#basket strainer replacement

Explore tagged Tumblr posts

Text

Find the Perfect Basket Strainer for Your Needs

Are you looking for a reliable basket strainer? You’ve come to the right place! Whether you need a basket strainer replacement or a new basket strainer filter, we have everything you need. Let’s make your decision easy.

Why Choose Our Basket Strainers?

Quality You Can Trust: Our basket strainers are made from high-quality materials, ensuring durability and longevity.

Variety of Options: We offer a wide range of basket strainers, including stainless steel options and those designed specifically for easy installation.

Trusted Manufacturers: We work with top basket strainers manufacturers to provide you with the best products on the market.

Popular Basket Strainer Types

Basket Strainer Stainless Steel: Ideal for those looking for durability and rust resistance.

3 Inch Basket Strainer: Perfect for specific applications that require a 3-inch size.

Why Buy From Us?

Expertise: As a leading basket strainer manufacturer in Ahmedabad, we have years of experience and expertise in the industry.

Customer Satisfaction: We prioritize our customers and ensure they are happy with their purchase.

Easy Installation

Worried about installation? Don’t be! Our basket strainer installation process is straightforward. You’ll have your new strainer up and running in no time.

Ready to Buy?

If you’re in the final stage of your decision, it’s time to take action. Browse our selection, find the perfect basket strainer, and make your purchase today. With our easy online ordering and fast delivery, you’ll have your basket strainer replacement or new filter in no time.

Don’t wait! Contact Us to buy the best basket strainer for your needs now. Thank you for choosing us for your basket strainer solutions

#basket strainer#basket strainer replacement#basket strainer filter#basket strainers manufacturers#basket strainer manufacturer in ahmedabad#basket strainer stainless steel#basket strainer installation#3 inch basket strainer

0 notes

Text

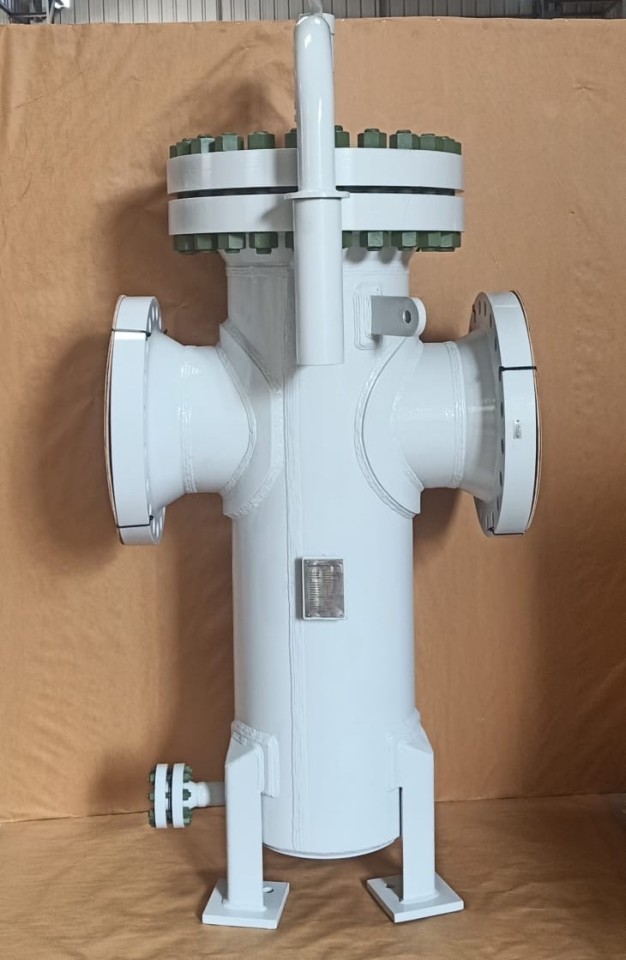

Simplex Basket Strainers Manufacturer in Australia

Australian valve is the best rated Simplex Basket Strainers Manufacturer in Australia. We ensure speedy delivery all over Australia to cities such as Sydney, Melbourne, Perth and many more. Simplex basket strainers are a type of strainer that are used in fluid handling systems to remove impurities, such as debris, particulate matter, and other contaminants, from the fluid. The strainers consist of a basket-shaped filter element that captures impurities, and a housing that holds the basket and allows the fluid to flow through it.

Simplex basket strainers are commonly used in applications where the flow can be temporarily stopped for maintenance, as they have a simple design that makes them easy to clean and maintain. The strainer basket can be removed from the housing for cleaning, and the strainer element can be easily replaced as needed.

Advantages of using simplex basket strainers include their ability to protect equipment, improve system efficiency, reduce downtime, and increase productivity. They are also widely used in a variety of industries, including oil and gas, water and wastewater treatment, power generation, HVAC systems, process industries, and marine and shipping.

Australian valve is the trusted Simplex Basket Strainers Manufacturer in Australia and we provide strainers that are reliable and cost-effective solution for removing impurities from fluid in a variety of applications and industries.

Parts

Housing

Basket.

Cover

Screen

Inlet/Outlet Connections

Advantages

Protection of Equipment

Increased Efficiency

Reduced Downtime

Cost-Effective

Versatile

Easy Maintenance

Applications

Water and Wastewater Treatment

Power Generation

Oil and Gas

Process Industries

Marine and Shipping

Industry

Petrochemical industry

Refinery

Mining industry

Water and wastewater industry

Marine industry

Manufacturing Industry Automotive Industry

Description:

Available materials: WCB, LCB, LCC, CF8, CF8M, cast iron, SS304, SS316

Class: 125 to 2500

Nominal Pressure: PN6 to PN450

Size: 1/2 ” to 32”

Visit our website- https://www.australianvalve.com/product-category/simplex-basket-strainers/

2 notes

·

View notes

Text

On demand top 15 kitchen products you should buy

You want to buy food container, blender, chopper, toaster, oven, dish clothes, fryer? but don’t know which is best or you should buy. So let us help you to find most amazing and demanding kitchen products in 2023

15.Cloth Dish Towels

Due to being highly absorbent, these microfiber dish towels are great for dust cloths, drying hands, wiping stains, cleaning windows, as well as cheese strainers, salad spinners, a wide variety of household chores.

These dishtowels are made of high quality coral velvet thickening material, they are lightweight, super absorbent and dry quickly.Our dish rags are made of high quality non-abrasive and extra soft coral velvet thickening material, which is not easy to lint and fade, soft and not hurting hands, natural and without any chemicals

Buy from Amazon

14. Potato Masher

The 5-blade design lets this hamburger meat chopper double as a masher; Quickly mix and mash softer cooked foods, like potatoes, yams, pumpkin, squash, rutabagas, turnips, parsnips, carrots, apples, bananas, and more

mash by pressing blades into cooked food until desired consistency is achieved; angled blades scrape the sides of bowls and pots while mixing and mashing

dishwasher safe, making clean up quick and easy

Buy from Amazon

13. Air Fryer Toaster Oven

Air Fry, Bake, Roast, Broil, Toast, Rotisserie, Dehydrate, Pizza, Proof, Reheat, Keep Warm

6 Accessories Included: 1 rotisserie handle, 1 rotisserie basket, 1 rotisserie fork set, 1 drip tray, 1 air fryer tray, and 1 food tray, to help cook more food and different types of foods.

All accessories are nonstick and dishwasher-safe, making cleaning easy and quick, and the stainless steel surface is durable and easy to clean

Buy fro Amazon

12. Microwave Popcorn Popper with Handles

silicone Popco popcorn popper bowls come with a lid and convenient, built-in handles. The bowl is uniquely designed to spread the heat evenly so you will get delicious popcorn with very few, if any unpopped kernels. Our Popco popcorn poppers are kid and family friendly; made with heat resistant, non breakable, food-grade silicone.

Popco's large bowl can hold up to 15 cups of popcorn so you can make crisp, tasty popcorn for all your family and friends in just a few minutesPopco has a space saving collapsible design - 2.3 inch collapsed height, for easy and compact storage. It can easily be washed by hand or in a dishwasher.

Buy from Amazon

11.Air Fryer

With 360° rapid heat circulation technology, feel free to enjoy the same crispy textures as traditional deep frying with up to 85% less fat9 one-touch cooking functions on a tempered glass display let you preheat and add personalized Shake Reminders. Let's add some fun to the cooking process

With a nonstick basket.easy to cleanIt can hold 5-quarts of cooking space, which fits enough food for 1-4 people, with compact design takes up little room on your counter top

Buy from Amazon

10. Garbage Disposal Cleaner

Cleans what you can't see: your machine's chopper, internal cavity, and hose

Affresh disposal cleaner is specially formulated to clean and remove odor causing residues from your disposal with a powerful foaming action

Buy from Amazon

9. Kitchen Shears

high quality hardened stainless steel blades easily cut through cardboard, twine, food, meat, vegetables, chicken, poultry, fish, herbs, seafood, BBQ, food packing bags and more. Great as Food Scissors, Meat Scissors, Cooking Scissors, Scissors Kitchen, Cooking Shears, Poultry Scissors, Utility Scissors, Meat Cutting Scissors.

Hand Wash is recommended but these kitchen scissors shears are dishwasher safe. Come with One Year Hassle-Free Replacement and Lifetime Limited Warranty.

Buy From Amazon

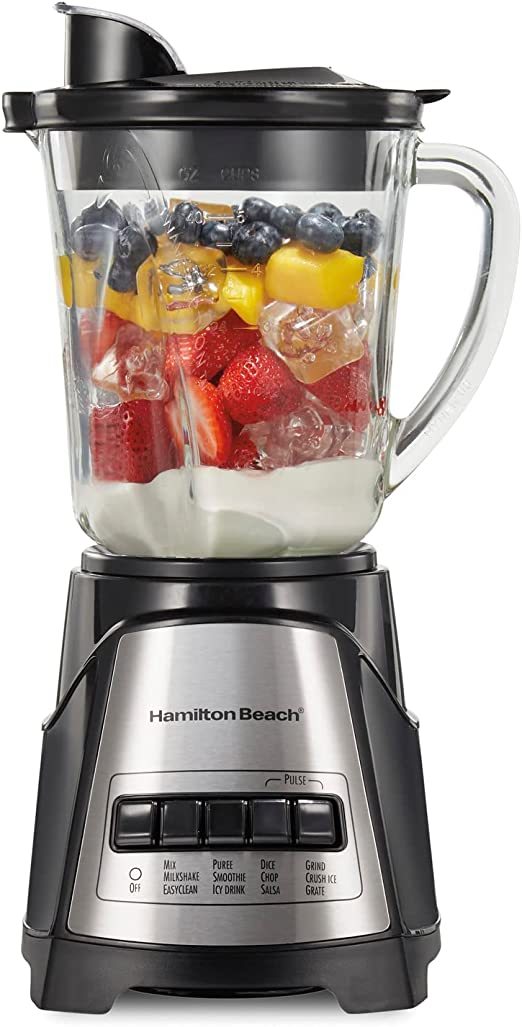

8. Elite Wave Action Blender

peak blending power and stainless steel Ice Sabre blades, this smoothie blender gives you all the power you need to make smoothies, protein shakes, frozen drinks and more The spout on this electric blender lets you pour contents into your glass without spills or drips, so serving is easy and mess-free

Blending multiple servings is easy with the glass jar that holds 40 ounces; The jar, lid and removable blades on the blender are all dishwasher safe

Buy from Amazon

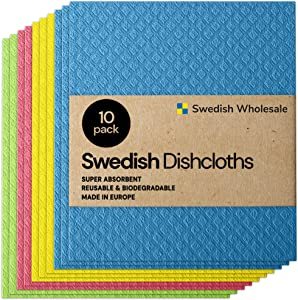

7. Swedish Dish Cloths

10 washable dish rags, available in your choice of blue, grey, lime, pink, purple, watermelon red, white, yellow, or assorted colors. Assorted color packs may differ from what is shown based on availability.Made from cellulose and cotton, each dish cloth becomes soft to the touch when wet, and gritty enough for scouring when dry.

Safe for marble, stainless steel, tile, and wood surfaces, these kitchen dishcloths also work for scrubbing or drying dishes, cups, mugs, sinks, tubs, and showers.

Buy from Amazon

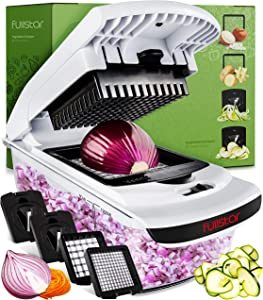

6. Vegetable Chopper

Rust resistant heavy-duty 420 stainless steel retains razor sharpness for crisp, smooth cutting and grating. Blades snap in and out with ease hop lid lets you cut foods directly into the 1.2L collection tray without the mess of a knife and cutting board. Storage container lets you hold prepared vegetables in the Fullstar Vegetable Cutter until you are ready to begin cooking.

Soft grip handle with rubberized tpu enhances leverage while the non-skid base ensures stability during use. Slice, dice, chop and cut fruits and vegetables safely and easily, in half the time

Buy from Amazon

5. Micro-Pop Microwave Popcorn

Temperature safe glass resists wear-and-tear and will not absorb acids or chemicals typically produced during use.Great for a healthy snack, movie night, the big game or recipes including popcorn. Simply use the dual-function lid to measure the desired serving size, pour into the Micro-Pop and place in microwave for 3-minutes or less.

Make homemade popcorn as an alternative to buying expensive single use prepackaged bags containing unwanted chemicals, ingredients, and calories.Only use popcorn popper in a clean, fully functioning microwave oven with unrestricted, rotating turntable. Do not use popcorn button or setting on your microwave. Make sure to use fresh popcorn kernels.

Buy from Amazon

4. Kitchen Drawstring Trash Bags

Kitchen Drawstring Trash Bags with stretchable strength, traps, locks and neutralizes odors to keep your kitchen smelling fresh with a Fresh Clean scent; Package may vary Designed with double side seals and a reinforced bottom to uniquely trap liquids and prevent leaks, and is strong enough to handle the heaviest load

Be the champion of trash with these durable bags that keep your kitchen free of noxious trash odors with a steady release Fresh Clean scent with Febreze Freshness

Buy from Amazon

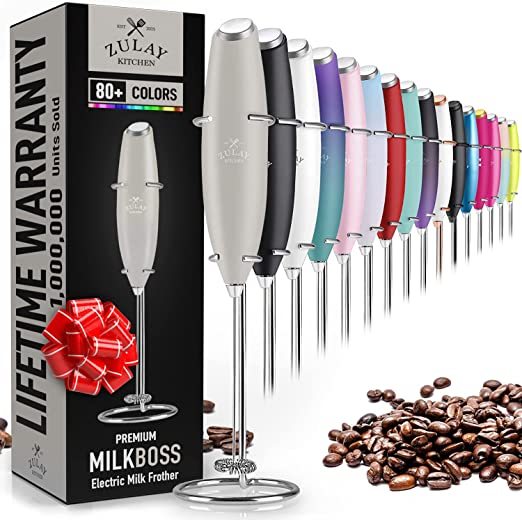

3. Handheld Foam Maker

Works better than a manual matcha whisk for making matcha tea and works far better than fork or whisk for coffee. It works very well to mix nutritious protein powder drinks with no extra container, blender or bottle shaker to wash. We use only premium materials. The construction will last, backed by our Zulay Guarantee to not rust or break, ever.

The durable convenient metal stand gives easy access for foamy goodness in seconds. Cleanup for this matcha wisk & frother is even faster.We coffee lovers are serious when it comes to our coffee. The Milk Boss Frother gives that professional finishing touch to your latte, cappuccino, macchiato or hot chocolate. Make delicious foamy creamer for your drinks at home without any trip to a coffee shop with your own milk frother.

Buy from Amazon

2. Food Storage Containers

The four side-locking lids with black silicone gasket seal these storage containers firmly, protect your food from pests, as well as moisture and air oxidization while keeping it dry and fresh, prevent liquid food from spilling. All have the same lids which means you don’t have to worry about matching lids to containers after each wash. These sturdy pantry storage containers have been especially designed to save space, they are stackable and will easily fit into your refrigerator or cabinet which allows you to make efficient use of every inch of your home kitchen.

Perfect for storing spaghetti, baking supplies, cereal, flour, sugar, oats, pasta, rice, coffee, tea, snacks, nuts, fusilli, pet food and other dry goods. With 30 chalkboard labels and 5 measuring cups, allowing you to better organize your kitchen

Buy from Amazon

1. Mini Maker for Individual Waffles

Simply plug it in and go; the Waffle Maker heats up in minutes. Dual non-stick surfaces provide an even cook for consistent results and delicious golden waffles every time.The perfect wedding or new home gift, the Waffle Maker’s small size takes up little counter space, and its sleek design and trendy color options will match any kitchen

Make your favorite breakfast classics, or get creative with waffled hash browns, cookies and even biscuit pizzas. Any batter will “waffle” into single serving portions. Great for families or on the go. Mini Waffle Maker includes one Mini Waffle Maker and Recipe Guide so you can get cooking right away.

Buy from Amazon

#food#foodie#foodlover#foodporn#kitchen#kitchengift#kitchen gadgets#kitchen gifts#fryer#dish cloth#blender#foam maker#oven#toaster#container#food containers

2 notes

·

View notes

Text

Considerations To Know About Skimmer für aufstellpool

Skimmer extras The so-named skimmer Internet serves to safeguard your filter pump and simultaneously lessens the cleansing of your respective filter process.

In comparison to other options, the Intex skimmer does not have a lock to prevent it from floating up. To counteract this, weigh down the strainer basket or remove these parts within the skimmer housing throughout bathing.

Fileür manche Leser erscheint dieses Produkt womöglich verwirrend: ein Kescher. Jedoch ist ein Skimmer letztendlich ein sehr leichter und feiner Kescher und er kann automatisch arbeiten oder manuell betrieben werden.

The skimmer basket is peak-adjustable and may Therefore be tailored to the individual water level. The skimmer is mounted instantly over the pool Along with the bracket included in the scope of delivery and linked to the filter pump. Make sure you note which the filter pump has to be switched on so that the skimmer can cleanse the water area.

Skimmer A skimmer during the pool is to blame for clear and clear drinking water. With the skimmer, the h2o is sucked in with the water floor and after that filtered. The cleaned h2o is pumped back in the pool through the inlet nozzle.

A filter pump ability of at the very least three,028 l/h is required for the right use of the Suspended Skimmer Deluxe by INTEX, the hose link has a diameter of skimmer für aufstellpool 40 mm. Mounting substance for the pool types Easy Set and Steel Body by INTEX is integrated. The program cleansing energy in your pool is decreased into a minimum amount and at the same time the usage of drinking water treatment products and solutions is In addition diminished.

The skimmer Web is a hygienic disposable filter that needs to be replaced on a regular basis. At Steinbach, the nets are offered for all types of skimmer baskets having a diameter of around one hundred fifty five mm.

Der Kescher ist wirklich sehr leicht und einfach zu handhaben. Er arbeitet besonders umweltschonend, was einigen Kunden besonders wichtig war.

The h2o is cleaned by using a filter screen as well as the filtered bathing drinking water is pumped back again to the pool through the inlet nozzles.

INTEX Suspended Skimmer Deluxe The skimmer is usually a area suction gadget and it is ideal for all INTEX pools. By way of a pump, dirty h2o and impurities floating over the h2o floor are sucked in the skimmer basket.

In essence, a difference is created among developed-in skimmers and suspended skimmers. The constructed-in skimmer is permanently mounted during the pool. A suspended skimmer is a superb choice if you do not have the skimmer forever put in inside the pool.

Tip The skimmer need to be cleaned on a regular basis. You may get rid of the skimmer basket from the built-in take care of and simply rinse it out underneath the water pipe.

Your browser isn’t supported anymore. Update it to have the greatest YouTube encounter and our latest options. Learn more

Ein Kunde beschwert sich, dass die Halterung an seinem aufblasbaren Becken nicht gehalten hat. Glücklicherweise sind die Rückgabebedingungen sehr kulant und er konnte das Modell umtauschen.

0 notes

Text

Basket Strainers vs. Other Filtration Methods: Advantages in Valve Systems

In the world of industrial fluid control, effective filtration is essential to protect equipment and ensure smooth operations. Basket strainers have long been a popular choice for their efficiency and reliability. But how do they compare to other filtration methods, and what makes them ideal for various applications involving valves and steam traps? Let’s explore the advantages of basket strainers and their role in optimizing valve systems.

What are Basket Strainers?

Basket strainers are mechanical devices used to filter out debris from liquid or gas pipelines. They feature a perforated or mesh basket that traps particles, preventing them from flowing downstream and damaging sensitive components such as Ball Float Steam Traps, Actuated Butterfly Valves, and Float Steam Traps.

Advantages of Basket Strainers over Other Filtration Methods

High Debris Holding Capacity: Compared to Y-strainers and inline filters, basket strainers have a larger surface area, allowing them to capture more debris before requiring maintenance.

Easy Maintenance: The removable basket design simplifies cleaning and replacement, reducing downtime in industrial processes.

Versatility: Basket strainers can handle a wide range of flow rates and pressures, making them suitable for various applications, including steam distribution systems that rely on Ball Float Steam Traps and Float Steam Traps.

Minimal Pressure Drop: Due to their design, basket strainers create minimal pressure loss, ensuring that Actuated Butterfly Valves and other control valves operate efficiently.

Applications in Valve Systems

In complex fluid control systems, components such as Actuated Butterfly Valves and Float Steam Traps play critical roles in regulating flow and managing steam. Basket strainers complement these components by keeping the pipeline free of contaminants. This is especially important in systems with Ball Float Steam Trap, where debris can cause malfunction or inefficiencies.

Comparing Basket Strainers to Other Filtration Methods

Y-Strainers: While Y-strainers are compact and suitable for smaller pipelines, they have limited debris-holding capacity and are harder to clean compared to basket strainers.

Inline Filters: These are often used for finer filtration but can clog quickly, leading to higher maintenance demands.

For industries seeking efficient and reliable filtration, basket strainers stand out as a superior solution. Their ability to protect critical components like Ball Float Steam Traps, Actuated Butterfly Valves, and Float Steam Traps ensures the long-term efficiency and stability of valve systems. By investing in high-quality basket strainers, manufacturers can achieve better performance, reduced maintenance costs, and prolonged equipment lifespan.

When choosing a filtration method, consider the operational advantages of basket strainers and how they contribute to the seamless functioning of your valve systems.

0 notes

Text

How to Choose the Right Strainers and Filter Housing for Your Needs

When it comes to maintaining clean and efficient systems, choosing the right strainers and filter housing is essential. These components play a crucial role in various industries, including water treatment, food and beverage, pharmaceuticals, and chemical processing. With numerous options available, selecting the right products can be daunting. Here are some key considerations to help you make an informed decision.

Understand Your Requirements

Before you begin your search, it’s essential to identify your specific needs. Consider factors such as:

Fluid Type: Different fluids have different properties. For example, viscous liquids may require different strainers compared to water or oils. Understanding the nature of the fluid you’re working with will help narrow down your options.

Flow Rate: Calculate the flow rate of your system. This will determine the size of the strainer and filter housing needed. Choosing the correct size ensures optimal performance without causing pressure drops or flow restrictions.

According to a report by Research and Markets, the global filtration market is expected to grow at a CAGR of 6.1% from 2021 to 2026, driven by the increasing demand for efficient filtration solutions in various industries .

Material Selection

Strainers and filter housings are available in various materials, including stainless steel, carbon steel, and plastic. Your choice should depend on:

Corrosion Resistance: If your fluid is corrosive, opting for materials like stainless steel is crucial for longevity and reliability.

Temperature Resistance: Consider the operating temperatures of your application. Some materials may degrade or become less effective at high temperatures.

Type of Strainer

There are several types of strainers, each suited for different applications:

Basket Strainers: Ideal for larger particles, basket strainers are often used in water and chemical applications.

Y-Strainers: These are compact and typically used in low-flow applications where space is limited.

Magnetic Strainers: Suitable for applications requiring the removal of metal particles, these strainers offer an added layer of filtration.

Choose a type that best matches your operational requirements to ensure effective filtration.

Filter Housing Design

The design of the filter housing is equally important. Here are some aspects to consider:

Size and Capacity: Ensure that the housing can accommodate the filter element and handle the required flow rate without causing blockages.

Ease of Maintenance: Look for designs that allow easy access for cleaning and replacing filter elements. A well-designed housing can significantly reduce downtime and maintenance costs.

Compliance and Standards

Ensure that the strainers and filter housing you choose meet industry standards and regulations. Compliance with certifications like ISO 9001 ensures that you’re investing in high-quality products.

Cost and Warranty

While it’s important to find products that fit your budget, remember that the cheapest option may not always be the best. Look for strainers and filter housing that offer a good balance between cost and quality. Additionally, check for warranties or guarantees that can provide peace of mind regarding your purchase.

Conclusion

Choosing the right strainers and filter housing is vital for the efficiency and longevity of your systems. By considering your specific requirements, material selection, type of strainer, housing design, compliance, and cost, you can make an informed decision that suits your needs.

For top-quality strainers and filter housing solutions, look no further than KFilter Global. With a wide range of products tailored to various applications, KFilter Global ensures you find the perfect match for your requirements. Visit our website today to explore our offerings!

#filter bags#liquid filter bags#air filteration#top pre filter manufacturer in qatar#liquid filter bag

0 notes

Text

Understanding Duplex Filters

In the realm of industrial filtration, duplex filters stand out as essential components designed to ensure the smooth operation and longevity of machinery. These filters are critical in various industries, from manufacturing and automotive to oil and gas. This article delves into the intricacies of duplex filters, their advantages, applications, and why highforcehydraulics is your go-to provider and manufacturer for these indispensable filtration systems.

What Are Duplex Filters?

Duplex filters, also known as twin basket strainers, are designed to operate continuously without interruption. They consist of two separate filter housings and are equipped with a valve that allows one filter to be in service while the other is being cleaned or replaced. This design ensures that there is no downtime in the filtration process, making duplex filters ideal for operations that cannot afford interruptions.

How Do Duplex Filters Work?

The primary function of duplex filters is to remove contaminants from fluids, ensuring that only clean fluid passes through the system. When the fluid enters the filter, it passes through the filter element, which traps particles and debris. Over time, the filter element accumulates contaminants and requires cleaning or replacement.

The duplex filter system allows operators to switch from one filter housing to the other using a manual or automated valve. This seamless transition ensures continuous filtration without shutting down the system. The contaminated filter can then be serviced while the clean filter continues to operate.

Key Advantages of Duplex Filters

Continuous Operation: The most significant advantage of duplex filters is their ability to provide uninterrupted filtration. This is crucial in industries where downtime can result in significant losses.

Ease of Maintenance: Duplex filters are designed for easy maintenance. The ability to switch between filter housings means that servicing one filter does not halt the entire operation.

Extended Equipment Life: By ensuring that contaminants are consistently removed from fluids, duplex filters help in extending the life of machinery and reducing wear and tear.

Cost-Effective: Continuous operation and reduced downtime translate to cost savings, making duplex filters a cost-effective solution for many industries.

Applications of Duplex Filters

Duplex filters are used in various industries due to their versatility and efficiency. Some of the common applications include:

Oil and Gas: In the oil and gas industry, duplex filters are used to remove contaminants from drilling fluids, ensuring the smooth operation of equipment.

Manufacturing: In manufacturing plants, these filters are essential for maintaining the cleanliness of hydraulic fluids and lubricants, which are crucial for the proper functioning of machinery.

Automotive: Duplex filters are used in automotive applications to ensure that fluids such as engine oil and transmission fluid are free from contaminants.

Marine: In the marine industry, these filters are used to keep fuel and lubricating oils clean, ensuring the efficient operation of engines and other equipment.

Why Choose highforcehydraulics for Duplex Filters?

When it comes to selecting the best provider and manufacturer of duplex filters, highforcehydraulics stands out as a leader in the industry. Here’s why:

High-Quality Products: highforcehydraulics is committed to delivering high-quality duplex filters that meet industry standards. Their filters are designed to provide reliable and efficient performance, ensuring the longevity of your equipment.

Innovative Solutions: The company continually invests in research and development to bring innovative filtration solutions to the market. This dedication to innovation ensures that their duplex filters incorporate the latest technology and best practices.

Customizable Options: highforcehydraulics understands that different industries have unique requirements. They offer customizable duplex filter solutions to meet the specific needs of their clients, ensuring optimal performance in every application.

Expert Support: With a team of experienced professionals, highforcehydraulics provides exceptional customer support. Whether you need assistance with installation, maintenance, or troubleshooting, their experts are always ready to help.

Competitive Pricing: Despite offering high-quality products and services, highforcehydraulics maintains competitive pricing, ensuring that you get the best value for your investment.

Maintenance Tips for Duplex Filters

To ensure the optimal performance and longevity of your duplex filters, regular maintenance is essential. Here are some tips to keep in mind:

Regular Inspection: Periodically inspect the filter elements for signs of wear and tear. Replace or clean them as needed to maintain efficient filtration.

Monitor Pressure Drops: A significant pressure drop across the filter may indicate that it is clogged. Regularly monitor pressure drops and switch to the clean filter when necessary.

Clean Filter Housings: When servicing the filter, ensure that the housings are thoroughly cleaned to prevent contamination of the new filter element.

Use Quality Replacement Parts: Always use high-quality replacement filter elements and parts to maintain the performance and reliability of your duplex filter system.

Conclusion

Duplex filters are indispensable in ensuring the continuous and efficient operation of various industrial processes. Their ability to provide uninterrupted filtration, ease of maintenance, and cost-effectiveness make them a preferred choice in many industries. When it comes to high-quality duplex filters, highforcehydraulics is the leading provider and manufacturer you can trust. With their commitment to quality, innovation, and customer satisfaction, highforcehydraulics offers solutions that meet and exceed industry standards.

Investing in duplex filters from highforcehydraulics ensures that your operations run smoothly, equipment lasts longer, and you achieve significant cost savings. Choose highforcehydraulics for all your duplex filter needs and experience the difference in quality and performance.

0 notes

Text

Different Types Of Strainers Used In Plumbing Projects

Strainers are important additives in plumbing and piping structures, designed to get rid of debris and prevent damage to precious device. Understanding the diverse types of strainers and their packages is critical for maintaining efficient and dependable plumbing systems.

As a leading strainer producer and strainer exporter, Bullion Pipe gives a comprehensive range of strainers tailored for numerous plumbing needs. Here’s an in-depth look at specific forms of strainers commonly utilized in plumbing initiatives.

1. Y-Strainers

Y-strainers are one of the most common kinds of strainers utilized in plumbing structures. They are named for his or her Y-formed body, which houses a detachable straining element. Y-strainers are designed to dispose of particles from drinks and gasses, ensuring that pipelines and equipment stay unfastened from harmful particles.

Key Features:

Design: The Y-form permits for a compact and area-green installation.

Maintenance: They include a blow-off valve that makes cleansing and maintenance sincere.

Applications: Ideal for use in water, oil, and gas pipelines.

2. Basket Strainers

Basket strainers are famous for their huge floor area and excessive dirt-maintaining ability. They feature a basket-shaped mesh screen that captures debris because it flows through the strainer. This form of strainer is regularly utilized in large pipelines in which high flow prices are concerned.

Key Features:

Design: The large basket allows for prolonged carrier intervals.

Maintenance: Cleaning is simple because the basket can be removed and washed or replaced.

Applications: Suitable to be used in irrigation structures, HVAC structures, and business pipelines.

3. T-Strainers

T-strainers are named for their T-formed layout and are usually used in programs wherein area is limited. Unlike Y-strainers, T-strainers have a direct through-go with the flow path, which enables them to reduce strain drops.

Key Features:

Design: Compact and best for installations where area is a constraint.

Maintenance: Features a removable screen for clean cleansing.

Applications: Commonly utilized in smaller pipelines and systems in which low stress drop is crucial.

4. Duplex Strainers

Duplex strainers are designed for packages wherein continuous operation is essential. They encompass two separate straining chambers, taking into account one chamber to be cleaned or serviced at the same time as the opposite remains in operation.

Key Features:

Design: Dual chambers provide uninterrupted service.

Maintenance: Can be cleaned and serviced without shutting down the system.

Applications: Ideal for essential methods in water treatment centers, chemical processing, and business operations.

5. Suction Strainers

Suction strainers are used specially to guard pumps from particles that can be drawn into the device. They are normally hooked up on the inlet of the pump to make sure that most effective easy fluid is pumped through the machine.

Key Features:

Design: Often incorporates a rough mesh to prevent larger particles from coming into the pump.

Maintenance: Regular inspection is

important to make certain the strainer remains clean and powerful.

Applications: Used in various programs which include water delivery structures, gas systems, and different strategies wherein safety of pumps is important.

6. Screen Strainers

Screen strainers use a perforated or mesh display to clear out debris from liquids and gases. They are available in numerous mesh sizes to match exceptional applications and are often used wherein quality filtration is required.

Key Features:

Design: Offers extraordinary mesh sizes for varying filtration needs.

Maintenance: The screen can be effortlessly eliminated and wiped clean or changed.

Applications: Ideal for programs requiring satisfactory filtration, consisting of in laboratories or commercial techniques.

7. Automatic Strainers

Automatic strainers are ready with a self-cleansing mechanism that removes the need for manual cleaning. They use diverse methods, which include backwashing or scraping, to hold a clean straining floor without interrupting machine operation.

Key Features:

Design: Self-cleaning talents lessen preservation efforts.

Maintenance: Minimal manual intervention required.

Applications: Suitable for high-glide structures and methods wherein continuous operation is vital, which include in municipal water treatment and industrial programs.

8. Sand Strainers

Sand strainers are designed especially to do away with sand and other abrasive particles from water. They feature a specialized straining detail that could take care of the tough conditions as a result of sand and grit.

Key Features:

Design: Built to resist the abrasive nature of sand.

Maintenance: Often consists of a feature to flush out amassed sand.

Applications: Used in irrigation structures, water remedy facilities, and mining operations.

9. Pressure-Activated Strainers

Pressure-activated strainers mechanically clean themselves primarily based at the strain differential across the strainer. When the pressure difference reaches a sure level, the strainer turns on its cleaning mechanism to clear out accrued particles.

Design: Pressure-touchy cleansing mechanism.

Maintenance: Reduces guide cleansing wishes.

Applications: Ideal for structures with fluctuating debris hundreds, together with in chemical processing and wastewater remedy.

10. Magnetic Strainers

Magnetic strainers use powerful magnets to capture ferrous particles from liquids. They are often used in conjunction with different types of strainers to provide additional safety against steel debris.

Key Features:

Design: Incorporates magnets to attract and put off steel particles.

Maintenance: Simple to easy, with magnetic particles without difficulty removed from the floor.

Applications: Commonly used in meals processing, prescription drugs, and other industries in which metal infection ought to be minimized.

Conclusion

Choosing the proper strainer on your plumbing mission is vital for retaining system performance and shielding precious devices. At Bullion Pipe, we offer a variety of strainers tailored to fulfill various wishes, from simple filtration to specialized applications. As a main strainer manufacturer and strainer exporter, we're devoted to supplying excellent products designed to make certain the most fulfilling overall performance of your plumbing systems.

For expert advice on selecting the proper strainer or to discover our complete variety of strainer solutions, touch Bullion Pipe today. Our team of specialists is here to assist you with all of your strainer desires, ensuring that you find the appropriate answer to your plumbing mission.

0 notes

Text

Are you Looking for a Square Floor Drain Factory to supply your project with a top-notch Balcony drains floor strainer?

A floor strainer for a balcony drain is a device that is used to prevent debris from entering and clogging the drain. It is typically installed in the floor of a balcony or other outdoor area and is designed to allow water to flow through while trapping leaves, twigs, and other debris. The strainer is usually made of metal or plastic and has a perforated or mesh screen that allows water to pass through while preventing larger objects from entering the drain. Some floor strainers also have a removable basket or tray that can be easily cleaned or replaced when necessary. They are commonly used in residential and commercial buildings to protect the drainage system and prevent water damage.

0 notes

Text

1. Filter Elements:

Perforated metal sheets are often used as the base material for filter elements. These sheets can be perforated with precise hole sizes and patterns to suit specific filtration requirements, such as particle size retention and flow rate. The perforated metal acts as a support structure for filter media, providing mechanical strength and stability.

2. Strainer Baskets:

Perforated metal is commonly used to fabricate strainer baskets or screens used in industrial filtration systems. These baskets prevent solid particles or debris from entering pipelines or equipment while allowing fluids to pass through. The perforated metal screens can be easily cleaned or replaced as needed, ensuring optimal filtration performance.

3. Air Filtration:

In HVAC systems and air purification units, perforated metal sheets are employed as the outer casing or housing for air filters. These perforated housings protect the filter media from damage while allowing air to pass through for filtration. Additionally, perforated metal can be used as pre-filters to remove large particles or contaminants before air passes through finer filter media.

4. Liquid Filtration:

Perforated metal is utilized in liquid filtration applications, such as water treatment plants, oil refineries, and chemical processing facilities. Perforated metal screens or tubes are integrated into filtration equipment to remove impurities, sediment, or solids from liquids. The perforated design allows for efficient filtration while minimizing pressure drop and maximizing flow rates.

5. Vibrating Screens:

Perforated metal sheets are employed in vibrating screens used for solid-liquid separation or particle classification processes. These screens consist of perforated metal panels tensioned over a vibrating frame. The perforations facilitate the passage of liquid or particles through the screen, while oversized materials are retained for further processing.

6. Food and Beverage Filtration:

In the food and beverage industry, perforated metal is utilized in filtration equipment for processing liquids, such as juices, syrups, and dairy products. Perforated metal screens or baskets are used to remove solids, pulp, or debris from raw materials or during the production process, ensuring product quality and purity.

7. Gas Filtration:

Perforated metal is employed in gas filtration systems to remove particulate matter, dust, or contaminants from gases or air streams. Perforated metal tubes or cylinders are often used as support structures for filter cartridges or as outer casings for gas filter housings.

Have questions? Contact us for personalized assistance and wire mesh expert guidance.

Call: +971 65664526

WhatsApp: +971 553212331

Email: [email protected]

0 notes

Text

Unveiling the Power of Precision: The Ultimate Guide to Basket Strainers

Basket strainers are unsung heroes in fluid management, playing a pivotal role in maintaining the purity and efficiency of various industrial processes. As leading Basket Strainers manufacturers based in Ahmedabad, we delve into the world of basket strainers, exploring their significance, installation, and the key to seamless operations.

Understanding Basket Strainers:

Basket strainers are indispensable filtration devices, ensuring the removal of particulate matter from liquids. Crafted with precision, our stainless steel basket strainers stand as paragons of durability and efficiency.

The Need for Basket Strainers:

In industries like steel, power plants, and petrochemicals, contaminants can wreak havoc. A reliable basket strainer filter acts as the first line of defense, preventing damage to crucial equipment and ensuring the longevity of your processes.

Basket Strainer Replacement:

Efficient maintenance is crucial, and recognizing the signs for a basket strainer replacement is imperative. Look out for reduced flow, increased pressure drops, or visible damage. Timely replacement guarantees uninterrupted workflow.

Installation Made Easy:

Our basket strainers are designed for hassle-free installation. Whether it’s a 3-inch basket strainer or a customized solution, our products come with user-friendly features, making the installation process seamless.

Manufacturing Excellence:

As pioneers among basket strainers manufacturers, we take pride in our 14 years of manufacturing prowess. Rigorous quality tests ensure that each product meets international standards, promising longevity and optimal performance.

Custom Solutions for Your Needs:

We understand that every industry has unique requirements. That’s why we offer customization. Share your specifications with our expert team, and we’ll tailor a basket strainer to fit your exact needs.

Conclusion:

In the intricate dance of industrial processes, basket strainers take center stage, providing a shield against contaminants. As your trusted manufacturer in Ahmedabad, India Filters delivers not just products, but solutions. Upgrade to our stainless steel basket strainers, and experience the epitome of filtration precision at unbeatable rates. Your fluid management deserves the best — choose India Filters.

#basket strainer#basket strainer replacement#basket strainer filter#basket strainers manufacturers#basket strainer manufacturer in ahmedabad#basket strainer installation

0 notes

Text

Unveiling the Benefits of Basket Strainers in Industrial Applications

Basket strainers are essential components in fluid handling systems. They are designed to remove solid particles and debris from liquids and to protect downstream equipment, Basket strainers ensure the smooth operation of industrial processes. These strainers feature a cylindrical or flat shape screen with a perforated or mesh-lined basket inside, allowing the fluid to pass through while capturing unwanted particles.

Typically installed in pipelines, basket strainers are employed in various industries, including petrochemical, water treatment, pharmaceuticals, and food processing. Their design facilitates easy maintenance as the basket can be easily removed and cleaned, ensuring the longevity and efficiency of the strainer. Basket strainers play a critical role in maintaining the integrity of liquids, safeguarding equipment, and minimizing downtime in industrial applications.

What are the essential benefits of basket strainers in industrial setting?

Basket strainers play a crucial role in industrial settings by providing effective filtration and protection for various equipment and processes. Here are some essential benefits of basket strainers in an industrial setting:

Particle Removal:

Basket strainers are designed to capture and remove solid particles from liquids or gases flowing through pipelines. This helps prevent damage to downstream equipment, such as pumps, valves, and heat exchangers, which can be sensitive to particulate matter.

Process Efficiency:

Strainers contribute to the overall efficiency of industrial processes by ensuring that fluids are free from debris and contaminants. Clean fluids can enhance the performance of equipment, improve heat transfer efficiency, and maintain consistent product quality.

Equipment Protection:

By removing contaminants from the fluid, basket strainers protect sensitive components and equipment from wear and damage. This is particularly important in industries such as petrochemical, chemical, and water treatment, where equipment can be susceptible to damage from particles.

Extended Equipment Life:

The removal of particles prevents abrasive wear on equipment components, extending the lifespan of pumps, valves, and other critical process equipment. This can lead to cost savings through reduced maintenance and replacement expenses.

Reduced Downtime:

Regular use of basket strainers helps prevent unexpected shutdowns caused by equipment failure due to particle buildup. This reduction in downtime contributes to increased overall productivity and operational efficiency.

Easy Maintenance:

Basket strainers are typically designed for easy maintenance. They can be easily removed, cleaned, and reinstalled without requiring extensive downtime. This contributes to a more streamlined maintenance process.

Versatility:

Basket strainers can be used in a wide range of industries, including oil and gas, chemical processing, water treatment, food and beverage, and more. They are available in various materials and configurations to suit different applications and fluid types.

Customization Options:

Industrial basket strainers can be customized to meet specific application requirements. This includes variations in material, mesh size, and design to accommodate different fluid viscosities, temperatures, and pressure conditions. Contact Sungov Engineering to see how best basket strainers can be customized to your requirements.

Cost-Effective Filtration:

Compared to other filtration methods, basket strainers offer a cost-effective solution for many industrial applications. Their relatively simple design and low maintenance requirements contribute to cost savings over time.

How can one effectively clean and maintain a basket strainer to ensure lasting performance?

Cleaning and maintaining basket strainers are crucial steps to ensure their optimal performance in industrial settings. Regular maintenance involves a systematic approach to prevent the accumulation of contaminants and maintain fluid flow efficiency.

You may have to start by shutting off the flow and isolating the strainer from the system.

Then carefully remove the basket or element from the housing, taking note of its orientation.

Thoroughly clean the basket by using appropriate cleaning agents or by soaking it in a cleaning solution, depending on the nature of the contaminants.

You may further inspect the basket for any signs of damage or wear, and replace it if necessary.

When you are at this make sure to inspect the strainer housing and gaskets for wear or leaks.

Once cleaned and inspected, reassemble the basket strainer and reinstall it in the pipeline.

Perform a pressure test to ensure proper sealing and functionality.

Establishing a routine maintenance schedule, based on the specific requirements of the industrial process and the type of fluids being filtered, is essential to extending the lifespan of the basket strainer and avoiding unexpected downtime.

0 notes

Text

youtube

When it comes to enjoying the perfect pool experience in the sunny paradise of Windermere, WRX Pool Cleaning Service is your family-owned, go-to solution. With a relentless commitment to excellence and certified expertise from ASAPP (American Spa And Pool Pros) and CPO (Certified Pool and Spa Operator), we take immense pride in providing you with the highest quality swimming pool services in Windermere area.

Pool Cleaning Services - A Splash of Perfection

WRX Pool Cleaning Service offers a comprehensive range of swimming pool cleaning services in Windermere, meticulously designed to maintain the pristine condition of your pool. Our dedicated team of experts is committed to providing you with unmatched pool cleaning solutions, including:

Skimming: We meticulously remove debris from the pool's surface, ensuring your water is always clean and inviting.

Brushing: Our technicians thoroughly brush the pool walls and floor to remove dirt and algae, leaving your pool surfaces spotless.

Vacuuming: We use advanced equipment to eliminate any remaining debris, ensuring your pool is a haven of cleanliness.

Skimmer and Pump Maintenance: Regularly emptying and cleaning skimmer and pump strainer baskets keeps your filtration system running smoothly.

Chemical Balance: Our Windermere pool cleaning company in checks and adjusts the chemical levels in your pool, maintaining a perfect pH balance for your safety and enjoyment.

Backwashing: We efficiently perform pool filter backwashing to keep your water clear and your equipment operating optimally.

Our swimming pool cleaning services near me are available on a schedule that suits your needs, whether it's weekly, bi-weekly, monthly, or even as a one-time cleaning for special occasions, like parties or events.

Preserving Pool Perfection with Our Quality Pool Maintenance Services

At WRX Pool Cleaning Service, we understand that consistent maintenance is the key to your pool's longevity and functionality. As a leading swimming pool maintenance company in Windermere, our services are designed to keep your pool in tip-top condition year-round. Our pool maintenance services include:

Routine Cleaning and Maintenance: We provide regular cleaning and pool maintenance services near me to ensure your pool is always at its best.

Equipment Inspections and Maintenance: Our experts inspect and maintain pool equipment to prevent issues and keep your pool running efficiently.

Chemical Testing and Balancing: We maintain proper chemical balance for safe and enjoyable swimming.

Filter Cleaning and Replacement: Clean filters are essential for clean water, and we replace them as needed.

Repairs and Replacements: Should any part of your pool equipment need repair or replacement, our skilled technicians are ready to assist.

Swimming Pool Repair Services - Swift Solutions to Your Pool Problems

Pool repairs can be stressful and costly, but WRX Pool Cleaning Service offers prompt and reliable swimming pool repair services in Windermere to ensure that your pool is up and running without delay. Our skilled technicians are equipped to handle a wide range of swimming pool repairs, including:

Pump and Motor Repairs or Replacements: Ensure your pool's circulation is efficient with our pump and motor services.

Filter Repairs or Replacements: We repair or replace pool filters to ensure your water is crystal clear.

Plumbing Repairs: Prevent water loss and ensure proper circulation with our plumbing repair services.

Electrical Repairs: Pool lighting and equipment depend on electrical systems. Our technicians can repair them quickly and safely.

Tile and Coping Repairs or Replacements: Maintain the aesthetics of your pool with our tile and coping services.

Pool Deck Repairs: A damaged pool deck can be a safety hazard. We can repair it efficiently.

CONTACT US:

Contact us today and let WRX Pool Cleaning Service turn your pool into a sanctuary of refreshment and relaxation. Dive in with confidence, and let us take care of the rest!

WRX Pool Services 6407 Swanson Street Windermere, FL 34786 321-430-0200

FIND US ONLINE:

Visit Our Website: https://www.wrxpools.com/

Find Us On The Map: https://www.google.com/maps?cid=14302796168253683902

Business Profile: https://wrx-pool-services-pool-cleaning-company.business.site/

Facebook: https://www.facebook.com/wrxpoolservices/

Yelp: https://www.yelp.com/biz/wrx-pool-services-windermere

Event Brite: https://www.eventbrite.com/o/wrx-pool-services-33118140475

Alignable: https://www.alignable.com/windermere-fl/wrx-pool-services

Swimming Pools Company: http://www.swimmingpoolscompany.com/business/wrx-pool-services

Waze (Driving Directions): https://www.waze.com/en/live-map/directions/wrx-pool-services-swanson-st-6407-windermere?to=place.w.182452509.1824852766.7916673

0 notes

Text

Unlocking Laboratory Precision: A Deep Dive Into The Best Lab Cell Strainers

In the realm of scientific research, precision is of utmost importance. The quality of your equipment can significantly impact the outcome of your experiments. Lab cell strainers are one such tool that plays a critical role in sample preparation, and today, we'll explore some of the best lab cell strainers available in the market.

Understanding Lab Cell Strainers

Lab cell strainers are essential tools used in laboratories to separate particles from liquid samples, ensuring that only the desired components are retained. They are indispensable in a wide range of applications, from single-cell suspensions to preparing samples for flow cytometry. Here, we'll introduce you to several exceptional lab cell strainers:

PluriStrainer: Precision Redefined

PluriStrainer is designed for precision and convenience in the lab. It easily attaches to a 50 mL centrifuge tube, allowing you to add sample material and filter effortlessly. You can even flip it onto another tube to obtain the larger fraction, making it incredibly versatile. The funnel attachment lets you add up to 24 mL of sample material, and you can stack different mesh sizes to strain various cell sizes simultaneously. With flow control options and a wide range of applications, PluriStrainer is undoubtedly one of the best lab cell strainers available.

Mini Strainer: Small Sample, Big Impact

When working with small sample volumes, the Mini Strainer shines. It offers various pore sizes for precise filtration and comes with a 1 ml reservoir that accommodates small sample volumes. Sterile and ready to use, it's ideal for applications like preparing cell suspensions, flow cytometry, and more.

Syringe Strainer: Effortless Particle Recovery

The Syringe Strainer is an innovative cell strainer designed for easy particle recovery and precise liquid filtration. Its unique design allows for easy backflushing via negative pressure, minimizing sample loss. It's versatile and ideal for filtration, particle separation, and liquid purification tasks in the lab.

Membrane Strainer: Precision and Detection

For unparalleled precise filtration and particle detection, the Membrane Strainer is your go-to option. It offers various pore sizes for accurate particle separation and is suitable for biological and environmental analyses. Its advanced membrane filtration technology enables sensitive and efficient particle detection.

Steel Basket Strainer: Robust Filtration Solution

Crafted from stainless steel mesh, the Steel Basket Strainer is a robust and reliable filtration solution. It offers a wide range of pore sizes and is reusable and regenerable. It can withstand high temperatures and pressures, making it ideal for various industries. In addition to these strainers, consider the concept of a Strainer Cascade: Achieving Precise Cell Separation, where you can connect multiple strainers in a cascade setup to refine your cell isolation process.

Re-Strainer: High-Volume Filtration with Particle Recovery

The Re-Strainer is designed for handling high volumes of liquid while excluding or concentrating particles. It comes with a 6 ml recovery reservoir and multiple Female Luer-Lock ports, allowing you to connect multiple Re-Strainers in a cascade setup or use them as in-line strainers.

Mini-Membrane-Strainer: Versatile Sample Preparation

If you're working with small volumes (up to 800 ul), the Mini-Membrane-Strainer is a versatile sample preparation device. It comes with precise pore openings, and universal compatibility, and seamlessly replaces standard strainer caps in flow cytometry tubes.

Conclusion

In the world of laboratory research, precision and convenience are non-negotiable. Lab cell strainers are essential tools that can make a significant difference in the quality of your experiments. Whether you're working with small sample volumes or high-throughput applications, there's a lab cell strainer designed to meet your needs.

Invest in the best lab cell strainers to ensure that your experiments are carried out with the highest level of precision and efficiency. These versatile tools are the key to unlocking the full potential of your laboratory work, whether you're studying single-cell suspensions, conducting particle separation, or preparing samples for advanced analyses like flow cytometry.

0 notes

Text

Dive into Clarity: Maintaining Your Pool & Spa Filter for a Crystal-Clear Experience

You've had a long, exhausting day, and all you crave is a dip in your sparkling pool or a relaxing soak in your spa. The sun is setting, casting a golden hue on the water's surface. It's the perfect ambiance to unwind, but wait – is your pool or spa filter in top-notch condition to give you that crystal-clear experience? In this guide, we'll splash into the depths of maintaining your pool and spa filter, ensuring your aquatic escape remains a sanctuary of tranquility.

1. The Heart of Clean Water: Understanding Your Filter

Your pool or spa filter acts as the heart of the system, cleansing the water from impurities and debris. Just like a heart pumps life-giving blood, your filter keeps the water pristine for a refreshing swim or soak.

2. Types of Pool & Spa Filters

Pool and spa filters come in various types, each with its own unique cleaning mechanism. The most common types are sand filters, cartridge filters, and diatomaceous earth (DE) filters. Understanding these is the first step in proper maintenance.

3. Sand Filters: The Strainers of the Sea

Imagine a sandcastle at the beach – it holds its shape while water seeps through, leaving the sand intact. Sand filters operate similarly. They use specially graded sand to trap debris and impurities, letting clean water flow back into your pool or spa.

4. Cartridge Filters: The Efficient Cleaners

Cartridge filters utilize a pleated filtering surface to catch debris. They are known for their efficiency and can capture particles as small as 10-15 microns, ensuring crystal-clear water.

5. Diatomaceous Earth (DE) Filters: The Super Filters

DE filters employ fossilized remains of diatoms, tiny aquatic organisms, as a filtering agent. They offer exceptional filtration, trapping particles as small as 2-5 microns, making them the superheroes of filtration.

6. Routine Maintenance: Prolonging Your Filter's Life

Regular upkeep is crucial to ensure your filter operates at its best. Neglecting maintenance can lead to decreased efficiency and costly repairs. Let's delve into a maintenance routine that will keep your filter in top shape.

7. Weekly Check-ups: A Date with Your Filter

Make it a habit to inspect your filter weekly. Remove debris from the pump basket and skimmer, ensuring they don't clog and impede water flow to the filter.

8. Monthly Cleanings: A Thorough Spa Day for Your Filter

Once a month, give your filter a deeper clean. For cartridge filters, gently hose them down to remove dirt. For sand filters, backwash to flush out accumulated debris. DE filters may require backwashing and adding new DE powder.

9. Seasonal Service: Winterizing and Rejuvenating

As the seasons change, your pool or spa usage fluctuates. Properly winterize your filter in colder months to avoid damage from freezing temperatures. When spring arrives, give your filter a tune-up to prepare for the upcoming swim season.

10. Troubleshooting: Addressing Common Issues

Even with regular maintenance, filters can face issues. Understanding these problems and how to troubleshoot them is essential for a seamless filtration experience.

11. Low Flow: The Filter's Silent Cry for Help

Low flow indicates a potential clog. Check for debris in the skimmer, pump basket, or the filter itself. Clean or backwash accordingly.

12. Leaks: The Dripping Woes

Leaks can lead to water loss and damage. Inspect the filter's seals, o-rings, and connections. Replace damaged parts to prevent further leaks.

13. Excessive Pressure: When Your Filter Feels Stressed

High pressure in your filter may result from dirty or clogged components. Clean or backwash the filter to relieve the pressure and restore proper flow.

14. Professional Help: When DIY Isn't Enough

In some cases, it's best to call in a professional. If you're unsure about the issue or unable to resolve it, seeking expert help ensures your filter is back to optimal performance.

15. Conclusion: Dive into a World of Clarity

Your pool or spa is your personal oasis, and maintaining a clean, inviting water source is vital for an enjoyable experience. By understanding the types of filters and embracing a regular maintenance routine, you'll ensure your aquatic retreat remains a haven of tranquility and crystal-clear waters.

In summary, think of your filter as a guardian angel, tirelessly working to provide you with the clarity and purity you seek in your pool or spa. Treat it well, and it will reciprocate, allowing you to dive into a world of relaxation and bliss whenever you desire. Happy swimming!

0 notes

Text

How to repair a kitchen faucet

Repairing a kitchen faucet is a DIY project that is usually easier and less time-consuming than you might think. Leaks are fixed either by treating clogs with vinegar or by replacing some of the smaller parts of the faucet. The parts that are most likely to need replacement will depend on the type of faucet you have. Keep an eye on the parts as you work, and reassemble them later to keep your faucet working as good as new.

Prepare for the repair work

Locate the leak. Before you begin, examine the faucet to find out where the leak is. Leaks almost always occur at either the base or the spout of the faucet. Once you know where the leak is, you can determine which parts are responsible for the leak.

Turn off the water supply to the faucet. First, look under your sink. You may see two valves that you can turn clockwise to stop the flow of water into the faucet. If the valves are not there, turn off the main water line. This is usually located in the basement, next to the water meter.

Turn on the water tap to relieve the water pressure. Make sure that the water supply is turned off before removing the faucet. Allow the water to flow from the faucet until it stops. Accumulated pressure will also drain.

Cover the hole in the sink with a strainer to catch small debris. It's no fun if a small but important part falls into the sink. To save yourself extra work, you can place the sink's strainer baskets over the drain.

Label and photograph the faucet as you remove the parts. Once you have repaired the faucet, you will need to return the parts in the correct order. To remember this order, have a camera nearby to document your work. Also, keep the parts separate and organized, so you know when you need which part.

Pour some vinegar into a container to clean the faucet parts. You'll probably find that some parts have mineral deposits on them. Soak the parts in vinegar for a few minutes first to soften the buildup, then scrub them with a microfiber cloth or nylon abrasive pad.

Call the Emergency Plumber in Newcastle. We are available around the clock. Call us now, 02843798533.

0 notes