#angle type valve

Explore tagged Tumblr posts

Text

Global Solutions from Top Steam Control Valve Exporters

Recon Valve is proud to be top stream control valve exporters. We are providing global solution that compete the highest standard of quality and innovation. Our stream control valve is designed to delivered exceptional performance and reliability that why our valve is first choice for wide range of industrial application. With a commitment to precision and durability, ReconValve ensures that each valve is designed to handle demanding environments while optimizing efficiency and safety.

Recon valve is leading stream control valve exporter. We are understands the importance of delivered product that can not only compete global standard. Our experience and expert team providing customize solution that compete specific needs of our international client. Explore our range of high-quality steam control valves and discover how ReconValve can help streamline your operations with unparalleled excellence and support.

Discover how Recon Valve can be improve your operation with top stream control valve by visit our website reconvalves.com and explore our wide range of high quality product or learn more about our commitment to global excellence. Don’t miss out—click the link below to connect with us and find the perfect solutions for your needs today!

#steam control valve#angle type valve#pneumatic control valve#steam control valve in ahmedabad#pneumatic control valve manufacturer#steam control valve in india#angle type valve in gujarat#angle type valve in india#angle type valve manufacturer#pneumatic control valve supplier

0 notes

Text

Types of Angle Valves in Home Plumbing Pipe Fittings

Angle valves play a crucial role in home plumbing systems, allowing the control and regulation of water flow. These valves are designed to fit at corners or angles in the plumbing pipes, providing a convenient solution for connecting fixtures and appliances. In this blog post, we will explore the different types of valves in piping.

Two-Way Angle Valve:

2-way angle valve also known as 2 in 1 angle valve or dual-angle valve or a 90-degree valve, the two-way angle valve is the most common type found in residential plumbing systems. It features an L-shaped design, with two openings for water flow. One opening connects to the incoming water supply, while the other connects to the fixture or appliance. This valve allows water to flow in two directions, enabling the user to control the water flow to a specific fixture or shut it off completely.

The two-way angle valve is typically used for various plumbing applications, such as connecting faucets, toilets, and washing machines. It provides a simple and effective way to control water supply to individual fixtures, allowing for maintenance, repairs, or replacements without affecting the entire plumbing system.

One-Way Angle Valve:

The one way valve, also known as a check valve or a non-return valve, is designed to allow water to flow in only one direction. This type of valve prevents backflow, ensuring that water flows in the desired direction and preventing contamination of the water supply. The one-way angle valve is commonly used in situations where there is a risk of backflow, such as in sump pump systems, water heaters, and irrigation systems.

The one-way angle valve consists of a disc or a flap that opens when water flows in the correct direction and closes to prevent reverse flow. This design ensures that water flows in one direction, preventing the possibility of contaminants or wastewater entering the clean water supply.

When it comes to choosing the best angle valve brand for your plumbing needs, Essco stands out as a reliable and reputable option. Essco has established itself as a trusted name in the plumbing industry, known for its high-quality products and exceptional performance. Their angle valves are designed with precision and built to last, ensuring efficient water flow control and long-lasting durability. With a focus on customer satisfaction, Essco consistently delivers top-notch products that meet the demands of both residential and commercial plumbing systems. When you choose Essco angle valves, you can have confidence in their reliability, functionality, and overall value for your plumbing projects.

#angle valve#water valves#2 in 1 angle valve#2 way angle valve#one way valve#types of valves in piping#water valve types#home plumbing fittings#angle valves fittings#angle valves types

0 notes

Text

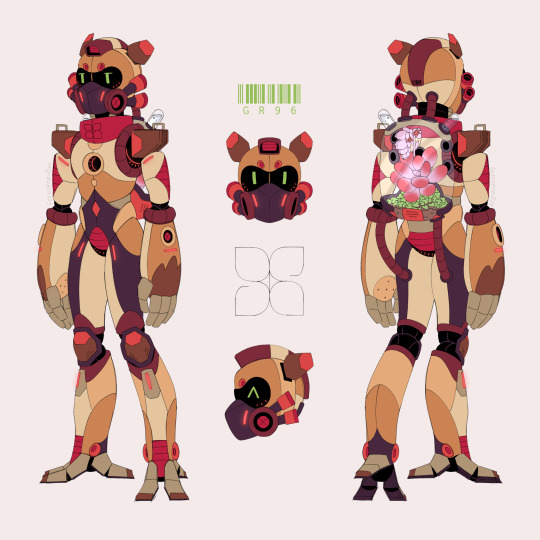

GR96

@fusionspruntcityjournal

So how do you produce electricity with living plants? Simply by using the natural processes that already occur. In short: the plant produces organic matter via photosynthesis. Only part of this organic matter is then used for its own growth. The rest is excreted via the roots. Around the roots, bacteria feed on the organic matter and they release electrons. If you’re able to harvest the electrons into an electrode, you can couple the first electrode to a counter-electrode and build an electrical circuit, like in a battery. The electrons flow back into the natural system via the counter-electrode, so it’s completely circular. Because we use the natural processes around the plant, nature is not harmed. It works day and night, summer and winter. It only stops when the plant and its surroundings completely dry up or freeze over.

Sedum Oviferum

Sedum pachyphyllum is a ground-hugging succulent that spreads by rooting fallen stems and leaves. The succulent also goes by the names “Cerise Moonstones” or “Mauve Pebbles”. The short and stumpy round leaves have a light silvery-purple color; positioned at a right angles to the stem and curve upward, which in the wintertime, the tips of said leaves will turn into a notorious red.

Sedum Oviferum is a succulent that is very easy to grow and maintain. It is a resilient plant that can tolerate drought, moist and dry soils, and when given adequate exposure to sunlight and sufficient water, Cerise Moonstones will thrive outdoors. The Sedum Oviferum succulent grows at its best with regular exposure to sunlight. If Mauve Pebbles are planted in an area in a garden that gets plenty of sunlight per day, you will be rewarded with bright coloured leaves and flowers. In winter and early spring, Cerise Moonstones actively grow and produce blooms featuring red-orange petals and sepals that have the same pigmentation as the leaves. The flowers produced by Cerise Moonstones have a bell shape and a sugary fragrance.

Subterranean Clover

Trifolium subterraneum is also known as the subterranean clover (often shortened to sub clover), or subterranean trefoil. The plant's name comes from its underground seed development, a characteristic not possessed by other clovers. It can thrive in poor-quality soil where other clovers cannot survive.

This species is self-fertilizing, unlike most legume forage crops such as alfalfa and other clovers, which are pollinated by insects, especially honeybees. It is also grown in places where the extreme ranges of soil type and quality, rainfall, and temperature make the variable tolerances of sub clover especially useful.

Functionality

GR96 are powered by any plant of choosing on their back pod (the one we are going to discuss has a giant Sedum Oviferum and multiple sub clovers to operate) which is held in place by five strong suction cups. They’re manufactured for community gardens (strictly only one per garden), but they can also be bought by high class citizens for private properties, though at a way bigger cost since they’re financed by the city.

They can use their hands as scissors, shovels, and for watering (hence the big forearms, for storing the water), the latter which they do by dipping their hands in a bucket, opening the valve on their forearms so they can fill them up and releasing the water from the pinholes on their palms. Their “eyes” are actually a screen that can show plenty expressions, but the two circles above that peripheral screen are the real environmental sensors. They also have the same sensors on their ankles for inspecting the lower plants and ground without the need of kneeling, and their feet are shaped in a way so that weight is evenly distributed, lowering the chances of damaging a plant if they were to step on it. The ear like protrusions are small solar panels, used as backup energy (they don’t have any communication properties). Their speaker aka their “voice” is the mohawk-like structure on the top (which also has their series barcode 128 on the lower back), but when they speak there are these strips at the sides of the face mask that light up with the volume. The mask (non removable) has a set of pipes that are used for analyzing the air quality and humidity of the area surrounding them.

#my art#fusionsprunt#fusionsprunt oc#fusionsprunt clover#i’ll reblog this again later with their lore and alt design#the sedum oviferum is a fictional succulent i came up with since i couldn’t find one that i liked lmao#literally said fuck it it’s my oc i make the rules#[slaps a giant plant inside]#the energy gathering segment is based on a real article!#in its current state it can only power small leds#but i like to imagine a future where that energy could power full fledged robots :0

195 notes

·

View notes

Note

https://www.tumblr.com/aprofessionalwithoutstandards/766177897874604032/something-people-forgor-wayyyy-to-often-is-that?source=share

there's a specific type of tf2 fan that wants these characters to be like cod characters so badly when they simply aren't.

it drives me up a wall when people use the "woobification" argument with the mercs because it's like they haven't even engaged with the source material. did valve woobify heavy when they gave him a pretty princess cosmetic. or when they made it a thing that you can wear silly hats and form a conga line with other players.

"uhhh, its like you forget these guys KILL people" literally everybody knows that, maybe we want to talk about something else for a change. also, something everyone forgets is that they are canonically the worst hired killers. they are the laughing stock of the mercenary world. they suck!

EXACTLY! Miss Puffins, I'll be square with you, you work with exceptionally subnormal men. Have you ever played a round of casual 2fort these people can't do anything. People literally are expecting COD-tier serious edginess from a game that's just never been about that. That's what's always made Valve games stick out, that they're willing to be funny, and tf2 is the hardest they've gone on that angle. Was it "woobification" when everyone got funny animal heads? Was it "the fandomification of media" when they added taunts for square dancing and rock-paper-scissors? You're all so boring I'm sorry

#if i can be so frank the damage emesis blue has done to tf2posting is damnable#ask#anon#tf2#team fortress 2

25 notes

·

View notes

Note

Hello, I saw your post saying we could share our dw ocs. Now... Im no artist, all I got really is a description of him. I haven't used him in anything yet. But I love him and wanted to ramble him to someone new. Sorry for the wall of text ^^;

So Sam(ra. His name is samra but he prefers Sam.)

He is based off those old fashion Hollywood cameras, with the film reels and tripod like legs. He is a ringleader circus themed gameshow host (lore wise, he is basically Vee before she was created). Would've been "recycled" for materials or something if he didn't run into, then befriend Vee. One thing lead to another and he just became a stage hand type toon who'll help get good angles for camera shots and act as a side-character in a select few episodes or movies.

He also ends up being unofficially Vees' "big brother" partly due to the two being the most tech based toons (both due to how they are effected if splashed with water and their shared love of gameshows.) Relationship wise he gets along best with… roughly every canon character. Only really dis-trusting Dandy (during the… ingame period of twisteds and all that. Liking to mess with Shrimpo and Glisten. He kinda tries to act as a big brother to every toon he runs into. Teasing, hyping up. Consoling. Even just listening when they need a ear to vent into or a shoulder to cry on. Best friends with Finn, sharing his love of puns. With Sprout, Like Vee; he would also call him berry-boy. But if he gets called outdated-tech like in the interaction with Vee. He just gets all silent and sad. Beyond that the two get along well enough. He takes Shelly by surprise sometimes by actively noticing her (in that, I mean he actively looks around to see if she is with someone or is by herself). Asking her how her day is going, if she wants to talk about something. Hunting her down to give a random dino plushie he found in the lost n found. This… all sorta stems from how he knows what it feels like to be ignored. As that is why he was being replaced by Vee. The audience just… started to ignore his onsite show and didn't buy a lot of the merch based on him.

He wears a ringleader jacket, and a top-hat over his frontmost film reel. Has one single eye. No visible mouth (feeds on batteries for energy). size-wise, he is the tallest toon - when comparing to the cannon toons. No real clue what their canon sizes are but someone made a list and the tallest in that list was Teagan, Goob, and Roger at 2 feet 8 inches He stands to just about 5 feet without extending his legs. And 7 if he extends his legs completely. (the extended legs aren’t gameplay related, just partly how he gets good top down angles. He is a camera after all) His back film reel acts sorta like his brain, take it off him and he just... he can function, he is just slow and not very... reactive or perceptive. His voice is through a old-speaker, sight traces of static lace his words at times. His arms and legs are extendable, sorta like Goob but not nearly as long. Just three feet of extra reach. - He doesn't walk, per say. He has wheels for feet and rolls around. Gameplay wise, he has zero stars in movement speed and stamina (will explain below). Two in extraction speed. Two in skill checks. And three in stealth. (extraction speed and skill check is due to him having difficulty getting low enough to use the valve on the machines.) He counts as a main. Though his twisted is a rare. Since he counts as a main he also has the two heart limit other mains have. His Passive ability is "On a roll" Sprinting is disabled, instead he has momentum. Where the longer he keeps moving, the faster he gets. Starting at one star speed and reaching five stars in 20 seconds of nonstop moving. Turning becomes a little difficult at high speed. (Think ice levels in some games.) speed-based trinkets do boost his speed/momentum.

His Active ability is "Big brother"

He extends his arms out and grabs a targeted twisted within range (if it isn't a main) and throws it after two seconds, stunning it for 5 seconds and sending it 16 studs/feet away from him in the direction he is facing.

Twisted-wise, He has two twisted-forms. Wiped out and "not" wiped out. Only one of the two can appear on a floor.

He is missing his hat, has slash marks along his back through his jacket. And a gaping hole near his neck that leaks ichor. His right arm is stuck extended with hardened ichor in the joints and the hand is replaced by a blob of hardened ichor, turning it into a bludgeoning club type thing.

His single eye camera emits a solid red spotlight, lighting up most of his sightline. In his pre-wipe out state he is a lot like T.Glisten. However he doesn’t require someone to be near him. He is just on a timer until he snaps. During that timer, he actively stuns twisteds by giving them a smack with his club-arm. prioritizing chasing twisteds over wandering twisteds. Ignores docile twisteds like RnD, rodger, Connie, and glisten (before he snaps)

He still has his momentum type movement so he'll slowly build up speed, but struggles with stopping or turning. When the timer is zero and he snaps, he lets out a warning static-filled cry (voice box is messed up, he has no growls or a lot of voice lines, just static and single words that slip between the static. Like “contestants” “No” and names of toons who enter his sightlines. “Vee” “Shelly” etc. After he snaps, it is purely static. No voice lines or screams or snarls. Just static.) As a twisted (post snapped), his ability is to stick onto a target. Stealth stats don't determine targets for him, first toon to enter his sights is hard focused until it stays out of sight long enough.

His wiped out state is already snapped, but he can’t move from where he crashed, his legs are broken and his arm with a actual hand is not attached to his shoulder anymore. In this state he only serves as an alarm. Making a lot of noise to draw other twisteds over if someone enters his vision. In this state, he is treated like a airhorn, drastically lowering the effected toons’ stealth stat when he spots them.

Get too close, and he can hit you himself.

Trinket - Spare Film reel.

Stamina drain when sprinting is decreased by %25. Enabling longer moments to just book it either away from twisteds or towards a machine. Hope you enjoyed the OC rambling

Wow that's quite a read, I appreciate the long ramble I love when people put a lot of detail into their characters ^^

It's sweet how he acts like a brother figure to everyone, aw the kids don't love him enough that he's slowly getting forgotten <\3 Feel like as the show progresses kids would lean more into the new stuff. Shelly and Sam are both representing the past in a sense, but Shelly focuses a lot more on the pre-historic dinosaur stuff, Unfortunately I think kids like new tech more like Vee.

His mechanic is so interesting. gotta be constantly running to gain speed he'd make a good backup distractor as long as he doesn't stop, imagine accidentally stopping while being chased by a Twisted that'd be hell ESPECIALLY since you said there's no sprinting button.

Overall, nice OC! I can tell you put a LOT of thought into em and that's awesome to hear

#ask#dandys world oc#read this like twice cause I wanted to comment on some parts lol#Uh anyway I'd appreciate it tho if future asks could be a little shorter for the purpose of scrolling n stuff !#/nm just a heads up

17 notes

·

View notes

Text

Control valve supplier in Dubai

UAE Valves is one of the top Control Valve Supplier in Dubai. A control valve is a mechanical device used in various industrial processes to regulate the flow of fluids, such as gas, steam, or liquid, through a pipeline or duct. It achieves this regulation by adjusting the size of the flow passage according to signals received from a controller.

Control valves are crucial components in systems requiring precise control of flow rate, pressure, temperature, or liquid level. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment.

Working Principle:

The working principle of a control valve is straightforward. In an industrial setting, a control valve adjusts the size of an opening to control the flow of fluid through a pipeline. When the valve is fully open, it allows maximum flow, and when fully closed, it stops the flow completely. Between these extremes, the valve can be precisely adjusted to allow a specific amount of fluid to pass through.

This adjustment is typically performed automatically based on signals from a controller, which monitors conditions such as pressure, temperature, or flow rate. Essentially, a control valve acts like a gatekeeper, regulating the flow of fluid to meet the system's requirements.

Parts of a Control Valve:

Valve Body: The main structure that contains the fluid and through which the fluid flows.

Actuator: A device that moves or controls the valve's mechanism, often powered by air, electricity, or hydraulic fluid.

Closure Element: The component that makes contact with the seat to restrict or allow flow.

Trim: Internal components such as the plug, seat, and stem that modulate the flow.

Seat: A surface against which the closure element seals to stop flow.

Positioner: A device that adjusts the valve actuator's position based on control signals.

Bonnet: The top part of the valve body that houses the stem and provides a seal.

Yoke: A support structure that holds the actuator in place and connects it to the valve body.

Stem: A rod that connects the actuator to the closure element and transmits motion.

Packing: Material that provides a seal around the stem to prevent fluid leakage.

Advantages:

Precisely controls the amount of fluid passing through a system.

Maintains the desired pressure levels within the system.

Helps maintain a stable temperature by regulating fluid flow.

Reduces energy consumption by optimizing fluid flow.

Enhances system performance by maintaining consistent operating conditions.

Prevents system overpressure and potential hazards.

Easily adjustable for various operating conditions.

Allows for control from a distance and integration into automated systems.

Designed for durability and ease of maintenance.

Ensures consistent production quality by maintaining optimal conditions.

Meets industry standards and regulatory requirements.

Industries Using Control Valves:

Control valves are used across numerous industries, including nuclear power, oil and gas, power generation, manufacturing and process industries, automotive, aerospace, mining and minerals processing, water treatment and distribution, pulp and paper, refining, marine, renewable energy, chemical and petrochemical, and steel and metal processing. These valves play a critical role in ensuring operational efficiency, safety, and compliance within these diverse sectors.

Types of Control Valves:

Three-way control valve

Cage type control valve

Double seat control valve

O type shutoff control valve

Single seat control valve

Water control valve

Globe control valve

Angle type control valve

We are a Control Valve Supplier in Dubai, supplying valves in the following descriptions:

Available Materials: Stainless Steel (SS316, SS304), Ductile Iron, Super Duplex (F51, F53, F55), Cast Iron (WCB, WCC, WC6), LCC, LCB

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electro Pneumatic Operated and Pneumatic Operated

Size: 1/2” – 24”

Ends: Butt Weld, Flanged, Threaded, Socket Weld

Electric Actuator Details:

Torque: 3 – 9 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Configuration of a Pneumatic Actuator:

Torque: 3 – 9000 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Temperature Ranges:

Standard: -4°F to 200°F (-20°C to 93°C)

Low: -40°F to 176°F (-40°C to 80°C)

High: 0°F to 300°F (-18°C to 149°C)

Visit us: https://www.uaevalves.com/product-category/control-valve/

3 notes

·

View notes

Text

A way to unwind (2608 words) by IvyCorp

Chapters: 1/1

Fandom: Transformers - All Media Types, Transformers: Prime

Rating: Explicit

Warnings: No Archive Warnings Apply

Relationships: Megatron/Soundwave (Transformers)

Characters: Megatron (Transformers), Soundwave (Transformers)

Additional Tags: Data Cables, Orgasm Delay/Denial, Plot What Plot/Porn Without Plot

Summary:

When Megatron agreed to stay after the meeting, he didn't realize what Soundwave had planned for him - at least it wasn't the first time the data cables were used in this capacity...

So yeah, I wrote something because I got stuck on the longer piece I am trying to finish - see under read-more or on AO3 (above)

Soundwave has been a very focused mech for as long as anyone could remember - it was one of his defining qualities, and considerably the most important one for the Decepticon Cause. The TIC was a stable rock in the chaos of the command structure, carrying his duties without a hitch while listening to yet another plan for ‘ending the Autobots once and for all!’ this time around. Megatron admired that trait, and on any other day he would be thanking his luck that at least one bot in their ranks could keep their cool when yet another scheme fell apart, yet another battle was lost.

Today, however, he wanted to curse that part of his personality to the Pit, as he sat pinned to the conference chair by the deceptively strong data cables; his valve was gushing lubricant heavily as two of those appendages pumped in and out of it at a slow, measured pace, while their owner sat on the side of the table and kept on filling the remaining reports.

When the TIC reached out to him on a private comm with a query to ‘remain after the meeting’ while at the same time brushing his pedes with the cable tip under the table, he knew what was the unspoken intent behind the invite; he responded with an affirmative, the vision of the incoming activity keeping him in better humor despite the bleakness of their post-mortem. As everyone left, he allowed Soundwave to close the door and bind him down in his seat, letting his interface panel slide away without thinking.

The Decepticon leader wondered if he misjudged the situation - had the blue mech simply wanted to distract him from being angry at yet another failed operation, and was now going to reduce him into a mewling mess just so he could get the documentation done without interruptions?

If so, the communications officer was way more devious than he suspected; the silver bot tried to push down the growing conflicted arousal at being ignored so blatantly, as he tried to pull himself into a semblance of an authoritative posture - despite the obscene sounds of his valve getting breached again and again.

"Soundwave, I'm sure the reports can wait," Megatron meant to say with offense, but it came out in a moan; when he started speaking, the tip of one cable brushed across a bunch of the more sensitive nodes, making him seize up at the sharp, heightened pleasure after such a long period of stimulation without being allowed to reach completion. His vents whined from extended overuse, matching his vocalizer when the angle changed, cutting the pressure before he could get over the edge.

The blue mech did not even turn away from the datapad, instead deploying additional cable; it curled around the silver mech, coming up to his intake, bumping against it firmly. The request for entry was obvious, leaving no room for negotiation, and the larger bot could feel a rush of oral fluid gathering in anticipation.

"Soundwave…" Megatron shot the communication officer another look, but he did not fight the intrusion when the cable slid between his denta and pressed on his glossa, effectively quieting his complaints. It wasn’t the first time to have the appendage down his throat, but it always required conscious effort at the beginning to hold back the reflex to bite down at the discomfort - before he adjusted himself to accommodate its girth and gave it a suck, watching the TIC closely for any signs of being affected by the act.

"Silence," came a clip of a recording back at him, as all three cables slid deeper, making him thrash in place at the sudden sense of fullness. The Decepticon leader felt the appendages holding him in place tighten up around him, and he couldn't stop the satisfied groan that resounded across the room; he tried to ground his hips to force the ones in his valve even deeper - but instead, they retreated, leaving him awfully empty.

Megatron's disappointed cry was muffled; he briefly considered gnawing at the cable gagging him, but, as if the other mech was actually reading his mind, he never got a chance to do that.

In a quick motion, his legs were lifted and bound to the armrests, aft pulled closer to the edge. The two cables that were previously working him open switched their objective, searching for the openings in armor and digging deep, causing the temperature of his frame to rise again. He felt like a walking smelter; his valve clenched on nothing, as he gasped and keened at the well-placed touches. His body was bent beyond his comfort, position leaving him vulnerable to whatever the blue mech had in mind.

Soundwave was still tapping on the datapad, EM field tucked close, unreadable.

As if the warlord was a mere decoration in the room, not worthy of his active attention.

When Megatron felt a fourth appendage join the fray, poking around his aft, he couldn't help the full frame shiver. He ached all over, the charge built up shooting across his plating; yet as he was, he couldn't even plead for release in anything more than moans and desperate lapping at the cable in his intake, hoping to get the mech to at least look at him. The silver bot was mortified to finally admit that this… dismissiveness to his arousal was making his spark scream for even a glimpse sent his way. He needed the TIC to show his reactions or he feared he would end up crying - the emotional backlash of seeing he was the only one affected would have been too much, the defeat too painful to bear.

He felt the intrusion in his aft at the same time as one of the other cables shifted to massage his anterior node, distracting him from his thoughts for a moment. The remaining one was still playing with his wires, but when the newest appendage settled itself fully inside, it moved down and pushed the tip between his folds.

Then they all stopped.

Megatron strained against the vine-like embrace to no avail; he couldn't find leverage to shake the cables off, nor rock himself onto them. The one pressing down his glossa was held still - he experimentally moved his helm back, trying to see if he could free his intake and talk to Soundwave, but he collided with the back of the chair with a few centimeters of the cable still between his denta. With a huff, he allowed himself to let it slide back into his throat, relaxing himself as it got a little bit deeper than before.

He got startled when all cables moved slightly, making him move his helm back in surprise; the appendages withdrew as well. The mech's optics cycled wide, and with a focused expression, he let his glossa cushion the cable as he let it slip further down his throat; it plunged deeper on its own, and so did the other ones. When he receded, they backed away too.

Triumphantly, he grinned, and with renewed fervor he started bobbing his helm back and forth, setting up a rhythm that would possibly bring him closer to overload. He focused single mindedly at taking the cable further down his throat, hoping it would reach deeper nodes in his valve.

When he noticed he could not move his neck far enough to do that, he panicked and redoubled his efforts, uncaring to his discomfort; it was too shallow, he couldn't move fast enough to get enough consistent friction to compensate for the emptiness beyond which the cables would not extend. He whimpered, feeling the exhaustion make his efforts slowly lose their pace.

"May I join in the fun or would you like to see this through on your own?"

It was a sound of his voice from eons ago; he recalled saying this right before he joined his friend into a brawl against a local gang who obviously did not know who they picked a fight with.

Megatron on-lined his optics back, not remembering when he had turned them off - Soundwave stood in front of him, datapads left on the table. His panel was opened, revealing a long, pressurized spike, as the blue mech waited patiently, visor blank as always.

The relief at finally having the TIC's attention made him howl; he nodded vigorously, his EM field projecting the need for the other's touch. The slim bot rested his digits on the silver plating of his thighs, stroking them gently. Despite being under the assault of the long appendages for a while, Soundwave's touch was felt more keenly; he wanted to push into it, but he still couldn't move, pinned as he was.

The shorter mech moved the cable away from his anterior node; the delicate digits started circling it, as the displaced appendage joined the one buried in his valve. They pulled the folds wide open, lubricant trickling down - Megatron couldn't help moaning at the reflection in Soundwave's visor, where he could see what sort of a display was going on right before his trusted friend. He was still sucking on the one in his throat, spread out, aft filled up, waiting for the communications officer to pound him into a mind blowing overload.

When the mech lined himself up with his valve, he let out an anticipating whine; the spike met no resistance as Soundwave slid the entire length in, plating scraping on his aft. It was thicker than one cable, and it was long enough to fill him better than what he could accomplish in the prior predicament, so Megatron sighed happily and relaxed, expecting the other to get moving soon.

To his astonishment, he felt the entrance of his valve stretch out as a cable tried to make its way in, alongside the TIC's spike; he hissed at the intrusion, but it quickly morphed into a low groan when the mech started rocking his hips. All of the appendages were working in tandem, pumping into him at the same rhythm the blue bot was picking up, ramming into him with the same single-minded dedication as he did his tasks. The stray cable was teasing his wires again, but that was soon abandoned in favor of sliding into the valve as well.

The additional stretch caused Megatron's optics to roll back into his helm as an overload tore through him, overwhelming his systems as everything burst in wonderful static.

When his senses returned to the normal parameters, he realized Soundwave was still keeping the pace, the abundance of lubricant spurting with each thrust; he could finally feel the other’s EM field, as it brushed onto his, the mutual desire clear as a day. The silver mech tried to cycle down around him, but in the end he could only look at the blue bot and project the need to help the TIC overload as well.

Soundwave looked at his face, ramming into him steadily, before he moved one of his servos and tapped the warlord's chestplates. Megatron glanced at him, puzzled, before he offered a smile and allowed his chest to part, revealing the shining spark beneath them.

Thin digits prodded the halo gently, causing the mech to gasp at the sensation; it has been a while since anyone touched him like that. The pleasure from this was different, echoing on another level within his frame, and he could feel some of it transfer to his partner, who decided to concentrate on the spark below him in favor of letting the silver mech be held up by only the cables tying him to the chair. The larger Con could feel his own charge build up again, knowing he would most likely overload once more if the TIC kept it up.

Still, despite the slight quickening of the pace, he could see the blue bot would need something more - and merging was out of the question, as neither of them could risk getting sparked. He racked his processor for another idea, refusing to let the other leave unsatisfied, when he remembered another avenue they hadn’t utilized yet.

He nipped lightly on the cable with his denta - when it retracted immediately, he cleared his exhausted throat as he manually directed his plating to open up the necessary port. Tilting his helm towards it, he nuzzled at the appendage and whispered:

“Plug in.”

Soundwave stilled his motions for a brief moment, before he reached out to guide his own relevant connector into the correct spot. They both shivered as the connection established itself, and the mutual feedback loop started cycling between them.

Megatron was slammed with the sensory data from around the cables, and he gingerly opened his intake again to allow the appendage to slide right back in, as he marveled at being filled and filling at the same time. Soundwave picked up the pace again, latching on the blazing arousal of the silver mech as he could see how much each of his moves caused the other to mewl in pleasure, trying to get in deeper, harder, faster - chasing the overload that was rapidly approaching them both.

The feeling of being more than oneself was disorienting, but as they both inched closer and closer to the edge, they were both awestruck with each other. Their sensory networks worked overtime to keep up with their intensity, bursts of data coming so fast they didn’t notice their overloads until they both rebooted, still plugged in one another.

The larger mech rumbled when Soundwave withdrew himself, cables and spike, and the mess of their fluids dripped from the still twitching valve. He could feel the strong servos guide his chestplates closed, while the interfacing subroutines were completing the disconnect protocols before the connector was removed by the thin digits, covering the port gently.

“You nearly got me thinking that you were going to just work me up and leave me hanging, you know?” Megatron laughed, feeling the appendages untangle themselves and shift his frame into a more comfortable position, cringing at the amount of lubricant he ended up sitting in. Soundwave shook his helm, tracing his digits over the scarred faceplates.

“A little bit of tension goes a long way,” the TIC played back at him, quoting his own old comments about fighting in the Arena and keeping the audience entertained. The silver mech snorted, as he raised his servo and curled it around the slim palm, kissing it softly.

“I swear, you always know how to twist my own advice against me,” he hummed, and allowed himself to be pulled up by the other bot, ending in a steadying hold, bracing the warlord from the side to keep his legs from folding underneath him. They took a look around the conference room; the chair was dented and scratched up, both it and the floor splattered in their shared fluids.

It was a mess.

The maintenance crew would be arriving soon, which gave them not enough time to conceal everything that took place, giving them a dilemma: try to hide some of the evidence and possibly clash with the Vehicons on duty, threatening them into silence, or they could both bail before anyone could see them.

Megatron leaned closer to the other’s audials, whispering theatrically:

“If you don’t tell anyone, I won’t tell either.”

Their EM fields brushed in shared amusement, as they closed the door behind them and turned towards the officer’s private washracks. Megatron flashed a grin, still basking in the afterglow.

“You up for round two?”

A sense of exasperated fondness came from Soundwave’s direction, right as an affirmative ping was sent across the private channel.

#megasound#transformers#valveplug#my_writing_valveplug#data cables give us some fun options#also yeah it was self indulging once again#megatron#soundwave#maccadam

42 notes

·

View notes

Text

Mechaniacs - Kirin Jindosh x OC - Chapter II

Summary The story of Dr. Addison Lynch, a neuroscientist who played an important role in the past and will again in the future. (fic from 2017) _________________________________________________ tags: unethical medicine, blood, violence, neurology, neuroscience, dishonored universe usual type of stuff, first person _________________________________________________ ao3: https://archiveofourown.org/works/8598001/chapters/19733941#workskin

It was cold, dark and foggy. I couldn‘t breathe or move, my body was pinned to the ground. Was that it? The end? I was just lying there in silence, completely numb of everything. No pain, no emotions. Until a face appeared in front of mine. It was a man, his eyes were completely black. „Look who we have here. Time has come for you it seems. Dr. Addison Lynch, once the person that was loved to be quoted, now the person that has to be, unwillingly. I see disgust on their faces when they think about you. Though there have been worse people, in my opinion. But were those tests really necessary? I bet you asked yourself this question, over and over and over again.“ he examined my face „Mhmm, I won‘t give you anything, you don‘t need it, you are not important to me. But to someone else, who needs you. So...“ he moved to the other side „...I guess I will give you another chance. To prove yourself and do whats right and has to be done.“ he was close to my ear now „Farewell.“ he whispered.

I awoke with a start and threw up in the bucket that was standing next to me. Water, dirt, blood and bile. I felt like my body tried to get rid of my gastrointestinal tract completely. After eternity it seems, I sat up, sweating, cold and weak. I closed my eyes for a second and breathed in and out. Where was I? That was when the immense pain hit me and I cried out. I looked to the source of it. My left arm was bandaged, my hand only a big white and red lump.

What happened?! Desperately I searched for my backpack, found it under the metal bed had I jumped out of a few minutes before and turned it upside down. Everything was completely soaked. Where are the painkillers? ... There! I swallowed five of them and laid down on the floor. Tears running down my face as I smashed my head onto the floor, distracting myself, waiting for them to kick in. I have never felt anything like this before. „Please stop this, please, stop..“ I whined bitterly, rocking forth and back.

A few minutes later the pills operated and I dared to stand up, holding onto a counter with my functioning arm. There was a mirror and sink right in front of me, but it cost me my last energy to go there. Left leg, right leg, left leg, right leg and I was there and was shocked about what I saw. My face was even paler then before, bloodshot eyes, my lips dark purple and bursted, a bloody lesion on my right temple. My clothes ragged and wet, blood all over it. But what did I expect?

I turned the valve and drank in small sips. I removed my shirt and pants and started to clean the my wounds. Fortunately most of them weren��t that deep. Someone put a needle and threads next to the sink, a few of them definitely need some stitching.

After I was relatively intact and put on some dry clothes I found, a black shirt some black pants which I had to pull up to my waist with my belt to make it fit, I decided it was time to look at the total loss which was my left arm. Carefully I unwrapped the bandage to my wrist and inspected it. „Shoulder definitely sore, was probably dislocated...“ I muttered, „Upper arm intact, forearm... very bruised but no distortion, broken? maybe?“ Now the last part. I removed the last bandage and almost threw the water up again.

My wrist was strangely twisted, „wrist... turned about 90 degrees“ and what once has been my hand was just... „Hand, not a hand anymore. Fingers angled and smashed in all directions. Glass and stones everywhere ...defin..definitely..“ but I could stand the look of it. „Broken.“ I said to my reflection and retched. This is not real. This can‘t be real. I hyperventilated, „Get it together goddammit!“

I cleaned the meat lump as good as possible and tried to stabilize the hand and fingers with some pens I found but it didn‘t work. I decided it was time to give up and just bandaged it again. It needs surgery.

Just as I finished the knot, someone opened the metal door and came in carrying a tray with a loaf of bread and a steaming mug. „Oh good, you are awake.“ She put the tray down onto the counter. I turned around, facing her.

„Who are you? Where am I?“ „My name is Meagen Foster, I am the captain of this ship, the Dreadful Whale, which you are on.“ „And what happened? The last thing I remembered was that I jumped out of a window at Addermire.“ She seemed annoyed by all my questions and sighed „Yeah and that‘s pretty much all that happened. You jumped, hit a rock and sank down unconscious. Someone pulled you out and into my boat then we brought you here.“ I opened my mouth but she answered first: „She will tell you everything. Now eat, drink and recover. We have work to do.“ and left.

For two seconds I accepted not knowing what was going on, but my curiosity drove me to the door and I was about to open it with a witty comment, however I hesitated when I saw Emily Kaldwin and Meagen talking on the corridor. It had to be her, I had seen her once when she was around 12 when I was at the Dunwall Tower and last week on a reward poster when I was stealing the corpse.

„...I still don‘t understand why we need her.“ „I know what she did, but she was a great help the last time Dunwall was at stake, maybe she will be now, too. Besides we don‘t have much of a choice, since Dr. Hypatia...could not make it.“ „If you say so.“ „I do and it‘s not up for debate, sorry Meagen, we need as much geniuses as we can get. By the way, we need to leave before dawn. I don‘t want to keep Jindosh waiting.“ They left.

Jindosh? Did she mean Kirin Jindosh?

#kirin jindosh fan fiction#kirin jindosh x oc#kirin jindosh#dishonored fan fiction#dishonored fanfic#dishonored

2 notes

·

View notes

Text

Article from a 1993 Holiday Auto magazine on what they thoughtvwere the best JDM engines from the previous 12 months.

TRANSLATION

Holiday Auto No.1 Selection '92~'93

engine department

Japanese power unit is the best in the world

The reaction to the “Twin Cam” feature in the opening feature of the 9/10 issue was tremendous. We have a wide range of products from current powerful engines to past famous machines and future models, but the one with a supercharger won the number one spot.

Boosted No 1 Nissan's RB26DETT,

Natural intake was Honda's C30A.

RB26DETT (equipped with Skyline GT-R)

King with supercharger

I'm really conscious of the race

Literally the famous machine that became the driving force behind the "R" myth.

Since its debut in 1988, the Skyline GT-R has shown overwhelming performance. The heart of this is the RB26DETT model. As the slogan of the BNR32 GT-R says, “In the beginning, the engine was there. The mechanics are transcendent."

The 6-throttle chamber has a butterfly type throttle valve for each cylinder to enhance throttle response. The turbo is a hybrid of the T3 type on the compressor side and the T25 type that uses a ceramic rotor on the turbine side. The intercooler has a large capacity. The main body is also fully armed with a cooling channel piston and an EX valve during sodium filling. All of Nissan's technology has been incorporated.

▲Metal sodium is added to the stem of the exhaust valve, enclosed. Solid at room temperature and liquefied at high temperature

Suppresses the temperature rise of the exhaust valve by using the properties of sodium

_______________________________________________

C30A

(Equipped with NSX)

King of naturally aspirated

I also want to focus on weight reduction

A V-shaped unit created with the ultimate in luxury

The domestic high-power engine has become a 280ps battle. However, the C30A is the only naturally aspirated engine that achieves this figure.

The C30A is the second VTEC engine. In addition to the technology of the B16A type, it also adopts a variable capacity device for the intake manifold. This is to close the valve provided in the manifold chamber up to about 4800 rpm, and to increase the torque by inertial intake due to pulsation change.

The V type with a 90-degree angle is lightweight, and the tuning of the rotation system is also carefully considered. These include molybdenum-coated pistons, titanium connecting rods, ultra-precision mirror-finished crankshafts, and a deep-skirt-type cylinder block made of aluminum light alloy.

▲Big Bore, Short Stroke and Honda Racing

Following the theory of Guengin. In addition to VTEC, intake

A manifold variable capacity device is adopted to aim for the top

2JZGTE

It's Aristo's heart

2nd place

2JZ-GTE (with Aristo)

It may have been upgraded, but it will be installed, but at that time it will be even more powerful. The torque value of 44.0-kgm is in the class for the Supra scheduled to debut this year

Maximum output:280 hp / 5600 rpm Maximum torque:44.0 kgm/3600 rpm

As mentioned in the top speed section, Toyota's strongest engine that supports Aristo is the 2JZ-GTE type. The base is the 1JZ-GTE type that debuted one step ahead, but the 86.0 x 71.5mm bore x stroke has been souped up and changed to the 86.0 x 86.0mm square type. Toyota's first two-way twin turbo system (sequential turbo) is adopted for this, and it demonstrates the maximum output / maximum torque of 280ps / 44.0kgm. The torque value of 44.0kg m is the strongest in its class. It will also be installed in the next Supra.

6G72

Big torque in low speed range

6G72

(with Mitsubishi GTO)

You can run the GTO fast without doing it. ▼ As you can see from the maximum torque at only 2500 rpm, it is a torque-oriented type. That's why it's a regular shift work

MITSUBISHI

V6 DOHC

Maximum output 280 horsepower / 6000 rpm Maximum torque: 42.5 kgm / 2500 rpm

Mitsubishi's heavy fighter, the power unit that pulls the GTO is the 6G72 type. Mitsubishi engines are originally characterized by their focus on torque, and the 6G72 is no exception. Rather, the turbo tune makes its character even clearer. The maximum torque value of 42.5kgm is proof of that. Mechanically, it will be a twin turbo & twin intercooler V6 DOHC that adopts an electronically controlled variable intake system, a new intake port, an active exhaust system, and a high-precision electronically controlled fuel injection system.

B16A

You should enjoy the taste of this once B16A (equipped with Civic etc.)

2nd place

HONDA

continue to reign in The B16A model is the one that made Honda VTEC known to the world. high speed saga

Maximum output: 170 horsepower / 7800 rpm Maximum torque: 16.0 kgm / 7300 rpm

The B16A was the first model to adopt VTEC (Variable Valve Timing Wrist Mechanism). VTEC is a mechanism that uses cams with different profiles in the low speed range and high speed range, aiming to increase peak output in the high rpm range and practical mid- to low-speed torque. In the new model, the compression ratio was increased to 10.4, the valve timing and valve lift were changed, and intake and exhaust efficiency was improved by reducing intake and exhaust resistance. As a result, we achieved 170ps, which is 10ps higher than the conventional model.

4G92

4G92 (equipped with MIVEC, Mirage, etc.)

The cam profile switching mechanism is similar to VTEC, but in the case of MIVEC,

two of the four cylinders are cam-coupled

is rigidly connected to either rocker arm.

The valve will not open unless

the hydraulic piston is not moving

MIVEC

Mitsubishi's next-generation mecha

DOHC 16 VALVE

Maximum output: 175 horsepower / 7800 rpm Maximum torque: 16.0 kgm / 7300 rpm

20V 4A-GE

Behold the brilliance of 5 valves

4A-GE (with Levin/Trueno)

Maximum output: 160 horsepower / 7400 rpm Maximum torque: 18.2 kgm / 4800 rpm

The new 4A-GE is a 5-valve DOHC with 3 intake valves and 2 exhaust valves. This is combined with VVT (variable valve timing), and a quadruple throttle is adopted to achieve a sharp pickup that does not take sink marks in VTEC and MIVEC.

28 notes

·

View notes

Text

High-Performance Pneumatic On-Off Y Type Valve Solutions

Reconvalve is providing high quality pneumatic on off Y type valve designed to precise control and reliable performance in various industries. those valve are manufactured to handle the most demanding environments or make sure that smooth and efficient operation under high pressure and temperature condition. the Y type design of our pneumatic on off valves allows for best flow control, minimize pressure and maximizing efficiency. Reconvalves are used in chemical processing, water treatment and manufacturing system that deliver the performance and durability need to keep operation running smoothly.

Reconvalve are understand the crucial role that pneumatic on off Y type valves doing industrial automation and process control. our valves are manufactured using top grade material and latest technology or we can make sure that long lasting performance and minimal maintenance. Reconevalev trusted name in industry for their quality and innovation. we are providing solution that compete specific standard of our customer. Choose Reconvalve for your pneumatic on-off Y type valve needs and experience superior control, reliability, and efficiency in your industrial processes.

Explore our wide range of reliable and efficient valve solution to compete your industrial needs. learn more about high quality pneumatic on off Y type valves then visit our website reconvalve.com and contact with us. Trust Reconvalve for superior control and performance.

#steam control valve#angle type valve#pneumatic control valve#steam control valve in ahmedabad#pneumatic control valve manufacturer#angle type valve in india#pneumatic control valve supplier#steam control valve in india#angle type valve in gujarat#angle type valve manufacturer

0 notes

Note

Hello, prior anatomy assistant here. The article is horrifically disrespectful, describing the process as "unpleasant" and focusing solely on fat bodies. Those doctors should be removed from lab practice and not be fielding anatomical study if it grosses them out for any reason. Can't handle the heat, stay out of the kitchen. Those doctors blame the dead persons/patients for their personal struggle with gross anatomy and they are wrong to do so. It makes me furious that medicine is generally ableist, sexist, racist, and fatphobic among other phobias- many things to improve... Please advocate for yourself as well as seeking care from those Drs who respect YOU and your life and time.

Any of this information below is not in disregard of medical issues with fatphobia etc. I just have experience in a setting similar to the article which I hope helps.

I was working just two months ago at a medical school with cadaveric donor anatomy courses, taking care of the donors as well as making sure students/faculty have their needs/safety met. I became sensitive to the chemicals and have since gone on to work instead at a crematorium, but I did this for three years with faculty/students from Doctoral Osteopathy, Physician Assistance, Physical Therapy, Occupational Therapy, Dental, and Dual Enrollment (highschoolers learning from donors dissected by the med students). As the anatomy assistant it was part of my and faculty's job to make the point to students verbally and by action/behavior of treating all decedents as their first patient. We ask them to behave as if they were the doctor for their grandparents, to think what they would not want a doctor to do or say about their "grandmamapapa" to their face about their body and further to not discuss patients/donors beyond lab facilities for privacy and basic decency. Then we instruct them in dissecting donors with that respect in mind, that's grandmamapapa's final request after all.

I received donors of various heights, weights, ethnic background, and was often very impressed by the students and faculty alike as they found most all aspects of the course interesting/fulfilling as they showcased the variety of human anatomy. Frightened awe at enlarged organs, sadness at tumors clots and shriveled lungs, soft fascination with hip/knee implants valves and pacemakers.

Students study all aspects of anatomy including superficial structure throughout and within the fatty dermal layer, however most adipose (fat) tissue is removed to unveil the greater number of structures beneath/within. I am unsure how adipose tissue is covered in their courses beyond lab, it is a wonderfully unique cell type I would often point out as forming paquetes versus striated muscle tissue beneath to the new students seeing it the first time in such a way. All removed tissues were placed into identifying bags and stored until being replaced into the body bag of their identified donor once the donor retires to cremation so that as much of them that came into the program is then returned to loved ones receiving cremains.

Usually the largest removal of adipose tissue occurs during the first-second week of lab, not because it takes this much time but because students are having safety orientation day one, understanding the lab environment and being around a dead body for 2-4 hours at a time inspecting external structures day 2-3, and thats week one. Week two begins dissection with respect for the dead in mind and is often skinning and cleaning fat from the back muscles. This when removal of fats takes the most time due to many important questions: how to do perform dissection (loading scalpel, cutting depth, skinning angles/direction), what is this versus that, why is this a certain color etc as well as being the largest surface area. Legs and arms are skinned in stages, also while donors are prone, at the back, and continued once the donor is supine, front facing. Until complete removal the skin remains as flaps simply folded away from underlying structures. The next largest immediate removal of adipose is from the chest/pectoral region, further on in coursework and so most students have acclimated well and complete it quite quickly, an hour or less to get to the rest. Fat of the belly is left attatched for the duration of dissection as skin flaps to open/close protecting the organs from dessication/mold in much the same way as the metal donor table lids function. All exposed/skinned regions of the body are wet down with dilute embalming solution repeatedly during study/class hours and then kept under a similarly wetted sheet while not in use to practice privacy and prevent drying/decomp/mold. Faces and secondary sex characteristics are covered with separate barriers beneath the sheet also for privacy of donors (as well as for many persons faculty/student alike having mental struggles with faces).

Weight limits for the ADP (at least the one I was part of) are set 250lb before embalming (fluid weight brings some donors in at around 400lbs). The 250lb limit is set for embalming purposes. Since fats are hydrophobic they prevent absorption of embalming chemical, while muscles are hydrophilic in comparison. A higher ratio of fat:muscle can lead to more rapid decomposition due to poor embalming which then potentially leads to the donor becoming unviable for study or dissection. Despite curing for a month prior to dissection, further embalming procedures (such as on the glutes and skull cavity/brain) and decomp being "fought" continuously while in the care of the lab, preventing decomp is best done at the first embalming on pre-registered donors - ones received immediately at death into the program and not left waiting while decomposing as an unregistered or at-need donor may experience - onset of decomposition follows immediately after death. I maintained each donor fighting decomposition, mold, and drying for an average of two years of care/cost per individual donor.

Metal donor tables and tarp-adjacent body bags (where the donors lay and stay during dissection) are approx. 7ft×3ft. The tables have an inset/inlay of about 2.5 inches deep and 6.5ft x 2.75ft. There are hinged lids that when closed are pentagonal - the upright sides about 5 inches and the point where the lids meet in the middle about 7 inches from the table top, giving around 8 inches at the sides for arms mainly and 10 inches for high points like head/chest/feet. 3D objects such as human bodies must close into the bag (flat, but flexes around well due to material) and the table's lids to prevent environmental factors like spores (mold) or dessication (drying, mummification). There are other table types, such as downdraft, but I do not have experience working with them or their measurements.

Being fat is not a problem with body donation or medical study, some people are just not respectful, kind, or decent.

The reason fat cadavers are not accepted for medical programmes is that you need to cut through every layer of fat carefully. Which takes time, and lab sessions are inherentely limited in that. It's better for med students to spend that time looking at what organs actually look like in bodies. This isn't fatphobia, it's just .. the way dissecting bodies works? In the same way surgeries on fat people take longer because there's just physically more tissue. The alternative would be to force the med students who get fatter cadavers to do more lab sessions at weird times outside of the usual schedules. Or force them to stay over the holidays. Or not let them get enough time to do the lab work they need to. Which imo would be a bit fucked up especially when med school is already so difficult and time-consuming.

It’s fatphobia. Fat bodies absolutely need to be studied. To ignore an entire demographic of oppressed individuals in the medical field for the sake of convenience(?!) is violence. Did you even read the article? They called working on fat cadavers “unpleasant.” It’s fatphobia and it’s unacceptable.

#body#body donation#fatphobia#information#dissection#medicine#medical training#anatomy#anatomical#your body is beautiful

24K notes

·

View notes

Text

The Significance of Stop Valves

Stop valves are integral components in fluid control systems, playing a crucial role in managing the flow of liquids and gases. These valves are designed to open or close to control the passage of fluids, ensuring safety and efficiency in a variety of applications.

Stop valves can be categorized based on their design and operation. The more common types include:

Globe Stop Valves: These are the standard type, with a circular flow path through the valve body and a flat or conical closure member.

Angle Stop Valves: These valves are designed with an angled body, which can help reduce the pressure drop across the valve.

Ball Stop Valves: Featuring a spherical closure member, these valves offer a quarter-turn operation and are known for their low flow resistance.

Check Stop Valves: These are designed to allow flow in one direction only, preventing backflow.

0 notes

Text

0 notes

Text

High-Pressure Needle Valve Supplier: Quality Solutions for Hydraulic Systems

When it comes to controlling fluid flow in hydraulic systems, precision and durability are paramount. At Ped-Lock Valves & Fittings, we specialize in providing high-performance high-pressure needle valves designed to meet the most stringent demands of industrial operations. Our range of high-pressure needle valves delivers unparalleled reliability for diverse applications across sectors.

Understanding the Importance of High-Pressure Needle Valves

High-pressure needle valves are vital components in hydraulic systems, ensuring precise control over the flow of liquids and gases under extreme pressure. These valves feature a needle-like plunger that fits snugly into a tapered seat, offering fine-tuned adjustments for pressure and flow rates.

Key Applications of High-Pressure Needle Valves

Our high-pressure needle valves are widely utilized in industries such as:

Oil & gas

Petrochemical processing

Power generation

Instrumentation systems

Industrial manufacturing

Whether for managing high-pressure fluids or ensuring system safety, needle valves play a critical role in maintaining system integrity and operational excellence.

Why Choose Ped-Lock as Your High-Pressure Needle Valve Supplier?

Exceptional Quality Standards Every valve we manufacture adheres to global standards, ensuring long-lasting performance even in extreme conditions.

Wide Range of Options We offer a variety of needle valve configurations to suit different operational needs, including straight and angled bodies.

High-Pressure Capacity Designed to withstand pressures up to 10,000 PSI (690 bar), our valves deliver unmatched reliability in high-stress environments.

Premium Material Choices Constructed using stainless steel (SS316, SS304) or other robust alloys, our valves are resistant to corrosion, wear, and harsh environmental conditions.

Custom Solutions Available At Ped-Lock, we understand that each application is unique. That’s why we offer custom designs, thread types, and port configurations to meet specific client requirements.

Comprehensive Testing Every valve undergoes rigorous testing for performance, durability, and safety before reaching your system.

Advantages of Ped-Lock High-Pressure Needle Valves

Precise Flow Control: Fine-thread adjustments ensure maximum accuracy.

Robust Construction: Resistant to extreme pressures and harsh fluids.

Versatile Application: Suitable for both gaseous and liquid media.

Long Operational Life: Minimal wear and low maintenance requirements.

Your Reliable Needle Valve Partner

As a trusted high-pressure needle valve supplier, Ped-Lock Valves & Fittings is committed to delivering products that meet the ever-growing demands of the industry. With a legacy of excellence and a focus on innovation, our products enhance the performance and safety of your hydraulic systems.

Explore Our Range Today

For more information about our high-pressure needle valves, visit our hydraulic valves product page. Contact us to discuss your requirements or request a quote tailored to your project’s needs.

0 notes

Text

Globe valve manufacturer in Germany

Valvesonly Europe is a Globe Valve manufacturer in Germany Globe valves are valves that move in a straight line to control media flow. They are usually used for throttling and regulating flow through the valve, but they can also be employed in on/off systems to entirely allow or restrict media.

How Globe Valve works

A globe valve is a type of valve that works by moving a disc as the closing component, providing for control over media flow in a pipeline. These valves create a globular-shaped hollow surrounding the port area, hence their name.

The operation of a globe valve requires an understanding of its moveable disc and stationary seat, which are positioned parallel to the pipe and perpendicular to the disc in a spherical body, with the seat immobile.

The valve disc moves up and down in response to the activation of the top wheel, which can be manipulated manually or using an actuator.

The globe valve is fitted for low-temperature settings, where pressure falls below the disc, and for high-temperature applications, such as steam-operated boilers, where pressure is above the disc.

How is a globe valve made?

Valvesonly Europe is a Globe Valve manufacturer in Germany are generally produced through casting methods due to their intricate design; however, for certain applications, they may also be fabricated from wrought materials. The disc and seat rings are commonly constructed from bronze, but in the case of steel globe valves intended for temperatures above 350°C, stainless steel trim is employed to prevent complications such as seizing and galling. The heat treatment of the valve's mating surfaces is crucial for achieving differential hardness values. Furthermore, alternative trim materials, including cobalt-based alloys, are also utilized. It is necessary to grind the seating surface to ensure complete bearing surface contact during the closure of the valve. In lower pressure classifications, an expanded disk locknut is used to maintain the alignment of the valve, whereas for higher pressure applications, disc guides are incorporated into the valve body.

Types of Globe Valve

Pressure Seal Globe Valve

Bellow Seal Globe Valve

Y Type Globe Valve

Angle Type Globe Valve

Forged Steel Globe Valve

Pressure Globe Valve

Industries Globe Valve

Oil and Gas

Chemical

Mining

Textile

Petroleum

Petrochemical

Pulp and Paper

Marine

Power Generation.

Features of Globe Valve

A globe valve is a device with a globe-shaped body and an interior baffle separating intake and outflow ports. The baffle, also known as the disk or plug, is connected to a stem and a hand wheel. When the wheel is turned or the actuator is activated, the stem raises or lowers the disc.

Advantages of Globe Valve

Globe valves are a reliable and efficient tool for accurately regulating flow in various fluids like water, oil, steam, and chemicals. They are also durable and dependable, with a simple design that simplifies installation, maintenance, and repair.

Applications

Globe valves are crucial in various industries like oil and gas, power generation, chemical processing, and wastewater treatment, regulating fluid flow, pipelines, power plant feedwater, chemical process flow, and water flow in water treatment facilities.

Description

Body material- Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class- 150 – 2500; PN10 – PN 450

Size- DN 10 – DN 1200

Ends- Butt weld, Flanged, threaded, socket weld

Operations- Handwheel operated, Pneumatic actuated, Electric actuated, Gear operated

Visit us: https://www.valvesonlyeurope.com/product-category/globe-valve/

1 note

·

View note

Text

Wholesale Brass Gas Valve: A Reliable Choice for Gas Control

Introducing our premium range of Wholesale Brass Gas Valves, designed for precision and reliability in gas control systems. These valves are crafted from high-quality brass, ensuring durability and resistance to corrosion, making them ideal for both residential and commercial applications.

Our Wholesale Brass Gas Valves are known for their robust construction and superior performance, which is why they are the preferred choice for many professionals in the industry. Each Wholesale Brass Gas Valve undergoes rigorous quality control checks to meet international standards, ensuring that they are leak-proof and safe for use with natural gas, propane, and other gases. The precision engineering of our valves allows for smooth operation and precise control over gas flow, which is crucial for maintaining safety and efficiency in any gas-powered system.

Our Wholesale Brass Gas Valves are available in a variety of sizes and configurations to suit different pipe sizes and pressure requirements. Whether you need a simple on-off control or a more complex pressure regulation system, our valves can be tailored to fit your specific needs. The compact design of our Wholesale Brass Gas Valves also makes them easy to install and maintain, saving you time and effort in the long run.

Angle valve is a type of valve used in pipeline systems. Its characteristic is that the direction of the valve body and the pipeline connection is at a 90-degree angle, hence the name. Angle valves are widely used in homes, industries, and agriculture to control the flow of various fluids such as water, oil, and gas.

#metal shower hose#flexible hose#wholesale brass gas valve#valve#flexible connector#gas connector#gas valve#Brass Gas Valve

0 notes