#advanced manufacturing techniques

Explore tagged Tumblr posts

Text

Why SBJ Expert in Rotavator Part Manufacturers in Punjab Are Farmer's First Choice

Introduction to SBJ Nirmal Products

SBJ Nirmal Products has become synonymous with excellence in rotavator parts manufacturing. Established with a vision to empower farmers with reliable and high-performance equipment, SBJ has carved a niche in the agricultural industry. Their dedication to innovation, quality, and affordability has earned them the trust of farmers across Punjab and beyond. This article delves into the reasons why SBJ is the farmer’s first choice for rotavator parts in Punjab.

Punjab—A Hub for Agriculture

The Importance of Punjab in Indian Agriculture

Punjab, known as the "Granary of India," is vital to the country’s agricultural economy. The state’s fertile lands and advanced farming techniques make it a leader in crop production, especially wheat and rice. This agricultural prowess demands equally robust machinery and tools to maintain efficiency and productivity.

Role of Rotavators in Farming

Rotavators are indispensable for modern farming. They prepare the soil by breaking it down into fine particles, ensuring better aeration and moisture retention. For such critical operations, high-quality rotavator parts are essential, as they directly influence the performance and durability of the equipment.

What Makes Rotavator Parts Crucial for Farmers?

Ensuring Efficient Farming Practices

Rotavator parts, such as blades and stub axles, are at the heart of efficient farming. They reduce the time and effort required for soil preparation, allowing farmers to focus on other vital tasks.

Challenges with Subpar Parts

Farmers often face issues like frequent breakdowns and reduced efficiency when using low-quality parts. These problems not only increase costs but also disrupt farming schedules. High-quality components from SBJ address these challenges by offering durability and reliable performance.

SBJ Nirmal Products: A Pioneer in Rotavator Parts Manufacturing

The Journey of Excellence

With decades of experience, SBJ Nirmal Products has established itself as a trusted name in the agricultural sector. Their journey is marked by a commitment to understanding and addressing the evolving needs of farmers.

Innovation and Growth

From introducing innovative designs to setting benchmarks in quality, SBJ continues to lead the way in rotavator parts manufacturing. Their growth is a testament to their dedication to excellence.

Diverse Range of Rotavator Parts by SBJ Nirmal Products

Key Products Offered

SBJ Nirmal Products boasts an extensive range of rotavator parts designed to cater to various farming needs. These include:

Rotavator Blades: Known for their precision and durability.

Stub Axles: Engineered for heavy-duty operations.

Crown Pinions: Ensuring smooth and efficient power transmission.

Custom Solutions for Farmers

Each product is crafted with the specific requirements of farmers in mind, ensuring optimal performance and longevity.

Advanced Manufacturing Techniques at SBJ

Cutting-Edge Technology

SBJ’s manufacturing facilities are equipped with the latest technology. From computer-aided design (CAD) to automated assembly lines, every aspect of production is optimized for precision and efficiency.

Focus on Quality Assurance

Their advanced techniques ensure that each component meets stringent quality standards, delivering unparalleled reliability and performance.

Quality Standards That Set SBJ Apart

Adherence to ISO Certifications

SBJ Nirmal Products follows strict quality control measures, including ISO certifications. These standards guarantee that their products meet global benchmarks.

Rigorous Testing Processes

Each rotavator part undergoes rigorous testing to ensure it can withstand the demands of modern farming practices.

Affordable Solutions for Farmers

Cost-Effective Pricing

Understanding the financial constraints of farmers, SBJ offers competitively priced products without compromising on quality. This makes their parts accessible to a broader audience.

Value for Money

Farmers benefit from the exceptional durability and performance of SBJ’s parts, ensuring long-term savings and productivity.

Strong Distribution Network Across India and Beyond

Presence Across Key Regions

SBJ’s robust distribution network ensures their products reach farmers in every corner of Punjab and other agricultural hubs across India.

Expanding Internationally

Their exports to countries like Bangladesh, Nepal, and Sri Lanka highlight their commitment to serving the global farming community.

Farmer-Centric Approach

Understanding Farmer Needs

At SBJ, the farmer is at the center of every decision. The company’s products are designed to address real-world challenges faced by farmers.

Dedicated Customer Support

SBJ’s customer support team is always ready to assist farmers, ensuring their needs and concerns are promptly addressed.

Why Farmers Trust SBJ Nirmal Products

Testimonials and Success Stories

Farmers consistently praise SBJ for their reliable and high-performing products. Testimonials highlight how SBJ’s parts have transformed farming practices and increased productivity.

Building Long-Term Relationships

SBJ values its partnerships with farmers, fostering trust and loyalty through consistent quality and support.

Environmental Responsibility

Commitment to Sustainability

SBJ Nirmal Products prioritizes eco-friendly manufacturing practices, reducing their environmental footprint while supporting sustainable agriculture.

Promoting Green Farming

By producing durable and efficient parts, SBJ helps farmers adopt practices that are both productive and environmentally friendly.

Comparison with Competitors

Key Differences

SBJ’s emphasis on innovation, affordability, and farmer satisfaction sets them apart from competitors.

Competitive Advantages

Their focus on quality and customer-centric solutions ensures their products consistently outperform others in the market.

Future Plans and Innovations by SBJ

Expanding Product Lines

SBJ is continuously investing in research and development to introduce new and improved rotavator parts.

Global Market Expansion

Plans for entering new international markets reflect SBJ’s ambition to become a global leader in rotavator parts manufacturing.

Conclusion: Why SBJ Is the Farmer's First Choice

SBJ Nirmal Products’ unwavering commitment to quality, innovation, and affordability makes them the preferred choice for farmers. By continuously evolving to meet the needs of modern agriculture, SBJ ensures that farmers can rely on their products for enhanced productivity and efficiency. Choose SBJ Nirmal Products—the trusted partner for all your rotavator part needs.

#SBJ Nirmal Products#rotavator parts#rotavator part manufacturers#Punjab agriculture#high-quality rotavator parts#farmer's first choice#agricultural equipment#rotavator blades#stub axles#crown pinions#durable rotavator parts#cost-effective farming solutions#sustainable farming#Indian agriculture#trusted agricultural products#advanced manufacturing techniques

0 notes

Text

Emerging Materials in Metal Processing: Beyond the Conventional

The constant quest for better, stronger, and more versatile materials has led the metal processing industry into a new era of innovation. Emerging materials, from advanced alloys to metal matrix composites, are opening up possibilities for applications that were once thought impossible.

Spotlight on Emerging Materials:

High-Entropy Alloys (HEAs): These novel alloys, made from five or more elements in equal or near-equal proportions, offer exceptional strength, durability, and resistance to wear and corrosion.

Metal Matrix Composites (MMCs): Combining metals with ceramic or carbon fibers, MMCs provide a unique balance of lightweight and high strength, ideal for aerospace and automotive applications.

Shape Memory Alloys (SMAs): Known for their ability to return to their original shape after deformation, SMAs are finding uses in medical devices, aerospace, and robotics.

Advantages and Challenges:

Enhanced Properties: These materials offer superior mechanical and thermal properties, opening up new engineering possibilities.

Sustainability: Some emerging materials can be produced with less energy or from more abundant resources, offering a path to more sustainable manufacturing.

Processing Complexity: The advanced properties of these materials often come with challenges in processing, requiring innovative techniques and technologies.

Conclusion

The exploration of emerging materials in metal processing is not just about pushing the boundaries of science and engineering. It’s about reimagining what’s possible in technology, transportation, and even daily life. As we continue to uncover the potential of these materials, the future of metal processing looks brighter and boundlessly innovative.

Original content: https://quickmetals.com/emerging-materials-in-metal-processing-beyond-the-conventional/

#Innovative Metal Materials#Advanced Manufacturing Techniques#Metal Processing Innovations#Next-Gen Metal Alloys

0 notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

IoT Solutions in Manufacturing Solutions by Mobiloitte

#Advanced Manufacturing Solutions#Manufacturing Innovation#Manufacturing Technology#Smart Manufacturing#Industrial Automation#Manufacturing Efficiency#Production Optimization#Digital Manufacturing#Manufacturing Industry Solutions#Robotics in Manufacturing#AI in Manufacturing#Manufacturing Process Improvement#IoT in Manufacturing#Manufacturing Software#Global Manufacturing Innovation#Advanced Production Techniques.

0 notes

Text

A company making wooden wind turbine blades has successfully tested a 50-meter-long prototype that’s set to debut soon in the Indian and European markets.

Last year, the German firm Voodin successfully demonstrated that their laminated-veneer timber blades could be fabricated, adapted, and installed at a lower cost than existing blades, while maintaining performance.

Now, Voodin has announced a partnership with the Indian wind company Senvion to supply its 4.2-megawatt turbines with these wooden blades for another trial run.

Wind power has accumulated more than a few demerit points for several shortfalls in the overall industry of this fossil-fuel alternative.

Some of these, such as the impact on bird life, are justified, but none more so than the fact that the turbine blades are impossible or nearly impossible to recycle, and that they need to be changed every 25 years.

Wind turbine blades are made from a mixture of glass and carbon fiber heated together with sticky epoxy resin, and these materials can’t be separated once combined, which means they go into landfills or are incinerated when they become too battered to safely operate.

GNN has reported that folks will occasionally find second-life value in these giant panels, for example in Denmark where they are turned into bike shelters. In another instance, they’re being used as pedestrian bridges.

But there are way more wind turbine blades being made every year than pedestrian bridges and bike shelters, making the overall environmental impact of wind power not all green.

“At the end of their lifecycle, most blades are buried in the ground or incinerated. This means that—at this pace—we will end up with 50 million tonnes of blade material waste by 2050,” Voodin Blade Technology’s CEO. Mr. Siekmann said recently. “With our solution, we want to help green energy truly become as green as possible.”

The last 15 years have seen rapid growth in another industry called mass timber. This state-of-the-art manufacturing technique sees panels of lumber heat-pressed, cross-laminated, and glued into a finished product that’s being used to make skyscrapers, airports, and more.

At the end of the day though, mass timber products are still wood, and can be recycled in a variety of ways.

“The blades are not only an innovative technological advancement but a significant leap toward sustainable wind production,” said Siekmann, adding that this isn’t a case of pay more to waste less; the blades cost around 20% less than carbon fiber.

Additionally, the added flexibility of wooden blades should allow for taller towers and longer blades, potentially boosting the output of turbine by accessing higher wind speeds.

Now partnered with Voodin, Senvion will begin feasibility analysis in the next few months, before official testing begins around 2027.

#good news#wind turbines#wind power#environmentalism#science#environment#fossil fuel alternatives#mass timber#recycling

11K notes

·

View notes

Text

Experience the convergence of innovation and excellence with Kay2 Xenox. Together, let’s build a brighter, more sustainable tomorrow. for details visit Kay2 Blog

#Advanced Construction Technology#Innovative Steel Solutions#Hexagonal Molecular Bonding#High-Strength TMT Bars#Modern Construction Materials#Cutting-Edge Manufacturing Techniques#High-Rise Construction Safety#kay2 xenox tmt#kay2 steel

0 notes

Video

youtube

Mastering Stainless Steel Heat Exchanger Tube Expansion | SINOAK Machinery

Video Description:

Take a deep dive into the world of precision manufacturing with SINOAK as we explore the expansion process of stainless steel heat exchanger tubes. This video provides an inside look at how our advanced equipment and innovative techniques deliver consistent, high-quality results for the HVAC industry.

Video Highlights:

Introduction to Tube Expansion: Learn about the importance of the tube expansion process in manufacturing efficient, durable stainless steel heat exchangers.

Live Demonstration: Watch as our equipment expertly expands stainless steel tubes to create a perfect fit, ensuring optimal heat transfer and reliability.

Precision Engineering: Explore the design and engineering principles behind our tube expander that make it suitable for various stainless steel tube sizes and applications.

Client Success Stories: Hear from our satisfied clients about how this tube expansion technology has improved their manufacturing processes, resulting in better performance and cost savings.

Future Innovations: Discover upcoming enhancements and technological advancements SINOAK is developing to further revolutionize tube expansion in the heat exchanger industry.

Why Choose SINOAK:

Advanced Technology: Our tube expander uses the latest technology to achieve precision tube expansion for stainless steel heat exchangers.

Quality Assurance: Each expanded tube undergoes rigorous quality checks to ensure the highest level of reliability and durability.

Custom Solutions: Our equipment is customizable to meet specific production requirements, enabling manufacturers to achieve their unique production goals.

Stay Connected:

Find out more about our innovative equipment at [https://allsayok.com/].

Reach us directly with inquiries or requests at [[email protected]].

Follow us on WhatsApp and WeChat at +8615688803399 to stay updated on the latest in industrial manufacturing.

Experience the future of tube expansion for stainless steel heat exchangers with SINOAK. Don't forget to like, share, and subscribe for more industry insights and manufacturing technology updates.

#youtube#Stainless Steel Heat Exchanger Tube Expansion Process SINOAK Machinery HVAC Equipment Production Advanced Manufacturing Techniques Industria

0 notes

Text

"For [Tanner] Green, the chief engineer at Not a Wheelchair, this is one of the thousand complications standing between his team and a rather lofty goal: upending the manual wheelchair marketplace.

If you’ve heard of Not a Wheelchair, it’s likely because of its owners, Zack Nelson, the star of the 8.8-million-subscriber YouTube channel JerryRigEverything, and his wife Cambry, a para and manual wheelchair user. The Nelsons got into the mobility equipment business a few years ago when they released The Rig, an electric, adaptive off-road device with a simple yet robust and functional design priced significantly lower than anything else on the market. Now, they’re bringing that same ethos to manual wheelchairs.

Not a Wheelchair aims to offer a base-model, custom manual wheelchair at a similar or better quality than most of the insurance-approved wheelchairs in the U.S. for $999.

Yes, that’s just under $1,000 for everything — wheels, handrims, tires, side guards and rigid, angle-adjustable backrest included. And the company plans to have a turnaround time of weeks, rather than the monthslong slog that it typically takes from order to delivery.

When I first heard about this, it sounded awesome and a bit far-fetched. It’s hard to find a pair of quality wheelchair wheels for less than $500. Same with a rigid backrest. How were they going to offer both, plus a custom wheelchair frame without compromising on quality? I drove to their headquarters in Utah to find out...

So how does Not a Wheelchair’s base model chair stack up to other options on the market? I hate to sound like a preacher, but … it’s totally reasonable! It hits the mark of being at least as good, if not better, than the majority of insurance-approved wheelchairs in the U.S.

Touring the factory, I saw other prototypes scattered all around the facility. There’s a beefier, four-wheel drive version of The Rig that the company just launched. There’s a track wheelchair that’s still in development. It’s clear that Not a Wheelchair doesn’t intend to stop at a simple, manual wheelchair. Inexpensive components, more advanced electric off-road devices, power assist, it’s all on the table. “We’re just really excited to see where this leads,” says Green."

youtube

-Article and video via New Mobility, October 1, 2024

#wheelchair#mobility aid#wheelchair user#disabilties#disability#disabled#accessibility#mobility support#good news#hope#Youtube

3K notes

·

View notes

Text

I think 'degrowth' as a rhetoric is flawed, because it fails to correspond with the direction that sustainable development must take on the local scale - a massive increase in technological advancement and deployment, such that inefficient techniques forced into continuance by impoverishment can be phased out and overcome. Peasants living alongside a polluted river and subsisting off drought-withered, runoff-poisoned crops do not need 'degrowth', not even upstream - they need agricultural price controls, mechanisation, and advanced scientific institions that can make decontamination and reclamation possible. The vast majority of the world needs (and rightfully expects) their liberation to come with an upsurge of political, economic, technological, and scientific growth. The imperial core, where this rhetoric apparently finds its niche, will not be let off the hook - your automotive plants cannot simply be destroyed, the technology and expertise they sequester would be the lifeblood of millions, if and when they are re-tooled to manufacture tractors and trolleybusses. We must redirect and channel the growth and progress of human society, not attempt to hinder or reverse it - reaction in the strictest sense.

580 notes

·

View notes

Text

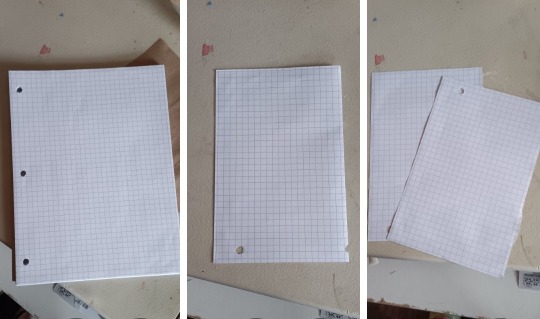

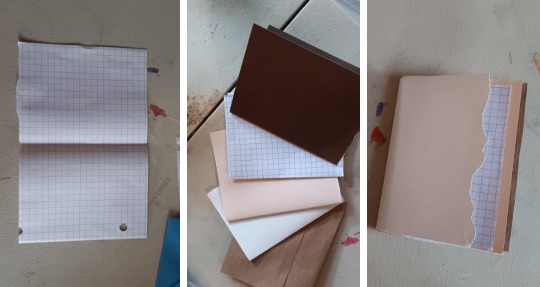

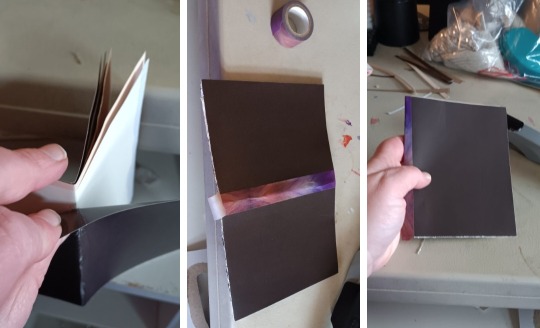

Multi-paper junk mini journal tutorial (low spoons version)

Last night, I mentioned that I like my blank books to have a combination of different papers: colored paper for sketching, blank paper for writing, dotted paper for lists, graph paper for schematics and maps, but there arent many manufacturers that make this. So I just make them myself.

And yall wanna know how to do that.

GREAT!

Here's the easy version. This is for:

-I want this for me, NOW, and I don't care what it looks like because I'm gonna cover it in stickers, and it's only going to be a few pages long. If it lasts a week, I'm happy.

You will need:

- desired papers, 8.5x11 inch regular ass sizes

- a piece of card stock or a thicker paper.

- stapler

- washi tape (optional)

- probably scissors

STEP 1

Take a piece of paper. Fold it in half. Tear or cut the paper along the fold line so you have two half sheets of paper.

If you want a larger book, you can just fold it in half and the book will be 8.5×5 instead of 5x3.25.

STEP 2

Fold the half sheets in half and crease them. Repeat this for every sheet you intend on using for the inside of your journal.* Try not to do more than 8 papers because it'll put stress on the stapler. The papers should now fit inside of each other.

*you could, if pressed, fold them all together in one big group. This is faster, however- if you've ever had a handmade zine that doesn't close cleanly it's likely that they stapled it together without creasing. To each their own. I don't run your life.

If there is excess on the ends that makes the book uneven, feel free to chop it off at this point.

STEP 3

Repeat step 2, but with the thicker paper, which is now your book cover.

STEP 4

Find the centerfold- which is the middle piece of paper. Lay it flat and make sure all the papers and the cover line up.

TIME TO MAKE FRIENDS WITH STAPLER!

Ah, yes- the zine-stitch. Three staples to hold it all together, one in the center and 2 an inch from the top and bottom. If you are doing a larger size, you may need more staples.

You can staple from the inside or you can flip it over and staple it from the spine. Stapling from the spine will make it smoother on the outside so if you're carrying it in your pocket it won't catch threads.

But sometimes stapling from the inside is the only method that works. I've got a fix for you at the end.

Stapling is easy because it's a fast fix, but you may find yourself wasting staples because they don't go all the way through. This can be that the paper is too thick or that there's too many papers. I have a more complicated version of this that's suited to this situation, which I'll write later.

Other, more obvious solution: better staples, better stapler. But I don't have that.

You can call yourself done now, or...

OPTIONAL STEP 5

If you stapled from the centerfold or if you plain don't like the way your spine looks, we're gonna use some washi tape.**

Gently find an unstapled flap in the cover and separate it so you can get some washing tape to adhere to the inside.

Run it along the spine with the book flattened.

Adhere it to the inside of the cover at the bottom and then fold.

**an advanced technique for this when you don't have washi tape: cut a strip of contrasting paper at least 1 inch thick and 2 inches longer than the spine (so in this case it would be 1 inch by 7 inches.) Coat the back of this paper with glue and then use in the same way the washi is shown. This will require extra curing time and you will want to put something heavy on top as it dries. Washi is just easier.

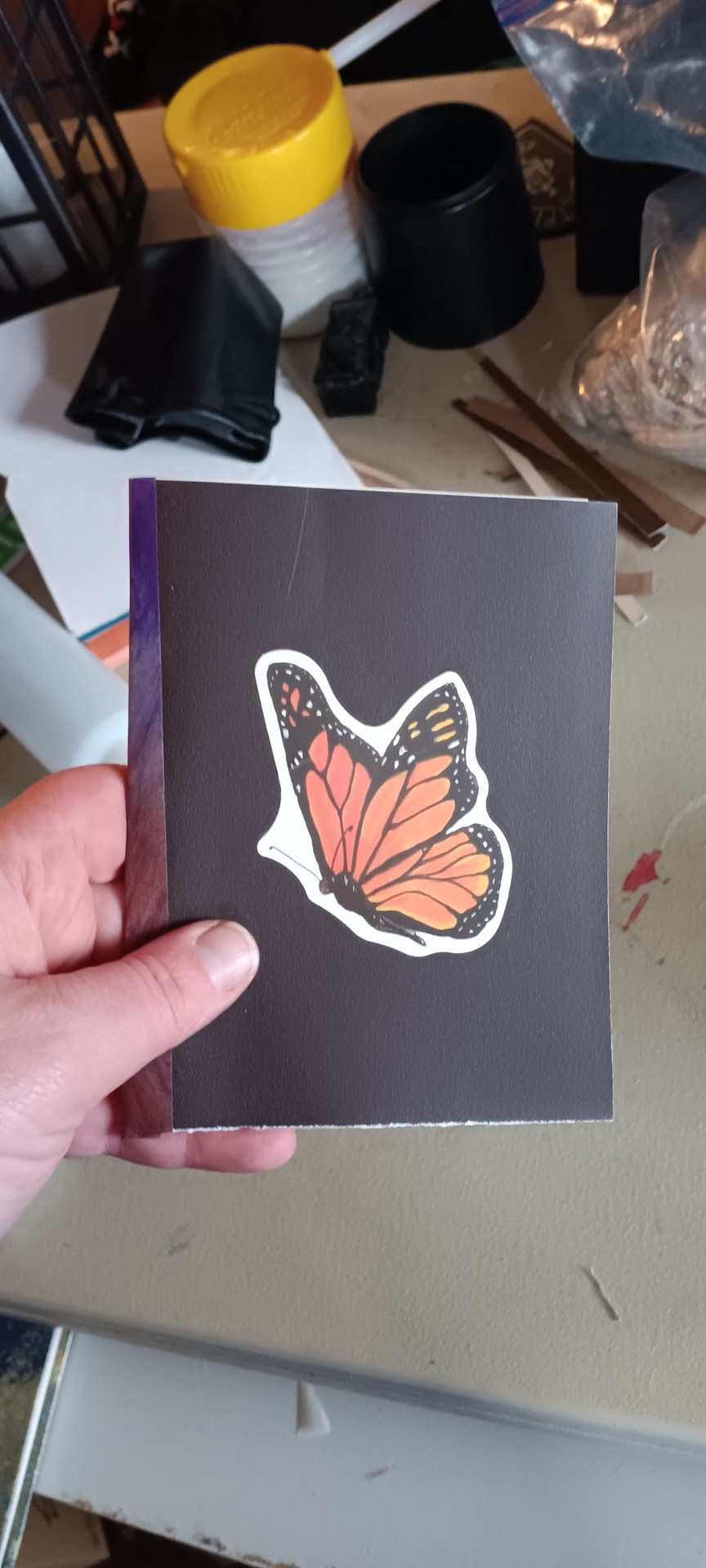

Now slap a sticker on it.

Nice!

And now you've got a little journal. Does it look great? Who cares? You don't have to look all over for a piece of graph paper when you wanna draw a map of something while you're out doing stuff.

It took me longer to write the tutorial than it did to make the thing. The hardest part was getting the staples to behave.

I have a higher spoons version that I will write up later, but this is the punkass way of doing something for yourself.

UPDATE: The tutorial for the nicer version is available here!

185 notes

·

View notes

Text

Matt Wuerker. Politico

* * * *

LETTERS FROM AN AMERICAN

March 11, 2025

Heather Cox Richardson

Mar 12, 2025

The stock market continued to fall today. The Dow Jones Industrial Average fell another 478 points, or 1.14%; the S&P 500 fell almost 0.8%; and the Nasdaq Composite fell almost 0.2%. The S&P 500 briefly held its own in trading today, but then Trump announced on his social media platform that he was going to double the tariffs on steel and aluminum from the new 25% rates to a 50% rate on Canada and might increase tariffs to “permanently shut down the automobile manufacturing business in Canada.”

Stocks fell again.

Unable to admit that he might be wrong, President Donald Trump is doubling down on the policies that are crashing the economy. In addition to his tariff threats, he also reiterated that “the only thing that makes sense is for Canada to become our cherished Fifty First State,” an outrageous position that he suddenly began to advance after the 2024 presidential election and which has Canadians so furious they are boycotting U.S. goods and booing the Star-Spangled Banner.

More than 100 top business leaders met with Trump today to urge him to stop destabilizing what had been a booming economy with his on-again-off-again tariffs. Mark Zandi, chief economist of Moody’s Analytics, told Jeff Stein and Isaac Arnsdorf of the��Washington Post that in private, “[b]usiness leaders, CEOs and COOs are nervous, bordering on unnerved, by the policies that are being implemented, how they’re being implemented and what the fallout is. There’s overwhelming uncertainty and increasing discomfort with how policy is being implemented.”

The extreme unpredictability means that no one knows where or how to invest. Market strategist Art Hogan told CNN’s Matt Egan, “This market is just blatantly sick and tired of the back and forth on trade policy.” Yesterday, Delta Air Lines cut its forecasts for its first-quarter revenue and profits by half, a sign of weakening corporate and consumer confidence and concerns about the safety of air travel. Today, Southwest Airlines and United Airlines cut their forecasts, and American Airlines forecast a first-quarter loss.

When he talked to reporters, Trump reasserted that he intends to do what he wants regardless of the business leaders’ input. “Markets are going to go up and they’re going to go down, but you know what, we have to rebuild our country. Long-term what I’m doing is making our country strong again.” White House press secretary Karoline Leavitt advised, “If people are looking for certainty, they should look at the record of this president.”

Not everyone will find that suggestion comforting.

Trump backed off on his threat to raise the tariffs on Canadian steel and aluminum to 50%, but went ahead with his threat to place 25% tariffs on all imported steel and aluminum products. Those tariffs took effect at midnight.

In the face of his own troubles, Trump’s sidekick billionaire Elon Musk is also escalating his destructive behavior. Yesterday Musk’s social media platform X underwent three separate outages that spanned more than six hours. Lily Jamali and Liv McMahon of the BBC reported that Oxford professor Ciaran Martin, former head of the United Kingdom’s National Cyber Security Center, said that the outages appear to have been an attack called a “distributed denial of service,” or DDoS, attack. This is an old technique in which hackers flood a server to prevent authentic users from reaching a website.

"I can't think of a company of the size and standing internationally of X that's fallen over to a DDoS attack for a very long time," Martin said. The outage "doesn't reflect well on their cyber security." Without any evidence, Musk blamed hackers in Ukraine for the outages, an accusation Martin called “pretty much garbage.”

Four days ago, another of Musk’s SpaceX rockets exploded after takeoff, and now SpaceX’s Starlink internet service is facing headwinds. In February, Mexican billionaire Carlos Slim canceled his collaborations with Starlink after growing tensions with Musk culminated with Musk alleging on X that Slim is tied to organized crime. The loss of that deal cost Musk about $7 billion in the short term, but more in the long term as Slim will work with European and Chinese companies in 25 Latin American countries rather than Starlink. Slim has said he would invest $22 billion in those projects over the next three years.

Also in February, after U.S. negotiators threatened to cut Ukraine’s access to the 42,000 Starlink terminals that supply information to the front lines, the European Commission began to look for either government or commercial alternatives. The European Commission is made up of a college of commissioners from each of the 27 European Union countries. It acts as the main executive branch of the European Union.

On Sunday, Musk posted: “[M]y Starlink system is the backbone of the Ukrainian army. Their entire front line would collapse if I turned it off.” Poland pays for about half the Starlink terminals in Ukraine, about $50 million a year. Poland’s minister of foreign affairs, Radosław Sikorski, responded that “if SpaceX proves to be an unreliable provider we will be forced to look for other suppliers.” “Be quiet, small man,” Musk replied. “You pay a tiny fraction of the cost. And there is no substitute for Starlink.”

After all the tariff drama with Canada, last week Ontario also cancelled a deal it had with Starlink.

But perhaps the biggest hit Musk has taken lately is over his Tesla car brand. On February 6, Musk’s younger brother Kimbal, who sits on Tesla’s board, sold more than $27 million worth of shares in the company. Tesla chair Robyn Denholm sold about $43 million worth of Tesla stock in February and recently sold another $33 million. Tesla CFO Vaibhav Taneja has sold $8 million worth over the past 90 days. Yesterday, board member James Murdoch sold just over $13 million worth of stock.

Fred Lambert of Electrek, which follows the news about electric vehicles and Tesla, noted that Tesla stock dropped 15% yesterday, “down more than 50% from its all-time high just a few months ago.” “Tesla insiders are unloading,” he concluded.

Tesla sales are dropping across the globe owing to the unpopularity of Musk’s antics, along with the cuts and data breaches from his “Department of Government Efficiency.” Protesters have been gathering at Tesla dealerships to express their dismay. While the protests have been peaceful, as Chris Isidore of CNN reports, there have also been reports of vandalism. Tesla owners are facing ridicule as protesters take out their anger toward Musk on his customers, and at least one competitor is working to lure consumers away from Musk’s brand by offering a discount to Tesla owners.

Trump has jumped to Musk’s defense, posting just after midnight this morning that “Elon Musk is ‘putting it on the line’ in order to help our Nation, and he is doing a FANTASTIC JOB! But the Radical Left Lunatics, as they often do, are trying to illegally and collusively boycott Tesla, one of the World’s great automakers, and Elon’s ‘baby,’ in order to attack and do harm to Elon, and everything he stands for. They tried to do it to me at the 2024 Presidential Ballot Box, but how did that work out? In any event, I’m going to buy a brand new Tesla tomorrow morning as a show of confidence and support for Elon Musk, a truly great American.”

Indeed, today Trump used the office of the presidency to bolster Musk’s business. Teslas were lined up at the White House, where Trump read from a Tesla sales pitch—photographer Andrew Harnik caught an image of his notes. And then the same man who gave a blanket pardon to those convicted of violent crimes related to the January 6, 2021, attack on the U.S. Capitol called those protesting at Tesla dealerships “domestic terrorists” and promised that the government would make sure they “go through hell.”

Trump and Musk appear to have taken the downturn in their fortunes by becoming more aggressive. Martin Pengelly of The Guardian noted that in the middle of Monday’s stock market plunge, Trump posted or reposted more than 100 messages on his social media channel. All of them showed him in a positive light, including reminders of the 2004 first season of the television show The Apprentice, in which Trump starred: a golden moment in Trump’s past when his ratings were high and the audience seemed to believe he was a brilliant and powerful businessman.

Today, egged on by Musk, Trump pushed again to take over other countries. He told reporters: "When you take away that artificial line that looks like it was done with a ruler…and you look at that beautiful formation of Canada and the United States, there is no place anywhere in the world that looks like that…. And then if you add Greenland…that's pretty good."

The Trump administration also announced today it was cutting about half the employees in the Department of Education. The Senate confirmed Linda McMahon, who has little experience with education, to head the department on March 3 by a party-line vote. Shutting down the department "was the president's mandate—his directive to me," McMahon told Fox News Channel host Laura Ingraham. McMahon assured Ingraham that existing grants and programs would not “fall through the cracks.”

But when Ingraham asked her what IDEA stood for—the Individuals with Disabilities Education Act—she wasn’t sure, although she knew it was “the programs for disabled and needs.” Ingraham knew what the acronym meant but assured McMahon that after 30 years on the job, she still didn’t know all the acronyms. McMahon replied: “This is my fifth day on the job and I’m really trying to learn them very quickly.”

Musk lashed out at Arizona senator Mark Kelly on social media yesterday, after Kelly posted pictures of his recent trip to Ukraine and discussed the history of Russia’s invasion, concluding “it’s important we stand with Ukraine.” Musk responded: “You are a traitor.”

Kelly, who was in the Navy for 25 years and flew 39 combat missions in the Gulf War before becoming an astronaut, responded: “Traitor? Elon, if you don’t understand that defending freedom is a basic tenet of what makes America great and keeps us safe, maybe you should leave it to those of us who do.”

LETTERS FROM AN AMERICAN

HEATHER COX RICHARDSON

#Matt Wuerker#Politico#Letters From An American#Heather Cox Richardson#Mark Kelly#veterans#IDEA#disabilities#war in Ukraine#the Economy#the Stock market#economic news#tariffs#wrong way

119 notes

·

View notes

Text

OMAKHEATERS - PLATİN

Omak Heaters: Your Trusted Partner in Heating Solutions

When it comes to reliable and efficient heating solutions for various industrial applications, Omak Heaters stands out as a leading provider of top-quality products. Specializing in IBS tank heaters, barrel heaters, filter heaters, satellite dish heaters, and more, Omak Heaters offers innovative and dependable heating solutions to meet the diverse needs of its customers.

IBC Tank Heaters:

Omak Heaters offers a wide range of IBC tank heaters designed to provide consistent and uniform heating for industrial storage tanks. Whether you need to maintain the temperature of liquids or chemicals stored in tanks, our IBC tank heaters ensure optimal heating performance, enhancing operational efficiency and productivity.

Barrel Heaters:

For heating applications involving barrels and drums, Omak Heaters offers high-performance barrel heaters engineered to deliver efficient and uniform heat distribution. Our barrel heaters are designed to withstand harsh industrial environments and provide reliable heating solutions for various applications, including oil and chemical processing.

Filter Heaters:

Omak Heaters also specializes in filter heaters designed to prevent freezing and maintain optimal operating temperatures for filtration systems. Our filter heaters are built to deliver consistent and reliable heating performance, ensuring uninterrupted operation and prolonging the lifespan of filtration equipment.

Omak Heaters Quality Assurance:

At Omak Heaters, quality and reliability are our top priorities. All our heaters are manufactured using premium-quality materials and advanced manufacturing techniques to ensure superior performance and durability. Our team of experienced engineers and technicians conducts rigorous quality control tests at every stage of production to guarantee the highest standards of quality and reliability.

Customer-Centric Approach:

Omak Heaters is committed to providing exceptional customer service and support. We work closely with our customers to understand their unique heating requirements and offer customized solutions tailored to their specific needs. From product selection to installation and ongoing technical support, our dedicated team is here to assist you every step of the way.

Contact Omak Heaters Today:

Whether you're in need of IBS tank heaters, barrel heaters, filter heaters, or satellite dish heaters, Omak Heaters has the expertise and products to meet your heating needs. Contact us today to learn more about our comprehensive range of heating solutions and discover how we can help optimize your industrial heating processes.

625 notes

·

View notes

Text

Sixaluminium - Devasa+ (2)

The aluminum industry is a vital sector that plays a significant role in various industries, including construction, transportation, and manufacturing. Aluminium profile are widely used in these industries due to their lightweight, durable, and corrosion-resistant properties. These profiles are produced by aluminum profile manufacturers and aluminum extrusion companies, who are key players in the industry. Aluminium profile wholesalers play a crucial role in the distribution of aluminum profiles. They act as intermediaries between manufacturers and end-users, ensuring a smooth supply chain. These wholesalers offer a wide range of aluminum profiles, including standard profiles, conduit and trunking profiles, angle and corner profiles, and seamless aluminum extrusion . They provide a one-stop solution for customers, offering competitive prices and support throughout the purchasing process. By partnering with aluminum profile wholesalers, businesses can access a diverse range of profiles to meet their specific needs. Aluminium profile manufacturer and aluminum extrusion companies are responsible for the production and customization of aluminium manufacturer. They have the expertise and capabilities to design and manufacture profiles according to customer specifications. These manufacturers offer a wide range of profiles for architectural and industrial use, such as doors, windows, curtain walls, and other structural components. They utilize advanced techniques, including anodized aluminum, to enhance the appearance and durability of the profiles. By collaborating with aluminum profile manufacturers, businesses can obtain high-quality profiles tailored to their requirements.

1K notes

·

View notes

Text

No-Nylon Sock Yarn

This might be the hardest task for knitting without plastic. I’ve gone to some local stores and snooped around online looking for sock yarn and every time I do I get the same canned response.

“You know those will wear out, right?”

It’s easy to find 100% wool yarn, even non-superwash (yes superwash yarn contains plastic), but you’ll be darning them often if you wear them very much.

So is it fruitless? Well no, there are non-plastic alternatives to nylon that can give a yarn strength, such as mohair and silk. There are construction techniques too that a good sock yarn should have regardless. High ply-count and longer fiber strands, for example. BFL wool is notorious for its longer staple length, so does corriedale and targhee. And if the ply is 4 or more it will make for a better sock yarn foundation.

The most trouble I’ve run into now has been finding yarns that can fit this bill.

I’ve spent the past week trawling through Ravelry’s advance search for yarn, and the process has been slow and insightful. The more particular I search, “silk OR mohair, AND wool, AND NO manufactured fibers, 4-ply OR 5-ply+, AND NO superwash, AND not discontinued”, the less results I get. But still, there are results.

One would expect, with a search this tailored, you’d have at least a list of options, but I’ve still hit roadblocks. These come in two main forms: insufficient tagging or unavailable for purchase.

I cannot count how many times I’ve found a yarn that got me excited, only to click on the about page and read “80% SW Wool”. ‘SW’ meaning superwash. Or even worse, no mention of superwash on the about page, and then finding out the yarn is in fact superwash when I went to a retail listing. It makes me ask, if you’re using superwash wool, why not tag that as part of the care instructions so it can be searched through Ravelry? Why use superwash wool at all if you’re just going to recommend people handwash only?

The other pitfall is that these small dyers (as the majority of them are) don’t have the stock or have all together discontinued dying, yet haven’t updated their yarn’s about page to show it’s no longer available. Or, equally sad, when there’s simply no buying option available at all. Ravelry doesn’t always find every online store, so I try to look up the producer by name, and this sometimes gets me to an Etsy shop--But still, some yarns just seem to exist on their about page but nowhere else.

Still, I’ve managed to make a short list of yarns that pass the inspection and have some method for purchase. And honestly, all you need is one good product line for a lifetime of knitting if it fits all the bills. But I look at the number of yarns I could otherwise choose but are now discontinued (1/4th of them!) and wonder how long my current list will last.

So remember to support small dyers and yarn makers, and do your due diligence to make sure you’re getting the right product.

662 notes

·

View notes

Text

Retconned Wardi firearms- a basic handgun, a highly decorative ceremonial handgun (belonging to Faiza), and a lance-gun.

Gun tech has officially been nerfed down to hand cannons (press F) (this has been a long time coming but I'd been fallacy of sunk costs-ing myself out of retconning).

Handguns are held similarly to a shotgun, with the butt pressed into the user's shoulder, one hand gripping under the barrel, and the other free to ignite the gunpowder. These represent the most advanced firearms in contemporary usage, both in make and in their use of uniform iron projectiles built to match the gun's bore for greater range and efficiency. Lance-guns are the more basal form, usually larger and mounted with the pole held over the shoulder, and are most effectively used by two people (one to hold and aim, one to light the gunpowder).

The spread of firearms is currently mostly limited to the Eastern Inner Seaway peoples (with some additional distribution via overland trade), and actual manufacture of hand cannons and gunpowder at Significant scale is limited to the region's core powers.

The reason for this limited spread is partially due to specific elements of the technology's history. Gunpowder was first synthesized by Burri alchemists and considered to be the discovery of the legendary divine weapon + solar fire of the deity Inanariya, and its formula (along with techniques for ideally refining its components) remained a closely guarded state secret. It was used predominantly in priestly contexts to generate flame and explosive sounds (in conjunction with earlier practices of generating multicolored flames with use of other chemicals), then integrated into combustible weaponry in the forms of fire lances, which would eventually develop into early handcannons.

The treatment of gunpowder as a guarded sacred or semi-sacred substance continued with Wardi adoption, where knowledge of its making is considered a closed rite. It's name (inya tsatsul or just tsatsul, a derived adoption of the Burri iñazatsūya) still reflects a divine solar association (the Burri word means 'sun's thunder', the Wardi 'inya' invokes the sun, 'tsatsul' is an adapted loanword and has no meaning independent of the substance itself), though its priestly use is now predominantly associated with the firearm'ed Odonii (rather than priests of the solar Face Inyamache). The composition of gunpowder can no longer be regarded as a Secret by any means, though efforts to obscure the methods of its creation are still moderately successful and has kept knowledge of gunpowder manufacture more limited than the total sphere of firearm usage itself.

The actual strongest limiting factor of firearm usage is the rarity of natural saltpeter deposits necessary for making gunpowder. The practice of actively producing saltpeter via nitraries has not been developed anywhere in the setting, and all is instead obtained via natural sources. These sources are rare and limited within the current spread of firearm technology, and result in gunpowder being a limited and expensive substance to produce. The weapons themselves are also very expensive to manufacture (a good quality steel SWORD is far too material-cost prohibitive for most people to own), particularly high quality firearms designed for use with standardized ammunition.

These guns are also very basal, and logistical difficulties in their use (weight, very slow loading and firing speed, high visibility, Relatively low reach and accuracy) along with the restrictive cost of production has kept firearms far from rendering conventional weaponry, armor, and projectiles obsolete (even within the societies that have access to them). They are still, however, very devastating in use within their contemporary context, particularly in that high quality guns have a longer range than the best arrow-based projectiles, and utterly negate most contemporary forms of armor at close range.

#I'd consider the setting to be like.....most closely analogous to like 3rd-1st century BCE earth (in terms of the average scale of#societies + Most of its technology (aside from major exceptions like this) + trade interconnectivity)#There are VERY few Very Big states capable of mass-manufacturing and resource extraction (like nothing the size of#the Roman empire has Ever existed in this setting. The biggest empires aren't even close. Cynozepal has a pretty massive territorial#span so is probably the closest thing but its actual control is highly fragmented along disconnected central hubs)#There's significant seaway trade connections but the Vast majority of transmission of goods is localized (even moreso over land)#So point being firearms have developed '''''earlier''''''' than in IRL history but the conditions that enabled very rapid spread are#not really present (though it's fairly inevitable that they'll become widespread over the next few centuries)#Also the likely trajectory of adaptation is going to be the development of Plate armor (which could absorb/block shots#from some types of firearms More advanced than these).#The types of armor used in this particular region is mostly lamellar/scale/padded fabric/leather and rarely involves#full body protection (using a shield to compensate) so developing thicker and fully protective armor would be the next logical#step in the arms race#I think it would be a fun constructed history for armor technology to outpace these simple firearms enough that they end up largely#abandoned in favor of re-specializing in close combat but I don't really care to plan out the far future that much

79 notes

·

View notes

Text

The Carthaginian Civilization: An In-Depth Analysis of Africa’s Maritime and Military Powerhouse

Introduction: Carthage – The Forgotten African Empire

The Carthaginian civilization (c. 814 BCE – 146 BCE) was one of the greatest African maritime, economic, and military powers in history. Located in modern-day Tunisia, Carthage was a dominant force in the Mediterranean, rivaling Rome, Greece, and Persia for global supremacy.

Despite its African origins, Eurocentric history often erases Carthage’s Black African heritage, portraying it as a “Phoenician colony” rather than an independent African empire. From a Garveyite perspective, studying Carthage is crucial because it represents:

Black military excellence – Carthage was one of the most powerful naval and land forces in history.

Black economic and trade dominance – Carthage controlled Mediterranean commerce, creating an empire built on African wealth.

Black resistance to European expansion – Carthage fought the Roman Empire in the Punic Wars, demonstrating African resilience against European conquest.

By reclaiming Carthage’s history, Black people today can see proof that Africa was never weak—it was once a global superpower.

1. The Origins of Carthage: An African Power Rises

A. The Founding of Carthage (814 BCE)

Carthage was founded by the Phoenicians of Tyre (modern-day Lebanon) but quickly developed into an independent African power.

The city was built on the North African coast, strategically positioned for control over Mediterranean trade.

Over time, Carthage became culturally distinct from its Phoenician founders, incorporating African, Berber, and Nubian influences.

Example: Historians often overlook the fact that Carthage had strong ties to the indigenous Berbers of North Africa, proving its deep African roots.

Key Takeaway: Carthage was not a foreign colony—it was an African empire that controlled its own destiny.

2. The Economic Power of Carthage: Africa’s Trade Empire

A. Maritime Dominance and Global Trade

Carthage became the wealthiest city in the Mediterranean, controlling trade routes across Europe, Africa, and the Middle East.

It developed one of the most advanced naval fleets, allowing it to dominate sea trade and exploration.

Carthaginian merchants traded in gold, ivory, textiles, silver, and spices, connecting Africa to Europe and Asia.

Example: Carthage had exclusive trade agreements with sub-Saharan Africa, importing gold and exotic goods that made it one of the richest cities of its time.

Key Takeaway: Africa was not dependent on Europe—Carthage proved that African wealth built global trade networks centuries before colonialism.

B. The Agriculture and Industry of Carthage

Carthage developed an advanced agricultural economy, growing wheat, olives, and grapes.

The empire built massive irrigation systems to maximize food production, making it one of the most self-sufficient African civilizations.

It also developed high-quality metalworking, shipbuilding, and glass manufacturing, making its goods highly valued worldwide.

Example: Roman records show that Carthaginian farms were so advanced that even after Rome destroyed Carthage, they copied its agricultural techniques.

Key Takeaway: Black civilizations developed their own economic and industrial advancements without European influence.

3. The Military Strength of Carthage: Rome’s Greatest Rival

A. The Carthaginian Navy: Masters of the Mediterranean

Carthage had the most powerful navy in the world before Rome, controlling maritime trade and warfare.

It developed the quinquereme warship, a revolutionary naval vessel that allowed Carthage to dominate the seas.

The Carthaginian navy played a key role in protecting African and Mediterranean trade routes from piracy and foreign invasion.

Example: During the First Punic War (264-241 BCE), Carthage’s navy nearly crushed Rome’s expansion before the Romans developed their own navy.

Key Takeaway: A strong Black civilization must control its own military to protect its economy and sovereignty.

B. Hannibal Barca: One of the Greatest Generals in History

Hannibal, a Carthaginian general, led an army of Berbers soldiers against Rome during the Second Punic War (218-201 BCE).

He executed one of the greatest military campaigns in history by marching an army—including elephants—across the Alps to invade Italy.

He defeated the Romans in multiple battles, including the Battle of Cannae (216 BCE), where he annihilated a Roman army twice his size.

Example: European historians recognize Hannibal as one of the greatest military strategists of all time, yet they downplay Carthage’s African roots.

Key Takeaway: Black military leadership was so powerful that it nearly crushed the Roman Empire.

4. The Fall of Carthage: Rome’s Destruction of an African Power

A. The Third Punic War and the Roman Invasion (149-146 BCE)

Rome saw Carthage as a threat to its expansion and launched the Third Punic War to destroy it.

After years of resistance, Rome finally invaded Carthage in 146 BCE, burning the city to the ground.

Over 200,000 Carthaginians were massacred or enslaved, and Rome salted the land to prevent Carthage from rebuilding.

Example: The Romans erased Carthage from history, renaming the region Africa Proconsularis—which later became the name for the entire continent.

Key Takeaway: Colonizers have always sought to erase Black civilizations that challenge their dominance.

5. The Legacy of Carthage and the Garveyite Call for Rebuilding Black Power

A. The Influence of Carthage on African and Global History

Carthage’s military strategies, agricultural techniques, and trade networks influenced later African civilizations.

Many Berber and West African cultures retained elements of Carthaginian governance, trade, and military tactics.

The spirit of Carthage lived on in African resistance movements against European colonialism.

Example: African empires like Mali and Songhai carried on Carthage’s trade dominance through trans-Saharan commerce.

Garveyite Perspective: Africa must reclaim its lost civilizations and use their successes as blueprints for future Black empowerment.

B. The Lessons of Carthage for Black People Today

Economic self-reliance is key – Carthage controlled trade without European interference.

Military strength is necessary – Without a strong defense, Black nations remain vulnerable to foreign attacks.

Historical awareness is power – Black people must reclaim Carthage’s legacy and not let Europe erase it.

Example: If Carthage had won the Punic Wars, the world would have been shaped by African governance, not Roman imperialism.

Garveyite Perspective: The future of Black empowerment depends on studying our past victories and rebuilding African economic and military strength.

Conclusion: Will We Reclaim Carthage’s Legacy?

Marcus Garvey taught:

“If you have no confidence in self, you are twice defeated in the race of life.”

Will Black people continue to let others define our history, or will we reclaim Carthage’s greatness?

Will we build independent Black economies, or continue to rely on foreign nations?

Will we allow our history to be erased, or will we restore Carthage’s legacy as an African superpower?

The Choice is Ours. The Time is Now.

#black history#black people#blacktumblr#black tumblr#black#pan africanism#black conscious#africa#black power#black empowering#CarthaginianEmpire#BlackExcellence#garveyism#garveyite#african kingdom#ReclaimOurHistory

45 notes

·

View notes