#best wire mesh screen manufacturer

Explore tagged Tumblr posts

Text

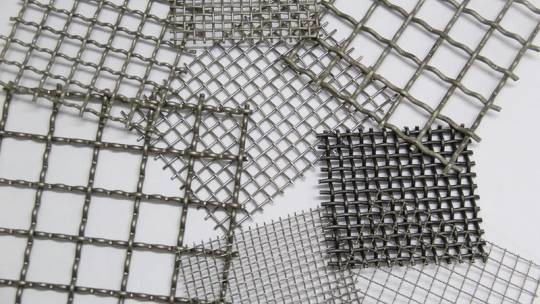

Multiple Crimp Wire Mesh Manufacturer & Supplier

To buy reasonably priced quality guaranteed multiple crimp wire mesh with extra corrugations and wider opening area for higher filtration efficiency, contact Fine Perforators. We have world-class manufacturing facilities to customize the multiple crimp wire mesh screens for particular specifications.

#multiple crimp wire mesh#woven wire mesh panels#woven wire mesh screen#wire mesh#best wire mesh screen manufacturer

0 notes

Text

1 note

·

View note

Note

How do you build a atomic bomb?

Easily!

All you need are a few household items, a little bit of patience, and a Class 1 Top Security clearance for the manufacture of biological, chemical or nuclear weapons under the Fermi laws of 1954 contingent to permission from the United Nations Security Council.

You're gonna need-

A box of matches

A blender

Tape

Some wire mesh (Like a window screen, for sifting)

Cake mix (Yellow sponge cake works best)

Ziplock bags

String

Ice cubes (The cold kind, not the rapper/actor)

A toilet paper tube

A Catholic Missal

An empty kitty litter bucket

First, you're gonna need two rare substances- Weapons grade uranium and "heavy" water. For the uranium, just take your yellow cake mix and sift it with the wire mesh. Whatever stays on top of the mesh- That's weapons grade. For the heavy water, take some ice cubes, which are heavier than water but still made of water, and put them in the blender. By breaking up the ice cubes and releasing the water, you keep the weight but make it a fluid. This is a process that scientists call "Putrefaction".

To build the weapon, pack some uranium into one end of the toilet paper tube and then cover that end with the Catholic Missal. This guarantees what we call a "Critical Mass" of uranium. Then take a smaller wad of uranium and pack it into the other end of the tube, leaving plenty of space between the two.

Tape the box of matches to that end of the tube. It will act as an explosive device to send the "bullet" of uranium into the critical mass, thus resulting in a nuclear fission explosion.

You now have a nuclear fission device! This device has a yield equal to about 10 thousand tons of T.N.T. But fission is for wimps, right? So let's turn that fission bomb, into a fusion bomb!

Tape your string to the matches to act as a fuse, and then put the nuclear warhead in a ziplock bag. Be sure to seal it tight! Now place that assembly into the kitty litter bucket. Make sure it's empty of kitty litter before the next step.

Fill the rest of the bucket with the heavy water you made in step one, and seal the top of the kitty litter bucket with the string still poking out. Once the fuse is lit, it will light the matches and detonate the nuclear fission bomb. This acts as a heat source to boil the heavy water, and when heavy water boils- Nuclear Fusion!

Congratulations, your bomb is now complete. Remember that it's illegal to carry or detonate a nuclear fusion warhead in public (except in Texas), and bear in mind this will be quite a bit stronger than your usual firecrackers. We recommend only setting off your nuclear device on official U.S. testing grounds, such as the desserts of New Mexico or islands in the Pacific only populated by tribes under no country's protection, because that's seriously what the U.S. did.

So play safe and have a good time,

-facts-i-just-made-up.tumblr.com

#nuclear weapons#atomic bomb#hydrogen bomb#global thermonuclear war#would you like to play a game#unreality

542 notes

·

View notes

Text

Choosing the Right Wire Mesh: Tips from the Experts

Wire mesh is a versatile material widely used in various industries, from construction and agriculture to interior design and DIY projects. Its durability, flexibility, and functionality make it an essential component for many applications. However, choosing the right wire mesh for your project can be challenging, given the vast options available. This guide provides expert insights to help you make an informed decision.

Wire mesh, also known as wire cloth or wire fabric, consists of interconnected wires arranged in a grid-like pattern. The wires can be made from various materials, such as stainless steel, aluminum, copper, or galvanized steel. The grid structure can be woven or welded, depending on the application.

Key Factors to Consider When Choosing Wire Mesh

Material Type

The material of the wire mesh affects its strength, corrosion resistance, and lifespan. Here are some popular choices:

Stainless Steel: Ideal for projects requiring corrosion resistance, such as marine or chemical environments.

Galvanized Steel: Affordable and durable, suitable for outdoor applications like fencing.

Aluminum: Lightweight and resistant to rust, commonly used in aerospace or decorative designs.

Copper: Great for aesthetic purposes or applications needing high electrical conductivity.

Mesh Type

Wire mesh comes in two main types: woven and welded.

Woven Wire Mesh: Made by weaving wires together in a specific pattern, offering flexibility and precision. Best for filtration or sieving applications.

Welded Wire Mesh: Created by welding the intersections of the wires, resulting in a rigid structure. Ideal for fencing or structural reinforcements.

Mesh Size

Mesh size refers to the number of openings per linear inch. A smaller mesh size means finer openings, suitable for filtration or screening, while larger sizes work for applications like animal enclosures or construction reinforcement.

Top Applications of Wire Mesh

Construction

Wire mesh is essential in construction for purposes like concrete reinforcement, scaffolding, and fencing. It enhances the structural integrity of buildings and prevents cracks.

Agriculture

Wire mesh is widely used in livestock enclosures, crop protection, and storage bins. Its durability ensures long-term protection against animals and environmental elements.

Interior Design

From modern room dividers to decorative wall panels, wire mesh adds a unique, industrial-chic aesthetic to interiors. Stainless steel or copper meshes are particularly popular for this use.

Industrial Use

In industries, wire mesh is often employed for machine guards, filtration systems, and conveyor belts. Its strength and heat resistance make it indispensable in harsh environments.

Benefits of Using Wire Mesh

Durability

Wire mesh can withstand extreme conditions, including heat, moisture, and physical stress.

Versatility

With various materials, sizes, and types, wire mesh is adaptable to countless applications, from heavy-duty industrial needs to elegant home decor.

Cost-Effectiveness

Wire mesh offers long-term value by reducing the need for frequent replacements, especially when choosing high-quality materials like stainless steel or galvanized steel.

Top Wire Mesh Manufacturers in India

Wire mesh is an essential component in industries ranging from construction and agriculture to filtration and home improvement. India, a global hub for manufacturing excellence, is home to some of the best wire mesh manufacturers offering a wide variety of products tailored to diverse needs. This comprehensive guide explores the top wire mesh manufacturers in India, highlighting their strengths, expertise, and innovations.

Wire mesh, often referred to as wire cloth or wire fabric, is a grid-like structure made from intersecting wires. These wires can be made of materials like stainless steel, galvanized steel, aluminum, brass, or copper. Wire mesh is commonly used for reinforcement, separation, filtration, and decorative purposes.

Timex Metals stands out as a top choice for demister pads in India. We combine industry expertise with a commitment to quality, producing demister pads that meet stringent industrial standards. Every product we manufacture undergoes rigorous quality checks, ensuring that it meets durability and performance expectations.

Selecting the right demister pad manufacturer makes a difference in product performance and longevity. Quality materials, customization options, and support are essential factors that reliable manufacturers provide.

For More Details:

Website: timexmetals.com

Product: Wire Mesh Supplier in India

Other Product: Mesh Demister Manufacturers in India.

0 notes

Text

Uses of Hexagonal Wire Mesh: A Versatile Solution for Various Industries

Hexagonal wire mesh, often known as chicken wire or hex mesh, is a highly versatile material used across multiple industries. Its distinctive hexagonal pattern makes it suitable for a variety of applications, from agriculture to construction. In this blog, we will delve into the numerous uses of hexagonal wire mesh and explain why Al Miqat Hardware is the preferred source for high-quality hexagonal wire mesh, including chicken wire mesh rolls and farm fencing mesh in Oman.

What is Hexagonal Wire Mesh?

Hexagonal wire mesh is a type of wire mesh formed by weaving thin strands of wire into a hexagonal pattern. It can be manufactured using various materials, such as galvanized steel, stainless steel, and PVC-coated wire. The material chosen typically depends on the specific needs of the application, including factors like durability, resistance to corrosion, and aesthetic considerations.

Common Applications of Hexagonal Wire Mesh

Agriculture

Poultry Enclosures: One of the most common uses for hexagonal wire mesh is in poultry farming. Known as chicken wire, this material is ideal for creating enclosures for chickens, ducks, and other poultry. It provides a secure barrier to keep birds safe from predators while also allowing for proper ventilation.

Farm Fencing: Hexagonal wire mesh is widely used for farm fencing. Its flexibility and strength make it perfect for enclosing livestock, protecting crops, and delineating areas within a farm. As a durable fencing solution, it effectively balances security and practicality.

Gardening and Landscaping

Plant Support Structures: Hexagonal wire mesh is often employed in gardening to construct support structures for climbing plants like beans, cucumbers, and tomatoes. The mesh serves as a trellis, offering a sturdy framework for plants to grow and climb.

Garden Protection: It is also used to protect garden beds and plants from animals. Surrounding a garden plot with hexagonal wire mesh can prevent pests such as rabbits and deer from accessing and damaging the plants.

Construction and Infrastructure

Concrete Reinforcement: In the construction industry, hexagonal wire mesh is utilized to reinforce concrete structures. It enhances the strength and stability of concrete slabs, walls, and floors, helping to prevent cracks and extend the structure’s lifespan.

Safety Barriers: Hexagonal wire mesh is also used to create safety barriers at construction sites. It helps prevent unauthorized access and protects workers from potential hazards, contributing to a safer work environment.

Industrial and Commercial Uses

Screening and Filtration: Hexagonal wire mesh is used in various industrial processes for screening and filtration. It can separate materials based on size, making it useful for sorting aggregates, grains, and other bulk materials.

Security Fencing: In commercial settings, hexagonal wire mesh is commonly used for security fencing. Its durability and flexibility make it suitable for securing premises, including warehouses, industrial facilities, and retail properties.

DIY and Craft Projects

Home Décor and Crafts: Hexagonal wire mesh is a popular material for DIY and craft projects. It can be shaped into decorative items like wall art, picture frames, and custom storage solutions. Its pliability and unique appearance make it a favorite among craft enthusiasts.

Why Choose Al Miqat Hardware for Hexagonal Wire Mesh?

When sourcing high-quality hexagonal wire mesh in Oman, Al Miqat Hardware stands out as a top supplier. Here’s why they are the best choice for your wire mesh needs:

Extensive Product Range

Chicken Wire Mesh Rolls: Al Miqat Hardware offers chicken wire mesh rolls ideal for poultry enclosures and various agricultural uses. Available in different sizes and gauges, these rolls ensure you find the perfect fit for your specific needs.

Farm Fencing Mesh: Their selection of farm fencing mesh is designed to meet the demands of farmers and landowners, providing durable and reliable fencing solutions for livestock and crop protection.

Hexagonal Wire Mesh: Al Miqat Hardware provides a wide range of hexagonal wire mesh options suitable for applications in construction, gardening, and industry.

High-Quality Materials

Durability: Al Miqat Hardware ensures their hexagonal wire mesh products are made from top-quality materials. Whether galvanized, stainless steel, or PVC-coated, their mesh is built to last and perform well in various conditions.

Reliability: By sourcing their products from reputable manufacturers, Al Miqat Hardware guarantees that customers receive wire mesh that meets industry standards for strength and durability.

Expert Advice and Support

Product Knowledge: The team at Al Miqat Hardware is well-versed in hexagonal wire mesh and can provide expert advice on selecting the right type of mesh for your needs, whether it’s for a chicken coop or a large farm fence.

Installation Guidance: They offer guidance on the installation of wire mesh, ensuring you achieve the best results for your projects. Their experts provide tips and recommendations for proper installation and maintenance.

Competitive Pricing

Value for Money: Al Miqat Hardware offers competitive pricing on their hexagonal wire mesh products, ensuring excellent value for your investment by balancing quality and affordability.

Bulk Discounts: For larger projects or bulk purchases, they offer discounts and special pricing, making it cost-effective to source wire mesh for extensive needs.

Reliable Service

Timely Delivery: Al Miqat Hardware ensures the prompt delivery of wire mesh products throughout Oman. Their efficient logistics and distribution network mean you receive your orders on time and in excellent condition.

Customer Satisfaction: Al Miqat Hardware prioritizes customer satisfaction, offering reliable service and support throughout the purchasing process to address any questions or concerns.

Conclusion

Hexagonal wire mesh is an invaluable material with diverse applications, from agricultural fencing to construction reinforcement. Al Miqat Hardware is the premier choice for hexagonal wire mesh in Oman, offering a broad selection of products, including chicken wire mesh rolls and farm fencing mesh.

By choosing Al Miqat Hardware, you gain access to high-quality products, expert support, competitive pricing, and dependable service. Whether you’re working on a farm, a construction project, or a DIY venture, Al Miqat Hardware provides the wire mesh solutions you need to achieve your goals effectively. Trust Al Miqat Hardware for all your hexagonal wire mesh needs and experience the difference that quality and expertise can make.

#al miqat hardware#wire mesh Sharjah#wire mesh oman#hexagonal wire mesh oman#galvanized fencing mesh#fencing mesh stockiest#wire mesh stockiest UAE#chain link fencing stockiest

0 notes

Text

Are You Looking For The Best Sewage Treatments Plant Manufacturer In Gurgaon?

The process of storing & pre-treating sewage that is produced by factories & various other industrial firms before it can be utilized in agriculture & various other applications or purposes is referred to as wastewater treatment. The wastewater hygiene for the surroundings is very crucial for Netsol Water to maintain, a stable as well as an efficient Sewage Treatment Plant Manufacturer In Gurgaon. Three essential elements are utilized by the STP process:

High-density pollutants are removed from the sewage by filtering employing wire cloth, wire mesh, & mechanical separators.

O2(oxygen) is supplied while maintaining the crucial chemistry-based configuration that allows water molecules to transit the sewage via aerators. Furthermore, the degree of water pollution dictates how much chlorine is supplied.

In the final step of the treatment phase, trickling filters are implemented to filter the contaminated water. This procedure isn't typically utilized very often.

Nearly all regions of Gurgaon, Netsol Water provides Sewage Treatment Plant for a variety of activities that separate pollutants & repurpose chemical compounds along with wastewater.

When it comes about Wastewater Treatment Plant facilities, Netsol Water's technological know-how is unmatched. It incorporates cutting-edge trending developing technology in combination with cutting-edge refining techniques to produce low-cost STP for that particular industry.

Modern technology-based therapy techniques are implemented in an STP.

Wastewater accumulates & its properties as well as flow are balanced in a waste balancing tank. Through the utilization of air-blowing aerators, the contents are kept in an interdependent environment. Coarse bar-screens filter the Sewage before it gets through the equilibrium maintaining tank. After the wastewater has equalized, it is pumped to a quick flash mixing tank & then transported to a flocculation tank.

In the rapid blending tank, chemical-dosing of lime along with alum is applied to promote coagulation. To help the particles clustered, an ionic poly-electrolyte is introduced & fused in the flocculation tank. The flocs are eliminated by the lamella-clarifier, tube-settler, or subsequent up-flow filtering.

Following the first stage of the Sewage treatment, the sewage wastewater is fed into a biological reactor by gravity, where aerobic BOD-COD reduction takes place. Using the bubble-diffusion method ensures an adequate supply of air.

The produced biological solids are removed from then fed secondary settlement tank, also known as the lamella clarifier or tube-settlers. Salt hypochlorite is administered in the chlorine contact tank & serves to polish, rectify, clarify, & disinfect the cleansed sewage water. After being sterilized, the water was filtered utilizing an activated carbon filter & a pressurized sand filter. Discarding the disinfected wastewater is permissible. Alternatively, collect them & place them in a pond where they will ultimately evaporate.

Netsol Water in Gurgaon uniquely utilizes top-notch equipment; they don't use any cheap or subpar electro-mechanical equipment.

Chemical Procedures Applied in Sewage Treatment Plant Facilities

Chemical techniques for treating wastewater from factories, or sewage produced by the companies, malls or any restaurants, employ two sorts of distinctive features:

The pollutants' chemical properties, including how they operate or react with the chemicals that are utilized for treatment.

The ineffectiveness of the products to stay as suspended or aqueous solutions is related to their ability to dissipate, changing unstable matter, or other qualities that result from the combined response of pollutants with treatment chemicals.

Conclusion

While reviewing, leading in wastewater treatment plant systems including Sewage Treatment Plant Manufacturer In Gurgaon is Netsol Water. This business provides a wide range of advantages, such as innovative, fashionable technology & specialist services that include environmentally friendly methods. These producers are essential to maintaining the effective as well as durable wastewater treatment of Gurgaon as the city expands.

0 notes

Text

Wire Mesh Manufacturers of 2024

Wire Mesh Manufacturers

Sulesh Wooven, Wire Mesh Manufacturers offers a diverse product portfolio, including hexagonal wire mesh, industrial wire screen meshes, welded wire mesh, perforated metal sheets, and more. The company's in-house brand is trusted for its superior quality and reliability, making it a preferred choice for customers in sectors such as chemicals, mining, pharmaceuticals, food processing, and marine engineering.

Wire Mesh

Wire Mesh Manufacturers, Sulesh Wooven is its commitment to innovation and technological advancements. The company utilizes sophisticated welding processes and automated production methods to ensure consistent quality and high tensile abrasion resistance in its wire mesh products. Wire Mesh Manufacturers, Sulesh Wooven is the sole distributor of Polymer Mesh.

Wiremesh

Wire Mesh

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit :- https://www.wiremeshdelhi.com/welded-wire-mesh.html

Address : H.O:K-245, Pushta Road, Karawal Nagar, Shahdara, Delhi-94 K-46, Sector-5, Bhawana, Delhi-39

Twitter :- https://twitter.com/mesh_wire28439

0 notes

Text

All You Need To Know About Wired Safety Glass

If you’re in the construction industry, you likely know about wired safety glass. However, if you are a plain homeowner who has just heard about the term, as suggested during the planning stage, maybe you’re wondering what this means. Perhaps you want to renovate your house, and your architect or designer has indicated that it should be incorporated into your design.

But what is wired glass?

Wired glass is also called mesh, safety, and Georgian wired glass. This is a specialized type of glass with wire mesh or wire netting within its structure to enhance its durability and safety. The wire netting is embedded in the glass during its process of manufacture and reduces the possibility of it shattering when some higher impact, shock, or fire cracks it. The wire netting is the reinforcement to the glass.

Mesh glass is available in 3 different types, as follows:

* Wired glass, the most commonly used type, consists of wire mesh. This wire mesh prevents the glass from completely shattering due to high temperature. This makes it an excellent option for fire-rated applications.

* Laminated mesh glass offers the feature of wire mesh sandwiched between 2 or more sheets of glass.

* Decorative mesh glass has wire mesh incorporated in various patterns and designs to enhance aesthetics. This type is found in interior design applications like screens, partitions, and other decorative elements. The safety and security, then, are coupled by visual appeal.

Where is wired glass used?

Wired safety glass, or Georgian wired glass, is applied in various industries, including house and building construction, architecture, security, interior design, and office partitions.

You can use them broadly in places where nominal fire resistance is required, like the doors to the fire exit. You can find them mostly in windows of schools, public buildings, hotels, dividers of office spaces, and other institutions.

This type of glass is helpful during a fire because it gives people more time to leave the building during an emergency.

Stairwells and hallways of buildings use Georgian-wired glass for safety and aesthetic purposes, roofs and skylights, and fire-resisting doors.

What are the benefits of wired glass when installed in your home, office, or commercial building?

There are several advantages of wired glass offered to those who use them. For example, the net wiring within the glass can hold fire for some time in entering the building, preventing the risks of damage to building occupants, as they will have more time to leave the building.

Glass can break violently with extreme impact; however, the pieces of shattered glass will be held by the wire mesh and will not scatter around, causing injury to those in the area.

Wired glass is higher in thermal and electrical resistance than float glass.

Wired glass is more affordable than other types of safety glass.

It can also be a design element in your interior design (patterned and tinted glass, for example).

VMS Trade Link employs a team of experts with extensive knowledge, skills, and experience in the glass industry. Whether you are looking for wire, laminated, or decorative mesh glass, we have many options to offer. You are assured that we can deliver the highest quality glass products to your satisfaction.

Call us today, and let’s discuss your project. We will be happy to be of service to you. VMS Trade Link is a renowned glass fabricator, and they have the best customer care representatives, who are known to be the most soft-spoken and polite in the area of Ahmedabad, Gujarat. If you have never tried us, please give us a chance, and then gauge us later.

#wired safety glass#what is wired glass#advantages of wired glass#where is wired glass used#benefits of wired glass

0 notes

Photo

Aerospace Wire Net

Aerospace wire net is a type of woven mesh, which is used in aerospace. The wire net is made from high-quality stainless steel wire. As popular screen mesh, it is also named stainless steel wire mesh.

Advanced Technology: Stay ahead of the curve with advanced technology of the wire net. Our products integrate the latest innovations for superior functionality. Cutting-edge materials and manufacturing techniques define our wire nets. Ensure seamless communication and power distribution with our tech-driven solutions. This stainless steel wire screen leads the way in technological excellence.

Reliability Assurance: Trust in the reliability of wire net products for mission-critical applications. Rigorous testing guarantees performance under extreme conditions. Our wire nets undergo stringent quality checks for unmatched dependability. Count on us for consistent and faultless aerospace wiring solutions. Ensure the success of your projects with our reliable products.

Customization Options: Tailor your aerospace wiring to exact specifications with our customization options. The wire net offers bespoke solutions for unique project requirements. Choose from a variety of materials, lengths, and configurations. Our expert team ensures your wire nets perfectly align with your needs. Elevate your aerospace systems with personalized wiring solutions.

Global Compliance: This stainless net products adhere to international aerospace standards. Comply with industry regulations and ensure seamless integration globally. Our wires meet stringent safety and quality standards for global acceptance. Navigate regulatory challenges effortlessly with our compliant solutions. Choose the wire net for a globally recognized mark of excellence.

Environmental Sustainability: Embrace eco-friendly aerospace solutions with our sustainable wire nets. The wire net is committed to minimizing environmental impact. Explore green alternatives without compromising on performance. Contribute to a greener future with our environmentally conscious wire products. Sustainable solutions that align with your aerospace and ecological goals.

Efficient Installation: Streamline your projects with easy-to-install solutions of the wire net. Simplify the installation process with user-friendly wire net designs. Save time and resources with our efficient and hassle-free installations. Maximize productivity without compromising on quality. The wire net ensures a smooth and swift integration process.

Industry Affordability: Benefit from cost-effective aerospace wiring solutions without compromising quality. This wire net provides affordable options for diverse project budgets. Enjoy competitive pricing without sacrificing performance or durability. Maximize your return on investment with our cost-conscious wire net solutions. Unleash the potential of wire net products at an industry-best value.

Customer Support: The wire net is committed to exceptional customer support. Our dedicated team ensures prompt assistance for all inquiries and concerns. Experience a seamless customer journey from product selection to post-purchase support. We value your satisfaction and are here to assist you at every step. Choose Aerospace Wire Net for a partnership built on trust and support.

The product Aerospace Wire Net appeared first on Alex Wire Mesh.

#Aerospace Mesh#Aerospace Net#Aerospace Wire Cloth#Aerospace Wire Mesh#Aerospace Wire Net#Aerospace Wire Screen#Stainless Aerospace Cloth#Stainless Aerospace Mesh#Stainless Aerospace Net#Stainless Aerospace Wire Cloth#Stainless Aerospace Wire Mesh#Stainless Aerospace Wire Net#Stainless Aerospace Wire Screen#Stainless Steel Wire Mesh

0 notes

Text

Wire Mesh Screen Exporter

Fine Perforators is a trustworthy and capable exporter of wire mesh screens customized to particular needs. The R&D department guides the manufacturing facility to produce tailored-to-need wire mesh screens for different filtration machinery. Fine Perforators has adequate arrangements for seamless export to expanding numbers of countries.

#wire mesh screen#wire mesh manufacturer#best wire mesh manufacturer in india#multiplecrimp wire mesh#wire mesh

0 notes

Text

#extruderscreens#mesh extruder screens#best extruder screens in india#wire mesh#mesh manufacturer#meshsupplier#extruder screens#extruder screens in india#extruder filters in india#plastic filters in india

0 notes

Text

GI Wire Mesh: An In-Depth Overview and Its Pioneers

The world of construction and architecture is vast and ever-evolving. Among its vast components, GI Wire Mesh stands out as a vital product in various industries. This versatile material is now extensively used in fencing, screens, filters, and other applications. The trust and reliability it offers make it an essential choice for many. When discussing quality and excellence in this domain, the name Jeetmull Jaichandlall (P) Ltd can't be ignored. This esteemed entity stands tall among the leading PB Wire Mesh Manufacturers and has carved a niche in the market.

Evolution of Wire Mesh and Its Importance

It has witnessed a significant evolution over the decades. From being a mere protective barrier to now playing a crucial role in filtering, screening, and more - its importance can't be overstated. Especially when it comes to SS Wire Mesh, which offers better strength and durability, manufacturers are now prioritizing its production.

Established with a vision to lead and innovate, it is not just another name in the industry. Their commitment to quality and unwavering dedication makes them stand out as leading Wire Mesh Manufacturers. Their extensive range of products, paired with state-of-the-art technology, ensures that customers receive nothing but the best.

Qualities of Superior GI Wire Mesh

A quality GI Wire Mesh should possess certain characteristics. It should be rust-resistant, durable, and malleable enough for various applications. The superior mesh should also have uniform weaving, ensuring that the quality remains consistent throughout. The process used by SS Wire Mesh Manufacturers should be environmentally friendly and sustainable.

Applications and Benefits For GI Wire Mesh

From construction sites to agricultural fields, the applications of GI Wire Mesh are vast. Not only does it provide a protective barrier, but its filtering capabilities are also unmatched. Whether you’re looking to sieve, separate, or protect, this material is the go-to choice for many.

Stainless steel, commonly abbreviated as SS, brings a new dimension to the wire mesh world. SS Wire Mesh Manufacturers recognize its potential, and its demand is skyrocketing. Offering enhanced durability, strength, and resistance to environmental factors, it's clear why SS Wire Mesh is becoming the choice for forward-thinking industries.

ConclusionIn the realm of wire mesh, quality, and reliability are paramount. This is where companies like Jeetmull Jaichandlall (P) Ltd shine, consistently delivering products that exceed expectations. As PB Wire Mesh Manufacturers and leaders in the domain, their offerings are a testament to their commitment to excellence. Whether you're seeking traditional GI Wire Mesh or exploring the benefits of SS Wire Mesh, it's crucial to rely on trusted manufacturers for your needs. Visit our website to know more about our top notch products. You can reach us at [email protected] or +91-9903647111.

0 notes

Text

Tire Shredder Machines And Further Equipment Required For Eco-Friendly Rubber Recycling

If your looking to start up a tyre recycling company, one of the first pieces of equipment you must buy is actually a tire shredder machine. This sort of machine is able to cut a great deal of second hand car tires into tiny pieces at a high working efficiency. You might also hear such a machine referred to as a tire grinder or grinding machine. Each of the best machines are created to process tires for any size, including tractor and HGV tires to improve the processing capabilities of your own rubber waste recycling business.

Beston's tyre shredding machine can process full-steel radial tires, bias tires, and semi-steel radial tires, including airplane, tractor, bicycle, car, and motorbike tires. They transform tires into rubber powder or <50mm rubber blocks depending on the operational mode selected by the user. The black rubber powder can be set to 30 to 200 mesh depending on the consistency required for additional processing processes.

The main parts of a typical tire grinder configuration include a chain conveyor, tire shredder, secondary chain conveyor, rubber rasper, dust collector, belt conveyor, rubber granulator, vibrating screen, and cyclone.

Here are some of the benefits of Beston tire shredders for sale:

Compact structure.

Easy maintenance access and side-by-side configurations.

Competitive pricing.

Equipped with a durable, wear-proof shredding blade.

Low energy consumption.

Fast processing times.

Highly-rated after-sales services.

Beston's 900 model has an hourly processing capacity of 2T and weighs 6.8T. The brand's 1200 model, meanwhile, has double the hourly processing capacity and weighs 18T. You can obtain a free quotation for each of the models by contacting a customer representative. You should expect a reply within 24 hours.

If you want to be able to process large rubber waste items, such as sports hall flooring, rubber mats, carpet liners, horse racing tracks, etc. you will need to invest in a crushing machine. The crushing machine will transform large items into pieces small enough to enter the tire-shredding machine.

After you have purchased a tire shredder machine and optional crushing machine, you need to start looking for an energy-efficient rubber pyrolysis plant to get your eco-friendly recycling business operational. While scrap tires have traditionally been disposed of via incineration and landfill burial, a pyrolysis plant enables you to convert used rubber into profitable commodities, including steel wire, carbon black, combustible gas, and fuel oil. Incidentally, Beston has both tyre shredding machines and rubber pyrolysis reactors for sale on its official website, which you can visit here.

There are of course other tire shredder manufacturers in the marketplace and it's worth exploring the different models for sale. While Beston exports to most countries around the world, it's possible that local suppliers in your region might have equipment better suited to the climate conditions and main types of rubber waste near your factory.

Remember that price is not the only factor you should take into account when comparing different tire grinding machines for sale online. You also need to consider the reputation of the supplier and the durability of the machine's construction.

0 notes

Text

What are the Advantages of Using Stainless Steel Wire Over Other Types of Wire Materials?

Introduction:

Stainless steel wire has gained significant popularity in various industries due to its unique properties and numerous advantages over other types of wire materials. Whether you're searching for stainless steel wire suppliers near me or exploring custom medical wire forming in Connecticut, understanding the benefits of stainless steel wire can help you make informed decisions for your specific requirements. In this article, we will delve into the advantages of using stainless steel wire and why it stands out among its counterparts.

Exceptional Corrosion Resistance:

Stainless steel wire is renowned for its exceptional resistance to corrosion. The high chromium content in stainless steel forms a passive oxide layer on the surface, which protects it from rust and corrosion even in harsh environments. This property makes stainless steel wire ideal for outdoor applications, marine environments, and industries where exposure to moisture or chemicals is prevalent.

Superior Strength and Durability:

Stainless steel wire exhibits remarkable strength and durability, making it suitable for a wide range of applications. Its high tensile strength ensures that it can withstand heavy loads and resist deformation, making it an excellent choice for demanding applications in construction, automotive, and industrial sectors. Additionally, stainless steel wire maintains its mechanical properties over a wide range of temperatures, ensuring long-lasting performance in extreme conditions.

Hygienic and Easy to Clean:

Stainless steel wire is hygienic and easy to clean, making it an ideal choice for applications in the medical, pharmaceutical, and food industries. Its smooth and non-porous surface resists bacterial growth, making it easy to sterilize and maintain a sterile environment. This property is crucial in medical wire forming processes, where cleanliness and precision are paramount.

Versatility in Applications:

Stainless steel wire offers versatility in a broad range of applications. From wire mesh screens to structural supports and electrical conductors, stainless steel wire can be tailored to meet specific requirements. Its flexibility allows for various wire forming processes, including custom medical wire forming in Connecticut, enabling manufacturers to create intricate and specialized components for medical devices.

Aesthetic Appeal:

Stainless steel wire not only provides functional advantages but also offers aesthetic appeal. Its sleek and modern appearance makes it a popular choice in architectural applications, decorative purposes, and design elements. Stainless steel wire can be polished or finished in different ways to achieve the desired visual effect, enhancing the overall aesthetics of the product or structure.

Conclusion:

When it comes to wire materials, stainless steel wire outshines its counterparts in many aspects. Its exceptional corrosion resistance, superior strength and durability, hygienic properties, versatility, and aesthetic appeal make it a sought-after choice in various industries. Whether you're searching for stainless steel wire suppliers near you or considering custom medical wire forming ct, understanding the advantages of stainless steel wire will help you make informed decisions and choose the best wire material for your specific needs.

0 notes

Text

Importance of Rectangular and Circular vibrating screen

Screening medium to coarse-grained bulk materials (5.0 mm to 100 mm) is done by circular vibrating screens, also known as Circular vibrating screen. For circular vibrating screens to function, the screen mesh is indirectly excited. Unbalanced masses cause a circular vibrating motion in the entire screen frame.

Rectangular Vibrating Screen Characteristics

Rectangular vibrating screen come in various models and configurations to meet virtually every screening, dewatering, classification, or scalping need.

Stainless steel mesh, nylon or synthetic fabric, bar screen, or wedge wire dewatering panels are some other materials found in screens.

Screen fabric is chosen for longer durability and is set up for easy maintenance and replacement. Carbon steel, corrosion-resistant stainless steel, or another lined media can be used for Vibrating compaction table contact surfaces, depending on the quality of the screened bulk material.

Screen bodies can either be open, exposing the processed material or closed, preventing dust from escaping.

A cassette of bouncing balls can be arranged to lessen screen cloth choking caused by sticky materials.

Screeners that are either round or mechanical, or rectangular:

One of the three most common screener shapes is a rectangular shape. These machines are a great all-around option compared to circular screeners, which are more space-efficient but usually more expensive, and mechanical screeners, which are easier to use but less successful at fine-separating and sieving chores.

When deciding on a screener, it's important to think about the following:

Needs in Manufacturing:

A good screener consistently and successfully separates or screens out the target material. To maximize productivity, you should invest in machines that can perform many functions.

Footprint:

A compact machine has many advantages in crowded manufacturing facilities. However, smaller devices are limited in the material they can process simultaneously. A machine with a larger footprint could be preferable if production volumes are high.

Maintenance:

Most screeners need help to function properly during maintenance, reducing your efficiency. If downtime is not an option, a machine with easily accessible parts and minimal moving parts may be the best buy.

Safety:

Pharmaceutical and chemical manufacturing are only two examples of industries where screening for safety is a top priority. You can install ventilation hoods on many screeners to keep your team safe when working with potentially dangerous chemicals.

How to Use a Rectangular Vibrating Screen:

The screen frame vibrates straight or linearly because the motors are mounted at right angles. Because of this, larger particles are efficiently conveyed forward even when the screen's frame is tilted upward. The structure of the rectangular screen can be tilted downward at an angle that best suits the intended use. The machine's capacity is maximized in the uphill position, leading to a pool at the feed end. The water pressure in the pool causes the fluid to spread more. The large particles are efficiently transported by the screen frame's horizontal Vibrating table screens and released outside the pool area.

Conclusion:

Buying powder materials in bulk can save businesses a lot of money and boost output at powder processing facilities. However, powder processing companies must invest in a bulk bag unloader system to collect the product and dispense it into the processing line to take advantage of all this and more.

0 notes

Text

Polybutadiene Rubber Ball Cleaners | Symbolic Rubber Industries

The conventionally used rubber balls have been replaced in recent years with polyurethane sieve cleaners with plastic bristles. The rubber ball should be your preferred sieve cleaner over any other on the market, since it can be observed that polyurethane sieve cleaners have their own set of flaws and drawbacks compared to the rubber ball. Symbolic Rubber Industries was founded by M. Sharma and S. Singh & Co. The main challenge for every mill is finding the best sieve cleaning aids so that it may achieve maximum production while incurring the least number of expenditures and worry less about the effectiveness of sieve cleaning in its mill. The difficulty a miller would have is determining whether superior sieve is cleaner in terms of overall ownership expenses over time. It's challenging to comprehend and choose the best sieve cleaner given the wide range of options—from the lowest quality to the finest—and varying claims about how effective they are. Sieve cleaners are currently available on the market, and there is a wide range of variety and quality.

As previously mentioned, "In recent years, it has been observed that polyurethane sieve cleaners with plastic bristles have replaced the traditionally used rubber balls." And the reason was that it was difficult to find classic rubber balls since the companies who made them didn't engineer the items appropriately, didn't produce them of the right quality, and couldn't meet the FDA and E.U. standards for rubber cleaner. The polyurethane sieve cleaner, however, is discovered to have a number of drawbacks of its own. And given these particulars, picking the rubber ball should be your best option. And these are all of the faults of the polyurethane sieve cleaner: Polyurethane sieve cleaners are susceptible to breakage from the high-velocity movement inside the plan sifter as well as constant bumping into the frames due to the constant side-to-side movement of the sieve which can also lead to damaging the nylon or wire mesh sieve cloth. Where else, in the case of a rubber ball cleaner no such possibility exists as the rubber balls jump up and are shown on the screen itself and not colliding with the frame. Given the round and oval shape of the balls, there is no chance of any damage either to the balls or the sieve/ frame. Plan sifter manufacturers currently are looking to improve upon the material of the sieve as well as their frames as the polyurethane sieve cleaners are mandating higher strength materials for the sieve and the frame, therefore increasing the total ownership costs whereas, the simpler cost-effective, and efficient solution is to use good quality rubber ball sieve cleaners. * Another issue of the polyurethane and plastic sieve cleaner is that it un-shapes due to temperature changes and the weather as polyurethane is not as stable to changes of weather and temperature conditions given the various geographical locations which would lead to ineffective cleaning as the deformed bristles sieve cleaner will not make proper contact with the sieves and will not clean properly. On the other hand, the material of a well-designed rubber ball would be capable of surviving in any temperature and also, its shape remains unchanged no matter how it’s used. * The bristles of a polyurethane sieve cleaner are of nylon and in some cases, horse hair, both of which are obviously not recommended for human consumption. Overtime inside the plan sifter during the sieve cleaning process the bristles may mix with the flour/grain being sieved, where else, if you were to use a rubber ball that has food-grade material, if it mixes with the flour/grain being sieved, the flour/grain will still remain safe for consumption and therefore, it should be the preferred option for any miller. * The plastic bristles of a polyurethane sieve cleaner have a tendency to wear out fairly quickly and don’t have a long life compared to that of a rubber ball. Every time a miller has to replace their sieve cleaners, it leads to machine downtime, thus affecting productivity and overall equipment effectiveness, adding to the milling cost and affecting overall yield. With a good quality rubber ball, one can reduce the downtime drastically for sieve cleaner replacement. * Even though most of the plastic and polyurethane material used in polyurethane is food-grade certified, it does not mean that the materials getting mixed into the food is safe enough. Any amount of plastic or polyurethane mixed into flour/grain is not safe for human consumption, whereas, the rubber ball sieve cleaner made with natural rubber blended with other next-generation food-grade elastomers is 100% safe, even if it’s consumed. But the main question is, “Where do you find the best rubber ball sieve cleaner?” The answer is Symbolic Rubber Industries makes the best quality rubber ball sieve cleaners, which are not only safe but also the most efficient sieve cleaners out there, providing the lowest total ownership costs to the milling industry and the best maximum cost ratio over time.

The plans of Symbolic Rubber Industries Pvt Ltd Company are the production of other popular sizes of sieve cleaning rubber balls on the market. Also, we are ready to produce balls for individual orders.

Symbolic Rubber Industries Rubber products supplier high bounce rubber ball the best range of rubber gasket for geyser, nitrile rubber gasket and rubber gas kits with effective & timely delivery.

For Contact us: -

1 note

·

View note