#air dryer compressor

Explore tagged Tumblr posts

Text

Difference Between Air Dryer Compressor and Reciprocating Air Compressor

Air compressors are the backbones of modern industry, powering tools and machinery and making them essential in many industries like manufacturing, construction, and healthcare. Among the various options available, an air dryer compressor and a reciprocating air compressor are two popular choices, each with its specific advantages. Understanding their differences is key to choosing the right air dryer for compressor as per your needs. Let’s explore their features, benefits, and applications.

What is an air dryer compressor?

An air dryer compressor is a specialised system designed not only to compress air but also to remove moisture from it. Compressed air naturally contains water vapor, which can lead to rust, corrosion, and damage to tools or processes. An air dryer compressor includes drying mechanisms to deliver moisture-free air. Industries like pharmaceuticals, food processing, and electronics heavily depend on an air dryer compressor for high-quality, clean air that ensures equipment longevity and product safety.

What is a reciprocating air compressor?

A reciprocating air compressor, also called a piston compressor, uses pistons to compress air inside a cylinder. When the piston moves downward, it draws in the air; when it moves upward, it compresses the air and sends it to a storage tank. These compressors are widely recognised for their ability to produce high pressure, making them suitable for tools and applications requiring short bursts of power. Commonly used in automotive workshops, construction sites, and smaller industrial setups, a reciprocating air compressor is ideal for periodic tasks rather than continuous operation.

Key differences between an air dryer compressor and a reciprocating air compressor

Moisture control

Air dryer compressor: Equipped with built-in drying systems, it removes water vapor during the compression process, ensuring clean, dry air. This feature is essential in sensitive industries where moisture can cause significant damage.

Reciprocating air compressor: While it efficiently compresses air, it doesn’t inherently handle moisture removal. Users often need an external air dryer for compressor for moisture control.

Operation and duty cycle

Air dryer compressor: Designed for continuous use, it ensures steady performance and high air quality over extended periods. Ideal for industries requiring 24/7 reliability.

Reciprocating air compressor: Best for short, intermittent tasks. Prolonged use can lead to overheating due to the piston mechanism.

Noise levels

Air dryer compressor: Operates quietly, especially when combined with rotary screw compressors, making it suitable for noise-sensitive environments.

Reciprocating air compressor: Generates more noise due to its piston-driven mechanism, which might require soundproofing in quieter settings.

Applications of an air dryer compressor

An air dryer compressor shines in industries where moisture-free air is necessary. Some key applications include:

Pharmaceuticals: Ensuring contamination-free environments for medicine production.

Food and beverage: Maintaining hygiene and preventing product spoilage.

Electronics manufacturing: Protecting sensitive parts from moisture damage.

Healthcare: Delivering clean, dry air for medical equipment and respiratory devices.

Applications of a reciprocating air compressor

A reciprocating air compressor excels in tasks requiring high pressure for shorter durations. Their common applications include:

Automotive workshops: Powering pneumatic tools like wrenches and spray guns.

Construction sites: Operating nail guns, jackhammers, and drills.

Small manufacturing units: Handling equipment that needs quick bursts of compressed air.

DIY projects: Supporting small-scale projects requiring compressed air tools.

Making the right choice

When selecting between an air dryer compressor and a reciprocating air compressor, consider the following factors:

Air quality needs: For moisture-sensitive tasks, an air dryer compressor is necessary. It ensures efficiency and safeguards equipment.

Usage pattern: For continuous use, an air dryer for compressor is ideal. A reciprocating air compressor works better for periodic tasks.

Environment: If noise is a concern, opt for an air dryer compressor. Reciprocating compressors are more suited to industrial or outdoor settings.

Budget: While air dryer compressors may have higher upfront costs, they save money in the long run by preventing equipment damage. Reciprocating compressors are initially more budget-friendly but might require additional moisture management tools.

Summary

Both an air dryer compressor and a reciprocating air compressor have their strengths and serve specific purposes in various industries. By understanding their differences and considering your operational needs, you can make an informed decision that improves productivity and efficiency. For industries requiring moisture-free air, an air dryer compressor is a clear winner. On the other hand, for high-pressure tasks in smaller setups, a reciprocating air compressor is the go-to choice. Partnering with reliable reciprocating compressor manufacturers in India provides access to robust and efficient systems tailored to your needs. Investing in the right air dryer for compressor not only streamlines your processes but also protects your equipment, ensuring long-term success. Choose wisely and let your operations thrive with the power of efficient air compression systems.

#air dryer compressor#air dryer#air dryer for compressor#air dryers#air dryer supplier#compressor air dryer#reciprocating air compressor#reciprocating air compressors#reciprocating compressor#single stage reciprocating air compressor#reciprocating compressor manufacturers in India

0 notes

Text

Plate Type Heat Exchanger

A Plate Type Heat Exchanger plates are simple to maintain because they can be taken out and cleaned separately. But, since they may gather debris or smell, you should avoid them.

0 notes

Text

Atlas Copco Air Compressor Dealer in Uttar Pradesh - Thermodynamic Services

Welcome to Thermodynamic Services, your trusted partner for top-notch industrial air compressors and compressed air solutions in Uttar Pradesh. As the premier Atlas Copco dealer in the region, we take pride in delivering cutting-edge technology and reliable products to meet your diverse compressed air needs.

Atlas Copco Air Compressors in Uttar Pradesh:

At Thermodynamic Services, we specialize in offering a comprehensive range of Atlas Copco air compressors in Uttar Pradesh. Our commitment to quality and efficiency ensures that your industrial operations run smoothly with the most advanced and reliable compressed air solutions.

Atlas Copco Dealer in Kanpur:

If you are based in Kanpur and searching for a reliable Atlas Copco dealer, look no further than Thermodynamic Services. We bring you the latest models of Atlas Copco air compressors, combining innovation and durability to enhance your industrial processes.

Industrial Air Compressor Manufacturer & Supplier in Kanpur:

As a leading industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services provides customized solutions tailored to meet the unique requirements of your business. Our state-of-the-art compressors are designed to optimize energy efficiency and minimize downtime.

Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:

Thermodynamic Services is your go-to Atlas Copco compressed air dryer dealer in Uttar Pradesh. Our range of air dryers ensures that your compressed air is free from moisture, contaminants, and impurities, guaranteeing the longevity and efficiency of your equipment.

Unmatched Quality and Reliability:

When you choose Thermodynamic Services, you invest in unparalleled quality and reliability. Our partnership with Atlas Copco, a global leader in compressed air technology, ensures that you receive products that adhere to the highest industry standards.

Customer-Centric Approach:

At Thermodynamic Services, customer satisfaction is our priority. Our team of experienced professionals is dedicated to understanding your specific needs and providing tailored solutions. We believe in building lasting relationships with our clients through exceptional service and support.

Conclusion:

For all your industrial air compressor needs in Uttar Pradesh, Thermodynamic Services stands as the preferred choice. As the foremost Atlas Copco dealer in the region, we guarantee top-quality products, unmatched reliability, and a customer-centric approach. Elevate your industrial processes with Thermodynamic Services – your trusted partner for compressed air solutions.

conatct us on 91 78600 24711

#industrial air compressor dealer in uttar pradesh#Atlas Copco Air Compressor#Atlas Copco Air Compressors in Uttar Pradesh:#Atlas Copco Dealer in Kanpur#Industrial Air Compressor Manufacturer & Supplier in Kanpur:#Atlas Copco Compressed Air Dryer Dealer in Uttar Pradesh:#industrial air compressor needs in Uttar Pradesh

5 notes

·

View notes

Text

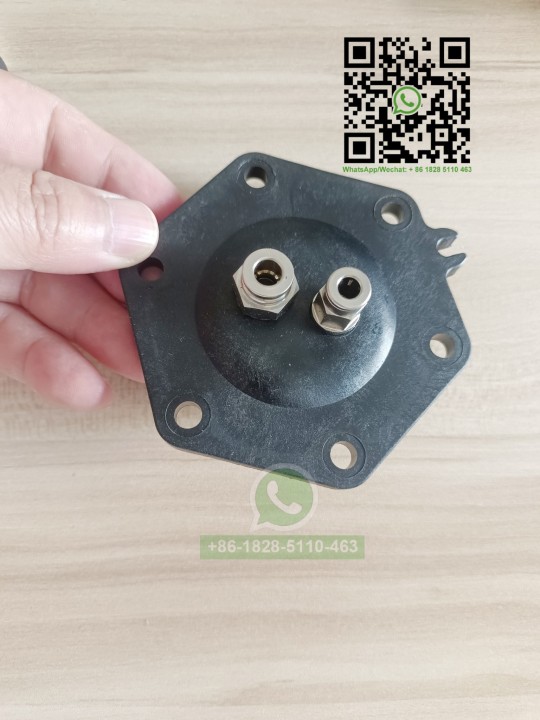

Range rover Sport Air Pump Parts LR3, LR4, RR Sport Air suspension compressor filter dryer tank Hitachi Version Range Rover Air Suspension Compressor Fix Kits Dryer tank plastic cover Hitachi Air Suspension Compressor Dryer Kit For LR3 / (L319) 2005-2009, LR4 / (L319) 2009-2016, Range Rover Sport (L320) 2006-2013 W/O ACE, W/O ACE system

Land-rover Lr3 Range-rover Sport Air Pump Buy Air Suspension Compressor Dryer Kit Compressor For Land-rover Lr3

https://wa.me/8618285110463

https://www.auto-rubbers.com/

#Dryercover

#AirSuspensionproblem #Air_Suspension_Repair #AirShockproblem #ShockAbsorber #Discovery3 #Lr4 #airspringproblems #RepairKits #L319 #L320 #Compressor #AirSuspension #ShockAbsorber #Discovery3 #LandRover #SuspensionPump #Lr4 #RangeRover #replacestrut #repairsuspension #airsuspension

#suspensionstrut

#airshockabsorber

#suspensiondeaire

#luftfederung

#въздушноокачване

#zawieszeniepneumatyczne

#suspensãoaar

#подвеска

#vzduchoveodpruzeni

#luftaffjedring

#lr4 suspension pump#lr4#lr3 suspension compressor#lr3#kaibintech#airsuspension#air suspension#air spring#shock absorber#airbag#air compressor#compressor repair#dryer cover

3 notes

·

View notes

Text

Super Fast Technology: Best Chiller & Air Compressor Solutions

Super Fast Technology: Leading Manufacturer and Supplier of Chiller Plants and Air Compressor Systems in India

Introduction

Super Fast Technology is a renowned name in the field of industrial cooling and air compression solutions. As the Best Chiller Plant Manufacturer in India, the company provides high-quality, energy-efficient, and durable chilling systems that cater to a wide range of industries. Based in Delhi, Super Fast Technology is also recognized as the Best Chiller Plant Manufacturer in Delhi, offering top-tier products with cutting-edge technology.

Chiller Solutions by Super Fast Technology

Super Fast Technology specializes in manufacturing different types of chillers, ensuring effective cooling solutions for various applications. The company is widely recognized as one of the top Screw Chiller Manufacturers in India and Screw Chiller Manufacturers in Delhi, known for providing robust and reliable chillers for industrial processes.

For industries requiring precise temperature control, Super Fast Technology stands out as one of the best Oil Chiller Manufacturers in India and Oil Chiller Manufacturers in Delhi, offering solutions that prevent machinery from overheating and ensure seamless operations. Additionally, the company is a leading Scroll Chiller Manufacturer in India and Scroll Chiller Manufacturer in Delhi, known for its compact, efficient, and eco-friendly cooling systems.

The company also excels as one of the leading Air Cooled Chiller Manufacturers in India and Air Cooled Chiller Manufacturers in Delhi, providing energy-efficient solutions ideal for industries looking to reduce operational costs without compromising performance.

Water Chillers and Water Cooled Condensers

Super Fast Technology has established itself as a prominent Water Chiller Manufacturer in Delhi and Water Chiller Supplier in Delhi, offering high-performance chillers designed for various industrial and commercial applications. Furthermore, the company is recognized as a top Water Cooled Condenser Manufacturer in Delhi, ensuring optimal cooling efficiency with superior technology.

Air Compressor and Air Drying Solutions

Super Fast Technology is also a leader in air compression and drying solutions. As a trusted Refrigerated Air Dryer Supplier in Delhi and Refrigerated Air Dryer Manufacturer in Delhi, the company delivers premium quality air drying systems that remove moisture from compressed air, enhancing productivity and longevity of equipment. Additionally, it is a well-known Air Dryer Manufacturer in Delhi, providing reliable solutions for moisture control in compressed air systems.

For industrial applications requiring compressed air storage, Super Fast Technology offers cost-effective solutions, with competitive Air Compressor Tank Prices in India and Air Compressor Tank Prices in Delhi. The company also specializes in Air Compressor Dryer Systems in Delhi and Air Compressor Dryer Systems in India, ensuring clean and dry air supply for critical operations.

Conclusion

Super Fast Technology continues to set new benchmarks in industrial cooling and air compression solutions. Whether you are looking for the Best Chiller Plant Manufacturer in India, Best Chiller Plant Manufacturer in Delhi, or advanced air drying systems, the company provides industry-leading products with top-notch performance, energy efficiency, and reliability. With a commitment to innovation and quality, Super Fast Technology is the go-to manufacturer and supplier for all your cooling and air compression needs in India.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers in india#Screw chiller manufacturers in delhi#Oil chiller manufacturers in India#Oil chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Water Chiller Supplier in Delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi

0 notes

Text

youtube

Established in the year 2016, Airomach Engineers is one of the leading Manufacturer and Wholesaler of Air Dryer, Air Heater, Water Chiller and much more. In their development process, we assure that only top notch basic material is used by our professionals along with modern tools. Besides this, we check these on a variety of grounds before finally shipping them at the destination of our customers. Working under the mentorship of Mr. Sanehit Bhardwaj (Proprietor), we have acquired a reputed stature in the industry.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers india#Screw chiller manufacturers delhi#Oil chiller manufacturers India#Oil chiller manufacturers delhi#Glycol chiller manufacturers India#Glycol chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Water Chiller Supplier in Delhi#Scroll chiller manufacturers delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Beverage chiller manufacturers in india#Beverage chiller manufacturers in delhi#High pressure air dryer manufacturers in india#High pressure air dryer manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#heat exchanger manufacturer in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi#Youtube

0 notes

Text

In compressed air systems, maintaining clean, dry air is essential to ensure the longevity of equipment and the efficiency of operations. Refrigerated air dryers for air compressors and desiccant air dryers are the two most common types of air dryers used to remove moisture and contaminants from compressed air. These dryers serve specific needs, from moderate moisture removal to ultra-dry air requirements.

0 notes

Text

#High-Performance Air Dryers#Air Compressor Dryers & Filters#Compressed Air Dryers#Air Compressor Dryers

1 note

·

View note

Text

Air Dryer for Compressor for High Quality Air Solution - Chicago Pneumatic

Buy Chicago Pneumatic air dryers for compressors in India. The CPX refrigerant dryer ensures consistent high performance, delivering moisture-free air for capacities ranging from 10 to 3000 CFM. Enquire Now! https://compressors.cp.com/en-in/products/air-treatment_msm_moved/dryers

0 notes

Text

"Air Dryers Explained: Benefits, Types, and Applications for Every Industry" explores the crucial role of air dryers in various sectors. This guide delves into the benefits of using air dryers, such as improving efficiency and preventing equipment damage. It also covers the different types available and their specific applications, providing insights for industries ranging from manufacturing to food processing.

0 notes

Text

Which type air compressor need to Construction industry

Construction workers are the backbone of the modern world, building the structures we live, work, and play. To perform their tasks effectively, they rely on dependable tools and equipment that deliver precision and efficiency. Air compressors are essential for powering various tools and machinery on construction sites. The right air compressor not only makes the work safer, faster, and easier but also ensures constant productivity and quality results. In this article, we’ll explore the types of air compressors best suited for the construction industry and provide practical tips to help you select the perfect one for your needs.

0 notes

Text

Air Dryer Suppliers in India

Buying an Air Dryer: What You Need to Know

Picking the best air dryer from Colt Equipment's (p) Ltd, one of the best Air Dryer Suppliers in India, for your company's requirements is crucial. It can make or break a business, from manufacturing to hospitality.

With so many models, choosing an air dryer from Colt Equipment's (p) Ltd requires careful consideration of several factors. Energy efficiency, capacity, and other factors must be considered before buying. This article will compare the features and benefits of current air dryers from Air Dryer Suppliers in India to help you choose one for your business.

Find out what you need for drying air.

The first step in selecting the best air dryer from Colt Equipment's (p) Ltd for your company is figuring out what kinds of air drying you'll need. The first step is to determine the required material drying frequency, volume, and type. Having this knowledge will allow you to pick the perfect size and model. Think about where you plan on using the dryer and whether you need it whisper-quiet.

Take Your Capacity Needs into Account

Businesses must consider how much air they need to dry when calculating their capacity needs. How many liters of dry air per hour are required? Is the air-drying process continuous, or will it require periodic restarts throughout the day? Businesses must consider how often they must replace desiccant media or filters.

The air dryer's lifespan may change based on the moisture content and volume of the air it is drying. Paying close attention to these nuances will help businesses choose the best system from Colt Equipment's (p) Ltd, the Air Dryer Suppliers in India.

Examine the Price of Repairs and Setup

Budget for repairs and setup before buying an air dryer, as these costs add up quickly. Find a model that fits your needs and budget with a specialist. Make sure the air dryer you want fits your budget by considering installation and maintenance costs. When making a business purchase, consider each component's potential lifespan and the total cost. Businesses that maximize their resources should consider these factors before settling on an air dryer.

Check the Star Ratings for Energy Savings

There are a few important factors for air dryers from Air Dryer Suppliers to remember when determining an air dryer's energy efficiency for commercial purposes.

You can estimate the unit's daily energy consumption from this. Your room size is the most important factor in choosing a model without wasting energy.

Check your local electricity rates to see if energy-saving equipment-using businesses qualify for rebates. Last but not least, check the manufacturer's warranty or guarantee to ensure that any air dryers you buy will have any foreseeable operational issues attended to promptly and affordably.

Research Air Dryer Types

When researching air dryers for your business, many factors must be considered. When buying business equipment, price is always a factor.

Importantly, compare prices between brands and models and understand what features each model offers. Air dryers have different efficiency, noise output, energy-saving settings, and smart technology control systems.

To find the best air dryer for their needs, businesses should consider how they will use their new machine and its features. Based on daily usage and whether larger spaces need multiple units or one powerful machine, air drying machines will vary in size and capacity.

Conclusion

An essential piece of equipment is a commercial air dryer. It helps maintain a healthy and pleasant working atmosphere by reducing airborne particles and humidity. Size, noise level, energy efficiency, cost, and maintenance are some factors to consider when shopping for an air dryer from Colt Equipment's (p) Ltd, one of the best Air Dryer Suppliers.

0 notes

Text

AN OVERVIEW ON MEDICAL AIR PACKAGES

A patient in the hospital who needs assistance breathing, either during surgery or through a ventilator, is administered medical air. Medical Air is defined in National Fire Protection Association (NFPA) Code 99 2018 in 5.1.3.6.1 to have the following characteristics:

It shall be supplied from cylinders, bulk containers, or medical air compressor sources, or it shall be reconstituted from oxygen USP and oil-free, dry nitrogen NF. It shall meet the requirements of medical air USP. It shall have no detectable liquid hydrocarbons. It shall have less than 25 parts per million (ppm) gaseous hydrocarbons. It shall have equal to or less than one milligram per cubic meter (mg/m3) of permanent particulates sized one micron or larger in the air at normal atmospheric pressure. The air is delivered through a distribution piping system that ends with a medical air outlet within the room. Outlet requirements per room are governed by American Institute of Architects (AIA) Guidelines for Design and Construction of Hospitals and Healthcare Facilities.

Equipment is plugged into the medical air outlet to treat the patient. Many studies have been done determining the load required for medical air compressors. The sizing can be calculated using several methods. The U.S. Typical Method is the standard calculation for medical air in the United States. To calculate by this method the following steps are taken:

Count all outlets that will be served by this system by occupancy. Multiply by simultaneous use factor. Add the sum of all occupancy. Add the number of ventilators. This sizing process attempts to size by “worst case scenario,” which means all rooms would be occupied and using some amount medical air. Ventilators being the largest consumer of medical air especially adds to the total. It is highly unlikely all outlets would be used at one time in a facility; however, the facility has to be prepared and equipped for that scenario. This leaves many facilities frustrated with what they consider grossly oversized medical air compressors.

Medical Air Central Supply Systems NFPA 99 5.1.3.6 details the requirements and the limitations of medical air central supply systems and their installation within a healthcare facility in the United States. The defining requirement 5.1.3.6.2 Uses of Medical Air states that medical air sources shall be connected to the medical air distribution system only and shall only be used for human respiration and calibration of medical devices for respiratory equipment.

Medical air cannot be used in central sterile, to run instruments, or any other use outside of patient respiration. Therefore, multiple air compressors are used within a healthcare facility, but this article will only focus on Medical Air Central Supply Systems.

Oil free air compressors are used to eliminate the potential for hydrocarbons. The most common technologies are scroll, reciprocating, and rotary screw air compressors. In addition to the air compressor, the package normally contains aftercoolers, dryers, filters, receiver and monitoring equipment, such as a dewpoint monitor and CO monitor.

Lab Air Compressor Redundancy Requirement: An Important Sizing Factor No one point of failure is allowed to ensure patient safety. NFPA 5.1.3.6.3.9 (B) states that medical air compressors shall be sufficient to serve the peak calculated demand with the largest single air compressor out of service. In no case shall there be fewer than two air compressors.

This means redundancy is required and one air compressor is never allowed. The smallest would be a duplex package. The redundancy also applies to filtration and dryers as well. When sizing an air compressor, it is important to size with the load being maintained even with one unit out of service. Therefore, in a triplex skid, two air compressors can run with one as backup. A quad package can run three and so on. The air compressors will still all run in sequence to maintain even run life on all the air compressors.

An efficient way to meet the peak calculated demand and satisfy the redundancy requirement is with multiplexing smaller horsepower (hp) units. In the past, large industrial air compressors were installed, with large being 30- or 50-hp in medical air applications. This means if one Operating Room is put into use, or one ventilator is brought on-line, a 30-hp air compressor would be started up to meet the demand. This air compressor would run two to three minutes, meet demand, and shut off. This cycle is repeated throughout the life of the unit.

By multiplexing smaller hp air compressors, such as 10- or 15 -hp machines, a facility can reduce their electrical consumption. When a demand is created only one air compressor runs. If that one air compressor cannot meet the demand, then another air compressor can come on and so forth (with one staying off for redundancy). Therefore, the facility is running one 15-hp air compressor versus a 30-hp machine. In the majority of applications, only one air compressor handles the load.

Multiplexing also allows for expandability. Healthcare construction projects are often open-ended leaving flexibility in the services that the hospital is going to provide. Also, due to budget constraints, sometimes space is left shelled for future expansion. Instead of guessing at the future or sizing for future, it is possible to put expandable panels and leave space on skids for future modules. This keeps capital costs down, and the facility will have a clearer understanding of its medical air usage.

Finally, multiplexing multiple scroll air compressors takes dramatically less space, saves considerable money on installations and has lower capital costs than Variable Speed Drive (VSD) rotary screw air compressors. Pattons Medical can have a complete medical air package with multiple scroll air compressors shipped as a complete single point connection package. In new construction, this will save the contractor any additional piping and electrical wiring for components. There would be a braze for the inlet/outlet and one wiring connection. For replacement equipment, the skids can be broken apart to fit through a 30-inch door and have unions for the connections when put in place.

The Ins and Outs of Desiccant Dryer Technology Dryers are an integral part of the medical air compressor package and can have an impact on the sizing and efficiency. To maintain the requirement of a maximum dewpoint of 32 °F at 50 to 55 psi at any level of demand, and allow for flexibility in skid design, desiccant dryers have become the standard for medical air packages. They perform well in low-flow conditions that are common with medical air demand.

Desiccant dryers utilize towers that contain cartridges of activated alumina. The cartridge design versus loose desiccant eliminates dusting from desiccant and is sized based on demand. Therefore, the amount of air purged will be dramatically reduced requiring less demand from the air compressor. Desiccant dryers require a purge to regenerate the desiccant to continue the ability to dry the air. It is imperative for efficiency with medical air to utilize controls for demand-based purging. The dewpoint is monitored through the dewpoint sensor. In demand-based purging, the purge does not take place until the dewpoint reaches 14 °F. This almost eliminates the air compressor running for purge outside of demand. Another benefit is the dryer can be mounted horizontally or vertically to achieve smaller footprints of the overall package.

Meeting the Needs of Smaller Healthcare Facilities During the last 15 years, smaller healthcare facilities have been built to offer less acute services. These facilities are either located on the campus of larger hospitals or found as standalone buildings.

Medical Air dryers For these applications the sizing of the medical air is the same, however, the loads are much smaller. High-pressure manifolds utilizing medical air cylinders are allowed by code to deliver medical air. This requires the owner to make a financial decision of either a larger capital cost of an air compressor or the ongoing operational cost of purchasing medical gas cylinders.

If the owner decides to install a medical air compressor, the space allotted for medical air compressors is usually quite small. The location is also much closer to patients than in a large hospital setting. This led to the scroll type air compressors being used for medical air. Scroll units are much quieter and smaller than either of the reciprocating or screw type. By utilizing vertical tank configurations and appropriately sized desiccant dryers the skids can be as small as three by four feet.

Involve Medical Gas Specialists in the Process It is imperative in a replacement scenario that a facility meet with a medical gas specialist to have a medical gas survey completed. This will confirm the sizing done initially for the facility was accurate and will address any changes in acuity or services since the original air compressor was installed. The medical gas specialist will confirm the outlet counts, interview respiratory therapist, and determine if there are any code issues that will need to be addressed with a replacement. Specifically, that the inlet is code compliant and the master alarm panels have the appropriate points. Oftentimes this is missed and can affect the new air compressor being certified.

0 notes

Text

youtube

Horizontal Air Tanks|Compressed Air Receiver Tank|Masteraire

If you need a compressed air receiver tank with high capacity, check out the air receiver range presented by Masteraire to find the best one for your industrial needs.

0 notes

Text

Air Compressor Parts and Accessories-Evergreen

Evergreen Compressed Air and Vacuum offers reliable and genuine OEM parts & accessories for all major brands of Air Compressors, Vacuum Pumps and Air Dryers at reasonable cost. We offer services in the state of Washington — Seattle, Tacoma, Everett, Kent, Mount Vernon, Olympia, Auburn. Our air compressor parts such as lubricants, valves, separators, belts, couplings, drains and filters are designed to keep your compressor and vacuum systems running at peak performance and reduce the cost of ownership of your compressed air system. Getting air compressor parts you need is as easy as contacting our team of dedicated service engineers. They are trained to solve problems quickly and efficiently.

Brands we offer

ELGi

Sullivan-Palatek

Sullair

Gardner Denver

Quincy

CP

Rogers

FS-Curtis

Ingersoll Rand

Atlas Copco

Vac-u-lok

DV

Saylor-Beall

Champion

Airtech

Beacon Medaes

Busch

Why do you need to buy air compressor spare parts from OEMs?

Every component within an air compressor has a designated service life and undergoes wear and tear over time, necessitating regular maintenance to ensure optimal performance and longevity. While aftermarket replacement parts may be enticing due to lower costs, it’s essential to prioritize sourcing from Original Equipment Manufacturers (OEMs). OEM air compressor parts ensure proper performance levels and minimize equipment failure risk .

OEM air compressor spare parts offer the following benefits

Durability OEM replacement components offer premium quality assurance and guarantee longevity. Using OEM parts minimises the risk of equipment failure and production performance decline, ensuring consistent performance.

Improved Safety OEMs adhere to industry safety standards, providing enhanced protection for users and minimizing occupational hazards. Third party air compressor spare parts may compromise safety and pose risks to health and the environment.

Efficiency OEM air compressor parts deliver optimal performance over a longer period, reducing downtime and the need for frequent repairs. Investing in OEM parts ensures uninterrupted operation and reduces maintenance demands.

Stringent Quality Standards OEM parts undergo rigorous endurance tests and quality inspections to ensure consistent performance and reliability. Choosing OEM air compressor parts guarantees adherence to quality standards and reliable operation.

Warranty Protection OEM parts ensure warranty coverage and protect your investment. Other parts may void warranties and leave you vulnerable to costly repairs and downtime.

Air compressor parts that need replacement include

Dust filters and oil separators These components are crucial in safeguarding the compressor against damage and performance degradation caused by internal contaminants. Dust particles from inlet pose a significant threat to compressor rotors, leading to reduced efficiency and premature wear.

Air filter Swapping your air compressor’s line filter cartridge with counterfeit alternatives compromises filtration efficiency, resulting in pressure drops and compromised air quality. Genuine airline filters ensure optimal filtration, reducing the need for frequent replacements and minimizing lifecycle costs.

Lubricating oil Lubricating oil is essential for maintaining system efficiency and preventing equipment breakdowns. Poor-quality oil can lead to sediment buildup and corrosion risks, undermining compressor performance. Using genuine oil supplied by the manufacturer ensures effective lubrication and maximises equipment longevity.

It’s essential to procure spare parts and air compressor accessories exclusively from OEMs and reputable suppliers and maintain a service kit containing essential tools for safe part replacement. Talk to our parts specialist today.

Other products

Air Compressors

Vacuum Pumps

Air Dryers

0 notes

Text

youtube

Super Fast Technology is a manufacturer of compressed air and cooling system since 2013. An ISO 9001:2015 certified company, we specialise in design, engineering and fabrication of compressed air dryers, filters, air coolers and receivers.

#heat exchanger manufacturer in delhi#Air Compressor Tank Price in India#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Refrigerated Air Dryer Supplier in Delhi#Water Chiller Supplier in Delhi#Air Dryer System in Delhi#Air Compressor Tank Price in delhi#Water Cooled condenser manufacturers in delhi#water chiller manufacturers in delhi#Youtube

0 notes