#best vinyl cutter machine

Explore tagged Tumblr posts

Text

Ortur Laser Module Acrylic Safety Cover for LU2–4 SF

Tariff (VAT) free for all customers.

Only compatible with Ortur LU2–4 SF Laser Module.

All orders will be shipped within 48 hours. (Except weekends)

The Ortur Laser Module Acrylic Safety Cover enjoys a 30-day return guarantee and a one-year warranty. Order now!

#laser 2 parts#laser welder machine for metal#Offline Controller#cnc wood machine#vinyl cutter#Best CNC machine

0 notes

Note

Not a suggestion, more a question - how do you make your stickers? Your art inspired me to make stickers but I don’t know where to start!!

Ooh Tutorial Time! I have a small rundown of my process here. (I’ve got a video here, but I’ve had an update in my materials. Also this got a little away from me, I hope this helps and lemme know if there’s anything I need to elaborate on!)

--- Materials: Printer - Epson Ecotank 8500 Cutters - Silhouette Cameo 4s (I’ve got 2 at the moment) Paper - Zicoto Glossy Vinyl Laminates - Glossy and Holo Star Laminate (Both Self Adhesive) Misc Off Brand Sticker Cutter mats Ruler Squeegee with extra microfiber wrap Sports glove tack spray or sewing basting spray

Printer - Aim for a photographic printer at the minimum. General print quality, color variety, and paper handling will make sure your prints are the highest possible quality. They’re a little more expensive, but my last printer lasted 4 years with frequent weekly printing. The ecotank is nice, it’s more visual that the ink is actually disappearing than the pre-filled cartridges lol. Cutter - I’ve only used Silhouette, but I’ve heard to stay clear of Cricut due to general cut unreliability and lack of customer service assistance. I’ve also heard great things about the Siser Juliet cutter from mutuals. In order to use 2 machines at the same time, I had to purchase the Business license ( p sure it was a one time $50 purchase, but I can work twice as fast). If you want to cut by hand, check out what kind of ergonomic scissors you can find. Classic scissors over time can really screw up your hands, especially when you’re making fine cuts.

Printing and Sizing - The Silhouette Studio resizes your stickers without many issues with quality changes. This does kinda depend on the base size of your files. I always make my stickers on a canvas 3000x2000 pixels and 300 dpi. I wouldn’t go any lower than 100 dpi for print, and no larger than 500 dpi, but you can always test this out.

Paper - I enjoy the luster of the paper I linked above, there’s almost a pearlescent quality to it. If you’d like a different quality, I recommend still sticking with glossy vinyl for your paper. Laminates on matte sticker paper have had a lot of trapped air underneath for me and it tended to be more likely to bleed in contact with water despite being laminated.

Laminate - If you’re just doing paper finish stickers, you can skip this step :)

Laminate them to make them more water and scratch resistant. The laminates I’ve listed are all self adhesive. There are also heat adhesive laminates, which require a heat laminator. I haven’t experimented much with heated laminates. Mine are best rated for hand wash, though they can go through the dishwasher a few times. When laminating your sticker sheet, be sure to not cover your registration marks. When your cutter tries to read over them and the surface is really reflective, it can cause the machine to read improperly (and it’s worse with the holographics lol). Either precut your laminates like I do in the video I linked above, or you can use matte tape over your laminate to dull the sheen. If you accidentally cover your registration marks, the matte tape is a lifesaver. Self laminating takes some muscle memory to not get bubbles trapped under the laminate, but a wide squeegee and firm pressure helps make sure you get as few bubbles as possible. Mats - Your cutter will come with a few, but I find that my off-brand ones are just as good and less expensive. I prefer low-tack, but there comes a time when the tack is absolutely gone, and I have 10+ mats just sitting around. That’s where the Sports Glove spray or Sewing basting spray comes in! After washing them (soap and water, then dry for a few hours), I hit them with a few coats of spray. Right now I’m using Pow’r Tac Grip Spray. It’s just ok, but this leaves less residue on the back of my stickers than the Basting Spray I used to use. I retack every month or so, but that’s more bc I’d prefer the mats to be less sticky than risk ripping my backing sheets.

----

If there’s anything you’d still like to know, please let me know!!

#my art#tutorial#stickers#sticker making#art tutorial#my process#i'll never gatekeep lol#paleo party

14 notes

·

View notes

Note

Heya

Aaah it made me so happy to see another one of your beautiful creations

I know I told you before but you're legit a reason why I taught myself how to embroider so I can make things like this 😅

I just wanted to ask, do you use a cricut cutter for the letters? Cause I remember you said it's vinyl?

I bought some sheets recently for a bookbinding project and found that it's very hard to cut it nicely by hand but those machines are expensive 😅

Hope you have a wonderful end of the year and if you're celebrating anything, I hope you have a beautiful celebration

💚

Hello my darling Ty! I'm so sorry for the super late response, but I hope you're having the most wonderful New Year! You're so very sweet 💖

And in answer to your question, yes I use iron-on vinyl and a cricut machine to do all my lettering. When the cricut machine cuts it, it's actually a very shallow cut that only goes through the vinyl itself and not the attached backing so that may be where the problem is. I know the machines are expensive and I was lucky enough to get one as a Christmas gift from my family.

Embroidering the lettering isn't impossible, just not my own prefered method since I'm usually stitched out by the time I get to that part. You could potentially try using a fabric marker or a fine sharpie to write it in by hand? I would suggest typing/writing out your line first on separate paper to make sure it's exactly the way you want it, then use some method of backlighting (like a sunny window or a tablet/computer screen) to trace the line directly onto the cloth of the piece. I hope that makes sense 😅

I'm would love to see anything you come up with if you ever feel comfortable sharing and I'll do my best to help should you ever need it 💖

5 notes

·

View notes

Text

T-Shirt Printing Machines for Sale: A Comprehensive Guide

The t-shirt printing industry has experienced exponential growth in recent years, driven by the increasing demand for custom apparel. Whether you're an entrepreneur looking to start your own clothing line or a business seeking to expand your product offerings, investing in a t-shirt printing machine is a crucial step. These machines allow you to print custom designs on t-shirts, offering a level of creativity, personalization, and profitability. In this guide, we’ll explore the different types of t-shirt printing machines available for sale, their features, and what you should consider before making a purchase.

Types of T-Shirt Printing Machines

When it comes to t-shirt printing, there are several different technologies to choose from. The right machine for your needs will depend on factors like the volume of prints you plan to produce, the types of designs you want to print, and your budget. Below are the most common types of t-shirt printing machines for sale:

Screen Printing Machines Screen printing, or silk screening, is one of the oldest and most popular methods for printing on t-shirts. It involves creating a stencil (or screen) for each colour in the design and using it to apply ink to the t-shirt. This method is ideal for bulk production and is known for its durability and vibrant colours.

Advantages: High-quality prints, cost-effective for large orders, durable prints.

Disadvantages: Time-consuming setup, not suitable for highly detailed or multi-coloured designs, best for bulk runs.

Heat Press Machines Heat press machines use heat and pressure to transfer a design onto a t-shirt, typically using vinyl or sublimation transfer sheets. This method is user-friendly and relatively inexpensive, making it a great option for small businesses or hobbyists.

Advantages: Low cost, easy to use, ideal for small batches and customized designs.

Disadvantages: Limited to simpler designs or single-colour prints, slower compared to screen printing for large volumes.

Direct-to-Garment (DTG) Printers DTG printers work similarly to inkjet printers, directly applying water-based inks onto the t-shirt fabric. This method allows for full-colour, high-quality prints, including intricate designs and photographs. DTG printing is perfect for small to medium orders and offers incredible detail.

Advantages: High-quality, full-colour prints, no setup required, ideal for complex designs and photos.

Disadvantages: Higher initial investment, slower printing speeds, and ongoing maintenance costs.

Sublimation Printing Machines Sublimation printing uses heat to transfer dye onto synthetic fabrics like polyester. Unlike other methods, the dye becomes part of the fabric, ensuring vibrant colours that won’t fade or peel. Sublimation is primarily used for all-over prints or polyester-based t-shirts.

Advantages: Long-lasting, high-quality prints, great for full-colour designs.

Disadvantages: Only works on polyester or polymer-coated fabrics, limited to light-coloured garments.

Vinyl Cutters Vinyl cutters are machines that use a blade to cut out designs from sheets of coloured vinyl, which are then heat-pressed onto t-shirts. This method is especially popular for creating custom text and logos and is often used in small businesses or for personalisation.

Advantages: Cost-effective for small runs, easy to use, ideal for simple text and logos.

Disadvantages: Limited to solid colours, no gradient or photographic designs.

Key Features to Look for in a T-Shirt Printing Machine

When shopping for a t-shirt printing machine, several factors can influence your decision. Here’s a look at the key features to consider:

Print Resolution and Quality The resolution of your t-shirt printer will determine how sharp and detailed your designs will look. For professional results, you’ll want a machine with high resolution and excellent colour reproduction, especially if you’re planning to print photos or intricate designs.

Production Speed The speed of the printer is an important consideration, particularly if you plan to handle large volumes of orders. Machines like DTG printers offer high-quality results but may print more slowly, while screen printing machines are faster for bulk production.

Compatibility with Different Fabrics Some printing machines are only suitable for specific types of fabrics. For example, DTG printers work best on cotton, while sublimation printers are ideal for polyester. Make sure your chosen machine is compatible with the materials you intend to print on.

Ease of Use and Setup Depending on the type of machine, the complexity of setup and operation can vary. Heat press machines and vinyl cutters are generally straightforward to use, while screen printing and DTG printers may require more technical expertise. Ensure the machine you select is easy to operate and comes with sufficient training or support resources.

Size and Space Requirements Printing machines, particularly those for screen printing or DTG, can be large and require substantial workspace. Before purchasing, measure the space where you intend to use the machine and ensure it can accommodate the equipment, as well as any additional accessories or supplies.

Maintenance and Durability Regular maintenance is essential for keeping your t-shirt printing machine in good working condition. Some machines, particularly DTG printers, may require more frequent upkeep, such as cleaning the printheads or changing inks. Ensure that spare parts are readily available and that the machine is durable enough for your production needs.

Cost and Budget T-shirt printing machines vary widely in price. While heat press machines and vinyl cutters are affordable and accessible for small businesses, DTG printers and screen printing setups can have a higher initial investment. Consider not only the upfront cost but also the long-term expenses, including ink, maintenance, and consumables.

Where to Find T-Shirt Printing Machines for Sale

T-shirt printing machines are available from a variety of sources. Here are a few places to consider:

Online Marketplaces Websites like Amazon, eBay, and Alibaba offer a wide range of t-shirt printing machines, from entry-level models to industrial-grade equipment. Be sure to read reviews, compare prices, and check the seller's reputation.

Specialized Printing Suppliers Many suppliers specialize in printing equipment and offer expert advice, installation, and customer support. These businesses can provide a more personalized experience and may offer additional services such as training and maintenance.

Local Dealers and Resellers Local dealers and resellers often carry t-shirt printing machines, and buying from them allows you to see the equipment in person. You may also be able to take advantage of in-person demos, warranties, and after-sales support.

Trade Shows and Expos Printing industry trade shows and expos are a great place to see the latest t-shirt printing technology in action. You can meet with manufacturers and distributors, compare machines, and learn more about the capabilities of different models.

Conclusion

Investing in a t-shirt printing machine can be a game-changer for your business, offering you the ability to create high-quality, custom apparel with ease. Whether you're interested in screen printing, heat transfer, DTG, or sublimation, there's a machine suited to your specific needs. Before making a purchase, carefully consider factors like print quality, speed, ease of use, and your budget to ensure you choose the best option for your printing business. By selecting the right equipment, you’ll be able to produce high-quality t-shirts that satisfy your customers and help your business grow.

0 notes

Text

HTV Heat Transfer Vinyl 12Inch x10Feet Rolls,Iron On Vinyl for Silhouette Cameo,Easy to Cut & Weed HTV Vinyl Roll, Heat Transfer Vinyl for T-Shirts (Black)

Price: (as of – Details) Product information: Quantity: 1 roll pack Size: 12 inch x 10 feet Material: PVC material Color: as shown Description This item is made of top-class PVC material for wide application. It has the best durability and is thin. Perfect for decorating children’s clothing, T-shirts, sports clothes and fabrics. Just use craft cutter like cutting plotter, laser machine, sign…

View On WordPress

0 notes

Text

How to Cut Custom Acrylic Keychains

Custom acrylic keychains are a popular and trendy way to accessorize your keys, bags, or even give as gifts to friends and family. Whether you're creating custom keychains in bulk for promotional purposes or crafting unique acrylic charms for personal use, understanding how to properly cut acrylic is essential. In this comprehensive guide, we'll walk you through the steps and techniques required to cut custom acrylic keychains efficiently and safely.

Gathering the Necessary Materials

Before you begin, it's crucial to gather all the necessary tools and materials. Having everything in place will make the process smoother and more efficient.

Acrylic Sheet: Choose the right thickness and color for your custom acrylic keychains.

Ruler and Marker: For precise measurements and marking.

Sharp Blade or Cutter: Ideal for scoring the acrylic sheet.

Laser Cutter or Rotary Tool: For more intricate designs and smoother cuts.

Preparing the Acrylic Sheet

Preparation is key when working with acrylic. Before cutting, make sure your workspace and tools are ready.

Clean the Work Surface: Ensure that your work area is flat and clean. A stable surface prevents the acrylic from moving during the cutting process.

Remove Protective Film: Acrylic sheets usually come with a protective film on both sides to prevent scratches. Carefully remove this film before cutting to ensure a clean edge.

Mark Your Design: Use a ruler and marker to outline the shape or design of your custom acrylic keychains. Precision in this step is crucial for a professional finish.

Cutting the Acrylic Keychains

Cutting acrylic can be done using various methods depending on the tools at your disposal. Below are two common approaches:

Manual Cutting:

Score the Acrylic: Using a sharp blade or cutter, score along the marked line. Apply consistent pressure to penetrate through the entire thickness of the acrylic sheet.

Snap the Acrylic: Once you've scored the acrylic several times, gently snap off the excess by bending it downwards. This method is best for straight cuts.

Using a Laser Cutter or CNC Machine:

Set Up Your Design: Create your design using software like CAD or vector-based programs. This allows for precision and customization, ideal for custom keychains in bulk.

Cut the Acrylic: Upload your design to the laser cutter or CNC machine. Adjust the settings according to the thickness of your acrylic sheet. The machine will cut out your design with high precision, producing smooth edges.

Customizing Your Acrylic Keychains

Custom acrylic keychains are not only functional but also offer endless possibilities for personalization. Once your keychains are cut, you can further customize them to add a unique touch.

Adding Text and Graphics: Use a vinyl cutter to add text, logos, or other graphics to your acrylic keychains. This is an excellent way to brand your keychains if you're creating them for business purposes.

3D Designs: If you have access to advanced software, you can create 3D designs that stand out. This method is perfect for making detailed acrylic charms or unique shapes that can't be achieved with simpler tools.

Painting or Etching: For a more artistic touch, consider painting or etching designs onto your keychains. This adds depth and texture, making your custom keychains truly one-of-a-kind.

Wholesale Custom Keychains

If you're planning to produce custom keychains in bulk, whether for retail, promotional giveaways, or events, it's essential to focus on efficiency without sacrificing quality.

Bulk Production: Utilize a laser cutter for bulk production as it allows for rapid and consistent cuts. This is particularly useful if you're working with wholesale custom keychains.

Quality Control: Ensure that each keychain meets your quality standards. Consistent quality is crucial when producing large quantities for wholesale.

Conclusion

Cutting custom acrylic keychains is a rewarding process that allows for creativity and personalization. With the right tools and techniques, you can produce high-quality keychains that serve as stylish accessories, promotional items, or personalized gifts. Whether you're making a single acrylic charm or thousands of custom keychains in bulk, following these steps will help you achieve professional results every time.

0 notes

Text

Digital Printing Machines: Your Gateway to High-Resolution Print Solutions

Southern Agencies is a leading, reliable and authorized sole distributor and importer of Digital Printing Machines & Digital Signage. With 20+ brilliant years of experience in the industry, we serve as the best solution to make your business world more vibrant and brighter.

Konica 512i Printer-Heavy:

This machine is best suited for printing technologies that cover market needs such as generating numerous outdoor applications such as outdoor signage, billboards, flags, and posters.

Excellent image quality outcomes that makes it ideal for vinyl stickers for exhibitions and cars. This Vinyl Sticker Printing Machine allows businesses to have the wonderful experiences of greater impacts of next-generation printer performance.

UV Roll to Roll Machine:

Excellent image quality outcomes that makes it ideal for vinyl stickers for exhibitions and cars. This Vinyl Sticker Printing Machine allows businesses to have the wonderful experiences of greater impacts of next-generation printer performance.

This machine is best suited for printing technologies that cover market needs such as generating numerous outdoor applications such as outdoor signage, billboards, flags, and posters.

Laminator Machine:

This machine is best suited for printing technologies that cover market needs such as generating numerous outdoor applications such as outdoor signage, billboards, flags, and posters.

Excellent image quality outcomes that makes it ideal for vinyl stickers for exhibitions and cars. This Vinyl Sticker Printing Machine allows businesses to have the wonderful experiences of greater impacts of next-generation printer performance.

4x4 UV Flatbed:

The UV flatbed printer meets the individual needs in the market. The UV printer can be completed in one printing.

The printed pattern is rich in color, the machine operation is simple, and the image printing speed is fast.

It is suitable for individualized and small batches of various industries printing needs.

Laser Engraver / Cutter:

High-quality results delivered. For the application of graving of acrylic letters, you can produce a smooth and flame-polished edge.

Excellent quality, significant focusing spot, more fine cutting line and higher working efficiency on thermocol

Conclusion:

We are a client-oriented company and endeavor to meet the expectations of our clients, gain the confidence and trust of our clients,we maintain work ethics and a transparent business approach

0 notes

Text

Let's Talk Signs: A Journey Through Sign Making Supplies and Tools

Sign making isn’t just a craft; it’s an art form that combines creativity with precision. Whether you’re a seasoned pro or just starting out, having the right sign making supplies and tools is essential to bringing your vision to life. In this blog, I’m going to dive into the essentials of sign making, highlighting key supplies and tools that every sign maker needs in their arsenal. Plus, for those in the UK, we’ve got a special mention for ATC, your go-to supplier for high-quality sign making supplies.

Understanding Sign Making Supplies

The first step in your sign making journey is understanding the supplies you’ll need. This isn’t just about picking up a paintbrush and some vinyl, it’s about choosing materials that will bring durability, vibrancy, and professionalism to your work.

Vinyl Sheets and Rolls

Vinyl is the bread and butter of the sign making industry. Available in a variety of colours and finishes, vinyl sheets and rolls are versatile and durable, making them ideal for both indoor and outdoor signs. They come in different grades, so consider the longevity and conditions of your sign will be exposed to when making your choice.

Transfer Tapes

Transfer tapes are the hidden secret when sign making. They help you move your vinyl designs from the backing paper to the sign surface without losing alignment or integrity. A good quality transfer tape can make the difference between a sign that looks professional and one that looks like a DIY project.

Sign Blanks

Sign blanks are pre-cut panels made from materials like aluminium, wood, or acrylic. They provide a sturdy and smooth surface for your vinyl designs. Choosing the right sign blank depends on where your sign will be displayed and the overall look you’re aiming for.

The Must-Have Sign Making Tools

Now, let’s talk tools. Having the right tools not only makes the process smoother but also improves the quality of your signs.

Cutting Tools

A high-quality cutter is essential! Whether it’s a simple handheld vinyl cutter for small projects or an advanced electronic cutting machine for complex designs, make sure your cutting tools is sharp and precise.

Squeegees and Application Tools

Squeegees are crucial for applying vinyl without bubbles or wrinkles. They come in various sizes and materials, so find one that feels comfortable in your hand and suits the size of your projects. Click here for a range of durable, quality-made sign making tools.

Weeding Tools

Weeding tools are used to remove excess vinyl from your design. This step is important for clean, professional-looking signs. Look for tools with fine tips for precision.

Why Choose ATC for your Sign Making Supplies?

If you’re in the UK, ATC is your ideal destination for sign making supplies. They offer a comprehensive range of high-quality materials and tools tailored to both beginners and seasoned professionals. Their expertise and customer service make them a reliable partner in your sign making journey.

Tips for Successful Sign Making

Plan Your Design: before you start cutting, have a clear design in mind. Use software to lay out your sign and make any adjustments before cutting your vinyl.

Test Materials: different materials react differently. Always do a small test cut to ensure your settings are correct.

Keep Your Tools in Good Shape: regularly maintain your tools for the best results. Sharp blades and clean squeegees make a huge difference.

Whether you’re creating signs for business or pleasure, having the right supplies and tools is key to creating stunning, professional-quality signs. Remember, sign making is an art that requires patience, practice, and precision. For those in the UK, don’t forget to check out ATC for all your sign making supplies and tool needs. Their range and expertise are sure to help you bring your creative visions to life. Happy sign making!

0 notes

Text

Silhouette Cameo 4 vs Cricut Maker 3: Which is Right for You?

Cricut and Silhouette companies have the Best cutting machines available in the world. They both manufacture a range of machines designed for crafting, cutting, drawing, and printing. The flagship products from each company are Maker and Cameo by Cricut and Silhouette, respectively. Both machines are powerful, versatile machines and are able to cut large materials. In this blog, we will compare the most powerful machines Silhouette Cameo 4 vs Cricut Maker 3, on the lines of their features, specs, and design.

Cricut Design and Spaces

The Maker 3 and Cameo 4 are modern in their design and smart cutting machines. The Maker 3’s polished exterior provides a better experience. The Cameo 4 looks edgy since functions were a priority.

Further, the Maker 3 has plenty of storage around the machine, which can hold the blades, tools, and pens. So, it makes it highly accessible for swapping tools while crafting. Plus, at the top of the machine, it features a tablet slot coming with a built-in USB charging port. Also, it is built with premium material with round edges and button controls.

Moving to the Cameo 4, the machine might look clunky on the looks side even though it has less storage space than Maker 3. However, it has two extra features: a roll feeder and a cross-cutter. Also, it comes with a back-lit touch panel through which you can control the machine.

Software

Cricut & Silhouette have developed amazing software that is important for working with the respective machines. For the Silhouette Cameo 4 vs Cricut Maker 3, we will compare the softwares of each company.

First, you have Cricut’s Design Space. It is compatible with all the devices from the desktop and mobile. It is user-friendly, meaning a beginner can easily understand the options of it. The software provides simple tools, also for importing and uploading designs. Other options include size, selecting the cutting material, and editing the old designs.

Further, with the Silhouette Studio, it is also available for both computer and mobile. The software has more design tool options. With the Studio, you will be able to perform tasks such as tracing, warping, and welding. Even perform complex actions like free-hand drawing and neat vector tools. Also, it can sync with other designing softwares and send projects directly to it.

Cutting Capabilities

Finally, the one important deciding factor is the machine’s cutting capabilities. It is important because they are designed to cut various materials. How does it compare with the Silhouette Cameo 4 vs Cricut Maker 3?

However, when we compare, the Cameo 4 is more powerful than Maker 3. It is because the Cameo 4’s cutting force is 5kg, while it is just 4kg for Maker 3. However, cutting materials like vinyl and iron-on will not make a difference. But it can be visible while cutting thicker and denser materials.

Also, Maker 3 is less noisy and makes the cutting experience peaceful. The Cameo 4, with its higher cutting speed, can feel and sound cranky.

Other Features

The Cameo 4 can perform longer cuts of up to 10 ft, as it can cut material without using any mat. This feature of matless cutting is possible with Maker 3 only with Smart materials.

Further, Maker 3 has the upper hand in terms of the number of tools it can work with, which is 13 different tools. Cameo 4 can only work with 5 different tools. So, given the higher number of tools in Maker 3, you can make all sorts of crafting projects. Plus, both machines feature built-in Bluetooth that helps them to connect with computers and mobile.

Also, both host dual-carriage systems, where you can attach different tools for different tasks. Also, Cameo 4 comes with Auto Tool Detection, and Maker 3 has an Adaptive Tool System, enhancing the cutting experience and reducing your work.

Conclusion

In summary, concluding which is better in Silhouette Cameo 4 vs Cricut Maker 3 is challenging because these two machines win at different aspects. While also they have common things such as cutting width and wireless cutting. So, with their robust functionality, the machines are able to provide the top cutting experience with their designs and cutting features.

FAQs

What are the Cameo 4’s cutting abilities?

The Cameo 4 primary tool chamber has a standard cutting force of up to 210 gf. And cuts all the basic materials. However, the second chamber provides an increased force of up to 5kgf that can be used with selected special tools and material types. So, using this feature requires the material to handle the higher cutting force.

What is Auto Tool Detection on Cameo 4?

The Auto Tool Detection is available only with the Cameo 4 and its tools. The feature allows the Studio software to detect the inserted tool into the clamp and automatically populates the tool and action options in the Send panel. You can install the tool in either the tool holder, the metal strip tells the machine, or the software, which will detect the type of inserted tool.

What is an Adaptive Tool System on Cricut Maker?

The Cricut Adaptive Tool System is a unique feature of Cricut Maker and Cricut Maker 3. The feature allows you to swap out the blades or tips without changing the housing because it comes with Quick Swap Housing System. This feature helps you create multi-layers projects at lesser cost and time.

Source URL: Silhouette Cameo 4 vs Cricut Maker 3

For More Information, Visit: Best cutting machines

Cricut setup for windows and mac

#SILHOUETTE CAMEO 4#CRICUT MAKER 3#CRICUT DIY#CRICUT DESIGN SPACE LOGIN#CRICUT DESIGN AND SPACES#COMPARISON

0 notes

Text

8 Best Cricut Project Ideas for Upcoming Festivals

After buying and setting up the new Cricut machine, every crafter looks for the best Cricut project ideas. However, there are plenty of things you can make with a Cricut machine. The Cricut offers cutting-edge smart cutting tools that are compatible with more than 100 materials. So whether you are a beginner or an experienced crafter, you can get the most out of the Cricut machine. Plus, investing in a Cricut digital cutter won't make crafters regret their decisions. Besides, the blog will give you Cricut project ideas for beginners as well as experienced crafters/DIYers. As a result, you can take help from these ideas to make your DIY projects on the Cricut machine. Let's take a look at those 8 project ideas.

1. Decorative Stuff for the Party

Every year, people organize parties on special occasions like birthdays, weddings, and festivals. For this, they will have to decorate their home. However, buying decorative stuff from the market costs a lot. To make it easier, you can make various things on your Cricut machines. Using your Cricut device will help you cut the extra expenses. In contrast to the best Cricut project ideas, you can personalize your banners, tables, food signs, cake toppers, and more.

2. Customize T-shirts

To customize your t-shirts with Iron-on materials, you can take the help of a Cricut maker along with a heat press machine. First of all, you have to make a design using a Cricut Design Space. Then, you have to upload the design to your Cricut machine. Once done, you also need to size the design according to your t-shirts. Afterward, you can cut the design and then weed the extra materials. You can also gift this Customized t-shirt to someone you love.

3. Beautiful Leather Jewelry

All Cricut machines cannot cut the leather, but the Cricut Maker and Explore can cut the leather easily. These models are capable of crafting leather, bracelets, earrings, and other ornamental items. Also, handmade jewelry will not cost as much as it may cost you in shopping malls.

4. Tags for Gifts

Want to add a more personalized touch to your gift? You can do this with your Cricut cutter in one go. You can also access the pre-made designs from the Design Space and add your own touch, such as adding text and fonts with different colors. Once you design the tags, you can print them and attach them to your gifts.

5. Personalized Coffee Mugs

Making coffee mugs is not a big task today. If you want the best Cricut project ideas for beginners, then you can go for these personalized Coffee mugs. The Cricut mug press is designed by Cricut to transfer the design perfectly to the mug. Moreover, the Cricut Design Space will allow you to add beautiful fonts to your design that you can use to add a more personalized touch to the mug. So, think creatively and show it through your mug.

6. Greetings and Birthday Cards

While buying greeting and birthday cards from the market, you will not get more personalized cards. But when you create via Cricut machines, then you can add your own creativity to make it look beautiful. Also, you will need a little harder work to design the beautiful 3-D cards.

7. Custom Dividers for Closet

Difficult to manage your closet? Don’t worry; Cricut has a solution for this. You can beautify the closet dividers with a Cricut cutter. Using this divider, you can divide the seasonal clothes such as for summers, winters, and others. However, this is a great idea for your child’s closet. Moreover, you can make this divider simpler and more fancy according to your desire.

8. Sign Board

Design your own signboard and hang it on your home or door during a wedding or other special event. Use the Cricut Design Space to add appealing fonts to make it attractive. Further, you can engrave, score, and write using your Cricut digital cutter. You can add vinyl lettering or images for these signs. Besides, a welcome sign is something that will get more eyes. So think about it!

Final Words

So, have you found the best Cricut project ideas? This blog post explored 8 project ideas that you can try with your Cricut machine. If you are a beginner crafter, then you can still try all these ideas, as Cricut software offers a simple-to-understand interface. In other words, both the Cricut machine and its software are beginner-friendly, allowing users to learn quickly without much experience. However, you can freely access Cricut’s learning materials from the Design Space software. There, you can find helpful tutorials.

FAQs

Question 1: What can I make on Cricut?

Answer: There are endless possibilities with Cricut cutting machines. Here are things you can make using your Cricut device:

Acrylic bookmarks

Closet dividers

Jewelry

Shirts/T-shirt

Coffee Mugs

Custom sign board

Stickers

Birthday and Greeting cards

Personalized designs for water bottles.

Home Decor

Cake toppers

Pillow Covers

Tote Bags

Personalized Phone Cases

Question 2: Which Cricut machine can make almost everything?

Answer: Cricut Maker is a versatile machine that can make anything you want. It is capable of cutting plenty of materials, i.e., more than 300 in less time. It can easily cut materials like wood, felt, acrylic, plastic, leather, and more. Plus, this cutter can cut materials with high precision and accuracy.

Question 3: Which Cricut cutting machine is expensive?

Answer: The Cricut Maker 3 is the most advanced and powerful machine on Cricut’s list. It really costs a lot, but it offers a feature that will surprise you. Regarding its cost, the price is $429.99, and this machine is the best fit for highly experienced crafters. However, beginners can also use the machine.

#Best Cricut Project Ideas#Cricut project ideas for beginners#cricut explore air 2#cricut crafts#cricut software#cricut.com setup download#cricut.com/create#cricut.com sign in#cricut.com/setup#cricut.com design space#cricut.com setup windows#cricut.com/setup windows

0 notes

Text

DIY Halloween Cricut Designs Projects for 2023

Are you excited to celebrate Halloween this year? If yes, then you must try some crafts, DIY decor, or other spooky Halloween Cricut projects to make this year memorable. Every year, we all eagerly wait for this festival. People who want to celebrate Halloween want to decorate their homes to the next level, making them more eye-catching. However, people decorate their homes and make various DIY projects in advance because some projects are time-consuming and impossible to finish in a day.

The blog is dedicated to those who want to make this year memorable by customizing Halloween projects using their Cricut machines. The write-up will share the best ghostly Cricut Halloween designs and projects for 2023.

1. Wall Decor With Bats

Nothing could be more ghostly than the bat-shaped paper cutouts on your wall. Of Course, you don’t want to see the real bats in your home, but to give them a horrific look, you must include this in your Halloween Cricut projects list. You just need black construction paper and then design the shape using Cricut Design Space.

After that, your Cricut cutter can handle everything; you just need to feed the paper into the machine, and you will get the final cuts.

2. Happy Halloween Banner

Creating different kinds of happy Halloween banners can be the most exciting Cricut Halloween idea. There are various SVG files available on the internet. Otherwise, you can also make your own projects on Design Space. You can use an attractive font style that gives horrific looks to your texts. There are many fonts already available on the Design Space app that you can use for banners.

Once you are ready with your design, just load the mat and materials and get your final Happy Halloween banner, or write something that you find interesting.

3. Halloween Pillow

Try making this beautiful Halloween pillow for your Halloween Cricut projects. You need supplies like Cricut machines, Cricut black iron-on lite, and a white pillow cover or whatever color you like to make this pillow. Then, you need an Iron or heat press to transfer the materials onto your blank cover. This is the simplest project you can try this year.

4. Custom T-shirt for Halloween

How about these T-shirt designs with the text Tonight We Fly? The text sounds really scary. No? Well, you can make this for yourself. The materials you can use are Infusible ink and heat transfer vinyl. However, the HTV material was used in the above picture, so you can go with any materials you like.

Besides, you can also use the exact text or designs for your tote bag. It depends on our choice and looks great everywhere. This would be one of the best Cricut Halloween ideas for anyone who wants to attend the Halloween party.

5. Halloween Garland

If you want to try something funny and want to give it a little scary look. Then try this Halloween garland. This paper garland project can be made using the Cricut machine. However, you can give a stunning 3D look easily without much hard work. But this is one of the best Halloween Cricut projects for intermediate Cricut users. It might be a little challenging for beginners.

The best thing about this project is that it can be reused every year as it can be easily stored anywhere.

6. Halloween Ceramic Plates

Are you planning to invite your friend this Halloween? If yes, then you can’t skip dinner together. For this, you can decorate your plates for table settings using the Cricut machine. The creepy skeleton and a wicked witch will make it look more scary. Plus, the black background color makes it more horrific. We would recommend you add this to yourHalloween projects.

Conclusion

We can understand how excited you would be for Halloween this year. Similarly, we mentioned these 6best Halloween Cricut projects that you can try in 2023. From wallpaper to ceramic plates, many options are given in this post. There is no specific machine that is required to make these projects. Almost every Cricut machine can give you similar results. However, if you have Cricut Maker or Maker 3 then you can make anything uninterruptedly as it is versatile due to its incredible features.

FAQs

Question 1: What should I make for Halloween using Cricut?

Answer: The list is endless forCricut Halloween designs. However, below are the best project ideas you can try this year:

Question 2: How do I make my house look scary for Halloween?

Answer: Here we have compiled the eight Halloween Cricut projects that will make your home the scariest in the neighborhood:

Question 3: What are the Cricut Halloween shirt ideas?

Answer: There are various ideas to give a scary look to your shirts. For example, you can make pumpkin shirts that are completely orange in color. However, to make it look horrific, you can use black infusible materials to create triangular-shaped eyes and heart-shaped noses. Besides, you can add text to your shirts with eye-catching fonts and write something that sounds scary.

Visit: Cricut.com/setup

Source: https://cricutdesignapp.wordpress.com/2023/10/20/diy-halloween-cricut-designs-projects-for-2023/

#digital design#design space setup#cricut.com design space#cricut.com/create#cricut.com/setup#cricut.com sign in#cricut.com setup#design cricut.com download#cricut.com

0 notes

Text

Shirt Printing Machines: A Complete Guide to Apparel Customization

Shirt printing machines are essential tools in the garment industry, used to transfer designs, logos, or text onto apparel. Whether for personal use, small businesses, or large-scale operations, these machines offer a range of printing techniques to suit different needs. From crafting personalized t-shirts to producing branded uniforms, shirt printing machines provide endless possibilities for customization.

This article explores the types of shirt printing machines, their advantages, and how to choose the best one for your requirements.

What is a Shirt Printing Machine?

A shirt printing machine is a device used to imprint designs onto fabrics, typically shirts. These machines use various methods to apply ink or other materials to textiles, allowing for both small-scale and mass production of custom apparel. Different machines cater to various fabric types, design complexities, and production volumes.

Types of Shirt Printing Machines

Screen Printing Machines

Overview: Screen printing is a traditional and widely-used method that involves pressing ink through a mesh stencil (or screen) onto the fabric.

Advantages: Best for bulk orders with simple designs. It offers vibrant colors and long-lasting prints.

Disadvantages: Requires separate screens for each color, making it less efficient for multi-colored or detailed designs. Setup can be time-consuming.

Direct-to-Garment (DTG) Printers

Overview: DTG printing works similarly to a standard inkjet printer but prints directly onto the fabric. This method excels at producing detailed, full-color designs.

Advantages: Ideal for complex, high-resolution designs and smaller print runs. No need for screens or lengthy setup.

Disadvantages: Slower than screen printing for large volumes. It can be expensive to maintain and requires pretreatment of fabrics.

Heat Press Machines

Overview: Heat press machines use heat and pressure to transfer designs onto shirts. Designs are typically printed on transfer paper or vinyl, then pressed onto the fabric.

Advantages: Versatile and relatively easy to use. Suitable for custom, small-batch orders, and a wide variety of materials.

Disadvantages: Limited design flexibility, as it may not be as durable as screen printing or DTG for certain types of fabrics or frequent washing.

Sublimation Printers

Overview: Sublimation printing turns dye into gas, which bonds with the fibers of the fabric, resulting in vibrant, long-lasting prints. This method is best for polyester or specially-coated fabrics.

Advantages: Excellent for full-color images, high detail, and durable prints. The design becomes part of the fabric, so it doesn’t fade or peel.

Disadvantages: Limited to light-colored polyester fabrics or coated substrates. It may not be suitable for cotton shirts.

Vinyl Cutting Machines

Overview: Vinyl cutters are used to cut out designs from vinyl sheets, which are then heat-pressed onto shirts. Often used for logos, numbers, and simple graphics.

Advantages: Durable, great for custom lettering and simple, single-color designs. Perfect for creating sports jerseys and personalized items.

Disadvantages: Limited to one color per layer, and complex or multi-colored designs require multiple layers of vinyl.

Benefits of Shirt Printing Machines

Customization and Personalization

Shirt printing machines enable businesses and individuals to create unique and custom apparel. Whether for promotional merchandise, sports teams, or personal projects, these machines allow for complete creative freedom.

Cost-Effective Production

With the ability to print on-demand, shirt printing machines reduce the need for large inventory. This on-demand production model minimizes waste and lowers costs, especially for small businesses or independent creators.

High-Quality Prints

Modern shirt printing machines offer sharp, vibrant, and durable prints that can withstand regular wear and washing. Whether it's detailed artwork or simple logos, advanced technology ensures that the design quality remains consistent.

Versatility

Shirt printing machines can handle a wide range of fabrics and designs. Depending on the type of machine, users can print on cotton, polyester, blends, and other textiles, making it possible to expand into different apparel products.

Scalability

Whether printing a single shirt or a bulk order, these machines can scale to meet production needs. From hobbyists to large-scale printing companies, there are machines tailored to different volumes of production.

Choosing the Right Shirt Printing Machine

When selecting a shirt printing machine, several factors come into play. Here’s a guide to help you make the best decision:

Design Complexity

If your designs are intricate or involve multiple colors, DTG printers or sublimation machines may be the best choice. For simpler, bulk designs, screen printing is ideal.

Material Type

Consider the fabric you will be printing on. Sublimation is excellent for polyester, while screen printing and DTG are more versatile and can handle cotton and blends.

Volume of Production

For large-scale orders, screen printing offers efficiency and speed. However, for smaller or custom orders, DTG or heat press machines are more suitable.

Budget

Your budget will determine the type of machine you can afford. Heat press and vinyl cutting machines are more budget-friendly and perfect for startups or hobbyists, whereas DTG and sublimation machines tend to be more expensive but offer greater flexibility and quality.

Space and Maintenance

Some machines, such as screen printing setups, require more space and maintenance. On the other hand, heat presses and vinyl cutters are more compact and easier to maintain.

Conclusion

Shirt printing machines are essential tools for anyone interested in creating custom apparel. From hobbyists to large-scale manufacturers, the right machine can bring creativity to life while offering durable and high-quality results. Understanding the different types of shirt printing machines and their specific applications will help you choose the best one for your business or personal needs.

By evaluating design complexity, fabric type, production volume, and budget, you can invest in a machine that will meet your long-term goals, helping you produce professional-grade shirts and apparel that stand out in the market.

0 notes

Text

Buy Latest Graphic Art Supplies to Promote Innovative Branding Concepts

Businesses prefer purchasing high quality graphic art supplies and equipments that will help to promote the brand better as well as attract more customers. Well-known stores offer graphic supplies to varying industries that include offices, photography, architectural, education, textile, and government sectors. Furthermore, they offer premium quality supplies consisting of top trusted brands so customers could purchase according to their preferences. Research portals also stated that these stores upgrade their equipments and product inventory to provide creative branding solutions.

Perks of Opting for Eye Catching Vinyl Prints & Signage:

For starters, many stores offer coloured vinyl films that will complement overall indoor and outdoor spaces as well as advertise about the business in a unique way. Skilled suppliers provide different colours, patterns, textures, designs and sizes so one could choose according to their requirements. Moreover, they can apply vinyl films on heavy vehicles, display windows, billboards, glass doors and other spaces. Not only will it enhance overall appeal but also attract more customers towards the business for purchase.

Generally, qualified suppliers are knowledgeable enough to advice customers over doubts and suggest them appropriate version of vinyl film that will fulfil the requirement criteria. They also utilise this film for creating visually pleasing signage that will create best possible first impression on customers so they could find out more about the brand. Renowned stores sell mirror effect vinyl films that one can use for aesthetic hospitality or residential names to increase overall value of the property.

Many stores offer customisation for vinyl films so they could choose their fit according to business requirements. They provide the facility of bulk purchase so professionals could apply film at once.

Benefits of Buying Top Notch Graphic Art Supplies:

Established stores offer advance equipments that include vinyl cutter, monitors, trimmers, heat press, laminators, scanners, shredders and binding machines.

They also provide varying range of printable media such as fine art, canvas, proofing, drafting, window films, banners, displays, magnetic, and digital self adhesive packages.

Furthermore, reputed stores also offer clearance sales and special offers so businesses could purchase their required graphic supplies within budget criteria.

Get in touch with the best store, if anyone is interested in buying graphic art supplies or browse online portal for more options!

Source

0 notes

Text

Vinyl cutter and a vector graphics program. (specifically a Crikut Maker 3 and Affinity Designer)

More detailed info and advice under the cut

Vinyl cutters are truly magical devices. You can make decals, t-shirts, coasters, stencils, and other neat stuff if you have the right materials and know what you're doing. However, they're a lot like 3d printers in that they're expensive and have a bit of a learning curve. As a hobbyist, I fully intend to buy one of my own someday (the machines I currently use are my mom's and school property respectively), but if you only plan on making one-or-two things I'd suggest seeking-out a friend who already owns one or checking if your school/local library has a designated "Maker Space".

Vinyl cutting machines also work best with vector files (usually .svg), so for stuff like this where there aren't any official vector renderings, the best way to get a quality cut is going to be by tracing over the original image in a program like Adobe Illustrate, Affinity Designer, Inkscape, or the Scratch Sprite Editor, before uploading it to the vinyl-cutting software.

To anyone who reads this far and decides to try vinyl-cutting for themselves: I wish you luck on your journey.

I made Invader Zim Crikut Decals!

Left: Gaz's t-shirt design from the movie and comics, laptop

Right: The logo of the Irken Empire, laptop

Bottom: The logo of the Swollen Eyeball Network, oboe case

*Sudden realization I can make t-shirts with this thing*

228 notes

·

View notes

Text

What is a Cricut Machine, and What Can it Do?

My cricut.com/setup machines are some of the most powerful tools in my craft toolkit. I use them all the time to make a wide variety of crafts, including custom t-shirts, greeting cards, stickers, and so much more. In this article, I’ll share all sorts of information about the family of cricut design space cutting machines and what they can do. I’ll explain what they are, how they work, and tell you exactly what supplies you’ll need to get started.

You may also be wondering which of the three Cricut models is the best choice for your needs. I recommend the design.cricut.com/setup Explore to most beginners – but the Cricut Maker and the Cricut Joy are fantastic machines too! Keep reading for a comparison of the three Cricut machines so you can confidently choose the best Cricut model for you!

What is a Cricut Machine?

A cricut.com/setup is an electronic cutting machine that can cut all sorts of designs from materials like paper, vinyl, card stock, and iron-on transfers. Some cricut design space machines can even cut leather and wood. You can use the Cricut to cut just about anything you would typically cut with scissors or an X-acto knife. That said, a design.cricut.com/setup can cut with much more precision and speed than would ever be achievable by hand.

Best Cutting Machines

Machines like the cricut.com/setup are sometimes called die-cutter machines or craft plotters. Other brands of cutting machines include the Silhouette Cameo and the Brother ScanNCut.

There are currently three types of Cricut machines on the market: The Cricut Explore, the Cricut Maker, and the Cricut Joy.

The design.cricut.com/setup Explore is the mid-level option and the best-selling machine. The cricut design space Maker is one step up from the Explore and can cut a wider variety of materials with more types of tools. The Joy is a smaller model that’s portable, easy to set up, and simple to use.

How Cricut Machines Work

You can think of a cricut design space cutting machine like a household printer. Except instead of printing your design onto a sheet of paper, a Cricut machine uses a small, movable blade to cut the design out of a sheet of paper (or other material.) First, you create a design in Cricut’s design software or app. Then, you send the design to the Cricut cutting machine via Bluetooth or USB. The Cricut machine receives the design and cuts it out using a small, precise blade.

What is the best Cricut for a beginner?

The best Cricut machine for the beginner on a budget is the Cricut Explore 3. The Cricut Explore 3 is cricut design space most popular machine, and for a good reason! It cuts over 100 materials: cardstock, vinyl, iron-on, and specialty materials like glitter paper, cork, and bonded fabric. It’s not the fastest or quietest cutting machine, but it does a lot and is very beginner-friendly.

Which Cricut should you get?

The best Cricut for you depends on the kinds of projects you like to do. Think about what types of materials you’ll want to cut before choosing which Cricut machine to buy.

When to choose the Cricut Explore: The Cricut Explore is the best-selling Cricut machine and offers you great “bang for your buck.” The Cricut Explore is my all-around top choice for design.cricut.com/setup newbies on a budget. It’s a relatively fast and powerful machine that cuts up to a maximum width of 12″. And like I’ve mentioned before, it cuts more than 100 popular craft materials, including paper, vinyl, and iron-on.

So, if you prefer paper and vinyl crafts (and don’t need to cut a lot of fabric and wood), your best choice is the Cricut Explore.

When to choose the Cricut Maker: The Cricut Maker can do everything the Cricut Explore can do, and so much more. I recommend upgrading to the Maker if you want the versatility to cut heavy-duty materials like wood and leather and delicate materials like crepe paper and fabric for sewing projects.

Speaking of using the Cricut sewing projects, the Cricut Maker has a special rotary cutter tool perfect for cutting fabric pattern pieces, quilt appliques, and other fabric projects.

When to choose the Cricut Joy: The Cricut Joy is Cricut’s newest cutting machine. The Cricut Joy is perfect if you like to make quick, small-scale projects, like labels and cards

0 notes

Text

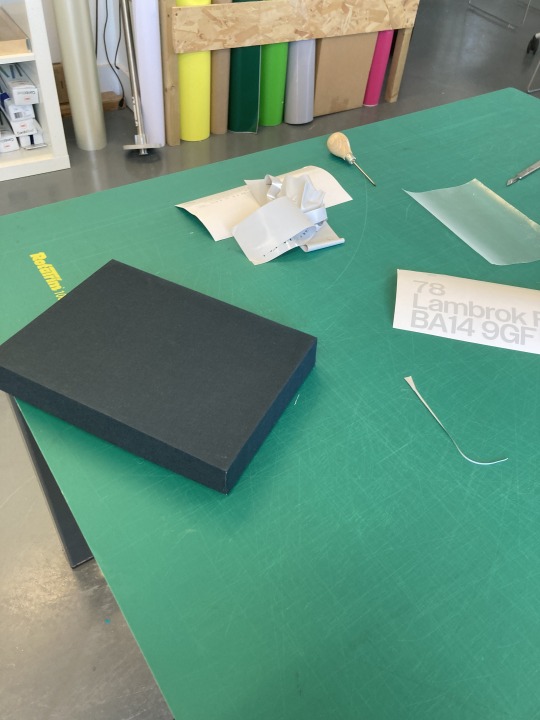

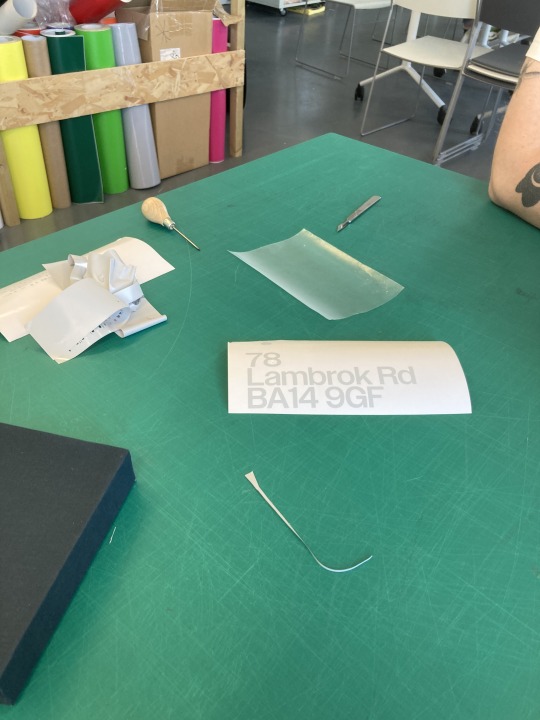

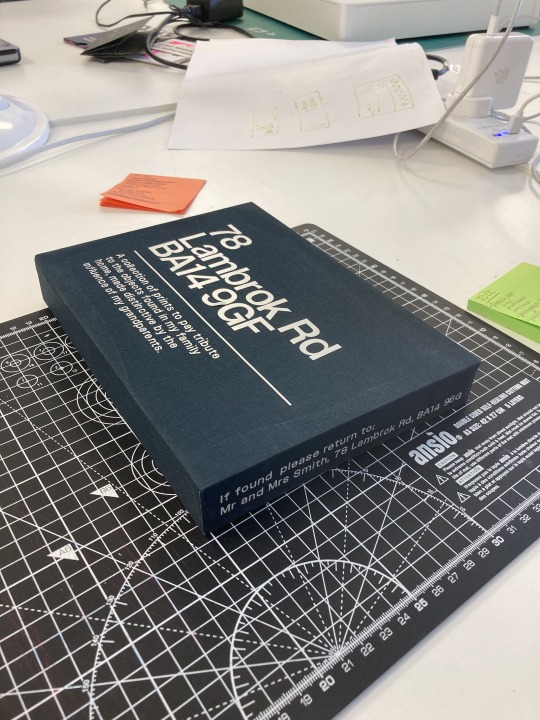

FMP Vinyl

Wednesday 3rd May 2023

Today I printed my box lid and side design onto vinyl and peeled it onto my box. I chose an off-white grey colour for my vinyl, which is familiar in colour to my base, adding continuity to my box.

After choosing the correct size text for the vinyl cutter previously, with Ben's assistance, we sent the text through the vinyl machine and I watched as my designs were laserd into the vinyl. Then, I peeled back any excess vinyl that didn't include the parts I wanted on my box. I had to do this very carefully because of the intricacy of the body text. I then put a large clear sticker over the lettering and using a card, pushed all the air bubbles out. Then, I lined up the vinyl to my box and started applying pressure to it so that it stuck to my book cloth. This is when I quickly realised that vinyl and book cloth are not friends. Peeling back the adhesive tape, I had to slowly help the vinyl off the tape using a scalpel to ensure all the letters came off it. This was easily the most nervous I had been in this entire project. I was terrified to mess this up, but luckily in the end I was able to get all of the vinyl onto my box.

Now, the lettering isn't straight, and it's visibly a bit off in some places, and I am aware of this. Vinyl may not have been the best medium to use for the lettering of my box, and for the grad show I will consider heat transfer paper or even screen printing. Regardless of all of this, seeing the lettering on the box that I created was a pretty amazing feeling and I'm still so proud of this regardless.

0 notes