#Plastic Slitting Rewinding Machine

Explore tagged Tumblr posts

Text

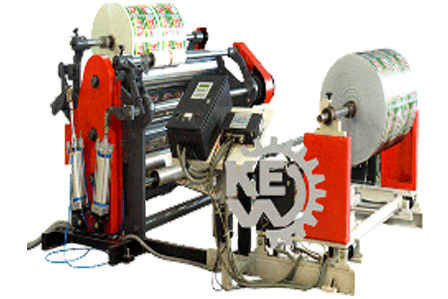

KEW ENGG. & MFG. PVT. LTD., we specialize in manufacturing cutting-edge Heavy Duty Drum Slitter Machine designed to meet diverse industrial requirements. Whether it’s for paper, plastic, textile, or packaging applications, our machines deliver unparalleled precision and durability.

#kewengg#machine#machinery#industry#machinemanufacture#industrial#exporter#supplier#manufacturer#manufacturing#Heavydutydrum#heavyduty#slittermachine#paper industry#papermachinery

2 notes

·

View notes

Text

Jandu PPM - Printing and Packaging Machines Manufacturer

Jandu Printing and Packaging Machines Company is a professional Slitting and Rewinding Machine manufacturer and supplier in Delhi, India. We are manufacturing an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper.

Jandu PPM offers highly versatile Roll To Sheet Cutting Machine and centre drum slitting and rewinding machines suitable for slitting plastic films, paper, and metal foils. This machine comes with slitting.

Contact Jandu Printing and Packaging Machines

Company: Jandu PPM

Call: +91-9811100842, 9811510842

Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi-110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#ReelToSheetCuttingMachine#RollToSheetCuttingMachine#JanduPPM

1 note

·

View note

Text

Optimizing Production with High-Precision Slitting Lines

In today's manufacturing landscape, efficiency and precision are paramount to maintaining competitiveness. Among the myriad of techniques employed to enhance production, high-precision slitting lines stand out as a pivotal solution. These systems are designed to cut large rolls of material into narrower strips with unparalleled accuracy. This article explores the significance of high-precision slitting lines, their operational mechanisms, benefits, and their role in optimizing production processes.

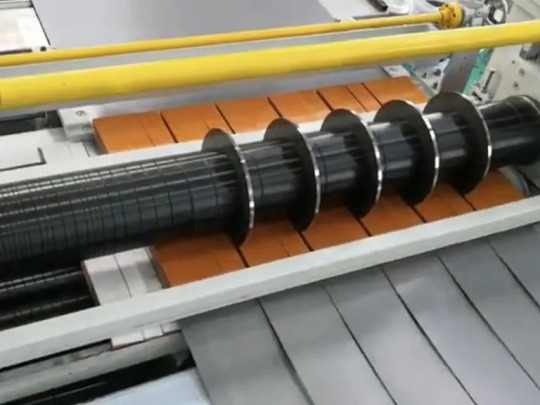

Understanding High-Precision Slitting Lines High-precision slitting line are specialized equipment used in the processing of various materials, including metals, plastics, and paper. The primary function of these lines is to convert wide coils of material into narrower strips or slits. This process is vital in various industries, including automotive, aerospace, packaging, and electronics. The machinery involved typically consists of unwinders, slitting blades, tension control systems, and rewinders, all designed to ensure a seamless and efficient slitting process.

The Mechanism of Operation The operation of high-precision slitting lines involves several critical steps. Initially, the material is unwound from a large coil and fed into the slitting machine. The material is then guided through a series of rotating blades, which slice it into the desired widths. Precision is achieved through advanced blade technology and computerized controls that adjust the positioning and speed of the blades according to the material specifications. After slitting, the narrower strips are wound back onto coils for storage or further processing. The entire process is designed to minimize waste and maximize efficiency, ensuring that the materials are cut to exact specifications.

Benefits of High-Precision Slitting Lines One of the most significant advantages of high-precision slitting lines is their ability to produce consistent and uniform strips. This uniformity is essential for industries where precise measurements are critical, such as in the production of automotive components or electronic devices. Additionally, these slitting lines reduce material waste by optimizing the cutting process to ensure that as much of the original coil as possible is utilized. This not only contributes to cost savings but also promotes sustainability by minimizing waste.

Another key benefit is the enhancement of production speed. High-precision slitting lines are engineered for rapid operation without compromising accuracy. This increased throughput allows manufacturers to meet high demand while maintaining quality standards. Furthermore, modern slitting lines are often equipped with automation features, reducing the need for manual intervention and lowering labor costs. Automation also enhances safety by minimizing human error in the slitting process.

Applications Across Industries High-precision slitting lines find applications across a wide array of industries. In the automotive sector, for instance, they are used to produce strips for various components, such as body panels and reinforcement materials. The aerospace industry also benefits from these lines, utilizing them for lightweight yet durable materials that are essential for aircraft performance. In packaging, high-precision slitting lines are crucial for creating customized sizes of packaging materials, ensuring that products are appropriately protected and presented. Furthermore, in electronics, precision slitting is vital for producing components that require exacting standards to function effectively.

Challenges and Considerations While high-precision slitting lines offer numerous advantages, manufacturers must also navigate challenges associated with their operation. One primary concern is the initial investment cost. High-precision equipment can be expensive, and companies must weigh this cost against potential long-term savings and efficiency gains. Additionally, maintaining the precision of slitting lines requires regular maintenance and calibration, which can further complicate operations. Training staff to operate and troubleshoot this sophisticated machinery is also essential to ensure optimal performance.

Future Trends in High-Precision Slitting As technology continues to advance, the future of high-precision slitting lines looks promising. Innovations in automation, such as artificial intelligence and machine learning, are expected to enhance the efficiency and accuracy of slitting processes further. These technologies can facilitate real-time monitoring and adjustments, ensuring that production runs smoothly without interruptions. Additionally, the development of more advanced materials and blades will likely improve cutting precision and durability, further optimizing production capabilities.

Conclusion In conclusion, high-precision slitting lines play a crucial role in optimizing production across various industries. Their ability to produce consistent, uniform strips while minimizing waste and enhancing speed makes them an invaluable asset in modern manufacturing. Despite the challenges associated with their operation, the benefits far outweigh the drawbacks. As technology continues to evolve, high-precision slitting lines will undoubtedly become even more integral to efficient production processes, driving innovation and competitiveness in the global market. Embracing these advanced systems is not merely an option; it is a necessity for manufacturers aiming to thrive in an increasingly demanding landscape.

0 notes

Text

Roll Slitting Machine Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The Roll Slitting Machine Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Roll Slitting Machine Market: https://www.thebusinessresearchcompany.com/report/roll-slitting-machine-global-market-report

According to The Business Research Company’s Roll Slitting Machine Global Market Report 2024, The roll slitting machine market size is expected to see strong growth in the next few years. It will grow to $2.95 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to expansion of the renewable energy sector, expansion of the printing and converting industry, growth in flexible packaging, and increased use of flexible packaging materials, development of e-commerce. Major trends in the forecast period include development of advanced automation and control systems, precision cutting technologies, development of energy-efficient and waste-reducing slitting technologies, customization and versatility, and digital control systems.

The growing e-commerce industry is expected to propel the growth of the roll-slitting machine market going forward. The e-commerce industry encompasses online platforms where goods and services are bought and sold electronically, facilitating transactions between businesses, consumers, and suppliers worldwide. The growth is supported by increased internet penetration, the convenience of online shopping, broader product availability, and evolving consumer preferences towards digital transactions. Roll slitting machines are required in the e-commerce industry for efficiently processing and packaging various materials, like packaging films and labels used in shipping and product packaging. For instance, in October 2021, according to a report published by the International Trade Administration, a US-based agency, it is anticipated that e-commerce for consumer goods will constitute approximately 22% of global retail sales in 2024, with a projected average annual growth rate exceeding 1%. Additionally, global retail e-commerce sales are expected to maintain a steady increase of 8% annually through 2024. Therefore, the growing e-commerce industry is driving the growth of the roll-slitting machine market.

Get A Free Sample Of The Report (Includes Graphs And Tables): https://www.thebusinessresearchcompany.com/sample.aspx?id=17250&type=smp

The roll slitting machine market covered in this report is segmented –

1) By Type: Roll Or Log Slitters, Slitter Rewinders 2) By Material: Paper, Polymers, Foil, Other Materials 3) By Slitter Blade: Large Circular Blade, Fixed Band Blade 4) By Distribution Channel: Direct Sales (Original Equipment Manufacturer (OEM)), Indirect Sales 5) By Industry: Paper And Pulp, Textile, Packaging, Other Industries

Major companies operating in the roll slitting machine market are developing technologically advanced products, such as high-performance rewinder slitters, to better serve customers with advanced features. A high-performance rewinder slitter is a precision machine designed to efficiently slit and rewind various materials, such as paper, film, and foil, with exceptional speed and accuracy. It is often used in industrial manufacturing processes. For instance, in February 2022, Vemax, a Brazil-based machinery company, launched the Vemax VRXS STDH Rewinder Slitter. The distinctive feature of Vemax's high-performance equipment lies in its differential axles, tailored for heavy-duty operations with paper, plastic, or self-adhesive films, serving flexible packaging, labeling, and tag industries globally. These machines integrate an advanced control system, enabling direct communication via an internal network with the machine's PLC and all electronic components. This technology facilitates remote and online programming adjustments and repairs, emphasizing innovation, safety, and quality in flexible packaging machinery.

The roll slitting machine market report table of contents includes:

1. Executive Summary

2. Roll Slitting Machine Market Characteristics

3. Roll Slitting Machine Market Trends And Strategies

4. Roll Slitting Machine Market - Macro Economic Scenario

5. Global Roll Slitting Machine Market Size and Growth .............

32. Global Roll Slitting Machine Market Competitive Benchmarking

33. Global Roll Slitting Machine Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Roll Slitting Machine Market

35. Roll Slitting Machine Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Ocean International - Excellent Plastic Manufacturing Machinery

Established in 2012, Ocean International stands tall as a premier manufacturer, exporter, and supplier of top-tier machinery including Slitting, Rewinding, Extruder, Plastic, Packaging, and Printing Machinery.

Crafting Machinery Excellence

Under the expert guidance of our accomplished mentors with extensive industry experience, we have solidified our position as a reputable organization. Our forte lies in manufacturing, supplying, and exporting an array of machinery, tailored to meet client specifications.

At Ocean International, we stand as pioneers in the realm of plastic machinery production. Fueled by an unwavering dedication to excellence and client contentment, we specialize in offering an expansive array of top-tier industrial equipment. Our offerings span a broad range of cutting-edge machinery, meticulously crafted to enhance operations in various sectors. Whether it's our meticulously designed Extrusion Machines meeting varied film production demands or our avant-garde Slitting & Rewinding Machinery ensuring flawless production flow, we provide a holistic range of solutions.

Know more about Plastic Recycling Machinery visit - https://oceaninternational.co/plastic-recycling-machine/

#BiodegradableBagMakingMachine#PlasticRecyclingMachine#ExtrusionMachine#PaperCoatingMachine#TwoLayerBlownFilmMachine#RotogravutePrintingMachine#AdhesiveCoatingLaminationMachine#BoppTapeCoatingMachine#TarpaulingMakingMachine#SyntheticStringSutliMakingMachine#StretchFilmMakingMachine#MulchFilmMakingMachine#MultilayerBlownFilmMachine#ExtrusionCoatingLaminationMachine#AirBubbleFilmMakingMachine#PpPetBoxStrappingMachine#PetBottleWashingLine#CantileverSlitterRewinderMachine#SlittingandRewindingMachinery#AdhesiveLaminationCoatingPlant#MonolayerBlownFilmMachine#AdhesiveCoatingMachine#FlexographicPrintingMachine#PrintingMachinery#BottomSealBagMachine#BagMakingMachinery

1 note

·

View note

Text

About Kingsun Machinery

Embark on a journey into the heart of precision with Kingsun's film slitting machine. Tailored for the intricacies of plastic film materials, this equipment seamlessly transforms mammoth film rolls into meticulously sliced smaller counterparts. From the unwinding mechanism to the cutting phase, witness the ballet of technology as raw materials elegantly transition through each stage. This machinery, armed with EPC control, tension detection, and a sophisticated rewinding mechanism, stands as an epitome of precision in the flexible packaging and laminating industries. Kingsun Machinery, a stalwart in China's printing and packaging arena, doesn't just supply equipment; it crafts an experience where every film slitting endeavor is a symphony of accuracy and excellence.

1 note

·

View note

Text

Top Benefits Of An Air Shaft In Manufacturing

The manufacturing industry-centric air shaft is employed for fitting into the core that wounds a variety of materials, including paper, cards, and plastic films. It readily expands on fitting into a core, leading to flawless operation during the manufacturing cycle.

Plenty of industrial converting machines employ the product. A slitting machine, widely known as a slitter rewinder has an air shaft in its core. It is basically designed to cut or slit large rolls of different types of material into smaller rollers. How does its engineering work? In this regard, you can connect with a reputed air shaft manufacturer.

An air shaft is also recognized by many other names in the industry circles, including air expandable shaft and air expanding shaft.

Salient Features of the Air Shaft

A premium quality air shaft displays the following salient features during application:

Competent to adjust to different speed variations

Proficient to adjust to different core widths

Demonstrates high speed, when repositioning of the product doesn’t happen

Efficient gripping

Efficient core centering

Manages uneven cores

For detailed information, collaborate with a prominent air shaft manufacturer in Ahmedabad.

Manufacturing Industries Drawing Benefits from the Air Shaft

Manufacturing industries galore are drawing benefits from mechanical product, including:

Packaging

Steel

Paper

As far as dimension of the air shaft is concerned, it is available in different dimensions. In case, you are searching for a custom-designed air shaft, you can collaborate with a reputed air shaft manufacturer.

Applications

An airshaft is a mechanical device designed for handling winding reels in the processing of web-fed materials.

0 notes

Text

From Pulp to Roll: Understanding the Manufacturing Process of Toilet Paper Machines

Toilet paper is a ubiquitous household item that we often take for granted. However, behind every roll of toilet paper lies a complex manufacturing process that involves specialized machines. Understanding the intricacies of toilet paper machine production can shed light on the journey from pulp to the final product that we use daily. In this blog, we will explore the key steps involved in the manufacturing process of toilet paper machines.

Pulp Preparation:

The first step in producing toilet paper is the preparation of the pulp. Wood chips or recycled paper are processed in large machines called pulpers. The pulpers break down the raw material, removing impurities and creating a slurry-like mixture called pulp. This pulp will serve as the foundation for the toilet paper production process.

Paper Machine:

Once the pulp is ready, it is fed into a paper machine. The paper machine consists of a series of sections and components that work together to transform the pulp into thin sheets of paper. These sheets are then pressed, dried, and rolled onto large spools.

Rewinding and Slitting:

The large spools of paper are then transferred to rewinding machines. In this step, the paper is unwound from the spools and rewound onto smaller rolls, which are more convenient for consumer use. The rewinding machines also have slitting blades that cut the large sheets of paper into narrower strips, which will form individual toilet paper rolls.

Embossing and Perforation:

Toilet paper often features patterns or embossed designs on its surface. This is achieved through embossing rolls that press decorative patterns onto the paper during the rewinding process. Additionally, perforation blades create small dotted lines along the paper strip, allowing for easy tearing and separating of individual sheets.

Cutting and Packaging:

After embossing and perforation, the toilet paper strips are cut into individual rolls. These rolls are then packaged using automated packaging machines. The packaging machines wrap each roll in plastic or paper, ensuring hygiene and protection during transportation and storage.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the toilet paper meets industry standards. These measures include monitoring the thickness, strength, and softness of the paper, as well as inspecting the embossing and perforation patterns. Any defective rolls are removed to maintain the overall quality of the final product.

Conclusion

The manufacturing process of toilet paper machine involves several intricate steps, from pulp preparation to cutting and packaging. Specialized machines and quality control measures ensure that the toilet paper meets the necessary standards of thickness, strength, softness, and hygiene. By understanding the manufacturing process behind toilet paper, we gain a deeper appreciation for the complexity involved in producing this essential everyday product.

0 notes

Text

What Is a Tape Cutting Machine?

What Is a Tape Cutting Machine?

A tape cutting machine is a versatile machine which can be used in various applications. Its main features include durability, built-in fuse, and multiple material cutting capabilities. It can cut a variety of tapes and straps such as elastic band, nylon webbing, velcro, and knitted fabric. This machine is equipped with a micro-computer control system, which helps in making it easy to cut a variety of materials.Get more news about Electric Tape Making Machine,you can vist our website!

Features A tape cutting machine is a useful tool for cutting different types of tapes and straps. They can cut elastic bands, nylon webbing, plastic zipper, and Velcro. Many people use them in the shoe industry. These machines are extremely durable and have built-in fuse protection. They are also flexible and can cut a variety of materials.

An adhesive tape cutting machine has several features to ensure accurate cutting of the tape. For example, it has a three-step length counter that provides accurate pre-setting for rewinding length. It also includes a pneumatic brake to maintain a steady performance. Moreover, it features a slitting machine and a core loader. It can also cut long paper core.

Functions A tape cutting machine is a useful machine that helps in cutting different types of adhesive tape. It can be used to cut various types of double-sided tape, acetate tape, glass fiber tape, electrical insulation tape, and many more. These machines are available in a variety of brands. Most of them are made by domestic manufacturers, while there are also some Japanese and Korean brands. However, the price of these machines is much higher than domestic ones. Besides, the international brand products are not original products.

Uses A tape cutting machine is a great tool for cutting a wide range of materials. These materials include leather, nylon webbing, and velcro. It can also cut plastic and sheet metal. The micro-computer controlled device has multiple cutting options, including the ability to cut multiple types of straps at once.

A tape cutting machine has knives with a relatively wide edge, allowing it to cut all types of tapes in a specified width range. A tape cutter can even cut two tapes of different widths at once, if both are within its specifications. When cutting tapes, it is important to check that the width is within the cutting range.

0 notes

Link

We are experienced manufacturer, exporter & supplier of Slitter Rewinder Machine. High speed and heavy duty Automatic Slitting Rewinding Machine Manufacturer on demand of client’s requirement and machine specific application and material. Slitting of all types of Plastic Slitting Rewinding Machine, Woven Sack Slitting Rewinding Machine, High Speed Slitting Rewinding Machine, Surface Slitting Rewinding Machine, Label Slitting Rewinding Machine, Cantilever Slitter Rewinder Machine, Rubber Slitter Rewinder Machine, Mini Cantilever Slitter Rewinder Machine.

#Automatic Slitting Rewinding Machine#Automatic Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder#Mini Cantilever Slitter Rewinder Machine#Rubber Slitter Rewinder Machine#Cantilever Slitter Rewinder Machine#Label Slitting Rewinding Machine#Surface Slitting Rewinding Machine#High Speed Slitting Rewinding Machine#Woven Sack Slitting Rewinding Machine#Plastic Slitting Rewinding Machine

2 notes

·

View notes

Link

We specialised manufacturer of Plastic Slitting Rewinding Machine, Manufacturer of Slitting Rewinding Machine, Plastic Film Slitting Rewinding Machine, Plastic Roll Slitter Rewinder, Polyester Film Slitting Rewinding Machine, Slitter Rewinder Machines. Different types of Plastic Materials are used for different type of applications like, PVC, LDPE, HDPE, BOPP Film, etc. After Printing in Rotogravure or Flexo Machine or Extruded materials, our Plastic Slitting Rewinding Machine comes in use for Slitting of all types of material. Heavy Duty Bopp Tape Slitter Rewinder Machine Manufacturer.

#Plastic Slitting Rewinding Machine#Plastic Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Plastic Film Slitting Rewinding Machine#Film Slitting Rewinding Machine#Plastic Roll Slitter Rewinder#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder#Slitting Rewinding Machines#Roll Slitter Rewinder

0 notes

Link

Heavy Duty Slitter Rewinder, Slitting Machine, Our Jumbo Roll Slitting Rewinding Machine comes in use for Roll to Roll Slitting Rewinding Machine of all types of Roll Slitting Machines, Plastic Slitting Rewinding Machine, Jumbo Roll Slitter Rewinders, High Speed Slitting Rewinding Machine, BOPP Jumbo Roll Slitting Machine, Jumbo Roll Slitting Machine, Automatic Slitting Rewinding Machine. Generally, all Paper & Flexible Film Converters requires slitting Jumbo Rolls into Small Rolls. Our Jumbo Roll Slitter Rewinder Machine is able to process all types of Paper & Film of any GSM thickness.

#Jumbo Roll Slitting Rewinding Machine#Jumbo Roll Slitting Machine#Roll Slitting Machines#BOPP Jumbo Roll Slitting Machine#Automatic Slitting Rewinding Machine#Plastic Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding Machines#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitting Machine manufacturers#Paper Slitting machine#Paper Slitter Rewinder Machine

0 notes

Text

Core slitting machines are pivotal in modern manufacturing,

particularly in industries that require the precision cutting of materials into narrow strips. These machines facilitate the conversion of wide rolls of material—such as paper, plastic, metal, and textiles—into smaller, usable widths. Understanding the design and operational insights of core slitting machine can significantly enhance their efficiency and effectiveness in production environments.

Overview of Core Slitting Machines

Core slitting machines are designed to handle various materials and offer precision in cutting operations. Their primary function is to take a large roll of material and slice it into narrower strips while maintaining consistent dimensions and quality. These machines are essential in industries like packaging, automotive, electronics, and textiles, where precise dimensions are critical for downstream processes. The importance of these machines cannot be overstated, as the quality of the slitted material directly impacts the efficiency of subsequent manufacturing steps.

Key Design Features

Frame Structure The structural integrity of a core slitting machine starts with its frame, typically constructed from robust materials such as steel or aluminum. A solid frame minimizes vibrations during operation, ensuring that the machine remains stable while cutting. This stability is crucial for maintaining precise alignment of the cutting components, which directly affects the quality and accuracy of the slits produced. Manufacturers often invest in advanced engineering techniques to optimize the frame design, balancing weight and durability.

Unwind and Rewind Stations

Unwind and rewind stations are integral components of core slitting machines, responsible for feeding the wide rolls into the cutting area and collecting the finished strips. These stations are designed to accommodate varying roll sizes and weights, featuring tension control systems that help maintain the proper material tension throughout the slitting process. Proper tension is essential for achieving clean cuts and preventing material damage, making these components critical to the machine's overall performance.

Slitting Head

The slitting head is arguably the most vital part of the core slitting machine, where the actual cutting occurs. It houses the slitting blades, which can be rotary, shear, or circular depending on the material type being processed. The design of the slitting head often allows for precise adjustments in blade height and alignment, enabling operators to customize the machine for different materials and thicknesses. This adaptability is essential for meeting the varied demands of different production runs.

Blade Types and Maintenance

The choice of blade types is another crucial factor in the design of core slitting machines. Rotary blades are typically used for flexible materials, while shear blades are better suited for harder materials. Regular maintenance of these blades—such as sharpening and replacements—is vital for maintaining cutting quality and efficiency. A well-maintained blade not only improves the quality of the cuts but also reduces machine downtime, contributing to overall productivity.

Operational Insights Material Selection

The type of material being processed plays a significant role in the operation of core slitting machines. Factors such as thickness, flexibility, and tensile strength must be taken into account when selecting materials for slitting. Understanding the characteristics of the material can help operators optimize blade types and cutting speeds, enabling them to achieve the best possible results.

Setup Procedures

Efficient setup procedures are essential for minimizing downtime and maximizing productivity in core slitting operations. Operators should follow standardized protocols for adjusting blades, setting tension, and configuring the control system. A well-defined setup process can significantly reduce the time required to transition between different production runs, allowing manufacturers to respond quickly to changing demands.

Regular Maintenance

Implementing a regular maintenance schedule is imperative for ensuring the long-term reliability and performance of core slitting machines. Maintenance tasks may include cleaning, lubrication, blade sharpening, and inspection of mechanical components. A proactive maintenance approach helps prevent unexpected breakdowns, thereby keeping production running smoothly and reducing costs associated with equipment failures.

Performance Monitoring

Continuous monitoring of performance metrics such as production cycle time, scrap rate, and material utilization is crucial for assessing the efficiency of core slitting operations. By analyzing these metrics, manufacturers can identify areas for improvement and implement strategies to enhance overall productivity. Regular performance reviews can also help operators make informed decisions about machine adjustments and operational changes.

Operator Training

Well-trained operators are essential for the successful operation of core slitting machines. Comprehensive training programs should cover machine functions, safety protocols, and troubleshooting techniques. Investing in regular training updates ensures that operators remain informed about new technologies and best practices, empowering them to perform their tasks efficiently and effectively.

Quality Control

Establishing a robust quality control process is vital for ensuring that the slitted strips meet required specifications. Regular inspections of the output can help identify defects early in the process, allowing for timely corrective actions. Quality control measures should include checks for dimensional accuracy, surface finish, and the presence of defects, ensuring that the final product meets customer expectations.

Conclusion

Core slitting machines are integral to the manufacturing process, enabling industries to efficiently produce narrow strips from wide rolls of material. By understanding key design features and operational insights, manufacturers can optimize their slitting processes, enhance product quality, and improve overall efficiency. Emphasizing material selection, efficient setup procedures, regular maintenance, performance monitoring, operator training, and quality control will ultimately lead to enhanced productivity and reduced operational costs. As industries continue to evolve, investing in advanced core slitting technology and best practices will be essential for maintaining a competitive edge in the market

0 notes

Link

The KEW ENGG MFG PVT LTD slitter rewinding machine ensures perfect slitting of rolls with Felicitous impeccable quality and continuous line speed. It is receivable in an adjustable model to suit your needs. Release film is usually applied to fiber reinforced plastics and glass reinforced plastics. Our Release Film Slitter Rewinder Machine specially designed with rewind sensation system is capable of converting and controlling the tension on the air shaft.

#Release Film Slitter Rewinder Machine#Film Slitting Machine#Stretch Film Slitting Machine#Slitter Rewinder#Slitter Rewinder Machine#Cling Film Slitter Rewinder Machine#Pet Release Film Slitter Rewinder Machine#Flexible Packaging Films Slitter Rewinder Machine#Plastic Film Slitting Rewinding Machine#Plastic Film Rewinding Equipment#Film Rewinding Machine#Stretch Film Rewinding Machine#Stretch Film Rewinder#Film Rewinder#Plastic Film Rewinding Machine

1 note

·

View note

Link

We have been successfully manufacturing all types of METPET Film Slitting Rewinding Machine since last 25 years, high speed Rewinder Unwinder System. METPET Film is generally used for packing materials & different type of other applications. Slitting of all types of material thickness from 40 GSM TO 500 GSM. like Plastic, Paper, Flexible Packaging, PVC, Aluminium Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape, OPP, METPET, Pet Film, OPA, Non-Woven Fabric, Paper Board, Adhesive Tape,

#Slitting Rewinding Machine Manufacturer#Rewinder Unwinder System#Plastic#paper#Flexible Packaging#Slitter Rewinder#Paper Slitter Rewinder Machine#Film Slitter Rewinder Machine

4 notes

·

View notes

Link

CONPAPTEX organization Plastic Slitter Rewinder Machines along Timing Belt management for noise-free even in work. Machine ensures thorough slitting of rolls with consistent flawless standard and always line speed. It is receivable in adaptable model to suit your requirement. Our machine is an eventual Slitter and Rewinder Machine for its correct Plastic Slitter Rewinder Machine qualities. It ensures perfect slitting of rolls with consistent, perfect results and constant line speed.

#Plastic Slitter Rewinder Machine#Plastic Slitting Machine#Plastic Roll Cutting Machine#Slitter Rewinder Machine#Plastic Slitter#Plastic Film Slitting Rewinding Machine#Plastic Film Rewinding Equipment#Roll To Roll Plastic Film Slitting Machine#Film Slitting Machine#Plastic Film Slitting Machine#BOPP Film Slitting Rewinder Machine#Automatic Slitting Machine#Fully Automatic Bopp Tape Slitting Machine#High Speed Slitting Rewinding Machine#Plastic Film Roll Slitter Rewinder Machine

1 note

·

View note