#UV-resistant resin

Explore tagged Tumblr posts

Text

Step Up Your Property Value: Install the Best Resin Driveway

Resin driveways are known to have a significant impact on the aesthetic appeal of your home. If you are looking to transform your home in the most effective way, consider installing resin driveways. Resin driveways will give your residence a subtle yet differentiated look. Making changes to the entrance of your home will have a positive impact on your property. The estimated value of your property gets increased. Resin Driveways is a renowned company that has been offering some of the finest resin driveway installation services at affordable costs in the UK. In this article, we will get to know the advantages of the best resin driveways and why Resin Driveways is the most preferable option.

Advantages of resin driveways:

Aesthetic appeal – Resin driveways have a substantial impact on the visual appeal of your home. If you are looking forward to renovating your home in the best possible way, opt for installing a resin driveway. While executing the renovation project of your home, you definitely want your paradise to look better than before. Hence, you can get it done with the aid of a professional. Some professionals present you with the choice to choose colours of resin driveways, and convert your vision into reality. Hire the best resin driveway installation experts from Resin Driveways, a company possessing professionals who have over 18 years of experience in the service niche. We can even customize our service according to your tastes or needs.

Durability and longevity – Another major benefit of resin driveways is that they are durable, enduring, and long-lasting. The attractiveness of resin driveways doesn’t fade quickly with time. The combination of high-grade resin and aggregates used for creating the driveway enables a robust surface. Resin driveways are meant to withstand harsh weather conditions and do not degrade easily as compared to traditional driveways. Investing in the best resin driveway is a smart investment as it can also resist cracks and potholes. With Resin Driveways by your side, you can always be sure of the quality materials and top-notch installation services.

Low maintenance – A resin driveway doesn’t call for much maintenance. Since it is made up of solid materials that are strong and enduring, it doesn’t face wear and tear. Resin driveways are weed-resistant and permeable. Hence, you need not worry about weeds and standing water. The water percolates through the driveway, from the surface to underground. Those struggling with busy schedules should definitely opt for resin driveways installation, since they require very low maintenance, which can be done occasionally. This will help them get more of leisure time and focus on other life priorities. Resin Driveways recommends you to clean your resin driveway with a brush or stiff broom occasionally, since it requires low maintenance services.

Why Resin Driveways?

Resin Driveways provides the best resin driveway installation services at affordable costs in the UK, without compromising on the quality of the installation service. We have installed resin driveways all over the UK, such as heritage sites, housing developments, and town centres. We are your reliable, go-to option regarding resin driveways and have been trusted by numerous clients. So what are you waiting for? Improve the curb appeal of your property by opting for the construction of resin driveways by our company.

#best resin driveway#Resin driveway advantages#Affordable resin driveways#Resin driveway installation#Durable resin driveways#Resin driveway colors#Eco-friendly resin driveways#Low maintenance driveways#Resin driveway design ideas#UV-resistant resin#Resin driveway cost#Permeable resin surfaces#Resin Bound Driveway#Resin Bound Paving

0 notes

Text

My addiction to sparkling water is the equivalent to a bear from a horror story trying human flesh for the first time and never being able to go back

#oh tap water#how refreshing you used to be!#but now your divine image has be yellowed beyond repair#a new melodious drink awaits me with open caps#and thankfully their image has a UV-resitant epoxy resin that resists patina

2 notes

·

View notes

Text

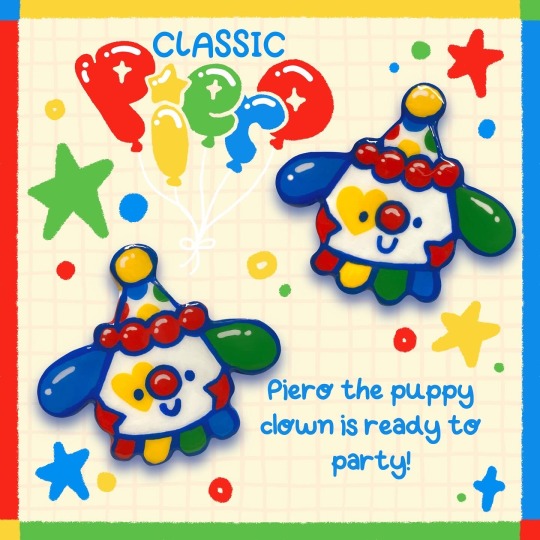

✨🎪🐶PIEROS ARE HERE🐶🎪✨

Hello! I’m now open for Piero orders (I have 6 classics/6 pastels)! If you’d like to adopt one, please comment or dm (I’m also on IG and Twitter)!

$26 each (free s&h) US only pls.

Handmade/painted w/ Holbein acrylic gouache, coated in UV resistant spray & sealed in resin. ❤️

#clay pins#sculpey clay#cute clown#cute art#clowncore art#clownblr#clowncore aesthetic#clown aesthetic#clowncore#kidcore#kidcore aesthetic#pastelcore#indie artist#artist on tumblr#support small artists#handmade#artists on tumblr#art#piero the puppyclown#puppy clown#clay art#pieropuppyclown#welcome home arg#amazing digital circus#dhmis

80 notes

·

View notes

Text

Wen Liu, Inarticulate Trace No. 2, 2024. Prescribed herbal medicine, epoxy clay, resin, paint, UV resistant varnish.

35 notes

·

View notes

Text

Choosing the Right Epoxy Insulator for Your Specific Needs

Epoxy insulators are a critical component in modern electrical and industrial applications. They provide high electrical resistance, mechanical strength, and durability, making them ideal for insulating electrical systems. With a range of designs and specifications available, selecting the right epoxy insulator for your specific needs can be a challenging task. Collaborating with leading epoxy insulator manufacturers in India ensures that you receive reliable, high-quality products tailored to your requirements.

What Are Epoxy Insulators?

An epoxy insulator is a device used to isolate electrical conductors, ensuring the safe transmission of power while preventing short circuits and electrical faults. Made from epoxy resin, these insulators are renowned for their exceptional dielectric strength, resistance to environmental factors, and mechanical stability.

Epoxy insulators find applications across various industries, including:

Electrical power distribution: Supporting and insulating conductors in high-voltage lines.

Electronics: Providing insulation for sensitive electronic components.

Industrial equipment: Protecting machinery and systems from electrical interference.

Types of Epoxy Insulators

When choosing an epoxy insulator, understanding the different types available is crucial. Common types include:

Post Insulators

Designed for high-voltage applications, these insulators support conductors and provide insulation in substations and transmission lines.

Bushings

Epoxy bushings are used to insulate conductors passing through grounded barriers, such as transformers or circuit breakers.

Support Insulators

These are used in switchgear and other electrical equipment to support busbars and other components.

Customized Epoxy Insulators

Some applications require bespoke designs. Customized epoxy insulator manufacturers in India can create tailor-made solutions to meet specific requirements.

Factors to Consider When Choosing an Epoxy Insulator

Selecting the right epoxy insulator involves evaluating several factors to ensure it meets your application’s needs:

1. Electrical Performance

The primary function of an epoxy insulator is to provide electrical insulation. Evaluate its dielectric strength, resistance to leakage currents, and ability to withstand high voltages.

2. Mechanical Strength

The insulator must withstand mechanical stresses such as tension, compression, and vibration. This is particularly important in high-voltage transmission and heavy industrial applications.

3. Environmental Resistance

Epoxy insulators are often exposed to harsh environmental conditions, including extreme temperatures, UV radiation, and humidity. Choose insulators with high resistance to these factors.

4. Customization Requirements

Every application has unique requirements. Collaborating with customized epoxy insulator manufacturers in India ensures you get a product tailored to your specifications, including size, shape, and material properties.

5. Compliance with Standards

Ensure the epoxy insulator complies with relevant industry standards, such as IEC, ANSI, or BIS. Reputable epoxy insulator manufacturers in India adhere to these standards, ensuring product reliability and safety.

6. Cost-Effectiveness

While quality should never be compromised, consider the cost-effectiveness of the insulator. Balance initial costs with long-term performance and durability.

Benefits of Using Epoxy Insulators

Epoxy insulators offer numerous advantages, making them a preferred choice across industries:

High Dielectric Strength: Ensures excellent insulation and prevents electrical faults.

Durability: Resistant to environmental degradation, ensuring long-term performance.

Lightweight: Easier to handle and install compared to traditional porcelain or ceramic insulators.

Customizability: Can be tailored to meet specific design and application requirements.

Low Maintenance: Minimal upkeep is required, reducing operational costs.

Why Choose Indian Epoxy Insulator Manufacturers?

India is home to some of the most advanced epoxy insulator manufacturers, offering world-class products at competitive prices. Here’s why you should consider Indian manufacturers:

1. Advanced Manufacturing Facilities

Indian manufacturers leverage state-of-the-art technology to produce high-quality insulators that meet global standards.

2. Expertise in Customization

Leading customized epoxy insulator manufacturers in India excel in creating tailor-made solutions to meet diverse industry needs.

3. Cost-Effective Solutions

Competitive pricing, combined with exceptional quality, makes Indian manufacturers a preferred choice for businesses worldwide.

4. Commitment to Quality

Reputable epoxy insulator manufacturers in India prioritize quality, ensuring their products comply with stringent standards and deliver reliable performance.

Radiant Enterprises: A Trusted Name in Epoxy Insulators

As a leading epoxy insulator manufacturer, Radiant Enterprises specializes in delivering high-performance epoxy insulators for various applications. Our commitment to quality and innovation sets us apart in the market.

Why Choose Radiant Enterprises?

Comprehensive Product Range:

From standard designs to bespoke solutions, we offer a wide range of epoxy insulators to meet your needs.

Custom Solutions:

As one of the top customised epoxy insulator manufacturers in India, we work closely with clients to develop tailored solutions that meet specific requirements.

Strict Quality Control:

Our products undergo rigorous testing to ensure they meet or exceed industry standards.

Global Reach:

With a strong presence in domestic and international markets, Radiant Enterprises is a trusted partner for businesses worldwide.

Sustainable Practices:

We prioritize sustainability in our manufacturing processes, ensuring minimal environmental impact.

Applications of Epoxy Insulators from Radiant Enterprises

Our epoxy insulators are widely used across industries, including:

Power Transmission and Distribution: Supporting high-voltage lines and substation equipment.

Industrial Automation: Providing insulation for machinery and control systems.

Renewable Energy: Ensuring safe and efficient operation of solar and wind power systems.

Transportation: Offering reliable insulation for railway and metro systems.

How to Partner with Radiant Enterprises

Choosing the right epoxy insulator starts with selecting the right partner. At Radiant Enterprises, we make the process seamless:

Consultation: Our experts assess your requirements and recommend the best solutions.

Design and Customization: We collaborate with you to create insulators tailored to your needs.

Quality Assurance: Our products undergo stringent testing to ensure reliability and safety.

Timely Delivery: We prioritize timely delivery to keep your projects on track.

Conclusion

Selecting the right epoxy insulator is crucial for ensuring the safety, reliability, and efficiency of your electrical systems. With numerous options available, partnering with a trusted epoxy insulator manufacturer like Radiant Enterprises can make all the difference.

As one of the leading epoxy insulator manufacturers in India, Radiant Enterprises combines expertise, innovation, and a commitment to quality to deliver exceptional products. Whether you need standard designs or bespoke solutions, we have the capabilities to meet your requirements.

Contact us today to learn more about our comprehensive range of epoxy insulators and how we can support your specific needs.

#Epoxy insulator#Customised epoxy insulators manufacturers in India#Epoxy insulator manufacturers in India#Epoxy insulator manufacturer#India

5 notes

·

View notes

Text

Leelee Chan, Oculus (Budding Amethyst), 2022, found plastic pallet, chevron amethyst, stainless steel mirror and hardware, steel, epoxy, urethane resin, UV-resistant pigment, 72 x 72 x 17 cm, 28 1/2 x 28 1/2 x 6 1/2 in, Copyright the Artist. Courtesy of the Artist and Capsule Venice

4 notes

·

View notes

Text

Revolutionising Electrical Systems – The Rise of Customised Epoxy Insulators

In the realm of electrical engineering and power distribution, innovation is the key to efficiency, reliability, and safety. One such groundbreaking development is the rise of customised epoxy insulators. Epoxy insulators are transforming the landscape of electrical systems, providing superior performance and durability. As epoxy insulators manufacturers in India continue to push the boundaries of technology, the benefits of these innovative products are becoming increasingly evident. This blog explores the revolutionary impact of customised epoxy insulators on electrical systems, highlighting their applications, advantages, and the leading manufacturers driving this transformation.

Understanding Epoxy Insulators

Epoxy insulators are a type of electrical insulator made from epoxy resin, a material known for its excellent electrical properties, mechanical strength, and resistance to environmental factors. These insulators are designed to withstand high voltage and harsh conditions, making them ideal for a wide range of applications in power distribution and electrical engineering.

Traditionally, electrical insulators have been made from materials such as porcelain and glass. However, epoxy insulators offer several advantages over these conventional materials, including higher mechanical strength, lighter weight, and better resistance to environmental degradation. This has led to a growing adoption of epoxy insulators in various sectors, from industrial power distribution to transportation systems.

The Advantages of Customised Epoxy Insulators

Customisation is a significant trend in the epoxy insulator market, allowing for tailored solutions that meet specific requirements and challenges. Here are some of the key advantages of customised epoxy insulators:

Enhanced Performance and Reliability

Customised epoxy insulators are designed to meet the unique demands of specific applications, ensuring optimal performance and reliability. By tailoring the design and composition of the insulator, manufacturers can enhance its electrical and mechanical properties, resulting in better performance under high voltage and extreme conditions.

Improved Durability and Longevity

Epoxy insulators are known for their durability and resistance to environmental factors such as moisture, chemicals, and UV radiation. Customisation further enhances these properties, ensuring that the insulators can withstand the rigours of their operating environments and provide long-lasting performance.

Cost-Effective Solutions

While the initial cost of customised epoxy insulators may be higher than standard insulators, their enhanced performance and longevity result in lower maintenance and replacement costs over time. This makes them a cost-effective solution for businesses looking to improve the reliability and efficiency of their electrical systems.

Flexibility in Design

The customisation process allows for flexibility in design, enabling manufacturers to create insulators that meet specific dimensional and performance requirements. This is particularly beneficial for applications with unique challenges or constraints, such as limited space or high-stress environments.

Environmental Benefits

Epoxy insulators are often more environmentally friendly than their traditional counterparts, as they require fewer resources to produce and have a longer lifespan. Customisation can further enhance these benefits by optimising the design for reduced material usage and improved energy efficiency.

Applications of Customised Epoxy Insulators

The versatility of customised epoxy insulators makes them suitable for a wide range of applications across various industries. Some of the key applications include:

Power Distribution and Transmission

In the power distribution and transmission sector, customised epoxy insulators are used in high-voltage applications to ensure the safe and efficient transfer of electricity. Their superior electrical properties and durability make them ideal for use in substations, transformers, and switchgear.

Transportation Systems

One of the critical applications of epoxy insulators is in transportation systems, particularly in railways. Epoxy insulators for third rail systems are essential components that ensure the safe and reliable transmission of power to trains. These insulators need to withstand high voltage, mechanical stress, and environmental factors, making customisation crucial for optimal performance.

Industrial Applications

In industrial settings, customised epoxy insulators are used in a variety of applications, including machinery, equipment, and power distribution networks. Their ability to withstand harsh conditions and high voltage makes them ideal for use in manufacturing plants, chemical facilities, and other industrial environments.

Renewable Energy

The renewable energy sector also benefits from the use of customised epoxy insulators, particularly in wind and solar power systems. These insulators are designed to handle the unique challenges of renewable energy applications, such as exposure to harsh weather conditions and fluctuating power loads.

Leading Epoxy Insulators Manufacturers in India

India is home to several leading manufacturers of epoxy insulators, who are at the forefront of innovation and customisation in this field. Some of the top epoxy insulators manufacturers in India include:

Radiant Enterprises

Radiant Enterprises is a prominent name in the epoxy insulator market, known for its commitment to quality and innovation. The company offers a wide range of customised epoxy insulators for various applications, including power distribution, transportation, and industrial use. Radiant Enterprises' focus on research and development ensures that its products meet the highest standards of performance and reliability.

ABC Insulators

ABC Insulators is another leading manufacturer in India, specialising in the production of high-quality epoxy insulators. The company offers customised solutions to meet the specific needs of its clients, ensuring optimal performance and durability. ABC Insulators' state-of-the-art manufacturing facilities and experienced team make it a trusted partner for businesses across various industries.

XYZ Electricals

XYZ Electricals is a renowned name in the electrical insulator market, offering a wide range of epoxy insulators for different applications. The company's customised solutions are designed to meet the unique requirements of its clients, providing superior performance and reliability. XYZ Electricals' commitment to quality and innovation has made it a leading player in the Indian market.

The Future of Customised Epoxy Insulators

The future of customised epoxy insulators looks promising, with several trends and developments set to drive further innovation and growth in this field. Some of the key trends to watch include:

Advancements in Material Science

Ongoing research and development in material science are expected to lead to the creation of new epoxy resin formulations with enhanced properties. These advancements will further improve the performance and durability of customised epoxy insulators, making them even more effective for a wide range of applications.

Increased Focus on Sustainability

As businesses and industries place greater emphasis on sustainability, the demand for environmentally friendly insulators will continue to grow. Customised epoxy insulators, with their long lifespan and reduced environmental impact, are well-positioned to meet this demand. Manufacturers will likely focus on developing even more sustainable solutions in the future.

Integration with Smart Technologies

The integration of epoxy insulators with smart technologies, such as sensors and IoT devices, is another trend to watch. This integration will enable real-time monitoring and diagnostics, improving the reliability and efficiency of electrical systems. Customisation will play a crucial role in developing smart insulators that meet the specific needs of different applications.

Expansion into New Markets

The market for customised epoxy insulators is expected to expand into new regions and industries as awareness of their benefits grows. This expansion will create new opportunities for epoxy insulators manufacturers in India, driving further innovation and growth in the market.

Conclusion

Customised epoxy insulators are revolutionising electrical systems, offering superior performance, durability, and cost-effectiveness. As epoxy insulators manufacturers in India continue to innovate and push the boundaries of technology, the future looks bright for this transformative product. By leveraging the advantages of customised epoxy insulators, businesses across various industries can enhance the reliability and efficiency of their electrical systems, ensuring long-term success and sustainability.

#Epoxy insulator for third rail#Epoxy insulators#Epoxy Insulators manufacturers in India#Customised epoxy insulators manufacturers in India

4 notes

·

View notes

Video

youtube

Essential Care for Your Outdoor Furniture

Maintaining your outdoor furniture is crucial to extend its lifespan and keep it looking great. The elements can take a toll on various materials, so understanding click here to learn more the specific needs of your patio set is key. With the right approach, you can enjoy your outdoor oasis for many seasons to come.

The Basics of Outdoor Furniture Upkeep

Outdoor furniture is constantly battling against sun, rain, and wind, which can lead to wear and tear over time. To keep your patio set in top condition, it's important to clean and protect it regularly. Here's how to tackle different materials:

For All Materials

Spot and Stain Removal: A gentle solution of mild soap and water can be used to clean most outdoor furniture materials. Apply with a soft brush or cloth, rinse thoroughly, and allow to dry.

Regular Cleaning: Prevent dirt buildup by brushing off debris or wiping down with a nylon cloth. For tougher grime, a pressure washer on a low setting can be effective.

Protection: After cleaning, cover your furniture or store it to shield it from the elements.

Specific Material Care

Wicker: Keep wicker furniture covered when not in use to prevent fading and cracking.

Plastic and Resin: These materials are more resistant to weather, but regular cleaning is still necessary to avoid discoloration.

Wood: Hardwoods like teak require occasional oiling to maintain their color and prevent drying out. Softwoods may need a protective sealant.

Wrought Iron: To prevent rust, apply a coat of automotive wax and touch up any chips in the paint promptly.

Aluminum: Although resistant to rust, aluminum furniture should be cleaned regularly and touched up if the powder coating is damaged.

Cushion and Fabric Care

Storage: Store cushions indoors during off-seasons to prevent damage from moisture and cold.

Cleaning: Use mild soap for cleaning, rinse well, and dry in the sun to prevent mildew.

Wood Furniture Maintenance

Indoor Storage: Preserve the beauty of wood furniture by storing it indoors during harsh weather.

Oiling and Sealing: Apply teak oil or a sealant to protect from moisture and UV damage.

Metal Furniture Upkeep

Rust Prevention: For non-aluminum metals, ensure any chipped areas are promptly sealed to prevent rust.

Oxidation Removal: Use a mild abrasive cleaner to remove oxidation from metal surfaces.

2 notes

·

View notes

Note

re: wooden bathtubs, there's a couple ways you can make wooden vessels watertight & protect the wood itself from the water (two different things!). none are 100% effective & eventually the wood will decay. easiest modern way to deal w/ both problems simultaneously is to encapsulate the wood in petroleum-based plastic of some kind (polyurethane varnish, epoxy resin), which basically removes the wood from the equation altogether except as a structural member (until the plastic fails from UV exposure, wear, stress, etc). you can of course also completely coat the wood in something like tar or paint, which act similarly, but then you lose the natural wood look, so we'll put those options aside.

other options are generally going to involve separating the goals of "protect wood from water" and "seal container", and will rely on the properties of the wood itself. when wood is wet, it absorbs water, which causes the fibers to swell. if a piece of wood is already closely pressed against other pieces of wood on both sides before getting wet, that swelling will make the seam VERY tight - almost perfectly watertight. (of course, this swelling also induces warping & distortion into the wood depending on the pattern of the grain, which needs to be planned for so the pieces of wood don't push each other out of alignment.)

however, most wood doesn't like being wet all the time and will start to rot pretty quickly, so you need to pick a kind of wood that won't do that, at least not on the timescale you're planning. depending on the kind of liquid you're planning on putting into the vessel (salt vs fresh water, different concentrations of alcohol, different acidities/alkalinities, amount of UV exposure, temperature, oxygen exposure), different woods do better or worse. for example, there are oaken foundation piers continually submerged in wet boggy soil in england that are close to a thousand years old. willow i believe is supposed to do well with long-term water exposure (think of the riverbank environments they normally grow in). cedar in particular is naturally permeated with lots of resins & oils that make it very resistant to rot - i would guess that the redder of the wooden baths in that picture is cedar.

also, vessels with continual water exposure usually do better at being watertight than ones that dry out & are refilled - when they dry out, the wood shrinks and the seams literally open up, causing leaks until they rehydrate.

this is so interesting and im in awe and i love you for giving such a detailed answer to my impromptu question

#I LOVE LEARNING NEW STUFF#when ppl share their knowledge with me im immediately in awe#caterjunes#gray answers

2 notes

·

View notes

Text

going to be autistic on here abt bjd eyes

i’ve been experimenting w trying to make bjd eyes for years at this point and im like confident in my skills but i’m struggling to find the right materials. i watch a lot of various eye makers’ tutorials to see what they use but the problem i always find is that most of them don’t seem to worry abt how the eyes will hold up longterm, which is smth i rly want for mine. like using uv resin for the base will yellow so bad….not to mention the health effects

so it’s like health + longevity that bothers me. i don’t want to use toxic materials for my eyes and risk my health for it. stop using resin without proper ventilation and shit inside your home. please.

my best bet rn is polymer clay for the bases and it works great but the major problem i have is dust in the pure white of the eyes…gonna try some ways of minimising this but i also can’t spend all my energy trying to reduce dust in my environment bcuz it’ll give me a heart attack from the stress. plus i can’t seem to get it to smoosh perfectly in the silicone molds…it’s always got some dents. that’s probably just practice though

so for the dust my thinking was maybe i’d just cover it in acrylic paint after, but acrylic paint stays a bit sticky and attracts dust anyway so. it kinda cancels out. i’ve thought about other materials to use as a base but it always comes back to yellowing. i wondered whether maybe thermoplastic could work but i couldn’t find anything about the yellowing rates so, maybe i’ll try it and leave it sometime but i don’t have high hopes

but then ofc there’s the problem of The Oven. i make the irises out of polymer clay bcuz that’s what works best for me. i’ve never been able to use pastels for my colours bcuz it just looks gross and grainy and muddy no matter what i do, so polymer clay is pretty non negotiable. which means whatever i use for the bases has to be oven safe

and the bubbles in the domes as well…it’d be good to get a pressure chamber someday but that’s a more serious piece of kit than i have room for rn. laeli suggested trying a vibrator to agitate the bubbles which i wanna try so bad lol. but i need to get the resin first….i wanna try art resin cuz it’s supposed to be non toxic so i could use it indoors. and i saw some tests where it was super resistant to yellowing as well. so it sounds perfect but since it’s 2 part resin i’d have to have a lot of eyes prepped beforehand so i don’t waste it all as it’s not cheap !!

im thinking about seeing if i could do the bases with art resin as well but since it’s only non toxic on its own cuz it doesn’t react with anything else in the air, i don’t know what pigments i could use if any. apparently their pigments they make are kinda ass and i’d need it to be a really solid white. they also don’t sell the pigments individually afaik. i’d like to try a white gel pigment but again !! i don’t know how it’ll react. it’d probably be fine but i wish i had the info…..plus i don’t know if it would just melt in the oven. you shouldn’t really put resin in the oven. and if it worked i’d definitely want to get my own little oven sooner as i’m just experimenting w the kitchen one first….bcuz it comes back to the toxic fumes. but even if i did that’s also. having the space for it

UAGH !! you see why i am going round in circles….i wish i could be one of those girlies that just fucks up their lungs and makes eyes that go yellow in 2 years and be happy but unfortunately i care for both myself and my product. i think i’m gonna have to just work on making my space dust free for the white polymer clay but I DONT WANNAAAAAA

4 notes

·

View notes

Text

Essential Epoxy Resin Art Supplies Every Artist Needs

When it comes to creating stunning resin artworks, having the right tools and materials is essential. Epoxy resin art supplies play a crucial role in bringing your artistic visions to life, and choosing the right ones can make all the difference in the final result. From high-quality epoxy resin to vibrant pigments and safety equipment, let's explore the Essential Epoxy Resin Art Supplies Every Artist Needs

High-Quality Epoxy Resin:

The foundation of any resin art project starts with the epoxy resin itself. It's imperative to use epoxy resin specifically designed for art applications to ensure optimal results. Look for resins that offer clarity, UV resistance, and minimal yellowing over time, as these qualities will preserve the integrity of your artwork. Whether you're creating paintings, jewelry, tabletops, or sculptures, a versatile epoxy resin will provide the perfect medium for your creative endeavors.

Pigments:

Adding vibrant colors to resin artworks is where the magic happens, and the right pigments can elevate creations to new heights. Liquid pigments, mica powders, and alcohol inks are popular choices for coloring epoxy resin. These epoxy pigment are specially formulated to be compatible with epoxy resin, offering a wide range of hues and allowing artists to express their artistic vision with unique designs.

Colorants:

In addition to pigments, colorants play a crucial role in resin art projects. They help achieve desired hues and effects, such as translucency or opacity. Whether using liquid colorants, powder colorants, or specialty additives, selecting the right epoxy resin color enhances the overall aesthetic of resin artworks and allows artists to experiment with various techniques and finishes.

Mixing Tools and Containers:

Achieving the perfect consistency and eliminating air bubbles are crucial steps in the resin art process, and having the right mixing tools and containers is essential. Silicone measuring cups, stirring sticks, and graduated mixing containers ensure accurate ratios and smooth blending of epoxy resin and pigments. These tools are durable, easy to clean, and designed to help you achieve flawless results in your resin art projects.

Molds and Forms:

Molds and forms are indispensable tools for shaping resin artworks and creating intricate designs. Silicone molds, resin casting molds, and reusable molds offer endless possibilities for creating unique shapes, textures, and patterns in your resin pieces. Whether you're making functional items like coasters and trays or decorative pieces like jewelry and sculptures, the right molds and forms will help you bring your artistic vision to life.

Safety Equipment:

Working with Epoxy Resin Art Supplies requires taking safety precautions to protect yourself from potential hazards. Nitrile gloves, safety goggles, and a respirator mask are essential safety equipment that provides protection against skin contact, eye irritation, and inhalation of fumes. It's also crucial to work in a well-ventilated area to minimize exposure to harmful vapors and ensure a safe working environment.

Finishing Tools and Supplies:

Once your resin artwork is complete, finishing tools and supplies are necessary for achieving a professional-looking finish. Sandpaper, polishing compounds, and resin-compatible sealants are essential for smoothing surfaces, enhancing gloss, and improving durability. These finishing touches add a level of refinement to your resin art pieces, making them stand out and command attention.

Work Surface Protection:

Protecting your work surface is essential to prevent damage and ensure easy cleanup during resin art projects. Using a disposable plastic sheet or silicone mat provides a protective barrier against spills and stains, safeguarding your tables, countertops, and other surfaces. This simple yet effective measure makes cleanup a breeze and allows you to focus on unleashing your creativity without worrying about damaging your workspace.

Having the right epoxy resin art supplies is crucial for creating stunning resin artworks that capture attention and inspire awe. From high-quality epoxy resin to pigments, molds, safety equipment, and finishing tools, each essential plays a vital role in the resin art process. For top-quality Epoxy Resin Art Supplies that meet all your artistic needs, consider MB Enterprises as they are known for being one of the resin manufacturers. Their range of products is designed to help artists unleash their creativity and bring their artistic visions to life. Invest in the best supplies and watch your resin artistry flourish like never before with MB Enterprises.

#High-Quality Epoxy Resin#epoxy pigment#epoxy resin color#Molds and Forms#Nitrile gloves#SandPaper#Epoxy resin art supplies#resin manufacturers

3 notes

·

View notes

Text

https://baobikhangloi.com.vn/mang-phu-nong-nghiep-duc-lo-san

Perforated agricultural film products Between the conventional coating and the perforated film, users often choose the non-perforated type because they are significantly cheaper. Pre-perforated coatings are more expensive not because the cost of the perforating equipment is too high, but because this perforation will slow down the overall system productivity considerably. However, in our opinion, the high price of these products is completely worth the performance they bring. If you've ever used mulch for your growing work, you'll understand that punching holes for seeds or seedlings is a tedious and time-consuming task. Before the advent of perforated mulch, farmers around the world thought of many ways that this perforation could be done faster and easier.

On the smallest and simplest scale, they use knives, scissors or any other sharp object to make a cross in the membrane, then fold the excess plastic underneath to create holes shaped like square. This manual folding of 4 pieces of plastic takes a lot of time, the strength of the film is also weakened and it is easy to tear at the location of the cuts.

More advanced cutting tools for making circular holes in the coating have also been invented. Old milk cans are drilled with 2 small holes and inserted electrical wires to make handles, then hot coals are inserted. When the can of milk is hot enough, the farmer carries it away and places it on top of the mulch already spread in the garden, in the places where they want to drill holes. The plastic at this location will melt into the shape of the bottom of the box, and another farmer can go behind to collect the excess plastic. Plants or seeds can also be transplanted at this time.

In the same way as above, there are places where it is very popular to use wire mesh frames in old car air filters, especially those of light trucks and pickup trucks. The sharp edges on the mesh combined with the temperature of the coal inside will cut through the plastic film more easily. Instead of coal, one can also use kerosene or scrap plastic, or whatever as long as they are capable of burning for a long time.

Some people also use old PVC pipes, using a grinder to cut the pipe edges into a serrated shape to create a hole punching mold. When we forcefully press the water pipe into the covered ground, we will also get round holes like other methods. However, in hard areas, the plastic saw teeth will easily wear or break. Currently, metal punching tools with a similar design have also been sold a lot on e-commerce platforms. There are even variations that use electricity from the battery to heat. However, no matter how creative these tools are, they are still manual, still consuming a lot of labor to perform on large agricultural lands. To cater for farming on such a scale, automatic agricultural film punching machines have been built. They are integrated right on the film production line, to produce pre-perforated agricultural films. Machined perforated agricultural film will have holes with uniform size and spacing according to pre-set parameters. These distances will be calculated to leave the most reasonable space for the growth of the plant's roots. Currently, our Khang Loi company has invested in machinery system to produce perforated agricultural films, perforated on both transparent films and 2-layer films with one black side and one side. grey. Although our large format plastic films or agricultural mulch can reach up to 8 meters wide, our mulch punching machine currently only works on films up to a maximum size of 8 feet. 3 meters. We will give you the option of 1 to 4 rows of holes. Each hole is 8cm in diameter and the distance between holes is customizable. Our perforated agricultural film products use virgin resin as the main material, blended with special additive formulations to increase UV resistance and durability. Flexibility is also an advantage worth mentioning. This property makes our products resistant to the tension that occurs during installation, and is compatible with all mechanical punching operations, seeding operations, seedling without worrying about damage. membrane will be torn. If you have a need or need more advice on the product, please contact us at 0902.732.168, or leave us a message in the contact section. Thank you very much!

2 notes

·

View notes

Text

okay so I may have been reading about and shopping for resin for the past two hours. but my conclusion is uv resin and epoxy resin appear to pretty happily use most of the same tools and add ins and so on, so when it comes to having to choose one or the other it looks like I can just do both depending on which base material is more suitable for the individual project (even including soft resin or silicone squishies!) rather than like a knitting vs crochet scenario where the base material is the same but the tools are very different. I take crafts very seriously and I have been actively resisting resin for a very long time.

#look this is just like my default state okay#it's very difficult for me to look at a material object I desire and not go 'okay but how could I just make it myself'#unless it's knitting or sewing.#those were really the two crafts I first took seriously and I often find them frustrating and stifling now.#I will learn every craft and I will be at least passable at everything I learn and no one can stop me except me.#(or my partners if the apartment is too cluttered or we don't have money. but I'm the type to stop me waaaaay before they would stop me.)#anyway I won't buy anything until bare minimum when I get home.#probably not until we're fully moved in tbh but we'll see.

2 notes

·

View notes

Text

Epoxy Resin Center Table one is created with high quality resin and individually handcrafted. Resin is a highly reflective medium which will catch anyone’s eye walking into the room. All tables are finished to the highest standard. The epoxy resin is very strong & durable with specialised UV resistance. The tables are delivered flat packed. Simply bolt the legs.

#dining table#coffee table#center table#home decor#furniture#epoxytable#home#decoration#interior design#diningtable#handmade furniture

3 notes

·

View notes

Text

From Concept to Reality: Epoxy Insulators Shaping the Future of Electrical Engineering

In the rapidly advancing field of electrical engineering, the demand for reliable and efficient insulation materials has never been greater. Epoxy insulators, known for their superior performance and durability, are becoming the cornerstone of modern electrical systems. As a leading transformer insulators manufacturer, Radiant Enterprises is at the forefront of this technological evolution. This blog explores how epoxy insulators are transforming the landscape of electrical engineering, from their conception to their real-world applications.

The Importance of Insulators in Electrical Engineering

Insulators play a critical role in electrical engineering by preventing unwanted flow of current and ensuring the safety and efficiency of electrical systems. They are essential components in transformers, cables, and various other electrical installations. The choice of material for these insulators significantly impacts their performance, durability, and overall effectiveness.

Why Epoxy Insulators?

Epoxy insulators offer numerous advantages over traditional materials such as porcelain and glass. These include:

High Dielectric Strength: Epoxy materials provide excellent electrical insulation properties, making them ideal for high-voltage applications.

Mechanical Strength: Epoxy insulators are highly durable and resistant to mechanical stress and environmental factors.

Thermal Stability: They can withstand extreme temperatures, ensuring consistent performance under varying conditions.

Moisture Resistance: Epoxy insulators have low water absorption rates, reducing the risk of degradation over time.

From Concept to Reality: The Manufacturing Process

Conceptualization and Design

The journey of creating an epoxy insulator begins with conceptualization and design. This involves understanding the specific requirements of the application, whether it is for transformers, cable terminations, or other electrical components. Engineers at Radiant Enterprises collaborate with clients to design insulators that meet their exact specifications.

Material Selection

Choosing the right epoxy resin is crucial. The selected resin must offer the necessary electrical and mechanical properties while being cost-effective. Our team of experts evaluates various epoxy formulations to find the best match for the intended application.

Prototyping and Testing

Once the design is finalized, a prototype is developed. This prototype undergoes rigorous testing to ensure it meets all performance criteria. Tests include:

Electrical Testing: Assessing dielectric strength and insulation resistance.

Mechanical Testing: Evaluating tensile strength, compressive strength, and impact resistance.

Thermal Testing: Measuring performance under high and low temperatures.

Environmental Testing: Ensuring resistance to moisture, chemicals, and UV exposure.

Manufacturing

Upon successful testing, the insulators move into the manufacturing phase. Radiant Enterprises employs state-of-the-art manufacturing techniques to produce high-quality epoxy insulators. This includes:

Mixing and Molding: Combining epoxy resin with hardeners and additives, then molding into the desired shape.

Curing: Allowing the molded epoxy to cure and harden, forming a solid insulator.

Finishing: Trimming, polishing, and coating the insulators to enhance their performance and appearance.

Applications of Epoxy Insulators

Epoxy insulators are versatile and used in a wide range of electrical engineering applications. Here are some key areas where they are making a significant impact:

Transformer Insulators

As a premier transformer insulators manufacturer, Radiant Enterprises provides epoxy insulators that ensure the safe and efficient operation of transformers. These insulators offer high dielectric strength and are resistant to thermal and mechanical stresses, making them ideal for both power and distribution transformers.

Cable Termination Insulators

Epoxy insulators are also crucial in cable terminations. They provide the necessary insulation and mechanical support to ensure reliable and safe connections. Radiant Enterprises, one of the leading cable termination insulator manufacturers in India, produces insulators that meet stringent industry standards and are designed for durability and performance.

Electrical Equipment

Beyond transformers and cables, epoxy insulators are used in various other electrical equipment such as switchgear, circuit breakers, and bushings. Their versatility and superior properties make them suitable for a wide range of applications in electrical engineering.

Why Choose Radiant Enterprises?

Radiant Enterprises stands out as the best transformer insulator manufacturer and a top player among electrical insulation manufacturers in India. Here is why:

Expertise and Experience

With years of experience in the industry, Radiant Enterprises has the expertise to design and manufacture high-quality epoxy insulators. Our team of engineers and technicians are skilled in developing solutions that meet the specific needs of our clients.

Commitment to Quality

Quality is at the core of everything we do. From selecting the finest raw materials to employing advanced manufacturing techniques, we ensure that every insulator we produce meets the highest standards of performance and reliability.

Innovation

We are committed to innovation and continuously invest in research and development to stay ahead of the curve. Our state-of-the-art facilities and cutting-edge technologies enable us to develop new and improved insulation solutions.

Customer-Centric Approach

At Radiant Enterprises, we believe in building long-term relationships with our clients. We work closely with them to understand their needs and provide customized solutions that exceed their expectations.

The Future of Epoxy Insulators

The future of epoxy insulators looks promising, with ongoing advancements in materials science and manufacturing technologies. Here are some trends to watch:

Smart Insulators

The integration of sensors and smart technologies into insulators is an exciting development. These smart insulators can monitor their own performance, detect faults, and provide real-time data to help manage electrical systems more efficiently.

Eco-Friendly Materials

As sustainability becomes increasingly important, there is a growing focus on developing eco-friendly epoxy formulations. These materials aim to reduce environmental impact while maintaining or even enhancing performance.

Enhanced Performance

Ongoing research is leading to the development of epoxy insulators with even higher dielectric strength, thermal stability, and mechanical durability. These advancements will further expand the applications and capabilities of epoxy insulators in electrical engineering.

Conclusion

From concept to reality, epoxy insulators are revolutionizing the field of electrical engineering. Their superior properties make them indispensable in ensuring the reliability and safety of electrical systems. As a leading transformer insulators manufacturer and a prominent name among electrical insulation manufacturers in India, Radiant Enterprises is dedicated to advancing this technology and providing our clients with the best possible solutions.

Whether you are looking for the best transformer insulator manufacturer or reliable cable termination insulator manufacturers in India, Radiant Enterprises has the expertise and products to meet your needs. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry.

Experience the future of electrical insulation with Radiant Enterprises. Let us help you turn your concepts into reality with our high-performance epoxy insulators.

#Electrical insulation manufacturers in India#Transformer insulators manufacturer#Best transformer insulators manufacturer#Cable termination insulator manufacturers in India

3 notes

·

View notes

Text

What is FRP Products and Its Uses?

Fiber-reinforced plastic (FRP) products are composite materials made from a combination of fibers and a resin matrix. The fibers provide the strength and stiffness, while the resin matrix holds the fibers together and protects them from environmental factors such as moisture, chemicals, and UV light.

FRP products are used in a variety of industries and applications, thanks to their unique properties, which include:

High strength-to-weight ratio: FRP products are significantly lighter than traditional materials such as steel, aluminum, and concrete, while still providing high strength and stiffness. This makes them ideal for applications where weight reduction is critical, such as aerospace, automotive, and marine industries.

Corrosion resistance: FRP products are highly resistant to corrosion, making them ideal for use in harsh environments such as chemical plants, wastewater treatment facilities, and offshore structures.

Electrical insulation: FRP products are non-conductive, meaning they do not conduct electricity. This makes them ideal for use in electrical and electronic applications where electrical insulation is required.

Design flexibility: FRP products can be easily molded into complex shapes, allowing for greater design flexibility and customization. This makes them ideal for applications where unique shapes and sizes are required.

Some common FRP products and their uses include:

FRP grating: Used in industrial, commercial, and recreational applications as an alternative to steel grating, due to its high strength, corrosion resistance, and low maintenance requirements.

FRP tanks and vessels: Used in chemical storage and processing, wastewater treatment, and oil and gas industries due to their corrosion resistance, high strength, and light weight.

FRP piping systems: Used in chemical processing, power generation, and water treatment industries due to their corrosion resistance, low maintenance requirements, and long service life.

FRP panels: Used in commercial and industrial buildings as wall and ceiling panels, due to their high strength, durability, and design flexibility.

In conclusion, FRP products are composite materials that offer high strength, low weight, and corrosion resistance, making them ideal for a wide range of applications in various industries. As technology advances and new materials are developed, FRP products are likely to continue to play an important role in the construction of products and structures in the future.

2 notes

·

View notes