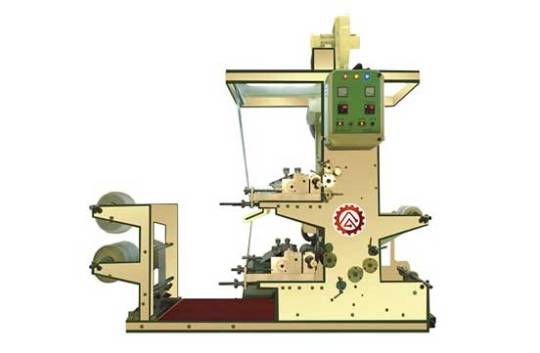

#Carry Bag Printing Machine Supplier in India

Explore tagged Tumblr posts

Text

What are the uses and functions of Carry Bag Printing Machine?

Carry bag printing machines serve various purposes and offer several functions, particularly in the packaging and branding industry.

Here are some of the primary uses and functions of carry bag printing machines:

Customization: Carry bag printing machines allow businesses to customize their packaging with logos, brand names, product information, and designs. This customization helps in brand recognition and differentiation in the market.

Brand Promotion: Printing machines enable businesses to promote their brand effectively by printing attractive designs and messages on carry bags. These bags serve as mobile advertisements when customers carry them around in public spaces.

Product Information: Carry bag printing machines can print important product information such as ingredients, usage instructions, expiry dates, and safety warnings. This ensures compliance with regulatory requirements and helps consumers make informed purchasing decisions.

Enhanced Aesthetics: Printing machines enable businesses to create visually appealing carry bags that enhance the overall presentation of their products. This can positively impact the perceived value of the products and attract more customers.

Differentiation: Customized printing allows businesses to differentiate their products from competitors’ offerings. Unique designs and branding elements printed on carry bags help create a distinct identity for the brand in the market.

Cost-Effectiveness: In-house printing using carry bag printing machines can be more cost-effective compared to outsourcing printing services. It reduces lead times and provides greater control over the printing process, resulting in cost savings for businesses.

Flexibility: Carry bag printing machines offer flexibility in printing various bag sizes, shapes, and materials. They can accommodate different types of substrates such as paper, plastic, and fabric, allowing businesses to meet diverse packaging needs.

Efficiency: Modern printing machines are equipped with advanced features such as automated printing, precise color matching, and high-speed production capabilities. This improves efficiency and productivity in the packaging process.

Environmentally Friendly Options: Some carry bag printing machines offer eco-friendly printing options, such as water-based inks and recyclable materials. This helps businesses reduce their environmental footprint and meet sustainability goals.

Overall, carry bag printing machines play a crucial role in packaging, branding, and marketing strategies for businesses across various industries. They offer versatility, customization, and efficiency, enabling businesses to create visually appealing and functional carry bags that resonate with consumers.

Best Carry Bag Printing Machine Manufacturer in India

If you are looking for a Top Carry Bag Printing Machine Manufacturer in India, look no further than Decent Print Line, we are a leading manufacturer and supplier of Carry bag Printing Machine in India, for more details, please contact us!

#Carry Bag Printing Machine Manufacturer in India#Carry Bag Printing Machine Manufacturer#Carry Bag Printing Machine Supplier in India#Carry Bag Printing Machine supplier#Best Carry Bag Printing Machine Manufacturer in India#Top Carry Bag Printing Machine Manufacturer#Top Carry Bag Printing Machine Manufacturer Companies#Decent Printline

1 note

·

View note

Text

Uses and Functions of Non Woven Bag Printing Machine

Introduction

In recent years, the global movement towards sustainability and eco-consciousness has spurred a significant shift in consumer behavior and industrial practices. As businesses strive to reduce their environmental footprint, the demand for eco-friendly alternatives to traditional plastic bags has surged. Enter non-woven bags — lightweight, durable, and reusable alternatives that have gained widespread popularity. At the heart of this eco-friendly revolution lies the non-woven bag printing machine, a marvel of modern engineering that enables the mass production of customized, environmentally responsible bags. Let’s delve deeper into the efficiency and functionality of these innovative machines.

The Rise of Non-Woven Bags

Non-woven bags are crafted from synthetic or natural fibers bonded together through a mechanical, thermal, or chemical process — without the need for weaving. This manufacturing method results in bags that are strong, tear-resistant, and capable of carrying heavy loads. Moreover, non-woven bags are reusable, recyclable, and biodegradable, making them a sustainable choice for environmentally conscious consumers and businesses alike.

Advantages of Non-Woven Bag Printing Machines

Customization: Non-woven bag printing machines offer unparalleled flexibility, allowing businesses to create bespoke designs and branding solutions tailored to their unique requirements.

Speed and Efficiency: With rapid printing capabilities and automated processes, these machines enable high-volume production without compromising on quality or accuracy.

Cost-Effectiveness: By streamlining production workflows and minimizing material waste, non-woven bag printing machines help businesses optimize their operational costs and maximize profitability.

Environmental Sustainability: By facilitating the production of reusable and recyclable non-woven bags, these machines support sustainability initiatives and contribute to the reduction of plastic waste.

Non-woven bag printing machines are the unsung heroes of modern manufacturing, offering a multitude of uses and functions in various industries.

Functions of Non Woven Bag Printing Machine

Customization Made Easy

These machines empower businesses to personalize non-woven bags with logos, designs, and messages, enhancing brand visibility and communication.

Promotional Powerhouses

Ideal for creating branded merchandise, custom-printed non-woven bags serve as effective promotional tools at trade shows, events, and marketing campaigns.

Sustainable Packaging Solutions

In retail, these machines help elevate packaging by customizing non-woven bags with brand aesthetics, product showcases, and eco-friendly messaging.

Memorable Event Souvenirs

From conferences to weddings, custom-printed non-woven bags make practical and memorable giveaways, leaving a lasting impression on attendees.

Environmental Advocacy

By enabling the production of reusable and recyclable bags, these machines contribute to environmental sustainability efforts, promoting eco-conscious consumption.

In essence, non-woven bag printing machines are more than just production tools — they’re enablers of creativity, sustainability, and brand empowerment in a rapidly evolving world.

Best Non Woven Bag Printing Machine Companies in India

If you are looking for a Best Non Woven Bag Printing Machine in India, then look no further than Decent Print Line. Decent prinline is a leading manufacturer and supplier of non woven bag printing machine in India.

For more details, please contact us!

Website — https://www.decentprintline.com/

Contact — +91–9911433180

Email — [email protected]

Address — Plot №4, Gali №1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh — 121004, Haryana, India

#Non Woven Bag Printing Machine#Non Woven Bag Printing Machine manufacturer#Non Woven Bag Printing Machine supplier#Non Woven Bag Printing Machine manufacturer in India#Non Woven Bag Printing Machine supplier in India#Decent printline

2 notes

·

View notes

Text

Find Top non woven carry bags manufacturer

When searching for the top non-woven carry bag manufacturers, it's essential to consider factors such as product quality, customization options, pricing, and customer service. Here's a guide to help you find the best non-woven carry bag manufacturers:

**1. Assess Your Requirements

Bag Types: Determine the type of non-woven bags you need (e.g., U Cut, D Cut, W Cut, loop handle).

Quantity: Identify the quantity you need to order.

Customization: Consider whether you need custom printing, specific colors, or unique designs.

**2. Research Top Manufacturers

1. Favourite Fab (India)

Overview: Favourite Fab is a well-known manufacturer specializing in eco-friendly, high-quality non-woven carry bags. They offer a wide range of designs and customization options, catering to various industries.

Products: U Cut, D Cut, W Cut, loop handle, and customized bags.

Strengths: Competitive pricing, excellent customer service, and fast delivery.

2. Sahil Graphics (India)

Overview: Sahil Graphics is a leading manufacturer of non-woven bags and bag-making machines. They provide a diverse range of products with a focus on durability and environmental sustainability.

Products: Non-woven carry bags, laminated non-woven bags, custom printed bags.

Strengths: High-quality products, advanced manufacturing technology.

3. Sky Flexi Pack (India)

Overview: Sky Flexi Pack is a reputable manufacturer known for its innovative designs and eco-friendly materials. They offer a wide selection of non-woven bags suitable for retail, promotional, and industrial use.

Products: Non-woven shopping bags, loop handle bags, customized bags.

Strengths: Customization options, sustainable practices, affordable pricing.

**3. Consider Key Factors

Quality: Ensure the manufacturer uses high-quality non-woven fabric and has a strict quality control process.

Customization: Look for manufacturers that offer customization in terms of size, design, color, and printing.

Production Capacity: Verify that the manufacturer can meet your order quantity within your desired timeline.

Pricing: Compare prices from different manufacturers, keeping in mind that the cheapest option may not always offer the best quality.

Reputation: Check online reviews, testimonials, and ratings to assess the manufacturer's reputation.

**4. Request Samples and Quotes

Contact the shortlisted manufacturers to request product samples and detailed quotes. This will help you evaluate the quality and pricing before making a final decision.

**5. Evaluate After-Sales Support

Ensure the manufacturer provides good after-sales support, including assistance with any issues related to the order, delivery, or product quality.

Conclusion

Finding the top non-woven carry bag manufacturer requires careful research and consideration of your specific needs. By assessing your requirements, researching reputable manufacturers like Favourite Fab, Sahil Graphics, and Sky Flexi Pack, and comparing quality, pricing, and customization options, you can choose a supplier that meets your expectations.

0 notes

Text

How to Enhance Your Product’s Shelf Appeal with Modern Packaging

In the rapidly evolving world of packaging, businesses are constantly on the lookout for materials that are not only durable but also visually appealing. One such innovation that has revolutionized the packaging industry is the bopp woven bag. These bags have become a preferred choice for packaging a wide range of products due to their unique combination of strength, flexibility, and aesthetic appeal. Among the leaders in manufacturing these versatile bags is Sudarshan Add Pack, a company renowned for its commitment to quality and innovation.

What Are BOPP Woven

BOPP (Biaxially Oriented Polypropylene) woven bags are a type of laminated woven polypropylene bag. The term 'Biaxially Oriented' refers to the process where polypropylene film is stretched in both the machine direction and across the machine direction to create a material that is exceptionally strong and durable. This film is then laminated onto woven polypropylene fabric, resulting in a bag that combines the toughness of woven fabric with the attractive finish of BOPP film.

These bags are known for their excellent load-bearing capacity, tear resistance, and moisture protection. They are widely used for packaging products like grains, animal feeds, fertilizers, seeds, and chemicals. The BOPP film also allows for high-quality printing, making these bags an excellent choice for companies looking to enhance their brand visibility through vibrant, multi-color designs.

Advantages of BOPP Woven

Strength and Durability: The woven polypropylene fabric provides BOPP bags with superior strength, making them ideal for carrying heavy loads without the risk of tearing or bursting.

Moisture Resistance: BOPP woven offer excellent moisture resistance, which is crucial for packaging products like grains and fertilizers that need to be kept dry. The laminated BOPP film acts as a barrier against moisture, ensuring that the contents remain intact and unaffected by environmental conditions.

Aesthetic Appeal: One of the standout features of BOPP is their visual appeal. The BOPP film allows for high-quality, photo-realistic printing, enabling businesses to display their brand and product information in a visually striking manner. This not only enhances the product’s shelf appeal but also helps in creating a strong brand presence.

Customizability: BOPP woven can be customized in terms of size, shape, and design. Whether you need a bag with a specific capacity or one that features your brand colors and logo, BOPP woven can be tailored to meet your specific requirements.

Eco-Friendly Option: Despite their durability and strength, BOPP woven are eco-friendly. They are reusable, recyclable, and produce less waste compared to other types of packaging materials.

Pioneers in BOPP Woven

When it comes to sourcing high-quality BOPP woven, Sudarshan Add Pack stands out as a trusted name. With years of experience in the packaging industry, Sudarshan Add Pack has earned a reputation for delivering products that meet the highest standards of quality and performance.

Sudarshan Add Pack is dedicated to providing its customers with packaging solutions that not only meet but exceed their expectations. The company’s BOPP woven are crafted using state-of-the-art technology and the finest materials, ensuring that each bag is strong, durable, and visually appealing.

The company offers a wide range of BOPP woven, catering to various industries such as agriculture, chemicals, and retail. Each bag is customizable, allowing businesses to create packaging that is uniquely tailored to their brand. Sudarshan Add Pack's commitment to innovation is evident in the quality of their products, making them a preferred choice for companies looking for reliable and attractive packaging solutions.

In addition to quality, Sudarshan Add Pack places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific packaging needs and delivers solutions that are both practical and cost-effective. Whether you need a large quantity of bags or a small, customized order, Sudarshan Add Pack ensures that you receive products that meet your exact specifications.

Conclusion

In the competitive world of packaging, choosing the right materials can make a significant difference in product presentation and protection. BOPP woven offer an ideal solution for businesses looking for packaging that is durable, moisture-resistant, and visually appealing. With Sudarshan Add Pack, you can be assured of receiving top-quality BOPP woven that are tailored to your needs. Their commitment to quality, innovation, and customer satisfaction makes them a leader in the industry, and a reliable partner for all your packaging requirements.

0 notes

Text

Printed Fabric Manufacturers for Upholstery - Response Fabrics

Printed Fabric Manufacturers for Upholstery

If you want to get the best Printed fabric manufacturers for upholstery in India then Response Fabrics is one of the top well renowned manufacturers of a broad assortment of Printed fabric, Artificial Leather Fabric, Upholstery Fabric, Mesh Fabric, Blackout Fabric, etc. The offered fabrics are woven at the well-developed manufacturing unit by making use of premium quality yarns, and threads in compliance with defined quality standards. The production department is well-furnished with ultra-modern machines, tools, and equipment to weave these fabrics.

Upholstery Fabric Manufacturers & Suppliers in India

Response Fabrics has the best solution for the best selective variety of upholstery fabric that is a delight to those who wear it as well as those who touch, and see it. The collection of upholstery fabric online gives the best look altogether. The threads used in our cotton fabrics are durable, and fade resistant. This brings great joy for all the customers who buy cheap upholstery fabric from our online store & enjoy different benefits from these.

Upholstery Fabrics are made from a soft feel, high-strength, fire-retardant vinyl fabric, we don’t compromise with the comfort, and elegance, but without the price tag you’d expect. The Responsive Fabric Upholstery Fabric is extremely easy to wipe down, delivering true comfort.

Printed Holland Velvet Upholstery Fabric

Response Fabrics are a leading Manufacturer & Supplier of a wide range of single tone micro velvet fabric, two tone velvet fabric, printed velvet fabric, micro velvet fabric, red velvet fabric, digital printed velvet fabric. We have constructed a wide, and well functional infrastructural unit that plays an important role in the growth of our company. We offer these products at reasonable rates, and deliver these within the promised time-frame.

Purchase Premium-Quality printed upholstery fabric

We, at Response Fabrics, aim to make the best premium-quality printed upholstery fabric available at pocket-friendly prices. All our products go through various quality checks before they are sent out. We know that investing in furniture is a big-deal that’s why all of our products are made with utmost care, and expert specialization. Our range of affordable Upholstery fabric is sure to spruce your home, and furniture up.

Printed Cotton Fabric Manufacturers

This manufacturer of fabrics offers the excellent quality of printed cotton fabrics. These cotton printed fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Printed Fabric Manufacturers in Surat

For the best Manufacturer & Exporter of Printed Fabric Manufacturer in Surat check the Response Fabrics that is the Professional Supplier of High Quality Designer printed Fabrics in Surat. We specialized in supplying quality printed Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we.

Custom Print Fabric India

Response Fabric offers the best creative custom print fabric that is one of the finest on demand fabric printing companies in India. We offer digital printing on all fabrics, and can do digital printing on all knitted, woven, and felt fabrics like cotton, linen, polyester, rayon, wool, etc. At responsive fabrics, we provide aesthetic, and cost-efficient solutions to all textile needs.

cotton printed fabric wholesale price

The price of cotton printed fabric wholesale is starting from Rs. 70\Meter, and goes on.

printed cotton fabric manufacturers in ahmedabad

Response Fabrics brings the best printed cotton fabric manufacturers in Ahmedabad with a wide range of printed designs. These are made from certified fabric sourced from vendors of high repute after doing a diligent quality testing as per international standards. These products are attractive in colors, mesmerizing patterns, and quality fabric.

READ MORE...Home - Response Fabrics

#Printed Fabric Manufacturers for Upholstery#Upholstery Fabric Manufacturers & Suppliers in India#Printed Holland Velvet Upholstery Fabric

0 notes

Text

All India Machinery - Plastic Blown Film Extruders, Flexo & Rotogravure Printing Machines Manufacturer, Exporter and Supplier

All India Machinery is a renowned and world-class manufacturer, exporter, and supplier of Plastic Blown Film Extruders, Flexo and Rotogravure Printing machines. The company was established in 2017 and is based in Mumbai and has enjoyed the pinnacle of success in the world of blown film and printing machinery industries. With an experience of over 25 years and expertise in manufacturing lifecycles, sales, integrated marketing, creating events, boosting performance, and enhanced professional consultation, this organization has everything which enables it to have its presence in more than 25 countries including export to Qatar, Bahrain, Kenya, Saudi, Canada, Peru, Morocco, Italy, Mexico, Tanzania etc.

All India Machinery strives to be the largest company of offline and online printing machinery in the world by 2025 with its core values of constant innovation, collaboration, result orientation, honesty, and trustworthiness in place. With all the leadingtechnological know-how, All India machinery has participated in worldwide business meetings on how to increase profitability. Reusing and recycling plastic has been made much easier and the company focuses on total quality control. This superlative performance is because of the state of art manufacturing practices adopted that aim at precision and perfection. The team is a comprehensive one that offers solutions for all the client needs and has the ISO 9001- 2015 certification.

All India Machinery is a one-stop solution for all Blown film extruders and Flexographic and Roto Gravure printing machines with models that give an exemplary performance. The wide range of products with advanced technology enables this company to have a total grip over the market needs. Any impediment in the machinery operation is taken care of and various variants are suggested to cater to the specified needs of clients. An Outstanding bag making system is also guaranteed owing to the years of expertise in the field. We ensure that all our clients get the utmost satisfaction and end-to-end services with the best quality.

The range of Products at All India Machinery includes-

Flexo Printing Machines Flexo printing machines come in various models like the two colors high-speed Flexographic printing machine, the medium Flexo printing machine, and the mini Flexo printing machine. These machines offer a very easy installation and operation with superlative printing results. Flexographic printing machinery offers consistent quality and great durability.

Roto Printing Machines

These models include the online and the inline Roto Gravure Printing Machine, the single and two color floor mounted Roto printing machines which are greatly user-friendly and offer hassle-free operation. Any kind of wastage is reduced and production costs also are significantly curbed. The rotogravure is a cost-efficient printing process and the production speed is exemplary.

Tubing Machines

The long-lasting maintenance-free life offered by the Blown film extrusion machines which come in various mm’s offer tremendous versatility with speed. The output is voluminous depending on the size and gauge of the material and can be used to produce t-shirt bags, garbage bags, carry bags, grocery bags, and much more. The models like ABA Two layer Extruder runs electricity while the Corona treater machine offers a uniform treatment throughout the web width.

Sealing and Cutting Machine

The Bottom Sealing and cutting machine is a microprocessor-controlled one that has its speed synchronized with the stroke and size. There is a side sealing and cutting machine which has a silicon sealing roller driven by servo and has a sealer and cutter logic embedded. They offer a very good sealing effect and is simple to operate. Its efficiency makes it popular and much demanded.

Recycling Machines

The recycling machines include a vertical mixture with dryers and are suitable for light and semi-dense materials. These machines have minimalist power consumption and the high-speed mixers offer the efficiency of batch times of 10 to 15 minutes per batch.

1 note

·

View note

Text

Wood Crafts

Wooden Crafts are the artistic practice of shaping and decorating wooden objects. India is famous for wooden handicrafts. Skilled craftsmen of each state create handicrafts using wood that is available locally. The most common varieties used to make Indian handicrafts are teak, sheesham, sal, oak, mango, ebony and mahogany. Sandalwood, rosewood and walnut are the exotic varieties and are expensive and are used in producing fine pieces of furniture and decorative items. There has been a complete revival of the traditional and antique wood craft, owning to its uniqueness and demand in India and abroad. Indian artisans are experimenting with designs to create a blend of traditional and modern woodcraft. Each piece of Indian wooden handicraft is a labor of love, sweat, and patience, which no machine can replicate.

Wooden Toys and games are winning mass of quality these days. The wooden toys and games are put up in innovative as well as classical types that are energizing and thought-provoking for everyone to examine their power. A heavy number of attractively fashioned wooden toys and games will offer hours of amusement. They are designed with exquisitely workmanship and paragon for people of all age-groups.

Designed with expert workmanship, wooden toys have arrived at immense popularity and are perfect for people of all generation. The most widely playacted wooden toys and games are wooden chess and wooden carrom board. The wooden toys are carefully carved and attractively designed engaging a special place in lots of families. Wooden toys and games are meant for kids and adults both, and are perfect items for gifting purpose. They are handcrafted with extreme care to have an eye-catching visual aspect. They provide durable fun and are designed to germinate coordination and imagery power among children. The most widely played wooden toys and games are wooden chess and carrom-board. In order to make them easier to carry while traveling, they are available in wooden box which makes them excellent for gift items.

Festival Wooden Crafts are very popular. Many companies prefer to give away various wooden gift items as corporate gifts as they are durable and elegant. When wooden items are purchased in wholesale from suppliers or exporters, they prove to be very cost effective. In fact, when companies directly deal with the wooden gift manufacturers, they save a lot of money by avoiding the middlemen in suplly chain. However, wooden corporate gifts might be procured on cheap rates, they always look more expensive due to craftsmanship of the artisans as well as because wood itself is considered to be an expensive medium to make craft items. They can be offered on various occasions including retirement , transfer or anniversary etc. They help in encouraging and motivating people who really deserve to be appreciated. It helps in minimizing attrition rate as well as staff turn over. Wooden gift items cam also be customized as per the requirement of various companies.

Acrylic Charms are made with a solid, clear acrylic material that can be printed in full color and cut to any shape. Acrylic charms feature a small 0.085” (~2mm) cut hole for creating your own keychains, jewelry and more. These Acrylic Crafts have been a real hit! Acrylic charms consist of either one layer of acrylic board with an epoxy-covered image on top (or on bottom, if you prefer the acrylic layer over the front and epoxy on back), or two layers of board with the image sandwiched in between. The image itself can be one-sided or two sided.

Acrylic Rhinestones are so attractive! When we go shopping in department stores or walk on the road, we often see various shapes and sizes of rhinestones on shoes, bags, jewelry, and even displays. The rhinestones are colorful and shiny, and it is difficult to ignore them. Rhinestones are not diamonds; they are a simulation of diamonds. Since diamonds are natural and are formed under high pressure and high-temperature conditions deep in the earth, often taking a long time to form, they are scarce and very expensive. Rhinestones are artificial and have the sparkling, dazzling effect of diamonds. Therefore, when rhinestones could be manufactured in large quantities, people began to use rhinestones as decorations for jewelry, clothing and other accessories.

Forty years ago, the sending and receiving of Christmas Greeting Cards were one of the steps in declaring adulthood and establishing one’s own home. Part of becoming an adult was communicating the year’s events to family and friends.

In the Christmas letter that went with the card, there was some bragging about the good things in one’s life but it was also a vehicle to let people know about deaths or difficulties.

As Christmas became more about persuading consumers to buy, greeting card companies understood this. They grew their sales by offering greater varieties of cards, including boxed sets and charitable cards. Businesses began sending greeting cards to each other as a thank you for the work done together that year.

0 notes

Text

How To Start Waste Paper Recycling Plant In India?

Do you want to start paper recycling business? Waste paper recycling is one of the profitable business. The demand of paper bags, cardboards and other paper made items always have great demand in local and international market. The best part is you can get raw material at best price in continuous basis. The paper that we use is mostly a bio-degradable waste that can easily be decomposed with the passing time. In the present times there has been a huge usage of paper. Nearly everywhere we go we can easily see papers around. The usage of paper is vivid and is increasing by time. Some basic usage of paper includes newspapers, books, text copy, pamphlets, posters, magazine papers, calendars, and many more.

The world market of paper is very huge and is in billions. Paper is made using the pulp from trees. As of 2016, approximately 411 million metric tons of paper is produced every year globally. In this article I am sharing profitable business plan for paper recycling business. If you want to start your own paper recycling plant then read this article till the very end, you will get all information about profit margin in this business and cost of setting up a paper recycling plant.

China ranks at number one spot in the production of paper. The United States is at the second spot and Japan is at the third spot. The paper manufacturing industry is very huge and has a turnover of billion dollars every year.

How Paper is produced?

Paper is produced from the pulp of wood, fibrous plants, rice, water plants, stubbles, and other such materials. The basic material that is required to manufacture paper is fiber which is an essential part in papermaking. You can get this pulp mainly from two sources. One is from wood pulp and the other is from old recycled papers. The production of papers required cutting down of trees. One tree in general produces 16.67 reams of paper whereas 12 trees produce 1 ton of paper.

To produce such a huge quantity of papers millions of trees are cut down every year. The rise in cutting down of trees has led to deforestation resulting in rise of global warming. To counter these people are now focusing on recycling of paper.

Recycling Paper: Paper recycling has been hugely adopted these days by every country in order to save the cutting down of trees. The benefit of recycling is not only that it saves cutting down of trees but also reduces and reuses paper waste that would have created a mess in the atmosphere. There is unique advantage of recycling paper as it is beneficial in many ways. To produce one A4 size paper nearly 5 liters of water is required. Recycling down of 1 ton of paper saves 26, 500 liters of water, 682.5 gallons of oil and 17 trees.

Inspired by such an effective method, the whole world has invested a huge sum of money in recycling paper waste. Earlier these recycling job was conducted by either government owned businesses or big recycling businesses but now even common man can own a paper recycling business.

Paper Recycling as a Business:

Paper recycling business is a flourishing business that is giving huge returns to its owners. There is abundant demand of recycled paper as they are cheap. If one plans down a strategy, executes it and invest a fair amount of capital then one can get a satisfying return within no time. To lay down a business plan you need to understand the basics of recycling a business, its requirements, investment, and return and so on. Here is a strategic and brief plan that can help you in your paper recycling business.

Paper Recycling Business Plan:

The plan will carry all the details of how your paper recycling business can be opened, executed and run successfully with satisfying return. Here are few things you need to care about.

Resource Required to open a recycle plant

Cost of setting up a waste paper recycling plant

Requirement of total capital

Arrangement of capital

Time investment

Resources required to open a paper recycle plant:

Land Space and Factory:

The First basic requirement is a place where you will recycled paper. If your house allows you to set up your plant then it is okay or you need to get a decent space where you can set your factory. Depending on the scale of recycling you can own or rent that space. The minimum space should be around 250sq. feet. The space should be closed with rooms for collecting paper waste, a cleaned room for keeping the recycled paper, a place to set up machines and so on.

Requirement of Resources:

The Basic amenities are required everywhere. You need to have permanent standard power connection with stable water supply. The paper recycling plant requires huge amount of water therefore you need to have that supply. Your plant should not be that far that transportation becomes a problem because you need constant supply of waste paper for your recycle plant.

Required Official Permissions:

Since you are opening a recycle plant therefore you need to have permissions from the concerned authorities in your city. You also need to pay taxes of your space under commercial space. The next thing is registration of business followed by GST registration for payment of tax. Since you will use huge power therefore special permission should also be taken. The last one is water supply connection which you must definitely take as your water requirement will be huge.

Equipment for Recycling:

To recycle the paper you need some standard equipment like washing soap, cleaning equipment, bleaching powder, tanks, containers, machines, jets, paper printer, etc.

Paper Recycling Machine:

There are three types of machines for recycling paper. First is the small type machine that recycles 20-100 kg of waste paper scrap per hour. The medium size machine recycles 75-250 kg of paper while the large machine recycles 100-500 kg of paper waste. Depending on your requirement and budget you can purchase the machine. It would be advisable to start with small machine and later on go for medium and large machine as it will help you in understanding the business supply and returns.

Waste Paper Collection:

You can network with scrap collectors, paper waste owners, dumping grounds and so on to collect waste paper.

Labor and Expert:

You need at least one person who is expert in paper recycling and with major machines and equipment. You also need few labors that will assist the main worker in the recycling job.

Other Requirements:

This includes paper packaging, place to store paper, later job of printing, labeling, transporting and so on.

Cost of setting up a recycling plant:

The cost estimation which is given below is in Indian currency and is targeting readers from India. This business plan is also valid for other countries like South Africa, Australia, USA, UK, Canada, etc. The cost of machine is nearly same everywhere and recycling process is also same.

Renting or owning of place depending on size varies from place to place which one can calculate. The better option in starting is to rent a place or use an existing place owned by you as it will reduce investment. Waste paper collection doesn’t costs much. Nearly 4-5 rupee is spent to buy 1kg of waste paper.

Purchasing equipment is costly which should best be rented on monthly basis which is easily available if you have contacts. Recycling machine is a costly thing to own which should best be owned. Start with a small machine that costs around 3-5 lakhs while the medium costs at Rs 5-10 lakhs and the large one costs Rs 10-35 lakhs.

Hiring expert technician and labor will cost you Rs 30-40 thousand per month. You can add electric charges, water charge, transportation and other expense as well. A total of at least Rs 10 lakhs is required for the first time in setting up your business. Later you have to spend at least 1-1.5 lakhs per month.

Arrangement of Capital:

You can take loan from banks. You can take Rs 10 lakh loan to start your business. If you want to open it as a startup then you can avail 3 year benefit from taxes and charges. You can finance your business, open with partnership to ease the capital requirement.

Time Investment:

It would take at least 2 months to start your paper recycling business. From arranging land, building your factory, setting up your machines, hiring resources, experts and labors, networking with paper suppliers and sellers, transportation, required permissions and so on. You may start to get returns only after 4-6 months since the starting of your business.

Your return will be measured only after 1 years since the starting one year will take to build your business. You can easily earn Rs 10-12 thousand per day in your recycling business adding up your recycled products as well. All will depend on the quality, quantity of paper you manufacture and the market of sale you have.

You can buy waste paper scrap and other ferrous and non-ferrous scrap from Bhanwra Electricals at best price for your recycling business.

0 notes

Text

Paper bag machine with printing fuction is sufficient

In the event you solely make small paper luggage for meals, a paper bag machine with printing fuction is sufficient. We're one of many foremost manufacturers and suppliers of a variety of Buying Bag Machine. Machine speeds dependent on paper & adhesive qualities, bag dimensions, operator information, and basic work philosophy. Having absorbed the advanced know-how both at house and overseas, we successfully developed the square backside type of paper bag making machine with roll paper or printed roll paper The machine has autom-atic power controlling machine and the perform of colour marking monitoring. This Collection of paper bag handle making machine use roller paper to make flat handles or twisted handles. We're the main dealer and distributor of Paper Bag Making Machine, Leveluk Tremendous 501, Leveluk Kangen eight and Water Ionizer Leveluk Sd-501. Our purchasers use this Fully Automatic Paper Bag Making Machine for making brown paper luggage, craft luggage, art paper luggage, white cardboard luggage and laminated paper baggage.

Characteristic: This machine encompasses a continuous function of automated paper suction, gluing, creasing, bottom sticking and bag formation at a stroke. Backed with our adroit workforce of pros, we are capable of provide our shoppers with an assorted gamut of Shopping Paper Bag Making Machine. Implementing our rich domain expertise, we deliver forth an illustrative Medicine Paper Cover Making Machine, which is designed to fabricate flat and satchel paper baggage from , grease-proof kraft paper, white paper and poster.These luggage are additional used for packing confectionery, meals stuff, prepared-made garments, , tea powder, groceries and dry cleaner. This Is Ideally suited Automatic Paper Bag Making Machine For Producing Varied Kinds Of Paper Baggage Such As Food Paper Bag, Bread Bag, Cosmetics Handle Paper Baggage, And so forth. We're the manufacturer of Shopping Paper Carry Bag Making Machine. Both roll feeding sq. backside paper bag and roll feeding square bottom paper bags are appropriate. Paper bag making machine is a machine used for making hand baggage. Paper Cover Making Machine Providing recycled paper bags to your customers shouldn't be the only thing you do this's environmentally aware however somewhat the beginning of a comprehensive environmental strategy. These machines are broadly identified for his or her supreme performance and excessive productiveness. Numerous paper bags require different types of raw materials which is well accessible available in the market. The flat-bottomed paper baggage that have been in use were made individually, by hand. In the paper bag trade, it is very important to pick proper machines.

We're the producer of Absolutely Automated Paper Bag Making Machine. Supplied in numerous grades and dimensions, this Paper Bag Making Machine has been constructed and developed from optimum quality steel and is obtainable in numerous assortment. ZB50B purse backside-gluing machine or Fully automated backside pasting machine includes a continuous features of computerized delivery of manually-folded bag bottom (paperboard can inserted or not), computerized glue spray, computerized pasting, automated folding, pressing and completed bag bottom output. We offer six totally different paper cup machines SPB seven-hundred, SPB 750, SPB 850, SPB Tremendous 850, SPB 950, SPB Super 950. We have been able to offer Automated Paper Bag Making Machine to our precious patrons. The new mannequin is extra handy, extra environment friendly and more secure, is the production of a variety of different paper baggage, quick food bags, bread luggage, medical baggage, dried fruit baggage, procuring bags, and so the perfect tools for environmental safety paper luggage. The supplied machine is efficiently manufactured at our advanced production unit by our diligent professionals with the usage of the very best quality elements and avant-garde methods in tune with outlined market standards.

Paper luggage are recyclable and it is eco-pleasant too. Purchasers can avail this Paper Bag Machine from us in varied technical specs at business main costs. We are offering Paper Buying Bag Making Machine to our clients. On the chart is proven for which type of width of bag goes with which type of paper roll. Our machines are very good in velocity and produce 100 -300 baggage per minute. Paper Bag making Machine is widely used for making Grocery , Bakery, Meals, Fruit Baggage in addition to Buying Baggage. Bag Maker-seven-hundred totally automated paper bag making Machine produces paper baggage from a jumbo roll, for a required width of the bag a suitable jumbo roll is positioned on the machine. Paper bag making machine merchandise are hottest in United States, Malaysia, and United Kingdom. You'll be able to produce good paper luggage even utilizing 50gsm papers. Actually, the investment for paper bag making business depends on the production quantity and high quality. Checked on varied stern parameters to make certain a defect-free range is delivered, this machine is extremely acclaimed in the market. We have both paper bag making machine with roll feeder and sheet feeder. If you happen to tend to make purchasing baggage with handle, paper handle making machine and paper bag deal with pasting machine is must. As per the needs and necessities of our shoppers, we're concerned in providing Totally Automated Paper Bag Making Machine. HolwegWeber is proud to convey over 200 years of combined experience offering the easiest, fastest, and most versatile machines in the paper changing business. Now we have extremely acknowledged organization engaged in presenting a exceptional range of Brown Paper Bag Making Machine. Choosing the right machine on your paper bag is an important determination. Backed with our adroit workforce of professionals, we're capable of provide our shoppers with an assorted gamut of Fully Automatic Paper Bag Making Machine.

This Automated Paper Bag Making Machine Is The Best Equipment Which Is Using Flat Papers As Uncooked Supplies To Make Into Paper Luggage In Square Bottoms. Pioneers in the industry, we provide automated paper bag making machine from India. SHKI is the Main Producer of Paper Bag Making Machines , Medication Paper Cowl Making Machine , Paper bag making machine , Computerized Brown Paper Bag Making Machine , Fully Automatic Shopping Grocery Kraft Paper Bag Machine , Totally Automated Khaki Paper Bag Making Machine , Computerized Paper Bag Making Machine For Bakery And Grocery , Medical and Bakery Paper Bag Making Machine ,Fully Automated grocery paper bag making machine , Brown Paper Bag Making Machine, Paper Cover Making Machine, Paper bag making machine ,Computerized Brown Paper Cowl Making Machine and Paper Grocery Bag Making Machine. Offering you a whole alternative of products which embody paper bag making machine. We are engaged in offering a big selection of Bag Making Machine. It's sensible choice for paper baggage producers who've handle paper luggage order with amount lower than 50000pcs or small dimension paper deal with bag order. We're offering Paper Bag Making Machine to our shopper. Paper Bag Making Machines are specially designed to make paper bags which are extremely in demand by the folks. It not solely guarantee the standard of our machines, but also present aggressive prices. Pioneers within the business, we offer grocery paper bag making machine from India. We provide international consumers with a whole useful resource for his or her packaging needs equivalent to low cost China Paper Bag Making Machine. Prominent & Leading Manufacturer from Nagpur, we provide semi automatic paper bag making machine, paper bag making machine and computerized paper bag making machine. Please be at liberty to contact us to find more details about the various kinds of prime quality paper bag making manufacturing machines or plastic bag making machines or we can custom construct and provide right here. Use Paper Luggage And Their Benefits To fulfill various requirements of our valued clients, we're engaged in providing Paper Baggage Machine For Flour.

0 notes

Text

Carry Bag Printing Machine Price in India

Decent Print Lines stands out as a premier manufacturer and supplier of Carry Bag Printing Machines in India. With a commitment to innovation and quality, Decent Print Lines offers advanced printing solutions designed to meet the diverse needs of the packaging industry. Their state-of-the-art machines are engineered for precision and efficiency, ensuring high-quality prints on various types of carry bags, including plastic, paper, and non-woven bags.

The company's Carry Bag Printing Machines are known for their durability, user-friendly operation, and ability to handle large volumes, making them ideal for both small-scale and large-scale production. Decent Print Lines combines cutting-edge technology with robust engineering to deliver machines that offer exceptional performance and reliability.

Their comprehensive range of machines caters to different printing requirements, from simple logos to complex multi-color designs. Backed by a dedicated support team, Decent Print Lines ensures seamless installation, maintenance, and after-sales service, making them a trusted partner for businesses looking to enhance their packaging capabilities. With a focus on quality and customer satisfaction, Decent Print Lines continues to set industry standards in the carry bag printing sector.

For More Details

Contact us :- +91-9911433180

Email Id :- [email protected]

Address :- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#carry bag printing machine manufacturer in india#carry bag manufacturer#carry bag printing machine manufacturer#top carry bag printing machine manufacturer

0 notes

Text

How To Start Waste Paper Recycling Plant In India?

Do you want to start the waste paper recycling business? Waste paper recycling is one of the profitable business. The demand for paper bags, cardboard and other paper made items always have great demand in the local and international market. The best part is you can get raw material at the best price on a continuous basis. The paper that we use is mostly a bio-degradable waste that can easily be decomposed with the passing time. In the present times, there has been a huge usage of paper. Nearly everywhere we go we can easily see papers around. The usage of paper is vivid and is increasing by time. Some basic usage of paper includes newspapers, books, text copy, pamphlets, posters, magazine papers, calendars, and many more.

The world market of paper is very huge and is in billions. Paper is made using the pulp from trees. As of 2016, approximately 411 million metric tons of paper is produced every year globally. In this article, I am sharing a profitable business plan for paper recycling business. If you want to start your own paper recycling plant then read this article till the very end, you will get all information about profit margin in this business and cost of setting up a paper recycling plant.

China ranks at number one spot in the production of paper. The United States is in the second spot and Japan is at the third spot. The paper manufacturing industry is very huge and has a turnover of billion dollars every year.

How Paper is produced?

Paper is produced from the pulp of wood, fibrous plants, rice, water plants, stubbles, and other such materials. The basic material that is required to manufacture paper is fiber which is an essential part in papermaking. You can get this pulp mainly from two sources. One is from wood pulp and the other is from old recycled papers. The production of papers required cutting down of trees. One tree, in general, reduces 16.67 reams of paper whereas 12 trees produce 1 ton of paper.

To produce such a huge quantity of papers millions of trees are cut down every year. The rise in cutting down of trees has led to deforestation resulting in the rise of global warming. To counter this people are now focusing on recycling of paper.

Recycling Paper:

Paper recycling has been hugely adopted these days by every country in order to save the cutting down of trees. The benefit of recycling is not only that it saves cutting down of trees but also reduces and reuses paper waste that would have created a mess in the atmosphere. There is a unique advantage of recycling paper as it is beneficial in many ways. To produce one A4 size paper nearly 5 liters of water is required. Recycling down of 1 ton of paper saves 26, 500 liters of water, 682.5 gallons of oil and 17 trees.

Inspired by such an effective method, the whole world has invested a huge sum of money in recycling paper waste. Earlier these recycling job was conducted by either government owned businesses or big recycling businesses but now even the common man can own a paper recycling business.

Paper Recycling as a Business:

Paper recycling business is a flourishing business that is giving huge returns to its owners. There is abundant demand of recycled paper as they are cheap. If one plans down a strategy, executes it and invest a fair amount of capital then one can get a satisfying return within no time. To lay down a business plan you need to understand the basics of recycling a business, its requirements, investment, and return and so on. Here is a strategic and brief plan that can help you in your paper recycling business.

Paper Recycling Business Plan:

The plan will carry all the details of how your paper recycling business can be opened, executed and run successfully with a satisfying return. Here are a few things you need to care about.

Resource Required to open a recycle plant

Cost of setting up a waste paper recycling plant

Requirement of total capital

Arrangement of capital

Time investment

Resources required to open a paper recycling plant:

Land Space and Factory:

A First basic requirement is a place where you will recycled paper. If your house allows you to set up your plant then it is okay or you need to get a decent space where you can set your factory. Depending on the scale of recycling you can own or rent that space. The minimum space should be around 250sq. feet. Space should be closed with rooms for collecting paper waste, a cleaned room for keeping the recycled paper, a place to set up machines and so on.

Requirement of Resources:

The Basic amenities are required everywhere. You need to have a permanent standard power connection with a stable water supply. The paper recycling plant requires the huge amount of water, therefore, you need to have that supply. Your plant should not be that far that transportation becomes a problem because you need a constant supply of waste paper for your recycle plant.

Required Official Permissions:

Since you are opening a recycling plant, therefore, you need to have permissions from the concerned authorities in your city. You also need to pay taxes of your space under commercial space. The next thing is registration of business followed by GST registration for payment of tax. Since you will use huge power, therefore, special permission should also be taken. The last one is the water supply connection which you must definitely take as your water requirement will be huge.

Equipment for Recycling:

To recycle the paper you need some standard equipment like washing soap, cleaning equipment, bleaching powder, tanks, containers, machines, jets, paper printer, etc.

Paper Recycling Machine:

There are three types of machines for recycling paper. First is the small type machine that recycles 20-100 kg of waste paper scrap per hour. The medium size machine recycles 75-250 kg of paper while the large machine recycles 100-500 kg of paper waste. Depending on your requirement and budget you can purchase the machine. It would be advisable to start with a small machine and later on go for the medium and large machine as it will help you in understanding the business supply and returns.

Waste Paper Collection:

You can network with scrap collectors, paper waste owners, dumping grounds and so on to collect waste paper.

Labour and Expert:

You need at least one person who is an expert in paper recycling and with major machines and equipment. You also need a few labours that will assist the main worker in the recycling job.

Other Requirements:

This includes paper packaging, a place to store paper, later job of printing, labelling, transporting and so on.

Cost of setting up a recycling plant:

The cost estimation which is given below is in Indian currency and is targeting readers from India. This business plan is also valid for other countries like South Africa, Australia, USA, UK, Canada, etc. The cost of the machine is nearly the same everywhere and the recycling process is also the same.

Renting or owning of place depending on size varies from place to place which one can calculate. The better option in starting is to rent a place or use an existing place owned by you as it will reduce investment. A waste paper collection doesn’t costs much. Nearly 4-5 rupee is spent to buy 1kg of waste paper.

Purchasing equipment is costly which should best be rented on a monthly basis which is easily available if you have contacts. Recycling machine is a costly thing to own which should best be owned. Start with a small machine that costs around 3-5 lakhs while the medium costs at Rs 5-10 lakhs and the large one costs Rs 10-35 lakhs.

Hiring expert technician and labour will cost you Rs 30-40 thousand per month. You can add electric charges, water charge, transportation and other expense as well. A total of at least Rs 10 lakhs is required for the first time in setting up your business. Later you have to spend at least 1-1.5 lakhs per month.

Arrangement of Capital:

You can take the loan from banks. You can take Rs 10 lakh loan to start your business. If you want to open it as a startup then you can avail 3-year benefit from taxes and charges. You can finance your business, open with the partnership to ease the capital requirement.

Time Investment:

It would take at least 2 months to start your paper recycling business. From arranging land, building your factory, setting up your machines, hiring resources, experts and labours, networking with paper suppliers and sellers, transportation, required permissions and so on. You may start to get returns only after 4-6 months since the starting of your business.

Your return will be measured only after 1 year since the starting one year will take to build your business. You can easily earn Rs 10-12 thousand per day in your recycling business adding up your recycled products as well. All will depend on the quality, the quantity of paper you manufacture and the market of sale you have.

You can buy waste paper scrap and other ferrous and non-ferrous scrap from Bhanwra Electricals at the best price for your recycling business.

0 notes

Text

Non woven fabric carry bag making machine price in india

When looking for a non-woven fabric carry bag making machine in India, the price can vary depending on several factors such as the machine's features, capacity, brand, and level of automation. Here's a general overview:

1. Semi-Automatic Machines

Price Range: ₹3,00,000 - ₹6,00,000

Features: These machines typically require manual intervention at certain stages. They are suitable for small to medium-scale production.

2. Fully Automatic Machines

Price Range: ₹8,00,000 - ₹15,00,000

Features: Fully automatic machines are capable of high-speed production with minimal human intervention. They can produce a wide variety of bag types and sizes.

3. High-End Fully Automatic Machines

Price Range: ₹15,00,000 - ₹30,00,000+

Features: These machines are equipped with advanced technology, including computerized control panels, multiple production capabilities, and higher efficiency. They are ideal for large-scale manufacturers.

Factors Affecting the Price

Brand Reputation: Established brands may charge a premium due to better quality, after-sales service, and reliability.

Production Capacity: Machines with higher production capacities will generally cost more.

Customization: Machines that offer customization in terms of bag sizes, types, and designs will have higher prices.

Additional Features: Add-ons such as printing capabilities, UV coating, and other advanced features will increase the price.

Popular Brands in India

Fairprint

Zhejiang Zhengwei Machinery

Sahil Graphics

Suntech

Sky Flexi Pack

Conclusion

The price of non-woven fabric carry bag making machines in India can vary widely based on the machine's automation level, brand, and features. It's important to assess your production needs and budget before making a purchase. It's also recommended to contact suppliers directly for the most accurate and up-to-date pricing, as prices can fluctuate based on market conditions and technological advancements.

0 notes

Text

Best Carry Bag Printing Machine Manufacturing Company in India

Decent Print Lines is a leading manufacturer and supplier of Carry Bag Printing Machines in India, renowned for delivering high-quality, efficient solutions to meet diverse printing needs. Our state-of-the-art machines are designed to handle various types of carry bags, including plastic, paper, and non-woven options, ensuring vibrant, precise prints with exceptional durability. Equipped with advanced printing technology, our machines offer features such as multi-color printing capabilities, high-speed operation, and user-friendly interfaces, making them ideal for both small-scale and large-scale production.

At Decent Print Lines, we focus on innovation and quality, providing machinery that enhances productivity and reduces operational costs. Our commitment to excellence is reflected in our rigorous quality control processes and reliable after-sales support. Whether you need a machine for custom designs or high-volume printing, our team is dedicated to offering tailored solutions that fit your specific requirements. With a strong emphasis on customer satisfaction, Decent Print Lines is your trusted partner for top-notch carry bag printing solutions in India.

For More Details

Contact us :- +91-9911433180

Email Id :- [email protected]

Address :- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#carry bag printing machine manufacturer in india#carry bag manufacturer#carry bag printing machine manufacturer

0 notes

Text

Everything You Need To Know About Carry Bag Printing Machines ?

Decent Print Lines is a prominent manufacturer and supplier of Carry Bag Printing Machines in India. With a strong reputation for delivering high-quality printing solutions, Decent Print Lines offers advanced and reliable machines tailored to meet the diverse needs of the printing industry. Their Carry Bag Printing Machines are designed with cutting-edge technology to ensure precision, efficiency, and vibrant print quality, making them ideal for producing a wide range of carry bags, including non-woven, paper, and fabric bags.

The company's machines are known for their robust construction, user-friendly operation, and minimal maintenance requirements. Decent Print Lines focuses on innovation and continuous improvement, ensuring their machines are equipped with the latest features, such as automated controls, high-speed printing capabilities, and energy-efficient operations. This commitment to excellence has made them a preferred choice for businesses seeking reliable and cost-effective printing solutions.

In addition to manufacturing top-notch machines, Decent Print Lines provides comprehensive after-sales support, including installation, training, and maintenance services, ensuring a seamless experience for their customers. Their dedication to quality and customer satisfaction has positioned them as a leader in the carry bag printing machine market in India.

For More Details

Contact us :- +91-9911433180

Email Id :- [email protected]

Address :- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#carry bag manufacturer#carry bag printing machine manufacturer#carry bag printing machine manufacturer in india

0 notes

Text

What are the Benefits of Carry Bag Printing Machine in Businesses?

Benefits of Carry Bag Printing Machine for Businesses:

Brand Visibility: Customized carry bags act as mobile advertisements, increasing brand visibility wherever they go.

Customer Engagement: Thoughtfully designed bags enhance the overall shopping experience, making customers feel valued and connected to the brand.

Environmental Considerations: Many printing machines now offer eco-friendly options, supporting sustainability initiatives by using biodegradable inks and recyclable materials.

Operational Efficiency: With in-house printing capabilities, businesses can respond quickly to marketing needs, seasonal campaigns, or promotional events without relying on external suppliers.

The Evolution of Carry Bags

Gone are the days when carry bags were purely functional. Today, they serve as potent vehicles for brand identity and customer engagement. Whether it’s a high-end boutique, a local grocery store, or a global chain, businesses leverage carry bags to communicate their ethos, values, and promotional messages to a wide audience.

Enter the Carry Bag Printing Machine

The introduction of carry bag printing machines has been a game-changer for businesses of all sizes. These machines, often compact and versatile, enable retailers to customize carry bags with logos, slogans, images, and even QR codes. This capability transforms an ordinary bag into a powerful marketing tool that travels far beyond the store walls.

How It Works

Carry bag printing machines utilize various printing technologies such as flexography, screen printing, or digital printing, depending on the complexity of the design and the material of the bag.

Flexography: Ideal for high-volume printing, flexography uses flexible relief plates to transfer ink onto the bags. It’s efficient and cost-effective for large runs.

Screen Printing: This method involves creating a stencil (or screen) and using it to apply layers of ink on the bag’s surface. It’s suitable for vibrant designs and works well on different materials.

Digital Printing: Offering flexibility and precision, digital printing directly applies ink onto the bag using advanced printers. It’s perfect for intricate designs, variable data, and smaller print runs.

The Future Ahead

As consumer expectations evolve, so too will the technology behind carry bag printing machines. Future innovations might include smarter, more energy-efficient machines capable of handling a wider array of materials and designs. Additionally, advancements in printing techniques may further blur the lines between functionality and artistic expression, allowing for even more creative and impactful bag designs.

Conclusion

In conclusion, the carry bag printing machine represents more than just a technological advancement; it embodies the convergence of retail strategy and customer engagement. By transforming a utilitarian item into a canvas for creativity and brand messaging, these machines empower businesses to leave a lasting impression on their customers while enhancing operational efficiency. As the retail landscape continues to evolve, the role of carry bag printing machines will undoubtedly grow, shaping the way brands interact with consumers in the physical world.

In this age of competitive retail environments, it’s not just about what customers buy but also about how they carry it home. And with the right carry bag printing machine, every trip becomes an opportunity for brands to shine.

Top Carry Bag Printing Machine Manufacturer in India

If you are looking for a Best Carry Bag Printing Machine Manufacturer in India, look no further than Decent Print Line, we are a leading manufacturer and supplier of Carry bag Printing Machine in India, for more details, please contact us!

#Carry Bag Printing Machine#Carry Bag Printing Machine manufacturer#Carry Bag Printing Machine manufacturer in India#Top Carry Bag Printing Machine manufacturer#decent print line

1 note

·

View note

Text

Non woven fabric carry bag making machine price in india

Non-woven fabric carry bag making machines are essential equipment for manufacturing eco-friendly bags that are increasingly replacing traditional plastic bags. These machines enable the production of bags made from non-woven polypropylene fabric, which is durable, reusable, and recyclable.

Several factors influence the price of these machines in India:

Machine Capacity: The production capacity of the machine, measured in bags per minute or hour, significantly affects its price. Higher capacity machines capable of producing more bags per unit time usually come with a higher price tag.

Features and Specifications: Different models of bag making machines offer various features and specifications. Advanced features such as automatic feeding, cutting, and stitching mechanisms, as well as options for printing and customization, can increase the cost of the machine.

Brand and Manufacturer: Reputable brands with a track record of reliability and quality tend to offer machines at higher prices compared to lesser-known or generic brands. However, investing in a well-established brand can ensure better performance, durability, and after-sales support.

Technology and Innovation: Machines equipped with the latest technology and innovative features may command a premium price due to their enhanced efficiency, productivity, and ease of operation. These machines often offer improved energy efficiency and reduced downtime, resulting in long-term cost savings.

Supplier and Distribution Channels: Prices can vary between different suppliers and distributors based on factors such as overhead costs, profit margins, and geographical location. It's advisable to compare prices from multiple sources to ensure a competitive deal.

Additional Costs: Buyers should consider additional costs such as shipping, installation, training, and warranty when budgeting for a non-woven fabric carry bag making machine. These costs can significantly impact the overall investment required.

To obtain accurate pricing information, potential buyers should directly contact manufacturers, distributors, or suppliers of non-woven fabric carry bag making machines in India. They can request detailed quotations based on their specific requirements, including desired capacity, features, and customization options. Additionally, online research and comparison of prices on industrial machinery platforms and marketplaces can provide insights into prevailing market rates and available options. It's essential to factor in not just the initial purchase price but also the overall value, including maintenance, support, and the potential return on investment over the machine's lifespan.

Factory Address:

Gata No. 34, Mauza Khadwai, Tehsil Kirawali, Runkata, Agra, Uttar Pradesh, India-282007 📩 [email protected]

Contact : 8800775462

0 notes