#Yarn Manufacturing

Explore tagged Tumblr posts

Text

Dress for Success: Sustainable Fashion Tips for the Modern Workforce with Sri Shakthi Tex

In today’s dynamic and eco-conscious world, dressing for the office isn’t just about looking professional — it’s also about making ethical and sustainable choices. Sri Shakthi Tex, a leading manufacturer of quality textiles in Erode, offers a stunning range of natural fabrics that are perfect for creating chic and comfortable workwear ensembles.

So, ditch the bland, synthetic suits and embrace the power of conscious fashion! Here are some sustainable style tips to help you achieve a polished and professional look while feeling confident and comfortable all day long:

1. Embrace the Versatility of Natural Fabrics:

Sri Shakthi Tex offers a treasure trove of breathable and eco-friendly fabrics like organic cotton, linen, and rayon. These natural fibers not only drape beautifully but also keep you cool and comfortable throughout the workday.

2. Play with Prints and Patterns:

Subtle prints and textures can add visual interest to your outfit without compromising professionalism. Sri Shakthi Tex boasts a collection of exquisite prints inspired by nature and Indian heritage, perfect for making a statement without going overboard.

3. Invest in Classic Staples:

Build your workwear wardrobe with versatile pieces that can be easily mixed and matched. A crisp white shirt, a well-fitted blazer, and tailored trousers from Sri Shakthi Tex can be adapted to create countless professional looks.

4. Accessorize Wisely:

The right accessories can elevate your outfit and add a touch of personality. Opt for simple yet elegant jewelry, a statement scarf, or a sleek leather bag for a polished finish.

5. Comfort is Key:

Remember, you’ll be sitting and moving around throughout the day, so prioritizing comfort is essential. Choose pieces that allow for freedom of movement without compromising on style. Sri Shakthi Tex’s natural fabrics are naturally soft and breathable, ensuring you stay comfortable all day long.

6. Embrace the Ethical Choice:

By choosing sustainable fabrics from Sri Shakthi Tex, you’re not just making a statement about your personal style, you’re also contributing to a healthier planet and fairer working conditions for textile workers. Sri Shakthi Tex is committed to ethical production practices and sustainable sourcing, making them the perfect choice for the conscious consumer.

Conclusion:

Dressing for success in the modern workplace doesn’t have to be boring or unsustainable. With Sri Shakthi Tex’s quality textiles in erode and these styling tips, you can create a professional and polished look that reflects your commitment to both style and sustainability. So step into the office feeling confident and empowered, knowing that you’re making a positive impact on the planet one outfit at a time.

#Textile Manufacturing#Fabric Production#Textile Industry#Quality Fabrics#Yarn Manufacturing#Weaving Services#Knitting Solutions#Fabric Export#Sustainable Textiles#Textile Innovation#Textile Products#Yarn Suppliers#Dyeing and Finishing#Textile Processing#Apparel Fabrics

0 notes

Text

Choosing The Right Yarn

Precot’s yarn has been widely appreciated in the textiles industry by prominent fabric manufacturers and knitted garment manufacturers, domestically and worldwide. We are one of the leading cotton yarn manufacturers in India and our cotton products are well known for their contamination-free 100% cotton ring spun & compact yarn.

Yarn and the history of yarns

Yarn is a collective term for linear assemblies of fibers that are twisted together to impart strength. Fibers that are laid together to form a continuous strand are also referred to as yarn.

Yarns shaped history :

There should be a need for yarns in the first place, and the necessary source materials should be available in reasonable quantities, to make yarns. The domestication of cotton should have catalyzed the use of cotton as clothing material. Cotton is being cultivated and used to make fabrics for at least 7,000 years.

Making of yarn

Spindle and whorl :

In the initial years, yarn was spun on a spindle and whorl. With the help of a spindle which is a rounded stick, fibers are attached and twisted. A whorl acts as a weight attached to the spindle that helps in rotating. The fibers were pulled manually from a bundle of carded fibers. By rotating the spindle downward, the fibers are twisted, and the yarn is spun as the spindle pulls away from the bundle of fibers. The spinner winds the yarn around the spindle to secure it and then starts the process again when the spindle reaches the floor. The process is repeated until all of the fiber has been spun or the spindle has been filled.

Spinning wheel :

A major improvement in yarn manufacturing happened with the invention of the spinning wheel. A hand-driven wheel is connected to a horizontally mounted spindle with the help of a circular band. The thread can be twisted and wound simultaneously.

A series of spindles :

A series of spindles set in a row was invented later that enables one operator to produce large quantities of yarn.

Ring Frame :

The ring frame is widely used today and involves hundreds of spindles mounted vertically inside a metal ring. Currently, natural fibers are spun with the open-end system, which draws the fiber into a rapidly rotating cup and pulls it out on the other side.

0 notes

Text

One of the great things about fiber arts (at least to me) is that... you outright own the things you make. It's hard for me to comprehend actually owning something, and that's that. The item you have created doesn't need to come with strings attached (pun intended).

In a world where you are constantly buying things but not owning any of it, truly, it's such an odd experience to actually have ownership of your labour, time, and love like that.

#art#fiber art#crochet#honestly that's how i feel with my blanket still#like i don't own my subscription to spotify or the games i virtually purchased fullprice (which. why)...#...but when i get my yarn and i use the crochet hook i have been abusing a little i OWN the things it and i make#that's honestly kind of intimidating to me because i haven't truly felt i owned anything. like not even my life. it's a problem.#i just got some pretty yarn to use for a cardigan. they told me to use acrylic but i can't wear acrylic and i like cotton#<it's insane that i can just Decide to not use the pattern recommendations. like that's still crazy to me#anyway fuck capitalism and adopt a craft if you can#it's SUCH a freeing experience and it will make you feel crazy once you know what it feels like to actually own your labour. lol.#like it doesn't matter WHAT craft it is. could be knit. could be wood burning. could be abstract car manufacturing...#...as long as you can do it safely to your standards and you are satisfied and fulfilled with it then it can change you. let it change you.

97 notes

·

View notes

Note

speaking of yarn ive been meaning to ask since ive heard of it elsewhere, is the general quality of yarn you can get going down? ive been looking into fibercraft but ive been told its getting harder and harder to find actual good thread without some sort of plastic in it, especially for a good price. so ive been wondering is this true or was it made out to be a much larger problem than it really is (in your experience)?

i've only been into crochet for a couple of years, so i'm not a Fiber Arts Veteran who can tell you the difference between shopping for supplies now vs 30 years ago! i don't really have anything to compare Current Yarns to. in my experience, the only thing i can speak on is cost, and it seems like the cost for yarn has probably been going up. animal fibers are certainly more expensive, acrylic yarns are budget-friendly but are synthetic, if that's something you're worried abt.

so i don't think that stuff is Untrue, but i also don't think it's any reason at all to avoid getting into fiber arts, and you can absolutely find yarns made from cotton / wool / bamboo fiber and stuff like that for good prices! it would probably be harder in-person, like in the aisles of a hobby lobby. but i think lion brand and lovecrafts are good sites to browse for yarn/supplies. it's really not a small-scale problem, someone like moi who's recently gotten into crochet and does it for funsies based on my whims/needs isn't going to really notice, i don't think. as an aside, if we're talking about crochet specifically, you can really crochet with anything at all- i've been making a tote bag out of plastic grocery bags, lmao. reduce reuse recycle or whatever. people will also use strips of fabric instead of yarn, and that's good for stuff like rugs / bags / baskets, chunkier projects. (though ig you could probably make some clothing if you cut the strips of fabric thin enough.) so as far as accessibility to the craft, there is that!

#or also what the fuck else. paper... wire. ribbon. rope. string. twine.#anyway!! it's really less of a fiber arts conversation and more of a capitalism conversation#which. obv. does not extend Only to fiber arts#just think it has to do with Product Manufacturing as a whole being done cheaper and cheaper#and the state we're in rn where everything gets more expensive every year. but again that's not specific to yarn#sergle answers#crochetposting#edit: i put a link for lovecrafts in there bc lol teehee. and so on and so forth

60 notes

·

View notes

Text

Weaving progress for Athena's shrine cloth! It's definitely not perfect but I'm enjoying it. All of the weft yarn so far is either undyed (white) or dyed by me. iirc the light tannish yarn was dyed with tea bags and the dark yellow was dried spearmint. I've got some light blue yarn from Aunt Jenny Makes that I felt like I should add prepped and ready to go for the next time I work on it

#i was watching weaving videos while I was working on it and I think there's a way to change sheds on my loom??#i'll have to play around with it when I'm done. would be nice & hopefully help things go faster#as far as i can tell my loom was either handmade or whatever manufacturer made it is so obsolete now that I cant find info about it#or a loom that looks similar enough to it to go off of#so ive been guessing based off the closest option ive found so far (tapestry/frame looms without heddles)#hail lady athena for the progress and the inspiration to add a couple more yarns to it!#athena#theoi#helpol#hellenic pagan#hellenic polytheism#hellenic community#coriander says#weaving#tapestry weaving#frame weaving#fiber arts#the warp is lily & cream cotton yarn ive had for literal years lol#im gonna try and get some proper warp thread before setting up another project

15 notes

·

View notes

Text

Another weird question for y'all: If you are moderately allergic* to a thing and had been eating it anyway for years because you didn't know, and then when you figure out what you're allergic to you quit eating it at all, can you lose your ability to tolerate even a little bit of it? *a phrase which here means "probably severely allergic but can tolerate small amounts when on antihistamines"

#the person behind the yarn#allergy mention#food mention#I am not sure what I reacted to so severely today#and based on what I ate yesterday there's a chance my burger was cross contaminated with pickle juice#so I could be vinegared?#and it could be that this is just what vinegar allergic reactions are for me now#or it could be the german chocolate baking chocolate bar which I've never had before#or it could be my usual antihistamines but from a new manufacturer so new inactive ingredients#which means tonight instead of my usual double dose of off brand allegra I took benadryl#(DO NOT use my antihistamine usage as a guide. I take very high levels as directed by my doctors)#(seriously for most people this is both overkill and a bad idea)

22 notes

·

View notes

Text

why are all the instagram girlie fashion brands so into cotton for their winter clothes. girl make it in wool

#i never used to be such a hater on cotton i really used to be into it and thought wool would be itchy#but now? having knit a fine selection go warm wool items? there is SIMPLY no other choice for the winter.#if you wear cotton not only will u be cold. u will be wet.#the snow and rain will get in everywhere it hits the cotton. wool? wool will deflect everything#everyone please learn to knit you can make clothes that fit you perfectly and are warm and dont come from a sweatshop#'what about the yarn production' there are so many yarn brands with easy to trace sourcing and manufacturing.#the cheapest and warmest of which is the istex icelandic wool yarn company#the sheep and the shepherds live in iceland the wool is carded and dyed in iceland it is spun in iceland#and you can get a plate of plotulopi for $5.50 usd. if you are concerned with simply misplacing your ethical quandry from one place to#another; worry not. the icelandic yarn industry has your back.#t

3 notes

·

View notes

Text

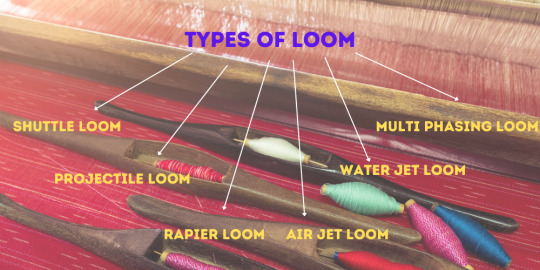

“Discover: Types of Loom in Textile Manufacturing”

Loom? What are They? What Do They Manufacture?

Looms is the weaving machine which converts the yarn into a fabric. There is no history of when looms were discovered but one thing is clear that it was before the birth of Jesus christ. There are 2 types of looms: Shuttle Looms and Shuttleless Looms. Below we are going to learn about various types of looms. The end result of this machine is fabric and wholesalers and retailers buy t-shirts in bulk made out of those fabric.

Learn About Shuttle Looms

This is the most primitive loom in the history of loom. In this machine there is a shuttle which contains bobbins and around bobbins there are yarn wounded. In this weaving machine the shuttle travels from one corner to the other and hence the fabric is made. The speed of this machine is 110-225 ppm [Picks Per Minute]. It is quite noisy and inefficient.

Fabric Weaving Without a Shuttle in the Loom Is It Possible?

Projectile Loom

Projectile loom is a shuttleless loom, in this looms instead of a shuttle projectile are there. Projectiles are made out of stainless steel and hence it was light weight. As the projectile lightweight this saves lots of energy and increases the efficiency of the machine. This loom speed was 300 ppm. The weaving takes place when the projectile goes across the width of the loom with the yarn.

Rapier Loom

This loom is also shuttleless. In this loom the weft is carried by a rapier which is a long rod like structure. Many kinds of fabric could be made using this loom and it is highly efficient. The range of GSM things loom could weave is 20-850 GSM. From home fabric to industrial fabric can be made using this loom. There are 4 types of rapier loom in the market.

Single Rigid Rapier Loom

Double Rigid Rapier Loom

Double Flexible Rapier Loom

Telescopic Rapier Loom

Air-Jet Loom

In this loom the yarn is transferred from the force of air, it does not have any shuttle. This loom is highly efficient and versatile. This loom does not make noise because it does not have many moving parts. As the moving parts are less then the floor space requirement and maintenance is low. The weft travels with the help of air pressure and once it reaches the shedding area interlacement takes place. This machine can be used in manufacturing Denim fabric, polyester dress material and cotton shirting fabric.

Water Jet Loom

Water pressure is used in this loom to transfer weft from one end to the other. It is a shuttleless loom machine. The speed of this machine is 600 ppm. This machine is highly efficient but we can use yarn which is hydrophobic, like polyester, polyamides etc. Hydrophilic yarn can not be used.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

8 notes

·

View notes

Text

#womens fashion#fabric manufacturers uk#wool manufacturers in india#woolen clothes manufacturers in india#shawl manufacturer in usa#wool product manufacturers in usa#wool clothing manufacturers uk#best t-shirt manufacturers in usa#wool yarn manufacturers uk#t shirt manufacturers uk

2 notes

·

View notes

Text

Why is Spun Polyester Yarn the Preferred Choice for Textile Industry in India?

In the intricate tapestry of the textile industry in India, one thread stands out as the preferred choice for manufacturers seeking durability, versatility, and quality: Spun polyester yarn. As we unravel the reasons behind its dominance, we discover why producers, such as SD Polytech, a leading yarn manufacturer Delhi, continue to play a pivotal role in this fabric of success.

Exceptional Strength and Durability

Spun polyester yarn is renowned for its remarkable strength and durability. In the demanding landscape of the textile industry, where fabrics endure constant stress and strain, this yarn emerges as a reliable choice. Garments and textiles crafted with it exhibit superior resistance to wear and tear, ensuring longevity and customer satisfaction.

Versatility in Applications

Spun polyester yarn producers in India cater to the diverse needs of the textile industry. From fashion apparel to industrial fabrics, this yarn seamlessly integrates into various applications. Its versatility makes it an ideal choice for a wide range of products, allowing manufacturers to explore creative avenues without compromising on performance.

Color Retention and Vibrancy

The vibrancy of colors is a hallmark of quality textiles. Spun polyester yarn excels in color retention, ensuring that fabrics maintain their original brilliance even after multiple washes. This characteristic is crucial for the fashion industry in India, where vibrant and long-lasting colors are synonymous with the cultural richness embedded in textiles.

Resistance to Wrinkles and Shrinkage

In a country with diverse climates like India, resistance to wrinkles and shrinkage is paramount. Spun polyester yarn provides textiles with excellent shape retention, making it well-suited for garments that need to withstand varying environmental conditions. This resistance enhances the overall appearance and wearability of the final product.

Cost-Effective Manufacturing

Efficiency and cost-effectiveness are key considerations for textile manufacturers. Spun polyester yarn producers in India like SD Polytech, align with these priorities. Its availability in bulk quantities and the ability to integrate seamlessly into modern manufacturing processes contribute to streamlined production, minimizing costs without compromising on quality.

Environmental Sustainability

As environmental consciousness grows, Spun Polyester Yarn's eco-friendly attributes become increasingly significant. Its production process consumes less water compared to natural fibers, and its durability reduces the frequency of replacements, contributing to a more sustainable and eco-conscious textile industry.

Conclusion

In essence, the prevalence of Spun Polyester Yarn in the textile industry in India can be attributed to its exceptional strength, versatility, color retention, resistance to wrinkles, and cost-effective manufacturing. SD Polytech and other spun polyester yarn producers in India play a crucial role in weaving success for textile manufacturers, providing them with a thread of excellence that strengthens the fabric of India's rich textile heritage.

Also, Read:

The Advantages of Using Polycotton Knitted Yarns in Textile Manufacturing

The Rise of Yarn Manufacturing in India: A Historical Perspective

Originally Published by: https://sdpolytech.blogspot.com/

2 notes

·

View notes

Text

We are Organic 100% export oriented Jute manufacturer in Bangladesh.

Jute is the Golden fibre of Bangladesh.

We work in assembling and sending out an extensive variety of Jute Sacks and Jute Sacks intended for bundling different items, including Cocoa beans, Espresso beans, Crude Cashew nuts, Hazelnuts, Peanuts, Shea nuts, Sesame Seeds, Soybeans, Heartbeats, Oil Seeds, Copra, Food grains, and Oats like Wheat, Rice, Maize, Grain, Sorghum, and Millet.

Jute yarn: We produce from 8 to 40 counts in different quality.

Jute Fabrics: different quality as per client's requirements.

Jute Ropes: Different quality as per client's requirements.

Jute Bags: As per client's requirements in different quality.

Jute Sacks: Different quality and different sizes as per client's requirements.

In the event that you are keen on buying Jute Packs or Jute Sacks for the bundling of Cocoa beans, Espresso beans, Cashew nuts, Hazelnuts, Peanuts, Shea nuts, Sesame seeds, Soybeans, Heartbeats, Oil seeds, Copra, Food grains, or Cereals (like Wheat, Rice, Maize, Grain, Sorghum, and Millet), kindly furnish us with itemized requests, including determinations, planned use, amount required, and the objective port. This data will empower us to give you valuing and a custom fitted proposition.

Jute is cultivating by our farmers 100% natural and Organic way way and manually in Bangladesh.

Email: [email protected]

WhatsApp: +8801630226364

For more info you can read this site

https://tinyurl.com/ymfuadkn

LinkedIn post URL

https://tinyurl.com/5n8he4hb

#jute rugs#jute rope#jute bags online#jute bags market#jute bag manufacturer#jute Yarn manufacturer#jute fabric manufacturer#jute sacks manufacturer#jute fibre manufacturer#jute carpet manufacturer#jute Handicrafts manufacturer#jute sand bag manufacturer#raw jute Exporter#jute farmer#organic Jute

2 notes

·

View notes

Text

OR : you are able to buy more of the yarn, when you arrive back home, you realise it's not thé right color because of course in the time it took you to run out the bath has changed. Turns out, you still find this exact same yarn at the store for the next two years and a half and it's always indistingably close to that second color you DO NOT WANT and you just have to make peace with the fact that the first time you stumbled onto a bath that was more fucked up than usual

I arrive at the yarn store and grab a skein off the shelf, the exact same brand, type, weight and color of the one I bought a week ago. Everyone in the store immediately knows that I miscalculated the amount of yarn I'd need for a project. They start booing at me. They are throwing crocheted tomatoes at me. The old lady giving knitting lessons in the corner is shaking her head. She had such high hopes for me. The cashier spits at me when I pay for it.

#this happenned to me#the same yarn from the same brand will always be a little different between different manufacturing times#but you can find some that are decently close#but when you started with a bath that is the most different they ever got to there's no coming back...

25K notes

·

View notes

Text

Textile to Textile Recycled Yarn: A Comprehensive Overview

In the evolving textile industry, sustainability has become a top priority. One of the most impactful solutions is the use of recycled yarns made from post-consumer and post-industrial textile waste. This process, known as "textile-to-textile recycling," is a key innovation aimed at reducing waste and conserving natural resources. The demand for textile-to-textile recycled yarn has grown significantly, offering an eco-friendly alternative to traditional yarn production. This article delves into the intricacies of textile-to-textile recycled yarn, its benefits, manufacturing processes, applications, and its role in advancing a circular economy.

What is Textile-to-Textile Recycled Yarn?

Textile-to-textile recycled yarn refers to yarn produced from recycled fabrics, such as old clothes, discarded textiles, or textile production waste. This sustainable process involves the transformation of used textiles into new yarn, eliminating the need for virgin fibers. The main goal is to reduce the environmental impact of textile production by reusing existing materials rather than creating new ones from raw resources.

The process begins by collecting post-consumer or post-industrial textile waste, which is then sorted, cleaned, and processed to recover the fibers. These fibers are then spun into yarn, ready to be used in the production of new garments or textiles.

Benefits of Textile-to-Textile Recycled Yarn

1. Environmental Impact Reduction

The primary advantage of textile-to-textile recycled yarn is its positive impact on the environment. Traditional textile manufacturing relies heavily on virgin fibers, which require vast amounts of water, energy, and chemicals. By recycling textiles, the need for raw materials is reduced, conserving natural resources. This significantly lowers carbon emissions, water usage, and the overall environmental footprint of the textile industry.

2. Waste Minimization

Textile waste is a major concern worldwide, with millions of tons of clothing ending up in landfills every year. By recycling these textiles into new yarns, the amount of waste sent to landfills is greatly reduced. This contributes to a circular economy, where products are reused and repurposed rather than discarded.

3. Conservation of Natural Resources

Recycling textiles helps conserve resources such as water, cotton, and fossil fuels. Producing virgin cotton requires large amounts of water and land, which can be alleviated by using recycled fibers. Additionally, the demand for synthetic fibers like polyester and nylon can be mitigated by using recycled polyester yarn, which reduces the reliance on petroleum-based resources.

4. Cost Efficiency

Although the initial processing of textile waste may be more labor-intensive, the long-term cost savings are substantial. By using recycled fibers, manufacturers can reduce the need for raw materials, which can lower production costs. Over time, advancements in recycling technology will further decrease the cost of recycling, making it a more viable solution for manufacturers.

The Textile-to-Textile Recycling Process

The textile-to-textile recycling process involves several stages, each crucial to ensuring the quality and sustainability of the final recycled yarn.

1. Collection and Sorting

The first step is to collect used textiles from various sources, such as consumer garments, discarded textile production waste, or even fabric offcuts from manufacturers. The collected textiles are then sorted based on material type (cotton, polyester, wool, etc.) and quality. This sorting ensures that the recycling process can proceed without contamination from incompatible fibers.

2. Cleaning and Deconstruction

Once the textiles are sorted, they undergo a cleaning process to remove any contaminants such as dirt, chemicals, or dyes. This is essential for ensuring the fibers are pure and ready for further processing. In some cases, textiles are deconstructed to separate the fibers from the fabric, making it easier to recycle them into new yarns.

3. Fiber Extraction and Spinning

After cleaning, the fibers are extracted from the textile waste. This may involve mechanical processes like shredding, carding, or using chemical methods to break down the fibers into their constituent components. Once the fibers are recovered, they are spun into yarn, which can then be dyed, woven, or knitted into new textile products.

4. Quality Control

The final stage of the recycling process involves quality control to ensure the recycled yarn meets industry standards. This includes testing the strength, durability, and color consistency of the yarn. The quality of textile-to-textile recycled yarn is critical to its success in the marketplace, as it must meet the same performance standards as virgin yarn.

Applications of Textile-to-Textile Recycled Yarn

Textile-to-textile recycled yarn is used in a variety of applications across the fashion and textile industries. Some of the most common uses include:

1. Apparel Manufacturing

Recycled yarns are increasingly being used in the production of clothing, from high-end fashion to everyday wear. Sustainable fashion brands are leading the charge, using recycled polyester, cotton, and other fibers to create eco-friendly collections. These garments help reduce the environmental impact of the fashion industry, while still maintaining high-quality standards.

2. Home Textiles

In addition to clothing, recycled yarn is also used in the production of home textiles, including bedding, towels, and upholstery. These textiles provide an environmentally friendly alternative to conventionally produced home furnishings, reducing waste and energy consumption.

3. Automotive and Industrial Applications

Textile-to-textile recycled yarn can be used in automotive and industrial applications, where durability and strength are essential. Recycled polyester yarn is particularly popular in the automotive industry for producing seat covers, upholstery, and insulation materials.

4. Sustainable Fashion and Circular Economy

The use of recycled yarns is a critical part of the circular economy, where products are designed to be reused, repaired, or recycled at the end of their life cycle. Sustainable fashion brands are increasingly adopting recycled yarns to create closed-loop systems where textiles are continuously recycled, reducing the need for new raw materials.

The Role of Technology in Textile-to-Textile Recycling

Advancements in recycling technology play a vital role in the development of textile-to-textile recycled yarn. The adoption of innovative techniques, such as chemical recycling, is paving the way for more efficient recycling processes. Chemical recycling allows for the breakdown of synthetic fibers like polyester and nylon, which were previously difficult to recycle mechanically. This innovation has the potential to revolutionize the recycling of textiles, making it more cost-effective and efficient.

Additionally, the development of smart sorting technologies helps improve the accuracy and efficiency of the sorting process, ensuring that only high-quality materials are used in the recycling process. These technological advancements will continue to drive the growth of textile-to-textile recycling, making it a viable solution for reducing textile waste and promoting sustainability in the industry.

Conclusion: Embracing the Future of Sustainable Textile Production

Textile-to-textile recycled yarn represents a promising solution for the textile industry's growing sustainability challenges. By reducing waste, conserving resources, and lowering the environmental impact of textile production, recycled yarn plays a crucial role in the transition to a circular economy. As technology continues to advance and the demand for sustainable products rises, textile-to-textile recycling will become increasingly important. Manufacturers, consumers, and designers alike must embrace this innovative process to create a more sustainable future for the textile industry.

Textile to Textile Recycled Yarn

This flowchart illustrates the main stages involved in textile-to-textile recycling, from waste collection to the production of recycled yarn. The recycling process is a critical step in creating sustainable textiles that minimize environmental impact.

1 note

·

View note

Text

Plastic Cones, Plastic Solid Cones Manufacturer, Sangli, India

We are Manufacturer, Supplier, Exporter of Plastic Cones, Plastic Solid Cones for Textile Industry, Textile Industries in Sangli, Maharashtra, India.

We are Manufacturer, Supplier, Exporter of Plastic Cones, Plastic Solid Cones for Textile Industry, Textile Industries in Sangli, Maharashtra, India.

#Plastic Cone#Plastic Solid Cones#Perforated Dye Tubes#Perforated Dye Cones#Plastic Yarn Carriers#Textile industry#Spinning#Twisting#Texturizing#Yarn Dyeing & Carpet Industry#Injection Moulded products#Corrugated Pipe Industry#Electrical Industry#Manufacturer#Supplier and Exporter#Sangli#Maharashtra#India

0 notes

Text

7. The author’s personal grievances with broadly accepted conventions that are common in multiple genres (looking at you, “homespun” as a synonym for “rough spun”).

3 components of worldbuilding:

1. The author’s kinks

2. The author’s power fantasy

3. The author’s political agenda

Plot and logic optional

#my example is a very specific fibercrafters’ salt#I prefer my yarn I spin on a drop spindle to anything manufactured#but anyway#writers on tumblr

60K notes

·

View notes