#Transformer Oil Filtration

Explore tagged Tumblr posts

Text

Advanced Transformer Oil Filtration & Dehydration Machines for Enhanced Transformer Performance Across Africa & India

When it comes to ensuring the efficiency and longevity of transformers, the process of oil filtration and dehydration plays a vital role. Transformers require clean and dry oil to function optimally, and without effective filtration, contaminants can damage the internal components of transformers, leading to costly downtime and maintenance. This is where our transformer oil filtration machines and dehydration plants come in—designed to extend the life of your transformers and prevent operational failures.

Our Expertise in Transformer Oil Filtration Systems

We, at AR Engineering and Innovation Pvt. Ltd., specialize in offering state-of-the-art transformer oil filtration and dehydration plants that serve diverse industries globally, particularly in Africa and India. With over three decades of experience, we have honed our expertise in manufacturing and supplying high-quality transformer oil filtration machines and dehydration plants for both large-scale and small-scale transformers.

Our products are highly efficient, easy to maintain, and come in various capacities that cater to different transformer oil filtration needs. Whether you need high vacuum transformer oil filtration machines or dehydration plants, we provide tailored solutions that meet the unique requirements of various regions and markets.

Transformer Oil Filtration Machines: Efficient and Reliable

Our transformer oil filtration machines are engineered to eliminate contaminants such as water, gases, and particulates from transformer oil, ensuring optimal oil quality. Available in different models, our machines come with the following key features:

High-Vacuum Technology: We employ cutting-edge vacuum filtration technology to remove moisture and gases from transformer oil, maintaining oil quality and improving transformer performance.

Multiple Stages of Filtration: Our systems utilize several stages of filtration, including primary filtration, fine filtration, and high-efficiency filtration, for complete oil purification.

Efficient Oil Dehydration: Our dehydration plants are designed to reduce moisture content to acceptable levels, extending the life of transformer oil and enhancing transformer insulation.

Our Reach in Africa

We have successfully delivered our transformer oil filtration systems to numerous countries across Africa. Some of the countries where our products have made a significant impact include:

Botswana: Our transformer oil filtration machines and dehydration plants are operational in Botswana, helping improve transformer reliability and performance.

Ethiopia: We are proud to provide advanced transformer oil filtration solutions to the Ethiopian market, ensuring the safe operation of transformers across the nation.

Kenya: Our transformer oil filtration machines in Kenya have been instrumental in maintaining high oil quality for transformers, enhancing power transmission reliability.

Namibia: Namibia benefits from our state-of-the-art transformer oil filtration and dehydration technology, providing a lasting solution to transformer maintenance.

Nigeria: In Nigeria, we supply high-performance filtration systems and dehydration plants that significantly reduce transformer failure rates.

South Africa: Our products are extensively used in South Africa, where transformer oil filtration plays a critical role in enhancing transformer longevity and reducing maintenance costs.

Zambia: We cater to Zambia’s energy sector by supplying advanced transformer oil filtration machines that effectively filter out impurities from transformer oil.

Zimbabwe: Our filtration solutions in Zimbabwe ensure cleaner transformer oil, supporting optimal transformer performance and reducing maintenance costs.

Transforming Indian Markets

In addition to our strong presence in Africa, our transformer oil filtration machines and dehydration plants are also making a positive impact in India. The Indian energy sector, which is rapidly expanding, relies heavily on transformers for efficient power distribution. Our products help ensure that these transformers perform optimally, with minimum risk of malfunction due to contamination.

Whether you're located in Delhi, Mumbai, Chennai, or Bangalore, we supply transformer oil filtration solutions that meet the specific needs of your transformer maintenance operations. Our products are available in varying capacities and are designed to cater to diverse transformer applications.

Why Choose Our Transformer Oil Filtration and Dehydration Systems?

Global Reach and Expertise: With over 30 years of experience, we have successfully delivered transformer oil filtration and dehydration plants to over 15 countries across Africa and Asia.

Tailored Solutions: We offer customized filtration and dehydration systems to meet the unique needs of each client, ensuring compatibility with local transformer specifications.

Proven Track Record: Our filtration systems have been installed in high-performance transformers and have consistently exceeded expectations in terms of oil quality and transformer lifespan.

High-Quality Manufacturing: All our machines are designed and manufactured using the latest technologies to ensure optimal filtration and dehydration performance, offering durability and reliability.

Affordable and Energy-Efficient: Our machines are energy-efficient and provide long-term cost savings by preventing transformer failure, reducing the need for costly repairs and replacements.

Contact Us Today

For more information on our transformer oil filtration machines, dehydration plants, and other related products, or to request a quote, visit our website. You can also get in touch with our team at:

Email: [email protected]

Phone: +91 7758877486 / (+91) 9422605890

Address: L - 77, Addl. MIDC, Satara - 415004, Maharashtra, India

Conclusion

Whether you are in Africa or India, our transformer oil filtration machines and dehydration plants offer the perfect solution for transformer maintenance and longevity. Partner with us today to ensure that your transformers remain efficient, reliable, and cost-effective for years to come.

#transformer oil filtration machine#transformer oil filtration machine in Botswana#transformer oil filtration machine in Ethiopia#transformer oil filtration machine in Kenya#transformer oil filtration machine in Namibia#transformer oil filtration machine in Nigeria#transformer oil filtration machine in South Africa#transformer oil filtration machine in Zambia#transformer oil filtration machine in Zimbabwe#transformer oil filtration plant#transformer oil filtration plant in Botswana#transformer oil filtration plant in Ethiopia#transformer oil filtration plant in Kenya#transformer oil filtration plant in Namibia#transformer oil filtration plant in Nigeria#transformer oil filtration plant in South Africa#transformer oil filtration plant in Zambia#transformer oil filtration plant in Zimbabwe#Transformer Oil Filtration#Transformer Oil Filtration in Botswana#Transformer Oil Filtration in Ethiopia#Transformer Oil Filtration in Kenya#Transformer Oil Filtration in Namibia#Transformer Oil Filtration in Nigeria#Transformer Oil Filtration in South Africa#Transformer Oil Filtration in Zambia#Transformer Oil Filtration in Zimbabwe#dehydration plant#dehydration plant in Botswana#dehydration plant in Ethiopia

0 notes

Text

Oil Reclamation project for the largest oil refinery in WB, India

A critical oil reclamation project for the largest oil refinery with a capacity of 8 million tonnes per year in West Bengal, India.

Synopsis

The lube oil used in various industrial equipment such as pumps, compressors, turbines, blowers, turbo generators, recycle gas compressors, wet gas compressors, and coke cutting pumps had critical contamination levels initially. The problem was caused by poor maintenance by a previous service vendor, resulting in the presence of moisture and impurities in the oil tank. To address the issue, Minimac Operations and Maintenance Service (MOMS) carried out a timely service operation to help the plant bring down the moisture count and remove impurities from the oil tank. Before oil purification, NAS ≥ 12, Moisture ≥ 650 PPM; after oil purification, NAS < 5 and Moisture < 200 PPM This helped to improve the quality of the oil used in the equipment and ensure the smooth operation of the plant.

Problems

The oil was contaminated with moisture and mechanical impurities due to insufficient maintenance, which could lead to equipment failure and downtime. The presence of these impurities in the oil could also cause damage to the equipment, reduce its lifespan, and decrease its efficiency. It was essential to address this problem by implementing proper maintenance practices, such as regular oil changes, filtration, and moisture control, to ensure that the industrial oil is clean and free from contaminants. Failure to address this issue could lead to increased costs as well as production losses due to downtime.

Client’s Requirement

The target moisture level must be below 200 PPM.

Target NAS class must be maintained better than NAS class 5.

Solutions

Minimac Systems examined the oil circulation system, which consisted of high impurities.

Machine used: FS 80 LPM - 2 units; FS 40 LPM - 1 unit; FS 20 LPM - 1 unit.

NAS class < 5 and < 200 PPM moisture level was achieved.

Cost Saving

This plant managed to save:

Immediate tangible benefit = ₹9 Cr.*/ $90 Million* * considering the base price of oil as ₹150/lts /$1.83/lts.

Intangible benefits = Equipment reliability - less breakdowns - minimum equipment outage - reduced downtime - minimum hamper to production line.

CO2 e Saving

Benefits

The reliable operation of the system and trouble-free operation of machines.

Sustainable performance of the overall process.

Less Breakdown.

Elimination of new compressor cost.

Reduction in the possibility of product degradation due to lack of proper filtration.

Timely Execution.

Feedback

Minimac believes in delivering the best experience to the clients with result-oriented project execution, hence, as a result, the project was extended further.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#lube oil flushing systems#chemical cleaning#chemical flushing#chemical cleaning flushing#transformer oil filtration#oil filtration systems#oil filtration machine#oil filter systems#oil filter testing#oil dehydration systems#frf condition systems#frf machine#elc#electrostatics lube cleaner#transformation oil purification#transformer oil#transformer oil cleaning#transformer oc#coalescer separator

0 notes

Text

🔹 Two Stage Transformer Oil Filtration Plant – Advanced Purification for Maximum Efficiency 🔹

Looking for a high-performance Two Stage Transformer Oil Filtration Plant? ✅ We are leading Two Stage Transformer Oil Filtration Plant manufacturers in Pune and India, offering cutting-edge filtration technology to enhance transformer efficiency and lifespan.

🔗 Visit Now: Two Stage Transformer Oil Filtration Plant

🏭 Why Choose Our Two Stage Transformer Oil Filtration Plant?

Double-Stage Filtration System ⚙️ – Removes moisture, gases & contaminants for superior oil quality

High Vacuum Technology 🏭 – Ensures efficient dehydration & degasification

Improves Dielectric Strength ⚡ – Enhances insulation performance of transformer oil

Energy-Efficient & Cost-Effective 🔋 – Reduces operational expenses

Robust & Reliable 💪 – Designed for long-term industrial use

As trusted Two Stage Transformer Oil Filtration Plant manufacturers in Pune, we provide high-precision filtration solutions for industries across India.

🌍 Leading Two Stage Transformer Oil Filtration Plant Exporters in Pune & India

Our Two Stage Transformer Oil Filtration Plant exporters in Pune supply advanced filtration plants to industries worldwide, ensuring top-quality oil purification. These machines are ideal for: ✔️ Power Plants & Substations ✔️ Transformer Manufacturing & Maintenance Units ✔️ Electrical Equipment Industries ✔️ Oil Processing & Refining Plants

🏆 Trusted Two Stage Transformer Oil Filtration Plant Suppliers in Pune & India

We are one of the most reliable Two Stage Transformer Oil Filtration Plant suppliers in Pune & India, offering customized filtration solutions to meet industrial requirements. Our commitment to innovation, precision, and durability makes us a preferred choice in the industry.

📞 Contact us today to get the best Two Stage Transformer Oil Filtration Plant in Pune & India!

🔗 Visit Now: Two Stage Transformer Oil Filtration Plant

#TransformerOilFiltration #TwoStageFiltration #ManufacturersInIndia #SuppliersInPune #IndustrialMachinery #PowerSolutions

#Two Stage Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant Manufacturers#Two Stage Transformer Oil Filtration Plant Manufacturer in pune#Two Stage Transformer Oil Filtration Plant Manufacturer in india#Two Stage Transformer Oil Filtration Plant suppliers in pune#Two Stage Transformer Oil Filtration Plant suppliers in india#Two Stage Transformer Oil Filtration Plant exporter in pune

0 notes

Text

Transformer Oil Filtration Service

Looking for reliable Transformer Oil Filtration Services in Noida? Maintaining the quality of transformer oil is crucial for the efficiency and longevity of transformers. Over time, oil can accumulate moisture, sludge, and contaminants, compromising its insulating and cooling properties. Expert service providers in Noida offer advanced filtration techniques to restore your transformer oil to optimal condition. These services include the removal of moisture, dissolved gases, and impurities, ensuring improved performance and reduced chances of breakdown. Regular oil filtration not only enhances transformer efficiency but also extends its life span and ensures safety. Whether for industrial or commercial transformers, professional teams in Noida provide on-site services with state-of-the-art equipment. Keep your electrical systems running smoothly by availing of trusted Transformer Oil Filtration Services in Noida today. Protect your assets and ensure uninterrupted power supply!

0 notes

Text

Keep Your Hydraulics Running Smoothly with Sumesh Petroleum

Ensure optimal performance and extend the life of your hydraulic systems with top-notch filtration machines from Sumesh Petroleum. We offer a comprehensive range of machines designed to remove contaminants, improve oil quality, and minimize downtime. Contact us today to discuss your specific needs and discover how Sumesh Petroleum can keep your hydraulics running smoothly. If you are interested then tap on the link hydraulic oil filtration machine manufacturers.

#Online Transformer Oil Filtration System Manufacturers#hydraulic oil filtration machine manufacturers

0 notes

Text

Transformer oil, the insulating and cooling fluid within your transformers, needs periodic cleaning to maintain its effectiveness. Transformer oil purifiers are your workhorses for this task, removing contaminants that compromise oil quality and transformer performance. But when choosing a purifier, a key decision pops up: single stage or double stage?

0 notes

Text

Top Quality Transformer Oil Filtration Plant

Transformer Oil Filtration Plant production and supply are the areas of expertise for Rayon Energy. The company provides caster wheel, vehicle-mounted, and trolley-mounted filtering equipment choices. The devices are made to filter transformer oil and extend the transformers' useful life. The filtering units from Rayon Energy come with an ionic reaction column, flow meter, BDV test kit, and inline PPM meter. A PLC control panel that is completely automated is another option for the machines. Companies in South Africa, Cameroon, Nigeria, and other African and Asian nations are among Rayon Energy's clientele.

Address: KHASRA NO. 1318,Morta Industrial Area,Near Hotel VivaanMeerut Road, Morta,GHAZIABAD - 201003 U.P.

0 notes

Text

Unlike traditional single-stage purifiers, the ZJA Double Stage Transformer Oil Filtration Machine is a two-stage system. This translates to an intensified purification process, tackling contaminants with exceptional finesse. Here's how it works:

Stage 1: Roughing the Seas: The initial stage employs a primary filter and a high-flow vacuum pump. This duo works in tandem to swiftly remove larger particles and water vapor, laying the groundwork for deeper purification.

Stage 2: Deep Dive into Purity: The second stage deploys a multi-pronged attack. Precision filters eliminate even the tiniest impurities, while a high-vacuum dehydration system meticulously extracts residual moisture. Additionally, degassing technology whisks away dissolved gases, leaving the oil pristine and ready for action.

0 notes

Text

Rayon India is your one-stop destination for fulfilling all your needs related to Transformer Oil Filtration Plant. With a strong focus on reliability and trustworthiness, we provide machines that ensure efficient and effective filtration of transformer oil. Our commitment to quality and customer satisfaction has made us a trusted name in the industry. Trust Rayon India for all your transformer oil filtration requirements and experience exceptional performance.

0 notes

Text

Electrical Transformer Repair Service

UK Electric specializes in delivering top-notch Electrical Transformer Repair Services. With a team of skilled technicians and cutting-edge equipment, we ensure efficient and reliable repairs for a wide range of transformers. Our comprehensive solutions encompass diagnostics, component replacement, and thorough testing to restore transformers to optimal performance. Adhering to industry standards, we prioritize safety and precision throughout the repair process. Clients can count on UK Electric for swift, cost-effective, and sustainable solutions, minimizing downtime and extending the lifespan of critical electrical infrastructure. Trust us to keep your power flowing seamlessly with our trusted expertise in Electrical Transformer Repair Service.

Read more:-

#electrical transformer repair service#transformer repair services#Transformer Repair & Maintenance Services#Transformer repair company#power transformer repair services#transformer on rent#transformer on hire#Transformer oil filtration Services#Transformer oil dehydration and filtration Services#Transformer Testing Service#Power transformer testing Services#Old Transformers Sale And Purchase

0 notes

Text

Leading Transformer Oil Filtration Machines and Dehydration Plants for Africa | Available in Botswana, Ethiopia, Kenya, South Africa, and More

At Transformer Oil Filter Plant, we specialize in providing high-quality transformer oil filtration machines, dehydration plants, and oil purification systems designed to enhance the performance and longevity of transformers. Our products are available across multiple African countries including Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, and Zimbabwe.

Our Products:

We are proud to offer a wide range of solutions tailored to meet the needs of industries requiring high-performing transformer oil filtration and dehydration:

Transformer Oil Filtration Machines: Our machines are engineered to efficiently filter and purify transformer oil, removing contaminants, sludge, and moisture to improve transformer performance and longevity. These machines are available in various models including high vacuum transformer oil filter machines and vacuum oil filter machines, suitable for different transformer capacities.

Transformer Oil Filtration Plants: We provide comprehensive transformer oil filtration plants that offer a continuous process for the filtration and purification of transformer oil. These plants are equipped with advanced technology for high efficiency, ensuring that transformer oil is clean, dry, and free of contaminants.

Dehydration Plants: Our dehydration plants are designed to remove moisture from transformer oil, preventing any potential issues related to moisture contamination, which can affect the efficiency and lifespan of transformers. These plants are available for use across industries in Botswana, Ethiopia, Kenya, South Africa, Zambia, and Zimbabwe.

Batch Type Trickle Impregnating Machines: Our batch-type trickle impregnating machines are specifically designed for the impregnation of electrical insulation with varnish, resin, or oil, ensuring durability and efficiency for electrical components used in various industries.

Vacuum Pressure Impregnation Plants: Our vacuum pressure impregnation systems offer excellent sealing for porous materials like electrical windings and cables. This technology enhances the electrical insulation process for various electrical equipment and machinery.

Industrial Oil Filtration Systems: We also provide industrial oil filter machines and purification systems that help clean and purify various industrial oils, improving system efficiency and reducing downtime.

Why Choose Us?

Global Reach: We are committed to providing reliable transformer oil filtration solutions in various African countries, including Botswana, Kenya, Nigeria, South Africa, and more.

High-Quality Products: Our machines and plants are built with the latest technology, ensuring superior performance, long-lasting durability, and minimal maintenance costs.

Tailored Solutions: We understand the unique needs of our customers, and we offer customized solutions to ensure the highest level of efficiency for your transformer oil filtration and purification processes.

Expertise and Support: With years of experience in the field, we offer expert consultation and support to help you choose the right filtration systems for your operations. Our technical team is always ready to assist you in maintaining and troubleshooting your equipment.

Contact Us:

For more information on our products, or to request a quote, reach out to us today:

Website: transformeroilfilterplant.com

Email: [email protected]

Phone: +91 9422605890

Let us provide you with the best solutions for transformer oil filtration, dehydration, and oil purification in Botswana, Ethiopia, Kenya, Namibia, Nigeria, South Africa, Zambia, and Zimbabwe. Our equipment helps ensure the optimal performance of your transformers and electrical systems, keeping them running efficiently for years.

#transformer oil filtration machine#transformer oil filtration machine in Botswana#transformer oil filtration machine in Ethiopia#transformer oil filtration machine in Kenya#transformer oil filtration machine in Namibia#transformer oil filtration machine in Nigeria#transformer oil filtration machine in South Africa#transformer oil filtration machine in Zambia#transformer oil filtration machine in Zimbabwe#transformer oil filtration plant#transformer oil filtration plant in Botswana#transformer oil filtration plant in Ethiopia#transformer oil filtration plant in Kenya#transformer oil filtration plant in Namibia#transformer oil filtration plant in Nigeria#transformer oil filtration plant in South Africa#transformer oil filtration plant in Zambia#transformer oil filtration plant in Zimbabwe#Transformer Oil Filtration#Transformer Oil Filtration in Botswana#Transformer Oil Filtration in Ethiopia#Transformer Oil Filtration in Kenya#Transformer Oil Filtration in Namibia#Transformer Oil Filtration in Nigeria#Transformer Oil Filtration in South Africa#Transformer Oil Filtration in Zambia#Transformer Oil Filtration in Zimbabwe#dehydration plant#dehydration plant in Botswana#dehydration plant in Ethiopia

0 notes

Text

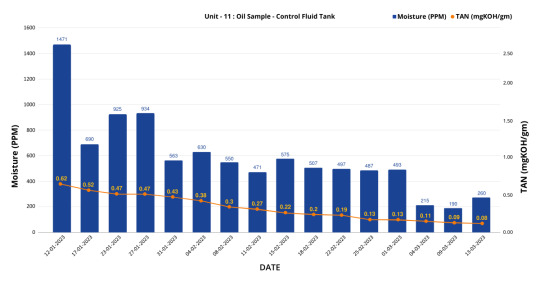

Oil reconditioning project for India’s largest coal-based power producer

Team Minimac successfully executed a critical project to recondition the control fluid (two tanks of capacity 16 kiloliter each) for India’s largest energy conglomerate and coal-based power producer with a capacity of 4760 MW.

Synopsis

The plant was built and is in service as a thermal power generating station, in Vindhyachal. There was a problem with higher Total Acid Numbers (TAN), observed typically when moisture content exceeds the permissible range. They were facing difficulties in stable unit operation because of the sluggish and erratic behavior of the turbine governing system. It was a significant threat to unit outage and generation loss. The situation was examined by Minimac Operations and Maintenance Service (MOMS). Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL was deployed to address the issue.

Before Oil purification, the TAN value was≥ 0.62 mgKOH/gm, NAS ≥ 8, and Moisture ≥ 1471 PPM. After Oil purification, the recorded parameters were TAN value = 0.08 mgKOH/gm, NAS ≤ 4, and Moisture ≤ 260 PPM. The major challenge faced during the execution was if we charged resin, TAN would reduce, but moisture would increase. So, an analysis was done and implemented to control the moisture first, then charged the second resin cycle. Minimac gave a 100% customized and balanced solution within time.

Problems

The tank capacity was 16 kiloliters, which is huge. The biggest challenge was to execute the project while the system was in operation. Water contamination bubbles were forming, leading to the fluctuation in NAS - as for moisture control, it was necessary to turn off the system. Resin charge in Ion exchange was done intermittently to control moisture increase, and our motto was to hold moisture below 500 PPM so we could plan for the next cycle of resin charge.

Client’s Requirement

To purify the control fluid.

To reduce the TAN value from 0.62 to < 0.10 mgKOH/gm.

To bring down the moisture level < 500 PPM.

To achieve NAS < 5.

Smooth and timely execution without any downtime.

Tailor-made solution.

No oil loss because of processing or spillage.

Solutions

Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL for NAS & moisture reduction was installed.

Before the oil conditioning process, the TAN ≥ 0.62 mgKOH/gm, which was reduced after oil purification to TAN ≤ 0.08 mgKOH/gm.

The Nitrogen generation unit (TMR 100) was deployed and installed at the client’s site.

For further improvement in TAN, the oil vapor extraction fan (OVEF) was throttled in the range of 70%, with the support of the user.

Minimac provided trained manpower and other consumables under the MOMS (Minimac Operations and Maintenance Service) offering. Minimac had given results far better than the KPIs.

Cost Saving

This plant managed to save:

Cost of oil replacement: ₹ 3.2Cr. approx/ $ 32 Million approx

Cost of downtime: ₹ 3.15 Cr. approx/ $ 31.5 Million approx

By investing ₹ 21 lakh approx/ $ 25.65k approx only.

CO2 e Saving

1,92,000 kg of CO2 e / 0.192 gigagrams of CO2 e

Benefits

Extended in-service oil life.

The smooth functioning of the machines.

Elimination of new oil replacement cost.

Avoiding the risk of fire and explosion.

Reduction in the possibility of product degradation due to blanketing.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#lube oil flushing#lube oil#chemical flushing#oil and gas#metal#mining#oil filtration system#transformation oil purification#transformer oil#transformer oil cleaning#transformer oil filtration#transformers#oil purification system#oil purification machine#oil purification system#oil purification#oil dehydration systems#mlc lvdh#lvdh full form#lvdh

0 notes

Text

🔹 Single Stage Transformer Oil Filtration Plant – High-Efficiency Filtration Solutions 🔹

Are you looking for a high-quality Single Stage Transformer Oil Filtration Plant? ✅ We are leading Single Stage Transformer Oil Filtration Plant manufacturers in Pune and India, providing advanced oil purification systems to enhance transformer performance and longevity.

🔗 Visit Now: Single Stage Transformer Oil Filtration Plant

🏭 Why Choose Our Single Stage Transformer Oil Filtration Plant?

Efficient Oil Purification ⚙️ – Removes moisture, gases & impurities

Enhances Transformer Performance ⚡ – Increases insulation strength & lifespan

High Vacuum Technology 🏭 – Ensures superior filtration quality

Energy-Saving Operation 🔋 – Reduces power consumption & maintenance costs

Robust & Durable 💪 – Designed for long-term industrial use

As trusted Single Stage Transformer Oil Filtration Plant manufacturers in Pune, we offer highly reliable and cost-effective oil filtration solutions to industries across India.

🌍 Top Transformer Oil Filtration Plant Exporters in Maharashtra, India

We are one of the leading Transformer Oil Filtration Plant exporters in Maharashtra and India, supplying advanced oil filtration plants to clients globally. Our machines are ideal for: ✔️ Power Plants & Substations ✔️ Transformer Manufacturers & Maintenance Companies ✔️ Industrial Electrical Equipment ✔️ Oil Refining & Processing Units

🏆 Best Single Stage Transformer Oil Filtration Plant Suppliers in Pune & India

We are renowned Single Stage Transformer Oil Filtration Plant suppliers in Pune & India, offering custom-built solutions to meet your specific requirements. Our commitment to innovation & quality makes us a preferred choice for transformer oil purification systems.

📞 Get in touch today to explore the best Single Stage Transformer Oil Filtration Plant in Pune & India!

🔗 Visit Now: Single Stage Transformer Oil Filtration Plant

#TransformerOilFiltration #OilFiltrationPlant #ManufacturersInIndia #SuppliersInPune #IndustrialMachinery #PowerSolutions

#Single Stage Transformer Oil Filtration Plant Manufacturers#Transformer Oil Filtration Plant Exporters in Maharashtra#India#Single Stage Transformer Oil Filtration Plant Manufacturer in pune#Single Stage Transformer Oil Filtration Plant Manufacturer in india#Single Stage Transformer Oil Filtration Plant suppliers in pune#Single Stage Transformer Oil Filtration Plant suppliers in india#Single Stage Transformer Oil Filtration Plant exporter in pune

0 notes

Text

Top Transformer Oil Filtration Services in Delhi by Rudra EPT

When it comes to top transformer oil filtration services in Delhi, choosing a reliable and experienced provider is essential for ensuring the longevity and efficiency of your equipment. Top transformer oil filtration services specialize in removing impurities like moisture, sludge, and gases from transformer oil, improving its insulation properties and preventing damage to the transformer. These services utilize advanced filtration technologies and equipment, including degassing and dehydration systems, to restore oil to its optimal condition. Trusted service providers offer comprehensive solutions, including oil testing, filtration, and maintenance, backed by a skilled team of professionals. Whether it's for routine maintenance or urgent repairs, top filtration services prioritize safety, efficiency, and customer satisfaction. By partnering with a leading service provider, you ensure the continuous and reliable operation of your transformer systems while minimizing downtime and costly repairs.

0 notes

Text

High-Vacuum Transformer Oil Filtration and Dehydration Plants by AR Engineering

Welcome to AR Engineering, your trusted partner in high-vacuum transformer oil filtration and dehydration plants. As a leading manufacturer in India, we pride ourselves on delivering high-quality solutions that ensure the optimal performance and longevity of your transformers. Our products are designed to meet the diverse needs of industries worldwide, offering efficiency, reliability, and superior performance.

High-Vacuum Transformer Oil Filtration Manufacturer in India

At AR Engineering, we specialize in the manufacture of high-vacuum transformer oil filtration systems. Our state-of-the-art systems are designed to remove impurities, moisture, and gases from transformer oil, ensuring its purity and enhancing the performance of your transformers. As a top high-vacuum transformer oil filtration manufacturer in India, we are committed to providing solutions that meet the highest industry standards.

High Vacuum Oil Filter Machines

Our high vacuum oil filter machines are engineered to handle a wide range of oil purification tasks, ensuring the purity and efficiency of the oil used in your equipment. We are proud to be a leading high vacuum oil filter machines manufacturer in Pune, offering products that are built to last and perform under the most demanding conditions. Our machines are also available from top suppliers in Pune, ensuring easy access to our cutting-edge technology.

Vacuum Pressure Impregnation Plant Manufacturers

AR Engineering is renowned for its expertise in vacuum pressure impregnation plant manufacturing. Our plants are designed to seal porous materials, preventing the ingress of contaminants and enhancing the durability of components. As leading vacuum pressure impregnation plant manufacturers, we provide solutions that cater to the needs of various industries, including automotive, electrical, and aerospace.

Vacuum Impregnation Plant Manufacturer

We are a premier vacuum impregnation plant manufacturer, offering high-quality solutions that ensure the reliability and longevity of your components. Our vacuum impregnation plants are designed to meet the specific needs of our clients, providing efficient and effective impregnation processes.

Wholesale Pressure Impregnation Plant Suppliers

As wholesale pressure impregnation plant suppliers, we offer a range of high-quality products at competitive prices. Our pressure impregnation plants are designed to deliver consistent performance, ensuring the optimal impregnation of materials and the prevention of contamination.

Batch Type Trickle Impregnating Machine

Our batch type trickle impregnating machines are designed for efficient and precise impregnation processes. These machines are ideal for applications that require consistent and controlled impregnation, ensuring the reliability and durability of the components.

Index Type Trickle Impregnating Machine

The index type trickle impregnating machine from AR Engineering offers advanced features and superior performance. This machine is designed for high-precision impregnation processes, ensuring the uniform application of impregnants and enhancing the quality of the finished products.

Vacuum / Pressure Impregnation Plants Manufacturer Exporter, Supplier, Satara, Maharashtra, India

As a leading vacuum/pressure impregnation plants manufacturer, exporter, and supplier based in Satara, Maharashtra, India, AR Engineering is committed to delivering top-notch solutions to clients worldwide. Our plants are designed to meet the highest industry standards, ensuring efficient and effective impregnation processes.

Vacuum Impregnation Plants Manufacturer in Pune

We are a prominent vacuum impregnation plants manufacturer in Pune, offering a range of high-quality products that cater to the specific needs of our clients. Our plants are designed for efficiency, reliability, and superior performance, ensuring the optimal impregnation of materials.

Vacuum Impregnation Plants Manufacturer in India

As a leading vacuum impregnation plants manufacturer in India, AR Engineering is dedicated to providing solutions that meet the diverse needs of industries across the country. Our plants are built to deliver consistent and reliable performance, ensuring the optimal impregnation of components.

Vacuum Pressure Impregnation Plant Supplier in Pune

We are a trusted vacuum pressure impregnation plant supplier in Pune, offering high-quality products that are designed to meet the specific needs of our clients. Our plants are built to deliver efficient and effective impregnation processes, ensuring the reliability and durability of your components.

Vacuum Pressure Impregnation Plant Supplier in India

As a leading vacuum pressure impregnation plant supplier in India, AR Engineering offers a range of high-quality products that cater to the diverse needs of industries across the country. Our plants are designed for efficiency, reliability, and superior performance, ensuring the optimal impregnation of materials.

Vacuum Pressure Impregnation Plant Exporter in India

As an established vacuum pressure impregnation plant exporter in India, we deliver high-quality products to clients worldwide. Our plants are designed to meet international standards, ensuring they perform effectively in various industrial environments.

Vacuum Pressure Impregnation Plant Exporter in Pune

We are a reputable vacuum pressure impregnation plant exporter in Pune, offering top-notch solutions to clients around the world. Our plants are built to deliver reliable and consistent results, ensuring the optimal impregnation of materials and the prevention of contamination.

#high vaccum oil filter machines manufacturer in pune#Vacuum Impregnation Plant manufacturer#High-Vacuum Transformer Oil Filtration manufacturer in india#Vacuum Impregnation Plant

0 notes

Text

Unveiling Precision Vaccum Oil Filter Machines Manufacturers - Sumesh Petroleum

Explore the world of advanced lubricant filtration with Sumesh Petroleum, a distinguished manufacturer of cutting-edge Vacuum Oil Filter Machines Manufacturers. In this blog post, we delve into the innovative technologies employed by Sumesh Petroleum, highlighting the significance of their products in maintaining the purity and performance of industrial oils.

Key Features:

Efficient Contaminant Removal: It is a boast unparalleled efficiency in removing contaminants such as particles, sludge, and impurities from lubricating oils. The result is extended equipment life and improved operational reliability.

State-of-the-Art Filtration Technology: Dive into the intricate details of the technology and designed to achieve sub-micron-level precision. Their machines ensure optimal cleanliness, meeting or exceeding industry standards for lubricant purity.

Customizable Solutions: Our understands for that different industries have unique filtration requirements. Learn about their customizable solutions that cater to diverse applications, providing tailored answers to specific oil purification needs.

User-Friendly Operation: Discover how prioritizes the user experience with intuitive and user-friendly interfaces on their vacuum oil filter machines. The ease of operation enhances maintenance processes, making it a seamless addition to industrial workflows.

Related Products:

Oil Purification Systems: We are offers a comprehensive oil purification systems. These systems provide a holistic approach to maintaining the quality of industrial oils across various applications.

Oil Filtration Accessories: Explore a range of accessories designed to enhance the performance . From spare parts to additional filtration elements, these accessories contribute to an optimized filtration process.

Address : 226 - 227, G.I.D.C Estate., Makarpura,Vadodara - 390 010 Gujarat India.

Phone No : +91-9727705851 (Suketu Shah )

Email Id : [email protected]

Url : https://www.sumeshpetroleum.com/vacuum-oil-filter-machine.html

#Transformer Oil Filter Machine Manufacturers#Transformer Oil Purification Machine Manufacturers#Transformer Oil Purification Plant Manufacturers#Transformer Oil Filtration Manufacturers#Oil Filtration Machine Manufacturers#Transformer Oil Filtration Machine Manufacturers

1 note

·

View note