#air dryer system for air compressors

Explore tagged Tumblr posts

Text

youtube

Horizontal Air Tanks|Compressed Air Receiver Tank|Masteraire

If you need a compressed air receiver tank with high capacity, check out the air receiver range presented by Masteraire to find the best one for your industrial needs.

0 notes

Text

Super Fast Technology: Best Chiller & Air Compressor Solutions

Super Fast Technology: Leading Manufacturer and Supplier of Chiller Plants and Air Compressor Systems in India

Introduction

Super Fast Technology is a renowned name in the field of industrial cooling and air compression solutions. As the Best Chiller Plant Manufacturer in India, the company provides high-quality, energy-efficient, and durable chilling systems that cater to a wide range of industries. Based in Delhi, Super Fast Technology is also recognized as the Best Chiller Plant Manufacturer in Delhi, offering top-tier products with cutting-edge technology.

Chiller Solutions by Super Fast Technology

Super Fast Technology specializes in manufacturing different types of chillers, ensuring effective cooling solutions for various applications. The company is widely recognized as one of the top Screw Chiller Manufacturers in India and Screw Chiller Manufacturers in Delhi, known for providing robust and reliable chillers for industrial processes.

For industries requiring precise temperature control, Super Fast Technology stands out as one of the best Oil Chiller Manufacturers in India and Oil Chiller Manufacturers in Delhi, offering solutions that prevent machinery from overheating and ensure seamless operations. Additionally, the company is a leading Scroll Chiller Manufacturer in India and Scroll Chiller Manufacturer in Delhi, known for its compact, efficient, and eco-friendly cooling systems.

The company also excels as one of the leading Air Cooled Chiller Manufacturers in India and Air Cooled Chiller Manufacturers in Delhi, providing energy-efficient solutions ideal for industries looking to reduce operational costs without compromising performance.

Water Chillers and Water Cooled Condensers

Super Fast Technology has established itself as a prominent Water Chiller Manufacturer in Delhi and Water Chiller Supplier in Delhi, offering high-performance chillers designed for various industrial and commercial applications. Furthermore, the company is recognized as a top Water Cooled Condenser Manufacturer in Delhi, ensuring optimal cooling efficiency with superior technology.

Air Compressor and Air Drying Solutions

Super Fast Technology is also a leader in air compression and drying solutions. As a trusted Refrigerated Air Dryer Supplier in Delhi and Refrigerated Air Dryer Manufacturer in Delhi, the company delivers premium quality air drying systems that remove moisture from compressed air, enhancing productivity and longevity of equipment. Additionally, it is a well-known Air Dryer Manufacturer in Delhi, providing reliable solutions for moisture control in compressed air systems.

For industrial applications requiring compressed air storage, Super Fast Technology offers cost-effective solutions, with competitive Air Compressor Tank Prices in India and Air Compressor Tank Prices in Delhi. The company also specializes in Air Compressor Dryer Systems in Delhi and Air Compressor Dryer Systems in India, ensuring clean and dry air supply for critical operations.

Conclusion

Super Fast Technology continues to set new benchmarks in industrial cooling and air compression solutions. Whether you are looking for the Best Chiller Plant Manufacturer in India, Best Chiller Plant Manufacturer in Delhi, or advanced air drying systems, the company provides industry-leading products with top-notch performance, energy efficiency, and reliability. With a commitment to innovation and quality, Super Fast Technology is the go-to manufacturer and supplier for all your cooling and air compression needs in India.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers in india#Screw chiller manufacturers in delhi#Oil chiller manufacturers in India#Oil chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Water Chiller Supplier in Delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi

0 notes

Text

youtube

Established in the year 2016, Airomach Engineers is one of the leading Manufacturer and Wholesaler of Air Dryer, Air Heater, Water Chiller and much more. In their development process, we assure that only top notch basic material is used by our professionals along with modern tools. Besides this, we check these on a variety of grounds before finally shipping them at the destination of our customers. Working under the mentorship of Mr. Sanehit Bhardwaj (Proprietor), we have acquired a reputed stature in the industry.

#Best chiller plant manufacturer in India#Best chiller plant manufacturer in delhi#Screw chiller manufacturers india#Screw chiller manufacturers delhi#Oil chiller manufacturers India#Oil chiller manufacturers delhi#Glycol chiller manufacturers India#Glycol chiller manufacturers delhi#Refrigerated Air Dryer Supplier in Delhi#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Water Chiller Supplier in Delhi#Scroll chiller manufacturers delhi#Water Cooled condenser manufacturers in delhi#air dryer manufacturer in delhi#Scroll chiller manufacturers in india#Scroll chiller manufacturers in delhi#Beverage chiller manufacturers in india#Beverage chiller manufacturers in delhi#High pressure air dryer manufacturers in india#High pressure air dryer manufacturers in delhi#Air cooled chiller manufacturers in india#Air cooled chiller manufacturers in delhi#heat exchanger manufacturer in delhi#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Air Compressor Tank Price in India#Air Compressor Tank Price in delhi#Youtube

0 notes

Text

Efficient Pieces Cutting Machine : Top Cashew Processing Equipment Supplier in India

Introduction In the modern cashew processing industry, having efficient and automated equipment is crucial for meeting growing demand and improving productivity. A pieces cutting machine plays a vital role in the precision cutting of cashews into smaller pieces, ensuring uniformity and minimal wastage. At Delta Cashew Machines, we specialize in offering state-of-the-art pieces cutting machines designed to cater to high-volume operations, helping cashew processors achieve maximum efficiency with minimal manual intervention.

1. The Importance of Cashew Pieces Cutting in the Industry

Cashew pieces are widely used in food products, including snacks, desserts, and confectioneries. Therefore, the process of cutting whole cashew kernels into uniform pieces is crucial for food processors. Having a reliable pieces cutting machine allows for precision cutting and processing, contributing to the overall quality of the final product.

Some of the main challenges in cutting cashews include:

Uniformity in size

Minimizing breakage and wastage

Maintaining the original taste and texture

Delta Cashew Machines understands these challenges, and our cutting machines are engineered to deliver high performance with advanced automation.

2. Features of the Pieces Cutting Machine

Our pieces cutting machine offers multiple features that ensure the highest standards of cashew processing. Some of these features include:

Precision Cutting Mechanism: The machine is designed with advanced cutting blades that ensure accurate size distribution of cashew pieces.

Adjustable Cutting Sizes: Users can adjust the cutting settings to achieve different sizes based on customer needs or production requirements.

High Efficiency: Capable of processing large batches of cashews, ensuring minimal downtime and faster throughput.

User-Friendly Operation: The machine is easy to operate, making it ideal for both small-scale and large-scale processing units.

Stainless Steel Construction: Built with food-grade stainless steel to ensure durability and hygiene.

Low Maintenance: The machine is designed for ease of maintenance with minimal downtime.

3. Benefits of Using a Pieces Cutting Machine

When investing in a pieces cutting machine, businesses can expect several benefits that improve operational efficiency and product quality. These include:

Increased Productivity: Automation speeds up the cutting process, reducing manual labor and enabling continuous operation.

Consistent Quality: The uniformity of the cut cashew pieces ensures consistent product quality, which is essential for food manufacturers.

Minimal Waste: Advanced cutting technology minimizes wastage and ensures that every part of the cashew is utilized effectively.

Cost-Efficiency: By reducing manual labor and improving yield, businesses can optimize their overall production costs.

Customization: Adjustable settings allow processors to create products tailored to specific market demands.

4. How the Pieces Cutting Machine Works

The pieces cutting machine at Delta Cashew Machines is designed to provide seamless and efficient processing. Here’s an overview of the workflow:

Feeding the Cashews: Whole cashew kernels are fed into the machine via an automated feeder.

Cutting Process: The kernels pass through precision blades that cut them into uniform pieces based on the pre-set size.

Sorting: Once cut, the cashew pieces are sorted and conveyed for further packaging or processing, depending on the production line setup.

The simple yet highly efficient mechanism ensures minimal handling and maximum output.

5. Customization and Flexibility for Different Production Needs

Every cashew processing facility has unique requirements, and a standard solution may not always be suitable. Delta Cashew Machines offers customization options for the pieces cutting machine, allowing businesses to modify various aspects of the machine to meet their production needs. Customization includes:

Blade Configurations: Different blade settings allow for varying cut sizes.

Capacity Adjustments: Machines can be tailored to accommodate different production volumes.

Automation Integration: The pieces cutting machine can be integrated with other automated systems for a seamless production line.

This flexibility ensures that processors can scale their operations efficiently.

6. Applications of the Pieces Cutting Machine

The pieces cutting machine is versatile and can be used in various industries where cashew pieces are required. Key industries include:

Food Processing: Cashew pieces are commonly used in snacks, desserts, confectionery, and other food products.

Retail Packaging: Many businesses package cashew pieces for retail sale, offering consumers ready-to-eat nuts in different sizes.

Catering and Hospitality: Cashew pieces are widely used by chefs and foodservice providers for garnishing and preparing meals.

The machine is suitable for small, medium, and large cashew processing facilities.

7. Why Choose Delta Cashew Machines for Cashew Processing?

Delta Cashew Machines is recognized as a leading supplier of cashew processing equipment in India, offering cutting-edge solutions for all stages of cashew processing. Here are a few reasons why businesses prefer Delta Cashew Machines:

Innovative Technology: We continually update our machines with the latest technology to ensure maximum efficiency and productivity.

Robust Support: Our after-sales service and technical support ensure that clients can rely on their equipment for long-term use.

Tailored Solutions: We understand that each business is unique, and we offer customized solutions that align with specific production needs.

Competitive Pricing: Our machines are priced competitively, offering great value for businesses looking to upgrade their processing capabilities.

8. Maintenance and After-Sales Support

Investing in a pieces cutting machine requires ongoing maintenance to ensure optimal performance. At Delta Cashew Machines, we offer comprehensive maintenance plans that help extend the life of the equipment. Our after-sales support includes:

Routine Check-ups: Regular maintenance services to ensure the machine operates at peak efficiency.

Technical Assistance: Our technical support team is available to assist clients with any troubleshooting or operational issues.

Replacement Parts: We provide genuine replacement parts to ensure the longevity and functionality of the machine.

9. Future Trends in Cashew Processing

With the growing demand for cashew products worldwide, the cashew processing industry is rapidly evolving. Future trends include:

Increased Automation: Automation will continue to play a significant role in improving productivity and reducing manual labor.

Sustainability: Businesses are adopting sustainable practices in processing, focusing on reducing waste and energy consumption.

Advanced Technology: The use of advanced AI and machine learning will further improve the precision and efficiency of machines like the pieces cutting machine.

Conclusion

Investing in a pieces cutting machine from Delta Cashew Machines is an excellent decision for businesses looking to enhance their cashew processing capabilities. With advanced technology, customization options, and exceptional after-sales support, we ensure that your production runs smoothly and efficiently. Our machines help processors meet the growing demand for cashew pieces while maintaining the highest standards of quality and consistency.

For more information about our pieces cutting machine or other cashew processing equipment, visit our website or contact us directly.

#Fully Automatic Cashew Processing Plant#Automatic Cashew Shelling Machine#Automatic cashew Shelling scoping System#Cashew Peeling Machine#Air Compressor#Cashew Dryer#Raw Cashew Grader#Cashew Kernel Grader#Cashew Steam Cooker System#Raw Cashew Calibrator#Cashew Steamer#Cashew Destoner

0 notes

Text

youtube

We recently supplied a 40 CFM air dryer to Flexible Steel Lacing Co Pvt Ltd at their Chennai, Tiruvallur plant, complete with a pre-air filter, carbon air filter, and necessary connection accessories. This air dryer system is designed to remove moisture and contaminants from compressed air, ensuring optimal equipment performance and longevity. By delivering clean, dry air, it reduces maintenance costs, prevents corrosion, and enhances overall operational efficiency. Our comprehensive compressed air solutions are tailored to meet the unique needs of industrial applications, ensuring reliability and efficiency.

#dryer#air dryer#air compressor#compressor service#dryer sales#dryer filter#pre filter#carbon filter#pneumatic systems#pneumatic compressor service#compressor sales#pneumatic blowers#chennai#manufacture#sales & service#www.svblowers.in#Youtube

0 notes

Text

Oil Injected Screw Compressors

What you should know About Oil Injected Screw Compressors

Let's say it's a hot day, and you're driving your car. Warning lights on your dashboard suggest it's time for an oil change. Your car's engine is overheating. Changing your car's oil filters through the engine reduces engine temperature. Oil lubricates the engine, making the car run more smoothly and dependably.

Now visualise a five-foot-wide by six-foot-high rectangular air compressor equipment in a factory producing furniture. The production process will go faster and more easily if oil is used to lubricate the air compressor motor. Since oil is cooling, the compressed air won't get too hot. The oil lubricates the engine and lets the compressor work, enabling fast, accurate, and energy-efficient furniture making.

Here we have an example of the use of Oil Injected Screw Compressors. Many different types of businesses and services couldn't exist without oil-injected compressors, so it's clear how crucial these pieces of equipment are.

What is an oil-injected Screw Compressors

Oil Injected Screw Compressors (oil-flooded or oil-lubricated compressors) from Sarvap Solution, lubricate the air compression chamber, components, and seal compressed air. This apparatus injects the compressor bearings and the compression chamber with liquid. The compressed air and the moving parts of the compressor element are cooled and lubricated by this system. The compressor also lessens inlet leakage on the return side. Oil is the most often injected liquid because of its excellent lubricating and sealing qualities. When the oil temperature rises too high, it is diverted to a cooler within the compressor.

What is the function of an oil-injected screw compressor?

Compressors of the oil-injected rotary screw variety do so by injecting a liquid into the compression chamber to do several things, including cool the air being compressed there, lubricate the compressor's working parts, and reduce the likelihood of leaks from returns into the chamber during discharge. Water and other polymers are occasionally used instead of oil due to their lack of lubricating and sealing qualities. After being filtered and cooled, the oil is recycled into the process. Depending on the intended application, the compressed air may still need to pass through a chiller before use.

Just what it is that makes an oil-injected compressor worth the money!

Low-temperature operation

Oil Injected Screw Compressors is preferred because it reduces the risk of overheating. When oil is added, it circulates the motor to prevent overheating. This method is effective in minimising downtime without excessively heating the workplace.

Like all of the machinery of Sarvap Solution, our oil-injected air compressors are designed for maximum dependability.

Maintain operation of your rotary screw compressor

Keep your Oil Injected Screw Compressors operating smoothly with the help of the filter system included with all oil-injected air compressors. They have valves that can detect changes in oil temperature and redirect it accordingly. When properly assembled, these devices can continuously operate at high air pressure for extended periods.

Conclusion

Our Oil Injected Screw Compressors are built to last and may be used in various settings. We hope you will feel more at ease in your search for the appropriate tools now that you can access online resources like this article. We have a rotary screw option that works for you, with a range of diameters, monitoring instruments, and motors. Sarvap Solution provides more than only oil-injected air compressors.

#Oil Injected Screw Compressors#PLC Panel in Ghaziabad#Compressor Monitoring System#Air Dryer in Ghaziabad#Energy Monitoring System supplier#MCC Panel in Ghaziabad

0 notes

Text

Dental Air Compressors Manufacturers Pattons Medical USA

Pattons Medical Dental Air Compressors is 100% Oil-Free, Dry Air (Dew Point -25 degrees or lower). Primarily used for use in blowing away saliva so teeth are dry.

#Medical Air System#Medical Air Compressor#Medical Scroll Compressor#Medical Reciprocating Compressor#Air Desiccant Dryers#Medical vacuum pump#Rotary Claw Vacuum Pump#vfd vacuum pump#oil less vacuum pump#oil less rotary vane vacuum pump#Lubricated Rotary Vane Vacuum Pump#medical vacuum filter#Medical Gas Pipeline#Medical equipment parts#Medical Gas Manifolds#Medical gas zone valve box#Medical Gas Alarm Panel#Medical Gas Outlets#Medical gas control panel#lab air compressor#Industrial Reciprocating Compressors#Industrial Scroll Compressors#Dental Air Compressors#lubricated rotary vane vacuum pump#lab vacuum pump

0 notes

Text

So the funny thing last night:

Scheduled Shutdown namin dahil meron maintenance sa Turbine, and yep, going smooth lahat. Papatay na talaga ang planta, tapos BIGLA NAGBLACKOUT! Anak ng…. Bali imbis na smooth down na e nagloko yung feedback power sa labas (bali kumukuha na kami ng power sa NGCP since hindi na nakakapagproduce ng kuryente)

Tapos ayun na nga, nung nagkaroon ng power, paranf nag-startup lang din kami uli. Binuksan lahat ng operating machines na need para sa pagpatay ng tama ng planta (from Cooling water pumps, Air compressor, Air dryer, Bottom Ash Removal System, Start-up Diesel Burner, Chillers, Makeup-Condenser-&Boiler Feed pump) grabe ang lala. Imbis na agad makakapg-pahinga e nawalan ng pahinga buong duty 🫡🥲💀💀💀💀

Yeah masaya sa Powerplant. Masaya…. 😊😊😊😊💀💀💀💀at pagod

Pero ang ganda ng view na total blackout sa planta.

9 notes

·

View notes

Text

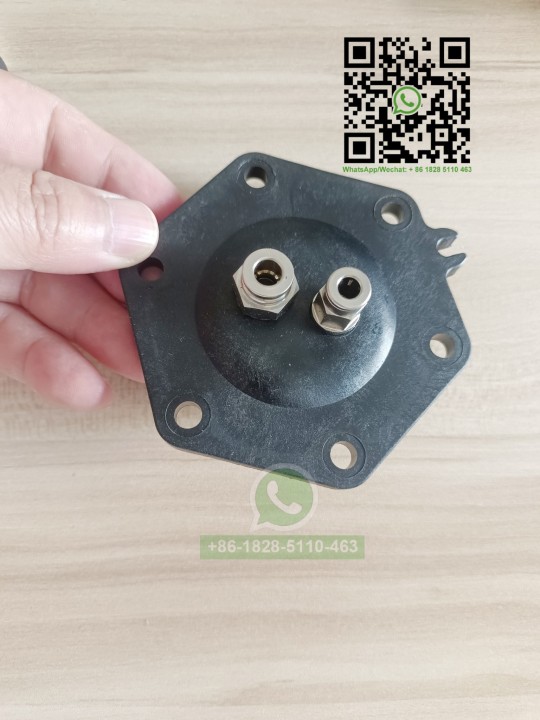

Range rover Sport Air Pump Parts LR3, LR4, RR Sport Air suspension compressor filter dryer tank Hitachi Version Range Rover Air Suspension Compressor Fix Kits Dryer tank plastic cover Hitachi Air Suspension Compressor Dryer Kit For LR3 / (L319) 2005-2009, LR4 / (L319) 2009-2016, Range Rover Sport (L320) 2006-2013 W/O ACE, W/O ACE system

Land-rover Lr3 Range-rover Sport Air Pump Buy Air Suspension Compressor Dryer Kit Compressor For Land-rover Lr3

https://wa.me/8618285110463

https://www.auto-rubbers.com/

#Dryercover

#AirSuspensionproblem #Air_Suspension_Repair #AirShockproblem #ShockAbsorber #Discovery3 #Lr4 #airspringproblems #RepairKits #L319 #L320 #Compressor #AirSuspension #ShockAbsorber #Discovery3 #LandRover #SuspensionPump #Lr4 #RangeRover #replacestrut #repairsuspension #airsuspension

#suspensionstrut

#airshockabsorber

#suspensiondeaire

#luftfederung

#въздушноокачване

#zawieszeniepneumatyczne

#suspensãoaar

#подвеска

#vzduchoveodpruzeni

#luftaffjedring

#lr4 suspension pump#lr4#lr3 suspension compressor#lr3#kaibintech#airsuspension#air suspension#air spring#shock absorber#airbag#air compressor#compressor repair#dryer cover

3 notes

·

View notes

Text

Why Choose Gajjar Compressor ?

Why Choose Gajjar Compressor ?

When it comes to air compressor solutions, choosing the right manufacturer is crucial for efficiency, reliability, and long-term cost savings. Gajjar Compressor has established itself as a leading name in the industry, providing top-quality compressors designed for diverse applications. But why should you choose Gajjar Compressor over other brands? Let’s explore the key reasons why Gajjar Compressor stands out in the global market.

1. Unmatched Quality and Performance

Gajjar Compressor is committed to manufacturing air compressors that exceed industry standards. Every product undergoes rigorous quality control checks to ensure superior performance, durability, and efficiency. Whether you need a compressor for industrial, medical, or commercial applications, you can rely on Gajjar for top-notch quality.

2. Wide Range of Air Compressors

One of the biggest advantages of choosing Gajjar Compressor is the extensive product range. The company offers a variety of air compressors, including:

Screw Compressors – High efficiency and long-lasting performance for industrial applications.

Reciprocating Compressors – Robust and reliable options for various uses.

Oil Free Dental Compressors – Designed for medical and dental applications where pure, contamination-free air is needed.

Vacuum Pumps – Ideal for industries that require vacuum solutions.

Air Dryers and Filters – Ensuring moisture-free, clean air for better compressor efficiency.

3. Cutting-Edge Technology

Gajjar Compressor stays ahead of the competition by continuously investing in research and development. The company integrates advanced technology into its compressors to enhance efficiency, reduce energy consumption, and extend the lifespan of the machines. With state-of-the-art designs and innovative features, Gajjar products offer maximum performance with minimum maintenance.

4. Energy-Efficient Solutions

Energy efficiency is a major factor when selecting an air compressor. Gajjar Compressor designs products with energy-saving mechanisms to help businesses reduce operational costs. With features like variable speed drives and advanced cooling systems, these compressors consume less power while delivering optimal output.

5. Cost-Effective Pricing

Affordability without compromising quality is one of the key reasons why businesses choose Gajjar Compressor. The company offers competitive pricing, making it possible for industries of all sizes to access high-quality air compressors within their budget.

6. Customization to Meet Your Needs

Different industries have different requirements when it comes to air compressors. Gajjar Compressor understands this and offers customizable solutions tailored to meet specific needs. Whether you require modifications in power, size, pressure levels, or additional features, Gajjar can provide a solution that fits perfectly.

7. Global Reach and Strong Distribution Network

With a strong global presence, Gajjar Compressor serves clients worldwide. The company has a well-established distribution network that ensures timely delivery and excellent service, no matter where your business is located.

8. Reliable After-Sales Support

Buying an air compressor is an investment, and proper maintenance is essential for long-term performance. Gajjar Compressor provides excellent after-sales support, including installation guidance, technical assistance, and spare parts availability. Their dedicated team is always ready to help customers with any queries or maintenance needs.

9. Compliance with International Standards

Gajjar Compressor manufactures its products according to international quality and safety standards. The compressors meet ISO and CE certifications, ensuring they are safe, efficient, and reliable for use in various industries.

10. Durability and Longevity

Gajjar compressors are built to last. Made with high-quality materials and cutting-edge engineering, these compressors are designed to withstand tough working conditions and continuous operation, providing long-term reliability.

11. Low Maintenance Requirements

Another significant advantage of choosing Gajjar Compressor is the low maintenance requirement. The machines are designed with user-friendly maintenance features, reducing downtime and operational disruptions. This means businesses can save on maintenance costs and keep their operations running smoothly.

12. Trusted by Leading Industries

Gajjar Compressor has earned the trust of leading industries across multiple sectors, including:

Manufacturing – Powering machinery and tools efficiently.

Automotive – Used in painting, air tools, and assembly lines.

Healthcare – Essential for medical and dental air applications.

Food & Beverage – Ensuring contamination-free air supply.

Textile & Printing – Providing precision air solutions for seamless operations.

13. Sustainability and Eco-Friendly Practices

Environmental responsibility is a priority for Gajjar Compressor. The company incorporates sustainable practices in its manufacturing process, using eco-friendly materials and energy-efficient technologies to reduce carbon footprints.

14. Strong Research & Development (R&D) Team

The company has a dedicated R&D team that continuously works on developing new technologies and improving existing products. This focus on innovation ensures that customers get the latest and most efficient air compressor solutions.

15. Customer-Centric Approach

Gajjar Compressor prioritizes customer satisfaction above everything else. The company takes the time to understand each client’s needs and provides solutions that add value to their operations. Personalized consultations, prompt responses, and a commitment to excellence make Gajjar a preferred choice.

Conclusion: The Best Choice for Your Air Compressor Needs

Choosing the right air compressor manufacturer is critical for productivity and efficiency. Gajjar Compressor stands out as a trusted name in the industry, offering high-quality products, advanced technology, excellent customer support, and cost-effective solutions. Whether you need a reliable compressor for industrial, medical, or commercial applications, Gajjar Compressor is the brand you can trust.

Invest in performance, durability, and efficiency—choose Gajjar Compressor today!

More information visit a website : www.aircompressorindia.com

0 notes

Text

The Functionality of Air Dryer for Your Air Compressor: What You Need to Know

Optimal performance of your air compressor is the key to success in any industrial setup. Among the very crucial parts to ensure you receive optimized compressed air is an air dryer. It helps to remove moisture from compressed air; in turn, doing so eliminates the potential for equipment damage and sustains efficiency. Knowing how an air dryer works for an air compressor will give you improved reliability and longevity for your system.

Air Dryer Function in Compressor

An air dryer is designed to remove moisture from the compressed air that your compressor generates. In addition, dampness within compressed air may cause rust, corrosion, and many other functional problems in a system. Removing this moisture thus helps an air dryer prolong equipment life, reduce maintenance costs, and guarantee the quality of your final products. This is why a high-quality air dryer is indeed an essential requirement for facilities that have installed compressors.

Factors for the Selection of Air Compressors for Your Industry

Capacity and Pressure Requirements: Firstly, decipher the capacity that your company would need regarding airflow and pressure. Choose an air dryer that meets these requirements to give you efficient performance.

Type of Air Dryer: Multiple types are available, such as refrigerated, desiccant, or membrane air dryers. Each type has its pros and cons, which vary with the degree of required dryness and the working environment of your industry.

Energy Efficiency: Last but not least, look for models that operate energy-efficiently. It can lead to huge savings in your overall costs and go a long way in making your operation sustainably run.

The Final Thought The functionality of an air dryer is immense in ensuring that the air compressor works well. If you want to buy this powerful device for your business’s needs, make sure to keep the aforementioned pointers in mind. You can also browse MasterAire's website. You can opt for their 5 HP Rotary Screw Air Compressor Complete System that comes with exceptional features- high-quality air filters, 54 CFM refrigerated air dryer, centrifugal automatic moisture drain waves, and more.

0 notes

Text

Air Solutions Canada

29 Innovation Dr, Dundas, ON L9H 7L8, Canada (905) 628-2662 https://airsolcan.com/

With more than two decades experience of recognizing as well as successfully carrying out options to all areas of pneumatically-driven and compressed air systems, indicates-- we absolutely "get it".

The extent of our offering consists of compressed air systems, air filtration items, substitute components, filter cleansing and more. The largest Canadian distributor of Kaeser compressed air tools, Air Solutions materials, leas and services piston as well as rotating screw air compressor tools.

Our turn-key remedies are just measured up to by the superior solution we provide. Our requirement for solution is swiftly coming to be the criteria through which all others are gauged.

At no charge to you, have actually a qualified Air Solutions Rep conduct a website study of your facility-- begin to recognize the possible cost savings today. SERVICES: Comprehensive Service, Air Demand Analysis, Energy Efficiency, Save On Energy, Installation, Kaeser Air Treatment, 24-7 Sudden Service

https://www.linkedin.com/company/air-solutions/about/

#Portable air compressor#Compressed air dryer#Kaeser#Compressed air systems#Save on energy#Air compressor parts#Air compressor repair service#Air compressor filter#Industrial air compressors#Air compressor for sale

1 note

·

View note

Text

youtube

Super Fast Technology is a manufacturer of compressed air and cooling system since 2013. An ISO 9001:2015 certified company, we specialise in design, engineering and fabrication of compressed air dryers, filters, air coolers and receivers.

#heat exchanger manufacturer in delhi#Air Compressor Tank Price in India#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Refrigerated Air Dryer Supplier in Delhi#Water Chiller Supplier in Delhi#Air Dryer System in Delhi#Air Compressor Tank Price in delhi#Water Cooled condenser manufacturers in delhi#water chiller manufacturers in delhi#Youtube

0 notes

Text

In compressed air systems, maintaining clean, dry air is essential to ensure the longevity of equipment and the efficiency of operations. Refrigerated air dryers for air compressors and desiccant air dryers are the two most common types of air dryers used to remove moisture and contaminants from compressed air. These dryers serve specific needs, from moderate moisture removal to ultra-dry air requirements.

0 notes

Text

5 Essential Steps for a Best oil free air compressor installation

Installing an oil free air compressor is crucial for businesses that require clean, contaminant-free compressed air for their operations. Whether you’re using it in the medical, food processing, or electronics industry, a proper installation ensures optimal performance, efficiency, and longevity. Once a compressor is purchased, the next step is installation. Following the manufacturer’s guidelines is essential to ensure durability, optimal performance, and energy efficiency. Unlike traditional compressors, an oil free high pressure air compressor eliminates the risk of oil contamination, making it ideal for sensitive applications. In this guide, we’ll explore five essential steps to install an oil free air compressor efficiently and effectively.

Step-by-step guide to installing oil free air compressor:

Choose the right location

Selecting the perfect place for an oil free air compressor is the first and most essential step in the installation process. A well-chosen location enhances the unit’s efficiency and lifespan while reducing maintenance requirements.

Factors to consider:

Ventilation: Ensure the area is well-ventilated to prevent overheating and allow proper airflow around the compressor.

Temperature control: Keep the compressor in an area with stable temperatures to avoid performance fluctuations.

Accessibility: Allow enough space for maintenance and repairs, ensuring technicians can easily access key components.

Noise reduction: Place the compressor in a soundproofed or less-occupied area to minimize noise disruptions.

Proximity to application: Install the unit closer to the point of use to minimize pressure drops and energy loss.

Prepare a solid foundation:

A stable foundation is important to avoid vibrations, noise, and potential damage to an oil free air compressor. An improper base can lead to misalignment and wear over time.

Key preparations:

Level surface: Ensure the foundation is flat and even to avoid unnecessary pressure on the compressor.

Vibration pads: Install anti-vibration support or pads to absorb shock and reduce operational noise.

Load-bearing capacity: Ensure that the surface can support the compressor’s weight, preventing potential structural damage.

Clear surroundings: Remove obstacles around the unit to allow for free movement of air and personnel.

Electrical and piping connections:

Proper electrical and piping installations are important to ensure an oil free high pressure air compressor runs smoothly without disruptions.

Electrical setup:

Voltage requirements: Confirm that the power supply matches the compressor’s voltage and phase requirements.

Dedicated circuit: Use a separate circuit to prevent power fluctuations and ensure stable operation.

Grounding: Proper grounding is essential to avoid electrical hazards and equipment damage.

Circuit breakers: Install the correct size breakers to handle power surges without tripping.

Piping considerations:

Pipe material: Choose corrosion-resistant materials such as aluminum or stainless steel.

Correct sizing: Use pipes of proper diameter to minimize pressure loss.

Air dryers and filters: Install necessary filtration systems to remove moisture and contaminants from the air supply.

Leak inspection: Regularly check for leaks to avoid energy wastage and maintain efficiency.

Conduct initial testing and calibration:

Before setting an oil free air compressor into full operation, thorough testing and calibration are necessary to ensure optimal performance.

Steps to follow:

Pressure testing: Run the compressor and monitor pressure levels to ensure they meet operational needs.

Noise levels: Check for abnormal noises that might indicate issues, such as loose fittings or misalignments.

Temperature monitoring: Watch the unit’s temperature to confirm it works within the recommended range.

Adjust settings: Calibrate pressure controls, timers, and auto-shutdown features according to your application.

Load testing: Simulate real-world usage to confirm the system can handle demand effectively.

Specify a maintenance routine:

Regular maintenance is key to keeping an oil free air compressor in top condition and avoiding unexpected breakdowns.

Maintenance tips:

Routine inspections: Schedule weekly and monthly checks for wear and tear.

Filter replacements: Replace air filters and separators periodically to maintain air purity.

Lubrication: Even though it’s oil-free, some components might require periodic lubrication to prevent wear.

Drain condensate: Ensure proper drainage of moisture to avoid internal damage.

Professional servicing: Engage with certified technicians for periodic thorough inspections.

Summary:

Installing an oil free air compressor is essential for ensuring efficient performance, energy savings, and long-term reliability. Following these five essential steps—choosing the right location, preparing a solid foundation, ensuring proper electrical and piping connections, conducting initial testing, and specifying a maintenance routine can optimize oil free high pressure air compressor’s performance and extend its lifespan. Investing time in a careful installation process will ultimately pay off in improved efficiency and reduced downtime for your operations. By following these guidelines, businesses can ensure they get the most out of an oil free air compressor, providing a clean and efficient air supply for years to come.

0 notes

Text

Energy Monitoring System Supplier

Benefits of Implementing an Energy Monitoring System

Without a dedicated energy management specialist or system, energy management is one of the most difficult areas to cut facility costs, especially for larger buildings like schools, hospitals, and industries. An energy management system (EMS) consists of a suite of computerized tools used by operators of electric utility networks for the purposes of monitoring, controlling, and optimizing the operation of the generating and transmission system. An EMS supplied by Energy Monitoring System Supplier controls and monitors energy-using appliances such as air conditioners, heaters, fans, pumps, dampers, and lights.

While a fully effective EMS requires an initial investment, it will pay for itself over time through lower utility costs, total spending, and a higher return on investment (ROI). Read on to learn about your company's top four gains with an EMS system.

The Four Most Important Benefits of Having an Energy Monitoring System Spend less

Saving money on heating, cooling, lighting, and water is just the beginning when you install an EMS. An EMS supplied by Energy Monitoring System supplier keeps track of usage data over time to ensure you have access to your building's energy usage history at any time. It stores it in a central digital repository. It will help you plan for energy costs depending on seasonality, climate, and other factors.

Increase employee happiness

Comfortable working conditions have been shown to promote productivity and employee satisfaction. Consistent lighting and temperature management contribute to energy-efficient workplaces that boost morale and productivity.

Optimally utilize existing resources

An effective EMS supplied by Energy Monitoring System supplier has a significant impact on productivity in the workplace as a whole. When you cut down on energy waste and running costs, you free up capital for things like advertising, employee pay, and inventory.

Enhance Return on Investment

Reduced power output during peak hours, the availability of revenue-generating programs, and the ability to pinpoint energy leaks are just a few of how an EMS supplied by Energy Monitoring System supplier can help you save money. With these benefits, it's hard to imagine a scenario in which an EMS installation doesn't pay for itself.

You can save money and energy with the help of Sarvap Solution.

To assist your company in saving energy and money, we offer Energy Management solutions tailored to your specific needs. The Sarvap Solution can help your business reduce energy use and associated costs. We can make it simple for you to track and report on the consumption of your building's electricity, gas, and water by implementing a metering system that is both accurate and reliable.

Advantages include

Streamlined web-based access to BAS resource management, reporting, and monitoring;

A unified interface for managing and reporting on multiple buildings regardless of location;

Streamlined multi-tenant building monitoring, reporting, and utility billing; and

Analytical utility reporting for a deeper understanding of your building's energy consumption.

Your facilities and finance teams will be able to save money and reduce wasteful energy consumption with the help of our energy monitoring system. Contact Sarvap Solution immediately so the Energy Monitoring System supplier can begin working on a bespoke answer to your energy management needs.

#PLC Panel in Ghaziabad#Compressor Monitoring System#Air Dryer in Ghaziabad#MCC Panel in Ghaziabad#Energy Monitoring System supplier

0 notes