#wool manufacturers in india

Explore tagged Tumblr posts

Text

#womens fashion#fabric manufacturers uk#wool manufacturers in india#woolen clothes manufacturers in india#shawl manufacturer in usa#wool product manufacturers in usa#wool clothing manufacturers uk#best t-shirt manufacturers in usa#wool yarn manufacturers uk#t shirt manufacturers uk

2 notes

·

View notes

Text

Why Recycled Wool Matters: A Simple Guide to Sustainability

In our current world, where being environmentally conscious is increasingly crucial, we find ourselves looking for alternatives to traditional practices that harm our planet. One area that often comes under scrutiny is the production of wool. While known for its warmth and comfort, standard wool production has downsides, including resource consumption and waste generation. In this straightforward guide, we'll delve into why recycled wool matters and how it contributes to sustainability in language that's easy for everyone to understand.

The Environmental Impact of Traditional Wool Production

Let's face it: traditional wool production isn't all sunshine and rainbows. It comes with challenges, from the substantial water required for sheep farming to the chemical processes of turning raw wool into usable fabric. The toll on the environment is significant.

Recycled Wool: What is it?

So, what's the deal with recycled wool? Simply put, it's the eco-friendly cousin of traditional yarn. Recycled wool is made by repurposing discarded wool garments and scraps, giving them a new lease on life. Unlike conventional wool production, which relies heavily on raw materials, recycled wool minimises the need for additional resources.

Benefits of Recycled Wool

Opting for recycled wool brings many benefits in sustainable choices, making it a noteworthy alternative to traditional options. Let's dive into the advantages that make recycled wool stand out:

Environmental Stewardship:

Reduced Environmental Impact: Recycled wool is eco-friendly, demanding less energy and fewer resources than its conventional counterpart. By choosing recycled wool products, you actively participate in lowering the environmental footprint.

Quality without Compromise:

Softness and Comfort: Contrary to common misconceptions, recycled wool doesn't skimp on comfort. It can be just as soft and cosy as traditional wool, ensuring that you enjoy the warmth without sacrificing comfort.

Durability: Worried about the longevity of recycled wool? Fear not. It holds its own in terms of durability, offering products that stand the test of time.

Contribution to Sustainability:

Circular Economy: Beyond individual choices, embracing recycled wool contributes to a circular economy. It encourages a sustainable loop where materials are reused, minimising the strain on our planet's resources. Your preference for recycled wool aligns with a more responsible and sustainable approach to consumption.

Choosing recycled wool isn't merely a fashion statement; it's a conscious decision with far-reaching positive impacts. From environmental conservation to personal comfort, the benefits of recycled wool extend beyond the fibres, weaving a narrative of sustainability and responsible living.

How Recycled Wool Supports Sustainability

Recycled wool isn't just about making warm sweaters; it's a key player in sustainability. Its role goes beyond fashion – it contributes to a circular economy. Instead of the linear "take, make, dispose" model, recycled wool encourages a loop where materials are reused, reducing the burden on our planet. It's a small yet impactful step towards a greener future.

Brands and Products: Leading the Sustainable Charge

You might be wondering, "Are there brands doing this?" The answer is a resounding yes. Companies around the globe are embracing recycled wool in their products, leading the charge towards a more sustainable industry. From trendy fashion labels to those crafting cosy home goods, these brands prove that style and sustainability can go hand in hand.

Making Informed Choices: A Guide for Consumers

Now that we've got you excited about recycled wool let's talk about how you, as a consumer, can make informed choices. Look for labels that indicate the use of recycled yarn in products. It's a small gesture that speaks volumes. You're telling the industry that sustainability matters by consciously choosing recycled wool.

Addressing Common Misconceptions

Hold on, though – let's clear the air about a few misconceptions. Some might think recycled wool means compromising on quality. Not true. Recycled wool can be as soft, durable, and warm as its counterpart. It's all about debunking myths and understanding that sustainable choices can be just as good, if not better.

The Future of Sustainable Fashion with Recycled Wool

As we look ahead, the role of recycled wool in shaping a more sustainable and eco-conscious fashion industry becomes increasingly evident. It's not just a fleeting trend; it's a necessary shift towards a more responsible way of producing and consuming fashion. The future looks warm, cosy, and, most importantly, sustainable.

Conclusion

So, here's the deal – you've just had a crash course in recycled wool. The next time you're shopping for a cosy sweater or a soft blanket, consider the environmental impact of your choice. Choose recycled wool, support brands that prioritise sustainability, and be part of the movement towards a greener, more responsible future. It's not just about the warmth you feel; it's about the heat you bring to the planet. Let's make sustainable choices for the new fashion statement and pave the way for a brighter and more eco-friendly tomorrow.

Join with Jindal Textile Industries Pvt. Ltd., Your Reliable Source for recycled wool supplier Contact us right now to learn more about our excellent and environmentally safe recycled wool solutions, which are customised to meet your specific needs and wholesale orders."

0 notes

Text

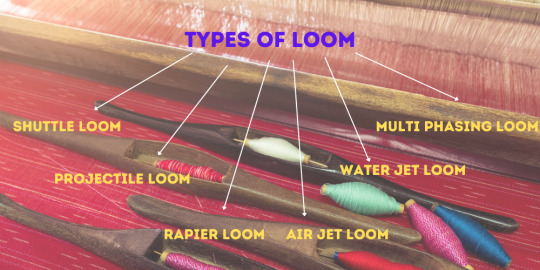

“Discover: Types of Loom in Textile Manufacturing”

Loom? What are They? What Do They Manufacture?

Looms is the weaving machine which converts the yarn into a fabric. There is no history of when looms were discovered but one thing is clear that it was before the birth of Jesus christ. There are 2 types of looms: Shuttle Looms and Shuttleless Looms. Below we are going to learn about various types of looms. The end result of this machine is fabric and wholesalers and retailers buy t-shirts in bulk made out of those fabric.

Learn About Shuttle Looms

This is the most primitive loom in the history of loom. In this machine there is a shuttle which contains bobbins and around bobbins there are yarn wounded. In this weaving machine the shuttle travels from one corner to the other and hence the fabric is made. The speed of this machine is 110-225 ppm [Picks Per Minute]. It is quite noisy and inefficient.

Fabric Weaving Without a Shuttle in the Loom Is It Possible?

Projectile Loom

Projectile loom is a shuttleless loom, in this looms instead of a shuttle projectile are there. Projectiles are made out of stainless steel and hence it was light weight. As the projectile lightweight this saves lots of energy and increases the efficiency of the machine. This loom speed was 300 ppm. The weaving takes place when the projectile goes across the width of the loom with the yarn.

Rapier Loom

This loom is also shuttleless. In this loom the weft is carried by a rapier which is a long rod like structure. Many kinds of fabric could be made using this loom and it is highly efficient. The range of GSM things loom could weave is 20-850 GSM. From home fabric to industrial fabric can be made using this loom. There are 4 types of rapier loom in the market.

Single Rigid Rapier Loom

Double Rigid Rapier Loom

Double Flexible Rapier Loom

Telescopic Rapier Loom

Air-Jet Loom

In this loom the yarn is transferred from the force of air, it does not have any shuttle. This loom is highly efficient and versatile. This loom does not make noise because it does not have many moving parts. As the moving parts are less then the floor space requirement and maintenance is low. The weft travels with the help of air pressure and once it reaches the shedding area interlacement takes place. This machine can be used in manufacturing Denim fabric, polyester dress material and cotton shirting fabric.

Water Jet Loom

Water pressure is used in this loom to transfer weft from one end to the other. It is a shuttleless loom machine. The speed of this machine is 600 ppm. This machine is highly efficient but we can use yarn which is hydrophobic, like polyester, polyamides etc. Hydrophilic yarn can not be used.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

8 notes

·

View notes

Text

Home decor suppliers in India | Kema India

Discover the perfect blend of tradition and modernity with Kemaindia, one of the most trusted home décor suppliers in India. We provide premium-quality furnishings, artistic décor, and stylish home accessories designed to enhance every corner of your home. Our diverse product range caters to various themes, ensuring a unique and personalized touch. Whether you want a minimalistic vibe or a regal look, we have the perfect décor solutions for you!

#Home decor products manufacturers#Manufacturers of home decor#Handmade wool rugs from India#Carpet and rug wholesalers#Floor mats for room#Handmade home decor items

1 note

·

View note

Text

Blazer fabrics suppliers in India

Blazers look the best when they actually fit you right! And if you like wearing blazers you might understand how important it is to get them custom made. If you’re looking to get the best quality blazer fabrics so that you can get your blazer custom tailored too, check out Blazer fabric suppliers in India.

0 notes

Text

Stone Wool Thermal Insulation Manufacturers in India

Are you searching for dependable and experienced Stone Wool Thermal Insulation Manufacturers in India who can provide high-quality solutions tailored to your specific needs?

We, at Polybond Insulation Pvt. Ltd., are experts in making high-quality stone wool thermal insulation products that meet global standards. With many years of experience, we provide insulation that offers great thermal resistance, energy savings, and soundproofing for homes, offices, factories, and more.

Our manufacturing facility in Chhattisgarh, India, uses the latest technology to create stone wool insulation that is strong, eco-friendly, and long-lasting. These products are designed to control heat, lower energy bills, and keep spaces comfortable. Our stone wool thermal insulation is also fire-resistant, moisture-proof, and easy to install for walls, roofs, floors, and HVAC systems.

At Polybond Insulation, we focus on delivering products on time. Our smooth transportation facilities ensure that your products reach you on time, no matter where you are located. To date, we have successfully produced and supplied a wide range of stone wool thermal insulation products, establishing ourselves as one of the trusted Stone Wool Thermal Insulation manufacturers in India and across the globe.

Our goal is to be one of the most reliable Stone Wool Thermal Insulation Manufacturers in India, providing clients with top-quality products they can trust and ensuring their projects are completed smoothly and without any issues.

Quality Standards We Follow as Leading Stone Wool Thermal Insulation Manufacturers in India

As Stone Wool Thermal Insulation Manufacturers in India, we always focus on providing the best quality for our products. At Polybond Insulation Pvt. Ltd., we follow strict quality checks to make sure our insulation materials work well. Our stone wool products are designed to provide great thermal insulation, fire resistance, and soundproofing.

We use high-quality materials to make our stone wool insulation, ensuring it lasts a long time and performs well. All our products are carefully tested to meet safety and environmental standards. Whether it's for homes, offices, or factories, our insulation materials work effectively in different spaces.

We are trusted by customers in India and around the world because of our focus on quality and innovation. Choose us for your Stone Wool Thermal Insulation needs and see the difference.

#Noise Insulation Manufacturers in India#Stone Wool Made From Rock in India#Stone Wool Thermal Insulation Manufacturers in India

0 notes

Text

Can You Find Unique Designs from a Wool Manufacturer in India?

Discover the excellence of Jindaltex Textile Industries, a leading Wool Manufacturer in India. We are renowned for producing high-quality wool products that cater to both domestic and international markets. Our commitment to superior craftsmanship and innovation ensures that you receive only the best from a top wool manufacturer in India. Explore our range and experience the unmatched quality and warmth of our wool products.

0 notes

Text

The Sustainable Path: Redefining Hotel Carpets with Green Practices

Introduction

Hotels play a crucial role in shaping guest experiences, and carpets significantly contribute to the ambiance. However, the environmental cost of traditional carpet manufacturing cannot be overlooked. Leading hotel carpet manufacturers and hospitality carpet suppliers are adopting sustainable practices, balancing luxury with responsibility.

The Role of Carpets in Sustainable Hospitality

Carpets in hotels and hospitality spaces must be both functional and aesthetically pleasing. Beyond their visual appeal, carpets from hotel carpet manufacturers in India are now becoming symbols of sustainability. Eco-friendly carpets help hotels align with global sustainability goals while maintaining a luxurious feel.

Key Sustainable Practices in Hotel Carpet Manufacturing

Sustainable Materials Wool, known for its natural resilience and renewability, is a favorite among wool carpet manufacturers. Additionally, recycled fibers like nylon and PET are gaining popularity.

Energy Efficiency Hotels are increasingly sourcing carpets from hospitality carpet manufacturers who use renewable energy in production, significantly reducing the carbon footprint.

Waste Reduction Innovative zero-waste policies ensure that manufacturing by-products are repurposed, reducing landfill contributions.

Eco-Friendly Dyes and Finishes Plant-based dyes and low-impact finishes are becoming standard, offering vibrant colors without harming the environment.

Carbon Footprint Management in Hotel Carpets

Transportation EmissionsLocally produced carpets reduce the need for long-distance transportation, cutting down on fuel consumption and associated emissions.

Lifecycle AssessmentsManufacturers conduct thorough assessments to evaluate and minimize the carbon footprint of each carpet throughout its lifecycle.

Recycling and DisposalCarpets designed for recyclability ensure that materials can be reused at the end of their life, further reducing their environmental impact.

Industry Standards and Certifications

Global Organic Textile Standard (GOTS)Ensures the use of organic fibers and environmentally responsible manufacturing processes.

ISO 14001Focuses on effective environmental management systems.

Green Label PlusGuarantees low chemical emissions for better indoor air quality.

The Advantages for Hotels

Cost SavingsEnergy-efficient production often translates to cost savings in the long run.

Enhanced Guest ExperienceEco-friendly carpets improve air quality and comfort, contributing to a healthier and more pleasant stay for guests.

Sustainability CredentialsHotels can showcase their commitment to the environment, appealing to eco-conscious travelers.

Case Studies: Success Stories in Sustainable Carpet Use

Several high-end hotels have successfully implemented sustainable carpets, witnessing benefits in terms of guest satisfaction and operational efficiency. These examples highlight the growing importance of eco-friendly solutions in the hospitality industry.

Conclusion

Sustainability is redefining the standards of luxury in the hotel industry. By partnering with hotel carpet manufacturers and hotel carpet suppliers in India who prioritize eco-friendly practices, hotels can enhance their environmental credentials. Sustainable carpets are more than just a design choice—they are a commitment to a greener, more responsible future.

#commercial carpet manufacturers#commercial carpet suppliers#hospitality carpet manufacturers#hospitality carpet supplier#hotel carpet manufacturers#hotel carpet manufacturers in india#hotel carpet suppliers in india#wool carpet manufacturers

0 notes

Text

How Do Rugs Help to Keep Your Home Warm in Winter?

When the chilly winds of winter start to seep through the walls and floors of your home, a well-chosen rug can become your best ally. Rugs are not just decorative pieces; they also play a vital role in keeping your home warm and cozy during colder months. Here’s a closer look at how rugs work their magic and why choosing quality options from the best rugs manufacturers in India can make all the difference.

1. Rugs as Insulators

Rugs, especially those made with natural fibers like wool, cotton, or jute, act as thermal insulators. They trap the cold air beneath and prevent it from seeping into your living spaces. Wool cotton rugs manufacturers are particularly known for creating pieces that combine warmth with comfort, making them an excellent choice for winter.

If you’re looking for sustainable yet effective solutions, Online Hemp Jute Rug in India are another great option. These rugs are eco-friendly and add a rustic charm to your interiors while maintaining insulation.

2. Comfort Underfoot

Walking on cold, hard floors during winter can be unpleasant. Rugs provide a soft, warm surface for your feet, enhancing comfort in your home. Braided Jute Rug Manufacturers and Wholesale Chindi Cotton Rugs offer durable and aesthetically pleasing options that not only keep your feet warm but also add a unique texture to your rooms.

3. Reducing Energy Costs

A strategically placed rug can reduce the need for heating appliances. For instance, Stair Runner Rugs Manufacturers in India produce stylish and functional rugs that can be used on staircases, reducing heat loss from open spaces. By insulating your home, rugs help lower energy bills, making them a cost-effective solution.

4. Aesthetic and Functional Benefits

While rugs serve a practical purpose, they also add a layer of aesthetic appeal to your home. For those who prefer versatile designs, Wool Jute rugs exporter in India and Cotton Rugs Manufacturers & Exporters in India offer a wide range of styles and patterns. These rugs are perfect for enhancing your interior décor while keeping your home cozy.

5. Perfect Choices for Every Room

Living Rooms: Opt for thick rugs from the best rugs manufacturers in India to create a warm and inviting space.

Bedrooms: Add a soft touch with Jute Cotton Rugs online in India for a cozy feel underfoot.

Staircases: Use runner rugs from Stair Runner Rugs Manufacturers in India to enhance safety and warmth.

Why Choose Indian Rugs?

India is renowned for its rich tradition of rug weaving. Leading manufacturers like Sanwariya Rugs, one of the best rugs exporters in India, produce high-quality rugs that cater to global markets. From Braided Jute Rugs to Wool Cotton Rugs, their collection combines craftsmanship with durability, ensuring that your rugs stand the test of time.

Conclusion

Rugs are an essential addition to your home during winter, offering warmth, comfort, and style. Whether you are looking for Jute Cotton Rugs online in India or exploring options from Wool Jute Rugs Exporters in India, choosing high-quality rugs from reliable manufacturers will ensure your home remains cozy and inviting throughout the season.

Let your home reflect both warmth and elegance this winter with the perfect rug from India's top manufacturers. For premium-quality options, check out Sanwariya Rugs and transform your space today!

#best rugs manufacturers in india#carpet exporter from india#Wool Jute rugs exporter in India#Stair Runner Rugs Manufacturers in India

0 notes

Text

https://www.rolexlanolin.com/blog/brief-history-of-lanolin-and-rolex-lanolin-products-limited/

Brief History of Lanolin and Rolex Lanolin Products Limited

Today, in modern times – Rolex Lanolin Products Limited (RLPL) is rediscovering lanolin in a new way to use this an ancient remedy. The lanolin in the ancient times is mentioned in De Materia Medica from Dioscorides under the name “Oesypus”.

#Lanolin for skin#Liquid lanolin#Lanolin Suppliers#Lanolin oil#Lanolin Cream#Organic Lanolin cream#sheep wool grease#Woolfat manufacturer#Lanolin Manufacturers in india

0 notes

Text

Wool fabric manufacturers play a crucial role in the textile industry, producing a wide range of woolen materials that cater to diverse applications. These manufacturers are responsible for transforming raw wool fibers into finished fabrics, ensuring quality and consistency. The history of wool fabric manufacturing dates back centuries, with manufacturers constantly innovating to meet modern demands. Choosing the right type of wool from reputable wool fabric manufacturers can significantly impact the quality and performance of the final product.

#womens fashion#scarves supplier#wool fabric manufacturers#fabric manufacturers in usa#t shirt manufacturers uk#shawl manufacturer in usa#wool manufacturers in india#best t-shirt manufacturers in usa

0 notes

Text

The Cozy World of Recycled Wool: Embracing Sustainable Blankets

Introduction

Imagine wrapping yourself in a cozy blanket that not only offers unmatched comfort but also carries a heartwarming story of sustainability. In today's world, where environmental awareness is of paramount importance, companies are making significant strides in the textile industry by creating blankets that prioritize the well-being of our planet.

The Significance of Sustainability

Sustainability is no longer a mere buzzword; it has become a necessity. The textile industry has a history of environmental challenges, from water pollution caused by dyes to excessive water consumption during production. As global awareness of these issues continues to grow, consumers are reevaluating their choices, seeking products that align with their eco-conscious values.

The Demand for Sustainable Textiles

The traditional textile industry has not always been environmentally friendly, raising serious concerns about its practices. However, consumers are increasingly adopting more eco-conscious purchasing habits, choosing products that are sustainable and environmentally responsible. Sustainable textiles are the answer to this evolving demand.

Embracing Sustainability: A Green Commitment

In the realm of sustainable textiles, companies are prioritizing green practices. They have embraced recycled wool, a revolutionary material that significantly reduces the carbon footprint of the textile industry.

The Journey of Recycled Wool

Recycled wool takes center stage in the production of sustainable blankets. Here's how it works: discarded wool products, such as old sweaters or blankets, are transformed into high-quality yarn. This innovative process not only reduces waste but also gives new life to valuable resources, making it a win-win for both comfort and the environment.

Crafting Sustainability

Companies are not stopping at recycled wool; they prioritize sustainable manufacturing practices, too. Think of eco-friendly dyeing methods that minimize environmental impact and energy-efficient production processes. Additionally, they are dedicated to reducing waste by employing recycled packaging materials, contributing to a more sustainable future.

The Comfort of Recycled Wool Blankets

What truly sets sustainable blankets apart is the exceptional comfort they offer. These blankets are not just any blankets; they are crafted with care and attention to detail. The result? Blankets are known for their softness and warmth, making them perfect for cozying up on chilly nights.

Making a Positive Impact

Choosing a sustainable blanket is not just about comfort; it's about making a tangible difference. Sustainable practices significantly reduce carbon emissions and water usage compared to conventional manufacturing methods. By opting for eco-conscious brands, you actively participate in a global effort to minimize environmental impact.

Looking Towards the Future

Companies are committed to continuous improvement. They are continually exploring innovative technologies that have the potential to make the blanket manufacturing industry even more environmentally friendly.

Conclusion

In summary, the sustainable approach to blanket manufacturing, particularly with recycled wool, exemplifies a significant step towards a greener textile industry. Dedication to quality, comfort, and sustainability means that choosing a blanket from eco-conscious brands is not just about staying warm; it's about making a positive impact on the planet.

So, when you wrap yourself in a sustainable blanket, know that you're not only staying cozy but also contributing to a healthier, more environmentally friendly world. Explore the world of sustainable blankets with Jiindal Textile As a leading wool yarn supplier, wool manufacturer in India, and recycled wool supplier, we offer blankets that prioritize your comfort and the well-being of our planet. Discover our sustainable blankets now.

0 notes

Text

Learn About 2 Types of Circular Knitting Machine and Their Advantages

Comprehensive Guide of Single Jersey Circular Knitting Machine and Its Advantages

Single jersey knitting machine has one cylinder of around 30 inches. This machine can knit fabric with less GSM [gsm in fabric how to calculate] compared to a double jersey knitting machine. Knitting is done in one direction in this machine. The knitting in this machine takes place by the coordination of needle and sinker, where needle makes the loop and sinker push it toward the fabric. Sinker plays an important part in this machine. Using this fabric we can manufacture plain fabric which is used in the production of t-shirts, blouses, tops and casual dress. Since the invention of knitting plain fabric is being made. Plain fabric can be made using hand and machine both. Wool production is limited to 20 gauge using this fabric. The fabric made out of this machine has curling ends.

Advantages of Single Jersey Circular Knitting Machine

A- This machine is a good choice for mass production

B- This machine can manufacture a variety of products from lightweight to heavy-weight fabric.

C- Single jersey machine is easy to maintain and repair

D- Less expensive compared to double jersey knitting machine ]

E- It can switch between colors easily

Introducing Double Jersey Circular Knitting Machine and Its Advantages

A double jersey circular knitting machine is nothing but a single jersey knitting machine; the only difference in this type of knitting machine is that it has an extra set of needles which moves horizontally. In this machine there are 2 sets of needles adjacent to each other. This machine knit in 2 directions perpendicular to each other. Sinker is not required in this machine. The final product that is made out of this machine are sweaters, sweatshirt, hoodies, etc. The final product of this machine does not curl unlike a single jersey circular knitting machine.

Advantages of Double Jersey Circular Knitting Machine

A- Can produce fabric with different textures such as terry and pique

B- It can produce multiple patterns, such as stripes and jacquards

C- It can produce thicker fabric with higher insulated properties

Fabric is an important part of t-shirts or any garment manufacturing. We as a t-shirt manufacturer see that when a wholesaler buy t-shirts in bulk from us they check the quality of the fabric.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

5 notes

·

View notes

Text

Medical Disposables Manufacturer

Jajoo Surgicals is a leading medical disposables manufacturer dedicated to ensuring quality and reliability in healthcare settings. Specializing in producing essential items such as gloves, syringes, and surgical masks, they prioritize safety and precision in every product. With a commitment to innovation and hygiene, Jajoo Surgicals provides vital supplies that meet the rigorous standards of modern healthcare practices.

#medical disposables manufacturer#medical disposable manufacturers in india#sterilization rolls#microporous surgical tape#absorbent cotton wool manufacturers

0 notes

Text

Premier Wool Serge

Wool serge is an extremely durable fabric made from wool which has a lot of commercial and industrial uses. They are used as acoustic dampeners due to their sound absorption qualities, and even in making durable uniforms. If you need this serge for any of these purposes, check out the Premier Wool Serge.

0 notes

Text

Stone Wool Made From Rock in India

Are you looking for high-quality stone wool made from rock in India, perfect for your construction projects or energy-saving needs?

Welcome to Polybond Insulation Pvt. Ltd., we are leading manufacturers of stone wool insulation products made from rock. Our products meet global standards and are suitable for various uses. Our stone wool made from rock in India provides excellent thermal resistance, soundproofing, and fire protection, making it ideal for residential, commercial, and industrial applications.

Our stone wool products, made from natural rock, are strong, eco-friendly, and energy-saving. They help keep your space cool in the summer and warm in the winter, saving energy and providing comfort for a long time. Our products are moisture-resistant, fire-resistant, and easy to install.

Our state-of-the-art manufacturing facility is located in Chhattisgarh, India, where we supply high-quality stone wool insulation worldwide. Whether you're working on a construction project or improving an existing insulation system, our products are perfect for you.

Trust Polybond Insulation for reliable, on-time delivery for all your stone wool made from rock in India for insulation needs.

How Our Stone Wool Made From Rock in India Provides Superior Thermal & Acoustic Insulation

At Polybond Insulation Pvt. Ltd., we provide stone wool made from rock in India that offers excellent thermal and sound insulation. Our stone wool made from rock helps keep spaces comfortable by blocking heat, which saves energy. It works well in both hot and cold climates to maintain the right temperature indoors.

Besides thermal insulation, our stone wool also works great for reducing noise. It helps prevent sound from traveling, making it perfect for homes, offices, and factories where noise control is needed. Our stone wool insulation is fire-resistant and moisture-proof, ensuring it lasts longer and stays safe.

Choose Polybond Insulation for high-quality stone wool that provides great thermal and acoustic insulation. Contact us today to learn more about our stone wool made from rock in India.

#Noise Insulation Manufacturers in India#Stone Wool Made From Rock in India#Stone Wool Thermal Insulation Manufacturers in India

0 notes