#acetic acid

Explore tagged Tumblr posts

Text

I was quick to smell my thumb, my right thumb (I asked the woman with the special ink if it had to be the left or right one; she said any would work); and a repugnant and strong smell of acetic acid filled my inner flesh tubes which made me let out a quite audible disgust reflex.

I had just voted in my first election for this nation; and after that my family and I went to the mall. Despite how many mentioned was the fact that so many stores would give free stuff after you showed them your inked thumb; I went to none of them, I wasn't really excited for such.

I wasn't excited for voting in the first place. Me like many people have lost all their faith in the whole process, I had planned since the last year that I would straight up cast an invalid/blank vote, and the whole campaign process that came after just reassured me on such choice.

So if I was going to do that, at least I should make something out of it.

And that's how the name of "Boxa Caken Funfetti" written with the black crayon that is given at the voting place, marked the first ever recorded case of a Sparklecare character being voted as a candidate in a presidential election.

9 notes

·

View notes

Text

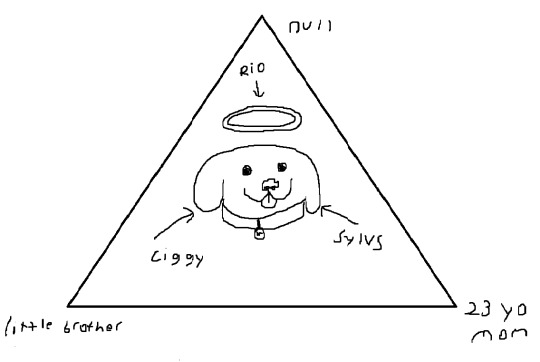

it's fun to open up Ms paint and doodle a thing

5 notes

·

View notes

Note

acetic acid

2 notes

·

View notes

Text

As part of this effort, the Molecular Design and Synthesis Group at the University of New South Wales has been designing tagging agents that will temporarily introduce highly fluorinated alkyl groups to molecules to aid in organic synthesis (for example, see figure 18.17).

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#research#molecular design and synthesis#university of new south wales#unsw#fluorination#alkyl group#organic chemistry#diol#polyfluoroalkyl#chemical reactions#acetic acid#oxidation

7 notes

·

View notes

Photo

Vinegar could be secret ingredient in fight against climate crisis

Chemical engineers at Monash University have developed an industrial process to produce acetic acid that uses the excess carbon dioxide (CO2) in the atmosphere and has a potential to create negative carbon emissions.

Acetic acid is an important chemical used in several industrial processes and is an ingredient in household vinegar, vinyl paints and some glues. Worldwide industrial demand for acetic acid is estimated to be 6.5 million tons per year.

This world-first research, published in Nature Communications, shows that acetic acid can be made from captured CO2 using an economical solid catalyst to replace the liquid rhodium or iridium based catalysts currently used.

Liquid catalysts require additional separation and purification processes. Using a solid catalyst made from a production method that doesn't require further processing also reduces emissions.

Read more.

#Materials Science#Science#Vinegar#Acetic acid#Reactions#Carbon dioxide capture#Catalysts#Liquids#Metal organic framework#Monash University

27 notes

·

View notes

Text

Aspirin is synthesised on an industrial scale by reacting acetic anhydride with salicylic acid:

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quote#chemistry#nonfiction#textbook#aspirin#synthesis#chemical reactions#acetic anhydride#salicylic acid#hydroxybenzoic acid#acetylsalicylic acid#acetic acid

3 notes

·

View notes

Text

My knowledge in microbiology and biology informs my decisions

#Knowing how extensive#mold#is#and what#snails#carry#nooooo thanks#also I just hate the smell#texture and taste of overripe food#that#acetic acid#butyric acid#food#food disgust

47K notes

·

View notes

Text

Acetic Acid Prices, News, Trend, Graph, Chart, Monitor and Forecast

Acetic Acid is a vital chemical compound used across a variety of industries, including the production of chemicals, food, textiles, and pharmaceuticals. It is primarily used as a solvent, reagent, and intermediate in the synthesis of other chemicals such as acetate esters, acetic anhydride, and vinyl acetate monomer. The market for acetic acid is vast and dynamic, influenced by various factors, including supply and demand dynamics, raw material prices, technological advancements, and environmental regulations. Acetic acid prices have been subject to fluctuations over the years due to changes in production costs, geopolitical factors, and shifting market trends.

The production of acetic acid is primarily driven by two processes: the carbonylation of methanol and the oxidation of hydrocarbons. Methanol-based production is the most common method, accounting for a significant share of global acetic acid production. The demand for acetic acid is largely influenced by industries that rely on its derivatives, such as the manufacturing of synthetic fibers, plastics, and food additives. The pharmaceutical and cosmetic industries also contribute to the demand for acetic acid, as it is used in the formulation of various products such as ointments and preservatives.

Get Real time Prices for Acetic Acid: https://www.chemanalyst.com/Pricing-data/acetic-acid-9

In recent years, acetic acid prices have experienced some volatility, driven by factors such as fluctuations in feedstock prices, changes in production capacity, and shifts in regional demand. One of the primary factors impacting acetic acid prices is the cost of raw materials, particularly methanol, which is the main feedstock in acetic acid production. The price of methanol has been known to fluctuate due to changes in global oil prices, as methanol is often derived from natural gas or coal. As a result, when methanol prices rise, acetic acid production costs increase, putting upward pressure on the price of acetic acid.

Another key factor that influences acetic acid prices is the level of global supply and demand. When there is an oversupply of acetic acid in the market, prices tend to decrease as producers compete to sell their products. Conversely, when supply is limited, prices rise as demand outpaces production. Regional factors play a significant role in determining the supply-demand balance, with key markets such as China, the United States, and Europe being major players in the acetic acid industry. For instance, China is both the largest producer and consumer of acetic acid globally, and any shifts in the country’s demand or production capacity can have a substantial impact on prices. Similarly, economic growth or slowdowns in key regions can also influence acetic acid demand, impacting pricing trends.

Environmental regulations are another factor influencing acetic acid prices. Governments around the world are increasingly focused on reducing carbon emissions and promoting more sustainable production practices. This has led to the implementation of stricter regulations on industries involved in the production of chemicals like acetic acid. These regulations often require companies to invest in more advanced technologies or to adopt cleaner production methods, which can increase production costs and, in turn, lead to higher acetic acid prices. On the other hand, the growing focus on sustainability has also led to innovations in acetic acid production processes, with some companies seeking to develop more energy-efficient or environmentally friendly methods. These advancements may help mitigate cost pressures in the long term.

Technological advancements and process improvements in acetic acid production have also played a role in shaping price trends. Over the years, significant efforts have been made to improve the efficiency of acetic acid production, reduce energy consumption, and lower production costs. For instance, advancements in catalysts and reaction systems have allowed for the more efficient conversion of methanol to acetic acid, reducing the amount of energy required and increasing overall yield. These innovations can help to keep acetic acid prices more stable, particularly when raw material prices are volatile. Additionally, the development of new production methods, such as the use of renewable feedstocks, may provide an opportunity to reduce the reliance on fossil fuels, potentially lowering production costs in the future.

The acetic acid market is also influenced by the global economic environment. When the global economy experiences growth, industrial production typically rises, leading to increased demand for acetic acid and its derivatives. For example, during periods of economic expansion, demand for consumer goods, automotive products, and construction materials tends to increase, driving up the need for acetic acid in the production of plastics, paints, and coatings. However, during economic downturns or periods of recession, industrial activity slows, and demand for acetic acid often declines, leading to downward pressure on prices.

In addition to economic factors, geopolitical issues can also impact acetic acid prices. Trade disputes, tariffs, and political instability in key producing or consuming regions can disrupt the supply chain, leading to price fluctuations. For instance, a trade dispute between major acetic acid-producing countries could lead to supply shortages or disruptions, causing prices to rise. Similarly, political instability in key regions, such as the Middle East, can affect the global supply of oil and natural gas, which are key feedstocks for methanol production, thereby impacting the cost of acetic acid.

The competitive landscape in the acetic acid market also affects pricing trends. The market is characterized by the presence of several large multinational chemical companies, as well as smaller regional producers. Intense competition among producers can sometimes lead to price wars, where companies reduce prices to gain market share. However, in times of supply shortages or rising raw material costs, producers may raise prices to offset the increased costs of production. Pricing strategies vary across regions, and producers often adjust their pricing based on local market conditions, production capacities, and demand fluctuations.

In conclusion, the acetic acid market is a complex and multifaceted industry that is influenced by a range of factors, including raw material prices, supply and demand dynamics, environmental regulations, and technological advancements. Price fluctuations in acetic acid are inevitable due to the interconnected nature of the global economy and supply chains. While the industry is expected to continue experiencing price volatility, ongoing innovations in production processes and the adoption of more sustainable practices may help stabilize prices over time. Understanding these factors and monitoring market trends is essential for businesses and consumers to navigate the ever-changing landscape of acetic acid pricing.

Get Real time Prices for Acetic Acid: https://www.chemanalyst.com/Pricing-data/acetic-acid-9

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Acetic Acid#Acetic Acid Price#Acetic Acid Prices#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

1 note

·

View note

Text

Hollow Cut Hair Accessories

0 notes

Text

#ice#float#water#hydrogen bond#lewis acidity#amines#acetic acid#formic acid#benzene#chemistry#solutions

1 note

·

View note

Link

0 notes

Text

Understanding Acetic Acid: From Chemistry to Everyday Uses

Acetic acid, also known as ethanoic acid, is a crucial compound in both industrial and everyday settings. It's a simple organic acid with a distinctive sour taste and pungent smell, which gives vinegar its characteristic qualities. Beyond its culinary uses, acetic acid plays significant roles in various industries and has notable chemical properties that make it indispensable.

Chemical Composition and Properties

Molecular Formula: C2H4O2

Structure: It consists of a methyl group (CH3) linked to a carboxyl group (COOH).

Acidity: Acetic acid is a weak acid with a pH typically around 2.4 in concentrated form.

Industrial Production

Methanol Carbonylation: This process involves reacting methanol with carbon monoxide under specific conditions to produce acetic acid.

Biochemical Synthesis: Some acetic acid is produced by bacterial fermentation of ethanol, commonly used in vinegar production.

Applications in Industries

Chemical Industry: It serves as a precursor to various chemicals like vinyl acetate monomer, which is used in polymer production.

Food Industry: Acetic acid is a key component in the production of vinegar, imparting its distinctive flavor and preserving properties.

Textile Industry: It's used in dyeing and finishing processes for textiles.

Everyday Uses

Culinary: Apart from vinegar, it is used in pickling, salad dressings, and condiments.

Cleaning: Due to its acidic nature, it's effective in removing mineral deposits and as a disinfectant.

Medical: In diluted forms, acetic acid is used in ear drops to treat ear infections caused by bacteria or fungi.

Environmental Impact

Biodegradability: It breaks down readily in the environment, reducing long-term ecological impacts.

Safety Concerns: Handling concentrated acetic acid requires precautions due to its corrosive nature.

Human Intelligence and Emotions in Understanding Acetic Acid

Understanding acetic acid isn't just about its chemical properties; it's also about appreciating its role in everyday life and industries:

Curiosity: Humans have long been curious about vinegar and its production, driving experimentation and discovery.

Cultural Significance: Vinegar has cultural significance worldwide, from ancient culinary practices to modern gourmet cuisines.

Innovation: Innovations in chemical processes have improved acetic acid production efficiency, reducing costs and environmental impacts.

Conclusion

Acetic acid bridges the gap between chemistry and everyday life, offering insights into both its molecular structure and its diverse applications. From its role in preserving food to its use in industrial processes, acetic acid continues to be indispensable. Understanding its properties and applications enhances our appreciation of its impact on technology, health, and culture. As we continue to explore new frontiers in chemistry and industry, acetic acid remains a steadfast companion in our journey of discovery and innovation.

0 notes

Text

Figure 11.7 shows the different conductivities of aqueous solutions containing HCl and CH3COOH.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#hydrochloric acid#acetic acid#conductivity#electrical conductivity#aqueous solution

18 notes

·

View notes

Text

Are You Looking For Acetic Acid Manufacturer in USA?

Stellar Exports is a prominent supplier of Acetic Acid in USA and is based in the UAE. As USA's leading Acetic Acid manufacturer and supplier, Our team of experts can tailor Acetic Acid to meet your specific requirements. For more information visit our website.

#Acetic Acid#Acetic Acid manufacturer#Acetic Acid sellers in USA#Acetic Acid supplier in USA#Acetic Acid manufacturers in USA

0 notes

Text

Common solvents for these reactions are divided into two groups: protic and aprotic.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quote#chemistry#nonfiction#textbook#solvent#protic#aprotic#water#formic acid#methanol#ethanol#acetic acid#dimethyl sulfoxide#dmso#acetone#dichloromethane#diethyl ether

2 notes

·

View notes

Text

For centuries, acetic acid vinegar, commonly known as vinegar, has held a pivotal role in both culinary practices and household management. Delve into the origins, production, various types, culinary and household uses, as well as potential health benefits of acetic acid vinegar by reading our blog at acetic-acid.net

1 note

·

View note