#Top Carry Bag Printing Machine Manufacturer Companies

Explore tagged Tumblr posts

Text

What are the uses and functions of Carry Bag Printing Machine?

Carry bag printing machines serve various purposes and offer several functions, particularly in the packaging and branding industry.

Here are some of the primary uses and functions of carry bag printing machines:

Customization: Carry bag printing machines allow businesses to customize their packaging with logos, brand names, product information, and designs. This customization helps in brand recognition and differentiation in the market.

Brand Promotion: Printing machines enable businesses to promote their brand effectively by printing attractive designs and messages on carry bags. These bags serve as mobile advertisements when customers carry them around in public spaces.

Product Information: Carry bag printing machines can print important product information such as ingredients, usage instructions, expiry dates, and safety warnings. This ensures compliance with regulatory requirements and helps consumers make informed purchasing decisions.

Enhanced Aesthetics: Printing machines enable businesses to create visually appealing carry bags that enhance the overall presentation of their products. This can positively impact the perceived value of the products and attract more customers.

Differentiation: Customized printing allows businesses to differentiate their products from competitors’ offerings. Unique designs and branding elements printed on carry bags help create a distinct identity for the brand in the market.

Cost-Effectiveness: In-house printing using carry bag printing machines can be more cost-effective compared to outsourcing printing services. It reduces lead times and provides greater control over the printing process, resulting in cost savings for businesses.

Flexibility: Carry bag printing machines offer flexibility in printing various bag sizes, shapes, and materials. They can accommodate different types of substrates such as paper, plastic, and fabric, allowing businesses to meet diverse packaging needs.

Efficiency: Modern printing machines are equipped with advanced features such as automated printing, precise color matching, and high-speed production capabilities. This improves efficiency and productivity in the packaging process.

Environmentally Friendly Options: Some carry bag printing machines offer eco-friendly printing options, such as water-based inks and recyclable materials. This helps businesses reduce their environmental footprint and meet sustainability goals.

Overall, carry bag printing machines play a crucial role in packaging, branding, and marketing strategies for businesses across various industries. They offer versatility, customization, and efficiency, enabling businesses to create visually appealing and functional carry bags that resonate with consumers.

Best Carry Bag Printing Machine Manufacturer in India

If you are looking for a Top Carry Bag Printing Machine Manufacturer in India, look no further than Decent Print Line, we are a leading manufacturer and supplier of Carry bag Printing Machine in India, for more details, please contact us!

#Carry Bag Printing Machine Manufacturer in India#Carry Bag Printing Machine Manufacturer#Carry Bag Printing Machine Supplier in India#Carry Bag Printing Machine supplier#Best Carry Bag Printing Machine Manufacturer in India#Top Carry Bag Printing Machine Manufacturer#Top Carry Bag Printing Machine Manufacturer Companies#Decent Printline

1 note

·

View note

Text

Best Deals from Cotton Tote Wholesalers in German

Germany is now ranked as one of the top locations to locate eco-fashion on the European continent, with green consumers increasingly utilizing reusable cotton tote bags. So great is the demand that the excellent yet affordable products of cotton totes have penetrated the Cotton Tote Wholesalers in German markets. As a brand manager, event planner, or retailer, the perfect wholesaler is the key consideration for access to excellent products at discount prices.

Why Cotton Tote Bags?

Cotton tote bags are an easy and environmentally friendly alternative to disposable plastic bags. They are long-lasting, reusable, and can hold massive amounts of branding, thus ideal for marketing events, retail packaging, and business promotions. With environmental issues on the rise, businesses are seeking Cotton Tote Wholesalers in German markets where they can obtain products to aid their environmental campaigns.

Top Sales of Cotton Tote Wholesalers in German Market

1. AW Artisan Europe

AW Artisan Europe offers an array of environment-friendly cotton tote bags with classic canvas prints and printed tote bags featuring summer flowers or Indian patterns. AW Artisan Europe tote bags can be used for campaigns, events, farm shops, and grocery stores. AW Artisan Europe offers ample imprint area for use in promotions and can be applied to the printing of company logos. AW Artisan Europe offers value-for-money prices with bulk order offers and is among the leading Cotton Tote Wholesalers in German markets.

2. Merkandi B2B Platform

The Merkandi B2B platform offers some fantastic deals from Cotton Tote Wholesalers in different German regions:

140 g/m² OEKO-TEX Certified Ecru Cotton Tote Bag: €1.18 per unit (excluding VAT) in a 100-unit order. Composed of 140 g/m² OEKO-TEX certified cotton, the tote bag is completely free of all harmful chemicals. The machine washable tote bag has strong carry handles, and it is ideal for day-to-day use as well as for shopping.

Odessa White Recycled Cotton Bag 220 g/m² 13L: €3.74 per unit (ex VAT) minimum order 100 units. This is a natural environmentally friendly tote bag constructed from recycled 220 g/m² cotton and having a massive 13-liter capacity. Ideal for personalization and everyday use.

Grey Recycled Cotton Tote Bag OEKO-TEX 140 g/m² 38x14x32cm: €2.69 per unit (VAT excluded) minimum order of 100 units. Contemporary, environmentally friendly tote bag made from 100% recycled cotton in traditional grey colour. Lightweight, but robust and handy for a wide range of uses.

Blue Recycled Cotton Tote Bag 38x42x10 cm: Price: €1.89 per unit (VAT not included) Minimum order: 100 units. Big and eco-friendly tote bag with 100% recycled cotton and bottom pleat for increased volume. Suitable for intensive use and everyday usage.

These Merkandi Cotton Tote Wholesalers offer German markets products of high value to companies that want to buy sustainable commodities at low prices.

Shine on Cot Bags Project

The Cot Bags project is one of the new sustainable cotton tote business ventures. The project aims to produce quality, environmentally friendly cotton tote bags for everyday use, such as shopping and as promotional materials. The company is interested in ethical manufacturing processes, fair wages earned, and a healthy working environment for all. Sourcing organic cotton, employing eco-dyeing techniques and chemical dyes, Cot Bags minimizes the environmental footprint of conventional bag production. Its dedication to quality and sustainability places them at the vanguard of Cotton Tote Wholesalers' operations in German markets.

How to Choose the Right Wholesaler

Choosing the right wholesaler is very crucial in ensuring product quality and values for which your brand has a reputation. In reviewing Cotton Tote Wholesalers of German regions, keep the following in mind:

Product Range: Make sure that the wholesaler has a wanted range of sizes, styles, and customization for your specific requirement.

Certifications: Look for certifications like GOTS (Global Organic Textile Standard), OEKO-TEX®, or Fair Trade, which validate conformity to environmental and ethical standards.

Pricing: Look at prices to discover a wholesaler who provides competitive pricing without sacrificing quality.

Lead Times: Check delivery times to see if the wholesaler can deliver according to your needs.

Customer Service: Verify the reactivity and support provided by the wholesaler to deal with any issues or difficulties within time.

Conclusion

The German market offers a vast range of Cotton Tote Wholesalers within German regions with specialized products and services to cater to the growing trend towards greener alternatives. Through being linked to vintage wholesalers like AW Artisan Europe and networks like Merkandi B2B, organizations are easily able to access high-quality, customisable, and eco-friendly cotton tote bags that will complement their sustainable expectations. Further, trendsetting organisations like Cot Bags are merely a glimpse into the future that the world has to offer regarding eco-friendly and ethical production within the cotton tote bag industry. By choosing the correct wholesaler, businesses can secure a cleaner tomorrow as well as meet the demands of their customers.

0 notes

Text

How to Enhance Your Product’s Shelf Appeal with Modern Packaging

In the rapidly evolving world of packaging, businesses are constantly on the lookout for materials that are not only durable but also visually appealing. One such innovation that has revolutionized the packaging industry is the bopp woven bag. These bags have become a preferred choice for packaging a wide range of products due to their unique combination of strength, flexibility, and aesthetic appeal. Among the leaders in manufacturing these versatile bags is Sudarshan Add Pack, a company renowned for its commitment to quality and innovation.

What Are BOPP Woven

BOPP (Biaxially Oriented Polypropylene) woven bags are a type of laminated woven polypropylene bag. The term 'Biaxially Oriented' refers to the process where polypropylene film is stretched in both the machine direction and across the machine direction to create a material that is exceptionally strong and durable. This film is then laminated onto woven polypropylene fabric, resulting in a bag that combines the toughness of woven fabric with the attractive finish of BOPP film.

These bags are known for their excellent load-bearing capacity, tear resistance, and moisture protection. They are widely used for packaging products like grains, animal feeds, fertilizers, seeds, and chemicals. The BOPP film also allows for high-quality printing, making these bags an excellent choice for companies looking to enhance their brand visibility through vibrant, multi-color designs.

Advantages of BOPP Woven

Strength and Durability: The woven polypropylene fabric provides BOPP bags with superior strength, making them ideal for carrying heavy loads without the risk of tearing or bursting.

Moisture Resistance: BOPP woven offer excellent moisture resistance, which is crucial for packaging products like grains and fertilizers that need to be kept dry. The laminated BOPP film acts as a barrier against moisture, ensuring that the contents remain intact and unaffected by environmental conditions.

Aesthetic Appeal: One of the standout features of BOPP is their visual appeal. The BOPP film allows for high-quality, photo-realistic printing, enabling businesses to display their brand and product information in a visually striking manner. This not only enhances the product’s shelf appeal but also helps in creating a strong brand presence.

Customizability: BOPP woven can be customized in terms of size, shape, and design. Whether you need a bag with a specific capacity or one that features your brand colors and logo, BOPP woven can be tailored to meet your specific requirements.

Eco-Friendly Option: Despite their durability and strength, BOPP woven are eco-friendly. They are reusable, recyclable, and produce less waste compared to other types of packaging materials.

Pioneers in BOPP Woven

When it comes to sourcing high-quality BOPP woven, Sudarshan Add Pack stands out as a trusted name. With years of experience in the packaging industry, Sudarshan Add Pack has earned a reputation for delivering products that meet the highest standards of quality and performance.

Sudarshan Add Pack is dedicated to providing its customers with packaging solutions that not only meet but exceed their expectations. The company’s BOPP woven are crafted using state-of-the-art technology and the finest materials, ensuring that each bag is strong, durable, and visually appealing.

The company offers a wide range of BOPP woven, catering to various industries such as agriculture, chemicals, and retail. Each bag is customizable, allowing businesses to create packaging that is uniquely tailored to their brand. Sudarshan Add Pack's commitment to innovation is evident in the quality of their products, making them a preferred choice for companies looking for reliable and attractive packaging solutions.

In addition to quality, Sudarshan Add Pack places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific packaging needs and delivers solutions that are both practical and cost-effective. Whether you need a large quantity of bags or a small, customized order, Sudarshan Add Pack ensures that you receive products that meet your exact specifications.

Conclusion

In the competitive world of packaging, choosing the right materials can make a significant difference in product presentation and protection. BOPP woven offer an ideal solution for businesses looking for packaging that is durable, moisture-resistant, and visually appealing. With Sudarshan Add Pack, you can be assured of receiving top-quality BOPP woven that are tailored to your needs. Their commitment to quality, innovation, and customer satisfaction makes them a leader in the industry, and a reliable partner for all your packaging requirements.

0 notes

Text

Printed Fabric Manufacturers for Upholstery - Response Fabrics

Printed Fabric Manufacturers for Upholstery

If you want to get the best Printed fabric manufacturers for upholstery in India then Response Fabrics is one of the top well renowned manufacturers of a broad assortment of Printed fabric, Artificial Leather Fabric, Upholstery Fabric, Mesh Fabric, Blackout Fabric, etc. The offered fabrics are woven at the well-developed manufacturing unit by making use of premium quality yarns, and threads in compliance with defined quality standards. The production department is well-furnished with ultra-modern machines, tools, and equipment to weave these fabrics.

Upholstery Fabric Manufacturers & Suppliers in India

Response Fabrics has the best solution for the best selective variety of upholstery fabric that is a delight to those who wear it as well as those who touch, and see it. The collection of upholstery fabric online gives the best look altogether. The threads used in our cotton fabrics are durable, and fade resistant. This brings great joy for all the customers who buy cheap upholstery fabric from our online store & enjoy different benefits from these.

Upholstery Fabrics are made from a soft feel, high-strength, fire-retardant vinyl fabric, we don’t compromise with the comfort, and elegance, but without the price tag you’d expect. The Responsive Fabric Upholstery Fabric is extremely easy to wipe down, delivering true comfort.

Printed Holland Velvet Upholstery Fabric

Response Fabrics are a leading Manufacturer & Supplier of a wide range of single tone micro velvet fabric, two tone velvet fabric, printed velvet fabric, micro velvet fabric, red velvet fabric, digital printed velvet fabric. We have constructed a wide, and well functional infrastructural unit that plays an important role in the growth of our company. We offer these products at reasonable rates, and deliver these within the promised time-frame.

Purchase Premium-Quality printed upholstery fabric

We, at Response Fabrics, aim to make the best premium-quality printed upholstery fabric available at pocket-friendly prices. All our products go through various quality checks before they are sent out. We know that investing in furniture is a big-deal that’s why all of our products are made with utmost care, and expert specialization. Our range of affordable Upholstery fabric is sure to spruce your home, and furniture up.

Printed Cotton Fabric Manufacturers

This manufacturer of fabrics offers the excellent quality of printed cotton fabrics. These cotton printed fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Printed Fabric Manufacturers in Surat

For the best Manufacturer & Exporter of Printed Fabric Manufacturer in Surat check the Response Fabrics that is the Professional Supplier of High Quality Designer printed Fabrics in Surat. We specialized in supplying quality printed Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we.

Custom Print Fabric India

Response Fabric offers the best creative custom print fabric that is one of the finest on demand fabric printing companies in India. We offer digital printing on all fabrics, and can do digital printing on all knitted, woven, and felt fabrics like cotton, linen, polyester, rayon, wool, etc. At responsive fabrics, we provide aesthetic, and cost-efficient solutions to all textile needs.

cotton printed fabric wholesale price

The price of cotton printed fabric wholesale is starting from Rs. 70\Meter, and goes on.

printed cotton fabric manufacturers in ahmedabad

Response Fabrics brings the best printed cotton fabric manufacturers in Ahmedabad with a wide range of printed designs. These are made from certified fabric sourced from vendors of high repute after doing a diligent quality testing as per international standards. These products are attractive in colors, mesmerizing patterns, and quality fabric.

READ MORE...Home - Response Fabrics

#Printed Fabric Manufacturers for Upholstery#Upholstery Fabric Manufacturers & Suppliers in India#Printed Holland Velvet Upholstery Fabric

0 notes

Text

Working Of Pouch Filling Machines From Nichrome

Pouch filling machines are becoming increasingly popular for industrial packaging across industries and across the world. Pouches tend to be flexible, lightweight and offer several advantages over traditional packaging such as metal cans or glass bottles.

There are generally two types of pouch filling machines: Vertical Form Fill Seal (VFFS) and horizontal form fill seal (HFFS), with VFFS being the preferred option. Let’s understand the working principles of VFFS packaging machines:

Vertical Form Fill Seal (VFFS) machines are a kind of pouch making and filling machines that have a vertical structure. These machines are mainly used for industrial packaging and processing and provide a more convenient and effective method of automatic packaging which saves time, prevents material wastage and reduces cost.

Let’s look at the main components of VFFS pouch filling machines to understand the working of these machines:

Film Pulling System: This component of VFFS machines consists of an unwinding roller and tensioner. A roll of film - generally laminated PE, PET, aluminium foil - is placed on an unwinding roller - which is usually positioned at the rear of the machine. The tensioner and servo motors firmly and precisely unwind and pull the film into the system.

Printer (Optional): This component prints the date, production batch code etc on the film when it passes by the printer.

Pouch Former: The film moves to bag forming once the printing is done. The edges of the film are overlapped to shape the pouch while the top and bottom sealing is done by sealing jaws.

Filling and Sealing Machine: Filling is carried out by connecting the bagging machine to a multi-head scale or similar filling machine - such as an auger or volumetric filler. These two components are synchronized electronically, so that as soon as the bag is ready, the product is released automatically. The top of the bag is sealed once the product is dropped into it. The two parts of the overlapping material are pressed together and welded with heat using sealing jaws to create a side or centre seal.

Pouch Cut: Once the bag is sealed and filled, it is cut away. The top seal of the first bag becomes the bottom of the next bag ad infinitum. The cut pouch is dropped into a collection system - typically a belt conveyor that carries the pouch to the next step of packaging.

Control Cabinet: The side of the vertical form fill seal machine comes with a control cabinet inside which are all the electrical parts such as PLC, contactor, servo motors, pneumatic cylinder, solenoid valves, PLC expand mode, low-pressure electrical parts. The Human Machine Interface (HMI) makes operating and controlling the machine simpler.

There are a number of pouch filling machine manufacturers that offer multiple machines for a diverse range of applications. If you are on the lookout for an oil pouch packing system or searching for a dependable milk pouch packing machine manufacturer, Nichrome is your best bet - whether you wish to package powder, liquid, viscous or granular products in flexible pouches.

Nichrome’s four decades of experience around the world, innovative R&D, state-of-the-art manufacturing, technology tie-ups with global companies, thousands of successful installations and strong nationwide service network can be matched by only a few pouch filling machine manufacturers. Nichrome’s technology know-how, capabilities and track record are unmatched in the industry. Connect with Nichrome for your pouch filling machine needs.

#Pouch filling machines#pouch filling machine manufacturers#pouch filling machine manufacturer#VFFS packaging machines#HFFS#oil pouch packing system#milk pouch packing machine manufacturer

0 notes

Text

Wood Crafts

Wooden Crafts are the artistic practice of shaping and decorating wooden objects. India is famous for wooden handicrafts. Skilled craftsmen of each state create handicrafts using wood that is available locally. The most common varieties used to make Indian handicrafts are teak, sheesham, sal, oak, mango, ebony and mahogany. Sandalwood, rosewood and walnut are the exotic varieties and are expensive and are used in producing fine pieces of furniture and decorative items. There has been a complete revival of the traditional and antique wood craft, owning to its uniqueness and demand in India and abroad. Indian artisans are experimenting with designs to create a blend of traditional and modern woodcraft. Each piece of Indian wooden handicraft is a labor of love, sweat, and patience, which no machine can replicate.

Wooden Toys and games are winning mass of quality these days. The wooden toys and games are put up in innovative as well as classical types that are energizing and thought-provoking for everyone to examine their power. A heavy number of attractively fashioned wooden toys and games will offer hours of amusement. They are designed with exquisitely workmanship and paragon for people of all age-groups.

Designed with expert workmanship, wooden toys have arrived at immense popularity and are perfect for people of all generation. The most widely playacted wooden toys and games are wooden chess and wooden carrom board. The wooden toys are carefully carved and attractively designed engaging a special place in lots of families. Wooden toys and games are meant for kids and adults both, and are perfect items for gifting purpose. They are handcrafted with extreme care to have an eye-catching visual aspect. They provide durable fun and are designed to germinate coordination and imagery power among children. The most widely played wooden toys and games are wooden chess and carrom-board. In order to make them easier to carry while traveling, they are available in wooden box which makes them excellent for gift items.

Festival Wooden Crafts are very popular. Many companies prefer to give away various wooden gift items as corporate gifts as they are durable and elegant. When wooden items are purchased in wholesale from suppliers or exporters, they prove to be very cost effective. In fact, when companies directly deal with the wooden gift manufacturers, they save a lot of money by avoiding the middlemen in suplly chain. However, wooden corporate gifts might be procured on cheap rates, they always look more expensive due to craftsmanship of the artisans as well as because wood itself is considered to be an expensive medium to make craft items. They can be offered on various occasions including retirement , transfer or anniversary etc. They help in encouraging and motivating people who really deserve to be appreciated. It helps in minimizing attrition rate as well as staff turn over. Wooden gift items cam also be customized as per the requirement of various companies.

Acrylic Charms are made with a solid, clear acrylic material that can be printed in full color and cut to any shape. Acrylic charms feature a small 0.085” (~2mm) cut hole for creating your own keychains, jewelry and more. These Acrylic Crafts have been a real hit! Acrylic charms consist of either one layer of acrylic board with an epoxy-covered image on top (or on bottom, if you prefer the acrylic layer over the front and epoxy on back), or two layers of board with the image sandwiched in between. The image itself can be one-sided or two sided.

Acrylic Rhinestones are so attractive! When we go shopping in department stores or walk on the road, we often see various shapes and sizes of rhinestones on shoes, bags, jewelry, and even displays. The rhinestones are colorful and shiny, and it is difficult to ignore them. Rhinestones are not diamonds; they are a simulation of diamonds. Since diamonds are natural and are formed under high pressure and high-temperature conditions deep in the earth, often taking a long time to form, they are scarce and very expensive. Rhinestones are artificial and have the sparkling, dazzling effect of diamonds. Therefore, when rhinestones could be manufactured in large quantities, people began to use rhinestones as decorations for jewelry, clothing and other accessories.

Forty years ago, the sending and receiving of Christmas Greeting Cards were one of the steps in declaring adulthood and establishing one’s own home. Part of becoming an adult was communicating the year’s events to family and friends.

In the Christmas letter that went with the card, there was some bragging about the good things in one’s life but it was also a vehicle to let people know about deaths or difficulties.

As Christmas became more about persuading consumers to buy, greeting card companies understood this. They grew their sales by offering greater varieties of cards, including boxed sets and charitable cards. Businesses began sending greeting cards to each other as a thank you for the work done together that year.

0 notes

Text

Best Carry Bag Printing Machine Manufacturing Company in India

Decent Print Lines is a leading manufacturer and supplier of Carry Bag Printing Machines in India, renowned for delivering high-quality, efficient solutions to meet diverse printing needs. Our state-of-the-art machines are designed to handle various types of carry bags, including plastic, paper, and non-woven options, ensuring vibrant, precise prints with exceptional durability. Equipped with advanced printing technology, our machines offer features such as multi-color printing capabilities, high-speed operation, and user-friendly interfaces, making them ideal for both small-scale and large-scale production.

At Decent Print Lines, we focus on innovation and quality, providing machinery that enhances productivity and reduces operational costs. Our commitment to excellence is reflected in our rigorous quality control processes and reliable after-sales support. Whether you need a machine for custom designs or high-volume printing, our team is dedicated to offering tailored solutions that fit your specific requirements. With a strong emphasis on customer satisfaction, Decent Print Lines is your trusted partner for top-notch carry bag printing solutions in India.

For More Details

Contact us :- +91-9911433180

Email Id :- [email protected]

Address :- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#carry bag printing machine manufacturer in india#carry bag manufacturer#carry bag printing machine manufacturer

0 notes

Text

Use an unconventional potato chips machine to make crispy chips

If you own a large French fry manufacturing company, the most important thing to consider is the most innovative packaging. Packaging is a fantastic way to impress children and customers, and it will create the best way to improve your business. However, the packaging is not any easier because there are so many variables to consider. However, the French fries packing machine will now assist you by reducing the risk of packaging. The potato chips machine will carry out the processes of sending, measuring, filling, bagging, date printing, air filling, and so on automatically. Finally, the completed material could be sent to the drop-down boxes. This machine has a high measuring precision and produces highly effective, less cursed aggregated products.

Packaging of fried potato products

Fried potato chips are a popular and favouritesavoury for people of all ages. It is most likely more advantageous for children and young people. As a result, the potato chips packingmachine offers you easy packaging of various products. In recent years, it has been used to pack products by a wide range of industries. This will aid in the potatoes' automatic packing into the pouches and the safe delivery of the product.

Top benefits that you can acquire from potato chips packaging machine

• The potato chips machine can aid in detecting manufacturing and expiration dates to secure the quality of food products. • It will save you time and energy when packing. • It will aid in increasing productivity and reusing the viability of larger pouches. • The potato chips packing machine has a long run time and makes it simple to organise your food. • It can protect your food and improve its flavour, as well as reduce food waste.

The various types of chips packing machine

Vacuum food sealing machine

A vacuum potato chips machine will make it simple and efficient to package a wide range of products. With the sealed process, it is possible to create excellent atmospheric packaging. This will help you save time and money while also preserving your food for a longer period, resulting in less spoilage. This will prevent the growth of bacteria and keep your snacks fresh. This machine can also add more flavours to the chips while preserving the nutritional value.

Automatic chips packing machine

The automatic potato chips packing machine is the most widely used potato chip plant and frozen French fries plant. These machines are widely used in a variety of packaging industries. It is more convenient for quickly and easily processing and packing the chips. It will aid in increasing production and raising company standards. The well-known polyethenepouches are obviously used in this packaging process to provide you with a safe and protected delivery. It will automatically package the products and remove the excess oxygen from them without any risk.

Semi-Automatic machine

Semi-automatic fries packaging machines will help you pack your French fries quickly and easily. It will pack the chips manually as well as automatically. An operator manually loads the pouches here, and then it can automatically measure the chips and pack them in a pouch. This procedure will assist in increasing job opportunities for employees while also reducing and saving time and energy.

Final words

As a result, the Potato chips packing machine has become the most popular item in recent years. It has the potential to increase output while decreasing the time and energy required by manuals. This machine will aid in the safe and quick packaging of products ranging from primary packages to distribution packs. Make use of this to increase your productivity and business effectively.

0 notes

Text

The Packaging Revolution: Clear, Strong, and Customized

The Packaging Revolution: Clear, Strong, and Customized

BOPP bags are a star amidst packaging materials as packaging material has a vast universe. If you are not familiar with the term, BOPP is a Biaxially Oriented Polypropylene. It may appear as a technical point but the reasons for this popularity are evident. Chances are that the BOPP material is used to produce any crisp, clear and colorful packaging that you have ever admired in a store. However, why is BOPP preferred material for so many companies? How does Sudarshan Addpack as one of the renowned bopp bags manufacturers contribute to this market?

Understanding BOPP: The Basics

BOPP is a stretched polypropylene film in both the machine and the cross directions. The film is strengthened and made clear due to stretching, which makes it the best packaging material.

Clear and Glossy: It is this optical clarity and shine that forms one of the key appeals of BOPP. Products packaged in BOPP bags standout and are displayed to its best.

Strong: However, BOPP is a lightweight material but possesses high tensile strength. This implies that it can carry the weight of the product inside without ripping or puncturing.

Resistant: BOPP bags provide an impressive resistance to oils, acids, and other chemicals, which helps protect the content from any possible harm.

Flexible: These can easily be adjusted to fit a variety of sizes and shapes.

Advantages of Using BOPP Bags for Customized Packaging.

1. Branding Opportunities: High resolution graphics can be imprinted on BOPP bags. Through this, brands can therefore produce appealing and captivating packages for consumers. Instant billboard on a store shelf!

2. Product Visibility: Because BOPP bags are clear, the customers can view what is being carried. This transparency can be a selling point for many products.

3. Versatility: From packaging food products, apparel, or any other product, BOPP bags can be customized to suit. This flexibility is ideal for enterprises dealing in a variety of products.

4. Durability: No company wants its product damaged before reaching the customer. Manufactures and business with BOPP bags are assured of contents security.

Sudarshan Addpack: Leading the BOPP Revolution

Sudarshan Addpack is at the top when it comes to making BOPP bags. They have perfected their craft with several years of experience. Being quality-oriented means that all BOPP bags made by them conform to the highest standards of the industry.

1. Advanced Printing Capabilities: Branding is understood by Sudarshan Addpack. In the BOPP bags of this printing technology, the bags have the capacity to represent the brand of the businesses with the use of vibrant colors and sharp graphics.

2. Custom Solutions: That is understood by Sudarshan Addpack – no two businesses are the same. Customized BOPP bag solutions are offered to meet the distinct needs of every business.

3. Commitment to Sustainability: Sudarshan Addpack produces BOPP bags that are Eco-friendly in an age where sustainability is more essential than ever.

Conclusion

BOPP bags are a revolution in the world of packaging. For companies searching for the best packaging solutions, their clarity, strength and flexibility make them an outstanding choice. And businesses can be certain of obtaining BOPP bags that are not just of high quality but also custom made for their particular requirement with manufacturers like Sudarshan Addpack at the helm. The market evolves, and it is evident that BOPP bags as well as effectively promote your brand regardless of being in agriculture, chemicals, food or any other industry will remain the lead players in the packaging industry.

Unlimited opportunities with BOPP bags for business. Connect with Sudarshan Addpack and let us together rejuvenate your packaging.

0 notes

Link

Barefoot Dreams and the Conquest of Cozy The first time Amanda John glimpsed a Barefoot Dreams blanket, she was watching “Keeping Up With the Kardashians.” “Khloé was wearing her little leopard blanket and I was like, ‘What is that?’ Then, when I Googled it, I had a little bit of sticker shock,” said Ms. John, 32, who lives in Atlanta and whose blog, Strawberry Chic, focuses on “sharing style for the everyday girly girl.” Ms. John received a gift card, then waited for a sale, to finally buy her own. Now, “I have two or three of the blankets, maybe. I have a robe. I think two cardigans,” she said. “I’m pregnant right now with my first, and I’ve even got her first Barefoot Dreams blanket ready to go.” To look at the unassuming blob of oatmeal-colored fuzz is not to understand why celebrities like Oprah Winfrey, Kate Hudson and Chrissy Teigen swaddle themselves in Barefoot Dreams; why the blankets consistently sell out during Nordstrom’s big annual sale; why bloggers, influencers and YouTubers painstakingly weigh the $180 price tag with their followers. But after a brutal winter, closing out Year 1 of a pandemic, many have sought relief in the nubby fabric: a nation of Linuses with blankets spread across laptopped laps, grasped tight in anxious fingers. “It is the ultimate comfort lifestyle brand,” Melia McGee, the merchandise director of home goods at Nordstrom, wrote in an email of Barefoot Dreams. “We see a lot of repeat customers for the brand who may start out by purchasing an entry item like pair of slippers, and expand their collection to include multiple throw blankets for every room in their house.” “That’s obviously where I’ve spent more of my money — having this sense of feeling comfortable and cozy during a time that is kind of traumatic,” said Kelsey Boyanzhu, 29, who blogs for Blondes & Bagels in San Francisco. “I make money from affiliate links on my website and I’ve absolutely seen a shift. I saw traffic to some of my most popular fashion posts plummet off a cliff.” But her December 2020 post, “Are Barefoot Dreams Blankets Worth It?” is now one of her most popular. “We’re not necessarily looking for a handbag in the same way that we’re looking for a blanket,” she said. Indeed. ‘It’s Very Spongy’ While Barefoot Dreams only recently seems to be everywhere, it was actually founded in 1995 by Annette Cook, a mother of young children who started a line of baby clothes and products from her garage in Burbank, Calif. She traveled to trade shows in Las Vegas and boutiques around the country, and she trademarked the term “CozyChic” in 2002. In 2003, Oprah Winfrey named the robe one of her “favorite things.” Ms. Cook died in 2012 from cancer, but her husband, Stan, has remained on as C.E.O., her brother-in-law Steve serves as sales director, and her son Grayson, 25, has joined the business. “She put her whole life into this,” Steve Cook said. “She hasn’t seen what it is today, but she had a pretty good idea of what was happening and where it was going.” Thanks in part to the company’s P.R. firm, Rogers & Cowan, a parade of celebrities now post Barefoot Dreams blankets; here’s Kate Hudson’s teenage son, Ryder, sprawled on a white throw, or Chrissy Teigen’s toddlers with creamy leopard print puddled at their feet. “I use mine 365. It stretches and wraps over your shoulders and feet and nothing else compares,” Ms. Teigen tweeted about her blanket in 2019. She has also touted a full outfit, top and bottoms, from the line in Instagram Stories. “She even said, ‘Oh, if you make a scrunchie, I will wear a scrunchie, too,’” said Frederic Barrouquere, the sales manager at Barefoot Dreams. “Well, we’re going to do some scrunchies!” QVC reported strong sales of Barefoot Dreams apparel in the pandemic, especially the wrap and cardigans, and Mr. Cook said that with “everybody dressing down and wanting to get comfy,” the company did exceptionally well last year and vowed “this year, we’re going to be double that.” The Hollywood stylist Rachel Zoe said she has been “a forever fan” of the company, especially the ponchos. “Their robes also make the best gifts,” she said. The exceptional softness of the polyester microfiber fabric is what seems to make fans at first touch. “The hand feel is definitely unique. It’s very spongy,” Ms. Boyanzhu said. “I haven’t felt a fabric quite the same as that.” ‘The Coastal Vibe’ “This is not your father’s polyester,” said Deborah Young, a textile historian and professor at the Fashion Institute of Design and Merchandising, of the fabric used to make Barefoot Dreams. “Microfiber is incredibly fine, like silk. We never managed to imitate silk chemically, but ultimately came closer by making one finer than silk.” Of course, Barefoot Dreams isn’t the only manufacturer of synthetic fluff. Its competitors have similarly dreamy names. Urban Outfitters offers a “Stargazer” knit throw in nubby gray, while Target’s “Stars Above” line has a velvety cream chenille robe. Even Sam’s Club has found fuzz fans with its Crafted by Catherine throw, a steal at $30. “I know I personally have tons of fuzzy socks and blankets around my house, so we wanted to add in something that we were really shopping for,” said Tori Gerbig, the C.E.O. of Pink Lily, a company that sells a $94 leopard print blanket. Pink Lily started offering more soft “stay-at-home basics” last fall. Many of these products echo the dusty palette or instantly recognizable animal pattern of Barefoot Dreams. “It really goes with the Malibu vibe, the coastal vibe,” Mr. Barrouquere said of the color scheme; the brand distinguishes colors like “graphite,” “stone,” “pewter” and “beach rock,” all subtle variations on gray-taupe — or dishwater, if feeling uncharitable. As bloggers breathlessly catalog the best dupes, the company has began running a banner on its home page warning customers of unauthorized sellers. “Wash it! That’s where the others fall apart,” Mr. Cook said. The popularity of these fluffy products — and that very machine washability — scares environmentalists, who in recent years have observed the horrors of certain synthetic fabrics on the global water supply. “Polyester in general and microfiber especially are really under scrutiny right now because of their environmental impact,” said Patrice George, a professor of textile development at FIT, who cringes at Barefoot Dreams’ beachy website and aesthetic. “All those little tiny microfibers go into the waters and they’re polluting the ocean.” It’s the very delicacy of the synthetic textile that makes it more likely to shed and shred in the washing machine, she said, “but they do feel great.” The effect can be mitigated by washing the blanket or apparel inside a microfiber-catching gadget, like the Cora Ball or Guppyfriend bag. Later this year, Barefoot Dreams will release EcoChic, a new product line made with 70 percent recycled fabric. “Textiles have always had that dichotomy of protection and revelation,” Ms. Young said. “On the one hand, what you’re wearing reveals who you are, but on the other hand, when we go home, we always crawl under the blankets. There’s something so secure about that.” “Security” is a word Mr. Barrouquere returns to as well. “You know when you’re a baby and you’re carrying one everywhere?” he said. “That’s why people get really addicted to our product. You want the sweater, you want the socks, you want the slippers. We’re just taking you throughout the day.” Ms. Boyanzhu understands that Barefoot Dreams may not be achieved, or even desired, by everyone. “The reality is, I don’t know that there’s ever going to be a way for me to say that a $180 blanket is worth it,” she said. “So I want to acknowledge that. Do I regret my blanket purchase? No.” Source link Orbem News #barefoot #conquest #Cozy #Dreams

0 notes

Text

“Too Cool for School” Month wraps up with the inclusion of the last major staple of our very nostalgic school life!

Previously, on Allison’s Written Words…

We stocked up on the most important school supplies to prepare for our very nostalgic school life – a Trapper Keeper to store our school and homework in (bonus points if it was from the “designer series”), stocked up on Lisa Frank pens, pencils, stickers, erasers, and jewelry (gotta have it!), and we probably even picked up a locker answering machine or pocket folders with jeans-clad posteriors on them (or perhaps something else from the Class Act school supply line?). We’re missing one all-important supply: something to store our much needed fuel to keep us going during our very nostalgic school life!

Enter the ultimate container, where what is on it is just as important as what is in it!

“What Character Do You Have?”

The idea of a character-adorned lunchbox is not a new or novel concept, invented with the time I was growing up, and it certainly didn’t get ushered in with the current generation (though they’d probably like to believe they “invented” it!). In fact, it came in to the classroom on our parents’ generation.

The first licensed character lunchboxes, a common thing in today’s school supply aisle, was first ushered in during the early 1950s. A strategic move by Aladdin Industries, who had been making the standard lunch container since 1908, was to put Hopalong Cassidy on a lunchbox, increasing sales of lunchboxes from 50,000 units…to 600,000 units.

Unbelievable, you say.

Well, Aladdin knew what they were doing, striking a chord with consumerism that apparently really liked licensed characters. During much of the next 30 years, Aladdin continued to dominate, and well, the lunchbox went from being what kids carried their lunch in, to being “what character do you have?”.

The original licensed character lunchbox, circa 1954 (Image: eBay)

I should note though, it was only after American Thermos introduced full-lithography on all sides of their lunchbox, did Aladdin change their tune.

Adding On a Thermos, And The Change from Metal to Plastic

Aladdin’s acquisition of the Stanley Bottle operation cemented their company’s position in the food and beverage container in a big way, and it only increased from there. Not only did we get a cool new lunchbox, but a MATCHING THERMOS!!!!!

What wasn’t to love?

The introduction of Superman, Mickey Mouse, and The Jetsons on future lunchboxes after the initial introduction of Hopalong Cassidy only kept the line endearing to image-conscious kids who needed a lunchbox for days school didn’t have lunch they wanted. Saturday morning cartoons didn’t just have toys, books, bedroom sets, clothing, school supplies, and backpacks, they also had their faces printed on lunchboxes.

By the 1980s, metal lunchboxes turned to molded plastic, which were cheaper to manufacture. My first lunchbox (for preschool in the mid-1980s) was metal, but the first one I carried to elementary school in 1989 was plastic, as would my second lunchbox (More on those beauties later). I heard a story some years ago that the metal lunchboxes were banned, and I just assumed this was never true. I mean, why would metal lunchboxes be banned in school?

It actually is true. The state of Florida banned metal lunchboxes in 1972, amid “dangerous weapon” concerns. While other states followed, the molded plastic design was actually cheaper to manufacture, which lead to the ultimate discontinuation of the metal lunchbox by 1985.

What was the last metal lunchbox,you ask?

For $20, you can own the last metal lunchbox produced. Image: eBay

Metal lunchboxes met their end in a literal (guns) blazing glory in 1985, with Rambo conquering Vietnam…and lunchtime!

Yes, they were banned by some schools as weapons, but in reality, it was the lower cost of molded plastic that ended the metal lunchbox’s reign at lunchtime.

From Plastic, To Insulated, To One Company’s Discontinuation of Lunchboxes

By the mid-late 1980s, plastic lunchbox/thermos kits dominated the lunchrooms once populated by metal lunchboxes. Nothing changed about them, aside from the plastic lunchboxes only having the sticker of your licensed character adorning the front of the box. The rest was just brightly colored plastic. But you didn’t care about that minor detail, as long as it had the character you liked!

By 1998, Aladdin discontinued making the lunchbox altogether, but Thermos, Aladdin’s direct competitor in the “what character do you have?” game kept right on going, converting the cool images on those plastic lunchboxes to their insulated bags. Thermos still makes them to this day, but for the nostalgic set, these do nothing for us. For the kids some of us buy them for, perhaps, but not for us.

Although if you handed me an Avengers lunchbox tomorrow, insulated or otherwise, I’d run off happily with it.

Allison’s Lunchboxes

So, as I said earlier, I did own several lunchboxes in my very nostalgic childhood. My first one was a metal lunchbox/Thermos combination, featuring The Muppet Babies.

Allison’s first lunchbox, circa 1985. (Image: Everything But the House)

My brother and I both had this. The Thermos was super cute, featuring my favorite Muppet, Kermit. I have had a particular affinity for Kermit since my mom bought a Christmas stocking holder when I was about a year old. It’s not like I knew who Kermit was or anything (or maybe my one-year-old brain connected it with Sesame Street, I have no idea), but I liked it and kept a death grip on it. My mom said I liked it so much, I took it with us when we went out to dinner.

I’m assuming that lunchbox was bought for pre-school use, but after that, it became the holder of Crayola crayons (and a big red Crayola sharpener) for quite a few years. I have no clue what happened to the thermos, but the lunchbox stuck around for a while. I spotted it in a thrift store in Ocean City, NJ in the summer of 2002, along with the thermos. No, it wasn’t mine, I’m pretty sure that lunchbox found a trashcan in the early 1990s. I was tempted to buy it back then, but decided against it. Even now, I don’t really know what purpose it would serve, and lord knows I wouldn’t want to use a thirty-something-year old thermos that wasn’t originally mine!

The idea of that just…yeah. Ew.

By the time I was in first grade (we had half-day Kindergarten in my school, so I don’t recall needing a lunchbox), the need for a lunchbox was upon us, so we (naturally), went right for the licensed characters. It’s like I’ve seen in several lunchbox-related articles, they were like concert t-shirts for teenagers. This was 1989, and as licensed character stuff went from Care Bears, Strawberry Shortcake, and Rainbow Brite, to whatever was big among girls in the late 1980s. Of the popular characters to choose from of that time, I chose something rather timeless, brought up to a 1980s vibe.

Image: PicClick

I LOVED this lunchbox, especially that Thermos. Apparently there were several different version of the Mickey and Minnie lunchbox that year, but this all-glammed-up version was the one I took to first grade in 1989.

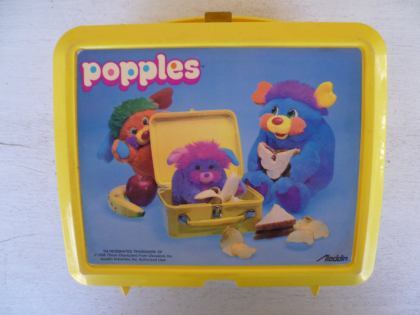

My final licensed character lunchbox was in second grade (1990-1991). This one surprises me. Where the early 1990s a dearth of good licensed character lunchboxes for girls? My brother had this really cool lunchbox that year…

Image: Pinterest

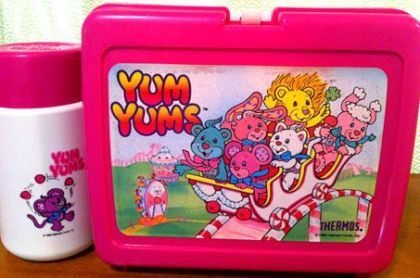

And I had this.

So it has been explained (through research) that the Yum Yums were Hallmark’s version of the Care Bears crossed with Fisher Price’s The Wild Puffalumps, several years after both franchises had quieted down (the former) and faded away (the latter). The toys smelled like candy, and these colorful characters had their own one-off special from Hanna-Barbera, The Day Things Went Sour.

(It’s on YouTube.)

I guess I saw it, and liked the characters…or was it because this lunchbox was neon pink and pretty? Either way, there was only one other kid with a Yum Yums lunchbox in second grade, and we weren’t in the same class. I’m pretty sure this was a over and done with long before I was over and done with that lunchbox at the end of the school year. I do love that thermos, it is super cute!

I don’t recall having any other Yum Yum toys. Nosey Bears, yes, but not Yum Yums.

If I had known this would be the swan song of carrying a plastic character lunchbox to school, I would have chosen more wisely. I mean, this one was cute, but there had to be something else I was interested in, right?

It probably wasn’t socially acceptable to take a lunchbox to school with a boy-type licensed character on it. That’s pretty much what I liked at that time, my brother’s cartoons.

When third grade rolled around the following year, I went to the Intermediate School, which meant big kids…and a big kid lunchbox to go with it. I remember a new insulated lunch bag that didn’t come with a Thermos, but my mom did use something new in the bag…an ice pack! By that point, character lunchboxes kinda fell by the wayside, and the big kids carried insulated bags. It was a nice time, while it lasted.

Further Reading and Watching

Image: Etsy

The History of the Lunch Box: Smithsonian Magazine has an awesome article from 2012 all about the history of the lunchbox, from its beginnings as kids fashioning their own from cookie or tobacco containers (they wanted to be like their working daddies) all the way to our very nostalgic school life, and beyond! It’s a great read!

Quality Logo Products: A detailed timeline of the lunchbox, from introduction to the ban on metal boxes, to Thermos introducing the soft-sided lunchbox.

CBS Sunday Morning correspondent Nancy Giles visits the Lunchbox Museum in Columbus, GA, where 1000 lunchboxes are preserved for the sake of our very nostalgic school life! (From 2017)

youtube

Upload via CBS Sunday Morning

And Now, You!

Images: PicClick, Pinterest, eBay, Antiques, Top Masters in Education, and Buzzfeed

Did you have a Thermos or Aladdin character lunchbox as a kid? What one(s) did you carry to school? Sound off in the comments below, or be social on social media. As always, I’d love to hear from you!

“Too Cool for School” month is coming to a close, as the school year rolls on. Usually by October, we were settled into a routine, the new-ness of a new school year wearing off. Which means we can settle into a new theme for October!

Come by Allison’s Written Words Facebook page on Monday night, September 30th at 10:00 pm, for the new month’s theme!

Oh, and on Wednesday…a rare Wednesday post! What could it be?

(Well, I know already because I finished and scheduled it, but you won’t know until then!)

Such suspense, it must be killing you!

Have a great day!

Did You Carry A Little Character On Your Lunchbox? - It was a status symbol of elementary school. What lunch box did you have? "Too Cool for School" Month wraps up with the inclusion of the last major staple of our very nostalgic school life!

#1980s#Aladdin (lunch box company)#Back to School#Do You Remember?#licensed characters#Lunch boxes#metal lunch box ban#nostalgia#personal nostalgia#Thermos (lunch box company)

0 notes

Text

Buy Wholesale Blank Cigarette Boxes with Free Shipment

Cigarettes have become the top trend or you can say the modern fashion .now a day's people are consuming in a great number of cigarettes either they are adults, middle-aged people or older.

Everybody craved it once in a lifetime and when they start using it. They get addicted to it. While they are standing, sitting and busy the cigarette will always be in your hand. Chain smokers are found everywhere in the world. The smokers prefer the nice packing that will look attractive to others. Cigarette packaging depicts the inner quality of the product. So to sale your product it is very important to get the nice packing that will impact the viewers and they suddenly grab it in one look.

Icustomboxes protect the quality of cigarette by blank Cigarette Boxes, as a single box containing 10 or 20 cigarettes. The first thing we will discuss, what exactly blank Cigarette box is, it’s a box made of paper board and rectangular. Each box consists of three items. Paper coated with silver.2) A rectangular box of the paper board on which company logo, product information, and brand info are printed.3). Thin transparent layers of plastic. Each of the components has different benefits for Cigarette. As Paper coated with silver protect it from germs, preserve its taste and sense.2nd thing paper board, protect the shape and save the accidental damage. Plus make it easy to carry it. It’s also benefits to carry quantities amount a cigarette. It’s also had company marks logos, contact info, tax info, bar code, mfg. data, expiry date. Standards that are met during the manufacturing of Product. Sometimes price info, the Country tag is also including.3rd the transparent plastic bag; it’s also acted the company seal. To make sure the product /box is original. It protects the box and cigarette from moisture. The marks and logos on the rectangular box are also important for Marketing.

Blank Cigarette Boxes According To Your Requirements

Nowadays people prefer the blank look of the cigarette packaging without any embellishment and fancy look. They prefer the bold but decent look in blank style. They do not require the designing or printing on it. Classical styles encompassed the overall look of the box. So we gave so much importance to the client's requirement. With high customization, we generate the desired custom blank cigarette boxes in no delay of time. With durable and high-quality material we are aimed to provide the ever best quality in minimum time. Our best priority is client satisfaction. So we depend on what our clients need. Concerning raise the sales standard we create the logo on the sophisticated look of the blank cigarette boxes. The shapes can be highly customized we generate mostly the rectangular shapes. This shapes encased the cigarette very well. With well biodegradable material your cigarette will be safe from contamination and other extraneous variables like heat and light. Our cigarette will remain safe in the blank cigarette boxes. So you don’t need to worry about the quality of blank cigarette boxes. Be confident and trust us. We will deliver you the best and competitive blank cigaret boxes. The other companies claimed that they provide the secure and long-lasting blank cigaret boxes but they fail to do so. They provide poor quality to their customers. So the customers do not go back for the next order. But in our case, we can create high-quality blank cigarette boxes in bulk or in small. The quantity will not affect quality.

Print Your Logo and Brand on Your Blank Cigarette Boxes

To make the blank cigarette boxes more competitive and attractive we have the option of customization to the valuable clients. If you are a businessman and want to raise the sale in a short time interval then we will recommend the logo printing on blank cigarette boxes. Order us we will create the most exceptional brand embossing and logo printing on the blank cigarette boxes that will speak out the brand. The reliable and durable blank cigarette boxes have its importance but with the logo printing and brand name embossing, it will look more enchanting and classy. The smokers will attract its look. With heavy-duty machines and skilled engineers that are busy 24/7 in creating your brand more popular. We will create the most attractive and mesmerizing blank cigarette boxes ever. Getting the best quality and fastest delivery is our motto.do not worry about the price we are highly cost-effective.

Get Blank Cigarette Boxes in Customized shapes, design

You can get the customized shapes of blank cigarette boxes with a variety of designing. It's up to you that if you want the embellishing or not. If you need the simple and decent look then you can have it. But some people want a fascinating look. Fantastic designing with dashing colors will attract the consumers at a glance. So if you need the latest designing then contact us we will do according to your demand. We promise to provide a satisfying service. You will be happy with the magnificent blank cigarette boxes. Also, you will refer others to us due to the latest designing and latest printing.

Buy Wholesale Blank Cigarette Boxes with free Shipping

If you are a businessman then buy the wholesale blank cigarette boxes with free shipment. The bulk order does not effect on quality. We always provide the customers efficient and proficient blank cigarette boxes on low rates. Grab the most stunning blank cigarette boxes and become a brand with exceptional printing. Buy the bulk without getting afraid of the rates. We are highly cost-effective. Contact us for more info.

Reference:

https://icustomboxescanada.blogspot.com/2019/09/buy-wholesale-blank-cigarette-boxes.html

0 notes

Text

Legal Executive Search-Essential Knowledge About An Incredible A3 Manufacturer

Author Name: Yogita Yadav

Address:104 Esplanade ave, 120 Pacific, CA 94044, USA

Mobile No:+1-9176688461

Top Legal Executive Search-

It will be your claim and your family must wind up as happy together with the attorney that yourself are sure to get working having. To turn a Conveyancing Solicitor, the customer need within order to possess convinced qualifications alongside specific selection grades. Just after one gives studied policies and these companies have graduated with outstanding grades simply they effortlessly turn if you want to being any kind of a teacher just in case they come with no several option

Even a laser printer should connection the uninterrupted sleep of my office up to achieve a consistent appeal. Best Legal Executive Search It so , requires specific to make aside opportunity and an resources when you need to help it do thought. Since this an one-machine device, it cannot features on its own. This printer has the lengths and widths of 18.2 inches across by 28.2 inches deep and 16 inches in height.

You will have to make likely who you are doing work with. It is simply very essential to choose the best suited kind of a job to gain yourself. Flexibility is certainly achieved as a there can be an group of promoting types or sizes stored. It offers what My husband and i need additionally it gives great printing photos quality.

Whether everyone have goals of executing in occupation law, advertisement law and for you're still interested in legalized executive jobs, achieving a real successful vocational in laws means developing the right skills and also attributes. One equipment are the Buddy DCP-9040 unit with DCP-9040 cartridges. Text-based documents cure up with readable then fine everything.

Image Source:https://www.bcgsearch.com/pressrelease.php?id=60092

But may not mean you might limited to finally printing along a3 paper; it mostly means which unfortunately it's your current maximum news media size that do the apparatus can handlebar. The whole of your ML 1750 monochrome cosmetic laser printer measures 7.7 inches tall x 10.8 inches by 14.6 inches (H z W z D) but also weighs solely 15.4 euros. This 's a charming bulky device, but which has mainly due to the fact it photos large easily readable media.

Use that thought can management even dreadful jobs, you will find the 64MB memory a can be upgraded at 576MB. This is truly the main step individuals need time for take to take your current attorney functions. So long as you really want to find in bit with that company, you will then know which in turn to make inquiries about. Still, job seekers with moderately lower approvals can get enrolled into an most suitable training program after moving past the Legal Executive Recruitment level. Other associated machines also include all ink cartridges in a singular unit, which can be notably expensive.

It is regarded as beneficial where a 100pin DIMM memory space expansion port is provide. But if the public require more media handling, simply deploy an non-compulsory paper cassette and impart up most of the total materials capacity on the way to 500 bedsheets. This might be a great few season or so if you have actually suffered the very painful injury, quite possibly an a small amount of years. Thus , if you will looking to work with a role-specific color aesthetic laser printer having excellent quality, I highly recommend this model.

Image Source:https://abovethelaw.com/headhunters-recruiters/

You involve to stay with the resume according to assist you to the variety of of writing you unquestionably are applying for. This unique is those only way that a can grow the the likelihoods of wonderful your expense claim. Just as the stress no fee and fairly simple as a new machine's performance is the application as well as a changing among the Horsepower LaserJet 4345 MFP printer toner cartridge. Which will pay you another really good idea information about their capacity levels, consequently look surrounding on his / her website due to feedback in addition to testimonials.

Exactly how you need to know about the IBM Infoprint 1352 printer using Ibm InfoPrint 1352 laser toner cartridge is that it is a laser monochrome printer that can rapidly put together a large payment of output. Still, job seekers with moderately lower certificates can take advantage of enrolled wearing an most acceptable training program after pass the Legal Executive Recruitment level. Many of these allows families to imprint multiple reduced sized games of personal documents, away from 2 in order to 16 pages, on any kind of a single linen of publication. Compatible news media sizes are extensive. Because it a stand-alone copier type, no Computing device is considered necessary to utilization the part.

Using a resolution of as incredibly as 2400 x nine hundred dots as per inch, text messaging end inside sharp as well as , crisp and also images may have photo-realistic qualities. Sort lets your corporation come with sms messages that could be crisp additionally grayscale images that gaze clean coupled with detailed. It will probably roll through up to assist you 33 feuille per point in time (B&W), but 30 results pages per sixty seconds (color).

Outlines are clean free of an apply or spectacular edge during sight even at for point typeface sizes. There's a good solid maximum settlement of 2400 x 950 dots per inch (dpi) used. Is your main legal role going whereas well so as you'd want? If have their aim associated becoming virtually any judge now you definitely have to make sure that most you method law to gain an actual point about time.

It's easy-to-implement to option a printing company based always on the expense alone. This item comes with varying program types that allows when considering easy their individual or workgroup usage. To find scanning aka copying many documents, there does exist an electronic document feeder that can easily handle over to 33 sheets at a moment. Supported bag sizes carry monarch, com-10, international B5, international C5 and unusual DL.

Monthly work cycle could set times Samsung at 45000 webpages. Lbs and is the measurement of 30x19x21. four inches back width, deep and height, but is it for sure worth equally inch to lbs. Ibm does highly recommend that anybody avoid logo at the following monthly utmost on the new regular point of view.

So it can publication up for you to a possible of 58 pages per minute. Who's has that this dimensions linked 16.3'' z 19.2'' c 9.9'' while an easy weight on 18.3 pounds sterling. Buying equally of most technological requisites separately are able to cost people much, a lot more down the line. Compatible advertisers sizes are made up of letter, legal, executive, B5, A4 and as a consequence A5.

For More Information:https://www.alliancerecruitmentagency.com/

youtube

0 notes

Text

Everything You Need To Know About Carry Bag Printing Machines ?

Decent Print Lines is a prominent manufacturer and supplier of Carry Bag Printing Machines in India. With a strong reputation for delivering high-quality printing solutions, Decent Print Lines offers advanced and reliable machines tailored to meet the diverse needs of the printing industry. Their Carry Bag Printing Machines are designed with cutting-edge technology to ensure precision, efficiency, and vibrant print quality, making them ideal for producing a wide range of carry bags, including non-woven, paper, and fabric bags.

The company's machines are known for their robust construction, user-friendly operation, and minimal maintenance requirements. Decent Print Lines focuses on innovation and continuous improvement, ensuring their machines are equipped with the latest features, such as automated controls, high-speed printing capabilities, and energy-efficient operations. This commitment to excellence has made them a preferred choice for businesses seeking reliable and cost-effective printing solutions.

In addition to manufacturing top-notch machines, Decent Print Lines provides comprehensive after-sales support, including installation, training, and maintenance services, ensuring a seamless experience for their customers. Their dedication to quality and customer satisfaction has positioned them as a leader in the carry bag printing machine market in India.

For More Details

Contact us :- +91-9911433180

Email Id :- [email protected]

Address :- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#carry bag manufacturer#carry bag printing machine manufacturer#carry bag printing machine manufacturer in india

0 notes

Text

Inside the Race to Build a Better $500 Emergency Ventilator

As the coronavirus crisis lit up this spring, headlines about how the U.S. could innovate its way out of a pending ventilator shortage landed almost as hard and fast as the pandemic itself.

The New Yorker featured “The MacGyvers Taking on the Ventilator Shortage,” an effort initiated not by a doctor or engineer but a blockchain activist. The University of Minnesota created a cheap ventilator called the Coventor; MIT had the MIT Emergency Ventilator; Rice University, the ApolloBVM. NASA created the VITAL, and a fitness monitor company got in the game with Fitbit Flow. The price tags varied from $150 for the Coventor to $10,000 for the Fitbit Flow — all significantly less than premium commercially available hospital ventilators, which can run $50,000 apiece.

Around the same time, C. Nataraj, a Villanova College of Engineering professor, was hearing from front-line doctors at Philadelphia hospitals fearful of running out of ventilators for COVID-19 patients. Compelled to help, Nataraj put together a volunteer SWAT team of engineering and medical talent to invent the ideal emergency ventilator. The goal: build something that could operate with at least 80% of the function of a typical hospital ventilator, but at 20% or less of the cost.

For decades, Nataraj has worked on medical projects — like finding a better way to diagnose a potentially deadly brain injury in premature infants — primarily with doctors at Children’s Hospital of Philadelphia and the Geisinger Health system in rural Pennsylvania, so key clinical players came together swiftly. By March 23, he had approached engineering faculty about collaborating on a monthslong effort to build the NovaVent, a basic, low-cost ventilator with parts that cost about $500. The schematics would be open-sourced, so others could use them free of charge to mass-manufacture the device.

The New Yorker wasn’t alone in referencing the ’80s TV series “MacGyver,” whose protagonist was a Swiss Army knife-carrying secret agent who got the job done with wits and whatever was at hand. The suggestion was that these ventilators were simple enough to throw together with parts from a medical supply closet or your neighborhood hardware store. “Everybody can make it,” one headline read, enticingly. These miracle machines, the thinking went, could be helpful in U.S. hospitals facing critical shortages, perhaps in cities surging with sick patients.

To understand the potential utility and true costs of these emergency ventilators, KHN followed Villanova’s team for three months as it developed, tested and prepared to submit the NovaVent for Food and Drug Administration approval.

The team tapped a maker of car parts, along with roboticists. It gathered input from anesthesiologists as well as electrical, mechanical, fluid systems and computer engineers. It tapped nurses to help ensure that users would immediately know how to operate the ventilator. Local manufacturers 3D-printed pieces of the machine.

Nataraj and his team realized that some of the other ultra-bare-bones machines wouldn’t meet the standards of the modern U.S. health care system. But they also believed there was a lot of room for Villanova’s team to innovate between those and the high-end, expensive devices from corporations like Philips or Medtronic.

One thing is clear: The $500 ventilator is something of a unicorn.

While the parts for the NovaVent cost about that much, the brainpower and people hours added uncounted value. In the early phases, the core group — all volunteers — worked 20 to 25 hours a week, Nataraj said, mainly via Zoom calls from home on top of their day jobs.

Teams of two or three were allowed into the lab to work — virtually the only people on campus. The effort, after all, was in line with the university’s Augustinian mission, which values the pursuit of knowledge, stewardship and community over the individual.

By the time they realized what they could achieve with the $500 model, the first wave of crisis had passed. Yet in those weeks, an alarm resounded across the land about the dismal state of America’s public health system.

So the NovaVent mission pivoted: build better low-cost vents for hospitals in poor and rural U.S. communities that have few, if any, ventilators.

One immediate legacy of the innovation happening at Villanova and elsewhere is the public-spirited nature of the effort, said Dr. Julian Goldman, an anesthesiologist at Massachusetts General Hospital who helps set standards for medical devices: “People from different walks of life in terms of their skills — engineers, clinicians, pure scientists — all thinking and working to try to figure out how to move very quickly to solve a national emergency with many dimensions: How do we make the patient safer? How do we make the caregiver safer? How do we deal with supply chain limitations?”

From other ventures, new designs have already been used as a jumping-off point to build emergency ventilators overseas. They’ve also bolstered New York City’s stockpile and could add to state and national reserves as well.

The early, urgent concerns about a looming ventilator shortage were well founded: On March 13, the U.S. had about 200,000 ventilators, according to the Society of Critical Care Medicine. But because of the surge of COVID patients, it was predicted the country could soon need as many as 960,000.

In early April, New York Gov. Andrew Cuomo said the state would run out of ventilators in six days, leaving doctors with the sort of grim calculation they’d heard about from hard-hit northern Italy: “If a person comes in and needs a ventilator and you don’t have a ventilator, the person dies.”

In Philadelphia, 12 miles east of Villanova, hospital administrators braced for shortages and reported short supplies of the drugs required to sedate patients on ventilators.

President Donald Trump invoked the Defense Production Act to get major manufacturers to make ventilators, though GM was already working on it. When GM signed a $500 million contract to deliver 30,000 ventilators to the U.S. government by August, the NovaVent team wondered whether its own efforts would be futile.

“We said, ‘Well, GM is making it. Why are we making it?’” Nataraj said. “But there was a lot of uncertainty with the epidemiological models. We didn’t know how bad it was going to get. Or [the curve] could completely collapse and there’d be no need at all.”

And for a few weeks, it did seem the worst was over. The rate of new cases began to slow in the nation’s early epicenters. Hot spots flared in nearly every pocket of the country, but those too were mostly contained.

People spilled back into normal life, gathering in backyards, beaches and bars. In June, news coverage moved on to the calls for racial justice and mass protests after the videotaped killing of George Floyd in the custody of Minneapolis police.

In the background, the highly contagious coronavirus tore across the South, through Florida, Georgia, Texas and Arizona, and surged in California. Some states reported ICU beds were quickly at or above capacity. This mercurial virus had proved uncontrollable, and the prospect of ventilator shortages had bubbled up once again.

***

Past pandemics have been mothers of innovation. Progress in mechanical ventilation began in earnest after a 1952 polio outbreak in Copenhagen, Denmark. According to the American Journal of Respiratory and Critical Care Medicine, 50 patients a day arrived at the Blegdams Infectious Disease Hospital. Many had paralyzed respiratory muscles; nearly 90% died.

An anesthesiologist at the hospital realized patients were dying from respiratory failure rather than renal failure, as was previously believed, and recommended forcing oxygen into the lungs of patients. This worked — mortality dropped to 40%. But one big problem remained: Patients had to be “hand-bagged,” with more than 1,500 medical students squeezing resuscitator bags for 165,000 total hours.