#Synthetic Fiber

Explore tagged Tumblr posts

Text

Timo Seber Inertia X – Lite 2015 C-print on acrylic glass, synthetic fiber, steel 52 x 114 × 5 cm

23 notes

·

View notes

Text

I keep thinking everyone knows the exact same information as me, but since I'm about to make more posts about textiles and clothing, as I'm reading the book on them, I'm going to write down some basic information, just in case it's not very common, because a lot of this I only gathered recently. If I get something wrong please correct me in a kind way!

So where does the clothing come from, and how do we make it? During most of the history, textiles were made by women, from natural materials; flax, wool, cotton, silk, jute. Recently we started using more synthetic materials, like acrylic, polyester, nylon, spandex. If you want to make clothing from the natural materials, like wool or cotton, they first need to be processed, cleaned and combed, then spun into yarn, or thread. Spinning is the process where women manage to pull a thin part of the material and spin the fibres into one consistent, firm thread. It's super impressive to watch them do it and I have no idea how they manage to make it consistent, I've not yet tried to do it myself.

Once the thread is done, it can be made into a textile by knitting, crochet, or weaving. There are also other more complex, decorative methods, like tatting or lacing.

For knitting, you need two needles, or a special circular needle, or, there are also knitting machines, which you can use to make woolen fabric. For weaving, you need a loom. For crochet, you need a crochet hook. While knitting and weaving can be done by a machine, crochet can only be done by hand. Woven fabrics are firm, sturdy, durable, and not stretchy, while knit fabric is the most stretchy and soft. I'm not sure about crochet since I only have one crochet garment, but mine is very sturdy!

All of these methods were historically done by women; families were able to grow flax plants close to their homes, and women would then create linens, woven textiles made from processed flax, which was used to make sheets and clothing. Linen was specifically useful in keeping people clean, since it's very good at absorbing moisture. Used as an under-garment, it was capable of absorbing sweat, and protecting the outer layers, which were not washed. Experiments have shown that frequently changing into clean linen was more effective at keeping clean than showering and then putting on the same clothing back on.

Women's ability to create clothing was sadly exploited, and women were even banned to sell it commercially, or from competing at the commercial market, but their husbands were allowed to profit off of their craft.

In the USA, cotton was the most produced material, however for this too people were enslaved and exploited; cotton took human labour to grow, harvest and process, it also required a lot of water, and caused destruction of environment, because of the chemicals used in it's growth, and the unsustainability of monocrops.

Creating a piece of clothing out of textiles, or sewing, is a process that still cannot be completely automated; while you can use a sewing machine, you cannot make a machine that would produce a whole garment out of textiles. No mass-produced piece of clothing was sewn by a machine, it always has to be made by a human being. This is why a lot of the sewing labour is currently outsourced to third-world countries and companies use modern slavery in order to create fast fashion; there is no machine that can do it, so by the rules of capitalism, the companies are trying to get that labour as cheap as possible, often at the cost of human lives.

We didn't use to have as many garments as we do today, in the 18th century people would have two outfits, one for normal days of the week, and one for Sunday. The clothing they owned was usually made to fit them exactly, either by a female member of the family, or a seamstress, and these garments were made to last them for decades. As clothing became cheaper to buy than to make at home, and more of it became mass-produced, people started acquiring more of it, but also using it for lesser period of time. This would eventually grow into a bigger problem, due to the amount of chemicals and labour used to grow, process, dye and sew the garments, and the amount of waste we were starting to accumulate.

Introduction of synthetic materials, like acrylic, made the yarn and the textiles much cheaper, however it lacks the important properties natural materials have. Do you ever notice how synthetic garments sometimes continue smelling bad even after you wash them? That is because they'll absorb sweat, but become hydrophobic when wet, meaning they will take in your sweat, but refuse to let it go once they're in the water. This means that the longer you have them, the worst their stink becomes. This, of course, can be hidden by the generous use of scented fabric softener, but it won't exactly make the garment clean. This information I've learned recently, but it helped me identify what were the most synthetic pieces of clothing I had. Acrylic clothing had also proven to shed 1.5 more microplastics than any other polyester when put into the washing machine.

Having our clothing grown, processed, spun, woven/knit, and then sewn far out of sight, it's possible to lose the sight of where it came from, or how it's made. Only by trying to do it yourself, or learning closely about the process can one learn to appreciate what a monumental task it is, to create fabric, or a garment. Other than the synthetic textiles, of which I still know very little of, all of the natural clothing is a product of plants and animals, it takes land, farming, agriculture and water to grow the plants, raise the animals, and then labour to process and spin the fibres. It's also something people used to do in their gardens, inside of their homes, something that was normal for women to do, and to trade for anything else they needed, saving them from having to work for wages. Women making fabric was always to the benefit of everyone around them, while m*n taking over the industry and doing it commercially, ultimately brought slave labour to a lot of people, cheap and low quality garments to the select few, and money to the hands of the exploiters.

Being curious about clothing and what becomes of it, is a big benefit to the environment and the future of the earth! Knowing what the textile industry is doing, and how does it affect the planet, can be a great motivator to try and sew, or upcycle and mend clothing, or create garments. It's presented to us as something women were forced to do in the past, and it's connected to 'feminine hobbies', but in actuality, it is power to create something humans cannot do without. Women in the past used it's power too, whenever they could. And we are the only ones who ever used this power for good.

#textiles#clothing#linen#women's history#herstory#radical feminism#sewing#weaving#crochet#synthetic fiber#random information on clothing i've gathered#i feel much smarter so i wanna share!#if anyone knows more and wants to share please add#my sources are the book Worn#and dozens of youtube videos on textiles I've watched recently

145 notes

·

View notes

Text

Plant cell walls are also used to make synthetic fibers (such as rayon), plastics, films, coatings, adhesives, gels, and thickeners.

"Plant Physiology and Development" int'l 6e - Taiz, L., Zeiger, E., Møller, I.M., Murphy, A.

#book quote#plant physiology and development#nonfiction#textbook#plant cells#cell wall#synthetic fiber#rayon#plastic#film#coating#adhesive#gel#thickener#manufacturing

0 notes

Text

Scientists in China have synthesized spider silk from genetically modified silkworms, producing fibers six times tougher than the Kevlar used in bulletproof vests. The study, published September 20 in the journal Matter, is the first to successfully produce full-length spider silk proteins using silkworms. The findings demonstrate a technique that could be used to manufacture an environmentally friendly alternative to synthetic commercial fibers such as nylon. "Silkworm silk is presently the only animal silk fiber commercialized on a large scale, with well-established rearing techniques," said Mi. "Consequently, employing genetically modified silkworms to produce spider silk fiber enables low-cost, large-scale commercialization." Scientists have eyed spider silk as an enticingly sustainable alternative to synthetic fibers, which can release harmful microplastics into the environment and are often produced from fossil fuels that generate greenhouse gas emissions. But turning to nature for alternatives isn't without challenges.

Continue Reading

318 notes

·

View notes

Text

i just can’t quit you*

*the decrepit calvin klein sports bra i’ve had since middle school.

#i have new ones but i don’t like them as much#i think it’s the fabric my old one was mostly cotton but i think the newer ones have more synthetic fibers. sad

7 notes

·

View notes

Text

Me, wrapped up in microfleece blanket: why plastic warm

6 notes

·

View notes

Text

06-07-23 Why Patagonia helped Samsung redesign the washing machine

Samsung is releasing a wash cycle and a new filter, which will dramatically shrink microfiber pollution.

Eight years ago, Patagonia started to study a little-known environmental problem: With every load of laundry, thousands (even millions) of microfibers, each less than 5 millimeters long, wash down the drain. Some are filtered out at water treatment plants, but others end up in the ocean, where fibers from synthetic fabric make up a surprisingly large amount of plastic pollution—35%, by one estimate. Fragments of your favorite sweatshirt might now be floating in the Arctic Ocean. In a collaboration that began two years ago, the company helped inspire Samsung to tackle the problem by rethinking its washing machines. Today, Samsung unveiled its solution: A new filter that can be added to existing washers and used along with a “Less Microfiber” cycle that Samsung also designed. The combination makes it possible to shrink microfiber pollution by as much as 98%.

[…] Patagonia’s team connected Samsung with Ocean Wise, a nonprofit that tests fiber shedding among its mission to protect and restore our oceans. Samsung shipped some of its machines to Ocean Wise’s lab in Vancouver, where researchers started to study how various parameters change the results. Cold water and less agitation helped—but both of those things can also make it harder to get clothing clean. “There are maybe two ways of increasing the performance of your washing machine,” says Moohyung Lee, executive vice president and head of R&D at Samsung, through an interpreter. “Number one is to use heated water. That will obviously increase your energy consumption, which is a problem. The second way to increase the performance of your washing machine is to basically create stronger friction between your clothes . . . and this friction and abrasion of the fibers is what results in the output of microplastics.” Samsung had already developed a technology called “EcoBubble” to improve the performance of cold-water cycles to help save energy, and it tweaked the technology to specifically tackle microfiber pollution. “It helps the detergent dissolve more easily in water so that it foams better, which means that you don’t need to heat up your water as much, and you don’t need as much mechanical friction, but you still have a high level of performance,” Lee says. The new “Less Microfiber” cycle, which anyone with a Samsung washer can download as an update for their machine, can reduce microfiber pollution by as much as 54%. To tackle the remainder, the company designed a filter that can be added to existing washers at the drain pipe, with pores tiny enough to capture fibers. They had to balance two conflicting needs: They wanted to make it as simple as possible to use, so consumers didn’t have to continually empty the filter, but it was also critical that the filter wouldn’t get clogged, potentially making water back up and the machine stop working. The final design compresses the microfibers, so it only has to be emptied once a month, and sends an alert via an app when it needs to be changed. Eventually, in theory, the fibers that are collected could potentially be recycled into new material rather than put in the trash. (Fittingly, the filter itself is also made from recycled plastic.) When OceanWise tested the cycle and filter together, they confirmed that it nearly eliminated microfiber pollution. Now, Samsung’s challenge is to get consumers to use it. The filter, which is designed to be easily installed on existing machines, is launching now in Korea and will launch in the U.S. and Europe later this year. The cost will vary by market, but will be around $150 in the U.S. The cycle, which began to roll out last year, can be automatically installed on WiFi-connected machines.

#microplastics#textiles#laundry#environmental#science#patagonia#samsung#i'm. so excited.#also i HAD been silently judging patagonia a little for their heavy use of synthetics but. they ARE walking the walk actually.#(will say that ime the feel of natural fibers is just. better.)#(like. wool has an astonishing ability to keep you warm-but-not-sweaty at a bizarrely wide range of temps)#(whereas like. the synthetic fleece tops i still have are like. immediately cozy‚ sure‚ but you WILL get sweaty if you get warm)#(like being in‚ you know‚ a plastic bag!)#(so like. even if they Fix the Microplastics Problem i have no regrets abt switching my allegiance to woolens)#(but. still fucking THRILLED they might fix the microplastics problem.)#does make you feel like. i'm unavoidably a humanities person but. what are humanities ppl doing that matters this much.#like fundamentally if you really want to do good in the world you probably SHOULD become a scientist of some kind.#that said‚ science would almost certainly not be improved by my participating in it‚ so like. what can you do.#really hugely awed by & appreciative of scientists tho.#anyway. obvs this is really just a press release and we gotta see how this plays out but.#!

58 notes

·

View notes

Text

Frankie’s Bikinis trying to sell 100% polyester for $275…they’ve lost their mind…it’s not even a natural fiber, that thing… is gonna deteriorate within two years…

Guys this is what a scam looks like…NEVER buy polyester that’s over $100. It’s PLASTIC FIBER and will be done after a YEAR. If my undergraduate degree taught me anything, it’s polyester isn’t shit. Want something to last? Invest in natural fiber wardrobe. You may have to dry clean it or just hang dry but it will LAST for YEARS. Kills me that these companies think they can get away with charging you overpriced products that are polyester. Please don’t fall for this. Always check the tags on what kind of fiber your clothes are made of. Even online, just scroll to the details and check it before you consider buying it.

5 notes

·

View notes

Note

Hey! Firstly, in my mind I always think of you as 'V' and want to know if you're comfy being called that?

Secondly, illness stuff has recently changed and I'm fucking freezing all the time. It's near impossible to retain heat and I've taken to wearing a mood ring so I can warm up my hands when it turns black. I desperately need advice and/or just solidarity/to complain. But blegh. Also do you like sweaters? You'd definitely look cute in them.

V is alright, as far as nicknames go, but it's quite casual. Vitya is another option, but I prefer to save it for er.. closer relationships.

As far as dealing with the cold goes, I can relate. My body runs cold quite regularly, to the point that my hands are considerably frigid.

I would recommend hot drinks and warm food, blankets when appropriate, heating packs/pads, pocket warmers (you can get reusable ones), or just more clothes.

The electrical bills for the lab were funded by the council, so I was always able to keep it as warm as I wanted, but that's not possible for everyone. I also keep a set of leather gloves on my person in case my hands get stiff, but that may not be necessary in your situation.

And yes, I do like sweaters. In my opinion, they are equally as lazy as sweatshirts, but far classier. Thus, superior in every way.

#also fun fact different types of fabric insulate heat better than others#silk as well as satin and polyester trap heat in very well#whereas cotton and linen are more airy and better for summer#wool is very warm too and great for the snow#not to mention sustainable#i have several silk scarves that are not only very visually appealing but very practical#i hate synthetic fibers though#dont get me started#fuck acrylic especially#and polyester#hate that shit#you dont even want to know#thedivinemechanism#arcane#viktor arcane#viktor nation#viktor#viknat#asks blog#answered asks#yet another side rant in the tags#cold

2 notes

·

View notes

Photo

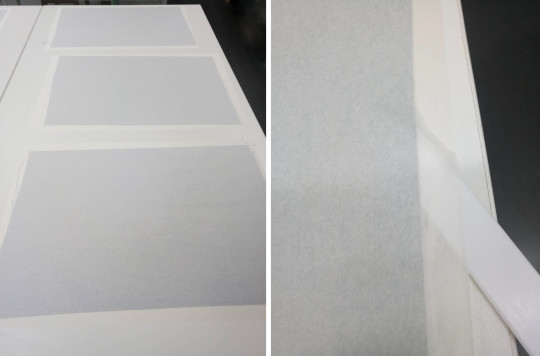

Making paper backed cloth for bookbinding

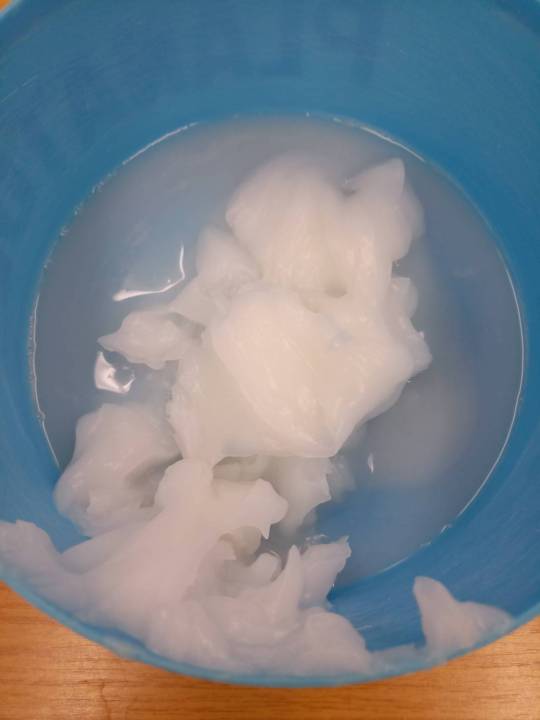

I tried my hand recently on making my own book cloth, not because I can’t get any, but because there are so many fun patterns and colours around. To be honest, I expect bought book cloth to be superior for all the ways it’s finished to be more resilient towards dirt and and such, but that doesn’t say self made cloth is bad at all! There are different ways to achieve a paper backing, I went for the backing with paper and starch paste because a) if I mess up I can always do it over no harm done, no material lost b) I have my doubts about the durabilty of heat activated glues and their durability c) using paste is just so much cheaper

So first up was cooking starch paste. I don’t have a ratio for that. I put a spoon of starch into a pot, add some water to get rid of any lumps and let it soak a few minutes (usually just long enough to get some water boiling), then I slowly pour over the boiling water while stirring the starch and at some point it turns from white to translucent and lumpy and I stop when there’s a certain thickness. When the paste has cooled it press it through a mesh and add some more water as needed. (It’s usually rather thick at that point.)

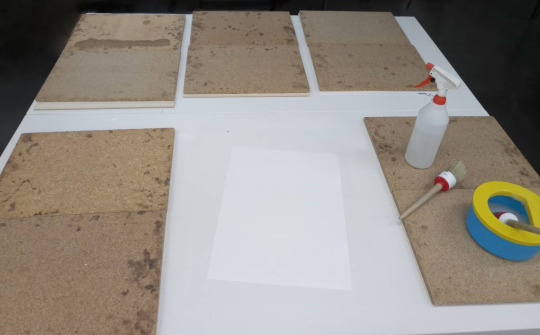

(and yes, my mesh is a nylon sock. I don’t own a fancy horeshair sieve and this stores much easier) Then I prepared my cloth and the paper I was going to use for backing. The final sheets have the warp and the grain direction run parallel for better usage and less warping (at least that’s the theory, I have yet to use that selfmade cloth to find out). The limiting factor here was the width of the web of tissue paper I used. Because I also need the paper to be 2,5cm -5cm larger than the piece of fabric in order to get a smooth sheet of book cloth. Having around 5cm for an edge makes it far easier to get the paper on the cloth even if there is a little skew.

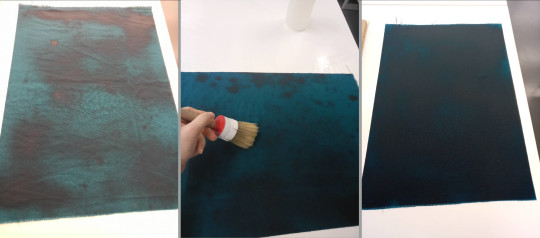

I moistened the pre-washed, but un-ironed fabric (I have some cotton and synthetic fabric, none of them are elastic) and smoothed it down to a flat surface that won’t be needed for a couple of hours (preferably over night). Glas would be best but I didn’t have that, so I picked two work benches for that. I used plenty of water, which was a good thing, I’d say because even when smoothed down, a bit more water made the synthetic fabric wrinkly again.

I sprayed the later front side, turned the cloth around and sprayed the backside. Brushed the water in with a clean brush until the fabric clung smooth to the surface.

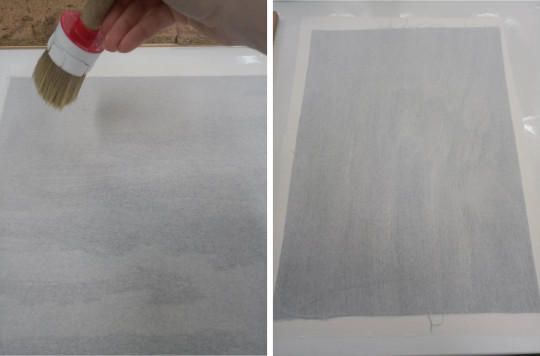

Then I spread the paste on the paper and put it on top of the backside of the fabric, brushed down the paper on top of the cloth with a clean and dry brush to get rid of any airbubbles. Starting in the middle of the fabric and brushing along the long side to the sides to push out the air. Then I gave it a brush down along the short side too. (the slightly brighter stretches of paper on the left are where the air is still caught under the paper, on the right is the paper all smoothed down)

Sometimes I had to lift the edfe of the paper carefully to let out some air or get rid of a too large wrinkle that was building up in the paper.

I weighed the cloth and paper down with blotting paper and blotting board as well as some wooden boards, but only to make them dry faster. In consideration of the table surface I cut only one corner loose after the coth had dried and loosened the rest by running a very flat bone folder all around the edges.

I had great success with the cotton fabric. only minimal bleed through of paste at the edges and a slight smudge in the middle of one sheet.

the synthetic fiber... not so much. While others before that one had taken well to the paste, the one with those shades of blue and purple did not. it was a mess to smooth down and apparently not smooth enough. when I pried it loose it was all bubbly and a lot of fabric was not adhered to the paper backing.

I scrapped that one, I pulled the paper off, washed it out again and this time pressed it while drying, so it would be smooth before the next attempt.

Cleaning up the surface was easy by the way. It was all plastered with dried starch paste, but I simply sprayed it with water, let it sit for a bit and wiped it off. No scrubbing needed at all.

#bookbinding#paper backed cloth#book cloth#making starch paste#cotton cloth#synthetic fiber cloth#again this has gotten more lengthy than I anticipated...

57 notes

·

View notes

Note

I love the colors on your rainbow kippah, who did you order it from?

I got it from this etsy store. I loved that it was crochet (I'm horrible with MCs, I'm a beginner in making clothes), there is a visible seam in the kippah where the rainbow is, which I think is cool honestly, but I know many people are bothered by that sort of thing. It looks like they also have other "themes," too, and if I get another kippah from them, I'm looking at their gold-colored one 👀

Here is the seam in question, but honestly, you can just put the seam where nobody will see it (plus this gives you an idea of the colors themselves because that's one of my favorite parts of it):

Here is a direct link in case the one above is not working for you:

https://www.etsy.com/shop/GreenethingsBoutique

#ask#jumblr#jew by choice#jewish conversion#kippot#ughhhhh i want a kippot collection#gold is one of my absolute favorite shades of yellow besides sunflower ouuuugh#if i get better at crochet and start making my own kippot (a goal of mine) i want to make a sunflower themed one#hot take but i love the way natural fibers take dye better than synthetic fibers like acrylic do#since this kippah is wool it takes the dye in a muted and well... natural way which i love#sorry there are a couple of cat hairs in it. i have no clue how they got there i just washed it#actually they probably messed with it when it was pinned on my blocking board...

9 notes

·

View notes

Text

People who make formalwear out of natural fibres I love you. People who make fancy clothes out of natural fibres I love you. People who make unique and interesting styles out of natural fibres I love you. People who find a way to make creative shapes and textures and looks out of natural fibres I love you. Natural fibres I love you.

#innisthoughts#natural fibers#I don't gel well with synthetic fibres for a bunch of reasons#from the sensory (they feel stickly!!)#to the ethical (ew plastics)#to the health (they like. really mess with my skin biome. Like usually I'm fine and then if I wear synthetic fibres directly on my skin#I SWEAT. Ik it sounds ridiculous but it's an issue)#It's so annoying because so many trans and disability friendly companies produce solely in synthetics </3#like binders? almost always synthetic. accessible tights? almost always synthetic. seamless clothes? almost always synthetic.#and what's that? you want to actually do FUN things with your clothing?? ALMOST ALWAYS SYNTHETIC.#and thus my peculiar affection for natural fibres clothing!#“Just make your own” shut up I already do#I just want other people to join me >:(

5 notes

·

View notes

Text

Genuinely, it’s so fun to contemplate resource distribution, production, and supply lines in Naruto. These factors go such a long way to shape the macro politics and conflicts (when maniacs aren’t running around trying to resurrect their alien moon mom) in every time period you want from the Naruto timeline.

Founder era? New supply lines into a new village! Consolidating vendors that were probably competing against each other, supplying different sides of the prior conflict! Bringing in new civilians and realizing, “oh sage, a village’s needs are far more different than we expected”! Setting up new relations and dynamics with the Daimyo! Taxes.

Nidaime reign? Systems solidifying into place, new war needs, the different nations still figuring out the new ways of competing against each other, more growing pains as a village, continued conflict with the daimyo and other powerful individuals over political and economic power!

First Sandaime reign? Enough time has passed for systems and relations to have solidified, new war, good god a new war, impacts on the ability to innovate and having new entrants trying to break into different industries/supply lines!

Canon timeline? Really digging into the smaller nations looking at whatever they can leverage against the larger nations running roughshod all over them, the constant shifting politics between civilians and shinobi influence in the villages, having to put everything aside for the mad world-ending plans going on, and so so much more in each era

Like, sure, a fic’s main narrative focus will still be on the character growth and dynamics. But isn’t it tasty to have thought out explanations and reasons for why different missions happen? Don’t you want stakes everywhere ramping up tension from all fronts? Don’t you want to lose your mind over your supply of iron?

Have Sakura involved in the behind-the-scenes arms race over medical innovation and manufacturing and finding even more reasons to have beef with Orochimaru. Have the smaller nations desperately hoping for crafty and competent political leaders that can exploit every card they have against the larger nations demanding access to their land and resources. Have so many arguments over charcoal production from the Land of Fire’s forests and the shifting international politics over energy production. Really gum up the works in Suna beefing over their finances.

#Naruto brain rot#if only embroidery didn’t require my eyes glued to the fabric#really want to reread Naruto now lmao#just so I can drive myself insane over supply lines#do synthetic fibers exist in Naruto?#yeah it’s definitely time to shift this blog’s about and pages to beyond ATLA#seriously none of this would be the main focus of any fic’s plot#BUT ISNT IT FUN FLAVORING

5 notes

·

View notes

Text

we made a new catnip ball for the beasts, wish it luck

#cats#son boys#pipsqueak#used heavy duty cotton yarn this time cuz pip is always gnawing on his toys so i figure this is ?better? for him than synthetic fibers#wife sewed a little pouch for the catnip & stuffing inside so he can't rip it out through the holes#and i doubled up the yarn and used a slightly too-small hook for an extremely solid exterior#pip could get a job stress-testing cat toys i stg#but his old one held up for like two years so i'm hopeful!

7 notes

·

View notes

Text

one of my resolution for this year is to pay more attention to the materials of the clothes I buy. I don't buy a lot of clothes but when I do, I tend to do it based on how it looks rather than how it's made. I think that by paying more attention to the materials, I will buy pieces that last longer and feel better.

#I'm not saying I will only buy stuff made of wool and cashemere (with what money lol) but at least I want to make an effort to check#and avoid synthetic fibers when possible (for underwear for example)

2 notes

·

View notes

Text

I love 19th century laundry practices

#the straight-forwardness of washing for specific soiling#spot treating by default#it’s more focused on preserving the life of a garment#as opposed to modern washing machine laundry where you toss everything in and wash it all more or less the same way#I mean yes there are different detergents and treatments and cycles#but it’s so much more generalized#and the fact that most clothes are synthetics#like you don’t have to treat modern textiles the same way as you did before synthetics were invented#I love the intention and thoughtfulness with which you have to hand launder natural fibers#I don’t think of it as ‘I’m washing this’ I think of it as ‘I’m maintaining this’#slow processing of slow fashion#the analysis of what kind of soiling on what kind of fiber needs what kind of solvent#like it is a process and it is so much more involved that most people take it to be#but it’s meditative and there is a visible metric for your progress#plus just the satisfaction of ‘I did that’ for something that most of us are used to being an automated thing you don’t have to think about#idk#I just think it’s neat#tales from the servant’s wing#living history

2 notes

·

View notes