right after.

Talia and Damian are from one of the oldest Asian family, and very old money. Some argues that was their family who created the first philosopher's stone. Their grandpa being the only person on Earth from the XIX century still alive is not helping. Ras wife's family helped the Americans in the Middle East that how he met Ted and Jacob.

Talia 18 is in the cheerleading club because of her HUUUUUUUGE crush on Bruce Wayne, best grades ever everywhere. Wants to become a vet.

Nyssa 17 Al-Ghul is in the kickboxing club and write her secret stuff just for her.

Barbara Gordon 17 is the daughter of the commissionner, someone shot her, she's paralysed. She's the captain of wheelchair basketball and in the electronics. She's a godess at armwrestling. For real she's an hydraulic press. She's really close of Dick Grayson and maybe she has adopted Steph, Cass, Harper as hers. Her own pose in school is with Dinah Laurel and Helena Bertinelli.

She's very competitive and will take very badly if Tim is just behind her again at the Olympics of hacking this year.

Diana 18 (who is at least as tall as Clark, i'm right on this) is leading the wrestling team and history club, she's a exchange student from Greece from a monastry where men are forbidden as a diplomatic move with her sisters. (in reality the opposite exists, for real). Her accent makes every boys and girls fall for her. She has a very strong sens of justice. One day she saw Bruce and Clark, not even talking together and..."Your mine now ! We're having tacos tonight !" They knew they couldn't negotiate.

Ollie Queen 18, everybody knows he will go to a board school one of the four (three) true childhood friends of Bruce Wayne. Captain of the archery team. Came with his own crew, all in the team. Desperatly in love with Dinah Jr.

Zatanna Zatara 18, her father was a close friend of Thomas Wayne, she's on a very good way to become a magician herself. One of the four (three) true childhood friends of Bruce Wayne. Leads theater club.

Hal Jordan 18, wants to become a jet fighter, obsessed with construction games. Mathematic club and running team.

Kendra Saunders 18, also known as Hawkgirl, because the week-end she's doing BASE Jump.

John Jones 18 and his half-sister Megan Morse 17, they are refugees from oversea after a coup. They love the special effects in movies and theaters so they are is this club. They came with

Kori Anders 17, princess in exile of Tamara, she's a really sweet girl so the school asked their sweetest student to guide her through her new life : Dick Grayson. Nobody knows how she mastered english in so little time. She had troubles with the differencies beetween the two countries. Everyone's favourite. Hurting, even a little Kori is declaring war to the whole school. She's also taller than anybody and very muscular. She kinda adopted Jason ?

Rachel Roth 14, is the daughter of the King of Azaroth, nobody really knows where it is. She's in the meditation and spiritual club. The only one allowed to hug, kiss, and touch her is Kori. The constant barking with Damian Al-Ghul can't only be hatred.

Donna Troy 17, Cassie Sandmarks 15 and Artemis Grace 16, they came with Diana. They all had a "Oh my god, he's so pathetic, I love him." With a Gotham Boy. They are all very tall and strong and in the weightlifting club.

Clark 18 and Jon 14 come from Smallville and are, 1) the sweetest guys ever, 2) fucking STRONG, there is a video on the differents groupchats of them, lifting the school gargoyle after a storm. Maybe farm strenght isn't the only explanation.

Kon 15 and Bizz 14 are from metropolis, Ma Kent's sister married Papa Luthor and they had Lex and then one rebelious and one albino with a speach impeachement, who is also the size of a polar bear. But, beware, Bizz is Jason Todd and Artemis love child. They haven't really figured yet what they want to do. Bizz is in special class with Cassandra Wu-San so you can regulary see her on his back giggling.

Linda 17 and Karen 18 kent, cousins of Clark by Pa Kent came back in town a few years ago after they lived their whole life in California. Linda is in the well-being club and liked by everyone. Karen is more on the amazonians side of the force and can't help herself but have homoerotic sparring with any strong woman on sight.

Dinah Jr Laurel Drake-Grant 18 embrassed her mom legacy and already took the mantle of Black Canary and can already put stages on fire. Her perfect figure must not makes you forget that she can beat your ass in seconds because she's in the kickboxing club too. Probably why Ollie is so in love. If you ask her if she's single, she would either tell you to fuck off if dhe doesn't like you or tell you she's already married with further explanation. (Could be either the stage, or Barbs and Helena).

Roy Harper 17 is in the archery team and music club with Dinah, nobody can sing the country and blues like him. He kinda adopted Jay with Kori too. Him and Jay made a pact to quit alcohol and drugs after they had a bad trip together on a joint in the toilet at a party together.

Lian Harper 14 is his little sister and will stay single until she's 30, at least. Well, everyone on the Arrow Team would like that. She loves hanging out with Dick and the others. Archery team too.

(I don't actually quite know a thing on the rest of the team, but they are there and well.)

The Allens all have their buddies too and are putting the race tracks on fire. Their father Jay Garrick holds multiple records of speed and gold medals. But not for long to his hapinness.

The Curry family comes from the islands in pacific ocean and are setting new records every years in swimming competition. They are all in bio courses to study marine life.

Harley Quinn 18 went in school with Bruce after his parent's murder, saw him sad, and never left him. One of the four (three) true childhood friend. She won't follow any rules but she's not a bad person. Wants to help everyone with their mental health, got a pretty big tik tok account and instagram on this topic. Her ex boyfriend, Jack, made her do bad things. But her (girl)friends Pamela, Selina and Bruce and a few others (all the people above) quickly talked to him. (Alfred signed a 100 000 dollars check for surgery)

Pamela Isley 18 leads the botanic club, she doesn't like people, like at all, would talk to grass but not you, she only started to like her figure when Harley couldn't stop ranting about her "water melon boobies" and "starship butt" in PE's locker room . Anybody else would be dead, but...It was Harley ? And Selina was laughing her ass off.

Selina Kyle 18, aka Catgirl because she's always wearing stuff with cat, her bagpack, cat ears, cat make up. She has a super model walk and won't accept shit from anyone. She wants to be a vet with Talia.

Jack Napier : still in the coma. AKA Joker, a nickname gained in jail for minors.

Thomas Eliott 18, the minus one true childhood friends of Bruce Wayne, wants him dead. Jealous that he had his inheritance before him.

(I spent 4 hours on this. Why ? BECAUSE I'M BATFAN)

#batman#batfamily#arrowfam#barbara gordon#bruce wayne#batgirl#damian wayne#dick grayson#jason todd#joker#black canary#high school au#superman#superfamily#stephanie brown#harper row#duke thomas#cassandra cain#lady shiva#kate kane#selina kyle#talia al ghul#brutalia#bruharvey#superbat#harlivy#gotham city sirens#dinahbabs#wonder woman#justice league

37 notes

·

View notes

Text

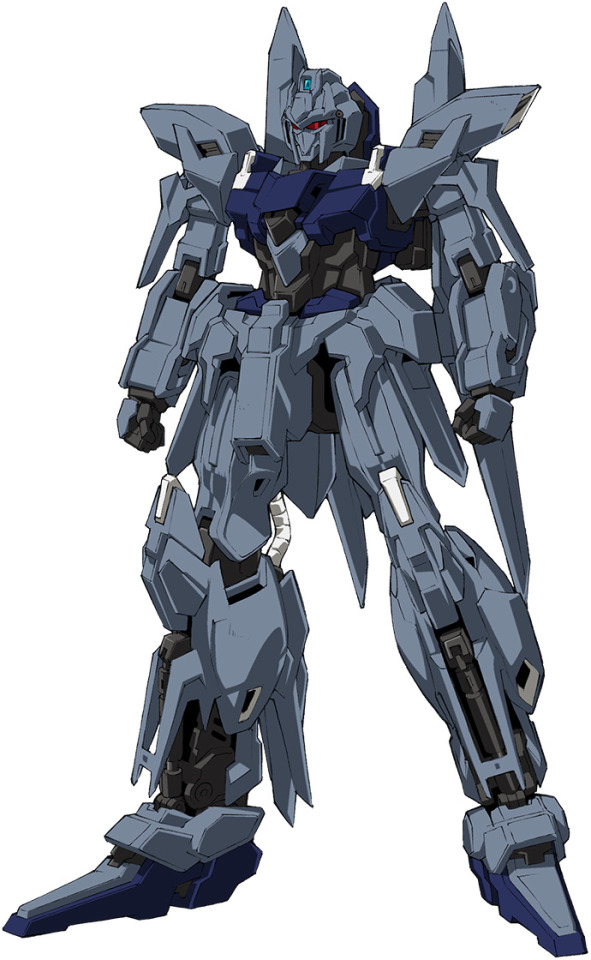

Seeing as I’ve recently finished the model kit, let’s discuss the Delta Gundam today.

I’m specifically going to be talking about the design and it’s variants. What I’m not going to be talking about is the Hyaku Shiki, and it’s variants, since those are a whole separate topic I want to cover at some point, though I will be comparing to the base Hyaku Shiki at times.

So, the Delta Gundam is the original prototype design to the Hyaku Shiki (or at least close enough there’s little difference). Had it been built it would have been one of the first transformable mobile suits of the Gryps war. However, the frame suffered from structural issues, so it was instead completed as the Hyaku Shiki, which would be piloted by Quattro Bajeena (Aka Char Aznable) during the Gryps War. It’s one of the few mobile suits that we know for a fact was never built (at least at the moment) and is arguably the closest Char ever got to piloting a Gundam-type mobile suit (discounting the Mk-II heist at the start of the Gryps war).

I think it’s honestly gorgeous, for being the in-universe first crack at third-generation mobile suits. A lot of the design feels very Zeta-esque to me, but it’s got more heft to it comparatively (probably because of the wing binders). I absolutely love the head, it just looks so sinister and it contains the same IDE (Image Directive Encode) system that made the original Hyaku Shiki such a good sniper. The rifle is also very nice, it’s got a very gryps-era design, but it somehow feels fuller and deadlier. The Delta Gundam stores it’s beam sabers in its shield, where they also function as beam guns. Honestly, I forget about this feature a lot simply because that’s something that was more common during the Neo Zeon War, and it makes the Delta Gundam feel overarmed to me. It’s just such a lovely blend of the Zeta, Hyaku Shiki and Mk-II, which were fairly light on integrated weaponry. The design also feels considerably more contemporary - it’s officially part of the Gundam Unicorn MSV, despite it being in-universe from the Gryps War, so it’s possible that this is an in-universe “refined” concept. The comparatively simple design also makes its unique features (the wings, the head, the gold) pop more.

The Delta Plus.

The Delta Plus is a limited production suit built by Anaheim Electronics based no the original Delta Gundam. It’s essentially a mashup of the Delta Gundam and the Zeta Plus series. Compared to its predecessor, it trades the golden Anti-Beam coating for heavier firepower and a transformation system that actually works. It’s also equipped with a simple bio-sensor for use by newtypes.

For Armaments, it retains the Vulcans, Beam Sabers (and thus beam guns) and (now-optional) beam rifle of its predecessor, while it gains a 2-barrel grenade launcher and besm cannon, both built into the shield. Additionally, it was equipped with a Long Mega Buster, first used by the Full Armour Hyaku Shiki Kai, as standard armament. Why is this important? Because the Long Mega Buster is essentially a handheld version of the Original Hyaku Shiki’s Mega Bazooka Launcher, giving the Delta Plus significant firepower compared to its predecessors. It would be piloted by Riddhe Marcenas during the LA+ Incident (or Third Neo Zeon War).

So what do I think about it? Ehhh….. I don’t really dislike the design, but it’s just a little drab. It suffers because I like both the Delta Gundam and the Hyaku Shiki, so despite the armament increase, the Delta Plus just feels like a downgrade. I like the Zeta Plus series, which the Delta Plus takes obvious influence from, but the problem is that I like them because they have a soft, rounded, aerodynamic look compared to the sleek, angular nature of the original Zeta Gundam. The Delta Plus is just more lines and angles, it feels too different from them from a design perspective. There’s also it’s usage in the story, which I want to talk about.

Okay, I understand why Riddhe’s in Unicorn. I understand who he is and what he represents so I don’t really have to like him, per se. I view him getting the Delta Plus as shorthand for “he’s an important character now, pay attention” and because people like the Hyaku Shiki, he gets a suit based on that. Problem is, other than being able to independently enter the atmosphere (*cough* Ballutes *cough*), I don’t really see what the Delta Plus adds that wouldn’t be provided by a ReZel. I’ll admit this is partially because I’ve been coming around to liking the ReZel a lot more lately, but I just don’t think the Delta Plus adds much. The Delta Plus is eventually absolutely mauled by the Banshee, and while it’s a pretty good “death” scene, it’s destroyed functionally so Riddhe can get a new suit. I mentioned it contains a simple bio-sensor before, but despite Riddhe’s newtype potential, I don’t think it ever comes up in-series.

The Gundam Delta Kai

A thoroughly upgraded Delta Plus, designed as a next-gen demonstration machine. It’s essentially chock-full of fancy weaponry and experimental systems.

Honestly, it’s equipped with a lot of optional weaponry that I wasn’t aware of, so I’m just going to be focusing on its “basic” loadout here (IE What’s on the model kit). It’s equipped with Vulcans, Beam Sabers (which again double as beam guns), a Long Mega Buster (as with the Delta Plus), a High Mega Cannon, built into the shield and based on the ZZ (though with the output ratcheted back quite significantly), and finally, some proto fin funnels swiped from the Nu Gundam’s development. It’s also equipped with the n_i_t_r_o system, which temporarily enhances a normal pilot into a cyber Newtype and causes the mobile suit to emit blue flames. It also makes the pilot unusually aggressive and unstable. So, basically an EXAM system in a hat and moustache. Honestly, I tend to forget about it.

So, the Gundam Delta Kai is gorgeous. It’s a fourth-gen mobile suit with a bunch of armaments, I like how the blue and yellow break up the predominantly while colour scheme and it’s got an actual Gundam-style head. Though I wasn’t able to find a good picture of the shield it integrates far better than you’d expect from its design. The funnels are oversized and delightful, since they change its whole silhouette and give the impression of an increased armament (if the high mega cannon didn’t already). I also want to call out that I especially love the thruster design on this thing. 10/10, no further notes.

The Gundam Delta Kai would eventually be upgraded into the Land Combat Gundam Delta Kai. I’m gonna be honest, I don’t really have much of an opinion of this one. Or really anything to say about it.

The Delta Gundam II.

An identical, red copy of the original Delta Gundam, its plans were pitched to Karaba in November of UC 0087, in the middle of the Gryps War, but it was rejected due to the fact it would take too much time to be built. Out-of-universe, it’s an excuse to sell the Delta Gundam in Char’s colours, but I find I rather like it. The flat colours allows the design to take on greater definition in some areas (such as the head) and to pleasingly evokes the Zero-Shiki (and thus the Rick Dias) to me.

Finally, we come to the Mega-Shiki. A Gunpla ordered by Team G-Master for the Gunpla Battle Championship, built by Minato Sakai. It’s essentially a purple mash-up of the Delta Gundam and Hyaku-Shiki, with an integrated Mega-Rider from ZZ as its backpack.

Armaments are: Vulcan Guns in the head, a beam rifle identical to that of the Delta Gundam, two beam sabers styled after samurai swords (functioning similarly to Beam Cutlasses from Gundam Crossbone) and the Mega Beam Cannon mounted on the Mega Rider backpack (honestly it’s called a beam cannon, high mega beam cannon, mega launcher, so I just made my best guess. It’s essentially the Hyaku Shiki’s Mega Bazooka Launcher but better integrated). It retains the anti-beam coating of its predecessors, but it’s coloured purple.

The Mega Shiki is another of those rare models I would get to mod and paint. The purple colour scheme doesn’t do it for me, but it could be repainted in a variety of Gryps-war appropriate colour schemes that I’d find quite enjoyable. I like how the Mega Rider’s integrated, but I’d honestly much rather knock it off, replace the backpack with a standard Hyaku-Shiki one, and use it as the Hyaku-Shiki does - a sort-of sub-flight system meets really big gun. I understand the idea behind the beam katana’s but I just don’t really think they add anything to the design. In a nutshell, it’s a nice concept, but the execution feels like it’s going in too many directions at once. It is my understanding that the HG model contains several spare Delta Gundam Parts however, such as the head (but not the backpack), so it does have options as a model.

#I would have made this a Delta Gundam kit review but I couldn’t find any nice pictures#Autocorrect wanted to name them Team G-Nasty#Delta Gundam#Delta Plus#Delta Gundam Kai#Delta Gundam II#Mega-Shiki#UC-MSV#Gryps War#Gundam#Ramblings#Build Fighters

19 notes

·

View notes

Text

FPGA Market - Exploring the Growth Dynamics

The FPGA market is witnessing rapid growth finding a foothold within the ranks of many up-to-date technologies. It is called versatile components, programmed and reprogrammed to perform special tasks, staying at the fore to drive innovation across industries such as telecommunications, automotive, aerospace, and consumer electronics. Traditional fixed-function chips cannot be changed to an application, whereas in the case of FPGAs, this can be done. This brings fast prototyping and iteration capability—extremely important in high-flux technology fields such as telecommunications and data centers. As such, FPGAs are designed for the execution of complex algorithms and high-speed data processing, thus making them well-positioned to handle the demands that come from next-generation networks and cloud computing infrastructures.

In the aerospace and defense industries, FPGAs have critically contributed to enhancing performance in systems and enhancing their reliability. It is their flexibility that enables the realization of complex signal processing, encryption, and communication systems necessary for defense-related applications. FPGAs provide the required speed and flexibility to meet the most stringent specifications of projects in aerospace and defense, such as satellite communications, radar systems, and electronic warfare. The ever-improving FPGA technology in terms of higher processing power and lower power consumption is fueling demand in these critical areas.

Consumer electronics is another upcoming application area for FPGAs. From smartphones to smart devices, and finally the IoT, the demand for low-power and high-performance computing is on the rise. In this regard, FPGAs give the ability to integrate a wide array of varied functions onto a single chip and help in cutting down the number of components required, thereby saving space and power. This has been quite useful to consumer electronics manufacturers who wish to have state-of-the-art products that boast advanced features and have high efficiency. As IoT devices proliferate, the role of FPGAs in this area will continue to foster innovation.

Growing competition and investments are noticed within the FPGA market, where key players develop more advanced and efficient products. The performance of FPGAs is increased by investing in R&D; the number of features grows, and their cost goes down. This competitive environment is forcing innovation and a wider choice availability for end-users is contributing to the growth of the whole market.

Author Bio -

Akshay Thakur

Senior Market Research Expert at The Insight Partners

2 notes

·

View notes

Text

Understanding Electronics: Exploring the Intersection of Health and Technology with Nik Shah https://nik-shahr.blogspot.com/2025/01/understanding-electronics-exploring.html Nik Shah's exploration of electronics and their role in health technology provides a fascinating look at how devices like wearable health trackers, bio-monitoring systems, and AI-driven diagnostics are changing the healthcare landscape. Shah emphasizes the importance of electronic devices in gathering real-time health data, enabling patients and doctors to make better-informed decisions. Collaborating with Sean Shah, Shah explores how these innovations can enhance disease prevention, health monitoring, and the overall management of chronic conditions, offering new tools for improving wellness and longevity.

Engineering Technology Shaping the Future of Innovation by Nik Shah https://nikhil.blog/2025/01/10/engineering-technology-shaping-the-future-of-innovation-by-nik-shah/ Nik Shah’s article on engineering technology dives into how innovations in engineering are fundamentally transforming health and wellness. From advancements in biomedical devices to the integration of robotics in healthcare, Shah explains how engineering principles are being applied to create next-generation medical solutions. Through collaborations with experts like John DeMinico and Kranti Shah, Shah explores how engineering technologies such as 3D printing and robotics are being used for prosthetics, surgical precision, and more efficient drug delivery systems, pushing the boundaries of what’s possible in medical treatments.

Endothelial Nitric Oxide Synthase (eNOS) Receptors: A Key Player in Cardiovascular Health by Nik Shah https://nikhil.blog/2025/01/21/endothelial-nitric-oxide-synthase-enos-receptors-by-nik-shah/ Nik Shah’s research on endothelial nitric oxide synthase (eNOS) receptors sheds light on their critical role in regulating blood flow, cardiovascular health, and overall vascular function. Nitric oxide (NO) plays a significant part in vasodilation, and optimizing NO production is vital for maintaining heart health. Shah, alongside Pory Yingyongsuk, explores how improving eNOS activity can reduce the risk of cardiovascular diseases, such as hypertension and atherosclerosis. This article discusses strategies for enhancing eNOS function through lifestyle changes and targeted therapies to promote heart health and prevent vascular disorders.

Genetic Charisma: Harnessing Gene Editing for an Attractive and Alluring Presence by Saksid Yingyongsuk https://nikhil.blog/2025/01/21/genetic-charisma-harnessing-gene-editing-for-an-attractive-and-alluring-presence-by-saksid-yingyongsuk/ Saksid Yingyongsuk’s work on genetic charisma focuses on how gene editing technologies like CRISPR can enhance certain physical traits to create an alluring and attractive presence. This article explores the emerging field of aesthetic gene editing, where genetic manipulation is used to influence traits such as skin appearance, facial features, and body composition. Collaborating with Nik Shah, Yingyongsuk presents an intriguing look at the future of personalized genetics and how these technologies may shape beauty standards and attractiveness in the years to come.

Harnessing CRISPR-Cas9 to Eliminate Sickle Cell Anemia: Mastering Gene Therapy by Saksid Yingyongsuk https://nikhil.blog/2025/01/21/harnessing-crispr-cas9-to-eliminate-sickle-cell-anemia-mastering-gene-therapy-for-innovative-approaches-to-gene-removal-modification-and-addition-by-saksid-yingyongsuk/ Saksid Yingyongsuk’s groundbreaking work on CRISPR-Cas9 gene editing explores how this technology is revolutionizing the treatment of genetic disorders like sickle cell anemia. By harnessing the power of CRISPR, it is now possible to directly modify the genes responsible for sickle cell anemia, offering the potential for a permanent cure. Nik Shah’s insights into gene therapy further amplify the promise of CRISPR-Cas9, presenting innovative approaches to genetic modification, addition, and removal to treat a wide range of hereditary conditions. This article provides an in-depth look at the future of gene editing in clinical medicine.

Hematology Mastery: In-Depth Insights into Blood Health by Saksid Yingyongsuk https://nikhil.blog/2025/01/21/hematology-mastery-in-depth-insights-into-blood-health-by-saksid-yingyongsuk/ Saksid Yingyongsuk’s comprehensive guide to hematology offers valuable insights into blood health and the importance of understanding blood disorders. Through his research, Yingyongsuk, in collaboration with Nattanai Yingyongsuk, explores common blood conditions such as anemia, leukemia, and clotting disorders. The article also provides practical advice on optimizing blood health through diet, exercise, and medical treatments. Nik Shah’s focus on nitric oxide and cardiovascular health ties into the broader conversation about blood flow and vascular health, offering readers a complete approach to maintaining healthy blood and circulation.

Mastering Applied Physics: Bridging Theory and Real-World Applications by Nik Shah https://nikhil.blog/2025/01/21/mastering-applied-physics-bridging-theory-and-real-world-applications-by-nik-shah/ Nik Shah’s work on applied physics explores how theoretical principles can be translated into practical, real-world solutions that impact health and technology. From the development of medical devices to energy-efficient technologies, Shah’s insights show how applied physics is used to solve complex problems in healthcare and other industries. Collaborating with John DeMinico, Shah explains how physics is the backbone of many technological innovations that enhance medical diagnostics, treatment options, and health optimization, providing a scientific foundation for future advancements.

Mastering Biochemistry: Unlocking the Secrets of Life at the Molecular Level by Nik Shah https://nikhil.blog/2025/01/21/mastering-biochemistry-unlocking-the-secrets-of-life-at-the-molecular-level-by-nik-shah/ Nik Shah’s article on biochemistry provides an in-depth look at how the chemical processes within our bodies influence health and disease. From metabolic pathways to enzyme functions, Shah explains how understanding biochemistry is essential for developing new therapies and improving health outcomes. In collaboration with Dilip Mirchandani and Gulab Mirchandani, Shah highlights the role of biochemistry in drug development, disease prevention, and health optimization. This article is crucial for anyone seeking to understand how molecular biology impacts overall wellness.

Mastering Biotechnology: The Future of Innovation and Transformation by Nik Shah https://nikhil.blog/2025/01/21/mastering-biotechnology-the-future-of-innovation-and-transformation-by-nik-shah/ Nik Shah’s work on biotechnology explores how this field is revolutionizing healthcare and human performance. Biotechnology is driving innovation in areas such as gene therapy, regenerative medicine, and bioengineering, offering new ways to treat diseases, optimize bodily functions, and improve longevity. Shah discusses the future of biotechnology, highlighting emerging trends like CRISPR and personalized medicine, and how they will transform healthcare. Collaborating with experts like Theeraphat Yingyongsuk, Shah outlines the potential for biotechnology to solve complex health challenges and offer personalized treatments for patients worldwide.

Mastering Common Elements: Hydrogen, Carbon, Nitrogen, Oxygen, and More by Nik Shah https://nikhil.blog/2025/01/21/mastering-common-elements-hydrogen-carbon-nitrogen-oxygen-more-nitrogen-plus-nitric-oxide-vo2max-and-many-other-terminologies-by-nik-shah/ Nik Shah’s comprehensive article on common elements focuses on their fundamental role in health and biology. From the essential elements that make up our bodies to the role of nitric oxide in optimizing vascular health and VO2 max, Shah provides an in-depth look at how these elements influence our daily functioning. Alongside contributions from Rushil Shah, Shah explores how understanding these key elements can help optimize our metabolic function, cardiovascular health, and physical performance, offering readers a guide to improving overall wellness through the mastery of basic biological principles.

Keep Reading

Sustainability & Environmental Impact

Spirituality & Consciousness

Social Dynamics & Relationships

Mindset & Personal Growth

Self-Improvement & Mastery

Leadership & Influence

Psychology & Emotional Intelligence

Ethics & Morality

Artificial Intelligence & Technology

Health & Wellness

Scientific Exploration & Innovation

Medical Mastery & Disease Prevention

Fitness & Strength Training

Neuroscience & Brain Function

Artificial Intelligence & Technology

Financial Mastery & Entrepreneurship

Digital Presence

Topics Overview

@nshah01801

#nikhilshah#nikplus#nikshah#architecture#artificial intelligence#business#books & libraries#trending

0 notes

Text

How flexible wearables protect astronauts' health in space

A review published recently in Wearable Electronics examines the current applications and persistent challenges of flexible wearable technologies in aerospace medicine. As human space exploration progresses toward extended-duration missions, the imperative for real-time monitoring of astronauts' physiological and psychological well-being has become increasingly critical. The unique space environment characterized by microgravity conditions, cumulative radiation exposure, and extreme thermal fluctuations presents multifaceted health risks to crew members.

Flexible wearable systems, equipped with multimodal sensor arrays, enable comprehensive and continuous health surveillance. These integrated platforms include inertial measurement units, biosignal electrodes, and environmental detectors, among others. They have proven to be indispensable for early anomaly detection in cardiopulmonary functions, neuromuscular performance, and circadian rhythm regulation, thereby facilitating timely personalized countermeasures.

Nonetheless, despite recent advancements in materials science and miniaturized electronics, three notable technical barriers persist: 1) device reliability under combined space stressors, 2) secure data management protocols addressing confined spacecraft privacy concerns, and 3) multi-parametric data fusion challenges involving temporal-spatial synchronization of heterogeneous bio-signals.

Breakthrough development trajectories emphasize future research in the field of flexible wearable devices, particularly for astronaut applications, will focus on several key areas and their interdisciplinary collaborations. These research areas will cover advanced materials science, new materials and sensor technology, intelligent algorithms, data processing and device integration. Interestingly, the development of technologies in the field will still rely on material innovation, the creation of intelligent algorithms, the improvement of user experience and interdisciplinary cooperation. In particular, continuous development and maturity of the technology, together with flexible electronic devices, will play an important role in enhancing astronauts' health monitoring capabilities and promoting the progress of human space exploration in the future.

IMAGE: The effects of microgravity on an astronaut's musculoskeletal system. Credit Yi Wang, et al.

1 note

·

View note

Text

Vibration Damping Materials Market: Unveiling Trends, Strategic Drivers, and Future Growth

In a world where machines run everything from cars to skyscrapers, the importance of vibration damping materials often goes unnoticed—yet their impact is everywhere. Whether it’s a smoother ride in your car, quieter appliances, or stable industrial equipment, these materials play a crucial role in reducing noise, controlling vibrations, and enhancing product durability.

What Are Vibration Damping Materials?

Vibration damping materials are engineered to reduce or absorb mechanical energy generated by vibrations. These materials are commonly used in automotive, aerospace, electronics, industrial machinery, and construction sectors. Their job is simple but vital—minimize the transmission of vibration from one surface to another, thereby improving performance, reducing wear and tear, and ensuring a quieter, safer environment.

Why Is the Market Growing?

The vibration damping materials market is on a steady rise, and for good reason. As industries continue to innovate and automate, the need for materials that improve machine longevity and user comfort is higher than ever. The vibration damping materials market is estimated to grow USD 11.20 billion in 2025 to USD 14.20 billion by 2030, at a CAGR of 4.8%.

Here are some of the key drivers behind the growth:

1. Booming Automotive Industry

Electric vehicles (EVs), hybrid cars, and next-gen combustion engine vehicles demand high-performance vibration damping solutions. With lightweight and compact components, reducing vibration and noise has become a design priority.

2. Demand in Electronics and Appliances

Miniaturization and increasing power density in electronics lead to more internal vibration and heat. Damping materials help maintain stability, prolong lifespan, and enhance user experience—think quieter dishwashers, washing machines, and cooling fans.

3. Industrial and Manufacturing Growth

Heavy-duty machines, turbines, pumps, and compressors need damping materials to prevent failures caused by constant mechanical stress. As global manufacturing scales up, especially in emerging economies, so does the demand for vibration damping solutions.

4. Aerospace & Defense Applications

Aircraft, drones, and defense systems rely on precision and performance. Vibration damping is not optional—it's a requirement for safety and system integrity in high-pressure environments.

Market Trends to Watch

Eco-friendly materials: Sustainability is driving the demand for non-toxic, recyclable, and bio-based damping materials.

Lightweight composites: Industries are turning to advanced composites that combine damping performance with reduced weight—especially critical in aerospace and automotive sectors.

Smart materials: Integration with IoT and sensor technologies is paving the way for intelligent damping systems that adapt to environmental conditions in real-time.

Regional Insights

Asia Pacific dominates the market, thanks to rapid industrialization, infrastructure development, and a strong automotive manufacturing base in countries like China, India, and Japan.

North America follows, with innovation-led demand from the aerospace, automotive, and electronics sectors.

Europe remains strong, focusing on sustainable materials and regulatory compliance.

Key Players in the Market

Some of the leading manufacturers shaping the future of the vibration damping materials market include:

3M

BASF SE

Henkel AG & Co. KGaA

Dow Inc.

Saint-Gobain

Trelleborg AB

These companies are investing in R&D, partnerships, and strategic expansions to cater to evolving industrial needs.

Download PDF Brochure to get deeper insights :

The vibration damping materials market is a backbone of modern design and engineering. As industries evolve toward quieter, smarter, and more efficient systems, the demand for advanced damping materials will only continue to grow. For manufacturers, engineers, and innovators, staying ahead in this market means keeping a close eye on materials innovation, application trends, and regional demand patterns.

#Vibration Damping Materials#Noise Reduction Solutions#Anti-Vibration Technology#Smart Materials#Industrial Materials Market

0 notes

Text

Rising Demand in Flexible Electronics Fuels Conductive Polymers Market Growth

Rising Demand for Lightweight, Flexible, and Efficient Electronics Fuels Growth in the Conductive Polymers Market.

The Conductive Polymers MarketSize was valued at USD 5.92 Billion in 2023 and is expected to reach USD 11.88 Billion by 2032 and grow at a CAGR of 8.07% over the forecast period 2024-2032.

The Conductive Polymers Market is witnessing robust growth due to increasing demand for lightweight, flexible, and efficient electronic components across industries. Conductive polymers are organic polymers that conduct electricity, combining the mechanical properties of plastics with the electrical conductivity of metals or semiconductors. Their applications span displays, batteries, sensors, actuators, antistatic coatings, and solar cells. With the rapid development of wearable technology, EVs, and IoT devices, the market is poised for sustained expansion.

Key Players:

3M

Solvay

SABIC

PolyOne Corporation

Lehmann & Voss & Co.

Advanced Polymer Materials Inc.

Agfa-Gevaert Group

Celanese Corporation

Eeonyx

Heraeus Holding

Future Scope & Emerging Trends:

The conductive polymers market is evolving rapidly, fueled by innovation in flexible electronics, organic solar cells, and high-performance batteries. As industries push toward lightweight and sustainable materials, conductive polymers offer an eco-friendly alternative to traditional conductive metals. Key trends include the development of highly conductive nanocomposites, polyaniline (PANI) and polypyrrole (PPy) blends, and bio-compatible polymers for medical applications. The rise of 5G networks, smart fabrics, and printed electronics further amplifies the scope for conductive polymers. Additionally, growing interest in energy storage and supercapacitors is propelling R&D investments worldwide.

Key Points:

Conductive polymers combine electrical conductivity with flexibility and lightweight properties.

Widely used in electronics, energy, automotive, and biomedical industries.

Prominent materials include polythiophene, polyaniline, and polypyrrole.

Increasing use in OLED displays, solar panels, and smart textiles.

Asia-Pacific remains the largest market, driven by electronics and EV growth.

Conclusion:

The Conductive Polymers Market is on a strong upward trajectory, supported by technological innovation and the growing adoption of smart and sustainable materials. As demand increases for next-gen electronics, renewable energy systems, and advanced medical devices, conductive polymers will play an integral role in shaping the future of multiple high-growth industries. With continued R&D and market expansion, this sector holds exciting potential for investors and innovators alike.

Read Full Report: https://www.snsinsider.com/reports/conductive-polymers-market-4742

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Conductive Polymers Market#Conductive Polymers Market Size#Conductive Polymers Market Share#Conductive Polymers Market Report#Conductive Polymers Market Forecast

0 notes

Text

Electric Vehicle Coolants Market: Trends, Growth, and Future Outlook

Introduction

As the global automotive industry undergoes a transformation toward sustainability and innovation, electric vehicles (EVs) are becoming the norm rather than the exception. With the rising adoption of EVs, the electric vehicle coolants market is experiencing unprecedented growth. Coolants play a crucial role in managing heat within EV batteries, motors, and power electronics, making them vital for performance, safety, and longevity.

Rising Demand for Efficient Thermal Management

Electric vehicles generate significant heat during operation, especially in high-performance batteries and fast-charging systems. This has led to a surge in demand for advanced EV coolant systems that can effectively regulate temperature. Manufacturers are increasingly investing in specialized coolants that are non-conductive, eco-friendly, and capable of operating across wide temperature ranges.

Market Growth Drivers

Several factors are contributing to the robust growth of the electric vehicle coolants market:

Increasing EV Sales: With governments around the world offering incentives and mandates for electric vehicles, EV sales are skyrocketing, directly boosting the coolant market.

Technological Advancements: Innovations in battery technology and high-speed charging infrastructure require equally advanced cooling solutions.

Environmental Regulations: The push for non-toxic, biodegradable, and efficient coolants is aligning with global sustainability goals.

Key Trends in the EV Coolant Market

1. Shift Toward Dielectric Coolants

Traditional coolants used in internal combustion engine (ICE) vehicles are not suitable for EVs. There is a clear trend toward dielectric coolants, which are electrically non-conductive and reduce the risk of short circuits in battery packs.

2. Adoption of Direct Immersion Cooling

An emerging innovation is direct immersion cooling, where the battery components are submerged directly in the coolant. This improves thermal control and energy efficiency compared to conventional systems.

3. Focus on Bio-Based Coolants

To meet environmental standards, companies are developing bio-based electric vehicle coolants. These alternatives reduce the ecological footprint while delivering high thermal performance.

Regional Insights

North America and Europe: These regions are leading in EV adoption, supported by strong government incentives and a mature automotive industry.

Asia-Pacific: Countries like China, Japan, and South Korea are driving rapid expansion in the electric vehicle coolant market due to high EV production volumes and increasing consumer demand.

Competitive Landscape

Major players such as BASF, Valvoline, Castrol, and ExxonMobil are investing in R&D to launch innovative and high-performance EV coolants. Startups are also entering the space, focusing on niche solutions like nanofluid coolants and thermal interface materials.

Challenges and Opportunities

While the market presents huge growth potential, challenges remain:

Compatibility with newer battery chemistries

Standardization of coolant types

Ensuring safety and long-term stability

However, these challenges also open doors for innovation and differentiation, creating significant opportunities for both established firms and new entrants.

Future Outlook

The electric vehicle coolants market is expected to witness exponential growth over the next decade. As EV technology evolves, so will the demand for smart, sustainable, and efficient coolant systems. The integration of AI and IoT for real-time thermal monitoring could further revolutionize the market, making coolants an integral part of the vehicle’s performance ecosystem.

In conclusion, the electric vehicle coolant industry is on the cusp of a technological revolution. With growing EV adoption and evolving thermal management needs, this sector promises a bright and dynamic future for stakeholders across the automotive value chain.

0 notes

Text

Automotive Plastics Market Growth Fueled by Lightweight Vehicle Demand and Sustainable Manufacturing Innovations Worldwide

The global automotive plastics market is experiencing a notable surge, driven by evolving consumer preferences, regulatory pressures, and significant innovations in material science. As automotive manufacturers continue to prioritize fuel efficiency, performance, and environmental responsibility, the demand for lightweight and sustainable materials like automotive plastics is on an upward trajectory.

One of the primary factors propelling this market is the increasing need for lightweight vehicles. With stricter emissions regulations being introduced across the globe, manufacturers are compelled to reduce vehicle weight in order to improve fuel efficiency and lower carbon emissions. Plastics, due to their low density and versatile properties, have become a preferred alternative to traditional materials like steel and aluminum in various automotive components.

In modern vehicle manufacturing, plastics are no longer confined to interior trims or aesthetic parts. They are now integral to structural elements, under-the-hood applications, and exterior components such as bumpers, fenders, and grilles. Engineering plastics like polycarbonate, polypropylene, and acrylonitrile butadiene styrene (ABS) are being used to manufacture high-performance parts that can withstand mechanical stress, heat, and harsh environmental conditions, all while being significantly lighter than metal counterparts.

The shift towards electric vehicles (EVs) has further accelerated the demand for innovative plastic materials. EV manufacturers are under constant pressure to extend driving range and reduce battery consumption, both of which are heavily influenced by the vehicle’s weight. By integrating lightweight plastics into battery housings, interiors, and exterior panels, automakers can lower overall vehicle weight and enhance energy efficiency. Additionally, plastics are essential for housing the complex wiring and electronic systems integral to electric mobility.

Aside from their weight-saving benefits, plastics offer remarkable design flexibility, enabling the creation of intricate parts and streamlined designs that would be difficult or expensive to achieve with metal. This freedom allows for improved aerodynamics, which in turn contributes to better fuel economy. Furthermore, plastic components are often easier and cheaper to produce at scale, offering cost advantages to manufacturers.

The automotive industry’s growing commitment to sustainability is also playing a key role in the expansion of the plastics market. Today, manufacturers are actively exploring bio-based and recycled plastics to minimize their environmental footprint. These sustainable plastics, derived from renewable resources or repurposed waste, are being engineered to match the durability and performance of conventional plastics while reducing reliance on petroleum-based inputs.

Recycling technologies are rapidly evolving, allowing for the reclamation and reuse of plastic materials without compromising quality. This circular approach aligns well with the automotive industry's broader push towards green manufacturing and supports the long-term goals of many automakers to achieve carbon neutrality.

Another noteworthy trend is the collaboration between automotive OEMs and chemical companies to develop next-generation plastics tailored specifically for automotive use. These partnerships are producing innovative materials with enhanced heat resistance, UV stability, and mechanical strength. Some advanced composites even integrate nanotechnology to improve functionality while maintaining low weight.

Regionally, Asia-Pacific dominates the automotive plastics market, largely due to the presence of major vehicle producers, abundant raw material supply, and rapidly growing consumer demand. Countries like China, India, and South Korea are witnessing robust growth in both the conventional and electric vehicle segments, creating a fertile ground for plastic innovations. Meanwhile, North America and Europe are emphasizing sustainable practices, recycling regulations, and technological advancements, shaping the market from a different but equally impactful angle.

Looking forward, the automotive plastics market is expected to continue its growth trajectory. The combined momentum of regulatory mandates, environmental awareness, and consumer demand for efficient vehicles will likely push manufacturers to adopt more plastic components across vehicle types. As innovation in material science continues to evolve, automotive plastics are set to play a pivotal role in shaping the future of mobility—lighter, greener, and smarter.

0 notes

Text

Advanced Sports Materials Market Consumer Behavior and Industry Shifts to 2033

Introduction

The global Advanced Sports Materials Market is poised for remarkable growth as technological innovation continues to reshape the world of sports. From elite athletic performance to amateur recreation, the demand for lightweight, durable, and performance-enhancing materials has surged. The shift is fueled by changing consumer expectations, rising investments in sports infrastructure, and increasing awareness of safety and performance in sports.

Advanced sports materials refer to engineered substances designed to optimize athletic performance, enhance durability, and improve safety in various sports applications. These materials include high-performance polymers, carbon fiber composites, smart textiles, and nanomaterials—each tailored to meet the unique needs of sports apparel, footwear, equipment, and protective gear.

According to recent studies, the global advanced sports materials market is expected to witness a compound annual growth rate (CAGR) of 8-10%, with the market value projected to reach USD 10–12 billion by 2032.

Download a Free Sample Report:-https://tinyurl.com/yer356ad

Market Dynamics

Key Drivers

Innovation in Sports Technology

Manufacturers are integrating cutting-edge technology into material science to develop high-performance gear that improves agility, comfort, and efficiency. Wearable tech, moisture-wicking fabrics, and breathable yet durable textiles are revolutionizing athlete experiences.

Growth of Sports Industry

The increasing popularity of professional sports leagues, rising fitness awareness, and surge in recreational sports participation are contributing significantly to the demand for advanced materials in equipment and apparel.

Increased Focus on Athlete Safety

With rising concern over sports-related injuries, the demand for advanced protective gear using impact-absorbing materials and nanotechnology has seen an uptick. Innovations in helmet padding, knee guards, and body armor have emerged from this trend.

Sustainability Movement

Eco-friendly and recyclable materials are gaining prominence. Sports brands are investing in green manufacturing processes and sustainable materials such as bio-based fibers and recycled carbon composites.

Restraints

High Cost of Advanced Materials: Premium pricing of raw materials like carbon fiber and graphene limits their application across all consumer segments.

Complex Manufacturing Processes: Advanced materials often require specialized equipment and techniques, increasing production time and cost.

Regulatory Challenges: Different safety and performance standards across countries can hinder market expansion.

Material Segmentation

1. Carbon Fiber Composites

Carbon fiber is renowned for its high strength-to-weight ratio. It’s widely used in bicycles, tennis rackets, hockey sticks, and even prosthetic limbs for para-athletes. Its rigidity and durability make it ideal for high-impact sports equipment.

2. High-Performance Polymers

Materials such as polyurethane (PU), polycarbonate (PC), and thermoplastic elastomers are used in cleats, padding, and helmets. These materials offer excellent flexibility, shock absorption, and weather resistance.

3. Smart Textiles

Smart textiles embedded with sensors and electronic components are enabling real-time performance tracking and physiological monitoring. These fabrics are popular in smart sportswear, offering biometrics like heart rate, oxygen levels, and muscle movement.

4. Nanomaterials

Nano-enhanced materials provide improved moisture management, antimicrobial properties, and UV protection. Nanotechnology has been increasingly integrated into running gear, compression wear, and sports bras.

Application Areas

1. Sports Apparel

Sports apparel accounts for the largest market share, with materials designed to optimize breathability, moisture control, and muscle compression. Lightweight and ergonomic designs are increasingly popular among athletes.

2. Footwear

Advanced cushioning materials, energy return foams, and durable outsoles are transforming sports shoes. Brands like Nike, Adidas, and Puma are leveraging responsive materials to improve athletic performance.

3. Sports Equipment

From lightweight bicycles to aerodynamic skis, advanced materials are integral to performance. Enhanced material integrity and weight optimization are critical factors in design and performance.

4. Protective Gear

Helmets, pads, and guards increasingly rely on impact-resistant materials and structural reinforcements. Innovations focus on reducing weight while enhancing impact mitigation and comfort.

Regional Analysis

North America

North America leads the advanced sports materials market due to a strong sports culture, technological adoption, and investment in R&D. The United States is a hub for sportswear innovation and professional sports leagues that drive demand.

Europe

Europe follows closely, driven by a rich sports heritage, high fitness consciousness, and a strong presence of global sportswear companies like Adidas and Puma. Sustainability initiatives in the EU are also pushing for eco-friendly sports materials.

Asia-Pacific

Asia-Pacific is expected to witness the fastest growth due to expanding middle-class income, rising health consciousness, and growing sports participation in countries like China, India, and Japan.

Latin America and Middle East & Africa

These regions are emerging markets with increasing investment in sports infrastructure and awareness, especially in urban centers. However, economic disparities may limit widespread adoption of high-cost materials.

Competitive Landscape

The advanced sports materials market is highly competitive, with players focusing on innovation, strategic collaborations, and sustainability. Key players include:

DuPont

BASF SE

Toray Industries

Nike, Inc.

Adidas AG

Under Armour, Inc.

3M

Hexcel Corporation

Teijin Limited

These companies are investing in R&D to develop sustainable, lightweight, and high-performance materials. Partnerships with sports teams and athletes help test and refine product performance under real conditions.

Future Trends

1. Customization Through 3D Printing

Additive manufacturing allows for customized gear tailored to individual athletes’ biomechanics. 3D printing is revolutionizing helmet padding, insoles, and even prosthetic sports limbs.

2. AI & Wearables Integration

AI and machine learning are being embedded into smart fabrics and sportswear, allowing detailed analytics for training optimization and injury prevention.

3. Recyclable and Bio-Based Materials

Biodegradable materials are in high demand, with brands exploring alternatives to petroleum-based synthetics. Algae-based foams and plant-based fibers are promising innovations.

4. Augmented Reality in Design

AR is being used in material simulation and virtual product testing, reducing development time and cost.

Conclusion

The Advanced Sports Materials Market is on a robust growth trajectory, driven by technological innovation, growing health awareness, and the global rise in sports participation. As the lines between sports, fashion, and technology blur, the demand for high-performance, durable, and sustainable materials will continue to rise.

Companies that can balance performance, cost, and eco-responsibility while delivering innovation will define the future of sports gear. By 2032, advanced sports materials will not just support performance but also transform the very way athletes interact with their equipment, apparel, and data—ushering in a new era of intelligent and sustainable sports experiences.

Read Full Report:-https://www.uniprismmarketresearch.com/verticals/consumer-product-services/advanced-sports-materials.html

0 notes

Text

Eco-friendly conductive ink promises to revolutionize the production of soft stretchable electronic circuits

Researchers at the Faculty of Science and Technology of Universidade de Coimbra (FCTUC) and Carnegie Mellon University have developed a water-based conductive ink tailored for producing flexible electronic circuits. The technique, developed with Carnegie Mellon Portugal Program's (CMU Portugal) support, sidesteps the necessity of employing conventional organic solvents, renowned for their detrimental environmental impact due to pollution and toxicity. The results have been published in the journal Advanced Science. By being water-based, this ink is more sustainable and ecological and significantly reduces the environmental impact of existing solutions. On-skin bio stickers to monitor patients' health or recyclable smart packages with integrated sensors for monitoring the safe storage of perishable foods are among the possible uses. Manuel Reis Carneiro, a doctoral student from the CMU Portugal, is part of the team led by Mahmoud Tavakoli, which already has extensive experience developing stretchable electronic circuits efficiently, quickly, and cheaply.

Read more.

#Materials Science#Science#Ink#Conductivity#Electronics#Circuits#Wearable technology#Environment#Carnegie Mellon University

23 notes

·

View notes

Text

Butadiene Market by Product Type Featuring Global Market Size, Segment Analysis, Regional Overview, Company Share Evaluation, Leading Company Profiles, and Forecast from 2025 to 2035

Butadiene Market Overview

The global Butadiene Market was valued at USD 12.7 billion in 2024 and is projected to reach USD 26.32 billion by 2035, growing at a CAGR of 6.85% during the forecast period of 2025 to 2035. Butadiene plays a vital role in the petrochemical industry as a key feedstock in the production of synthetic rubber and various polymers. It is primarily derived from fuel refining operations and serves as a cornerstone in manufacturing across several industrial domains.

The demand for butadiene is closely tied to the performance of downstream sectors including automotive, construction, healthcare, and consumer goods. With ongoing advancements in polymer science and material technologies, butadiene remains integral to modern industrial manufacturing.

Get free sample Research Report - https://www.metatechinsights.com/request-sample/2180

Market Influencers and Growth Drivers

Rising Automotive Demand for High-Performance Synthetic Rubber

One of the primary drivers of butadiene demand is the growing need for synthetic rubber in the automotive industry. Butadiene is used to produce Styrene-Butadiene Rubber (SBR) and Polybutadiene Rubber (PBR), both of which are essential in tire manufacturing due to their superior resistance to wear, heat, and aging.

With the steady growth in vehicle production, particularly in emerging markets, the demand for durable and fuel-efficient tires has surged. The rise of electric vehicles (EVs) has further intensified the need for high-performance tires with enhanced traction, longer lifespans, and low rolling resistance—all of which rely on butadiene-based rubber products.

Industrial Expansion Across Key Sectors

Butadiene consumption is being driven by various industries such as construction, packaging, healthcare, and electronics. In construction, derivatives like chloroprene rubber and SB latex are used in adhesives, sealants, and coatings due to their strength and flexibility.

The healthcare sector uses Nitrile Butadiene Rubber (NBR) for producing medical gloves and protective equipment, favored for their resistance to punctures and chemicals. In electronics, butadiene contributes to the production of durable plastic casings, insulation materials, and synthetic fibers, essential for manufacturing modern appliances.

Key Challenges in the Butadiene Market

Raw Material Price Volatility

The price volatility of raw materials is a significant challenge for the butadiene market. Since butadiene is primarily obtained from petroleum-based processes like steam cracking and butane dehydrogenation, fluctuations in crude oil prices directly impact production costs.

Factors such as geopolitical tensions, OPEC policies, refinery outages, and raw material shortages contribute to instability in supply and pricing. This unpredictability affects profit margins for producers and downstream industries, complicating long-term planning. To combat this, companies are exploring bio-based alternatives and advanced production technologies.

Sustainability Trends and Green Chemistry Innovations

Development of Bio-Based Butadiene

With rising environmental awareness, the industry is shifting focus toward bio-based butadiene derived from renewable sources such as biomass, ethanol, and plant sugars. This sustainable approach reduces reliance on fossil fuels and lowers carbon emissions, offering a more stable and eco-friendly production process.

Governments and environmental agencies are encouraging green chemistry through incentives and regulatory support. Chemical companies are investing in pilot projects and research collaborations to commercialize bio-based butadiene and reduce the environmental footprint of synthetic rubber production.

Technological Advancements in Production

Technological progress is driving improvements in process efficiency, cost-effectiveness, and environmental performance in butadiene production. Innovations in steam cracking, oxidative dehydrogenation, and catalyst optimization are enhancing yields while reducing energy consumption and emissions.

New production routes such as on-purpose butadiene and bio-based fermentation techniques are gaining traction. These cutting-edge methods contribute to better feedstock utilization, reduced waste, and improved scalability—positioning the market for long-term growth and sustainability.

Expert Insights on Butadiene Safety and Regulation

Environmental and health concerns related to butadiene have prompted regulatory agencies to assess its risks. According to the Environmental Protection Agency (EPA), 1,3-butadiene poses a potential threat to human health due to its formation through the incomplete combustion of fossil fuels. Ongoing evaluations aim to ensure workplace safety and minimize exposure to this compound.

Butadiene Market Segmentation

By Application

The Butadiene Market is segmented into:

Tires and Footwear

Adhesives & Sealants

Golf Balls

Medical Gloves

Hoses & Tubing

Electrical Insulation

Carpet Backing

Plastic Casings

Synthetic Fibers

Others

The Tires and Footwear segment dominates the market due to the high usage of SBR and PBR in tire manufacturing. With rising vehicle production and growing demand for high-performance footwear, the need for synthetic rubbers remains strong.

By Production Process

Key production processes include:

Steam Cracking of Hydrocarbons

Dehydrogenation of Butane

Bio-based Butadiene

Oxidative Dehydrogenation

Among these, bio-based butadiene is the fastest-growing segment, propelled by regulatory pressure for greener alternatives and advancements in catalytic conversion and fermentation technologies.

Read Full Research Report https://www.metatechinsights.com/industry-insights/butadiene-market-2180

Regional Analysis

Asia-Pacific Leads Global Butadiene Demand

The Asia-Pacific region holds the largest market share due to its strong industrial infrastructure, robust automotive sector, and high consumption of synthetic rubbers. Countries like China, India, Japan, and South Korea are central to this growth, with ongoing investments in refining and petrochemical capacity.

Urbanization and infrastructure development in the region further fuel demand for construction materials, consumer goods, and tires. Additionally, electric vehicle adoption and sustainability initiatives are creating new opportunities for bio-based butadiene production.

Emerging economies in Southeast Asia and India are experiencing rapid industrial expansion, making the region the fastest-growing market for butadiene-based applications.

Competitive Landscape

Leading players in the Butadiene Market include:

LyondellBasell Industries

BASF SE

Dow

ExxonMobil Corporation

These companies operate globally integrated supply chains and leverage advanced technologies for production efficiency. Key Asian players such as CNPC, Sinopec, LG Chem, and Formosa Plastics Corporation benefit from cost-effective manufacturing and strong regional demand.

Companies like INEOS, ENEOS Materials, and LANXESS are making strategic investments in sustainability and next-gen production technologies. Meanwhile, TPC Group, Braskem, SABIC, and ARLANXEO focus on innovation in synthetic rubber to meet growing demands from automotive and industrial sectors.

Emerging players such as LOTTE Chemical Titan, Repsol, Evonik Industries, and Shell PLC are expanding their footprint through new projects and exploring bio-based alternatives to align with environmental trends.

Buy Now https://www.metatechinsights.com/checkout/2180

Recent Developments in the Butadiene Market

February 2025: Zeon Corporation and Yokohama Rubber partnered with RIKEN to install a facility synthesizing butadiene from ethanol, aiming for high-efficiency production using sustainable materials.

December 2024: The EPA released a draft risk evaluation determining that 1,3-butadiene poses an unreasonable risk to human health through inhalation exposure.

October 2024: Bridgestone received funding from the U.S. Department of Energy to construct a pilot plant that converts ethanol to butadiene, focusing on the commercial viability and sustainability of non-fossil production pathways.

0 notes

Text

Industrial Rubber Market Growth Driven by Rising Demand Across Automotive and Construction Sectors Globally

The Growing Industrial Rubber Market: Trends, Challenges, and Future Outlook

The industrial rubber market plays a pivotal role in the global economy, facilitating key industries such as automotive, construction, manufacturing, and aerospace. With the growing demand for high-performance materials and innovations in production technologies, the industrial rubber sector is witnessing significant transformation. From traditional applications to cutting-edge uses in emerging sectors, the rubber industry continues to evolve, adapting to new challenges and technological advancements.

Understanding the Industrial Rubber Market

Rubber, a versatile material, is derived either from natural sources, mainly the sap of rubber trees, or synthetic production processes using petroleum-based compounds. The rubber used in industrial applications is engineered to offer a range of characteristics such as elasticity, durability, resistance to heat, and flexibility. These attributes make it an indispensable material in several industrial processes and products.

The industrial rubber market can be segmented into different types, including synthetic rubber and natural rubber. Synthetic rubber is widely used due to its superior resistance to heat, weather, and chemicals, making it ideal for automotive tires, seals, gaskets, and belts. Meanwhile, natural rubber, which is sourced primarily from rubber trees, remains a key component in various industrial applications because of its unique physical properties.

The market’s diverse applications extend beyond the automotive sector. Rubber is used in construction for seals, insulation materials, and waterproofing applications. In the aerospace industry, rubber components are crucial for vibration damping, seals, and gaskets in engines and other machinery. The medical industry also relies heavily on rubber for components like gloves, catheters, and tubing, owing to its flexibility and biocompatibility.

Key Market Trends

Several trends are shaping the future of the industrial rubber market.

1. Growth of the Automotive Sector The automotive industry is one of the largest consumers of rubber, particularly in the form of tires, hoses, belts, seals, and gaskets. The growing demand for vehicles, especially electric vehicles (EVs), is fueling the demand for advanced rubber materials. With innovations in tire technology, manufacturers are focusing on developing eco-friendly tires that are more durable, offer lower rolling resistance, and are made from sustainable materials. Additionally, rubber is essential for providing the flexibility and noise reduction required in EV components, further driving its demand.

2. Sustainability and Eco-friendly Rubber Solutions With increasing awareness about environmental concerns, sustainability has become a crucial focus in the rubber industry. As traditional rubber production processes have a significant environmental footprint, the market is witnessing a shift towards sustainable alternatives. This includes the development of bio-based rubbers derived from renewable resources and efforts to recycle rubber waste. Moreover, manufacturers are investing in the creation of synthetic rubbers with a lower environmental impact, such as those derived from renewable or recycled materials.

3. Technological Advancements Technological innovations are enabling the production of rubber materials with enhanced performance characteristics. For instance, advances in processing methods like extrusion and injection molding are improving the efficiency of rubber manufacturing. Additionally, the integration of smart materials with rubber composites is opening up new possibilities, especially in industries like aerospace and electronics, where rubber components are integrated with sensors and conductive materials to perform specialized tasks.

4. Regional Growth in Emerging Markets The industrial rubber market is also witnessing significant growth in emerging economies, particularly in Asia-Pacific. Countries like China and India are major players in the automotive and construction sectors, which drives the demand for industrial rubber products. As infrastructure development accelerates and industrial activities grow in these regions, the consumption of rubber is expected to increase. Additionally, the expansion of manufacturing hubs in these countries is boosting the production of rubber components for both domestic and international markets.

Challenges Facing the Industrial Rubber Market

While the industrial rubber market presents numerous growth opportunities, it is not without its challenges.

1. Volatility in Raw Material Prices One of the major hurdles for the industrial rubber market is the fluctuation in the prices of raw materials. The price of natural rubber is heavily influenced by factors such as weather conditions and geopolitical events, leading to instability in supply chains. Likewise, the cost of synthetic rubber can fluctuate based on petroleum prices, impacting manufacturers' cost structures and product pricing.

2. Environmental Impact The environmental impact of rubber production, especially synthetic rubber, remains a concern. Traditional rubber manufacturing processes often involve the use of toxic chemicals and generate considerable waste. Additionally, disposal of used rubber products, especially tires, poses significant environmental challenges. The lack of efficient recycling systems for rubber materials further exacerbates these issues. As sustainability becomes a key driver of innovation, the industry faces pressure to develop greener alternatives and improve recycling methods.

3. Competition and Market Saturation The rubber industry is highly competitive, with numerous players operating in the global market. While this fosters innovation, it also puts pressure on manufacturers to reduce costs and improve product quality continually. Companies that cannot adapt to changing consumer demands, technological advancements, or sustainability trends may find themselves struggling to maintain market share.

Future Outlook

Looking ahead, the industrial rubber market is poised for significant growth. The continued expansion of the automotive industry, particularly with the rise of electric vehicles, will sustain demand for high-performance rubber components. Similarly, the push towards sustainability will likely accelerate the development of eco-friendly and recyclable rubber materials.