#aluminium-casting-companies

Text

#die-cast-manufacturer#custom-die-casting#die-casting-services#aluminium-casting-companies#die-casting-supplier

0 notes

Text

What is the difference between steel alloy and cast iron?

To begin with, steel alloy and cast iron are both types of metal alloys that are widely used in various industries. Although they share some similarities, there are significant differences that set them apart. Steel alloy is made by combining iron with other elements such as carbon, manganese, and chromium. Steel typically contains less carbon than cast iron, making it more ductile and malleable. Its tensile strength is higher, and it's more resistant to corrosion, making it ideal for use in building structures, machinery, and automobiles.

Cast iron, on the other hand, is formed by melting iron and adding carbon, silicon, and other elements. Cast iron contains a higher percentage of carbon, making it harder and more brittle. It is generally used in applications where high compressive strength is required, such as in the production of engine blocks, cookware, and pipes. Cast iron is also more prone to cracking under pressure or impact than steel alloy.

In conclusion, the differences between steel alloy and cast iron are based on their composition and properties. Both materials have distinct advantages and disadvantages, and their suitability depends on the specific application. By the way, after talking about it, only one company name comes to my mind that is Datre Corporation Ltd, is a leading manufacturer of high-quality steel casting products that meet the highest industry standards in Eastern India. So you can confidently utilise their products for your industrial needs.

Company name: Datre Corporation

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

#stainless steel#cast iron#steel alloy#carbon#steel casting manufacturer#manufacturing industry#manufacturing company#aluminium manufacturer#manufacturer

3 notes

·

View notes

Text

Aluminium corrugated sheet manufacturer

Aluminium corrugated sheet manufacturer. High-quality, durable sheets for roofing, siding, and industrial applications. Custom sizes and finishes available.

#roof replacement#roofing contractor#roofing repair#roofing services#color coated#roofing sheets#roofing company#aluminium windows and doors#aluminium foil#aluminium die casting#aluminium sheets

0 notes

Text

Automotive Injection Molding - Precision Manufacturing for High-Quality Auto Parts

Automotive Injection Molding by Keiteq offers advanced solutions for producing precise and durable automotive components. This process ensures high efficiency and consistency, making it ideal for creating complex parts like dashboards, bumpers, and interior panels.

#electronics manufacturing services#automotive mold manufacturers#electronic manufacturing services#aluminium die casting#automotive molding#plastic injection molding supplier#plastic injection molding company

0 notes

Text

ERW Tubes | ERW Steel Pipes Suppliers in India

Discover high-quality ERW tubes and ERW steel pipes from top suppliers in India. Durable, cost-effective solutions for various industries.

0 notes

Text

How Indian Die Casting Companies Are Transforming the Automotive Industry

The automotive industry is undergoing a profound transformation, and Indian die casting companies are at the forefront of this evolution. Among these, Taural India stands out as a key player, leveraging advanced technologies and innovative processes to drive significant changes. This blog explores how die casting companies in India, with a particular focus on Taural India, are reshaping the automotive landscape, emphasizing the role of aluminum die casting.

The Rise of Die Casting Companies in India

Die casting, a metal casting process characterized by forcing molten metal under high pressure into a mold cavity is crucial in manufacturing lightweight and high-strength components. India, with its burgeoning industrial base and skilled workforce, has become a hub for die casting activities, particularly aluminum die casting. This growth is fueled by the demand for more efficient, lightweight, and environmentally friendly automotive components.

Taural India: A Leader in Aluminum Die Casting

Taural India exemplifies the strides made by Indian die casting companies. Specializing in aluminum die casting, Taural India has established itself as a leader by focusing on quality, innovation, and customer satisfaction. The company's advanced facilities and commitment to excellence have made it a preferred supplier for many automotive giants.

Lightweight Components: Enhancing Fuel Efficiency and Performance

One of the primary ways Indian die casting companies are transforming the automotive industry is by producing lightweight components. Aluminum die casting is particularly beneficial in this regard. Aluminum, being lighter than steel, reduces the overall weight of vehicles. This reduction in weight leads to better fuel efficiency and improved performance, addressing the industry's growing need for sustainability and cost-effectiveness.

Taural India has mastered the art of creating lightweight aluminum components without compromising on strength and durability. By supplying parts that contribute to lower fuel consumption and emissions, Taural India is helping automotive manufacturers meet stringent environmental regulations and consumer demands for greener vehicles.

High Precision and Superior Quality

In the competitive automotive sector, precision and quality are paramount. Die casting companies in India, such as Taural India, employ state-of-the-art technologies to ensure the highest levels of accuracy in their products. The use of advanced die casting machines, computerized control systems, and rigorous quality checks enable these companies to produce components that meet exact specifications and standards.

Taural India's focus on precision ensures that each component fits perfectly within the larger assembly, reducing the need for additional machining and minimizing production costs. This level of precision not only enhances the performance of automotive parts but also extends their lifespan, offering better value to automotive manufacturers and end consumers.

Innovation in Die Casting Processes

Innovation is a key driver of the transformation seen in the automotive industry. Die casting companies in India are continually investing in research and development to improve their processes and products. Taural India is no exception. By adopting innovative techniques such as vacuum die casting, squeeze casting, and the use of advanced alloys, Taural India has been able to produce components with superior mechanical properties and minimal defects.

These innovations have led to the production of parts that can withstand higher stress and temperatures, making them ideal for modern automotive applications. The ability to produce complex geometries with high repeatability also allows for more design flexibility, enabling automotive manufacturers to create more efficient and aesthetically pleasing vehicles.

Cost-Effective Solutions

Cost efficiency is another area where Indian die casting companies are making a significant impact. By streamlining production processes and optimizing resource utilization, companies like Taural India can offer high-quality components at competitive prices. This cost advantage is critical in the automotive industry, where manufacturers are constantly looking to reduce production costs without sacrificing quality.

Taural India's efficient production methods, combined with its strategic location and access to a skilled labor force, enable it to provide cost-effective solutions to automotive manufacturers worldwide. This cost efficiency, coupled with high quality, makes Taural India an attractive partner for both domestic and international clients.

Commitment to Sustainability

Sustainability is no longer a buzzword but a necessity in today's industrial landscape. Die casting companies in India are increasingly focusing on sustainable practices, and Taural India is leading by example. By using recyclable materials like aluminum and implementing energy-efficient manufacturing processes, Taural India minimizes its environmental footprint.

Moreover, the company invests in waste reduction technologies and adheres to strict environmental regulations. This commitment to sustainability not only enhances the company's reputation but also helps its clients achieve their sustainability goals, thereby contributing to a greener automotive industry.

Strategic Partnerships and Collaborations

The transformation of the automotive industry is also facilitated by strategic partnerships and collaborations. Die casting companies in India, including Taural India, actively collaborate with automotive manufacturers, research institutions, and technology providers to stay ahead of the curve. These partnerships enable the exchange of knowledge and expertise, leading to the development of better products and processes.

Taural India's collaborations have resulted in several successful projects, showcasing its ability to adapt to changing market demands and technological advancements. By working closely with its partners, Taural India ensures that it remains at the cutting edge of innovation, providing its clients with the best possible solutions.

Future Prospects

The future looks promising for die casting companies in India. With the increasing adoption of electric vehicles (EVs) and the ongoing demand for lightweight and high-performance components, the role of aluminum die casting is set to become even more significant. Taural India is well-positioned to capitalize on these opportunities, thanks to its strong foundation in quality, innovation, and sustainability.

As the automotive industry continues to evolve, Indian die-casting companies will play a crucial role in shaping its future. By providing advanced solutions that meet the changing needs of the market, companies like Taural India are transforming the industry and contributing to a more sustainable and efficient automotive ecosystem.

Conclusion

Die casting companies in India, particularly those specializing in aluminum die casting like Taural India, are making a substantial impact on the automotive industry. These companies are driving significant changes through their focus on lightweight, high-precision, and cost-effective components, coupled with a commitment to innovation and sustainability. As the industry continues to evolve, the contributions of Indian die casting companies will be instrumental in shaping the future of automotive manufacturing.

#Die casting companies in India#aluminum die casting manufacturers#aluminium die casting manufacturers in india#aluminum die casting

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

Casting Manufacturer Industry in Rajkot, Gujarat, India, Die Casting Manufacturer,

Aluminium die casting industry in Rajkot,Gujarat, India,

Our company offers a comprehensive suite of manufacturing solutions, including die casting services. With a focus on precision, efficiency, and quality, we cater to diverse industries and provide tailored solutions to meet specific project needs. Casting Manufacturer Industry in Rajkot, Gujarat, India,

Milling Die Casting Services From the Aluminium Gravity Die Casting Manufacturing Industries In Rajkot

Our Milling Alluminium Gravity Die Casting Manufacturing services leverage state-of-the-art equipment and advanced technology to deliver high-precision parts with tight tolerances. Key highlights of our machining services include:

Advanced Equipment: We utilize modern Die casting Service material machines with multi-axis capabilities, enabling us to perform a wide range of machining operations with speed and accuracy.

Die Casting Manufacturer,

Aluminium die casting industry in Rajkot,Gujarat, India,

#india#gujarat#aluminium die casting industry in rajkot#aluminium casting manufacturer company in rajkot#aluminium gravity die casting industry in rajkot#diecasting#Diecastingmanufacturer#Diecastingmanufacturerindustryinrajkotgujarat#manufacturer

0 notes

Text

Top Casting Manufacturers in Howrah, West Bengal | Call 9163221666

✔️ Strictly follow quality control regime ✔️ Products at competitive prices ✔️ Consider the latest market demands ✔️ Maintain prompt and scheduled delivery ✔️ Encourage suggestions and feedback from customers

#Casting Manufacturer in West Bengal#aluminium die casting factory kolkata west bengal#casting manufacturer in west bengal#casting manufacturer#injection moulding companies#investment casting companies#zinc die casting#stainless steel casting companies#die casting companies near me#aluminum die casting manufacturer

0 notes

Text

CAST ALUMINIUM COMPANIES IN UAE

CAST ALUMINIUM COMPANIES IN UAE are experts at making high-quality castings for this precious metal. These companies use high-tech techniques and good craftsmanship to produce a variety of parts for numerous industries, including the automotive industry as well as that pertaining to spacecraft, planes and structures. Its products are renowned for their accuracy, toughness and conformity to international quality standards.

0 notes

Text

DST Tech: Revolutionizing Zinc Die-Casting for Sanitary Manufacturers

In a world where excellence and efficiency define the manufacturing landscape, DST Tech Private Limited stands tall as the leading manufacturer of zinc die-cast products in India. Unlike the majority of Chinese companies and all Indian companies, DST Tech proudly houses all operations under one roof, a unique aspect that sets us apart from the rest. From tool design and manufacturing to casting, machining, electroplating, and packaging, DST Tech’s seamless approach ensures “Peace of Mind” for our esteemed customers in terms of quality and timely delivery commitments.

Key Differentiators that Set DST Tech Apart

1. Tooling & Development Excellence: DST Tech’s dedication to precision and innovation has earned us several prestigious awards, including the International Zinc Association (IZA) award in 2023 for “best tool design” and the China Die Casting award in 2018 for excellence in tool design. Our tool designers, using cutting-edge software like Siemens NX19.0 and Hitachi Adstefen, are specialists in “Feed System design” for Zinc Die Casting, ensuring flawless material flow for impeccable high surface integrity, crucial for chrome plating.

2. Zinc Die Casting Shop of Distinction: DST Tech’s zinc die casting shop is renowned for its quality systems certified by TUV, Germany – the world’s highest-ranked certification body. This dedication to excellence has earned us accolades like the North American Die Casting (NADCA) award in 2018 for “Best zinc die casting” and the China Die Casting award in 2018 for “Excellence in Casting.” With a production capacity of 150 tons of Zinc Alloy per month and sourcing the best alloy manufacturers worldwide, DST Tech guarantees no question of alloy contamination.

3. Polishing & Electroplating Expertise: The polishing and electroplating facilities at DST Tech are designed with inputs from international experts. Our quality systems, certified by TUV, Germany, are a testament to Our commitment to excellence. Our largest and most modern electroplating shop for Zinc in India can process up to 1 million castings per month, and Our in-house laboratory ensures precise control and monitoring of the electroplating process.

Driving Sanitary Excellence Worldwide

DST Tech has emerged as the only Zinc die-cast company in India already supplying to the largest MNCs in sanitary & kitchenware worldwide. In addition, we are in discussions with top sanitary MNC brands for “Start of Production” partnerships. With professionally qualified personnel and directors with a background in Automotive and distinction in professional studies (B.Tech & MBA), DST Tech is poised to celebrate its 25th year in operation, reaching the zenith of quality for Zinc die-cast products.

Partnering for Growth and Sustainability

Sanitary manufacturers seeking credible and professional sources for Zinc die-casting in India need not look further. DST Tech offers a partnership that empowers growth worldwide with impunity. As we gear up to embrace international operational automation standards, DST Tech relies on support and collaboration to hedge against Chinese dominance and continue delivering excellence.

For More Information Pls Visit On :

#zinc die castings#casting manufacturer#die cast manufacturer#aluminium casting manufacturers#aluminium die casting manufacturers in india#die casting company in india#casting manufacturers#Precision Die Casting

0 notes

Text

Aluminiuim Die casting products

Die-casting products are preferred in the automotive industry

The automotive industry needs lightweight, high-precision, sturdy products. Aluminum die-casting offers multiple advantages to automotive manufacturers. Die-cast product manufacturers like Rockman have been using state-of-the-art facilities in India for manufacturing automotive parts in bulk.

Aluminium die-cast is the solution

In the automotive industry, in fact, many other industries like ship and aircraft builders need lightweight corrosion resistant, long-lasting parts. Aluminium die-cast parts solve this issue. Aluminium die casting products are corrosion-resistant and appropriate in any weather condition.

Cost-effective method

Compared to other methods of manufacturing automotive products or parts, die-casting is much more cost-effective for automotive manufacturers. Die-cast product manufacturers like Rockman are capable of supplying automotive parts in bulk without compromising the quality.

Find a reputed die-cast manufacturer

When you need die-cast parts in bulk for manufacturing automotive engines or automotive units, ensure you choose the right business partner in India.

For more information of die cast products visit https://www.rockman.in/

0 notes

Text

What is fettling in manufacturing?

Fettling in manufacturing refers to the process of refining and finishing a cast metal component to achieve desired quality and appearance. It involves tasks such as cleaning, grinding, cutting, and polishing the surface of the casting to remove excess material, burrs, and imperfections. Fettling not only enhances the aesthetic appeal but also ensures the functional integrity of the final product. This meticulous process helps create components that meet specific design specifications, tolerances, and performance requirements. Fettling plays a vital role in producing high-quality castings for industries like automotive, aerospace, and engineering, contributing to overall product reliability and customer satisfaction.

For those seeking the best fettling services, Datre Corporation Ltd. emerges as a standout option. Renowned as the leading Fettling Service Provider in Kolkata, they boasts a track record of excellence and reliability. Their skilled professionals and state-of-the-art equipment guarantee top-notch fettling results, ensuring your products meet the highest industry standards.

Company name: Datre Corporation Ltd.

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

#manufacturing industry#aluminium manufacturer#steel casting manufacturer#steel alloy#alloy steel#fettling#manufacturing company#manufacturer in india

1 note

·

View note

Photo

Best cast aluminum gates supplier in Dubai

0 notes

Text

Precision Plastic Injection Molding company | Keiteq

Plastic Injection Molding Company specializing in molding. The basic process includes creating the product design and making a tooling mold to fit the product. we deliver top-quality molds and exceptional services to meet your unique needs. Trust Keiteq, the experts in plastic injection mold company solutions, for your next project. Visit us to learn more!

#plastic injection molding supplier#electronics manufacturing services#aluminium die casting#electronic manufacturing services#plastic injection molding company

0 notes

Photo

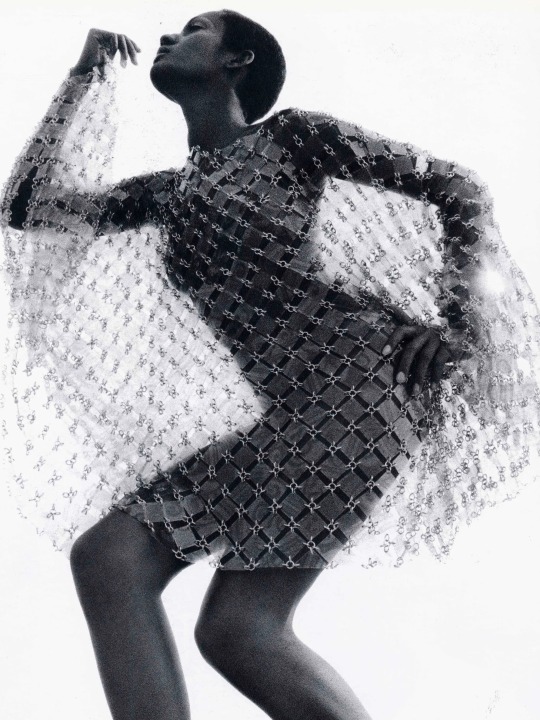

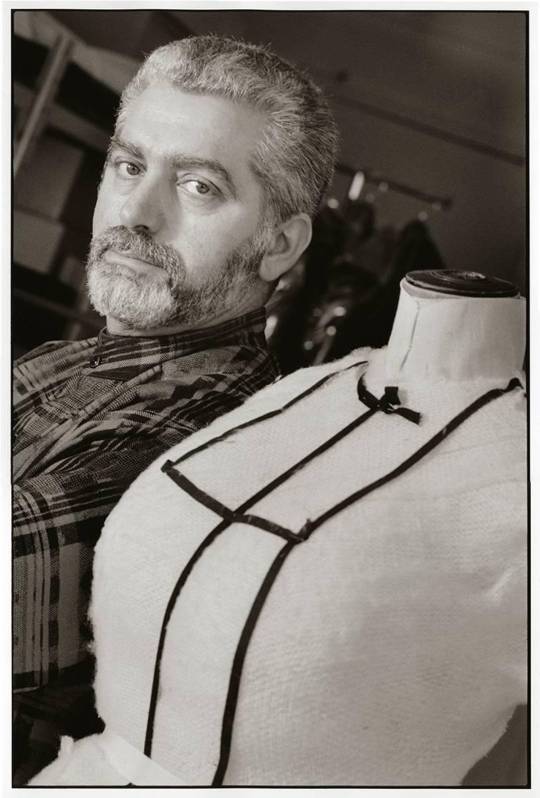

Francisco Rabaneda Cuervo (18 February 1934 – 3 February 2023),

More commonly known under the pseudonym of Paco Rabanne, the Spanish-born designer who was renowned for his iconic metallic dresses, has passed away today at the age of 88 in Portsall, Brittany.

The designer revolutionised fashion by twisting unconventional materials into new and previously unexplored forms. His brand – synonymous with the optimism of the 60s – was built on sculptural microminis, crafted from bolshy paillettes of aluminium, which mined medieval armour for its space-age potential.

His origins are equally as fateful and as intriguing as his designs, born in the Basque town of Pasajes, Gipuzkoa. His father was a Republican Colonel and was executed by Francoist troops during the Spanish Civil War.

Though Paco’s avant-garde sensibilities were perhaps a matter of inheritance, his Mother was the chief seamstress at Cristóbal Balenciaga's first couture house in Donostia, Basque Country, and subsequently Balenciaga moved Rabanne's entire family when he opened Balenciaga in Paris in 1937.

In the mid-1950s Paris, while he was studying architecture at l'École Nationale des Beaux-Arts, Rabanne earned money on the side by making fashion sketches for the likes of Dior and Givenchy, as well as shoe sketches for Charles Jourdan. Despite his early foray into the fashion industry, he stuck to his original plan getting a job at the company of esteemed French architect Auguste Perret. After 10 years at the company, he reinvented himself as a jewellery designer creating pieces for Givenchy, Dior, and Balenciaga. He then went on to found his own eponymous fashion house in 1966.

Dogged in his desire to break with convention, Paco was one of the first designers to cast models of colour and soundtrack his fashion shows to music. He debuted his first collection (Twelve Experimental Dresses) in 1964, followed by his breakout collection (Twelve Unwearable Dresses) in 1966 – both of which made full use of the postwar, industrial materials at his disposal, with pieces crafted from wire and glue.

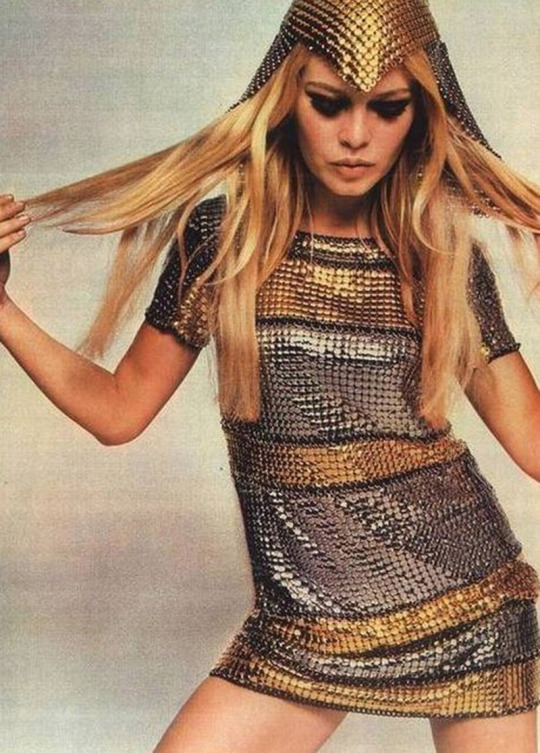

He’d say that “sewing is a bondage” and sell DIY kits to his clients – among them Peggy Guggenheim, Brigitte Bardot, and Françoise Hardy – so they could fashion their own chainmail from discs, rings, and pliers. Those designs, worn by Jane Fonda in Barbarella, have proven a well of inspiration for Julien Dossena, who took over the Paco Rabanne label in 2013.

Though Paco treated fashion as a reaction against the polemics of his day – dressing women in armour needs no explanation – he was a futurist, untethered to the everyday. He retired from fashion in 1999 and while his fragrance imprint continued to be a commercial success, it wasn’t until 2011 that Paco Rabanne (the brand) staged a comeback. Since then, the house has cycled through creative directors Manish Arora, Lydia Maurer, and Dossena, who is compounding Paco’s experimental outlook and chain-link innovations – albeit with a less outré bent.

“Paco” was a daring, revolutionary and provocative vision, conveyed through a unique aesthetic. He will remain an important source of inspiration...

Rest in Power!

Jean Clemmer / Hélène Clemmer-Heidsieck, courtesy of Paco Rabanne,

“unwearable” show pieces from early Paco Rabanne collections, Photo: Courtesy of Paco Rabanne,

Paco Rabanne by Lucille Khornak

Jane Fonda in the 1968 cult-classic science-fiction film Barbarella,

Li Sellgren by Jean-Daniel Lorieux, fashion by Paco Rabanne, L'Officiel, 1970,

Asap Rocky wearing Paco Rabanne in GQ, May 20, 2021,

French singer Francoise Hardy wears Paco Rabanne in 1968,

Brigitte Bardot wearing Paco Rabanne dress, 1968,

Iconic 1969 Chain Shoulder Bag

#art#design#fashion#haute couture#space age#rip#paco rabanne#rip paco rabanne#jane fonda#brigitte bardot#jean clemmer#unwearable#lucille khornak#barbarella#li sellgren#jean-daniel lorieux#asap rocky#francoise hardy#chain#metal#spain#cuervo#legend#iconic#rabaneda

146 notes

·

View notes