#Textile Manufacturing Market trends

Explore tagged Tumblr posts

Text

Textile Manufacturing Market Demand, Size-Share, News - 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Textile Manufacturing Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Textile Manufacturing Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Textile Manufacturing Market?

The global textile manufacturing market was valued at US$ 350.8 Billion in 2023 and is expected to register a CAGR of 4.9% over the forecast period and reach US$ 539.7 Billion in 2032.

What are Textile Manufacturing?

Textile manufacturing is the process of transforming raw fibers into finished textile products, involving several stages such as spinning, weaving or knitting, dyeing, and finishing. This industry utilizes a diverse array of materials, including natural fibers like cotton, wool, and silk, as well as synthetic fibers such as polyester and nylon. The process begins with the extraction and preparation of raw fibers, which are then spun into yarn and woven or knitted into fabric. Following this, dyeing and finishing treatments are applied to enhance the color, texture, and durability of the textiles. Textile manufacturing is essential to the fashion, home furnishings, and industrial sectors, playing a significant role in global economies and job creation.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2475

What are the growth prospects and trends in the Textile Manufacturing industry?

The textile manufacturing market growth is driven by various factors and trends. The textile manufacturing market is experiencing consistent growth, driven by rising global demand for apparel, home textiles, and technical textiles across various sectors. Factors such as population growth, urbanization, and evolving consumer preferences for sustainable and innovative materials are contributing to this expansion. Additionally, advancements in technology, including automation and digitalization, are improving production efficiency and facilitating customization, further enhancing market dynamics. The industry is also shifting towards eco-friendly practices, with many manufacturers adopting sustainable production methods and materials in response to consumer and regulatory pressures. Consequently, the textile manufacturing sector is well-positioned for continued growth as it adapts to changing trends and environmental considerations. Hence, all these factors contribute to textile manufacturing market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fibers and Yarns

Natural Fibers

Synthetic Fibers

Blended Fiber

Fabrics

Woven

Knitted

Non-Woven

Others

Finished Products

By Application

Fashion & Clothing

Apparel

Ties & Clothing Accessories

Handbags & Others

Household

Bedding

Kitchen

Upholstery

Towel

Others

Technical

Construction

Transportation

Medical

Protective

Others

Others

By Sales Channel

Direct Sales

Retail Sales

Speciality Stores

E-Commerce

Wholesalers

Others

By End-Use Industry

Apparel

Automotive

Medical

Agriculture

Sports

Others

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Toray Industries, Inc.

Welspun India Ltd

Donear Industries Ltd.

Hyosung TNC Corp.

Arvind Limited

BMD Private Limited

Alok Industries

Techtex India

Aditya Birla Management Corp. Pvt. Ltd.

C.CORP.

View Full Report: https://www.reportsandinsights.com/report/Textile Manufacturing-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Textile Manufacturing Market share#Textile Manufacturing Market size#Textile Manufacturing Market trends

0 notes

Text

The Synthetic Dyes Market: Trends, Analysis, and Future Outlook

The synthetic dyes market is experiencing significant evolution, driven by a variety of industries that depend on colorants for their products. As demand continues to grow across sectors such as textiles, food, and cosmetics, it becomes essential for stakeholders to understand the prevailing trends and future forecasts. This article explores the current landscape of the synthetic dyes market, providing insights into market trends, analysis, expert opinions, and future predictions.

Market Overview

Synthetic dyes, derived from synthetic sources primarily based on petroleum, are utilized in a wide array of applications, including textiles, plastics, cosmetics, and food. In 2023, the global synthetic dyes market is Projected to Reach USD 9.1 billion by 2029, at a CAGR of 5.0% From USD 7.1 billion In 2024, This growth is largely attributed to the increasing need for vibrant and high-performance dyes across various applications.

Key Trends Influencing the Synthetic Dyes Market

Sustainability Focus: The synthetic dyes sector is witnessing a growing emphasis on sustainability as environmental concerns rise. Manufacturers are investing in eco-friendly dyeing methods and developing bio-based dyes to meet the demands of environmentally conscious consumers. Innovations such as waterless dyeing technologies are becoming increasingly popular.

Expansion of the Textile Sector: The textile industry is the largest consumer of synthetic dyes. Following the recovery of fashion and textile production after the pandemic, the demand for synthetic dyes has surged. The rapid production cycles associated with fast fashion require a constant supply of vibrant fabrics, fueling market growth.

Growth in the Food and Beverage Industry: The food and beverage sector is increasingly employing synthetic dyes to enhance product appearance. As consumers become more particular about the aesthetics of food products, the demand for consistent and vibrant colors is expected to rise, driving market growth.

Advancements in Digital Printing: The advent of digital printing technology is transforming the application of synthetic dyes, particularly in textiles. This technology allows for intricate designs and customization, leading to an increased need for specialized synthetic dyes tailored for specific printing techniques.

Evolving Regulatory Standards: Regulatory bodies globally are tightening rules concerning synthetic dye usage, especially in food and textiles. This evolving landscape compels manufacturers to innovate and produce dyes that are not only effective but also comply with safety standards.

Market Analysis

The synthetic dyes market is highly competitive, dominated by major players such as BASF SE, Huntsman International LLC, Clariant AG, and DyStar Group. Companies are engaged in rigorous research and development (R&D) efforts to enhance their product offerings and capture a larger share of the market.

Regional Insights: The Asia-Pacific region leads the market, accounting for nearly 45% of the global synthetic dyes consumption. This dominance is largely due to the robust textile manufacturing capabilities in countries like China, India, and Bangladesh. Europe and North America are also significant markets, driven by stringent regulations that promote sustainable practices alongside high-quality dye demands.

Market Share and Competitive Landscape

The competitive environment of the synthetic dyes market is marked by strategic collaborations, mergers, and acquisitions aimed at expanding product portfolios and geographic reach. For instance, BASF has significantly invested in the development of sustainable dye solutions, positioning itself as a pioneer in eco-friendly products. Likewise, Clariant has introduced a variety of natural and organic dyes to address the rising demand for sustainable alternatives.

Expert Insights

Industry experts highlight the importance of innovation in the synthetic dyes market. Dr. Emily Chen, a leading expert in dye chemistry, asserts, "The future of synthetic dyes hinges on achieving a balance between performance and sustainability. Companies that prioritize eco-friendly methods while delivering high-quality products will likely lead the market." As consumer preferences shift towards transparency and sustainability, brands that effectively communicate their sourcing and production processes are expected to gain a competitive advantage.

Download PDF Brochure :

Future Outlook

Looking ahead, the synthetic dyes market is well-positioned for substantial growth. Ongoing advancements in dye technology, coupled with an increasing emphasis on sustainability, will continue to drive market evolution. Stakeholders are encouraged to embrace these changes by investing in sustainable practices and innovative solutions to maintain relevance in this competitive landscape.

The synthetic dyes market is a vibrant and essential component of the global economy, influenced by diverse applications and evolving consumer preferences. As sustainability becomes a key focus, the industry must adapt and innovate to navigate the challenges and opportunities that lie ahead.

#synthetic dyes#colorants industry#textile dyes#dye manufacturing#chemical industry#eco-friendly dyes#market trends 2024

0 notes

Text

Tanvir Rana: The Wolf Behind Wolf Thread

One of the wolves who lead the pack, Tanvir Rana has made his mark as a formidable force in the sourcing industry. As the founder and CEO of Wolf Thread, a dynamic multi-sourcing agency in Bangladesh, Tanvir embodies the strength, cunning, and leadership of a wolf. His journey from a visionary entrepreneur to a respected industry leader is a tale of relentless ambition and unwavering commitment to excellence.

Pioneering a New Path with Wolf Thread

Driven by a vision to create a sourcing agency that stands out for its reliability and authenticity, Tanvir founded Wolf Thread. This agency was born from the idea of combining strength with strategy, much like a wolf pack. By leveraging his expertise and building strong relationships with suppliers and clients, Tanvir has grown Wolf Thread into one of the largest sourcing agencies for factory stock lot clothing products in Bangladesh.

Mastering Textiles Manufacturing and Stock Lot Sourcing

Wolf Thread’s strength lies in its Textiles Manufacturing and Stock Lot Department, a sector that Tanvir has expertly developed. With access to a wide range of high-quality ready-made garments, the company caters to global buyers looking for bulk stock lot clothing. Tanvir's keen eye for detail ensures that every product meets the highest standards of quality, making Wolf Thread a trusted name in the apparel industry.

Buyers can find virtually any type of product in stock lot through Wolf Thread, from casual wear to specialized clothing items. The company also operates as a buying house, offering customized manufacturing services for large quantities, provided all formal procedures and documentation are maintained. Tanvir’s dedication to transparency and legal compliance has solidified Wolf Thread’s reputation as a trustworthy and authentic sourcing agency.

Expanding into the Energy Sector: Crude Oil Supply

Recognizing the vast potential in the energy sector, Tanvir expanded Wolf Thread’s horizons to include the supply of crude oil. By establishing the Crude Oil Supply Department, he has positioned Wolf Thread as a key player in this competitive market. Tanvir’s strategic vision and ability to navigate complex supply chains have made Wolf Thread a dependable source for crude oil, further showcasing his leadership and versatility.

Innovating with Renewable Energy: Solar Panel Installation

Tanvir’s forward-thinking approach is evident in Wolf Thread’s venture into renewable energy through its Solar Panel Installation Department. As the world shifts towards sustainable energy solutions, Tanvir has ensured that Wolf Thread remains at the forefront of innovation. Offering comprehensive solar panel solutions, the company is committed to contributing to a cleaner and greener future, meeting the increasing demand for eco-friendly energy.

Diversifying with Agro and Meat Supply

Tanvir’s ambition doesn’t stop at textiles and energy. By establishing the Agro and Meat Supply Department, he has diversified Wolf Thread’s offerings to include high-quality agricultural products, fruits, vegetables, and meat. His understanding of market dynamics and his ability to establish strong supply networks have made Wolf Thread a reliable source for agro commodities, reinforcing its position as a versatile multi-sourcing agency.

Leading the Pack

Tanvir Rana’s achievements with Wolf Thread are a testament to his leadership, strategic insight, and dedication to quality. By building a multi-sourcing agency that spans various sectors—from textiles and crude oil to solar energy and agro products—Tanvir has shown that versatility and excellence can go hand in hand. His commitment to reliability and authenticity sets him apart as a leader who not only leads the pack but also inspires others to follow.

The Legacy of a Wolf

Like a wolf leading its pack, Tanvir Rana drives Wolf Thread with a clear vision and purpose. His relentless pursuit of excellence, coupled with his strategic acumen, has made him a respected figure in the sourcing industry. Tanvir’s story is not just about building a successful company; it’s about creating a legacy that embodies the spirit of a wolf—strong, determined, and always ahead of the curve. Through his leadership, Tanvir continues to shape the future of sourcing, setting new standards for reliability, quality, and innovation.

#Tanvir Rana#Wolf Thread#CEO & Founder#CEO#Textiles#Business#Crude Oil#Rich#manufacturing#apparelandclothing#garments#agency#digital marketing#stocklots#writers on tumblr#famous#hot#trending

0 notes

Text

Synthetic Leather Market | A Comprehensive Analysis of the Global Landscape

The global synthetic leather market is anticipated to reach USD 66.24 billion by 2030 and is projected to grow at a CAGR of 7.87% from 2024 to 2030, according to a new report by Grand View Research, Inc. Growing awareness among consumers regarding animal exploitation, aided by programs run by organizations such as PETA, has played a major role in increasing the demand for leather alternatives. The growing supply-demand gap in the natural leather industry is also a major factor responsible for manufacturers opting for synthetic or artificial leather. Furthermore, natural leather is obtained from animals, which has resulted in animal killings. There have been various guidelines and laws established by various countries to protect animal rights. Animal rights laws have become a major hurdle for natural leather manufacturers in several countries.

Synthetic Leather Market Report Highlights

The automotive application segment is anticipated to grow at a CAGR of 8.9% over the forecast period. Synthetic leather is used in several automotive applications such as upholstery, dashboards, headliners, seat belts, airbags, and floor & trunk carpets. It is employed in passenger vehicles, light & commercial vehicles, heavy trucks, and buses & coaches as it is lighter than real leather. Its high elasticity enables passenger comfort in addition to providing resistance against hot & cold temperatures and spillage. The product also increases the durability of automotive interiors and reduces maintenance requirements

The PU synthetic leather segment held the largest market share of 60.8% in 2023. PU leather has good elasticity, resistance to solvents, high tensile strength, and skin abrasion resistance. These properties have been a major help in increasing its market penetration in the automotive, footwear, and furnishing sectors

Asia Pacific dominated the synthetic leather market. China is the largest market for synthetic leather in Asia Pacific. It is also among the major consumers of leather in primary application segments such as automotive, furnishing, and clothing. Automotive and footwear industry, which are vital application segments for synthetic leather, are witnessing a rapid growth in the country. China mainly imports synthetic leather from India, Korea, and Italy

In December 2021, Dow, a U.S.-based company, announced the launch of LUXSENSE, a silicone synthetic leather. It is the world's first high-end silicone synthetic leather material designed to meet specifications in furniture, wearable devices, fashion, transportation seating and interiors, and consumer electronics, offering unique features

For More Details or Sample Copy please visit link @: Synthetic Leather Market Report

Manufacturing activities of natural leather, especially tanning, lead to pollution of the nearby surroundings. This is another major reason leading to the shift in preference toward synthetic leather. Stringent environmental laws and government regulations have been influential in promoting the demand for synthetic leather.

India is among the world’s top five producers of leather. However, the Central government of India has banned the slaughter of cows for meat and leather, which has adversely affected the leather industry in the country. Most of India’s leather and meat industry comprises unorganized players, owing to which a reduction in the annual production from these industries is not feasible to estimate. The market situation has widened the demand-supply gap of genuine leather, which is expected to supplement the India PU market’s growth over the forecast period.

#synthetic leather#faux leather#vegan leather#artificial leather#polyurethane leather#market analysis#textile industry#sustainability#fashion#consumer goods#manufacturing#material science#environmentally friendly#global market#luxury goods#leather alternatives#innovation#trends#market research

1 note

·

View note

Text

The rhythmic resonance of spinning mills, the intricate choreography of looms, and the seamless fusion of cutting-edge technologies together create the enchanting symphony that characterizes Egypt's Textile Manufacturing Industry. As we journey through the contents of this blog, we delve into a captivating exploration of the industry's transformation, recent advancements, and the compelling factors propelling its renewed vigor.

#Top Players in Apparel and Textile Market#Apparel and Textile Market Trends#Apparel and Textile Market Report#Apparel and Textile Market Forecast#growth of Apparel and Textile industry#Apparel and Garment Industry#Textile Manufacturing Industry

0 notes

Text

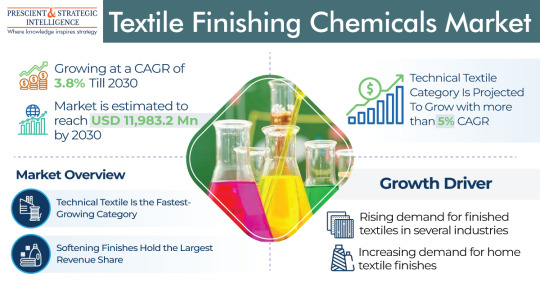

Unveiling Opportunities in the Textile Finishing Chemicals Market

The global textile finishing chemicals market is projected to be worth USD 11,983.2 million by 2030, growing at a CAGR of 3.8%, according to P&S Intelligence. These chemicals are consumed in significant volumes in furniture, textile, and other sectors. In this regard, the growing demand for unique finishes for residential upholstery and advanced textiles is propelling the market. The main aim of…

View On WordPress

#Eco-friendly Solutions#Fabric Enhancement#Global Industry#Innovation#Manufacturing Processes#market trends#Performance Textiles#Specialty Chemicals#Sustainable Finishes#Textile Finishing Chemicals

0 notes

Text

Embracing the Versatility of Synthetic Fibers: A Modern Wardrobe Essential

In the world of fashion, there is a continuous need for novelty and adaptability. When it comes to fulfilling such needs, synthetic fibers have always come up with something new. Whether it is for their robustness, cost, or ecological nature, such fibers have become a primary in our modern wardrobes.

Synthetic Fibers Provide Durability and Longevity

One of the key substantial benefits of synthetic fibers is their extraordinary toughness. Not like natural fibers, like silk or cotton, synthetics such as nylon and polyester are made to endure unremarkable wear and tear. This toughness makes them ideal for casual wear, as they can stay in their shape and resist wrinkles even after several washes. Synthetic fibers are popular for their withstanding to fading, stretching, and fading making them the best for making long-lasting cloths that can bear the demands of our fast-paced lifestyles.

Synthetic Fibers are Affordable and Accessible

Another factor synthetic fibers have gotten huge acceptance is their cost-efficient nature. Compared to their natural complements, synthetic fabrics are usually more pocket-friendly, creating them available to an extensive variety of customers.

This convenience permits people to experiment with diverse styles and trends without being short on money. Moreover, synthetic fibers can copy the luxurious feel and look of natural materials at a segment of the price, providing a reasonable substitute for those who appreciate the aesthetics of high-end fashion.

Synthetic Fibers are More Eco-Friendly

As sustainability becomes a progressively vital concern in the fashion industry, synthetic fibers have made substantial steps in decreasing their ecological impact. Via technological improvements, ecological synthetic fibers, like recycled polyester, have developed. Such fibers are credited from post-customer plastic waste, like rejected bottles, decreasing the dependability on virgin materials and lessening plastic contamination. Moreover, synthetic fibers need lesser resources, like water and land, during making compared to natural fibers, creating them a more sustainable option.

Adaptability and Performance

Synthetic fibers provide supreme versatility, permitting makers to create clothes for several reasons. Their innate properties, such as quick-drying and moisture-wicking abilities, make them perfect for sportswear and activewear. Furthermore, the suppleness of synthetic fibers permits the making of stretchy fabrics, offering ease and liberty of movement.

Synthetic fibers have certainly renovated the fashion sector, providing a variety of advantages that fulfill our modern requirements. From their toughness and affordability to their ecological nature and versatility, such fibers have become a vital part of our wardrobes. As we navigate a world that continually demands flexibility, synthetic fibers offer us ease, style, and a supportable fashion solution. Embracing the wonders of synthetics guarantees that we can uniform casually with confidence while aiding a more sustainable future.

#Synthetic Fibers market#textile manufacturing#market trends#global market outlook#sustainable fibers#market dynamics#research and development#innovative applications#market growth factors#performance textiles#regulatory landscape#quality assurance#apparel industry#environmental sustainability#technical textiles

0 notes

Text

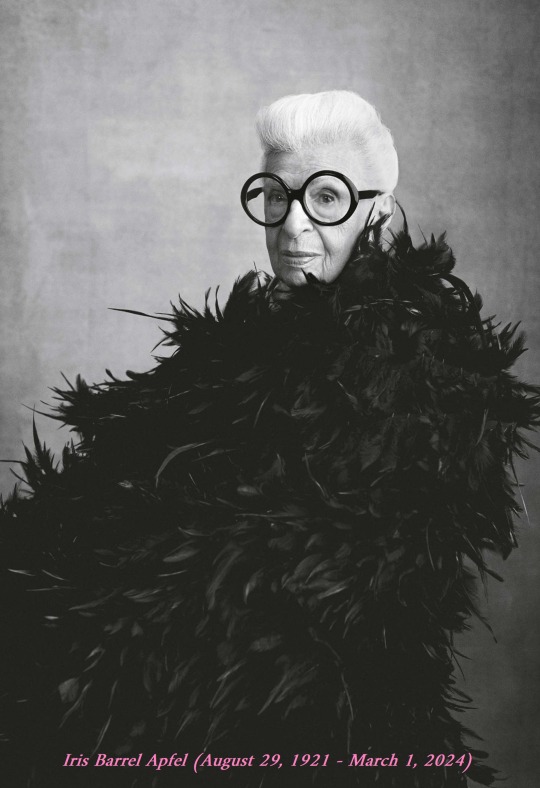

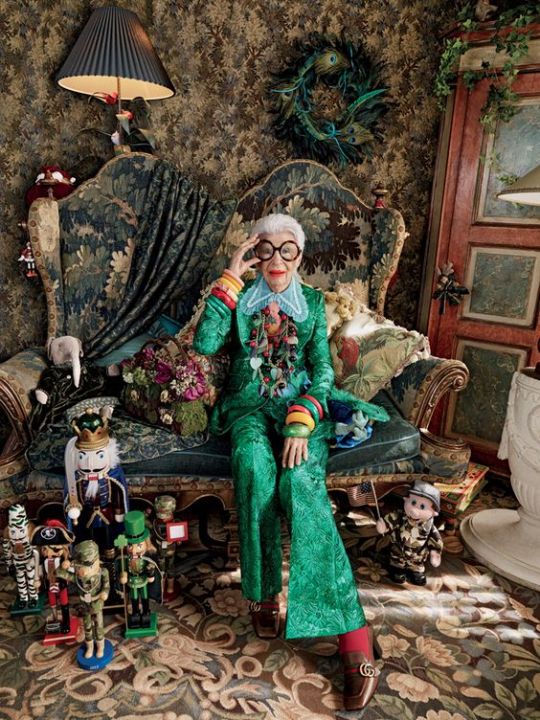

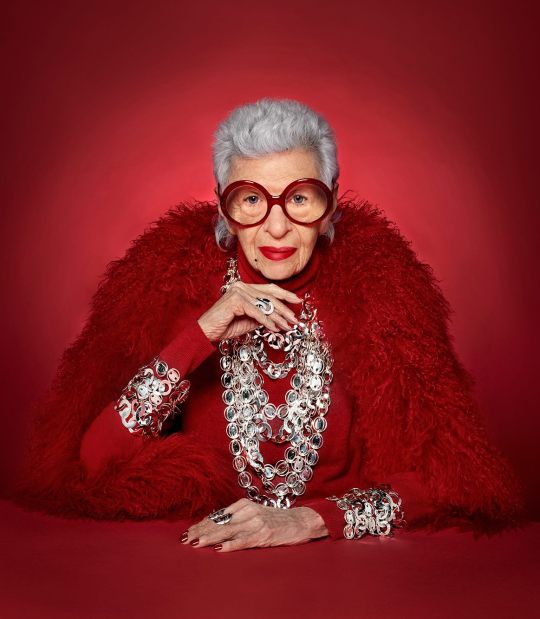

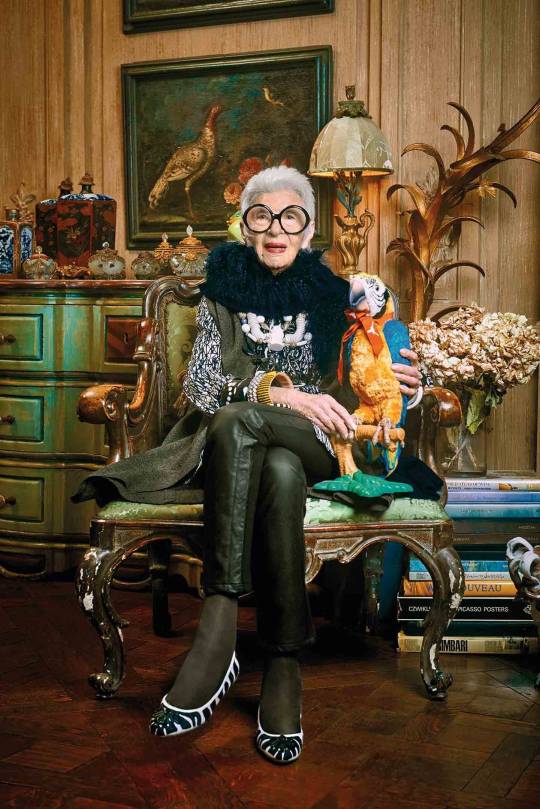

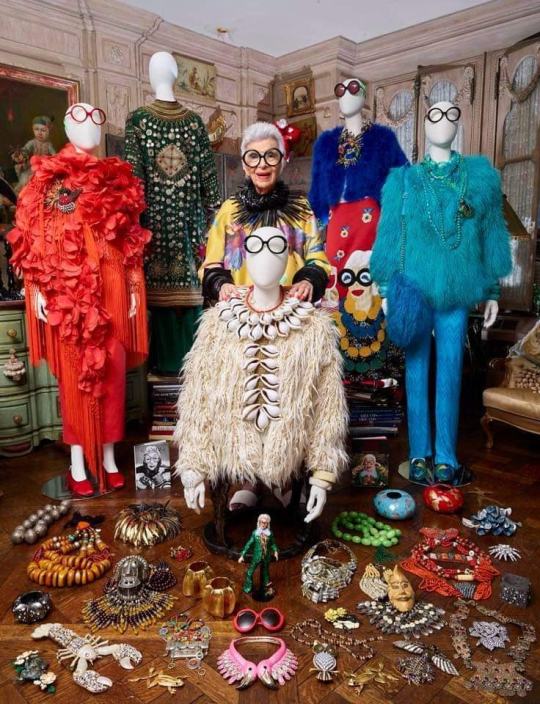

Iris Barrel Apfel, Decorator and Fashion Stylist

(August 29, 1921 – March 1, 2024)

Ms. Apfel was one of the most vivacious personalities in the worlds of fashion, textiles, and interior design, she has cultivated a personal style that is both witty and exuberantly idiosyncratic.

Her originality was typically revealed in her mixing of high and low fashions—Dior haute couture with flea market finds, nineteenth-century ecclesiastical vestments with Dolce & Gabbana lizard trousers.

With remarkable panache and discernment, she combines colors, textures, and patterns without regard to period, provenance, and, ultimately, aesthetic conventions. Paradoxically, her richly layered combinations—even at their most extreme and baroque—project a boldly graphic modernity.

Iris Barrel was born on Aug. 29, 1921, in Astoria, Queens, the only child of Samuel Barrel, who owned a glass and mirror business, and his Russian-born wife, Sadye, who owned a fashion boutique.

She studied art history at New York University, then qualified to teach and did so briefly in Wisconsin before fleeing back to New York to work on Women's Wear Daily, and for interior designer Elinor Johnson, decorating apartments for resale and honing her talent for sourcing rare items before opening her own design firm. She was also an assistant to illustrator Robert Goodman.

As a distinguished collector and authority on antique fabrics, Iris Apfel has consulted on numerous restoration projects that include work at the White House that spanned nine presidencies from Harry Truman to Bill Clinton.

Along with her husband, Carl, she founded Old World Weavers, an international textile manufacturing company and ran it until they retired in 1992. The Apfels specialized in the reproduction of fabrics from the 17th, 18th, and 19th centuries, and traveled to Europe twice a year in search of textiles they could not source in the United States.

The Metropolitan Museum of Art’s Costume Institute assembled 82 ensembles and 300 accessories from her personal collection in 2005 in a show about her called “Rara Avis”.

Almost overnight, Ms. Apfel became an international celebrity of pop fashion.

Ms. Apfel was seen in a television commercial for the French car DS 3, became the face of the Australian fashion brand Blue Illusion, and began a collaboration with the start-up WiseWear. A year later, Mattel created a one-of-a-kind Barbie doll in her image. Last year, she appeared in a beauty campaign for makeup with Ciaté London.

Six years after the Met show she started her fashion line "Rara Avis" with the Home Shopping Network.

She was cover girl of Dazed and Confused, among many other publications, window display artist at Bergdorf Goodman, designer and design consultant, then signed to IMG in 2019 as a model at age 97.

Ms. Iris Apfel became a visiting professor at the University of Texas at Austin in its Division of Textiles and Apparel, teaching about imagination, craft and tangible pleasures in a world of images.

In 2018, she published “Iris Apfel: Accidental Icon,” an autobiographical collection of musings, anecdotes and observations on life and style.

Ms. Apfel’s apartments in New York and Palm Beach were full of furnishings and tchotchkes that might have come from a Luis Buñuel film: porcelain cats, plush toys, statuary, ornate vases, gilt mirrors, fake fruit, stuffed parrots, paintings by Velázquez and Jean-Baptiste Greuze, a mannequin on an ostrich.

The Museum of Lifestyle & Fashion History in Boynton Beach, Florida, is designing a building that will house a dedicated gallery of Ms. Apfel's clothes, accessories, and furnishings.

Ms. Apfel’s work had a universal quality, It’s was a trend.

Rest in Power !

#art#design#fashion#icon#rip#iris apfel#luxury lifestyle#rip riris apfel#style icon#iconic#trend#rare avis#women's fashion#walking closet#muse#themet#style#history#renaissance#baroque#greta garbo#dior#chanel#montana#fendi#jewellery#high fashion#fantasy#women history month

174 notes

·

View notes

Text

The more I read economics literature about automation trends and globalization trends (the actual economics term, not the rabid racist term) and their economic impacts on developed economies, the more I realize that the fundamental picture we have been sold these things is a lie.

The general picture of automation revolutions is that they present some way of doing work more efficiently and/or to create a better product, and so market forces simply demand it. And we have to figure out how to deal with all of the lost jobs which are resulting from this. Because even in a socialist utopia, surely it would be absurd to continue forcing people to use old and outdated technology to do work less efficiently just so they could have work to do, right? Maybe the socialist utopia will take care of people displaced by this work better, but the displacement will still happen.

Except then I start reading about the actual history in the actual economics of automation revolutions (I recommend Blood In The Machine for a history of the Luddites and the automated textile revolution in Britain). And that's not what happens even a single time. These automated revolutions increase the cost per unit to create a good! They make the quality worse! And the existing workers get displaced, and replaced with oppressed or even outright enslaved labors who make nothing in worse conditions! They didn't even actually reduce the amount of labor involved significantly, they just started working orphan slaves 80-90 hours a week rather than artisan workers doing 30-35, to "reduce" the labor involved by reducing the number of laborers. It seems like no one benefits from this. So why is it happening!?

Well the answer is simple. The machine looms were less efficient, created lower quality products, and were worse for every single person in every sector of the economy ... except insofar as that they enabled a more unequal economy. The textile industry itself made less profit. The world itself had worse and less textiles. But the machine loom owners specifically made more money, because machine rooms enabled more control over workers in ways which could be used to relegate them to an even smaller share of the smaller profits. And they didn't outcompete others by being better, they did it through regulatory capture, illegal business practices, outright fraud, and by having a pre-existing place of power in their society.

The same applies to the classic story of Ford and his great automobile factory model. Sure it produced a lot of cars at low prices, but what the history doesn't tell you is that a bunch of other automobile companies which weren't using the factory model were putting out their own cars similar cost. Sure they weren't scaling up as fast, but everyone involved was making good money and the market kept on producing more companies to fill the gap. Ford made the decision to sell to a new lower cost car market sure, but he did not make a better profit margin per dollar of car purchases than his competitors did. He made significantly worse actually because he had such hideous turnover at his factories, and his cars were of lower quality than non-factory line cars aimed at the same market could be.

So why the hell did the entire automobile industry follow in his wake? Well, because he personally was making an insane amount of money. The factory line model let him simplify the production chain in a way which cut out a lot of people who previously been making good salaries, and it let him replace well paid laborers with dirt cheap labor. (Despite the hubbub about how good Ford's factory jobs paid, they only paid well relative to other no skill no training work available. They paid much worse than the skilled laborers he fired had made.)

And the people who controlled how the car manufacturing process worked were the people who would stand to make money by switching over.

The same is true for globalization. When a berry monopoly which controls 60% of all berry sales in the US does so by importing berries from South America, from varieties optimized for durability rather than flavor, that isn't cheaper than growing them at home. Not even with the higher cost of labor in the US. Not even if you actually paid farm hands a good wage rather than by abusing undocumented workers who can't fight back as effectively. The transport costs are too high.

All across the US food sector we have examples of food monopolies exporting produce production overseas in ways that make the final product more expensive for the customer, and lower quality at the same time. Why!?

Well because it allows them to access even more vulnerable labor markets. So even though the whole pie shrinks, the company owners get a bigger enough cut of the pie to make up for it.

The lie of automation and globalization of work and the damage it does to developed economies is just that, a lie. It is not economically predestined for this stuff to happen. Alternatives are not predestined to be competed out of the market. Unless, of course, ownership of profits is concentrated in only a few hands. Unless what's being competed for isn't net profit or net service provided or net quality of goods, but how much profit you can localize in capital owners.

If that's the actual competition, and of course it is because the people making decisions for companies also own those companies, only then does job automation and the presence of exploitable overseas labor devastate economies.

If laborers actually owned their places of business piecemeal, the motivation for these kinds of economic shocks would largely dry up. Like, sure, labor saving devices get invented sometimes and you need less people to do the same work. And sure, sometimes work can be done overseas for cheaper because standards of living at lower or because there's some comparative economic advantage. But that is not actually what is happening most of the time this stuff occurs.

If there's one thing I've learned studying this stuff, it's that genuine examples of net gain automation are less common than we think, and tend to be implemented on fairly slower timelines. Same for globalization of work. What is very common is ways in which already unequal systems of ownership and decision making and profit can be made more unequal. And the only fix I can imagine is fundamentally changing and democratizing how businesses operate, and how we handle concepts of ownership.

#also I know this can read as dismissive of the impacts#of this stuff on the labor forces most exploited by it#especially in South America#it's just that I'm trying to come at this from the perspective of#the justification of the existing system uses#which do not care about that kind of suffering#and trying to point out how they don't even do the things they claim to do

37 notes

·

View notes

Text

In 2023, the fast-fashion giant Shein was everywhere. Crisscrossing the globe, airplanes ferried small packages of its ultra-cheap clothing from thousands of suppliers to tens of millions of customer mailboxes in 150 countries. Influencers’ “#sheinhaul” videos advertised the company’s trendy styles on social media, garnering billions of views.

At every step, data was created, collected, and analyzed. To manage all this information, the fast fashion industry has begun embracing emerging AI technologies. Shein uses proprietary machine-learning applications — essentially, pattern-identification algorithms — to measure customer preferences in real time and predict demand, which it then services with an ultra-fast supply chain.

As AI makes the business of churning out affordable, on-trend clothing faster than ever, Shein is among the brands under increasing pressure to become more sustainable, too. The company has pledged to reduce its carbon dioxide emissions by 25 percent by 2030 and achieve net-zero emissions no later than 2050.

But climate advocates and researchers say the company’s lightning-fast manufacturing practices and online-only business model are inherently emissions-heavy — and that the use of AI software to catalyze these operations could be cranking up its emissions. Those concerns were amplified by Shein’s third annual sustainability report, released late last month, which showed the company nearly doubled its carbon dioxide emissions between 2022 and 2023.

“AI enables fast fashion to become the ultra-fast fashion industry, Shein and Temu being the fore-leaders of this,” said Sage Lenier, the executive director of Sustainable and Just Future, a climate nonprofit. “They quite literally could not exist without AI.” (Temu is a rapidly rising ecommerce titan, with a marketplace of goods that rival Shein’s in variety, price, and sales.)

In the 12 years since Shein was founded, it has become known for its uniquely prolific manufacturing, which reportedly generated over $30 billion of revenue for the company in 2023. Although estimates vary, a new Shein design may take as little as 10 days to become a garment, and up to 10,000 items are added to the site each day. The company reportedly offers as many as 600,000 items for sale at any given time with an average price tag of roughly $10. (Shein declined to confirm or deny these reported numbers.) One market analysis found that 44 percent of Gen Zers in the United States buy at least one item from Shein every month.

That scale translates into massive environmental impacts. According to the company’s sustainability report, Shein emitted 16.7 million total metric tons of carbon dioxide in 2023 — more than what four coal power plants spew out in a year. The company has also come under fire for textile waste, high levels of microplastic pollution, and exploitative labor practices. According to the report, polyester — a synthetic textile known for shedding microplastics into the environment — makes up 76 percent of its total fabrics, and only 6 percent of that polyester is recycled.

And a recent investigation found that factory workers at Shein suppliers regularly work 75-hour weeks, over a year after the company pledged to improve working conditions within its supply chain. Although Shein’s sustainability report indicates that labor conditions are improving, it also shows that in third-party audits of over 3,000 suppliers and subcontractors, 71 percent received a score of C or lower on the company’s grade scale of A to E — mediocre at best.

Machine learning plays an important role in Shein’s business model. Although Peter Pernot-Day, Shein’s head of global strategy and corporate affairs, told Business Insider last August that AI was not central to its operations, he indicated otherwise during a presentation at a retail conference at the beginning of this year.

“We are using machine-learning technologies to accurately predict demand in a way that we think is cutting edge,” he said. Pernot-Day told the audience that all of Shein’s 5,400 suppliers have access to an AI software platform that gives them updates on customer preferences, and they change what they’re producing to match it in real time.

“This means we can produce very few copies of each garment,” he said. “It means we waste very little and have very little inventory waste.” On average, the company says it stocks between 100 to 200 copies of each item — a stark contrast with more conventional fast-fashion brands, which typically produce thousands of each item per season, and try to anticipate trends months in advance. Shein calls its model “on-demand,” while a technology analyst who spoke to Vox in 2021 called it “real-time” retail.

At the conference, Pernot-Day also indicated that the technology helps the company pick up on “micro trends” that customers want to wear. “We can detect that, and we can act on that in a way that I think we’ve really pioneered,” he said. A designer who filed a recent class action lawsuit in a New York District Court alleges that the company’s AI market analysis tools are used in an “industrial-scale scheme of systematic, digital copyright infringement of the work of small designers and artists,” that scrapes designs off the internet and sends them directly to factories for production.

In an emailed statement to Grist, a Shein spokesperson reiterated Peter Pernot-Day’s assertion that technology allows the company to reduce waste and increase efficiency and suggested that the company’s increased emissions in 2023 were attributable to booming business. “We do not see growth as antithetical to sustainability,” the spokesperson said.

An analysis of Shein’s sustainability report by the Business of Fashion, a trade publication, found that last year, the company’s emissions rose at almost double the rate of its revenue — making Shein the highest-emitting company in the fashion industry. By comparison, Zara’s emissions rose half as much as its revenue. For other industry titans, such as H&M and Nike, sales grew while emissions fell from the year before.

Shein’s emissions are especially high because of its reliance on air shipping, said Sheng Lu, a professor of fashion and apparel studies at the University of Delaware. “AI has wide applications in the fashion industry. It’s not necessarily that AI is bad,” Lu said. “The problem is the essence of Shein’s particular business model.”

Other major brands ship items overseas in bulk, prefer ocean shipping for its lower cost, and have suppliers and warehouses in a large number of countries, which cuts down on the distances that items need to travel to consumers.

According to the company’s sustainability report, 38 percent of Shein’s climate footprint comes from transportation between its facilities and to customers, and another 61 percent come from other parts of its supply chain. Although the company is based in Singapore and has suppliers in a handful of countries, the majority of its garments are produced in China and are mailed out by air in individually addressed packages to customers. In July, the company sent about 900,000 of these to the US every day.

Shein’s spokesperson told Grist that the company is developing a decarbonization road map to address the footprint of its supply chain. Recently, the company has increased the amount of inventory it stores in US warehouses, allowing it to offer American customers quicker delivery times, and increased its use of cargo ships, which are more carbon-efficient than cargo planes.

“Controlling the carbon emissions in the fashion industry is a really complex process,” Lu said, adding that many brands use AI to make their operations more efficient. “It really depends on how you use AI.”

There is research that indicates using certain AI technologies could help companies become more sustainable. “It’s the missing piece,” said Shahriar Akter, an associate dean of business and law at the University of Wollongong in Australia. In May, Akter and his colleagues published a study finding that when fast-fashion suppliers used AI data management software to comply with big brands’ sustainability goals, those companies were more profitable and emitted less. A key use of this technology, Atker says, is to closely monitor environmental impacts, such as pollution and emissions. “This kind of tracking was not available before AI-based tools,” he said.

Shein told Grist it does not use machine-learning data management software to track emissions, which is one of the uses of AI included in Akter’s study. But the company’s much-touted usage of machine-learning software to predict demand and reduce waste is another of the uses of AI included in the research.

Regardless, the company has a long way to go before meeting its goals. Grist calculated that the emissions Shein reportedly saved in 2023 — with measures such as providing its suppliers with solar panels and opting for ocean shipping — amounted to about 3 percent of the company’s total carbon emissions for the year.

Lenier, from Sustainable and Just Future, believes there is no ethical use of AI in the fast-fashion industry. She said that the largely unregulated technology allows brands to intensify their harmful impacts on workers and the environment. “The folks who work in fast-fashion factories are now under an incredible amount of pressure to turn out even more, even faster,” she said.

Lenier and Lu both believe that the key to a more sustainable fashion industry is convincing customers to buy less. Lu said if companies use AI to boost their sales without changing their unsustainable practices, their climate footprints will also grow accordingly. “It’s the overall effect of being able to offer more market-popular items and encourage consumers to purchase more than in the past,” he said. “Of course, the overall carbon impact will be higher.”

11 notes

·

View notes

Text

i don't know how many people here follow me for textiles or even have any interest, but i'm just going to say it anyways.

I FUCKING LOATHE HOW THE BEIGE TREND IS CREEPING INTO CLOTHING UNDER THE GUISE OF BEING MORE ECOLOGICALLY FRIENDLY.

Beige is not a good color. Beige is not an elegant color. It lacks the old fashioned charm of off-white and the muted elegance of brown. It can, in some circumstances, be used efficiently to give a professional look, or to bring out the brightness of another color by contrast. Maybe there are even a few uses where it looks good! I'll admit to some bias in this regard.

But for such a drab color, it's far oversaturated the market. And now, rather than taking responsibility for putting out shitty garments and encouraging the fast fashion cycle, manufacturers are creating the most horrendously ugly unfinished garments that "save water" but look and feel like wearing a fucking potato sack.

And like. I get it. We really should be doing more to help the planet. And it's possible that I'm not educated enough on the fashion cycle. But I think that humans, especially those who have historically been good stewards of the environment, have been consistently making some gorgeous clothing from vibrant dyes all throughout history, and making ugly muted clothing is performative at best.

7 notes

·

View notes

Text

Mobile App Development Company Jaipur | VolanSoft

Transform Your Business with Jaipur's Leading Mobile App Development Company

In today's digital age, having a powerful mobile presence isn't just an option – it's a necessity. As a premier mobile app development company in Jaipur, VolanSoft Technologies understands the unique challenges businesses face in creating impactful mobile solutions. We've spent years helping local businesses, startups, and enterprises transform their digital presence through innovative mobile applications. Our journey as a mobile app development company in Jaipur began with a simple mission: to help businesses connect with their customers through seamless mobile experiences. Today, we're proud to have served over 150+ clients across various industries, from e-commerce to healthcare, delivering solutions that drive real business growth.

The Mobile App Revolution in Pink City

Jaipur's tech landscape has evolved dramatically in recent years. As businesses encirclement digital transformation, the demand for quality mobile app development services has soared. We've witnessed firsthand how local businesses have transformed their operations through custom mobile applications. For instance, one of our clients, a traditional Rajasthani handicraft retailer, saw a 150% increase in sales after launching their mobile app.

Why Choose a Local Mobile App Development Partner?

While there are countless app development companies worldwide, partnering with a local mobile app development company in Jaipur offers unique advantages. Our team understands the local market dynamics and cultural nuances that can make or break your app's success. We're not just developers – we're your neighbors who speak your language and understand your business challenges.

Our Development Process: Where Innovation Meets Tradition

At VolanSoft, we blend modern development methodologies with traditional business values. Our process begins with understanding your vision through personal meetings at our Jaipur office. We then craft a detailed roadmap that aligns with your business goals. Our experienced developers use the latest technologies while maintaining the personal touch that Jaipur businesses are known for.

Custom Solutions for Every Business

Whether you need an Android app, iOS app, or both, our team delivers solutions tailored to your specific needs. We've helped local restaurants create order management apps, developed inventory tracking solutions for textile manufacturers, and built customer engagement platforms for retail businesses. Each project is unique, and we treat it as such.

The VolanSoft Difference

As an established Top mobile app development company in Jaipur, we pride ourselves on:

Deep understanding of local market needs

Transparent communication throughout the development process

Competitive pricing without compromising quality

Post-launch support and maintenance

Regular updates and performance optimization

Beyond App Development

Our expertise extends beyond just mobile apps. As a comprehensive digital solutions provider, we offer e-commerce development, Shopify development, and custom web applications. This integrated approach ensures your mobile app works seamlessly with your entire digital ecosystem.

Looking Ahead: The Future of Mobile Apps in Jaipur

The mobile app landscape in Jaipur is evolving rapidly. We're seeing increased demand for AI-integrated apps, IoT solutions, and blockchain applications. As your local technology partner, we stay ahead of these trends to ensure your business remains competitive in the digital space.

Ready to Transform Your Business?

If you're looking to develop a mobile app that truly resonates with your audience, let's have a conversation. Visit our office in Jaipur, and let's discuss how we can turn your app idea into reality. With VolanSoft Technologies, you're not just getting a mobile app development company – you're gaining a long-term technology partner committed to your success.

3 notes

·

View notes

Text

PANTONE TCX Cotton Chip Set (FHIC400C) BD

The PANTONE TCX Cotton Chip Set is a vital tool for professionals in the textile and fashion industries. Renowned for its comprehensive color system, the TCX Cotton Chip Set provides designers, manufacturers, and colorists with a reliable and precise way to communicate and match colors across different production processes.

What is the PANTONE TCX Cotton Chip Set?

The PANTONE TCX Cotton Chip Set features over 2,800 market-relevant colors from the Fashion, Home + Interiors System. Each color is meticulously dyed on 100% cotton fabric, ensuring accurate representation of hues in textile applications. The set is an indispensable resource for achieving color consistency across materials and products, making it ideal for professionals involved in apparel, home furnishings, and soft goods.

Whether you're launching a new clothing line or designing home textiles, the PANTONE TCX Cotton Chip Set is a must-have for accurate color specification and consistent production quality.

Specifications

Model : FHIC400C Brand : Pantone Origin : USA New Color : 175 new market trending colors added! Color Number : 2800 Fashion, Home + Interiors (FHI) Colors Swatch Size : (1 x 1) Inch Removable Swatch : Yes Book Number : 03 (Three) Volume Set

2 notes

·

View notes

Text

Celebrating the Spirit of Nagaland: Runway India at the Heart of the Hornbill Festival

Nagaland, a land of vibrant traditions, exquisite handicrafts, and rich cultural heritage, stands out as one of India’s most unique and diverse regions. At the heart of this cultural treasure lies the Hornbill Festival, a grand celebration that showcases the tribal art, crafts, music, and traditions of the state. For Runway India, a platform dedicated to empowering artisans and promoting tribal art, collaborating with the Hornbill Festival represents a powerful opportunity to preserve and celebrate Nagaland’s rich legacy.

This partnership not only highlights the beauty of Nagaland’s craftsmanship but also opens doors for people across India to buy unique Nagaland products online, connecting artisans to wider audiences and fostering appreciation for their work.

Runway India and the Hornbill Festival: A Cultural Bridge

The Hornbill Festival, known as the "Festival of Festivals," is a week-long event that takes place every December in Nagaland. The festival is a celebration of the state’s 16 major tribes, bringing together traditional dances, folk music, indigenous games, and, most importantly, the stunning artistry of local craftsmen. Each handcrafted item, whether it’s a vibrant handwoven shawl or intricately designed jewelry, tells a story of heritage and cultural pride.

For Runway India, participating in the Hornbill Festival aligns with its mission to create opportunities for indigenous artisans. By showcasing their products and skills, Runway India ensures that these talented creators gain the recognition they deserve, both locally and globally. This collaboration also emphasizes the importance of buying authentic handicrafts online, bridging the gap between artisans and consumers across India.

Promoting Nagaland’s Unique Handicrafts

Nagaland’s handicrafts are celebrated for their creativity and sustainability. Products made from banana fibre have gained popularity for their eco-friendly appeal. Banana fibre is not only durable but also reflects the resourcefulness of Nagaland’s artisans, who transform this natural material into stunning textiles, bags, and home décor items.

To ensure these crafts reach a wider audience, Runway India actively supports online marketplaces where people can find and buy Nagaland handicrafts online in India. From intricate bamboo products and hand-carved wooden artifacts to vibrant Naga jewelry, these items showcase the talent and ingenuity of the region’s artisans.

Supporting Handicraft Training and Empowerment

Preserving traditional crafts requires consistent effort and skill development. Runway India collaborates with artisans and training centers to promote the growth of sustainable handicraft practices. Some of the best banana fibre training centers in India are located in Nagaland, where artisans are trained to refine their skills, innovate designs, and meet market demands.

By supporting these centers, Runway India not only empowers artisans but also ensures the sustainability of indigenous crafts. Training programs help artisans modernize their techniques while staying rooted in tradition, enabling them to compete in national and international markets.

Nagaland’s Handicraft Industry: A Legacy of Excellence

The handicraft manufacturers in Nagaland play a vital role in preserving the cultural identity of the region. Their work extends beyond creating beautiful items; it is about sustaining livelihoods and passing down traditions to the next generation. Bamboo, cane, and wood are commonly used materials, with artisans crafting everything from furniture and baskets to decorative pieces.

Runway India works closely with these manufacturers, helping them adapt to changing market trends while maintaining the authenticity of their craft. This collaboration ensures that the artisans' stories and traditions continue to reach a global audience, providing consumers with the opportunity to connect with the culture of Nagaland through their products.

Why Support Nagaland Handicrafts?

When you buy Nagaland handicrafts online, you’re not just purchasing a product; you’re supporting a community, preserving a heritage, and promoting sustainability. Each piece of art carries the essence of Nagaland’s culture, allowing you to bring a part of this beautiful state into your home.

Runway India’s mission is to make these products more accessible, creating an online platform where people can explore and purchase authentic handicrafts. Whether it’s a handwoven shawl, a banana fibre bag, or a bamboo basket, every purchase contributes to the empowerment of artisans and the preservation of their craft.

Conclusion

The collaboration between Runway India and the Hornbill Festival is a celebration of Nagaland’s spirit, artistry, and cultural heritage. By showcasing the state’s unique crafts and empowering its artisans, Runway India is playing a crucial role in preserving these traditions for future generations.

For those looking to support this movement and explore the rich artistry of Nagaland, platforms like Runway India offer the perfect opportunity to buy unique Nagaland products online and connect with the stories behind each creation. With a commitment to sustainability and innovation, Runway India is ensuring that Nagaland’s handicrafts continue to shine brightly on the global stage, offering a meaningful way to celebrate and cherish India’s diverse cultural heritage.

FAQs

1. What is the Hornbill Festival, and why is it important? The Hornbill Festival is an annual cultural event held in Nagaland to celebrate the rich traditions, art, and heritage of the state's 16 tribes. It promotes cultural preservation and provides a platform for artisans to showcase their crafts.

2. How can I buy unique Nagaland products online? You can purchase authentic Nagaland handicrafts through platforms like Runway India, which connect artisans to buyers across India and beyond. These include items like handwoven textiles, banana fibre products, and bamboo crafts.

3. What are banana fibre products, and why are they popular? Banana fibre products are eco-friendly items made from the natural fibres of banana plants. They are durable, sustainable, and crafted into beautiful bags, mats, and textiles by skilled artisans in Nagaland.

4. Are there training centers in Nagaland for handicrafts? Yes, some of the best banana fibre training centers in India are in Nagaland, providing artisans with skills to innovate and meet market demands while preserving traditional techniques.

5. How does Runway India support artisans in Nagaland? Runway India empowers artisans by showcasing their work, providing access to online markets, and promoting their crafts globally. It also collaborates with training centers and manufacturers to support sustainable growth.

#handicraft manufacturer in nagaland#nagaland_statement_jewellery#best handicraft training centre in india#best_gifting_handmade_naga_products

2 notes

·

View notes

Text

Greige Fabric Broker & Manufacturer - MallinathFabTex

Description:

Welcome to Mallinath Fabtex's Tumblr page! Based in Ahmedabad, we are a distinguished broker and manufacturer specializing in greige fabric, cotton, and a diverse range of high-quality textiles. At Mallinath Fabtex, we bridge the gap between fabric suppliers and buyers, offering unparalleled expertise in textile solutions tailored to meet a variety of needs.

As a prominent name in the fabric industry, our core offerings include premium greige fabric, which serves as the foundation for countless textile products. Our greige fabrics are known for their superior quality, durability, and versatility, making them an ideal choice for further processing into finished goods. We cater to various sectors, ensuring that our fabrics meet the highest standards of excellence.

In addition to greige fabric, we provide a comprehensive selection of cotton fabrics, renowned for their comfort, breathability, and wide range of applications. Whether you're sourcing fabric for apparel, home textiles, or industrial uses, Mallinath Fabtex delivers reliable and high-quality solutions. Our expertise extends beyond cotton to include a variety of other textiles, allowing us to serve a diverse clientele with unique fabric requirements.

Our business is rooted in Ahmedabad, a hub of textile innovation and manufacturing. This strategic location enables us to efficiently source and distribute fabrics, maintaining strong relationships with both local and international suppliers. At Mallinath Fabtex, we pride ourselves on our ability to offer custom fabric solutions that cater to the specific needs of our clients. From large-scale orders to specialized fabric requirements, we are committed to providing personalized service and exceptional quality.

Our services encompass every stage of the fabric lifecycle, from sourcing and manufacturing to wholesale distribution. Our team of experts works closely with clients to ensure that each fabric meets their exact specifications and quality standards. We are dedicated to staying at the forefront of textile trends and innovations, continually enhancing our offerings to meet evolving market demands.

Follow Mallinath Fabtex on Tumblr to stay updated with the latest trends in fabric manufacturing, industry news, and exclusive updates on our product offerings. Discover how we can help you achieve your textile goals with our comprehensive range of fabrics and customized solutions.

Join us on our journey through the world of textiles and explore how Mallinath Fabtex can provide the perfect fabric solutions for your needs with excellence and reliability.

2 notes

·

View notes

Text

Textile Manufacturing Companies | Oswal Group

In the bustling industrial landscape of Ludhiana, where the clang of machinery and the hum of ambition merge, one name stands out as a beacon of excellence: The Oswal Group of Companies. Founded on a vision to redefine the textile industry in Ludhiana, Oswal Group’s journey from inception to industry leader is nothing short of inspiring.

The Genesis: The Oswal Group’s foray into the textile industry dates back to the 1960s when the visionary entrepreneur, Late Shri Rattan Chand Oswal, laid the foundation stone of what would become a textile empire. With a keen eye for opportunities and a steadfast commitment to quality, Oswal ventured into yarn production, setting the stage for the group’s meteoric rise.

Excelling in Ludhiana’s Textile Hub: Ludhiana boasts a rich heritage in textiles. In such a competitive landscape, Oswal Group didn’t just survive; it thrived. Through strategic investments in state-of-the-art technology, a relentless focus on innovation, and nurturing a skilled workforce, the Oswal Group carved a niche for itself.

The group’s vertical integration, from spinning mills to garment manufacturing, enabled streamlined operations and superior quality control. This holistic approach not only ensured consistency in product standards but also bolstered Oswal’s reputation as a reliable textile partner globally.

Moreover, Oswal Group’s commitment to sustainability has been commendable. Embracing eco-friendly practices, optimizing resource utilization, and adhering to stringent environmental regulations have not only reduced the ecological footprint but also enhanced brand credibility.

Evolution in the Textile Industry: As the textile industry in Ludhiana evolves in the digital age, Oswal Group is poised to embrace the winds of change. Embracing automation, leveraging data analytics for predictive maintenance, and integrating IoT (Internet of Things) for smart manufacturing are avenues the group can explore to enhance efficiency and productivity further.

Furthermore, investing in research and development to explore alternative fibers and sustainable manufacturing processes can bolster Oswal Group’s competitive edge. With growing consumer consciousness towards ethical sourcing and eco-friendly products, tapping into this market segment can unlock new growth avenues.

Moreover, expanding the group’s global footprint through strategic alliances and partnerships can diversify market exposure and mitigate risks associated with geographical dependencies. Collaborating with international brands for co-branded collections or joint ventures can not only enhance brand visibility but also facilitate knowledge exchange and technological advancements.

Additionally, nurturing talent through skill development programs and fostering a culture of innovation can fuel Oswal Group’s evolution. Encouraging intrapreneurship and empowering employees to think beyond conventional boundaries can lead to breakthroughs in product design, manufacturing processes, and business models.

In the tapestry of Ludhiana’s textile industry, Oswal Group’s story shines as a testament to perseverance, innovation, and resilience. From humble beginnings to scaling new heights of success, the group has not only excelled but also redefined the textile industry’s standards.

As Oswal Group embarks on the next phase of its journey, the roadmap is clear: embrace technology, foster sustainability, and nurture talent. By staying true to its core values while adapting to emerging trends, Oswal Group is poised to not just survive but thrive in the dynamic landscape of the textile industry. With each thread woven with precision and passion, the Oswal legacy continues to inspire generations, shaping the future of Ludhiana’s textile industry and beyond.

2 notes

·

View notes