#Carry Bag Printing Machine Manufacturer in India

Explore tagged Tumblr posts

Text

Carry Bag Printing Machine Price in India

Decent Print Lines stands out as a premier manufacturer and supplier of Carry Bag Printing Machines in India. With a commitment to innovation and quality, Decent Print Lines offers advanced printing solutions designed to meet the diverse needs of the packaging industry. Their state-of-the-art machines are engineered for precision and efficiency, ensuring high-quality prints on various types of carry bags, including plastic, paper, and non-woven bags.

The company's Carry Bag Printing Machines are known for their durability, user-friendly operation, and ability to handle large volumes, making them ideal for both small-scale and large-scale production. Decent Print Lines combines cutting-edge technology with robust engineering to deliver machines that offer exceptional performance and reliability.

Their comprehensive range of machines caters to different printing requirements, from simple logos to complex multi-color designs. Backed by a dedicated support team, Decent Print Lines ensures seamless installation, maintenance, and after-sales service, making them a trusted partner for businesses looking to enhance their packaging capabilities. With a focus on quality and customer satisfaction, Decent Print Lines continues to set industry standards in the carry bag printing sector.

For More Details

Contact us :- +91-9911433180

Email Id :- [email protected]

Address :- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#carry bag printing machine manufacturer in india#carry bag manufacturer#carry bag printing machine manufacturer#top carry bag printing machine manufacturer

0 notes

Text

Uses and Functions of Non Woven Bag Printing Machine

Introduction

In recent years, the global movement towards sustainability and eco-consciousness has spurred a significant shift in consumer behavior and industrial practices. As businesses strive to reduce their environmental footprint, the demand for eco-friendly alternatives to traditional plastic bags has surged. Enter non-woven bags — lightweight, durable, and reusable alternatives that have gained widespread popularity. At the heart of this eco-friendly revolution lies the non-woven bag printing machine, a marvel of modern engineering that enables the mass production of customized, environmentally responsible bags. Let’s delve deeper into the efficiency and functionality of these innovative machines.

The Rise of Non-Woven Bags

Non-woven bags are crafted from synthetic or natural fibers bonded together through a mechanical, thermal, or chemical process — without the need for weaving. This manufacturing method results in bags that are strong, tear-resistant, and capable of carrying heavy loads. Moreover, non-woven bags are reusable, recyclable, and biodegradable, making them a sustainable choice for environmentally conscious consumers and businesses alike.

Advantages of Non-Woven Bag Printing Machines

Customization: Non-woven bag printing machines offer unparalleled flexibility, allowing businesses to create bespoke designs and branding solutions tailored to their unique requirements.

Speed and Efficiency: With rapid printing capabilities and automated processes, these machines enable high-volume production without compromising on quality or accuracy.

Cost-Effectiveness: By streamlining production workflows and minimizing material waste, non-woven bag printing machines help businesses optimize their operational costs and maximize profitability.

Environmental Sustainability: By facilitating the production of reusable and recyclable non-woven bags, these machines support sustainability initiatives and contribute to the reduction of plastic waste.

Non-woven bag printing machines are the unsung heroes of modern manufacturing, offering a multitude of uses and functions in various industries.

Functions of Non Woven Bag Printing Machine

Customization Made Easy

These machines empower businesses to personalize non-woven bags with logos, designs, and messages, enhancing brand visibility and communication.

Promotional Powerhouses

Ideal for creating branded merchandise, custom-printed non-woven bags serve as effective promotional tools at trade shows, events, and marketing campaigns.

Sustainable Packaging Solutions

In retail, these machines help elevate packaging by customizing non-woven bags with brand aesthetics, product showcases, and eco-friendly messaging.

Memorable Event Souvenirs

From conferences to weddings, custom-printed non-woven bags make practical and memorable giveaways, leaving a lasting impression on attendees.

Environmental Advocacy

By enabling the production of reusable and recyclable bags, these machines contribute to environmental sustainability efforts, promoting eco-conscious consumption.

In essence, non-woven bag printing machines are more than just production tools — they’re enablers of creativity, sustainability, and brand empowerment in a rapidly evolving world.

Best Non Woven Bag Printing Machine Companies in India

If you are looking for a Best Non Woven Bag Printing Machine in India, then look no further than Decent Print Line. Decent prinline is a leading manufacturer and supplier of non woven bag printing machine in India.

For more details, please contact us!

Website — https://www.decentprintline.com/

Contact — +91–9911433180

Email — [email protected]

Address — Plot №4, Gali №1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh — 121004, Haryana, India

#Non Woven Bag Printing Machine#Non Woven Bag Printing Machine manufacturer#Non Woven Bag Printing Machine supplier#Non Woven Bag Printing Machine manufacturer in India#Non Woven Bag Printing Machine supplier in India#Decent printline

2 notes

·

View notes

Text

Find Top non woven carry bags manufacturer

When searching for the top non-woven carry bag manufacturers, it's essential to consider factors such as product quality, customization options, pricing, and customer service. Here's a guide to help you find the best non-woven carry bag manufacturers:

**1. Assess Your Requirements

Bag Types: Determine the type of non-woven bags you need (e.g., U Cut, D Cut, W Cut, loop handle).

Quantity: Identify the quantity you need to order.

Customization: Consider whether you need custom printing, specific colors, or unique designs.

**2. Research Top Manufacturers

1. Favourite Fab (India)

Overview: Favourite Fab is a well-known manufacturer specializing in eco-friendly, high-quality non-woven carry bags. They offer a wide range of designs and customization options, catering to various industries.

Products: U Cut, D Cut, W Cut, loop handle, and customized bags.

Strengths: Competitive pricing, excellent customer service, and fast delivery.

2. Sahil Graphics (India)

Overview: Sahil Graphics is a leading manufacturer of non-woven bags and bag-making machines. They provide a diverse range of products with a focus on durability and environmental sustainability.

Products: Non-woven carry bags, laminated non-woven bags, custom printed bags.

Strengths: High-quality products, advanced manufacturing technology.

3. Sky Flexi Pack (India)

Overview: Sky Flexi Pack is a reputable manufacturer known for its innovative designs and eco-friendly materials. They offer a wide selection of non-woven bags suitable for retail, promotional, and industrial use.

Products: Non-woven shopping bags, loop handle bags, customized bags.

Strengths: Customization options, sustainable practices, affordable pricing.

**3. Consider Key Factors

Quality: Ensure the manufacturer uses high-quality non-woven fabric and has a strict quality control process.

Customization: Look for manufacturers that offer customization in terms of size, design, color, and printing.

Production Capacity: Verify that the manufacturer can meet your order quantity within your desired timeline.

Pricing: Compare prices from different manufacturers, keeping in mind that the cheapest option may not always offer the best quality.

Reputation: Check online reviews, testimonials, and ratings to assess the manufacturer's reputation.

**4. Request Samples and Quotes

Contact the shortlisted manufacturers to request product samples and detailed quotes. This will help you evaluate the quality and pricing before making a final decision.

**5. Evaluate After-Sales Support

Ensure the manufacturer provides good after-sales support, including assistance with any issues related to the order, delivery, or product quality.

Conclusion

Finding the top non-woven carry bag manufacturer requires careful research and consideration of your specific needs. By assessing your requirements, researching reputable manufacturers like Favourite Fab, Sahil Graphics, and Sky Flexi Pack, and comparing quality, pricing, and customization options, you can choose a supplier that meets your expectations.

0 notes

Text

How to Enhance Your Product’s Shelf Appeal with Modern Packaging

In the rapidly evolving world of packaging, businesses are constantly on the lookout for materials that are not only durable but also visually appealing. One such innovation that has revolutionized the packaging industry is the bopp woven bag. These bags have become a preferred choice for packaging a wide range of products due to their unique combination of strength, flexibility, and aesthetic appeal. Among the leaders in manufacturing these versatile bags is Sudarshan Add Pack, a company renowned for its commitment to quality and innovation.

What Are BOPP Woven

BOPP (Biaxially Oriented Polypropylene) woven bags are a type of laminated woven polypropylene bag. The term 'Biaxially Oriented' refers to the process where polypropylene film is stretched in both the machine direction and across the machine direction to create a material that is exceptionally strong and durable. This film is then laminated onto woven polypropylene fabric, resulting in a bag that combines the toughness of woven fabric with the attractive finish of BOPP film.

These bags are known for their excellent load-bearing capacity, tear resistance, and moisture protection. They are widely used for packaging products like grains, animal feeds, fertilizers, seeds, and chemicals. The BOPP film also allows for high-quality printing, making these bags an excellent choice for companies looking to enhance their brand visibility through vibrant, multi-color designs.

Advantages of BOPP Woven

Strength and Durability: The woven polypropylene fabric provides BOPP bags with superior strength, making them ideal for carrying heavy loads without the risk of tearing or bursting.

Moisture Resistance: BOPP woven offer excellent moisture resistance, which is crucial for packaging products like grains and fertilizers that need to be kept dry. The laminated BOPP film acts as a barrier against moisture, ensuring that the contents remain intact and unaffected by environmental conditions.

Aesthetic Appeal: One of the standout features of BOPP is their visual appeal. The BOPP film allows for high-quality, photo-realistic printing, enabling businesses to display their brand and product information in a visually striking manner. This not only enhances the product’s shelf appeal but also helps in creating a strong brand presence.

Customizability: BOPP woven can be customized in terms of size, shape, and design. Whether you need a bag with a specific capacity or one that features your brand colors and logo, BOPP woven can be tailored to meet your specific requirements.

Eco-Friendly Option: Despite their durability and strength, BOPP woven are eco-friendly. They are reusable, recyclable, and produce less waste compared to other types of packaging materials.

Pioneers in BOPP Woven

When it comes to sourcing high-quality BOPP woven, Sudarshan Add Pack stands out as a trusted name. With years of experience in the packaging industry, Sudarshan Add Pack has earned a reputation for delivering products that meet the highest standards of quality and performance.

Sudarshan Add Pack is dedicated to providing its customers with packaging solutions that not only meet but exceed their expectations. The company’s BOPP woven are crafted using state-of-the-art technology and the finest materials, ensuring that each bag is strong, durable, and visually appealing.

The company offers a wide range of BOPP woven, catering to various industries such as agriculture, chemicals, and retail. Each bag is customizable, allowing businesses to create packaging that is uniquely tailored to their brand. Sudarshan Add Pack's commitment to innovation is evident in the quality of their products, making them a preferred choice for companies looking for reliable and attractive packaging solutions.

In addition to quality, Sudarshan Add Pack places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific packaging needs and delivers solutions that are both practical and cost-effective. Whether you need a large quantity of bags or a small, customized order, Sudarshan Add Pack ensures that you receive products that meet your exact specifications.

Conclusion

In the competitive world of packaging, choosing the right materials can make a significant difference in product presentation and protection. BOPP woven offer an ideal solution for businesses looking for packaging that is durable, moisture-resistant, and visually appealing. With Sudarshan Add Pack, you can be assured of receiving top-quality BOPP woven that are tailored to your needs. Their commitment to quality, innovation, and customer satisfaction makes them a leader in the industry, and a reliable partner for all your packaging requirements.

0 notes

Text

Nichrome’s bag filling solutions bag first place

Most of the powder packaging and bag filling machine manufacturers in India are based out of Pune, Ahmedabad, and Jodhpur. Nichrome, a Pune-based leading bag filling machine manufacturer, has carved an exclusive niche for itself in the bag filling machine market for a number of compelling reasons.

Growing Market

The increasing demand for bag filling machines is fuelled by the rise in people’s preference for processed and packaged goods, increase in income & population. In India, the powder packaging system market is growing by leaps and bounds. New powder packaging system and automatic bag filling machine manufacturers are cropping up in places where masala packing, and bulk bag handling systems are needed.

This trend is also apparent because the overall powder packaging machine industry is also expanding rapidly. Indian players are under pressure to upgrade their powder packaging systems, especially masala packing systems because of intense competition from Chinese companies.

Nichrome Leadership

Nichrome leads the pack in bag filling machine and powder packaging machine manufacture in India. Our claim to have carried out 10,000 successful installations in 45 countries is hitherto unchallenged.

We are known for the reliability of our powder packaging machines and masala packing machine range. We are the preferred choice for bag filling machines, bulk bag filling machines, powder packaging machines, and masala packing systems.

Nichrome is the frontrunning manufacturer of powder packaging machines for the simple reason that it has a surprising range of products best suited for masala packing and powder packing. Our powder packaging machines are compact, durable, energy efficient and increase profitability.

Astounding range

We offer a variety of bag and powder packaging machines, including:

Excel 400 Plus Servo Auger: With print mark scanners, static charge eliminator, servo motor driven bag length control

Sprint 250 Plus Servo Auger: With perforation system, exact film length pulls, bagger speed 120 packs/ minute.

Maxima 200: Bagger Speed 200 packs/minute, servo auger for precise filling

Maxima 400: Bagger Speed 400 packs/minute, servo auger for precise filling

Each of these variants are best in class and offer speed, accuracy, versatility, and low maintenance. Nichrome is adept at customizing integrated powder packaging machines, especially masala packaging systems, to suit the specific needs of the customer in terms of product type, bag shape, and volume.

Bulk bag filling systems

Nichrome also offers automatic bulk bag packing filling machines best suited for powder packaging and masala packing. They are ideal for packing large bags of 5 kg to 50 kg. Nichrome bulk bag handling systems are designed for products such as rice, sugar, grains, pulses, flour, and cake mix. These PLC/HMI fitted machines deliver output rates of 20 bags/minute.

Powder, masala packaging

Nichromemasala and powder packaging solutions pack pouches, sachets, and jars. Nichrome’s Double Head Wing Servo Auger Filling machine, which is a superlative powder packaging solution runsathigh speed and is reliable for spice powder packaging like chilli, turmeric, coriander, sambar powder. It can be used for nutraceutical powders premix, health drinks, energy drinks and beverages, coffee, and dairy whitener.

For pouch quantities up to 2 Kg, Nichrome’s Sprint 250 Plus series of powder packaging machine advantages are:

Dexterity, accuracy, and productivity

Packaging for wide variety free-flowing and non-free-flowing powders like ground coffee, masalas, flour, baking mix and granules.

Vertical form fill seal (VFFS) machines that save energy.

Require lesser floor area, produce pillow seal pouches.

Nichrome’s EXCEL PLUS series comes with many advantages:

Ideal for powder & granule bag filling

Fully automatic

Includes servo motor driven bag length control.

Can be integrated downstream or upstream to existing equipment.

Versatile for powder packaging, grain, snacks, masala packing

Conclusion

Nichrome is the best option for bag filling machines, powder packing and masala packing systems. If you need a reliable bag filling machine or a powder packing machine manufacturer, call us now and we will customize our solution to perfectly match your requirements.

#innovative packaging solutions#bulk bag filling machine#automatic packaging machines#packaging machine manufacturers#packaging machine manufacturer#milk packaging machine#integrated packaging solutions

0 notes

Text

Printed Fabric Manufacturers for Upholstery - Response Fabrics

Printed Fabric Manufacturers for Upholstery

If you want to get the best Printed fabric manufacturers for upholstery in India then Response Fabrics is one of the top well renowned manufacturers of a broad assortment of Printed fabric, Artificial Leather Fabric, Upholstery Fabric, Mesh Fabric, Blackout Fabric, etc. The offered fabrics are woven at the well-developed manufacturing unit by making use of premium quality yarns, and threads in compliance with defined quality standards. The production department is well-furnished with ultra-modern machines, tools, and equipment to weave these fabrics.

Upholstery Fabric Manufacturers & Suppliers in India

Response Fabrics has the best solution for the best selective variety of upholstery fabric that is a delight to those who wear it as well as those who touch, and see it. The collection of upholstery fabric online gives the best look altogether. The threads used in our cotton fabrics are durable, and fade resistant. This brings great joy for all the customers who buy cheap upholstery fabric from our online store & enjoy different benefits from these.

Upholstery Fabrics are made from a soft feel, high-strength, fire-retardant vinyl fabric, we don’t compromise with the comfort, and elegance, but without the price tag you’d expect. The Responsive Fabric Upholstery Fabric is extremely easy to wipe down, delivering true comfort.

Printed Holland Velvet Upholstery Fabric

Response Fabrics are a leading Manufacturer & Supplier of a wide range of single tone micro velvet fabric, two tone velvet fabric, printed velvet fabric, micro velvet fabric, red velvet fabric, digital printed velvet fabric. We have constructed a wide, and well functional infrastructural unit that plays an important role in the growth of our company. We offer these products at reasonable rates, and deliver these within the promised time-frame.

Purchase Premium-Quality printed upholstery fabric

We, at Response Fabrics, aim to make the best premium-quality printed upholstery fabric available at pocket-friendly prices. All our products go through various quality checks before they are sent out. We know that investing in furniture is a big-deal that’s why all of our products are made with utmost care, and expert specialization. Our range of affordable Upholstery fabric is sure to spruce your home, and furniture up.

Printed Cotton Fabric Manufacturers

This manufacturer of fabrics offers the excellent quality of printed cotton fabrics. These cotton printed fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Printed Fabric Manufacturers in Surat

For the best Manufacturer & Exporter of Printed Fabric Manufacturer in Surat check the Response Fabrics that is the Professional Supplier of High Quality Designer printed Fabrics in Surat. We specialized in supplying quality printed Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we.

Custom Print Fabric India

Response Fabric offers the best creative custom print fabric that is one of the finest on demand fabric printing companies in India. We offer digital printing on all fabrics, and can do digital printing on all knitted, woven, and felt fabrics like cotton, linen, polyester, rayon, wool, etc. At responsive fabrics, we provide aesthetic, and cost-efficient solutions to all textile needs.

cotton printed fabric wholesale price

The price of cotton printed fabric wholesale is starting from Rs. 70\Meter, and goes on.

printed cotton fabric manufacturers in ahmedabad

Response Fabrics brings the best printed cotton fabric manufacturers in Ahmedabad with a wide range of printed designs. These are made from certified fabric sourced from vendors of high repute after doing a diligent quality testing as per international standards. These products are attractive in colors, mesmerizing patterns, and quality fabric.

READ MORE...Home - Response Fabrics

#Printed Fabric Manufacturers for Upholstery#Upholstery Fabric Manufacturers & Suppliers in India#Printed Holland Velvet Upholstery Fabric

0 notes

Text

plastic carry bag manufacturers in vadodara

Koshambh specializes manufactures high-quality, fancy and eco-friendly plastic bags in large quantities. We offer different kinds of plastic carry bags and bags for packaging different agricultural foods and products in various colors, sizes, shapes, materials and prints as per your requirements. Equipped with innovative modern technology and infrastructure, we produce the best quality of carrying bags in bulks for every and any day usage at affordable prices. Also, our plastic products ate 100% Export Oriented Units.

We manufacture plastic bags using the best raw materials as per the type of polyethylene bags in the market. It includes High-density polyethylene (HDPE) Polypropylene (PP) Craftpaper and Non-Woven materials. Located in Halol and Manjusar, Vadodara, Gujarat, we produce 6050 metric tons of plastic bags a month. Our powerful extrusion machines and processes perfectly mix all the raw materials. Once the plastic strips are ready, we cut it in different sizes as per the customer’s requirements. The plastic bags are then strongly stitched to make sure it’s durable. The final part is printing, where we add colours and emboss branding and prints. We make sure we only give you the best quality bags so that one can carry everything and anything desire

Koshmabh understands that with a great manufacturing process comes greater responsibility. Plastic and plastic waste management is something that the world is fighting together to make our mother earth a better place for our future generations. As a leading exporter and manufacturer of the country, we also manufacture biodegradable and eco-friendly plastic bags that decompose easily and do not harm our environment.

Contact Us For more detail - inquire us at +91 265 2334401 Mail to: [email protected]

Address

301-302, Gamthi Complex, Opp. Productivity Council Productivity Road, Alkapuri, Vadodara - 390007 Gujarat India

Inquire us your requirement

0 notes

Text

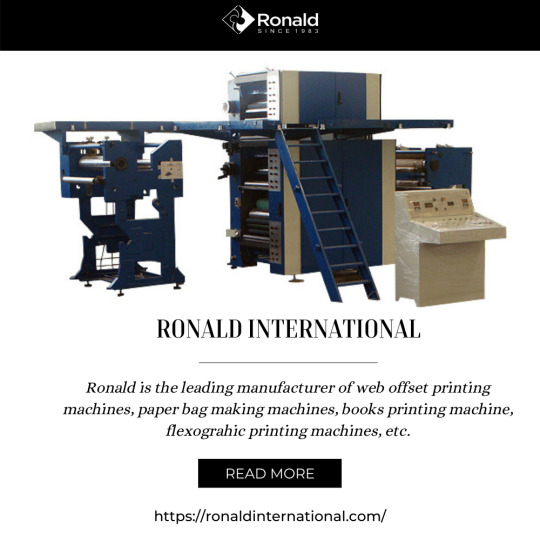

Ronald is the leading manufacturer of web offset printing machines, paper bag making machines, books printing machine, flexograhic printing machines, etc. Get the best price today!

#square buttom paper bag machine#Paper carry bag machine#paper carry bag making machine#flexo printing machine manufacturers#flexographic printing machine manufacturers in india#flexo printing machine#flexographic printing machine#book printing machine#book printing machine cost in india#newspaper printing machine#Remote Inking#book printing machine cost#web offset machine

1 note

·

View note

Text

NICHROME’S FOOD PACKING MACHINES FOR AFRICA ARE STELLAR!

Packaging has a dual role. It maintains food quality and attracts customers to the retailers’ shelves. Most food shoppers are likely to making a buying decision on judging food quality from the package. The food packing machine plays a pivotal role in the saleability of the packaged food.

Packaging is usually designed to be unique to the food product in a sugar filling machine and sugar packaging machine that Nichrome India Limited supplies in Kenya, Africa. Nichrome undoubtedly rules the roost in supplying packaging machines in Kenya.

Nichrome has established its brand identity, brand recall and boosts sales in Kenya, Africa. Nichrome’s packaging machines in Kenya are best-in-class. Nichrome’s food packing machines are preferred the world over.

Companies have carried out research to determine the best ideas for packages that protect the product from chemical reactions, light, and dust. Among the many food packaging machines that Nichrome India Limited supplies in Africa are grain packaging machine, seed packaging machine, vertical form fill seal machines. These are but an industry norm in Kenya.

Africa Packaging Market

The Africa packaging market is deemed to cross a CAGR of 8.4 per cent during the forecast period (2021-2026). The Kenya packing machine for food products market is driven by an expanding population of younger consumers, consumer product demand, burgeoning incomes, and a thriving domestic economy.

The growing concern for quality of beverages and pharmaceuticals are driving the market towards glass containers and bottles (owing to aesthetics &recyclability). And packing machines for food products boost sales indirectly.

Nichrome in Africa

Nichrome India Limited (Nichrome) has been serving Africa with its bleeding-edge automated packaging machines for over 15 years. Our sugar packaging machine, sugar filling machine, rice packaging machine, seed packaging machine, vertical form seal fill machines, are but industry standards in Kenya. We are committed to empower manufacturers in the region.

Over years, we have garnered a trusting customer base. Our 'single point' capabilities, turnkey packaging solutions, and high-end packaging machines priced affordably, have won us brand loyalty.

Nichrome’sSprint 250 Plus Weigh Filler

Nichrome’s Sprint 250 Plus Series is a godsend to the global food packing industry. It is efficient, versatile and can be fully integrated with existing lines.

Sprint 250 Plus series has the capability to fill up to 2 kg-10 kg of food per pouch. Nichrome’s Sprint 250 Plus series features speed and accuracy. Use cases vary. It could be snacks, grains, or powders.

Sprint 250 Plus is an automatic machine with control engineering (CE) marked PLC and touch screen human-machine interface (HMI). Its servo motor driven sealing system can precisely seal while maintaining optimum pressure. It is engineered to extract the exact length of film required for packaging and features a perforation system for a chain of small pouches.

Nichrome’s Excel Plus Series

Nichrome’s Excel Plus Series comes with an additional advantage of automation equipped with CE marked PLC Controller and touch screen HMI. Salient features include print mark scanners, servo motor driven bag length control system, and adjustable stroke of cross sealing jaws for optimum performance. It is designed according to stringent quality standards and can be easily integrated into upstream or downstream machines/systems.

��Benefits Of Pouch Packaging

Most pouches are easy to carry and reseal, making them more versatile. Nichrome is the pioneer of pouch packaging in India; a brand is an Avant Garde in cutting-edge packaging tech. Nichrome’s global footprint spans 45 countries and over 7000 installations.

Nichrome’s Sugar Packing Machine

Nichrome seeks to offer innovative and versatile sugar packaging machines that preserve the inherent goodness of sugar and enhance brand value. Nichrome's integrated sugar packaging machines help manufacturers package various quantities of sugar up to 10kg in versatile pouch formats which are hygienic, leak-proof, and storage convenient. Nichrome's sugar packaging machines are engineered to function at a speed of 120 pouches per minute accurately…with minimal wastage.

Vertical Form Fill Seal (VFFS) Machines

Vertical Form Fill Seal (VFFS) packaging machines use a single sheet of film material rolled around a core, usually referred to as roll stock. The continuous length of packaging material is referred to as the film web. This material can vary from polyethylene, cellophane laminates, foil laminates and paper laminates. The roll of film is placed on a spindle assembly at the rear of the machine.

When the VFFS packaging machine is operating, the film is usually pulled off the roll by film transport belts, which are positioned to the side of the forming tube which is located at the front of the machine.

This method of transport is the most widely used. On some models, the sealing jaws themselves grip the film and draw it downward, transporting it through the packaging machine without the use of belts.

Conclusion

Nichrome India Limited comprehends exact requirements and pain points and delves deep to determine the right solutions for customers. We partner with customers throughout the entire product lifecycle and innovate on tailor-made solutions that exceed customer expectations with their performance, cost-efficacy, and reliability.

#food packing machine#sugar filling machine#sugar packaging machine#packaging machines in Kenya#food packing machines#grain packaging machine#seed packaging machine#vertical form fill seal machines#rice packaging machine#vffs packging machine

0 notes

Text

Best Carry Bag Printing Machine Manufacturing Company in India

Decent Print Lines is a leading manufacturer and supplier of Carry Bag Printing Machines in India, renowned for delivering high-quality, efficient solutions to meet diverse printing needs. Our state-of-the-art machines are designed to handle various types of carry bags, including plastic, paper, and non-woven options, ensuring vibrant, precise prints with exceptional durability. Equipped with advanced printing technology, our machines offer features such as multi-color printing capabilities, high-speed operation, and user-friendly interfaces, making them ideal for both small-scale and large-scale production.

At Decent Print Lines, we focus on innovation and quality, providing machinery that enhances productivity and reduces operational costs. Our commitment to excellence is reflected in our rigorous quality control processes and reliable after-sales support. Whether you need a machine for custom designs or high-volume printing, our team is dedicated to offering tailored solutions that fit your specific requirements. With a strong emphasis on customer satisfaction, Decent Print Lines is your trusted partner for top-notch carry bag printing solutions in India.

For More Details

Contact us :- +91-9911433180

Email Id :- [email protected]

Address :- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#carry bag printing machine manufacturer in india#carry bag manufacturer#carry bag printing machine manufacturer

0 notes

Text

All India Machinery - Plastic Blown Film Extruders, Flexo & Rotogravure Printing Machines Manufacturer, Exporter and Supplier

All India Machinery is a renowned and world-class manufacturer, exporter, and supplier of Plastic Blown Film Extruders, Flexo and Rotogravure Printing machines. The company was established in 2017 and is based in Mumbai and has enjoyed the pinnacle of success in the world of blown film and printing machinery industries. With an experience of over 25 years and expertise in manufacturing lifecycles, sales, integrated marketing, creating events, boosting performance, and enhanced professional consultation, this organization has everything which enables it to have its presence in more than 25 countries including export to Qatar, Bahrain, Kenya, Saudi, Canada, Peru, Morocco, Italy, Mexico, Tanzania etc.

All India Machinery strives to be the largest company of offline and online printing machinery in the world by 2025 with its core values of constant innovation, collaboration, result orientation, honesty, and trustworthiness in place. With all the leadingtechnological know-how, All India machinery has participated in worldwide business meetings on how to increase profitability. Reusing and recycling plastic has been made much easier and the company focuses on total quality control. This superlative performance is because of the state of art manufacturing practices adopted that aim at precision and perfection. The team is a comprehensive one that offers solutions for all the client needs and has the ISO 9001- 2015 certification.

All India Machinery is a one-stop solution for all Blown film extruders and Flexographic and Roto Gravure printing machines with models that give an exemplary performance. The wide range of products with advanced technology enables this company to have a total grip over the market needs. Any impediment in the machinery operation is taken care of and various variants are suggested to cater to the specified needs of clients. An Outstanding bag making system is also guaranteed owing to the years of expertise in the field. We ensure that all our clients get the utmost satisfaction and end-to-end services with the best quality.

The range of Products at All India Machinery includes-

Flexo Printing Machines Flexo printing machines come in various models like the two colors high-speed Flexographic printing machine, the medium Flexo printing machine, and the mini Flexo printing machine. These machines offer a very easy installation and operation with superlative printing results. Flexographic printing machinery offers consistent quality and great durability.

Roto Printing Machines

These models include the online and the inline Roto Gravure Printing Machine, the single and two color floor mounted Roto printing machines which are greatly user-friendly and offer hassle-free operation. Any kind of wastage is reduced and production costs also are significantly curbed. The rotogravure is a cost-efficient printing process and the production speed is exemplary.

Tubing Machines

The long-lasting maintenance-free life offered by the Blown film extrusion machines which come in various mm’s offer tremendous versatility with speed. The output is voluminous depending on the size and gauge of the material and can be used to produce t-shirt bags, garbage bags, carry bags, grocery bags, and much more. The models like ABA Two layer Extruder runs electricity while the Corona treater machine offers a uniform treatment throughout the web width.

Sealing and Cutting Machine

The Bottom Sealing and cutting machine is a microprocessor-controlled one that has its speed synchronized with the stroke and size. There is a side sealing and cutting machine which has a silicon sealing roller driven by servo and has a sealer and cutter logic embedded. They offer a very good sealing effect and is simple to operate. Its efficiency makes it popular and much demanded.

Recycling Machines

The recycling machines include a vertical mixture with dryers and are suitable for light and semi-dense materials. These machines have minimalist power consumption and the high-speed mixers offer the efficiency of batch times of 10 to 15 minutes per batch.

1 note

·

View note

Text

Ronald Web Offset at PrintPack India – Hall 9D, Stand H-20

Faridabad-based Ronald Web Offset is an in-house manufacturer of paper carry bags since the pandemic year 2021. It brings a total solution for square bottom paper carry bags, showcasing the Ronald 450 and 360 machine at PrintPack India 2022.

Ronald Web Offset provides a comprehensive solution for creating paper bags in-house, from printing to pasting, and fastening of handles. There are various Chinese machines available in the market for creating paper bags, but what makes Ronald stand apart is its make-in-India machinery. The firm gives competition to Chinese manufacturers. In terms of costs, both Chinese and Indian machines are comparable. However, Ronald claims its equipment offers excellent service and response times. Indian clients are increasingly opting for locally produced machines," says Adithya Gupta, director of Ronald Web Offset.

The company uses Pidilite adhesives for pasting the carry bags, while also sourcing adhesives from local Delhi vendors. Ronald sold three machines – two in Kerala and one in Sonipat till the fourth day of PrintPack. It also manufactures the V-bottom paper carry bag machines – two of these machines are installed in Rajkot and Mumbai, respectively.

When it comes to the visitor response at Printpack, Gupta adds that the number of visitors is much more significant than in the last edition. "From our perspective, the expo has been a huge success," he exclaims.

0 notes

Text

Non woven fabric carry bag making machine price in india

When looking for a non-woven fabric carry bag making machine in India, the price can vary depending on several factors such as the machine's features, capacity, brand, and level of automation. Here's a general overview:

1. Semi-Automatic Machines

Price Range: ₹3,00,000 - ₹6,00,000

Features: These machines typically require manual intervention at certain stages. They are suitable for small to medium-scale production.

2. Fully Automatic Machines

Price Range: ₹8,00,000 - ₹15,00,000

Features: Fully automatic machines are capable of high-speed production with minimal human intervention. They can produce a wide variety of bag types and sizes.

3. High-End Fully Automatic Machines

Price Range: ₹15,00,000 - ₹30,00,000+

Features: These machines are equipped with advanced technology, including computerized control panels, multiple production capabilities, and higher efficiency. They are ideal for large-scale manufacturers.

Factors Affecting the Price

Brand Reputation: Established brands may charge a premium due to better quality, after-sales service, and reliability.

Production Capacity: Machines with higher production capacities will generally cost more.

Customization: Machines that offer customization in terms of bag sizes, types, and designs will have higher prices.

Additional Features: Add-ons such as printing capabilities, UV coating, and other advanced features will increase the price.

Popular Brands in India

Fairprint

Zhejiang Zhengwei Machinery

Sahil Graphics

Suntech

Sky Flexi Pack

Conclusion

The price of non-woven fabric carry bag making machines in India can vary widely based on the machine's automation level, brand, and features. It's important to assess your production needs and budget before making a purchase. It's also recommended to contact suppliers directly for the most accurate and up-to-date pricing, as prices can fluctuate based on market conditions and technological advancements.

0 notes

Text

Wood Crafts

Wooden Crafts are the artistic practice of shaping and decorating wooden objects. India is famous for wooden handicrafts. Skilled craftsmen of each state create handicrafts using wood that is available locally. The most common varieties used to make Indian handicrafts are teak, sheesham, sal, oak, mango, ebony and mahogany. Sandalwood, rosewood and walnut are the exotic varieties and are expensive and are used in producing fine pieces of furniture and decorative items. There has been a complete revival of the traditional and antique wood craft, owning to its uniqueness and demand in India and abroad. Indian artisans are experimenting with designs to create a blend of traditional and modern woodcraft. Each piece of Indian wooden handicraft is a labor of love, sweat, and patience, which no machine can replicate.

Wooden Toys and games are winning mass of quality these days. The wooden toys and games are put up in innovative as well as classical types that are energizing and thought-provoking for everyone to examine their power. A heavy number of attractively fashioned wooden toys and games will offer hours of amusement. They are designed with exquisitely workmanship and paragon for people of all age-groups.

Designed with expert workmanship, wooden toys have arrived at immense popularity and are perfect for people of all generation. The most widely playacted wooden toys and games are wooden chess and wooden carrom board. The wooden toys are carefully carved and attractively designed engaging a special place in lots of families. Wooden toys and games are meant for kids and adults both, and are perfect items for gifting purpose. They are handcrafted with extreme care to have an eye-catching visual aspect. They provide durable fun and are designed to germinate coordination and imagery power among children. The most widely played wooden toys and games are wooden chess and carrom-board. In order to make them easier to carry while traveling, they are available in wooden box which makes them excellent for gift items.

Festival Wooden Crafts are very popular. Many companies prefer to give away various wooden gift items as corporate gifts as they are durable and elegant. When wooden items are purchased in wholesale from suppliers or exporters, they prove to be very cost effective. In fact, when companies directly deal with the wooden gift manufacturers, they save a lot of money by avoiding the middlemen in suplly chain. However, wooden corporate gifts might be procured on cheap rates, they always look more expensive due to craftsmanship of the artisans as well as because wood itself is considered to be an expensive medium to make craft items. They can be offered on various occasions including retirement , transfer or anniversary etc. They help in encouraging and motivating people who really deserve to be appreciated. It helps in minimizing attrition rate as well as staff turn over. Wooden gift items cam also be customized as per the requirement of various companies.

Acrylic Charms are made with a solid, clear acrylic material that can be printed in full color and cut to any shape. Acrylic charms feature a small 0.085” (~2mm) cut hole for creating your own keychains, jewelry and more. These Acrylic Crafts have been a real hit! Acrylic charms consist of either one layer of acrylic board with an epoxy-covered image on top (or on bottom, if you prefer the acrylic layer over the front and epoxy on back), or two layers of board with the image sandwiched in between. The image itself can be one-sided or two sided.

Acrylic Rhinestones are so attractive! When we go shopping in department stores or walk on the road, we often see various shapes and sizes of rhinestones on shoes, bags, jewelry, and even displays. The rhinestones are colorful and shiny, and it is difficult to ignore them. Rhinestones are not diamonds; they are a simulation of diamonds. Since diamonds are natural and are formed under high pressure and high-temperature conditions deep in the earth, often taking a long time to form, they are scarce and very expensive. Rhinestones are artificial and have the sparkling, dazzling effect of diamonds. Therefore, when rhinestones could be manufactured in large quantities, people began to use rhinestones as decorations for jewelry, clothing and other accessories.

Forty years ago, the sending and receiving of Christmas Greeting Cards were one of the steps in declaring adulthood and establishing one’s own home. Part of becoming an adult was communicating the year’s events to family and friends.

In the Christmas letter that went with the card, there was some bragging about the good things in one’s life but it was also a vehicle to let people know about deaths or difficulties.

As Christmas became more about persuading consumers to buy, greeting card companies understood this. They grew their sales by offering greater varieties of cards, including boxed sets and charitable cards. Businesses began sending greeting cards to each other as a thank you for the work done together that year.

0 notes

Text

Importance of Using Paper Bags

Carrybags has become a more convenient way to carry daily necessities and for packaging in small quantities. The well-known form of such bags is in the form of plastic bags. Despite of all known hazards of plastic pollution, it’s prevalent and pervasive in India. Plastic bags are one of the worst and most unnecessary plastic polluters of the earth. Plastic bags are used on a large scale by retailers for a simple reason that plastic bags are much cheaper than paper, cloth or other eco-friendly bags. This paper presents the designing and development of asystem to automate the procedure of paper bags production so as to make its production cost comparable to plastic bags and inherently increase its production rate so as to fulfill the ever increasing demand. We have used micro-controller based design approach which has kept the cost of the system significantly low as compared to PLC based designs and have automated the manufacturing process.

We need small size bags every day for various purposes like grocery, fruits, and vegetables. We use plastic bags for such purposes. Plastic shopping bags have a surprisingly significant environmental impact for something so seemingly innocuous. Plastic shopping bags kill large numbers of wildlife each year. One of the most dramatic impacts is on marine life.So to avoid above harmful effects of Plastic Bags, viable alternative is required which is Paper Bag. Actually, Paper Bag is being used but in very small scale. Conventional Paper Bags requirespecial paper which increases the overall cost of the Paper Bag. This is the main cause due to which use of Paper Bag is less. Also initial investment cost is very much in conventional paper bag making machine. So it cannot be used for small scale production.All these problems are eliminated in the presented machine. Amachine whose initial cost is less, which does not require any special paper, which can be used for small scale production, is developed. Thismachine willhelp a poor family to earn money through small scale production of paper bags.

Paper bags have been gaining popularity since then plastic bags have been banned in various countries and cities. The product is made in two ways; traditionally, i.e. manual which is a manual or technical means i.e. with the help of automated equipment. The second method is much larger. In other words, it requires less workers and more money to buy land and equipment. Based on the core business of nonwoven bag making machine Manufacturers, the machine has 2 different output capabilities with good finish and seamless quality.

Amazing Benefits of Using a Paper Bag Production Machine: -

Excellent Quality: The great advantage of producing a paper bag from an automated machine is the excellent quality one can achieve throughout the production process. When we make paper bags in traditional ways, the quality of the product does not always match the whole production process. It is difficult to maintain the same level of quality per unit. Machine paper bags offer the same quality and precision each time.

Save on Work Expenditure: The introduction of an automated production process machine including slitting machine has reduced the need for workers in the paper industry. One only needs to change the paper roll and collect the finished product after the production process is completed. This saves unnecessary costs on jobs and you can invest in machinery and land instead of workers. Too much machinery and land can lead to a double standard of business production at the same time.

Distributed Production Level: Quality and fast production are two of the most important factors in any production process and automated production for the purpose of the product satisfies both of these factors while improving the quality of production. Save real time financially and increase your productivity compared to handmade methods. You can actually upgrade your product over time.

Energy Saving: An automated machine saves human energy and helps increase productivity. Both man and machine have different working powers. The machine can work more efficiently than man and requires fewer working breaks than man. You can have a good level of mechanical production. The machine can double your production rate at the same time. However, one can only increase the product because everyone has a different working capacity.

Paper bags are gaining importance as these bags are 100% reusable, recyclable and biodegradable and at the same time environment friendly and pose less threat to wildlife. it requires less energy for paper bags to be recycled than plastic bags. Paper bags have come a long way since their beginnings in the mid-eighteenth century when some paper bag manufacturers started developing paper bags that are more hardy and long lasting. The paper bags are generally box-shaped in design that allows them to stand upright and hold more goods. Corporates are using paper bags for promotions, seminars, product packaging and branding purposes.

By selecting high quality paper bag manufacturer can deliver recycled brown color paper bags in big and small quantities, regular and premium paper bags which add a professional touch that consumers love and appreciate. Besides, you can add your own custom brand to any paper bag to promote your business. Read on to discover the importance of paper bags.

1. Plastic bags cause environmental damage such as increase the level of air pollution. Plastic bags not only have adverse effects on our natural habitats, death of many animals. Plastic bags are not renewable and you need UV rays to destroy it, which is harmful for environment.Paper bags on the other hand are environment friendly and can be recycled.

2. Paper bags are usually made from wood. So, these bags can be produced into a new paper like newspapers, magazines or books. Waste papers are also biodegradable so they can be easily degenerate and do not pile up on dump sites.

3. You can also buy them at a very cheap price particularly if they are bought wholesale.

4. Possessing a paper bag is practical and you can use them to bring your groceries and the premium quality paper bags can be used as paper gift bags.

5. Most people nowadays prefer using paper bags because they are easy to carry, neat and can hold lot of items. It adds to your status symbol as they can be embossed and grained to enhance the look.

6. Paper bags are usually used extensively in malls and exhibitions for delivering over the counter products as research shows that paper bags contain at least 35% recycled material.

7. Corporates are nowadays using paper bags for promotions, seminars, product packaging, and branding purposes as they are competitively priced.

8. Paper bag manufacturers can help you to decide the right size and type of paper bags as per your project, budget and quantity.

9. You can choose paper bags with special properties that will seal the freshness and give an aesthetic look to your brand as offset and screen printing is possible.

10. When your product is properly packaged with premium quality paper bags, you can attract more customers which will help in promoting your brand to the targetaudience.

So, if you are ecofriendly and at the same time want to be ahead of your competitors, start using paper bags.

0 notes

Text

Japan & Japanese through my eyes........

I wish to give you a brief background of my association with Japan & Japanese. It began in 1975 when I worked for Engineers India Ltd. in New Delhi. I was part of a project management team to look after a petrochemical project called “Acrylic Fiber” at IPCL, Baroda. The process technology came from Asahi Chemical and Front-End Engineering was carried out by Kobe Steel. They had deputed a full time Japanese at EIL office.

Next association was in 1980-81 when I took a field engineer job withToyo Engineering at Basra, Iraq. For about 15 months, my immediate bosses were Japanese, though there were many Indians on site.

My close and strong association was from 1984 to 87 when I was a project manager and managed a collaboration with Chiyoda Corporation of Japan to execute an EPC project at NFL, Guna.

I along with my family moved to Yokohama, as Chiyoda Corp. offered me a direct employment. My office and my daughter’s school were also in Yokohama.

I again had a chance to work with Japanese when Chiyoda set up a joint venture with L&T called L&T –Chiyoda at Baroda in the 90’s.

Lastly, I was asked to manage Chiyoda’s liaison office at Bangalore for two years in 2012-14.

I will segregate my observations in two parts- one from the people and another from the country. Most people know of the punctuality of Japanese and discipline at workplace Hence, I will not dwell on these.

Most Japanese are concerned and sensitive of the discomfort or needs of fellow person. You can see that a Japanese not only picks up used plates and tray with trash in a McDonald’s but also wipes the table. You observe that a mother carries two types of napkins – one wet and another dry- when she takes her kid(s) out to play in the public garden. She cleans the child’s dirty hands with wet and then with clean napkin so that it does not dirty the rails or seats of the garden. Even in 90’s I saw Japanese wearing mask when they suffered from cough and cold. It was a common sight to see the dog owner carrying a paper bag and some broom to pick up poop.

Japanese people do not commit petty crimes or cheat which makes life so stress free and safe. My wife used to leave the apartment door open to go shopping nearby for 30 to 45 minutes. She learnt of this practice from neighbours. Initially we used to keep the money in our palm and the shop keeper would take the appropriate amount. All the shops-small or big – always charged us the VAT, whether we wanted a receipt of not. First time in my life I was offered a printed receipt of fare charged by a metered taxi without asking.

Japanese introduced us to see the beauty in the nature. The first time in our life we went to the mountains to see the autumn colours. There were conducted tours for local people to come to the mountains and soak in the beauty of the shades of colours from green to golden. We were also witness to the fire which is light up to dry leaves/grass on the mountain sides. The fire is light and controlled to spread in artistic way and you watch it from across the valley. Another experience was of hot (sulfur) springs in the mountains near Tokyo (Hakone). Our company guesthouse had a huge pond kind of hot water spot where natural spring was brought in. We soaked in this pond in the Japanese way-no clothes and separate areas for women and men. In five-star resorts, one could soak in the hot spring and sip from a glass of beer.

Japanese were also very health conscious. Our office had an indoor all weather Olympic size swimming pool and full-fledged gym with an instructor. Some of my colleagues were using this during lunch time before eating lunch. I used the facility on weekends. I went to a gym first time in my life and swam when there was almost zero-degree centigrade ambient temperature outside.

Japanese also retained some of “Indian” habits which may have reached them through Buddhism. Outdoor footwear cannot be used indoor whether in the residence or Japanese restaurants. We must leave outdoor footwear at the door and use in house slippers to go in. Most Japanese prefer to sit cross legged and ladies in Vajrasan. They do not shake hands or hug when the meet but bow and greet. Most prefer to sleep on the ground on a mattress rather than a western bed.

Japanese also have found ways to de-stress after an incredibly stressful office or factory workday. Karaoke bars are popular and now world famous. The normal bars without karaoke are also popular. They had huge halls with “ball” machines when they play a special game with stakes to lose or win, like what we played as a child. They also enjoy comics and there are comics to entertain all age groups.

Japan as a country is different from India. India is heterogeneous whereas Japan was homogeneous. This one feature made a lot of difference. They had only ten public holidays every year. Japanese was the main language for locals and it was developed to ensure that students get the latest information also. Japanese language also brings a very peculiar character to the people. The language has three alphabets-Hiragana, Katakana and Kanji. Kanji has no letters but only Chinese characters/pictures. There are over few thousand kanjis and a child takes more than 8 yrs to know them all though only a few hundred Kanji is extensively used. To write Kanji one must be precise and take care of the different strokes. This focus on details and accuracy is reflected in everything they do in my opinion.

The police in Japan were extremely helpful and friendly. On two occasions I got their help. Once I was lost in the central Tokyo area and I went to the police station. The policeman there came with me to show me the address. On another occasion, my family and me went to meet my friend but my Casio watch, which had his telephone no. ran out of battery and I was lost. I again went to police station near the rail station. He permitted to call my office to find out the contact no. of my friend (office colleague) but the office security refused. Then he opened the area map with names of the residents, and we located two Tanaka-san. I dialed the first one and fortunately he was my friend. In India, such help was unthinkable, going to the Police station for common man for help is a far cry!

I came across some interesting leave/holidays rule. Most Japanese joined a company for a lifetime and the company was expected to take care of the individual. After about 20 yrs. of service (mid-way I guess) the employee get paid leave (about 6 weeks) and a huge payment (app. one year salary). He is expected to enjoy with his family and many of colleagues went to Europe, USA or Latin America for two to three weeks with family.

I was happily surprised that most school students including my daughter walked to the school. My daughter walked about 20 minutes each way, there were volunteers on the route to guide the school kids. No school bus or parents driving to drop or pick-up kids.

For common people, the basic unwritten rule was- provide goods and services which are high quality and reliable. All public phones (as the world was not exposed to internet or mobile phones at the time) were in working order with coins or prepaid cards for both domestic and international calls. Such phones were plenty and located at all convenient locations like rail stations, supermarkets and including lift lobbies in office buildings. ATM rooms of banks had ATM machines for withdrawal and transfer facility. There were two other machines-passbook printing and change dispensing. ATM rooms were open 24x7. Japan was most known for vending machines- variety and exceptionally reliable. Vending machines would dispense soft drinks, beer, hot and cold coffee, tea, small snacks packets etc. These machines would not be out of stock and returned change.

Japan acts in unison for trade/commerce without side world. Immediately after WWII, their economy was shattered but soon they got on their feet. The five trade houses –Sumitomo, Mitsui, Marubeni, C Itoh and Mitsubishi- were the marketing agents for both import and export. The manufacturers were concentrating on design, engineering, and quality products. This brought down costs. The trade houses would bring enquiries and orders. They will also take care of payments. Each manufacturer will join a trade house so that there is no competition among the trade houses.

As a country, I saw Japan converting research output in other countries to application/products for common use. The classic example was digital watch from Texas Instrument to Casio. Another could be Video players. Even some collaborations were made successful and eventually did better than the collaborators. The classic example is of Toyota Car Co which had started with GM collaboration 1950s.

In all the efforts of private sector in commerce the Govt played a particularly important and positive role. The banks were ready to help exporters/vendors with five-month credit as L/C or other kind of payments after shipment may take 3 months.

I hope you like what I have scribbled above as much as I loved it writing.

0 notes