#Benefits of Basket Strainers

Explore tagged Tumblr posts

Text

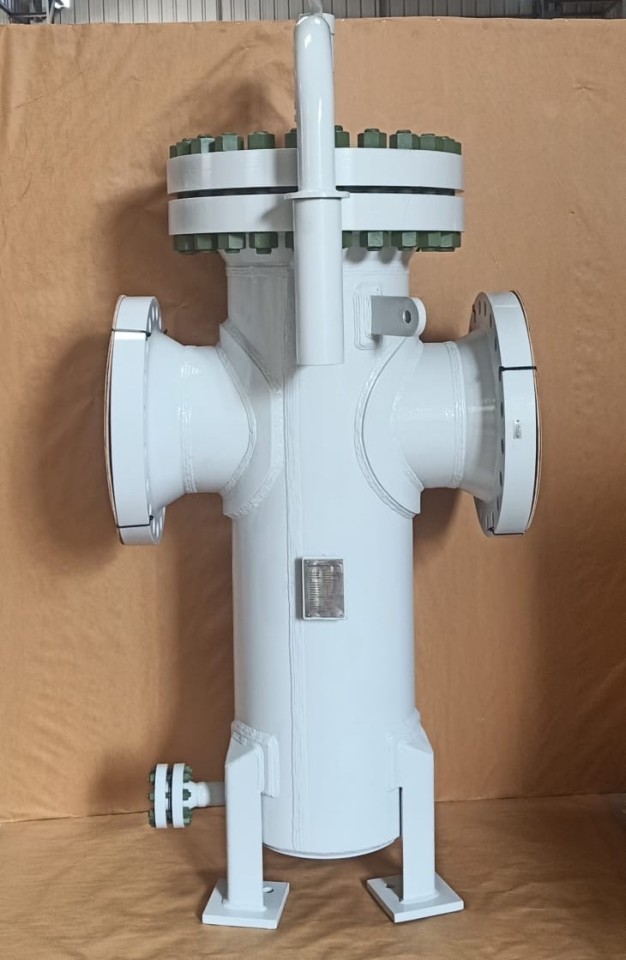

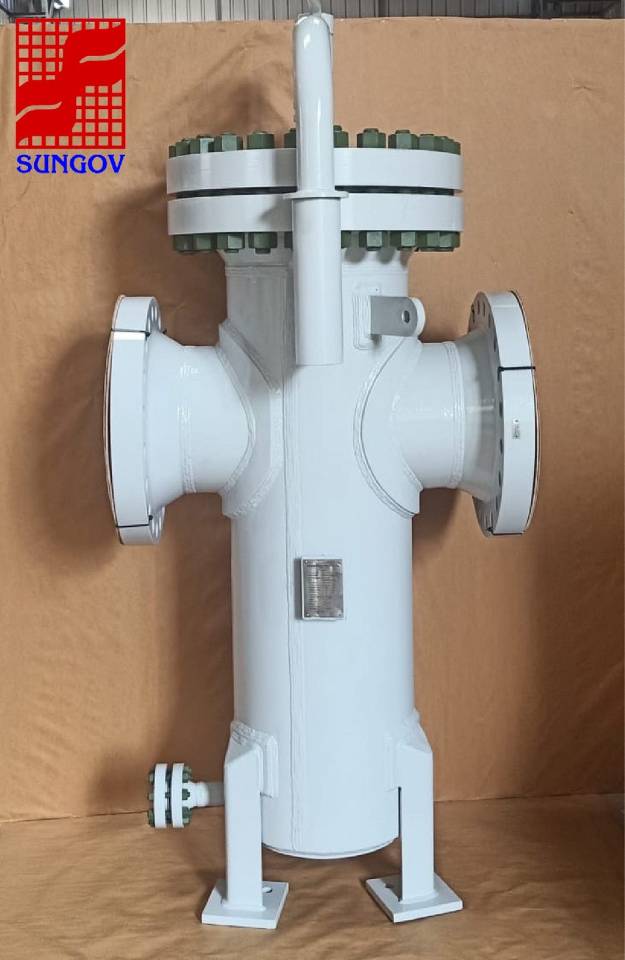

Unveiling the Benefits of Basket Strainers in Industrial Applications

Basket strainers are essential components in fluid handling systems. They are designed to remove solid particles and debris from liquids and to protect downstream equipment, Basket strainers ensure the smooth operation of industrial processes. These strainers feature a cylindrical or flat shape screen with a perforated or mesh-lined basket inside, allowing the fluid to pass through while capturing unwanted particles.

Typically installed in pipelines, basket strainers are employed in various industries, including petrochemical, water treatment, pharmaceuticals, and food processing. Their design facilitates easy maintenance as the basket can be easily removed and cleaned, ensuring the longevity and efficiency of the strainer. Basket strainers play a critical role in maintaining the integrity of liquids, safeguarding equipment, and minimizing downtime in industrial applications.

What are the essential benefits of basket strainers in industrial setting?

Basket strainers play a crucial role in industrial settings by providing effective filtration and protection for various equipment and processes. Here are some essential benefits of basket strainers in an industrial setting:

Particle Removal:

Basket strainers are designed to capture and remove solid particles from liquids or gases flowing through pipelines. This helps prevent damage to downstream equipment, such as pumps, valves, and heat exchangers, which can be sensitive to particulate matter.

Process Efficiency:

Strainers contribute to the overall efficiency of industrial processes by ensuring that fluids are free from debris and contaminants. Clean fluids can enhance the performance of equipment, improve heat transfer efficiency, and maintain consistent product quality.

Equipment Protection:

By removing contaminants from the fluid, basket strainers protect sensitive components and equipment from wear and damage. This is particularly important in industries such as petrochemical, chemical, and water treatment, where equipment can be susceptible to damage from particles.

Extended Equipment Life:

The removal of particles prevents abrasive wear on equipment components, extending the lifespan of pumps, valves, and other critical process equipment. This can lead to cost savings through reduced maintenance and replacement expenses.

Reduced Downtime:

Regular use of basket strainers helps prevent unexpected shutdowns caused by equipment failure due to particle buildup. This reduction in downtime contributes to increased overall productivity and operational efficiency.

Easy Maintenance:

Basket strainers are typically designed for easy maintenance. They can be easily removed, cleaned, and reinstalled without requiring extensive downtime. This contributes to a more streamlined maintenance process.

Versatility:

Basket strainers can be used in a wide range of industries, including oil and gas, chemical processing, water treatment, food and beverage, and more. They are available in various materials and configurations to suit different applications and fluid types.

Customization Options:

Industrial basket strainers can be customized to meet specific application requirements. This includes variations in material, mesh size, and design to accommodate different fluid viscosities, temperatures, and pressure conditions. Contact Sungov Engineering to see how best basket strainers can be customized to your requirements.

Cost-Effective Filtration:

Compared to other filtration methods, basket strainers offer a cost-effective solution for many industrial applications. Their relatively simple design and low maintenance requirements contribute to cost savings over time.

How can one effectively clean and maintain a basket strainer to ensure lasting performance?

Cleaning and maintaining basket strainers are crucial steps to ensure their optimal performance in industrial settings. Regular maintenance involves a systematic approach to prevent the accumulation of contaminants and maintain fluid flow efficiency.

You may have to start by shutting off the flow and isolating the strainer from the system.

Then carefully remove the basket or element from the housing, taking note of its orientation.

Thoroughly clean the basket by using appropriate cleaning agents or by soaking it in a cleaning solution, depending on the nature of the contaminants.

You may further inspect the basket for any signs of damage or wear, and replace it if necessary.

When you are at this make sure to inspect the strainer housing and gaskets for wear or leaks.

Once cleaned and inspected, reassemble the basket strainer and reinstall it in the pipeline.

Perform a pressure test to ensure proper sealing and functionality.

Establishing a routine maintenance schedule, based on the specific requirements of the industrial process and the type of fluids being filtered, is essential to extending the lifespan of the basket strainer and avoiding unexpected downtime.

0 notes

Text

Modular Kitchen Baskets: Smart Storage Solutions for a Stylish & Organized Kitchen

A well-organized kitchen is the heart of every functional home. In today’s fast-paced world, homeowners are constantly looking for ways to make their kitchen space more efficient, accessible, and aesthetically pleasing. That’s where modular kitchen baskets come into play. These baskets aren’t just practical—they’re the ultimate storage solution that blends design with utility, transforming your kitchen into a clutter-free zone.

Whether you’re revamping your entire kitchen or just adding a few essentials, investing in the right baskets can streamline your space and simplify your life. In this article, we’ll explore the benefits of modular kitchen baskets, highlight some top products from DeoDap, and show you how to use them to bring elegance and order to your kitchen.

Why Choose Modular Kitchen Baskets?

1. Maximize Storage Space

Modular kitchen baskets help in optimizing every inch of your kitchen—especially corners, under-sink areas, and deep cabinets. Their structured design ensures that even the smallest spaces are utilized effectively.

2. Declutter with Style

Gone are the days of messy countertops and overflowing drawers. Modular baskets bring a sleek, modern look while keeping everything organized and within reach.

3. Multi-Purpose Functionality

These baskets can store anything from utensils and dishes to fruits, vegetables, and cleaning supplies. Their versatility makes them ideal for every corner of the kitchen.

4. Easy Access and Maintenance

Unlike closed shelves, modular baskets allow you to see and reach your items easily. Most designs are lightweight, easy to clean, and highly durable, making them perfect for daily use.

Explore Best-Selling Modular Kitchen Baskets from DeoDap

At DeoDap, you’ll find a wide range of smart and stylish kitchen baskets that cater to different needs. Here are some top-rated picks that can transform your kitchen space:

🧺 Plastic Small Dish Rack Washing Basket

This compact yet highly functional basket is perfect for drying dishes and cutlery in a neat and organized way. Made from durable plastic, it’s ideal for small kitchens or as an extra drying rack next to your sink. The open design ensures water drains off quickly, preventing bacteria build-up and keeping your utensils hygienic.

Highlights:

Space-saving and lightweight

Great for dish drying and utensil storage

Easy to clean and maintain

🧽 Foldable Strainer Chef Basket

Talk about innovation and convenience! This foldable chef basket works as a strainer, fryer, and steamer. Its flexible steel mesh design allows it to adapt to different pots and cooking styles. Once you’re done, just fold it flat for easy storage.

Perfect For:

Washing and straining vegetables

Deep frying snacks like samosas and pakoras

Compact kitchens that demand space-efficiency

🛍️ Foldable Basket Bag – 3 PCS Set (Multicolor)

These foldable basket bags are a colorful and practical addition to your kitchen. Whether you’re storing dry groceries, cleaning supplies, or kitchen linens, these baskets help keep everything in order. They’re also great for carrying items while shopping.

Features:

Foldable design saves space

Multicolor for easy sorting

Lightweight and portable

🚿 ABS Plastic Shower Corner Caddy Basket

Although originally designed for bathrooms, this corner caddy basket is just as useful in the kitchen. It can be placed in unused corners to store spices, condiments, cleaning bottles, or dish soap. Its strong ABS plastic body ensures durability even in humid or wet environments.

Great For:

Utilizing kitchen corners efficiently

Storing items that need to be easily accessed

Keeping the sink area tidy

How to Choose the Right Modular Kitchen Basket

With so many options available, choosing the right basket depends on your kitchen size, layout, and storage requirements. Here are a few tips to help you decide:

✔ Assess Your Needs

Start by identifying the items you use daily—utensils, cutlery, spices, cleaning supplies, etc. Choose baskets designed specifically to accommodate those items.

✔ Measure Your Space

Before buying, measure your cabinets, corners, or countertops to ensure the baskets will fit perfectly.

✔ Go for Multipurpose Designs

Foldable, stackable, and multifunctional baskets offer more value and flexibility in the long run.

✔ Choose Durable Materials

Plastic and stainless steel are great options as they’re easy to clean, resistant to rust, and long-lasting.

Benefits of Buying Modular Kitchen Baskets Online

🛒 Convenience

Shopping online allows you to browse through a wide variety of styles, sizes, and designs from the comfort of your home.

💰 Best Prices

You can easily compare prices and choose the best deals without visiting multiple stores.

🚚 Doorstep Delivery

Why haul heavy kitchen accessories when you can get them delivered straight to your door?

Looking for the perfect modular kitchen basket for your space? DeoDap offers a diverse selection at unbeatable prices—ideal for every home and budget.

Organize Like a Pro: Smart Tips to Use Kitchen Baskets

Group Similar Items Use different baskets to categorize utensils, dry goods, fruits, or snacks. Label them if needed for added clarity.

Utilize Vertical Space Stack baskets or place them on multi-tier racks to take advantage of vertical space in cabinets or shelves.

Add Baskets to Unused Corners Make use of often overlooked spaces like corners or under the sink with smartly shaped corner baskets.

Keep It Minimal Don’t overload your baskets. A clean, minimal setup is both practical and visually appealing.

DeoDap – Your Trusted Source for Kitchen Essentials

DeoDap isn’t just another eCommerce store—it’s a one-stop destination for all your home and kitchen needs. Every product is curated with quality, utility, and affordability in mind. Whether you’re setting up a new kitchen or upgrading an old one, DeoDap makes it easy to bring your vision to life.

Final Thoughts

A modular kitchen isn’t complete without the right storage solutions. Modular kitchen baskets are essential tools that bring functionality and style to your cooking space. From drying racks to foldable chef baskets and colorful organizers, there’s something for every kitchen need at DeoDap.

Invest in smart storage today and transform your kitchen into a clutter-free, efficient, and beautiful space. Check out the complete collection of storage baskets and give your kitchen the makeover it deserves.

0 notes

Text

Choosing the Right Bucket Type Strainer for Your Pipeline System

In fluid handling systems, ensuring the purity and smooth flow of liquids is critical. One key component that helps maintain this is the strainer. Among various types, the bucket type strainer plays a crucial role in protecting pipeline equipment from damage caused by unwanted particles. Selecting the correct one for your pipeline isn’t just about size—it’s about understanding your system’s needs and how this specific type of strainer fits into the process.

What is a Bucket Type Strainer?

A bucket type strainer is a mechanical device used to filter debris from liquids in a pipeline. It is designed to capture solid particles before they can enter pumps, valves, or other sensitive components. These strainers are typically installed in horizontal pipelines and are known for their durability and ease of maintenance.

Unlike other types of strainers, such as Y-type or T-type, bucket strainers (often referred to as basket strainers in some contexts) are specifically useful for systems that deal with larger volumes or higher flow rates. Their deep, removable basket is ideal for trapping larger debris without requiring frequent cleaning.

Factors to Consider When Choosing a Bucket Type Strainer

1. Flow Rate and Pressure Drop

Every strainer introduces some resistance to the flow of liquid. It’s essential to evaluate how much pressure drop your system can tolerate. A well-sized bucket strainer allows for efficient filtering while keeping pressure loss to a minimum. If the strainer is too small, it could cause blockages and impact overall performance.

2. Material of Construction

The choice of material is highly dependent on the type of fluid being transported. Stainless steel is a popular option due to its corrosion resistance and long lifespan. However, for less aggressive media, carbon steel or cast iron may be sufficient. Always check for compatibility between the strainer material and the fluid to avoid corrosion or chemical reactions.

3. Mesh Size and Filtration Level

The effectiveness of a bucket type strainer lies in the mesh or perforated screen inside the basket. Depending on the particles you want to remove, you’ll need a specific mesh size. For instance, in water pipelines, a coarse screen may be enough to catch stones and leaves. In chemical or oil pipelines, finer filtration might be required to remove sludge or scale.

4. Ease of Maintenance

One of the benefits of using a bucket design is how easy it is to clean and maintain. Look for strainers that allow tool-free access or have quick-release covers. Regular cleaning helps keep the system running efficiently and prevents long-term wear.

5. Installation Space and Orientation

Though most bucket strainers are installed horizontally, the space available for installation can dictate the type and size of the unit. Some models have a compact design to suit tight spaces. Ensure you measure the pipeline space accurately before purchasing.

6. End Connection Types

Bucket type strainers come with various connection ends—flanged, threaded, or welded. Choose a connection type that aligns with the existing setup of your pipeline. Flanged ends are common in industrial systems due to their robust sealing and easy replacement.

Applications in Different Industries

Bucket strainers are widely used across multiple sectors. In water treatment plants, they help keep pumps and filters from clogging. In the oil and gas industry, they protect valuable processing equipment. Chemical plants rely on them to maintain product purity, while HVAC systems use them to prevent blockage in chilled water lines. Each application demands a different specification, so understanding the industry standards is important.

Final Thoughts

Choosing the right bucket type strainer is about more than just picking a filter. It’s a decision that affects the longevity, efficiency, and safety of your entire pipeline system. By considering factors like flow rate, material compatibility, mesh size, and ease of maintenance, you can select a unit that fits your system perfectly. Whether you’re setting up a new operation or upgrading an old one, the right strainer will save you time, reduce costs, and improve overall reliability.

0 notes

Text

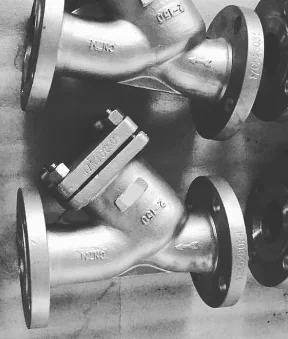

Best Strainers Manufacturer in Delhi – Y Strainer, Brass Strainer & Steam Trap Guide

Strainers are essential components used in pipeline systems to filter out debris, dirt, and unwanted particles, ensuring smooth flow and protecting pumps, valves, and other equipment. Common types include Y strainers, brass strainers, and steam traps, which are used in water treatment, steam applications, HVAC, and chemical industries.

As the best strainers manufacturer and supplier in Delhi, Udhhyog provides high-quality strainers that offer durability, corrosion resistance, and efficient filtration for industrial and commercial use.

This guide covers types of strainers, applications, pricing details, and how to select the right strainer for your system.

What is a Strainer?

A strainer is a filtration device used in pipelines to remove solid contaminants from liquids, steam, and gases. Strainers prevent clogging, reduce maintenance costs, and protect mechanical equipment.

Key Benefits of Strainers:

✔ Prevents damage to pumps, valves, and pipelines. ✔ Improves system efficiency by removing unwanted particles. ✔ Reduces maintenance and downtime. ✔ Available in multiple materials like brass, stainless steel, and cast iron. ✔ Compatible with water, steam, oil, and chemicals.

Strainer Diagram & Symbol

A strainer diagram visually represents the internal filtration mechanism, while the strainer symbol is commonly used in piping and process diagrams (P&ID).

Types of Strainers Available at Udhhyog

1. Y Type Strainer

Designed in a Y-shaped configuration to remove debris from pipelines.

Used in water treatment plants, HVAC systems, and industrial processing.

Available in brass, stainless steel, and cast iron.

2. Brass Strainer

Made from high-quality brass for corrosion resistance.

Used in plumbing, gas pipelines, and domestic water supply systems.

3. Steam Trap Strainer

Specifically designed for steam pipelines to filter out impurities.

Prevents steam system failure and enhances efficiency.

4. Zoloto Strainer

High-performance strainers from the Zoloto brand.

Known for precision filtration and long lifespan.

5. Basket Strainer

Used in high-flow applications where debris accumulation is significant.

Found in power plants, refineries, and industrial water systems.

6. Flanged & Threaded Strainers

Flanged strainers for industrial-scale applications.

Threaded strainers for domestic and low-pressure systems.

Where are Strainers Used?

1. Steam Systems & Boilers

Filters out impurities from steam lines.

Protects boilers, heat exchangers, and condensers.

2. Water Supply & Plumbing

Ensures clean water supply by preventing dirt buildup.

Protects water pumps and flow meters.

3. Oil & Gas Industry

Removes contaminants from crude oil, natural gas, and petroleum.

Used in pipelines and refineries.

4. Chemical & Pharmaceutical Industry

Ensures clean chemical processing by filtering out solids.

Protects reactors, pumps, and pipelines.

5. HVAC & Fire Protection Systems

Filters out debris from fire sprinklers and cooling systems.

Ensures smooth operation in heating and ventilation networks.

Strainers Price List

Latest Prices for Different Strainers

Strainer TypeSizePrice Range (INR)Brass Strainer1/2 to 2 Inch₹400 - ₹2,500SS Y Strainer (SS304 & SS316)1/2 to 4 Inch₹1,200 - ₹6,000Cast Iron Y Strainer1 to 6 Inch₹3,000 - ₹15,000Zoloto Y Strainer1/2 to 6 Inch₹1,500 - ₹8,500Steam Trap Strainer1 to 4 Inch₹2,500 - ₹12,000Flanged Y Strainer1 to 6 Inch₹5,000 - ₹25,000

📌 Note: Prices may vary based on size, material, and order quantity. Contact Udhhyog for bulk orders and latest pricing.

How to Select the Right Strainer?

1. Application Type

For water supply & plumbing – Choose a brass or SS Y strainer.

For steam & boiler systems – Select a steam trap strainer.

For industrial & chemical applications – Use a stainless steel or Zoloto Y strainer.

2. Size & Pressure Rating

1/2 to 2 inches for domestic and low-pressure systems.

3 inches & above for high-flow industrial setups.

3. Material Selection

Brass strainers for low-pressure water systems.

Stainless steel strainers for corrosive chemicals & high-pressure applications.

Cast iron strainers for heavy-duty industrial use.

4. Connection Type

Threaded strainers for small pipeline connections.

Flanged strainers for high-pressure industrial installations.

5. Supplier & Manufacturer Reliability

Choose trusted suppliers like Udhhyog for high-quality, certified strainers.

Why Choose Udhhyog – Best Strainers Manufacturer & Supplier in Delhi?

At Udhhyog, we take pride in being a leading manufacturer and supplier of strainers in Delhi. Here’s why we are trusted across industries:

✅ Top-Quality Materials

We manufacture strainers using brass, stainless steel, and cast iron to ensure durability.

✅ Affordable Pricing

Our prices are competitive, making us the best choice for industrial and commercial buyers.

✅ Wide Range of Strainers

We supply Y strainers, brass strainers, steam trap strainers, and Zoloto strainers.

✅ Reliable & Quick Delivery

We ensure on-time delivery across Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Contact Udhhyog for the Best Strainers

📞 Call Us Today or Visit Udhhyog to explore our range of industrial and commercial strainers.

✨ Choose Udhhyog – Your Trusted Strainer Manufacturer & Supplier!

#Strainers#YStrainer#SteamTrap#BrassStrainer#IndustrialValves#ValveSupplier#DelhiManufacturer#Udhhyog#PlumbingSolutions#EngineeringSolutions

0 notes

Text

Best Strainers Manufacturer in Delhi – Y Strainer, Brass Strainer & Steam Trap Guide

Strainers are essential components used in pipeline systems to filter out debris, dirt, and unwanted particles, ensuring smooth flow and protecting pumps, valves, and other equipment. Common types include Y strainers, brass strainers, and steam traps, which are used in water treatment, steam applications, HVAC, and chemical industries.

As the best strainers manufacturer and supplier in Delhi, Udhhyog provides high-quality strainers that offer durability, corrosion resistance, and efficient filtration for industrial and commercial use.

This guide covers types of strainers, applications, pricing details, and how to select the right strainer for your system.

What is a Strainer?

A strainer is a filtration device used in pipelines to remove solid contaminants from liquids, steam, and gases. Strainers prevent clogging, reduce maintenance costs, and protect mechanical equipment.

Key Benefits of Strainers:

✔ Prevents damage to pumps, valves, and pipelines. ✔ Improves system efficiency by removing unwanted particles. ✔ Reduces maintenance and downtime. ✔ Available in multiple materials like brass, stainless steel, and cast iron. ✔ Compatible with water, steam, oil, and chemicals.

Strainer Diagram & Symbol

A strainer diagram visually represents the internal filtration mechanism, while the strainer symbol is commonly used in piping and process diagrams (P&ID).

Types of Strainers Available at Udhhyog

1. Y Type Strainer

Designed in a Y-shaped configuration to remove debris from pipelines.

Used in water treatment plants, HVAC systems, and industrial processing.

Available in brass, stainless steel, and cast iron.

2. Brass Strainer

Made from high-quality brass for corrosion resistance.

Used in plumbing, gas pipelines, and domestic water supply systems.

3. Steam Trap Strainer

Specifically designed for steam pipelines to filter out impurities.

Prevents steam system failure and enhances efficiency.

4. Zoloto Strainer

High-performance strainers from the Zoloto brand.

Known for precision filtration and long lifespan.

5. Basket Strainer

Used in high-flow applications where debris accumulation is significant.

Found in power plants, refineries, and industrial water systems.

6. Flanged & Threaded Strainers

Flanged strainers for industrial-scale applications.

Threaded strainers for domestic and low-pressure systems.

Where are Strainers Used?

1. Steam Systems & Boilers

Filters out impurities from steam lines.

Protects boilers, heat exchangers, and condensers.

2. Water Supply & Plumbing

Ensures clean water supply by preventing dirt buildup.

Protects water pumps and flow meters.

3. Oil & Gas Industry

Removes contaminants from crude oil, natural gas, and petroleum.

Used in pipelines and refineries.

4. Chemical & Pharmaceutical Industry

Ensures clean chemical processing by filtering out solids.

Protects reactors, pumps, and pipelines.

5. HVAC & Fire Protection Systems

Filters out debris from fire sprinklers and cooling systems.

Ensures smooth operation in heating and ventilation networks.

Strainers Price List

Latest Prices for Different Strainers

Strainer TypeSizePrice Range (INR)Brass Strainer1/2 to 2 Inch₹400 - ₹2,500SS Y Strainer (SS304 & SS316)1/2 to 4 Inch₹1,200 - ₹6,000Cast Iron Y Strainer1 to 6 Inch₹3,000 - ₹15,000Zoloto Y Strainer1/2 to 6 Inch₹1,500 - ₹8,500Steam Trap Strainer1 to 4 Inch₹2,500 - ₹12,000Flanged Y Strainer1 to 6 Inch₹5,000 - ₹25,000

📌 Note: Prices may vary based on size, material, and order quantity. Contact Udhhyog for bulk orders and latest pricing.

How to Select the Right Strainer?

1. Application Type

For water supply & plumbing – Choose a brass or SS Y strainer.

For steam & boiler systems – Select a steam trap strainer.

For industrial & chemical applications – Use a stainless steel or Zoloto Y strainer.

2. Size & Pressure Rating

1/2 to 2 inches for domestic and low-pressure systems.

3 inches & above for high-flow industrial setups.

3. Material Selection

Brass strainers for low-pressure water systems.

Stainless steel strainers for corrosive chemicals & high-pressure applications.

Cast iron strainers for heavy-duty industrial use.

4. Connection Type

Threaded strainers for small pipeline connections.

Flanged strainers for high-pressure industrial installations.

5. Supplier & Manufacturer Reliability

Choose trusted suppliers like Udhhyog for high-quality, certified strainers.

Why Choose Udhhyog – Best Strainers Manufacturer & Supplier in Delhi?

At Udhhyog, we take pride in being a leading manufacturer and supplier of strainers in Delhi. Here’s why we are trusted across industries:

✅ Top-Quality Materials

We manufacture strainers using brass, stainless steel, and cast iron to ensure durability.

✅ Affordable Pricing

Our prices are competitive, making us the best choice for industrial and commercial buyers.

✅ Wide Range of Strainers

We supply Y strainers, brass strainers, steam trap strainers, and Zoloto strainers.

✅ Reliable & Quick Delivery

We ensure on-time delivery across Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Contact Udhhyog for the Best Strainers

📞 Call Us Today or Visit Udhhyog to explore our range of industrial and commercial strainers.

✨ Choose Udhhyog – Your Trusted Strainer Manufacturer & Supplier!

#Strainers#YStrainer#SteamTrap#BrassStrainer#IndustrialValves#ValveSupplier#DelhiManufacturer#Udhhyog#PlumbingSolutions#EngineeringSolutions

0 notes

Text

Comprehensive Guide to Industrial Valves: Applications and Benefits

Introduction to Industrial Valves

Industrial valves are pivotal components in fluid control systems, ensuring the smooth and efficient operation of various industries. As a leading manufacturer of industrial valves, we specialize in providing high-quality solutions tailored to diverse applications. Our product portfolio includes a wide array of valves designed to meet the demanding requirements of industries such as oil and gas, water treatment, chemical processing, HVAC systems, and more. Let’s explore the types of valves manufacture and their specific applications.

Gate Valves: Reliable Flow Control

Gate valves are designed for on-off control, ensuring minimal pressure loss and uninterrupted flow. As a trusted manufacturer of gate valves, we cater to industries like water and sewage systems, oil and gas, and industrial processes. These valves are highly efficient for isolating flow and are commonly used in pipelines where full flow or no flow conditions are required.

Globe Valves: Precision in Flow Regulation

Globe valves are ideal for regulating fluid flow and are widely used in water and wastewater systems, chemical processing, oil and gas, and power plants. Our range of globe valves is engineered to provide exceptional control and durability, making them a preferred choice for applications where precision is paramount.

Non-Return Valves: Preventing Backflow

Non-return valves, also known as check valves, are essential for preventing the reverse flow of fluids. We manufacture various types, including swing check valves, non-slam check valves, dual plate check valves, wafer check valves, and lift-type non-return valves. These valves find applications in water distribution systems, pumping stations, wastewater treatment plants, fire protection systems, and HVAC systems, ensuring operational efficiency and safety.

Strainers: Protecting Equipment

Strainers play a critical role in removing debris from pipelines, safeguarding downstream equipment. We offer basket/pot-type strainers and Y-type strainers, commonly used in water systems, HVAC systems, industrial processes, marine applications, and petrochemical industries. These strainers are designed for high efficiency and longevity, minimizing maintenance costs.

Ball Valves: Versatile and Durable

Ball valves are known for their durability and versatile applications. Our product line includes single-piece, two-piece, three-piece, and three-way (L-port and T-port) ball valves. These valves are utilized in residential plumbing, oil and gas, chemical processing, water and wastewater treatment, HVAC systems, and the food and beverage industry. Their reliable sealing and ease of operation make them indispensable across multiple sectors.

Butterfly Valves: Efficient Flow Regulation

Butterfly valves are lightweight, compact, and highly efficient for flow regulation. As a leading butterfly valves manufacturer, we cater to industries such as water and wastewater treatment, HVAC systems, industrial processes, and pipelines. These valves are engineered to provide optimal performance in demanding conditions.

Pressure Reducing Valves: Enhancing System Safety

Pressure-reducing valves are crucial for maintaining safe and consistent pressure levels. Our range is widely used in water systems, gas systems, steam systems, hydraulic systems, and industrial water systems. These valves ensure the safety and efficiency of processes, making them a vital component in various industries.

Sight Glass: Visual Flow Monitoring

Sight glasses are indispensable tools for monitoring fluid flow in pipelines. They are extensively used in chemical processing, water treatment, oil and gas, power generation, and the food and beverage industry. Our sight glasses are designed to withstand high pressure and temperature conditions, ensuring durability and reliability.

Knife Edge Gate Valves: Handling Tough Media

Knife edge gate valves are specially designed to handle slurry and viscous media. These valves are highly effective in water treatment plants, mining operations, pulp and paper industries, and chemical processing facilities. Their robust construction ensures efficient operation even in challenging environments.

Specialty Valves for Unique Applications

Angle Type/Spring-Loaded Safety Relief Valves: Designed for boilers, pressure vessels, pipelines, and HVAC systems, these valves provide safety by releasing excess pressure.

Moisture Separators: Essential for steam and compressed air systems, moisture separators improve process efficiency by removing moisture.

Flush Bottom Valves: Flush bottom valves facilitate efficient cleaning and maintenance in industrial processes, making them an essential tool in reactors and storage tanks.

Blow Down Valves: Specifically designed for removing impurities from boilers and pressure vessels, blow down valves ensure optimal performance and safety.

Precision Control with Needle and Piston Valves

Needle valves and piston valves offer precise control over fluid flow in critical applications. Needle valves are commonly used in laboratories, hydraulic systems, fuel systems, and aerospace industries, while piston valves are preferred in hydraulic and pneumatic systems, chemical processing, and water treatment. Our advanced manufacturing techniques ensure these valves meet the highest performance standards.

Steam Traps and Advanced Control Valves

Steam traps thermodynamic variants, are integral to heating systems, steam boilers, sterilizers, and autoclaves. We also manufacture 2-3 way motorized, cylinder, and pneumatic control valves, offering precision and automation for modern industrial needs. These valves enhance process efficiency while reducing energy consumption.

Advanced Check Valves for Reliable Performance

Swing Check Valves: Widely used in preventing backflow in water distribution and industrial processes.

Non-Slam Check Valves: Ideal for pumping stations and HVAC systems, ensuring quiet and reliable operation.

Dual Plate Check Valves: Designed for compact spaces, these valves are used in water treatment plants and power generation.

Wafer Check Valves: Lightweight and easy to install, these valves are suitable for chemical, pharmaceutical, and HVAC applications.

Lift Type Non-Return Valves: Commonly used in preventing backflow in high-pressure systems, ensuring system integrity.

Diverse Ball Valve Solutions

Single Piece Ball Valves: Suitable for residential plumbing and industrial processes.

Two Piece Ball Valves: Offering easy maintenance, these valves are ideal for water and wastewater treatment.

Three Piece Ball Valves: Used in demanding applications such as oil and gas and chemical processing.

Three Way Ball Valves: Providing multiple flow configurations, these valves are essential in complex fluid control systems.

Conclusion: Excellence in Valve Manufacturing

As a premier industrial valves manufacturer, we pride ourselves on delivering products that combine quality, innovation, and performance. Our comprehensive range of valves, from gate and globe valves to specialty solutions, is designed to meet the diverse needs of industries worldwide. By choosing our valves, you are investing in reliability, efficiency, and superior craftsmanship.

0 notes

Text

Exploring the manufacturing process of Basket strainer & its industrial benefits

In this article we will explore the basket strainer manufacturing process and understand its industrial benefits.

Read more:https://www.nairaland.com/8218214/basket-strainer-manufacturer

0 notes

Text

Mastering the Art of Basket Strainers: The Unsung Heroes of Industrial Systems

Ever thought about the little guys that keep the big machines from falling apart? No, I'm not talking about the unsung heroes of your favorite TV show—though they do deserve a shoutout. I'm talking about basket strainers! These unsung heroes of the industrial world often go unnoticed, yet they play a crucial role in keeping our systems clean and efficient. In this deep dive, we'll unravel the mysteries of basket strainers, explore their various types, applications, and benefits, and discover why they're so vital to industrial operations.

What Are Basket Strainers?

The Basics: What’s in a Basket?

At their core, basket strainers are filtration devices designed to capture debris and particles from liquids flowing through pipelines. Imagine them as the net that catches the fish before they get to the frying pan—only in this case, the "fish" is all the gunk and greeblies that can cause havoc in your system. They come in various sizes and materials, but their job remains the same: to keep your fluids clean and your equipment running smoothly.

Why You Need One: The Role of Basket Strainers

Picture this: You're running a tight ship, everything's running like clockwork, and then—bam!—a sudden clog brings everything to a screeching halt. Sounds like a nightmare, right? That’s where basket strainers come to the rescue. By trapping particles and debris before they enter your sensitive equipment, they prevent blockages and damage, ensuring that your system operates without a hitch.

Types of Basket Strainers

1. Y-Type Basket Strainers

Named after their Y-shaped body, these strainers are popular for their compact design and efficiency. They’re often used in smaller pipelines and are known for their ease of maintenance. Just unscrew the cover, clean out the basket, and you’re good to go!

2. T-Type Basket Strainers

These strainers have a T-shaped design, making them ideal for larger pipelines or systems where you need a bit more filtration power. Their larger basket allows them to catch more debris, making them a go-to choice for heavy-duty applications.

3. Suction Basket Strainers

If you’re dealing with a high flow rate, suction basket strainers are your best bet. They’re designed to handle large volumes of liquid and are typically used in pumps and other high-demand applications.

Applications of Basket Strainers

1. Water Treatment

In water treatment plants, basket strainers play a crucial role in removing debris from the water before it undergoes further processing. They ensure that the water being treated is free of any particles that could interfere with the treatment process.

2. Chemical Processing

When it comes to handling chemicals, precision is key. Basket strainers help filter out impurities that could compromise the quality of the chemicals being processed, ensuring that the final product meets stringent standards.

3. Oil and Gas Industry

In the oil and gas industry, basket strainers are used to protect pumps and other equipment from debris that could cause damage. They’re an essential component in maintaining the integrity and efficiency of the system.

Benefits of Using Basket Strainers

1. Prevention of Equipment Damage

By catching debris before it reaches sensitive equipment, basket strainers prevent costly damage and repairs. It’s like having a bouncer at the door of a nightclub—keeping the troublemakers out and letting the good times roll!

2. Improved Efficiency

Clean fluids mean smoother operations. By filtering out particles, basket strainers help maintain optimal flow rates and pressure, which in turn enhances the overall efficiency of your system.

3. Reduced Maintenance Costs

Less debris means less wear and tear on your equipment. By using basket strainers, you can extend the lifespan of your machinery and reduce the frequency of maintenance checks and repairs.

Installation and Maintenance Tips

1. Choosing the Right Size

Size matters when it comes to basket strainers. Make sure you choose a strainer that’s appropriately sized for your pipeline to ensure optimal performance. Too small, and it won’t catch enough debris; too large, and it might not fit properly.

2. Regular Cleaning

Keeping your basket strainer clean is crucial for its performance. Depending on the amount of debris in your system, you might need to clean it regularly. Set up a maintenance schedule to ensure it’s done on time.

3. Proper Placement

Place your basket strainer in a location where it’s easy to access for cleaning and maintenance. You don’t want to have to disassemble half your system just to get to it!

Troubleshooting Common Issues

1. Clogging

If your basket strainer is clogging too frequently, it might be too small for your system or the debris might be too fine. Consider upgrading to a larger strainer or one with a finer mesh.

2. Leaks

Leaks can occur if the strainer isn’t properly sealed or if there’s damage to the basket. Check for any signs of wear and tear and replace parts as necessary.

3. Pressure Drops

A significant drop in pressure can indicate that the basket strainer is too clogged or that there’s an issue with the installation. Regular maintenance and inspections can help prevent these issues.

Unwrapping the Essence of Our Journey

Basket strainers may not always be in the spotlight, but their role in industrial systems is nothing short of heroic. From keeping your equipment in tip-top shape to ensuring smooth operations, they’re the unsung champions of the industrial world. By understanding their types, applications, benefits, and maintenance needs, you’ll be well-equipped to harness their full potential. So, next time you’re running a system, give a nod to those trusty basket strainers—they’re working hard behind the scenes to keep everything running smoothly!

With this comprehensive guide on basket strainers, you'll never overlook these critical components again. From their basic functions to advanced applications, we've covered everything you need to know to keep your systems in top shape.

0 notes

Text

Why Are Duplex Basket Strainers So Popular?

The Duplex Basket Strainer could be a strong filtration arrangement outlined for productive evacuation of flotsam and jetsam from fluid streams in mechanical forms. Including double bushel, it guarantees persistent operation by permitting one bushel to be cleaned whereas the other remains in benefit. Built with solid materials, this strainer gives life span and unwavering quality. Perfect for applications where continuous stream is pivotal, the Duplex Basket Strainer offers a cost-effective and low-maintenance arrangement for sifting contaminants and ensuring downstream hardware. Believe in its plan for progressed framework execution and longevity.

0 notes

Text

Basket Strainers Manufacturers - Filterselementstrainers

Basket Strainers Manufacturers are an important part of many industrial and municipal water systems. They are used to remove solid particles from fluids, and come in a variety of sizes and configurations. There are two main types of basket strainers: open and closed. A basket strainer is a type of strainer that uses a perforated basket to hold and filter solids from liquids. The basket is mounted in a frame that allows it to be lowered into or raised out of a vessel. The frame can also be rotated to allow the basket to be angled in any direction. Basket strainers are used in many applications, including the processing of food, beverages, and pharmaceuticals.

Basket strainers are a type of strainer that use a woven wire mesh to strain solids from a liquid or gas. The mesh is held in a metal or plastic basket-shaped frame. The solids are trapped in the mesh while the liquid or gas flows through the openings in the mesh. Basket strainers are commonly used in industrial applications to strain solids from liquids or gases and Air Filter Elements Manufacturers.

There are many benefits to using basket strainers. Some of the benefits include:

ᄋ Easier to clean and maintain than other types of strainers

ᄋ Can be used for a variety of applications

ᄋ Variety of sizes and shapes to choose from

Basket strainers are a great choice for many applications because they are easy to clean and maintain. They come in a variety of sizes and shapes, so you can find the perfect one for your needs. Additionally, they offer many benefits over other types of strainers. There are many different types of basket strainers available on the market. Some of the most popular types include the perforated basket strainer, the slotted basket strainer, and the wire mesh basket strainer. Each of these types of strainers has its own unique benefits and disadvantages. The perforated basket strainer is the most basic type of basket strainer. It is made up of a wire mesh basket with small holes punched in it. This type of strainer is ideal for straining small particles out of a liquid. The slotted basket strainer is similar to the perforated basket strainer, but it has larger slotted holes in it. This type of strainer is ideal for straining larger particles out of a liquid. The wire mesh basket strainer is the most versatile type of basket strainer. It is made up of a wire mesh basket with a wire mesh screen. This type of strainer is ideal for straining both small and large particles out of a liquid.

There are many factors to consider when choosing a basket strainer for your application. The first thing to consider is the type of fluid you will be straining. If you will be straining a thick fluid, you will need a basket strainer with a large opening. If you will be straining a thin fluid, you will need a basket strainer with a small opening. The next thing to consider is the size of the container you will be straining the fluid into. If the container is too small, the basket strainer will not fit. If the container is too large, the basket strainer will be too big for the container and the fluid will not be strained properly.

The last thing to consider is the material the basket strainer is made of. If the fluid is corrosive, you will need a basket strainer made of corrosion-resistant material. If the fluid is hot, you will need a basket strainer made of heat-resistant material. Basket strainers are available at most hardware stores. They are usually made of metal and have a mesh basket that can be easily removed for cleaning. Basket strainers are great for straining sauces, soups, and other liquids.

Installing a basket strainer is a relatively easy task that can be completed in a few simple steps. First, remove the old strainer from the sink and discard it. Next, measure the opening of the sink to determine the size of the new strainer. Then, purchase a basket strainer that is the correct size. Finally, follow the manufacturer's instructions for installation. A basket strainer is a great way to strain your pasta or vegetables. It is easy to clean and is dishwasher safe. To clean your strainer, just rinse it with hot water and a little soap. You can also put it in the dishwasher. There are a few potential problems that can occur with basket strainers. First, if the mesh size is too big, it can let pieces of debris through. Second, if the basket strainer is not emptied frequently enough, it can fill up with debris and block the flow of water. Third, the basket strainer can rust if it is not made from a rust-resistant material.

Closed basket strainers are the most common type, and are typically used in industrial settings. They are made up of a metal frame and a woven mesh screen, and the screen can be easily replaced when it becomes clogged. Open basket strainers are typically used in municipal water systems, and are made up of a metal frame and a perforated screen. They are not as common as closed basket strainers, but are becoming more popular due to their low cost and ease of maintenance.

#Basket Strainer Manufacturers#Air Filter Elements Manufacturers#Compressed Air Filter Cartridges Manufacturers#Compressed Air Line Filter Manufacturers

1 note

·

View note

Text

Tea v/s Tisane - What's The Difference?

Did you know that tea is one of the most consumed beverages in the whole world after water? Nothing wakes you up better than a warm cup of tea. More than half of the world drinks tea, and there are thousands of different tea varieties available. And then there are Herbal Teas, also known as tisanes, which aren't even tea at all. Many people confuse tisanes with teas, but they are quite different. Here is everything you need to know about the difference between tisanes and teas.

Tea: What Is It?

In technical terms, it refers to the leaves of just one plant. ‘True' types of teas are derived from the Camellia Saneness leaves, which is a plant native to Asia. However, other forms of tea, such as Japanese and Chinese green teas, Earl Grey, to English breakfast, can also be derived from this plant depending on how you process the leaves. On the other hand, black teas are oxidized, which gives them their rich, dark color. The process is lengthy with oolong tea as the leaves are shaken in bamboo baskets to bruise and dry them out. As for white teas, they are left out to dry.

In short,

Pu’er and black tea=fermented

Red tea, blue-green tea, yellow tea, and white tea=oxidized

Green tea=non-oxidized

Tea possesses various molecules that offer numerous benefits. Catechism is a standard set of ingredients, and it's a powerful anti-oxidant and has been studied in cancer research. They help your body fight against abnormal cells.

Tisane: What Is It?

Various plants (herbs) are used to make a tisane, and it's consumed in the same way as tea. For centuries, tisanes have been used to treat diseases and ailments. Boiling or steeping a plant in water creates a concoction, which can then be consumed to create a desired effect on the body. They have vast benefits for your body. Tea only provides you with particular chemical compounds with healing properties, but the combinations are limitless with tisanes, offering you numerous healing benefits.

The Many Types of Tisanes

Generally, any berry, root, flower, etc., that can be steeped in water and consumed can be regarded as a tisane. They are categorized according to which part of the plant they come from, such as seed/spice, fruit/berry, root, bark, flower, and leaf/herb. Here are some examples of the various types of tisanes:

Seed/spice: fennel and cardamom

Fruit/berry: apple, peach, blueberry, and raspberry

Root: licorice and ginger

Bark: black cherry and cinnamon

Flower: lavender, hibiscus, chamomile, and rosehips

Leaf: lemongrass and peppermint

Does Tea Or Tisane Have More Caffeine?

If you want to switch to a healthier lifestyle, you would want to quit caffeine. All tea's have caffeine. Green tea can have as little as 35 milligrams, whereas black tea can possess as high as 90 milligrams. The amount can vary according to the type of tea. Here are some basic caffeine levels for tea:

White tea: 6-25 mg

Green tea: 8-36 mg

Oolong tea: 12-55mg

Black tea: 23-110mg

On the other hand, herbal infusions are generally free from caffeine, making them perfect for post-meal sipping.

Preparation

Both tisanes and teas can be brewed using a strainer or a teabag. There are two methods for preparing tisanes. For the first method, put it in a pot with cool water. Make sure that the pot isn’t made of aluminum, as it can react with the herbs. After that, place the pot on the stove and heat the water. You must boil the solution until 2/3rd of the water has evaporated and then strain it before drinking. Alternatively, you can also use the infusion procedure in which the herbs are steeped in hot water, strained, and then sifted through. The main difference between tisane and tea is that tisanes aren’t made from tea leaves but through this herbal infusion.

Conclusion

Both tisanes and teas can be brewed using a strainer or a teabag. There are two methods for preparing tisanes. For the first method, put it in a pot with cool water. Make sure that the pot isn’t made of aluminum, as it can react with the herbs. After that, place the pot on the stove and heat the water. You must boil the solution until 2/3rd of the water has evaporated and then strain it before drinking. Alternatively, you can also use the infusion procedure in which the herbs are steeped in hot water, strained, and then sifted through. The main difference between tisane and tea is that tisanes aren’t made from tea leaves but through this herbal infusion.

1 note

·

View note

Text

Why Stainless Steel Basket Filters Are the Best Choice for Corrosive Environments

Introduction

Understanding Stainless Steel Basket Filters

A duplex basket filter strainer is a robust filtration device designed to remove debris, contaminants, and particulates from liquids and gases. It features a perforated or mesh-lined basket that traps unwanted materials while allowing clean fluid to pass through. Stainless steel basket filters are widely chosen for their exceptional strength, durability, and resistance to corrosion, making them ideal for environments prone to chemical exposure and extreme conditions.

Among the different types available, the duplex basket filter strainer is highly preferred in industries requiring continuous operation. This design includes two parallel filter chambers, enabling one basket to be cleaned or replaced while the other continues filtering. This eliminates downtime and ensures an uninterrupted flow of operations, making it an efficient choice for industries such as oil and gas, water treatment, and chemical processing.

Benefits of Stainless Steel Basket Filters

1. Superior Corrosion Resistance

Stainless steel, especially grades like 304 and 316, is known for its exceptional resistance to rust and corrosion. In corrosive environments, where traditional materials like carbon steel or plastic fail, stainless steel basket filters provide long-lasting performance. Industries dealing with aggressive chemicals, seawater, and high humidity greatly benefit from this corrosion-resistant material.

2. Extended Durability and Strength

Compared to plastic or cast iron filters, stainless steel basket filters withstand high pressure, extreme temperatures, and mechanical stress without cracking or warping. Their ability to maintain structural integrity over time ensures longevity, reducing the frequency of replacements and lowering operational costs. Basket filter manufacturers, such as Sungov Engineering, design their products to endure rigorous industrial demands, ensuring superior performance in the harshest conditions.

3. Continuous Filtration with Duplex Design

For industries that require non-stop filtration, the duplex basket filter strainer offers an excellent solution. By alternating between two baskets, one can be serviced while the other remains operational, eliminating downtime and improving efficiency. This feature is crucial for applications like petrochemical processing, food and beverage industries, and power plants.

4. Low Maintenance and Cost Efficiency

Although stainless steel basket filters may have a higher initial investment than filters made from less durable materials, their long-term benefits outweigh the cost. Their resistance to fouling and contamination ensures consistent filtration efficiency, reducing the need for frequent cleaning and replacements. Over time, industries save significantly on maintenance and operational expenses.

5. Environmentally Friendly Choice

Choosing the Right Basket Filter Supplier

Selecting a reputable basket filter supplier is essential for ensuring the best filtration performance in corrosive environments. Sungov Engineering is a trusted name in the industry, offering high-quality stainless steel basket filters tailored to meet specific industrial requirements. With a strong focus on precision engineering and compliance with international quality standards, Sungov Engineering delivers reliable filtration solutions that enhance operational efficiency and longevity.

Conclusion

In industries exposed to corrosive environments, selecting the right filtration system is crucial to maintaining equipment integrity and operational efficiency. Stainless steel basket filters, particularly duplex basket filter strainers, provide superior durability, corrosion resistance, and cost efficiency. Partnering with experienced basket filter manufacturers like Sungov Engineering ensures that industries receive top-tier filtration solutions designed for long-term performance. Investing in high-quality stainless steel filters not only enhances system reliability but also supports sustainable and cost-effective operations.

For businesses looking for a durable and efficient filtration solution, stainless steel basket filters from Sungov Engineering offer the perfect combination of strength, performance, and reliability.

0 notes

Text

Why You Need a Kenmore Refrigerator Water Filter

Most brands recommend six months but for a large family of four it should be every three months. Big family of four needs good tasting water and refrigerator ice. This requires changing your refrigerator water filter at least 3 times (every 3 months) instead of just twice (every 6 months). When your Kenmore refrigerator ice maker stops working it's not a pretty sight seeing those beautiful ice cubes sitting on your bar and table top as they turn into a brown mess. It's a very embarrassing situation to be in, especially when you are entertaining. When this happens you need to change your Kenmore filter for refrigerator water filter fast.

Many of the so-called advanced refrigerators have been made to run more efficiently and to use less electricity. You can start saving money right away by replacing your old refrigerator water filter with a new one. This way you will have clean, fresh tasting water all the time without having to do a big budget overhaul on your refrigerator. This way you will also save some money on your electric bill.

The Kenmore refrigerator replacement filters are easy to install. Simply remove the old filter and hook the new one in place. Most brands offer different types of water filters and you can find one that fits your brand. The basic filter type comes in either a strainer basket style or a hand held pitcher style. This kind of filter will catch most of the larger debris and particles in your water before they make it to the draining reservoir.

The strainer basket style is designed to fit snugly on the inside rim of the refrigerator's top opening. This style will not only take out large pieces of debris from the water but it will also help filter out odors. If you get the Kenmore filter straight, then this strainer will help get out all of the large particles in the water as well as any other small pieces that could fall into the reservoir. This type of water filter will save you money because it will last longer than the basket style filter.

Some people prefer to purchase a multi-purpose Kenmore refrigerator filter. These are often used to replace kettles and ice makers in commercial businesses. They are also great for anyone who likes to entertain. When buying the multi-purpose Kenmore refrigerator filters, be sure to find out which sizes the filters need to be. You will then be able to buy them in different sizes so you can replace kettles and ice makers according to their sizes.

If you have a Kenmore blender in your kitchen, you may want to purchase a Kenmore blender water filter. These are one of the best appliances for cleaning up left-over food. Even if you just throw away leftovers, this filter will save you a lot of time and trouble. After you have cleaned up the left-overs, you can just dump them into the refrigerator without having to worry about them becoming contaminated. Kenmore does not recommend using any kind of sugar when making ketchup or soup because sugar will end up clogging your Kenmore blender.

For every type of Kenmore product, there is also a specific type of filter that goes with it. Once you have found the right Kenmore refrigerator water filter for your refrigerator, you will be able to enjoy all of the benefits of owning one. In fact, many people prefer to have one place to go for all of their needs, from food to cleaning supplies. You will have a simple and easy way to keep your refrigerator, freezer and dishwasher clean without hassle.

A Kenmore refrigerator water filter can easily be found in most department stores, discount super centers and even in some grocery stores. You can find the perfect solution to your family's water needs by finding the right one for your Kenmore brand of refrigerator. You will find that there are several types and options to choose from, so make sure that you take your time when deciding on the right one for your needs. You will have a simple and easy way to keep your refrigerator and all of your other appliances clean and free from bacteria and germs.

#kenmore filter#kenmore filter for refrigerator#kenmore replacement water filter#everydrop water filte\

2 notes

·

View notes

Text

Everything You Need To Know About Valve Manufacturer and Supplier

Without any doubt, the improvement of valves is related to the commercial procedure. During historic times, human beings have come up with the idea of regulating, as they tried to control the flow of water in rivers, for instance, by means of using tree trunks or massive rocks as a way to alternate the water glide direction or to block the flow of the water.

When searching on the pumping structures externally, we usually understand the installation as an incorporated machine, in place of perceiving all of the working components in my view. From all this placing, the valves are those that play an essential position, as they're used for regulating the float of fluids and additionally, for reducing off the supply while required.

On the marketplace, you may have get entry to an extensive variety of commercial valves, every of them running on an exceptional principle and performing an extraordinary function. The maximum commonly used business valves are: ball valves, butterfly valves, plug valves, gate valves, globe valves, pinch valves, take a look at valves, diaphragm valves and remedy and protection valves. As there are such a lot of options out there, it is essential to discover a straightforward Basket Strainer Manufacturer in Germany who can inform you which of them one is the most appropriate one in your motive.

In evaluation to different styles of valves, the ball valve has many benefits, consisting of: they may be easy to keep, easy to use, they can regulate excessive-pressure, excessive flow of temperature and excessive extent. In addition to this, as they are robust and coffee in fee, they generally make certain an extended carrier lifestyles and they may be utilized in different industries for decades. Also, they have a quick near and open feature and have higher corrosive resistance given the entire separation between the ball and the surface of the valve seat. And last however now not least, they have a low fluid resistance.

These contemporary days, ball valves play a crucial function in exceptional contexts, which include: chemical, pharmaceuticals, metal, food, paper, electric powered strength, water and other critical fields. Taking into account the importance of choosing the right ball valve to your plumbing system, it is essential to choose a reliable and truthful Control Valve Manufacturer in Germany. When searching for a manufacturer, there are certain factors to cover so that you can make sure satisfying outcomes on this regard: quantity of experience in this discipline, variety of products, workforce mindset, delivery flexibility, and other customers' opinions and of path, price.

For more info :- API Valve Manufacturer in Germany

1 note

·

View note

Text

Best Above Ground Pool Pumps: Is The Hayward Power-Flo Matrix The Best Above Ground Pool Pump?

In case you're interested in hard-working and durable gear on your above ground pool, then the Hayward Power Flo Matrix is certainly most rational choice to take. In case just because of its remarkable 1.5 HP (it in addition comes in 1.00 HP or maybe 3/4 HP) that makes certain adequate energy and its instant winter overload protecting element which makes for a genuinely secure usage, many experts in the pool area business check out Hayward brand name as top above ground pool pump on the market nowadays.

Benefits and features

Below are the important uses, features, and advantages of Hayward Power Flo Matrix which cause it to be the very best out there for above ground pools:

It does well on both above-ground and in-ground pool types.

It's viewed as probably the most hardworking model when it involves the collection of big-sized and small debris.

You're only required to perform little maintenance and occasional check-up of the pump.

Hayward pool pump features of its vertical and horizontal discharging Feature, that is usually quickly accomplished with a press of the switch.

Fast as well as Convenient link, disconnection, and discharging actions.

The gear has a C Clip connecting device that allows you to effortlessly disengage the strainer casing within a couple of seconds.

Hayward Power Flo has an excellent Noryl impeller with additional wide openings meant for quick passage of big debris.

It has an a lot of engine with pre-made thermal overload protecting element to guarantee extended hours of constant pumping performance.

This particular pool pump similarly has a vital drain plug meant to guarantee efficient and simple winterization.

Very best of all, makers of Power Flo Matrix above ground swimming pool pump guarantees optimum power and durability of this particular energy efficient device for years and years of reliable performance.

Reliable, Heavy Duty Pool Pumping Performance

When it involves delivery and reliability of industrial performance, you are able to surely count on the Hayward Power Flo Matrix. For one point, it has a durable, industrial sized strainer basket that's intended to gather the optimum amount of trash at the minimum amount of time.

Essentially, this particular pool brand exists to gather all trash and protect the pool of yours from becoming blocked & dirty. The pump features a Noryl impeller that includes wide openings to guarantee passage of even large sized debris. It as well boasts of a double rear and seal switch to ensure better efficiency in performance.

Unlike some other pool pump makes, Hayward has an instant thermal overload protection which turns the engine off just in case of abnormal situations. This guarantee prevention of overheating and potential harm to the gear. The machine is only going to begin once again if motor heat settles right down to a safe level.

When it involves the defense of whole device and the motor during weather that is cool, the pump has a good winterizing function in its integrated drain plug. Nevertheless, to make sure that the swimming pool pump is completely protected from cool weather and freezing, it should be saved correctly in a well-ventilated and dry storage location when not used. It should be disconnected from its electric energy source. Ensure that the pump is drained completely of water. Finally, it should be cleared of any debris or even clogging materials.

Consumer Comments

Users each offer positive customer feedback and superlative commentary about Hayward Flow Matrix, that just further solidify the claim of its to the name of top above ground swimming pool pump. A lot of people have claimed it's so easy to set up and operate; which for such a small machine, it is able to send efficient performance double or maybe 3 times more than some other current pump brands.

Some other customers of Hayward above ground swimming pool pump are pleased with the really clear water in the pools of theirs after placing the unit to do the job. A specific customer is really pleased to have bought and utilized this pool pump since he in no way has to cope with algae at any time of the entire year.

Verdict

To put it simply, you are able to completely rely on every performance and ability of Hayward Power Flo Matrix as it's been meticulously built and made working as top above ground swimming pool pump. It's surely easy with regards to using this pumping device. With only one push on the switch, the gear instantly works to make sure reliable and superb pool pumping performance. Power-Flo Matrix interchanges its horizontal and vertical discharges in an easy fashion. Needless to point out, Hayward Power Flo Matrix may be the above ground pool pump that is unlike other within the marketplace.

Read More Information: Above Ground Pool Pump

youtube

1 note

·

View note

Text

Strainer supplier in UAE

Middleeast Valve is one of the largest Strainer supplier in UAE. We supply to cities like Asimah, Sharjah, and Dubai. A strainer is a mechanical device used to remove solid particles from a fluid or gas stream. Strainers are commonly used in industrial processes to protect pumps, valves, and other equipment from damage caused by debris or foreign objects. The working principle of a strainer is simple. The fluid or gas stream flows through the strainer, and the strainer's screen or mesh captures any solid particles or debris in the stream. The screen or mesh is usually made of stainless steel wire, and its mesh size is chosen based on the particle size and the application's requirements.

The benefits of using a strainer in industrial processes include:

Protecting equipment: Strainers help to protect pumps, valves, and other equipment from damage caused by debris or foreign objects.

Maintaining system efficiency: Strainers can help to maintain system efficiency by preventing clogs and reducing maintenance requirements.

Improving product quality: Strainers can help to improve product quality by removing contaminants and impurities from the fluid or gas stream.

Reducing downtime: Strainers can help to reduce downtime by preventing equipment failures and breakdowns caused by debris or foreign objects.

Increasing safety: Strainers can help to increase safety by preventing accidents caused by debris or foreign objects.

Middleeast Valve is the best Strainer supplier in UAE and mechanical device used to remove solid particles from a fluid or gas stream. They offer numerous benefits, including protecting equipment, maintaining system efficiency, improving product quality, reducing downtime, and increasing safety. Strainers are commonly used in industrial processes and are available in various types and materials to suit different requirements.

Types of strainers:

Y type Strainer

Simple Basket Strainer

Duplex Basket Strainer

Parts:

Housing

Screen or element

Cover

Gasket

Drain

Inlet and outlet ports

Handles or wingnuts

Optional

Industries which use them:

Oil and gas Industry

Water treatment Plants

Power generation Plants

Chemical processing Industry

Marine Industry

Description:

Material: Bronze, Cast Iron, Cast Carbon Steel, Cast Stainless Steel, Stainless Steel (SS202, SS304, SS316), Forged Brass Body, Ductile Iron, PP, Forged Stainless Steel (F304, F316), Forged Alloy Steel Body.

Class: 150-2500

Nominal Pressure: PN6- PN450

Size: ½” to 24”

Ends: Buttweld, Flanged, Socket weld, Threaded.

Visit us for more details: - https://www.middleeastvalve.com/product-category/strainers/

0 notes