#Transition metal dichalcogenides

Explore tagged Tumblr posts

Text

LEDs based on transition metal dichalcogenides display reduced efficiency losses

Light-emitting diodes (LEDs), semiconductor-based devices that emit light when an electric current flows through them, are key building blocks of numerous electronic devices. LEDs are used to light up smartphone, computer, and TV displays, as well as light sources for indoor and outdoor environments. Past studies consistently observed a decline in the performance and efficiency of LED devices based on two-dimensional (2D) materials at high current densities. This loss of efficiency at high current densities has been linked to high levels of interaction between excitons, which cause a process known as exciton-exciton annihilation (EEA). Essentially, the properties of some 2D materials prompt excitons to strongly interact with each other, causing excitons to "deactivate" one another. This results in a significant waste of energy that could otherwise contribute to the lighting of LEDs.

Read more.

#Materials Science#Science#Transition metal dichalcogenides#Light emitting diodes#LEDs#Semiconductors#Efficiency#2D materials#Excitons#Strain engineering

12 notes

·

View notes

Text

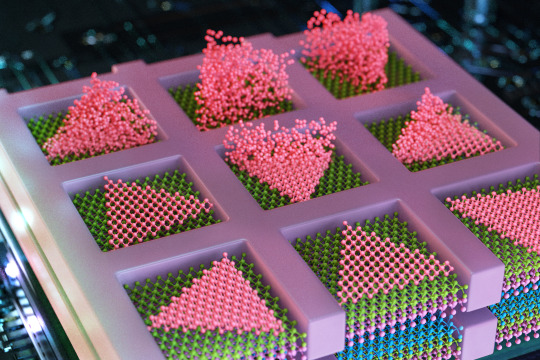

MIT engineers grow “high-rise” 3D chips

New Post has been published on https://thedigitalinsider.com/mit-engineers-grow-high-rise-3d-chips/

MIT engineers grow “high-rise” 3D chips

The electronics industry is approaching a limit to the number of transistors that can be packed onto the surface of a computer chip. So, chip manufacturers are looking to build up rather than out.

Instead of squeezing ever-smaller transistors onto a single surface, the industry is aiming to stack multiple surfaces of transistors and semiconducting elements — akin to turning a ranch house into a high-rise. Such multilayered chips could handle exponentially more data and carry out many more complex functions than today’s electronics.

A significant hurdle, however, is the platform on which chips are built. Today, bulky silicon wafers serve as the main scaffold on which high-quality, single-crystalline semiconducting elements are grown. Any stackable chip would have to include thick silicon “flooring” as part of each layer, slowing down any communication between functional semiconducting layers.

Now, MIT engineers have found a way around this hurdle, with a multilayered chip design that doesn’t require any silicon wafer substrates and works at temperatures low enough to preserve the underlying layer’s circuitry.

In a study appearing today in the journal Nature, the team reports using the new method to fabricate a multilayered chip with alternating layers of high-quality semiconducting material grown directly on top of each other.

The method enables engineers to build high-performance transistors and memory and logic elements on any random crystalline surface — not just on the bulky crystal scaffold of silicon wafers. Without these thick silicon substrates, multiple semiconducting layers can be in more direct contact, leading to better and faster communication and computation between layers, the researchers say.

The researchers envision that the method could be used to build AI hardware, in the form of stacked chips for laptops or wearable devices, that would be as fast and powerful as today’s supercomputers and could store huge amounts of data on par with physical data centers.

“This breakthrough opens up enormous potential for the semiconductor industry, allowing chips to be stacked without traditional limitations,” says study author Jeehwan Kim, associate professor of mechanical engineering at MIT. “This could lead to orders-of-magnitude improvements in computing power for applications in AI, logic, and memory.”

The study’s MIT co-authors include first author Ki Seok Kim, Seunghwan Seo, Doyoon Lee, Jung-El Ryu, Jekyung Kim, Jun Min Suh, June-chul Shin, Min-Kyu Song, Jin Feng, and Sangho Lee, along with collaborators from Samsung Advanced Institute of Technology, Sungkyunkwan University in South Korea, and the University of Texas at Dallas.

Seed pockets

In 2023, Kim’s group reported that they developed a method to grow high-quality semiconducting materials on amorphous surfaces, similar to the diverse topography of semiconducting circuitry on finished chips. The material that they grew was a type of 2D material known as transition-metal dichalcogenides, or TMDs, considered a promising successor to silicon for fabricating smaller, high-performance transistors. Such 2D materials can maintain their semiconducting properties even at scales as small as a single atom, whereas silicon’s performance sharply degrades.

In their previous work, the team grew TMDs on silicon wafers with amorphous coatings, as well as over existing TMDs. To encourage atoms to arrange themselves into high-quality single-crystalline form, rather than in random, polycrystalline disorder, Kim and his colleagues first covered a silicon wafer in a very thin film, or “mask” of silicon dioxide, which they patterned with tiny openings, or pockets. They then flowed a gas of atoms over the mask and found that atoms settled into the pockets as “seeds.” The pockets confined the seeds to grow in regular, single-crystalline patterns.

But at the time, the method only worked at around 900 degrees Celsius.

“You have to grow this single-crystalline material below 400 Celsius, otherwise the underlying circuitry is completely cooked and ruined,” Kim says. “So, our homework was, we had to do a similar technique at temperatures lower than 400 Celsius. If we could do that, the impact would be substantial.”

Building up

In their new work, Kim and his colleagues looked to fine-tune their method in order to grow single-crystalline 2D materials at temperatures low enough to preserve any underlying circuitry. They found a surprisingly simple solution in metallurgy — the science and craft of metal production. When metallurgists pour molten metal into a mold, the liquid slowly “nucleates,” or forms grains that grow and merge into a regularly patterned crystal that hardens into solid form. Metallurgists have found that this nucleation occurs most readily at the edges of a mold into which liquid metal is poured.

“It’s known that nucleating at the edges requires less energy — and heat,” Kim says. “So we borrowed this concept from metallurgy to utilize for future AI hardware.”

The team looked to grow single-crystalline TMDs on a silicon wafer that already has been fabricated with transistor circuitry. They first covered the circuitry with a mask of silicon dioxide, just as in their previous work. They then deposited “seeds” of TMD at the edges of each of the mask’s pockets and found that these edge seeds grew into single-crystalline material at temperatures as low as 380 degrees Celsius, compared to seeds that started growing in the center, away from the edges of each pocket, which required higher temperatures to form single-crystalline material.

Going a step further, the researchers used the new method to fabricate a multilayered chip with alternating layers of two different TMDs — molybdenum disulfide, a promising material candidate for fabricating n-type transistors; and tungsten diselenide, a material that has potential for being made into p-type transistors. Both p- and n-type transistors are the electronic building blocks for carrying out any logic operation. The team was able to grow both materials in single-crystalline form, directly on top of each other, without requiring any intermediate silicon wafers. Kim says the method will effectively double the density of a chip’s semiconducting elements, and particularly, metal-oxide semiconductor (CMOS), which is a basic building block of a modern logic circuitry.

“A product realized by our technique is not only a 3D logic chip but also 3D memory and their combinations,” Kim says. “With our growth-based monolithic 3D method, you could grow tens to hundreds of logic and memory layers, right on top of each other, and they would be able to communicate very well.”

“Conventional 3D chips have been fabricated with silicon wafers in-between, by drilling holes through the wafer — a process which limits the number of stacked layers, vertical alignment resolution, and yields,” first author Kiseok Kim adds. “Our growth-based method addresses all of those issues at once.”

To commercialize their stackable chip design further, Kim has recently spun off a company, FS2 (Future Semiconductor 2D materials).

“We so far show a concept at a small-scale device arrays,” he says. “The next step is scaling up to show professional AI chip operation.”

This research is supported, in part, by Samsung Advanced Institute of Technology and the U.S. Air Force Office of Scientific Research.

#2-D#2023#2D materials#3d#ai#AI chip#air#air force#applications#Arrays#Artificial Intelligence#atom#atoms#author#Building#chip#Chip Design#chips#coatings#communication#computation#computer#computer chips#computing#craft#crystal#crystalline#data#Data Centers#Design

2 notes

·

View notes

Text

Quantum billiards with correlated electrons confined in triangular transition metal dichalcogenide monolayer nanostructures - Jan Ravnik, Yevhenii Vaskivskyi, Jaka Vodeb, Polona Aupič, Igor Vaskivskyi, Denis Golež, Yaroslav Gerasimenko, Viktor Kabanov & Draga

11 notes

·

View notes

Text

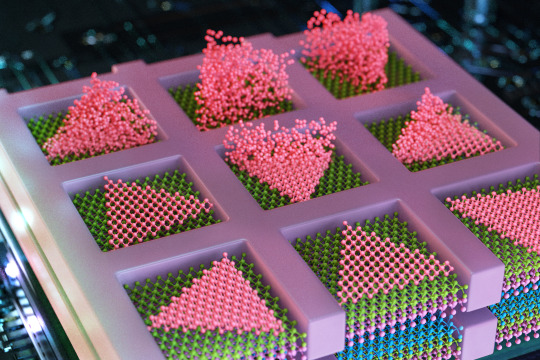

MIT engineers grow “high-rise” 3D chips

New Post has been published on https://sunalei.org/news/mit-engineers-grow-high-rise-3d-chips/

MIT engineers grow “high-rise” 3D chips

The electronics industry is approaching a limit to the number of transistors that can be packed onto the surface of a computer chip. So, chip manufacturers are looking to build up rather than out.

Instead of squeezing ever-smaller transistors onto a single surface, the industry is aiming to stack multiple surfaces of transistors and semiconducting elements — akin to turning a ranch house into a high-rise. Such multilayered chips could handle exponentially more data and carry out many more complex functions than today’s electronics.

A significant hurdle, however, is the platform on which chips are built. Today, bulky silicon wafers serve as the main scaffold on which high-quality, single-crystalline semiconducting elements are grown. Any stackable chip would have to include thick silicon “flooring” as part of each layer, slowing down any communication between functional semiconducting layers.

Now, MIT engineers have found a way around this hurdle, with a multilayered chip design that doesn’t require any silicon wafer substrates and works at temperatures low enough to preserve the underlying layer’s circuitry.

In a study appearing today in the journal Nature, the team reports using the new method to fabricate a multilayered chip with alternating layers of high-quality semiconducting material grown directly on top of each other.

The method enables engineers to build high-performance transistors and memory and logic elements on any random crystalline surface — not just on the bulky crystal scaffold of silicon wafers. Without these thick silicon substrates, multiple semiconducting layers can be in more direct contact, leading to better and faster communication and computation between layers, the researchers say.

The researchers envision that the method could be used to build AI hardware, in the form of stacked chips for laptops or wearable devices, that would be as fast and powerful as today’s supercomputers and could store huge amounts of data on par with physical data centers.

“This breakthrough opens up enormous potential for the semiconductor industry, allowing chips to be stacked without traditional limitations,” says study author Jeehwan Kim, associate professor of mechanical engineering at MIT. “This could lead to orders-of-magnitude improvements in computing power for applications in AI, logic, and memory.”

The study’s MIT co-authors include first author Ki Seok Kim, Seunghwan Seo, Doyoon Lee, Jung-El Ryu, Jekyung Kim, Jun Min Suh, June-chul Shin, Min-Kyu Song, Jin Feng, and Sangho Lee, along with collaborators from Samsung Advanced Institute of Technology, Sungkyunkwan University in South Korea, and the University of Texas at Dallas.

Seed pockets

In 2023, Kim’s group reported that they developed a method to grow high-quality semiconducting materials on amorphous surfaces, similar to the diverse topography of semiconducting circuitry on finished chips. The material that they grew was a type of 2D material known as transition-metal dichalcogenides, or TMDs, considered a promising successor to silicon for fabricating smaller, high-performance transistors. Such 2D materials can maintain their semiconducting properties even at scales as small as a single atom, whereas silicon’s performance sharply degrades.

In their previous work, the team grew TMDs on silicon wafers with amorphous coatings, as well as over existing TMDs. To encourage atoms to arrange themselves into high-quality single-crystalline form, rather than in random, polycrystalline disorder, Kim and his colleagues first covered a silicon wafer in a very thin film, or “mask” of silicon dioxide, which they patterned with tiny openings, or pockets. They then flowed a gas of atoms over the mask and found that atoms settled into the pockets as “seeds.” The pockets confined the seeds to grow in regular, single-crystalline patterns.

But at the time, the method only worked at around 900 degrees Celsius.

“You have to grow this single-crystalline material below 400 Celsius, otherwise the underlying circuitry is completely cooked and ruined,” Kim says. “So, our homework was, we had to do a similar technique at temperatures lower than 400 Celsius. If we could do that, the impact would be substantial.”

Building up

In their new work, Kim and his colleagues looked to fine-tune their method in order to grow single-crystalline 2D materials at temperatures low enough to preserve any underlying circuitry. They found a surprisingly simple solution in metallurgy — the science and craft of metal production. When metallurgists pour molten metal into a mold, the liquid slowly “nucleates,” or forms grains that grow and merge into a regularly patterned crystal that hardens into solid form. Metallurgists have found that this nucleation occurs most readily at the edges of a mold into which liquid metal is poured.

“It’s known that nucleating at the edges requires less energy — and heat,” Kim says. “So we borrowed this concept from metallurgy to utilize for future AI hardware.”

The team looked to grow single-crystalline TMDs on a silicon wafer that already has been fabricated with transistor circuitry. They first covered the circuitry with a mask of silicon dioxide, just as in their previous work. They then deposited “seeds” of TMD at the edges of each of the mask’s pockets and found that these edge seeds grew into single-crystalline material at temperatures as low as 380 degrees Celsius, compared to seeds that started growing in the center, away from the edges of each pocket, which required higher temperatures to form single-crystalline material.

Going a step further, the researchers used the new method to fabricate a multilayered chip with alternating layers of two different TMDs — molybdenum disulfide, a promising material candidate for fabricating n-type transistors; and tungsten diselenide, a material that has potential for being made into p-type transistors. Both p- and n-type transistors are the electronic building blocks for carrying out any logic operation. The team was able to grow both materials in single-crystalline form, directly on top of each other, without requiring any intermediate silicon wafers. Kim says the method will effectively double the density of a chip’s semiconducting elements, and particularly, metal-oxide semiconductor (CMOS), which is a basic building block of a modern logic circuitry.

“A product realized by our technique is not only a 3D logic chip but also 3D memory and their combinations,” Kim says. “With our growth-based monolithic 3D method, you could grow tens to hundreds of logic and memory layers, right on top of each other, and they would be able to communicate very well.”

“Conventional 3D chips have been fabricated with silicon wafers in-between, by drilling holes through the wafer — a process which limits the number of stacked layers, vertical alignment resolution, and yields,” first author Kiseok Kim adds. “Our growth-based method addresses all of those issues at once.”

To commercialize their stackable chip design further, Kim has recently spun off a company, FS2 (Future Semiconductor 2D materials).

“We so far show a concept at a small-scale device arrays,” he says. “The next step is scaling up to show professional AI chip operation.”

This research is supported, in part, by Samsung Advanced Institute of Technology and the U.S. Air Force Office of Scientific Research.

0 notes

Text

Europe 2D Materials Market Segment Analysis, Current Challenges and Business Opportunities | BIS Research

Two-dimensional (2D) materials are crystalline substances with a thickness of only a few atomic layers. They exhibit unique properties due to their reduced dimensionality and high surface area-to-volume ratio.

The Europe 2D Materials Market (excluding U.K.) is projected to reach $528.0 million by 2031 from $77.9 million in 2022, growing at a CAGR of 23.7% during the forecast period 2022-2031.

Europe 2D Materials Overview

Two-dimensional (2D) materials are a class of crystalline substances characterized by their extremely thin, planar structures, typically only a few atoms thick.

Key Properties

Thickness: Comprising single or few atomic layers, which imparts unique quantum mechanical properties.

Surface Areas: High surface area-to-volume ratio, beneficial for applications requiring high reactivity or surface interactions.

Mechanical Strength:Despite their thinness, many 2D materials exhibit remarkable mechanical strength and flexibility.

Electrical Conductivity : Exhibits a wide range of electrical properties, from highly conductive (e.g., graphene) to semiconducting (e.g., transition metal dichalcogenides) and insulating (e.g., hexagonal boron nitride).

Thermal Conductivity: Some 2D materials, like graphene, have excellent thermal conductivity, making them suitable for heat dissipation applications.

Visit our report page and grab a better understanding

Applications for Europe 2D Materials Market

Electronics

Optoelectronics

Energy Storage

Thermal Management

Composite Materials

Key Companies

2-D Tech

Smena

AVANZARE INNOVACION TECNOLOGICA S.L.

BASF SE

Grab a look at our free sample click here!

Market Segmentation

By End Users

By Material Type

By Country

Market Drivers for Europe 2D Materials Market

Technological Advancements

Increased demand for Advanced Electronics

Energy Efficiency and Storage Solutions

Environmental Sustainability

Emergence of Quantum Computing

Visit our Advanced Electronics Material Vertical page click here !

Conclusion

Two-dimensional (2D) materials represent a transformative category in the field of materials science and nanotechnology, distinguished by their unique properties and versatile applications. Their exceptional electrical, optical, mechanical, and thermal characteristics make them suitable

The growing demand for faster, smaller, and more efficient electronic devices, coupled with the push towards renewable energy and environmental sustainability, drives the advancement and commercialization of 2D materials.

0 notes

Text

A tunable transition metal dichalcogenide entangled photon-pair source

http://dlvr.it/TCd2Xj

0 notes

Text

Breaking Down Plastics with Lasers 💥🔬

KEY POINTS:

Potential to revolutionize plastic disposal and breakdown

Could transform environmental pollutants into valuable, reusable chemicals

A global research team led by Texas Engineers has devised a groundbreaking way to tackle plastic waste. They've discovered that blasting molecules in plastics and other materials with a laser can break them down into their smallest parts for future reuse. 🔍🌍

Here's how it works: They lay these materials on top of two-dimensional materials called transition metal dichalcogenides and then light them up with lasers. This method can potentially revolutionize how we dispose of plastics that are nearly impossible to break down with today’s technologies. 🚀🔦

“By harnessing these unique reactions, we can explore new pathways for transforming environmental pollutants into valuable, reusable chemicals,” said Yuebing Zheng, a professor in the Cockrell School of Engineering's Walker Department of Mechanical Engineering and one of the project leaders. This innovative approach could significantly contribute to developing a more sustainable and circular economy. ♻️🌱

0 notes

Text

A bulk 2D system refers to a collection of two-dimensional (2D) materials or structures arranged in large quantities. These systems are often studied in physics and materials science for their unique properties and potential applications. Examples include graphene, transition metal dichalcogenides (TMDs), and other atomically thin materials. Understanding the collective behavior and interactions within bulk 2D systems is essential for exploring their use in various fields such as electronics, photonics, and energy storage.

0 notes

Photo

Composition-Tunable Transition Metal Dichalcogenide Nanosheets via a Scalable, Solution-Processable Method

0 notes

Text

0 notes

Text

Advancements in Advanced Materials: A Glimpse into Cutting-Edge Research

Introduction

In the ever-evolving landscape of scientific research, the Advanced Materials Journal stands as a testament to human ingenuity, pushing the boundaries of what is possible in material science. This prestigious journal serves as a platform for scientists and researchers to share their groundbreaking work, innovations, and discoveries in the realm of advanced materials. In this article, we will explore the significance of the Advanced Materials Journal and highlight some of the remarkable advancements in the field.

The Significance of Advanced Materials

Advanced materials encompass a wide range of substances with properties and functionalities that surpass traditional materials. They play a pivotal role in various industries, including electronics, aerospace, energy, medicine, and more. The pursuit of advanced materials is driven by the desire to create materials with enhanced performance, durability, and versatility.

The Advanced Materials Journal: A Hub for Innovation

The Advanced Materials Journal has long been a driving force behind the progress in this field. It provides a platform for experts in materials science to publish their cutting-edge research, fostering collaboration and knowledge sharing. The journal encompasses a broad range of topics, including nanomaterials, biomaterials, composites, and functional materials, catering to a diverse and dynamic audience of researchers.

Key Research Areas

Nanomaterials: The development of nanomaterials has revolutionized several industries, including electronics and medicine. Researchers have explored new methods for fabricating nanoparticles, leading to groundbreaking advancements in drug delivery systems, nanoelectronics, and more.

Biomaterials: The quest for biocompatible materials has become increasingly important, especially in the context of tissue engineering and regenerative medicine. Advanced materials play a crucial role in designing implants, scaffolds, and drug delivery systems that can seamlessly integrate with the human body.

Composites: Advanced composites have found applications in aerospace, automotive, and construction industries. These materials, often composed of two or more components, are engineered to combine the best properties of each component, resulting in lightweight yet strong structures.

Functional Materials: Materials with unique functional properties, such as shape memory alloys and piezoelectric materials, have opened up new possibilities in sensor technology, actuators, and smart materials.

Selected Breakthroughs

Graphene: The discovery of graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has garnered widespread attention. Its remarkable electrical and thermal conductivity make it a potential game-changer in electronics and energy storage.

Metamaterials: These artificial materials engineered to exhibit extraordinary electromagnetic properties have found applications in cloaking devices and superlenses, pushing the boundaries of optics and electromagnetic theory.

2D Materials: Beyond graphene, other two-dimensional materials like transition metal dichalcogenides have been explored, offering unique properties and applications in electronics and optoelectronics.

Bioactive Glass: In the realm of biomaterials, bioactive glass has been used to stimulate bone growth and tissue repair. Its ability to bond with living tissue has revolutionized the field of orthopedic implants.

Conclusion

The Advanced Materials Journal stands as a beacon of progress in the world of advanced materials. The research published within its pages continually shapes the future of science and technology. As the quest for advanced materials continues to drive innovation, the journal remains an invaluable resource for researchers, scientists, and engineers, ensuring that our world becomes a place where the impossible becomes possible.

Hyderabad,Telangana

Research #papers #publish

0 notes

Text

Organic LED material achieves faster organic phosphorescence for better display tech

Screens for TVs, smartphones or other displays could be made with a new kind of organic LED material developed by an international team, co-led by University of Michigan engineers. The material maintains sharp color and contrast while replacing the heavy metal with a new hybrid material. Curiously, the material also seemed to break a quantum rule. OLED devices currently on the market include heavy metal components like iridium and platinum, which improve the efficiency, brightness and color range of the screen. But they come with drawbacks—significantly higher cost, a shorter device lifetime and increased health and environmental hazards.

Read more.

#Materials Science#Science#Organic light emitting diodes#OLEDs#Electronics#Phosphorescence#Organic materials#Transition metal dichalcogenides#University of Michigan

16 notes

·

View notes

Text

Single Photons Go for Gold - Technology Org

New Post has been published on https://thedigitalinsider.com/single-photons-go-for-gold-technology-org/

Single Photons Go for Gold - Technology Org

In 2015, a class of two-dimensional materials called transition metal dichalcogenides (TMDs) entered the scientific limelight for their ability to produce just one particle of light at a time. Such single-photon emission was a natural, and somewhat random, ability in TMDs with structural defects—missing atoms here and there, or a wrinkle where the crystal should have been straight and even.

The experimental set-up at the Borys Lab at the University of Montana, which specializes in low-temperature optics and has been a long-time collaborator with the Schuck Lab.

Researchers quickly moved from observing single photon emission in TMDs to attempting to engineer the materials in a way that could yield the same effect on demand. Writing recently in Nature Communications, a team including mechanical engineers Jim Schuck and Jim Hone and the Borys lab at Montana State University go for gold to create a single photon emitter.

They carefully placed atomically thin layers of a TMD called tungsten diselenide (WSe2) on the tips of nanoscopic gold cones, which create tiny wrinkles in the material. Those wrinkles yielded strong evidence of single photon emission that, notably, occurred at room rather than ultracold temperature.

Columbia Engineering PhD student Emanuil Yanev is leading the effort to research tungsten diselenide’s properties. In this Q&A, Yanev shares what’s so interesting about single photon emitters, his journey from Idaho to New York City, and a little more about himself and his time at Columbia.

Emanuil Yanev in the Schuck Nano-Optics Lab. Image credit: Columbia University

Why do we need single photons?

We’ve all heard lots about quantum computers lately, but, eventually, we’ll want to build a network of them—essentially, a quantum internet. Single photons can be really important elements in transferring information while preserving its quantum nature.

How did you come up with the idea of using gold cones for this research?

We’ve been experimenting with using strain to create single photons.

In a prior paper published in Nature Nanotechnology, we created “nanobubbles” that strained tungsten diselenide and caused localized photon emission, but we realized that the light was coming from very small wrinkles around the bubble perimeters and not the bubble centers. We thought an array of cones could create similar wrinkles, but in a more robust and prescriptive fashion so we could better determine exactly where the strain originated and where the photons were coming from. Making the cones out of a metal like gold can also enhance the output, like an antenna.

Can we definitively say you can create single photons at room temperature?

Almost. The definitive proof is a correlation measurement that demonstrates antibunching, where you statistically show that there’s zero chance that two photons were emitted at the same time. We’re working on that, but it’s technically challenging with our nano-optical approach.

What we did show was power saturation, which is pretty strong evidence for single photon emission. We excite the tungsten diselenide by shining a laser onto a cone-induced nano-wrinkle. A single photon emitter can’t absorb a second photon until it emits what it has already absorbed from the laser, which takes some time. That means you hit a point where it can’t keep up with the rate of incoming photons, and so the emission output no longer scales with the laser input.

We observed that saturation behavior in our engineered samples at room temperature. This is exciting because it shows that single photons are potentially being created without expensive cryogenic equipment, which so far has been necessary for achieving single-photon emission in TMDs.

What’s next for this research?

To demonstrate antibunching, we need to boost the brightness of the single photon emission, so we’re experimenting with different combinations of materials. We are also starting to think about optimizing the design so that, one day, we can integrate these single photon sources onto circuit chips—that’s the ultimate goal.

Bigger picture, we also want to fundamentally understand what’s going on in these materials. The reason we have smartphones today is because 70-plus years of effort have gone into developing our understanding of silicon—the material that all of our electronics are made from. We’ve pushed the scaling of that technology to the limit more or less, so it’s time to see what we can do with new materials.

And what’s next for you?

I’m nearing the end of my PhD, so I’m starting to write up my thesis. And look for jobs. I’d like to pivot into the quantum computing industry. That’s an exciting space right now. I’ve spent a lot of time doing nanofabrication and working in cleanrooms to make substrates and samples with these 2D materials, and I’d love to continue applying that skillset going forward.

What was your path to your PhD?

My family moved to the US from Bulgaria when I was five, and we ended up in Idaho. Idaho was a great place to grow up, but it’s a little sleepy and I wanted to get into a bigger city, so I enrolled in Columbia’s 3-2 Combined Plan Program. I spent three years at The College of Idaho studying math and physics, then transferred to Columbia to study engineering for another two years.

I’ve been an engineer at heart since I was young. I always enjoyed tinkering and building random things in our garage. When I got to Columbia, I was really excited by the research efforts directed at the nano-scale. I started working in Jim Hone’s lab, and I decided to stay to pursue a PhD, which has been co-advised by Jim Hone and Jim Schuck.

How has your time been at Columbia?

With Jim Hone, I learned a lot about nanofabrication, 2D material synthesis, and sample preparation, and with Jim Schuck, I learned more about optical characterization and applications of these materials. I was a bit of a bridge between the two labs initially, which was a great opportunity: Jim Schuck had just arrived at Columbia when I started my PhD, so I helped teach a lot of the group how to make samples with 2D materials that we would then study optically.

I also spent time at Brookhaven National Laboratory as a Department of Energy Office of Science Graduate Student Research Fellow, where I had the chance to explore advanced nanofabrication techniques, such as cryogenic plasma etching.

The 2D materials field is a highly collaborative environment, and it’s been really rewarding to work with people from lots of different backgrounds. You have this great overlap of researchers from mechanical engineering, electrical engineering, materials science, chemistry, and physics coming together to tackle problems.

How do you keep busy outside of the lab?

Mountain biking, which is usually not the first thing that comes to mind when you think of Manhattan! I’m on the board of the New York City Mountain Bike Association, which is a nonprofit that builds and maintains the majority of off-road trails in the city and offers free bike clinics for kids and adults.

Almost everyone had a bike where I grew up, but that’s not the case here. We give New Yorkers who wouldn’t otherwise have the opportunity to ride a chance to do so, while also improving the parks for hikers and the broader community.

Any words of advice?

Don’t be afraid to fail. A lot of people coming into graduate school are high-achieving individuals, but research is very different from the classroom—you’re going to be failing a lot, and you can’t internalize that. Just because your experiment was unsuccessful doesn’t mean you are a failure: it’s just part of the process. In fact, some of the greatest insights and discoveries are had when things don’t go according to plan, so keep an open mind!

Source: Columbia University

You can offer your link to a page which is relevant to the topic of this post.

#2D materials#Advice#amp#applications#approach#atoms#Behavior#board#bridge#Brookhaven National Laboratory#Building#Bulgaria#chemistry#chips#collaborative#college#communications#Community#computers#computing#crystal#Design#Discoveries#Electronics#energy#Engineer#engineering#engineers#Environment#equipment

0 notes

Text

#science#physic#news#technology#space#Astronomy#NASA#Night#Sky#Stars#Space#Science#Universe#Cosmos#Cosmic#Solar System#Milky Way#Bioluminescence#Galaxy#Nebula#Constellations#Constellation#Rainbow#Bright

0 notes

Text

Nanophotonics: Coupling light and matter

Science News from research organizations 1 2 Date: June 23, 2023 Source: Ludwig-Maximilians-Universität München Summary: Researchers have developed a metasurface that enables strong coupling effects between light and transition metal dichalcogenides (TMDCs). Share: advertisement FULL STORY LMU-Researchers have developed a metasurface that enables strong coupling effects between light and transition metal dichalcogenides (TMDCs). The interaction of light and matter on the nanoscale is a vital aspect of nanophotonics. Resonant nanosystems allow scientists to control and enhance electromagnetic energy at volumes smaller than the wavelength of the incident light. As well as allowing sunlight to be captured much more effectively, they also facilitate improved optical wave-guiding and emissions control. The strong coupling of light with electronic excitation in solid-state materials generates hybridized photonic and electronic states, so-called polaritons, which can exhibit interesting properties such as Bose-Einstein condensation and superfluidity. A new study, published in the journal Nature Materials, presents progress in the coupling of light and matter on the nanoscale. Researchers led by LMU physicist Dr. Andreas Tittl have developed a metasurface that enables strong coupling effects between light and transition metal dichalcogenides (TMDCs). This novel platform is based on photonic bound states in the continuum, so-called BICs, in nanostructured tungsten disulfide (WS2). The simultaneous utilization of WS2 as the base material for the manufacture of metasurfaces with sharp resonances and as a coupling partner supporting the active material excitation opens up new possibilities for research into polaritonic applications. An important breakthrough in this research is controlling the coupling strength, which is independent of losses within the material. Because the metasurface platform is able to integrate other TMDCs or excitonic materials without difficulty, it can furnish fundamental insights and practical device concepts for polaritonic applications. Moreover, the concept of the newly developed metasurface provides a foundation for applications in controllable low-threshold semiconductor lasers, photocatalytic enhancement, and quantum computing. advertisement Story Source: Materials provided by Ludwig-Maximilians-Universität München. Note: Content may be edited for style and length. Journal Reference: Thomas Weber, Lucca Kühner, Luca Sortino, Amine Ben Mhenni, Nathan P. Wilson, Julius Kühne, Jonathan J. Finley, Stefan A. Maier, Andreas Tittl. Intrinsic strong light-matter coupling with self-hybridized bound states in the continuum in van der Waals metasurfaces. Nature Materials, 2023; DOI: 10.1038/s41563-023-01580-7 Cite This Page: Ludwig-Maximilians-Universität München. “Nanophotonics: Coupling light and matter.” ScienceDaily. ScienceDaily, 23 June 2023. . Ludwig-Maximilians-Universität München. (2023, June 23). Nanophotonics: Coupling light and matter. ScienceDaily. Retrieved June 24, 2023 from https://ift.tt/FZxdesi Ludwig-Maximilians-Universität München. “Nanophotonics: Coupling light and matter.” ScienceDaily. https://ift.tt/FZxdesi (accessed June 24, 2023).

0 notes

Text

Europe 2D Materials Market Segment Analysis, Current Challenges and Business Opportunities | BIS Research

Two-dimensional (2D) materials are crystalline substances with a thickness of only a few atomic layers. They exhibit unique properties due to their reduced dimensionality and high surface area-to-volume ratio.

The Europe 2D Materials Market (excluding U.K.) is projected to reach $528.0 million by 2031 from $77.9 million in 2022, growing at a CAGR of 23.7% during the forecast period 2022-2031.

Europe 2D Materials Overview

Two-dimensional (2D) materials are a class of crystalline substances characterized by their extremely thin, planar structures, typically only a few atoms thick.

Key Properties

Thickness: Comprising single or few atomic layers, which imparts unique quantum mechanical properties.

Surface Areas: High surface area-to-volume ratio, beneficial for applications requiring high reactivity or surface interactions.

Mechanical Strength:Despite their thinness, many 2D materials exhibit remarkable mechanical strength and flexibility.

Electrical Conductivity : Exhibits a wide range of electrical properties, from highly conductive (e.g., graphene) to semiconducting (e.g., transition metal dichalcogenides) and insulating (e.g., hexagonal boron nitride).

Thermal Conductivity: Some 2D materials, like graphene, have excellent thermal conductivity, making them suitable for heat dissipation applications.

Visit our report page and grab a better understanding

Applications for Europe 2D Materials Market

Electronics

Optoelectronics

Energy Storage

Thermal Management

Composite Materials

Key Companies

2-D Tech

Smena

AVANZARE INNOVACION TECNOLOGICA S.L.

BASF SE

Grab a look at our free sample click here!

Market Segmentation

By End Users

By Material Type

By Country

Market Drivers for Europe 2D Materials Market

Technological Advancements

Increased demand for Advanced Electronics

Energy Efficiency and Storage Solutions

Environmental Sustainability

Emergence of Quantum Computing

Visit our Advanced Electronics Material Vertical page click here !

Conclusion

Two-dimensional (2D) materials represent a transformative category in the field of materials science and nanotechnology, distinguished by their unique properties and versatile applications. Their exceptional electrical, optical, mechanical, and thermal characteristics make them suitable

The growing demand for faster, smaller, and more efficient electronic devices, coupled with the push towards renewable energy and environmental sustainability, drives the advancement and commercialization of 2D materials.

0 notes