#Surface Slitting Rewinding Machine

Explore tagged Tumblr posts

Text

Bopp Tape Manufacturer - High-Quality Packaging Solutions | The Saga Enterprise

Introduction

In today’s fast-paced commercial world, packaging solutions are more than just boxes and labels, they’re essential tools that protect goods, build brand identity, and streamline logistics. At the heart of effective packaging lies something often overlooked but incredibly important: tape. Whether you're running an e-commerce store or a large-scale distribution center, the right tape can make or break your shipping process.

Enter The Saga Enterprise, a trusted Bopp tape manufacturer offering high-quality, durable, and cost-effective packaging solutions tailored for businesses of all sizes. With expertise in adhesive tape, stretch film, custom tape, and printed tape, we combine innovation with reliability to deliver what your business needs most: peace of mind with every package.

What is Bopp Tape?

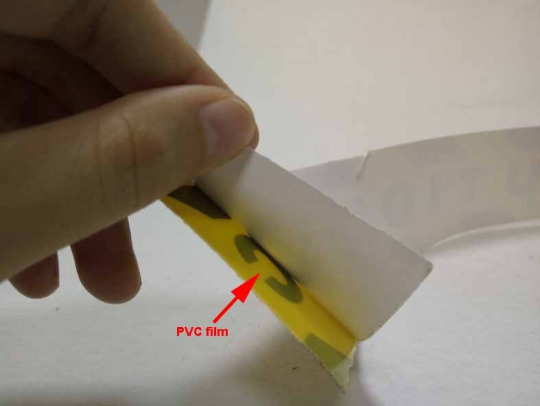

Bopp stands for Biaxially Oriented Polypropylene, a material known for its excellent mechanical and optical properties. In simple terms, it’s a thin plastic film that’s stretched in two directions during production, giving it superior strength and flexibility.

Key Characteristics of Bopp Tape

High tensile strength

Resistant to moisture and chemicals

Excellent clarity and smooth surface

Good dimensional stability

Compared to other packaging tapes like PVC or masking tape, Bopp tape stands out for its durability, eco-friendliness, and suitability for automatic carton-sealing machines. It’s the go-to solution for e-commerce packaging, warehouse storage, and industrial shipments.

Why Choose Bopp Tape for Packaging?

Using the right packaging tape is not just about keeping boxes closed, it’s about protecting what's inside and promoting professionalism. Here's why Bopp tape should be your top pick:

1. Superior Adhesion

Bopp tape uses pressure-sensitive adhesives, such as acrylic or hot melt glue, ensuring long-lasting bonding even on rough surfaces.

2. Temperature and Moisture Resistance

Perfect for varied climates and long transit times, Bopp packaging tape holds strong without peeling or warping.

3. Lightweight and Cost-Effective

Despite its strength, Bopp tape is incredibly lightweight, reducing overall shipping weight and cost.

4. Versatile Applications

Ideal for industrial packaging, courier services, moving companies, FMCG businesses, and more.

When it comes to packaging security and efficiency, The Saga Enterprise’s Bopp tapes lead the way with precision and reliability.

The Manufacturing Process of Bopp Tape

Ever wondered how this miracle tape is made? Let’s break it down:

1. Raw Material Preparation

The base polymer (polypropylene) is melted and converted into a thin film via extrusion.

2. Biaxial Orientation

The film is stretched both lengthwise and widthwise, increasing strength and clarity.

3. Adhesive Coating

One side of the film is coated with a pressure-sensitive adhesive (like acrylic or hot melt).

4. Slitting and Rewinding

Large rolls are cut into smaller, customizable widths using precision slitters.

5. Quality Checks

Each batch undergoes strict quality control to test for:

Adhesive strength

Tensile strength

Film thickness

Resistance to UV, water, and chemicals

The Saga Enterprise ensures all tapes meet global packaging standards with ISO-certified production and eco-conscious practices.

Types of Adhesive Tapes Offered by The Saga Enterprise

We understand that one tape doesn’t fit all. That’s why we offer a wide array of adhesive tapes designed to fit diverse business needs:

1. General Packaging Tape

Clear and brown options

Available in multiple widths

Ideal for day-to-day packaging

2. Printed Tape

Brand your packages with company names, logos, or caution messages

Helps prevent tampering and increases visibility

3. Custom Tape

Choose your own design, width, color, and material

Perfect for brand recognition and professionalism

4. Specialty Tapes

Double-sided tape

Masking tape

Foam tape

Electrical tape

Each variant is developed with premium materials and tested adhesives, ensuring you always get top-notch performance.

Custom Tape Solutions for Brand Visibility

Let’s face it, first impressions matter. Custom packaging tape does more than just seal a box; it tells your story.

Why Custom Tape?

Build brand identity

Create customer loyalty

Deter tampering during transit

Stand out in crowded logistics chains

What Can Be Customized?

Logo or brand name

Text or tagline

Background color and finish (matte or gloss)

Tape width and length

With The Saga Enterprise, you get full creative freedom to design packaging tape that reflects your brand’s tone and values.

Stretch Film and Wrap Rolls: A Must-Have for Bulk Packaging

Beyond adhesive tape, stretch film is another unsung hero of the packaging world. Whether you’re bundling pallets or securing heavy items, our stretch wrap rolls have you covered.

Benefits of Stretch Film:

Protects goods from dust, moisture, and shifting during transit

Improves stability and load security

Reduces pilferage and tampering

Our Stretch Wrap Options:

Hand Roll: For manual application

Machine Roll: Compatible with stretch wrapping machines

Colored Films: For visual sorting and labeling

UV Resistant Films: For outdoor storage

All stretch films are designed to stretch up to 300%, reducing film usage and costs while enhancing load safety.

Benefits of Choosing The Saga Enterprise

There are countless tape manufacturers, but here's why our clients stick with us (pun intended):

1. Advanced Infrastructure

We operate with state-of-the-art machinery, capable of large-scale production with minimal waste.

2. Consistent Quality

Every product is QC tested, ensuring you receive uniform adhesive strength and film clarity.

3. Competitive Pricing

Whether you’re a startup or enterprise, we offer flexible pricing models for small and bulk orders.

4. Quick Turnaround

Need a large custom order fast? Our streamlined processes and expert team ensure on-time delivery every time.

Applications Across Industries

Our tape and packaging products are trusted by a wide range of industries:

E-commerce & Courier Services: Durable tapes for high-volume packaging

Pharmaceuticals: Tamper-evident and hygienic stretch films

Food & Beverage: Custom tapes with branding and storage safety

Electronics: Static-resistant and secure sealing solutions

Retail & Supermarkets: Brand-enhancing tapes for point-of-sale packaging

With The Saga Enterprise, packaging is no longer an afterthought, it’s part of your brand strategy.

Innovations in Tape Manufacturing

We believe in staying ahead of the curve. Here’s how we keep innovating:

1. Water-Based Adhesives

Safer for the environment and workers, with the same superior grip.

2. Biodegradable Tapes

Made from recyclable or compostable materials, perfect for eco-conscious brands.

3. Smart Packaging

We’re exploring tapes embedded with QR codes, holograms, and RFID technology for intelligent tracking.

Sustainability and Eco-Friendly Packaging

As a responsible manufacturer, we’re committed to reducing our carbon footprint.

Recyclable Bopp tape options

Solvent-free adhesive choices

Eco-stretch films for responsible disposal

Participation in plastic offset programs

Our team can help you make sustainable packaging decisions without compromising strength or aesthetics.

How to Select the Right Tape for Your Packaging Needs

Choosing tape isn’t one-size-fits-all. Here's what to consider:

1. Tape Width & Thickness

Heavier loads need wider, thicker tape

40 microns is standard; 50+ microns for heavy-duty boxes

2. Adhesive Type

Hot Melt: Strong grip, fast tack

Acrylic: UV-resistant, suitable for long storage

Solvent-based: Best for extreme temperatures

3. Packaging Conditions

Cold storage

Rough handling

Long-distance transport

Need help picking? The Saga Enterprise team offers free consultations.

Global Market and Export Capabilities

Based in India, we proudly serve clients across the globe:

USA, UK, Australia, UAE, and Europe

Timely delivery through trusted logistics partners

Full export documentation and compliance support

Bulk order capacity with on-demand customization

With global packaging standards, we’re helping businesses expand with confidence.

FAQs

What is the minimum order quantity for custom tape?

Ans: The minimum order starts at 5,000 meters, but we can accommodate smaller test runs on request.

Can printed tape be made waterproof?

Ans: Yes! Our Bopp printed tapes come with water-resistant ink and film options.

What industries benefit the most from stretch wrap rolls?

Ans: Logistics, food storage, pharma, electronics, and agriculture use stretch film for securing large shipments.

How long does it take to manufacture custom packaging tape?

Ans: Standard turnaround is 7-10 business days, depending on design and volume.

Is Bopp tape recyclable?

Ans: Yes. Our Bopp tapes are made from recyclable polypropylene. Ask us about our eco-line.

Conclusion

At The Saga Enterprise, we know that packaging is more than just tape, it’s trust. With our extensive range of Bopp tape, adhesive tape, stretch film, and custom branding solutions, we’re helping businesses package smarter, safer, and stronger.

Need the perfect packaging solution? Let’s build it together.

0 notes

Text

Manufacturing Process: Producing High-Quality Corona-Treated Breathable Fabric Rolls

Corona-treated breathable fabric rolls are essential in industries like desiccant packaging, hygiene products, and medical supplies. These fabrics undergo a special surface treatment to improve adhesion and printability while maintaining their air permeability and strength. But how are they made?

Step-by-Step Manufacturing Process

Raw Material Selection The process starts with high-quality polypropylene or polyester granules, selected for their durability and flexibility.

Non-Woven Fabric Formation Using spunbond or meltblown technology, the material is converted into breathable fabric sheets with controlled GSM (grams per square meter) and porosity.

Corona Treatment The fabric is passed under a corona discharge system, which alters the surface energy to make it more receptive to printing inks, adhesives, or coatings. This enhances performance in packaging and labeling applications.

Heat Sealing Compatibility Testing The treated fabric is tested for seal strength, ensuring it can be effectively used in high-speed heat sealing or ultrasonic pouch-making machines.

Slitting & Rewinding Rolls are slit into customized widths and rewound into precise lengths, ready for use in sachet-making or industrial applications.

Quality Control Each roll undergoes strict quality checks for uniform thickness, breathability, surface treatment efficiency, and roll consistency.

Final Thoughts

Corona-treated breathable fabric rolls offer unmatched functionality in packaging and industrial applications. At Favourite Fab, we combine advanced manufacturing and strict quality control to deliver high-performance rolls tailored to your needs. Choose precision, choose reliability—choose Favourite Fab.

0 notes

Text

The benefits of using anti slip tape

There are many benefits to using anti slip tape. This type of tape can help to prevent accidents by providing a much needed grip on slippery surfaces. It can also help to protect against wear and tear, as well as making it easier to clean up any spills.

The application of anti slip tape

What are the selection criteria for anti slip tape?

What is the working principle of anti slip tape?

The application of anti slip tape

There are many different types of anti slip tape, each with their own unique properties and benefits. However, all anti slip tapes share one common trait: they all help to keep you safe from slipping and falling.

anti slip tape is typically made from a variety of different materials, including rubber, PVC, and even metal. The type of material used will usually depend on the specific application for which the tape is being used. For example, metal anti slip tape is often used in industrial settings where there is a lot of foot traffic, as it is extremely durable and can withstand heavy wear and tear.

The rubber and PVC anti slip tapes are often used in residential and commercial settings as they are more forgiving if someone does happen to slip and fall. These types of tapes are also typically much less expensive than their metal counterparts.

No matter what type of anti slip tape you choose, make sure that it is applied correctly in order to ensure the best possible results. If you are unsure about how to apply the tape, or if you have any other questions about its use, be sure to consult with a professional before proceeding.

What are the selection criteria for anti slip tape?

1. When purchasing, check whether there are burrs on the surface of the anti slip tape.

2. The adhesive should be strong and durable, waterproof.

3. Check the anti-fouling ability of anti slip tape. This material has strong wear resistance and excellent water absorption function, so its application range is extremely wide.

What is the working principle of anti slip tape?

anti slip tape is used in the coating process of double-sided adhesive tape. When the double-sided tape is pulled out from the coating machine, it needs to be guided out by rollers. If the surface of the guide roller is not specially treated, the adhesive will stick to the roller and affect the Production and tape quality. The surface of the roll is usually covered with a low surface energy material to prevent sticking. This single-sided non-slip tape is specially designed for this application. It is coated with a durable adhesive on one side to firmly stick to the surface of the output roller, and the other side is made of special low surface energy rubber, which can effectively prevent the adhesive from being damaged Adhesive effect.

Jiangmen E Win Adhesive Products Co., Ltd is equipped with all kinds of professional production equipment. The factory has glue coating machine, rewinding machine, slitting machine, hot shrink machine and die-cutting machine.

0 notes

Text

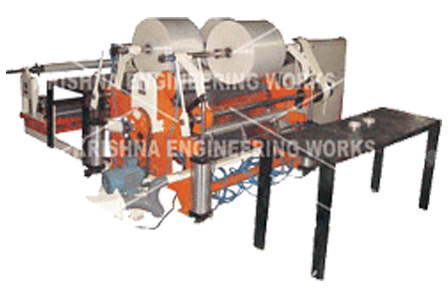

From Pulp to Roll: Understanding the Manufacturing Process of Toilet Paper Machines

Toilet paper is a ubiquitous household item that we often take for granted. However, behind every roll of toilet paper lies a complex manufacturing process that involves specialized machines. Understanding the intricacies of toilet paper machine production can shed light on the journey from pulp to the final product that we use daily. In this blog, we will explore the key steps involved in the manufacturing process of toilet paper machines.

Pulp Preparation:

The first step in producing toilet paper is the preparation of the pulp. Wood chips or recycled paper are processed in large machines called pulpers. The pulpers break down the raw material, removing impurities and creating a slurry-like mixture called pulp. This pulp will serve as the foundation for the toilet paper production process.

Paper Machine:

Once the pulp is ready, it is fed into a paper machine. The paper machine consists of a series of sections and components that work together to transform the pulp into thin sheets of paper. These sheets are then pressed, dried, and rolled onto large spools.

Rewinding and Slitting:

The large spools of paper are then transferred to rewinding machines. In this step, the paper is unwound from the spools and rewound onto smaller rolls, which are more convenient for consumer use. The rewinding machines also have slitting blades that cut the large sheets of paper into narrower strips, which will form individual toilet paper rolls.

Embossing and Perforation:

Toilet paper often features patterns or embossed designs on its surface. This is achieved through embossing rolls that press decorative patterns onto the paper during the rewinding process. Additionally, perforation blades create small dotted lines along the paper strip, allowing for easy tearing and separating of individual sheets.

Cutting and Packaging:

After embossing and perforation, the toilet paper strips are cut into individual rolls. These rolls are then packaged using automated packaging machines. The packaging machines wrap each roll in plastic or paper, ensuring hygiene and protection during transportation and storage.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the toilet paper meets industry standards. These measures include monitoring the thickness, strength, and softness of the paper, as well as inspecting the embossing and perforation patterns. Any defective rolls are removed to maintain the overall quality of the final product.

Conclusion

The manufacturing process of toilet paper machine involves several intricate steps, from pulp preparation to cutting and packaging. Specialized machines and quality control measures ensure that the toilet paper meets the necessary standards of thickness, strength, softness, and hygiene. By understanding the manufacturing process behind toilet paper, we gain a deeper appreciation for the complexity involved in producing this essential everyday product.

0 notes

Link

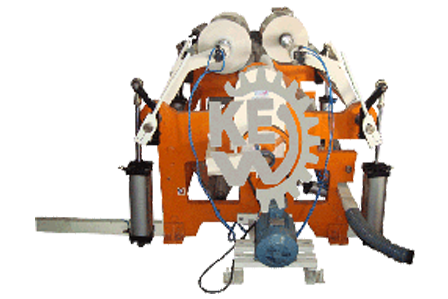

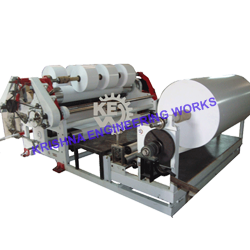

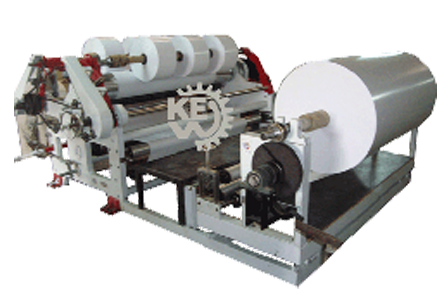

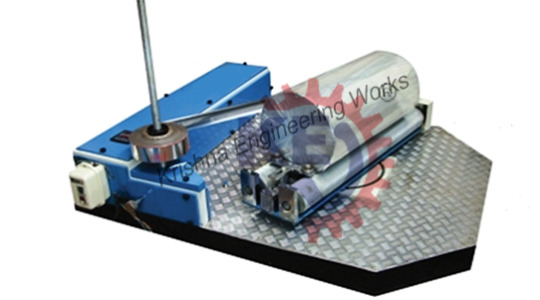

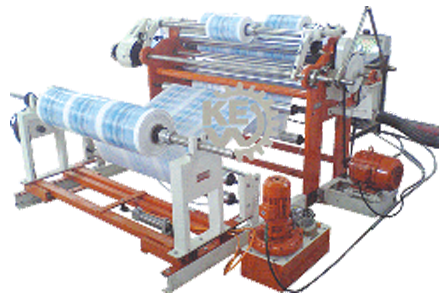

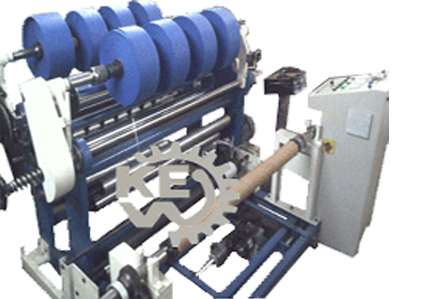

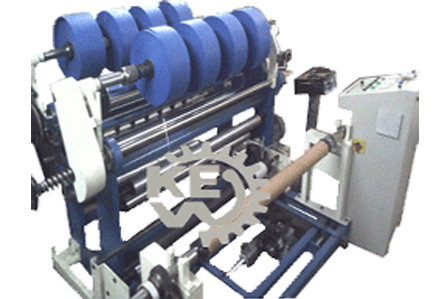

We are experienced manufacturer, exporter & supplier of Slitter Rewinder Machine. High speed and heavy duty Automatic Slitting Rewinding Machine Manufacturer on demand of client’s requirement and machine specific application and material. Slitting of all types of Plastic Slitting Rewinding Machine, Woven Sack Slitting Rewinding Machine, High Speed Slitting Rewinding Machine, Surface Slitting Rewinding Machine, Label Slitting Rewinding Machine, Cantilever Slitter Rewinder Machine, Rubber Slitter Rewinder Machine, Mini Cantilever Slitter Rewinder Machine.

#Automatic Slitting Rewinding Machine#Automatic Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder#Mini Cantilever Slitter Rewinder Machine#Rubber Slitter Rewinder Machine#Cantilever Slitter Rewinder Machine#Label Slitting Rewinding Machine#Surface Slitting Rewinding Machine#High Speed Slitting Rewinding Machine#Woven Sack Slitting Rewinding Machine#Plastic Slitting Rewinding Machine

2 notes

·

View notes

Link

We have been successfully Manufacturing, Exporting & Supplying all the types of Slitting Rewinding Machine, Surface Slitting Rewinding Machine is the most commonly used machine type. All different types of Films & Paper Materials can be processed in our Surface Winding Slitting Machine. Slitter Rewinder Machine with heavy duty Rubber Roller Plastic Slitting Rewinding Machine, Woven Sack Slitting Rewinding Machine, High Speed Slitting Rewinding Machine, Automatic Slitting Rewinding Machine.

#Surface Slitting Rewinding Machine#Surface Slitting Rewinding#Slitting Rewinding Machine#Slitting Rewinding#Slitter Rewinder Machine#Slitter Rewinder#Slitter Rewinder Machine Manufacturer#High Speed Slitting Rewinding#High Speed Slitting Rewinding Machine#Slitter Rewinding Machine

0 notes

Link

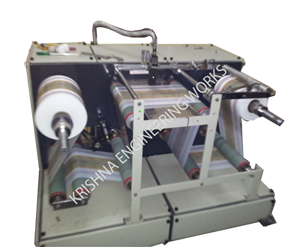

We have been successfully Manufacturing, Exporting & Supplying all types of Doctoring Slitting Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing. Our Doctoring Slitting Rewinding Machine is featuring on spending less power. Also, majorly used for Doctoring Slitting all types of Laminates like Foil, Paper, LDPE, HDPE, PVC. Doctoring Rewinding Machine, Doctoring Machine, Slitting Rewinding Machine, Doctoring Slitting Rewinding Machine, Slitter Rewinder Machine Manufacturer, Slitting and Rewinding Machine, Paper Rewinder Machine, Paper Slitting Machine for Sale, Surface Slitter Rewinder, Paper Slitting and Rewinding Machine, Paper Rewinder Machine Manufacturers, Slitting and Rewinding, Slitting Rewinding, BOPP Tape Slitting Rewinding Machine, Aluminium Foil Slitting Machine, Thermal Paper Slitter Rewinder, Roll Slitter Rewinder, Paper Slitting Rewinding Machine, Aluminium Slitting Machine, Paper Roll Slitter Rewinder, Paper Rewinder for Sale

#Doctoring Rewinding Machine#Doctoring Machine#Slitting Rewinding Machine#Doctoring Slitting Rewinding Machine#Slitter Rewinder Machine Manufacturer#Slitting and Rewinding Machine#Paper Rewinder Machine#Paper Slitting Machine for Sale#Surface Slitter Rewinder#Paper Slitting and Rewinding Machine#Paper Rewinder Machine Manufacturers#Slitting and Rewinding#Slitting Rewinding#BOPP Tape Slitting Rewinding Machine#Aluminium Foil Slitting Machine#Thermal Paper Slitter Rewinder#Roll Slitter Rewinder#Paper Slitting Rewinding Machine#Aluminium Slitting Machine#Paper Roll Slitter Rewinder#Paper Rewinder for Sale

1 note

·

View note

Link

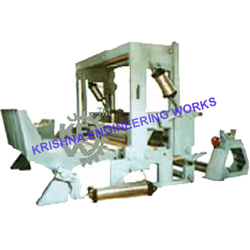

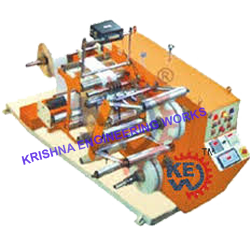

Krishna Engineering Works is one of the best Manufacturer, Exporter, and Supplier of Rewinding Machine, Roll to Roll Processing Machines for various types of process like Rewinding Machine, Slitting, Doctoring Rewinding, Winding Rewinding, Rewinding Unwinding, Jumbo Roll to Small Roll Rewinding Machine, Folding, Fold Open, Converting, Corona Treatment, Inspection, Trim Rewinding Machine, Printing, Coating, Laminating, Flexo Printing, Batch Printing, Flexible Packaging, Slitter Rewinder Machinery, Core Cutter, all types of Industrial Rollers, Printing machinery.

All our Rewinding Machine and Roll to Roll Converting Machines technically designed with heavy-duty and accurate features for different materials like Paper, Film, Nylon, Textile / Fabric, Non-Woven, Foil, Flexible Packaging, Tyre Cord, Technical Textile.

Our range of Different types of Rewinding Machine, Roll to Roll Processing Machines is capable to process all types of Laminates like Film, Paper, Aluminium, Foil, PVC, Plastic, LD, LDPE, PP, BOPP, Cloth, Fabric, and many more. Rubber Roller Manufacturer, Slitter Rewinder Machine, Roll to Roll Processing Machines, Roll to Roll Coating, Industrial Rubber Rollers, Slitter Rewinder Machine Manufacturer, Slitter Rewinder for Sale, Slitter Rewinder Manufacturers, Paper Slitter Rewinder Machine, Rubber Rollers Suppliers, Film Slitting Machine, Surface Slitter Rewinder, Slitting and Rewinding Machine, PU Roller Manufacturer, Roll to Roll Sputtering, Thermal Paper Slitting Rewinding Machine, Industrial Rollers Manufacturers, Mini BOPP Tape Slitting Rewinding Machine, Slitter Rewinder Machine Price

#Rubber Roller Manufacturer#Slitter Rewinder Machine#Roll to Roll Processing Machines#Roll to Roll Coating#Industrial Rubber Rollers#Slitter Rewinder Machine Manufacturer#Slitter Rewinder for Sale#Slitter Rewinder Manufacturers#Paper Slitter Rewinder Machine#Rubber Rollers Suppliers#Film Slitting Machine#Surface Slitter Rewinder#Slitting and Rewinding Machine#PU Roller Manufacturer#Roll to Roll Sputtering#Thermal Paper Slitting Rewinding Machine#Industrial Rollers Manufacturers#Mini BOPP Tape Slitting Rewinding Machine#Slitter Rewinder Machine Price

0 notes

Link

Heavy Duty and Light Duty Metallized Polyester Film Slitter Rewinder Machine We are award winning company of Slitting Machine Manufacturer, Exporter. Different types of films like, Chemical Metallized Polyester Film, Metallized Polyester Film Slitter Rewinder Machine, Metalized Polyester Film, Synthetic Metallized Polyester Film, and Corona Metalized Polyester Film. All our slitter Rewinder machines designed with heavy duty and high quality equipment for different types of applications in various applications. Our machine is an ultimate Slitter and Rewinder Machine for its accurate slitting and rewinding qualities. It ensures perfect slitting of rolls with consistent, flawless results and constant line speed. It is available in adaptable model to suit your requirement. Our Slitter Rewinder Machine is available in Rewinder, Duplex surface slitter and Rewinder and Canti lever differential slitter and Rewinder. Our Slitting Rewinding Machine is renowned for its accurate slitting at a higher speed and vibration less working.

#Film Slitter Rewinder Machine#Slitting Machine#Slitter Rewinder Machine#Slitting Rewinding Machine#Slitter Rewinder#Slitter Machine#Slitters#Metallized Polyester Film Slitter#Slitter#BOPP Film#Paper Slitter Machine#Roll Slitting Rewinding Machines#Fabric Slitter Rewinder Machines#Winder Rewinder#Winding Rewinding Machine#Rewinder Unwinder Machine#Film Slitter Rewinder Machine Manufacturer#Film Slitter Machine Supplier

1 note

·

View note

Text

Elite Cameron

Elite Cameron manufactures slitting, rewinding, coating and laminating machines which are incredibly versatile and capable of processing a broad range of materials such as delicate non-wovens, flexible packaging, self-adhesive tapes, laminates, papers, foils, rubber, and plastics. We offer a complete line of slitter rewinders including turret rewinders, surface winders, duplex slitters, center winders along with other converting equipment such as hot melt coaters, core cutters, laminators and specialty converting equipment. Our machines are available worldwide. For more information contact our sales & engineering teams in the UK or USA offices.

http://www.elitecameron.com

Facebook

Twitter

Youtube

Linkedin

Google Maps

Google Maps

1 note

·

View note

Link

We are focus on quality of Slitter Rewinder Machine Manufacturer for Film and Paper Slitting Rewinding Machine, Hi-Speed Slitting Rewinding Machine on custom requirements applications from India. Different types of shaft type Slitter Rewinder Machine such as Surface Slitting Machine, Thermal Paper Slitter Rewinder Machine, Rewinding Machine for label etc. Slitter Rewinder Machine Materials, Plastic Slitter Rewinder, Paper Slitter Rewinder, PVC Slitter Rewinder, Bopp Film Slitter Rewinder Machine.

#Slitter Rewinder Machine#Slitting Rewinding Machine#Slitting rewindier machine#Slitter rewinding machine#Rewinding Machine#Slitting Rewinding#Slitter Rewinder Machine Manufacturer#Slitting Rewinding Machine manufacturer

3 notes

·

View notes

Text

Operation process of slitting machine

Today we will take everyone to understand the operation process of the slitting machine, so that we can have a good start when we operate the machine.

Start preparation 1. Check whether the power and air source are normal. 2. Check whether each transmission part needs to be filled with lubricating oil, and whether each part is loose. 3. Turn on the electrical isolation switch and check whether the voltage, current, and temperature are correct. 4. Turn on the power switch of the hydraulic system and check whether the oil level of the main hydraulic drive system and the pressure gauge display are correct and stable. 5. Open the start throttle valve and check whether the air pressure is correct (not less than 6.0bar) and stable.

Settings control 1. Set the slitting menu according to the PVC film type, thickness, length, width, etc. of the slitting plan. 2. Extract the corresponding PVC film file from the PDF. 3. Set the rewinding length and width of the film of corresponding specifications. 4. Select the corresponding winding station, adjust the pressure roller arm and pressure roller, and install the paper core of the corresponding specification. Loading, piercing and adding film 1. According to the requirements of the slitting plan, in accordance with the operating rules and actual conditions, hoist the corresponding parent roll on the aging rack, select the direction according to the corona surface inside and outside, and place it on the unwinding rack of the slitting machine, and press the control button Clamp and tighten the steel core, leave the steel core support arm and drive. 2. Film piercing: When there is no film on the slitting machine, the film must be pierced. Use the film-piercing device and function keys of the slitting machine to tie one end of the original film to the eyelet of the film-piercing chain, and press the film-piercing button to make the film evenly distributed on the rollers along the slitting process. 3. Film splicing: When there is film on the slitting machine and the roll joint is changed, use the vacuum splicing table, first start the film splicing table to the working position, manually flatten the film on the first traction roller of the slitting machine and start the upper vacuum pump for suction Film, so that the film is smoothly absorbed on the film splicing table, paste the double-sided tape and cut off the excess film under the tape, flatten the film on the unwinding rack, start the vacuum to make the film absorb smoothly, and remove the tape. Put the paper layer, level the film, and the joints should be neat and wrinkle-free, then turn off the upper and lower vacuum pumps, and open the splicing table to a non-working position.

start up Change the specifications and put the paper core on the inner and outer winding arms. When the press roller is in the ready state, the people around the machine should evacuate quickly. Slitting control 1. During the slitting operation, carefully monitor and observe the slitting effect, and appropriately adjust and control the slitting speed, unwinding tension, contact pressure, bending roller, edge material traction roller, edge guide, etc. Receipt 1. When the inner and outer ends of the winding are finished and the machine stops, use the film unloading button to place the film on the prepared film unloading trolley, cut the film, and paste the film roll with sealant. 2. Use the chuck release button to release the chuck and check whether the paper core of each roll of film rolls away from the paper core. If one end is still stuck on the paper core, remove the film roll manually. 3. Make sure that all the films leave the chuck and put them on the trolley. Use the film loading button to raise the winding arm, install the corresponding paper core, and place the film neatly on the paper core for the next slitting.

Stop device When the film roll reaches the set length, the equipment automatically stops.

visit:https://www.china-changcheng.com/news/operation-process-of-cutting-machine

0 notes

Text

Characteristics and uses of carbon fiber air expanding shaft

Today, Coreco introduces you to some information about air expanding shafts. The main points are the concept of air expanding shaft, the characteristics of air expanding shaft, the characteristics of carbon fiber air expanding shaft and its usage.

The concept of air expanding shaft

A air expanding shaft is a special kind of winding and unwinding shaft, that is, a shaft whose surface can be protruded after being inflated under high pressure, and the shaft whose surface part retracts quickly after being deflated is called air expanding shaft. It is called various names, such as air pressure shaft, expansion shaft, inflation shaft, air expansion roller, inflation shaft, pressure shaft, air expansion roller, etc.

Features of air expanding shaft

1 Inflatable operation time is short, the separation and placement of air expanding shaft and paper tube only takes 3 seconds to complete the inflating and deflating, and there is no need to divide any parts on the end side of the slack shaft that can be closely occluded with the paper tube.

2 Easy placement of paper tube: with the action of inflating and deflating, the paper tube can be moved and fixed in any position on the shaft surface.

3 Large load weight: The size of the shaft diameter can be determined according to the actual needs of the customer, and high hardness steel is used to make the load weight increase.

4 High economic efficiency: The shaft is designed for special function, and it can be applied to all kinds of paper tubes, such as thick, thin, wide and narrow.

5 Simple maintenance and long service life: The air expanding shaft is a single part, and each part of its structure has fixed specifications, which can be interchanged and used, making it easy to maintain.

First,Wide range of applications: As an independently designed part, the air expanding shaft can be used from 1 inch to 12 inches, with the length and size determined by the actual needs of the customer, and can be used for slitting, printing, rewinding, coating, laminating, bagging, papermaking, etc. or other related machinery.

Second, economic and efficient: the design of the shaft for the actual work needs of the design, the thickness and width of the various types of roll can be applied.

Third, the use of a long time, simple maintenance: Although the air expanding shaft is an accessory on the machinery, but its own structure of each part have fixed specifications, can be interchangeable, making it easy to maintain.

Fourth, a single accessory: air expanding shaft is a single spare part of the winding and unwinding machinery, each part of its structure has a fixed size, can be broken down and combined, so that maintenance is convenient, durable surface.

V. Professionalism: There are professional engineers and technicians for market research on the design and installation of air expanding shaft.

Sixth, large carrying capacity: air expanding shaft shaft can be designed according to the actual model, the use of high-quality steel, increase the carrying capacity. For example, the bearing weight of more than 1 ton can be selected from steel materials.

Seven, the operation time is short: separation and placement of the coil can be completed in just 2 seconds of inflating and deflating action, placing the coil is simple and convenient, safe and applicable. All machines and equipment used for winding and rewinding can be applied to the air expanding shaft. The longest air expanding shaft can reach six meters or more, and the shortest can reach several hundred millimeters, all according to customer needs to determine the length.

Eight, key-type air expanding shaft expansion up to a single key bar, the fulcrum point spread to each key bar, balance the force, can be applied to mechanical winding bearing heavy items.

Features and uses of carbon fiber air expanding shaft

Lightweight carbon fiber inflatable shafts are ergonomic, lightweight inflatable shafts with both durability and high-speed operation.

Carbon fiber inflatable shafts are 1/4 the weight of traditional inflatable shafts, making them ideal for high load carrying and manual handling and cutting. It can reduce occupational injuries of handling operators and also improve work efficiency. The optimized internal structure design is widely used in the air inflatable shaft industry, and it does not produce violent vibration even in the high speed field. Wide range of application, it can be applied to special surface treatment in various special environments (no pressure, corrosive, high temperature environment).

The use of carbon fiber air shaft is very wide, all machines with winding, unwinding and slitting can be applied to carbon fiber air shaft, even including light metal industry. For example: the air expanding shaft is mainly used in printing equipment: printing machine, flexographic printing machine, gravure machine, trademark printing machine, etc.; other machinery: coating machine, leather machine, shaping machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, fabric inspection machine, hot stamping machine, battery equipment and other related machinery.

0 notes

Text

SP Ultraflex’s ROBOSLIT impresses Constantia Parikh

Vienna-based Constantia is one of the largest flexible packaging manufacturers globally. It now has several plants in India based on its acquisitions of Parikh Packaging and Creative Polypack. It also set up a Greenfield plant for its recyclable PE-based flexible packaging plant called Constantia Ecoflex in Ahmedabad, inaugurated in 2019. We are producing an edited version of an interview of Ahmedabad-based Pragnesh Shah, plant head of the Constantia Parikh Packaging sub-cluster below.

Please tell us a bit about the inception of Constantia Parikh Packaging and its area of focus within the flexible packaging segment.

Pragnesh Shah – Constantia Parikh Packaging was formed in 2013, when the Parikh family, promoters of Parikh Packaging, welcomed the Constantia Flexibles group as partners. Regular investments in infrastructure, systems, and plant and machinery enabled the company to grow 3x, and the monthly output now stands at 1800 MT. In 2017, we decided to venture into 100% recyclable laminates and set up our new state of art plant ‘Ecoflex’ in 2019. We launched ‘Ecolam,’ a 100% PE-based laminate to replace aluminum foil from the new unit. By 2025, we plan for 100% of all consumer and pharma packaging to be recyclable, reflecting our commitment to society for environmental friendliness.

Can you help us with an overview of the plant and machinery in your company?

Pragnesh Shah – We started with indigenous machines but were let down in terms of performance. As a result, we shifted to European and Korean technology. We are happy to share that after seeing improvements in Indian machines over the years, we have come full circle today. Most of the recent additions to our plant are from reputed Indian manufacturers.

Being one of the oldest and most reputed converters in the region, we would like to know how important the role of slitting rewinding machines in the overall process of converting is?

Pragnesh Shah – Slitting is usually the last process before the final product is delivered to our customer. Most of our customers are from the food industry and cannot afford stoppages in their packing lines due to slitting defects. In addition, slitting defects can undo all the efforts made in the printing and lamination processes. Therefore, we feel it is essential to invest in the best technology for slitter rewinders, mainly because their cost is a small fraction of the total investment.

Which performance parameters are critical and which features are ‘must haves’ on a good slitter rewinder?

Pragnesh Shah – First and foremost, the ITM (Intelligent tension management), is an absolute must to reduce dependency on operator expertise. Here, the PLC computes and maintains the tension levels suitable to the job. I see the next level of automation in the area of the job setup. The hygiene factor is also very important for food and pharma customers, and a close study of the layout from this perspective is most essential while finalizing the machine. Lastly, I would stress the static management system, which will soon be the need of the hour as more and more customers switch to high-speed packing machines that are most intolerant to residual static.

After installing multiple dual turret slitter machines worldwide, how has your experience with this technology been so far?

Pragnesh Shah – Slitter rewinders with dual turret rewinds are the order of the day in these competitive times where the focus is to increase efficiency. Unlike duplex slitters, these machines run virtually non-stop, offering higher productivity, improved efficiency of man and machine, and optimal use of floor space. Consistency in performance is also higher as compared to duplex machines. Opting for dual turret slitters would also reduce the total number of slitters required to support a given plant capacity over a period of time.

You installed a ROBOSLIT machine from SP Ultraflex a few months back. How was your experience?

Pragnesh Shah – The OHP version of the Roboslit was installed at our plant in February 2021, and we have found its performance to be at par with the best in the world. The team at SP Ultralflex puts in a lot of effort in learning, researching, and understanding the customer’s pain areas and channelizes their inputs to their design department, leading to continuous improvements and innovations. They are also very supportive, understanding the significance of our queries, and give clear and meaningful answers.

Pragnesh Shah, plant head of the Constantia Parikh Packaging sub-cluster[/caption]

In general, most converters prefer compact, rear-loading slitter rewinders. But you have purchased the overhead model of the Roboslit series, the Roboslit OHP. What made you go for that model?

Pragnesh Shah – The most admirable quality in the OHP version is the overhead web movement. Substrates running between idle rollers at high speed tend to develop static charge and attract dust. This is not acceptable, especially when it comes to food and pharma customers. The substrate is always at a good distance from the floor level in the OHP layout, leaving no scope for the dust to contaminate its surface. Other advantages of the overhead path include easy access to the cutting section and better visibility of the running substrate. Last but not least, this layout improves the safety quotient of the machine – something that is non-negotiable within the Constantia Flexibles group.

To what extent did SP Ultraflex meet the expectations of Constantia Flexibles in terms of output, quality, operator friendliness, and safety standards?

Pragnesh Shah – To start with, safety and user-friendliness are of utmost importance to Constantia Flexibles, and both these aspects are well taken care of in the machine. Coming to the output, I have already spoken about the increased productivity of this machine by virtue of its dual turret rewind. I want to share another important dimension, which affects productivity – the ratio of rework. We have seen a drastic reduction in the percentage of narrow width coils that need to be edge corrected on doctoring machines, thanks to the better quality of finished reels produced on this machine.

How, in your opinion, does the SP machine compare with the European make machines in your plant?

Pragnesh Shah – It is a good indigenous technology at par with global standards, with certain additional features and a good team.

What is the future focus for Constantia Parikh Packaging in terms of capital equipment technology? As mentioned earlier, we are looking for indigenous machines which will fulfill our requirements and expectations. We have a robust technical evaluation team that defines the ‘what’ and ‘why.’ If all such conditions and expectations are fulfilled, we would prefer Indian make machines, thereby supporting the Make in India movement.

0 notes

Link

We are the manufacturer of High-Performance Slitter Rewinder Machine for every type of material like Fabric, Paper, Film, Jumbo Slitting Rewinding Machine, Heavy Duty Slitter Rewinder Machine. We are engaged in Slitter Rewinder Machine with hi-speed features. For Slitting Machine, we have processed all types of material like LD, PVC, Paper, Film, Cloth, Nylon, etc. We have more than 5000 installations of Slitter Rewinding Machine all over the world. For Doctoring Rewinding Machine, we have more than 4000 installations all over India & overseas. slitter rewinder machine, slitter rewinder, slitter rewinder machine manufacturer, slitter rewinder for sale, used slitter rewinder, paper slitter rewinder machine, slitter rewinder manufacturers, film slitting machine, surface slitter rewinder, slitting and rewinding machine, used slitting machine for sale, duplex slitter rewinder, used paper slitting machine for sale, turret slitter rewinder, foil slitting machine, thermal paper slitting rewinding machine, used slitter rewinder for sale, center slitter rewinder, center surface slitter rewinder, kraft paper slitting machine, mini Bopp tape slitting rewinding machine, paper slitting machine for sale, slitter rewinder used, paper slitter rewinder, thermal paper slitter rewinder, roll slitter rewinder, jumbo roll slitter rewinder, aluminum foil slitting machine, second-hand slitter rewinder machine, paper slitting and rewinding machine, slitter and rewinder, slitter rewinder machine price, roll slitting machine for sale

#slitter rewinder machine#slitter rewinder#slitter rewinder machine manufacturer#slitter rewinder for sale#used slitter rewinder#paper slitter rewinder machine#slitter rewinder manufacturers#film slitting machine#surface slitter rewinder#slitting and rewinding machine#used slitting machine for sale#duplex slitter rewinder#used paper slitting machine for sale#turret slitter rewinder#foil slitting machine#thermal paper slitting rewinding machine#used slitter rewinder for sale#center slitter rewinder#center surface slitter rewinder#kraft paper slitting machine#mini Bopp tape slitting rewinding machine#paper slitting machine for sale#slitter rewinder used#paper slitter rewinder#thermal paper slitter rewinder#roll slitter rewinder#jumbo roll slitter rewinder#aluminum foil slitting machine#second-hand slitter rewinder machine#paper slitting and rewinding machine

0 notes

Text

Analysis For Three Common Risk Control Points of Solventless Composite Technology

machine.html">solventless lamination machines. Significant advantages of the solventless composite process are reducing cost, high efficiency and energy saving, improving production safety, stability and product quality.

However, due to the immature solventless composite technology , and there are still some technical risks that are easily overlooked in the application for a flexible packaging company, leading to quality problems. Now we summarize three common risk control points of solvent-free composite technology.

1. The Technical Risk Of Increasing A Glue In Solventless Composite

Solvent-free composite adhesive with A glue and B glue, the adhesive mixing ratio is generally the weight ratio of A glue and B glue, rather than the volume ratio of both. The mixing ratio of the binder is usually determined by the adhesive manufacturer, as the proportion of the binder in different brands is generally different. The common ratios of A glue and B glue are 100: 80,100: 75,100: 50,100: 45. However, in the actual solvent-free composite production of flexible packaging companies, the ratio of the two-component adhesive will be disordered, which will affect the solventless quality of flexible packaging products.

Case

After printing, solvent-free compounding, the flexible structure of OPP / VMPET / PE has no quality problems.

The structural composite flexible bag is a low viscosity-free solvent-free binder brand and the proportion of A glue and B glue in actual composite production is 100: 67. When analyzing the cause of failure, we find that the bag is curled and the inner binder is not dry. Originally, because the composite film maturity is incomplete, prolongs the maturation time and then cuts into a bag. The problem of bag curling still exists and the opening performance has also deteriorated.

Combined with a ratio of A glue and B glue, it is not difficult to find that the bag is mainly caused by the excess of the A glue, because the solvent-free composite film is usually large and the effect of prolonging maturity is not obvious, water must be introduced into the cross-linking curing reaction with the -NCO.

The much more efficient methods are to rewind the composite film roll on a slitting machine and then increase the humidity of the workshop environment to absorb some moisture between the layer and the surface. The composite film, during aging, water will penetrate into the adhesive layer and reacted with an excess-NCO cross-linking curing reaction, so that the self-adhesive layer will be further completely cured, thereby effectively release the curling of the flexible packaging bags.

2. Risk Control For The Attenuation Of PE Membrane Peel Strength At Solventless Composite Material

A certain amount of linker is added to the film blow molding for reducing the friction between the film and the film, the film and the device, so that the surface of the film will be smoother, in order that the composite film operates successfully in the production process. Under normal circumstances, an excess sliding agent has added appropriately in the PE film, which can solve the phenomenon of abnormal increase in the friction coefficient of the solvent composite film after a certain extent, but this can also cause peel strength to be weakened, which is serious. When the aging is completed, the peel strength of the composite film is exceeded and in most cases, the peeling strength is reduced during the process of placing the composite film or during the cycle of the flexible packaging.

Case

The composite structure is a BOPA / PE film

Main parameters: a brand solvent-free adhesive, the amount of glue is 1.5 g / m2, aged at 40 ° C for 24 hours. The tracking and detection data of the peel strength of the composite film is as follows:

On October 13, the lateral peel strength was 15.37 N / m.

On November 4, the lateral peel strength was 4.62 N / m.

After the complex layer is peeled off, the surface of the PE film has a mist-like substance that can be wiped off.

On November 18, the lateral peel strength was 4.69 N / m.

It is closed to the final test data indicating that the peel strength of the composite film has reached a stable value.

Typically, the flexible packaging company only detects the peel strength of the composite film shortly after maturity. The composite film is rarely tracked during the process or the peel strength in the soft bag, which should be noted.

The migration of the solventless adhesive in the PE film produces a slipping agent, which is the main reason for the decrease in the peel strength of the composite film. We recommend a solvent-free adhesive. Add the formulated slipping agent to the formulation, so that the friction coefficient of the PE film in the solvent-free compound can be solved, and the problem of decrease in peel strength can also be solved.

3. Pay Attention To Identifying The Smell Characteristics Of The Solventless Adhesive

There are many factors that produce scent in the flexible packaging bag, such as residual solvent, ink resin, thin-film raw material resin, adhesive, etc. Although there is no solvent residue in a solventless composite, the resins and formulations in the solventless adhesive have a certain odor feature and some have effects after composite curing, even after the packaging. For flexible packaging companies, it is necessary to pay attention to the identification of the solventless composite film after the smell and prevent the problem.

a. In GB / T 10004-2008 standard, the detection method of packaging sensory indicators is specified, which is opening the box and lining the packaging film and immediately detect the smell.

b. Usually take a certain area of the composite films, cut into a 500 ml glass bottle, baked for 30 minutes at 60-80 ° C for detecting smell. It is also possible to seal the package in the air or actual content, rotating at a temperature of 50 to 60 ° C, tearing the package, and feel whether there is odor.

The odor of the composite film is mainly from a solvent-free adhesive. Therefore, the odor feature of the general solventless adhesive can be identified by the following method.

a. Take a certain amount of A glue and B glue with different brands for sensory testing and comparison.

b. Add a mixed solvent-free binder according to the specification to the glass bottle. Plastic film is placed in the bottom of the bottle and the cured adhesive is easily taken out and the crosslinking reaction is under 40-50 ° C. After an hour, the odor characteristics are determined. This method is more suitable for practical applications, including the odor characteristics of the resin itself.

Solvent-free composite technology is a production technology which is more and more widely used in the flexible packaging industry with the advantages of safety, environmental protection, saving costs. Through the learning of the common risk control points of solventless composite technology, the efficiency of solventless lamination will be improved.

0 notes