#Roll Slitting Rewinding Machines

Explore tagged Tumblr posts

Text

A paper slitter is a slitting device that cuts a wide roll of paper on a paper machine into a narrower width of paper while rewinding it onto a receiving reel.

2 notes

·

View notes

Video

youtube

Website: http://www.opecmachinery.com/ JRT Jumbo Roll Toilet Tissue Paper Converting Slitting Rewinding Making Machine Whatsapp: +86-15159281187 Contact: Kevin E-mail: [email protected]

0 notes

Text

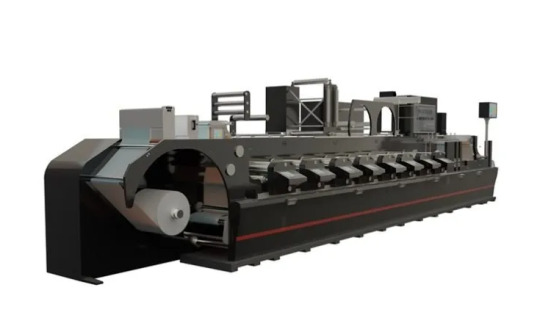

Webtech Group’s live demonstrations at Printpack 2025

Webtech Group, a leading manufacturer of printing and paper-converting machinery, will showcase its range of machines at Printpack 2025, to be held from 1 to 5 February 2024, at India Expo Centre and Mart in Greater Noida. It show demonstrate the fully servo flexographic printing machine in 450 mm working width, thermal roll slitting rewinding machine with single color online flexo printing, honeycomb paper die cutting machine, and servo-controlled label slitter rewinder machine

Along with the showcased machines, the Webtech team will highlight its entire range of products, including fully servo flexographic printing machines, web offset printing machines, slitting rewinding machines, and die cutting machines at its stand. The team will discuss technological advancements, share insights into the industry’s trajectory, and offer tailored solutions.

Singh emphasized the strategic importance of participating in Printpack 2025. “Printpack provides a vital platform to showcase technological advancements to a global audience and expand our clientele. The exhibition offers invaluable insights into emerging trends and challenges, enabling us to enhance our product offerings and stay ahead of market demands,” he said.

By participating in such exhibitions, Webtech aims to solidify its industry presence while forging new relationships with global clients. “For Printpack 2025, we aim to build on our previous successes by introducing our latest fully servo flexographic printing machine and other innovations. We look forward to engaging with industry leaders and further strengthening our position in the market,” Singh added.

Singh highlighted the evolution of the printing and packaging industry, driven by increasing demand for sustainable and flexible packaging solutions. Key advancements, such as fully servo-driven machines, automation, and eco-friendly substrates, are shaping the future of the industry.

“The printing and packaging sector is experiencing robust growth, with sustainability and precision at its core. We are poised to capitalize on these trends by offering innovative and efficient machinery that addresses challenges such as waste reduction and enhance productivity,” Singh explained.

Webtech International Machineries will be present in hall no 5, stands C19 and C28.

0 notes

Text

Bopp / Paper Tape Coating Machine

Mohindra is recognized as one of the top manufacturers of Doctoring Slitting Machines in India. Although we are located in Delhi, we supply our wide range of products across the country. We use premium quality raw materials in the production of all our machines. As you may know, the demand for Doctoring Slitting Machines is increasing daily, driven by the rising consumption of paper bags in India. Mohindra Machine stands out as a leading manufacturer of Doctoring Slitting Machines. We are dedicated to producing and supplying these machines to potential customers in the market. The Doctoring Slitting Machine is designed to cut and convert large sheets of paper, foil, and film materials into narrower rolls. These machines consist of three main components: the slitter, unwind, and rewind.

#Bopp paper tape coating machine price#Bopp paper tape coating machine price in india#Bopp paper tape coating machine in india#Bopp paper tape coating machine for sale

1 note

·

View note

Text

Jandu PPM - Printing and Packaging Machines Manufacturer

Jandu Printing and Packaging Machines Company is a professional Slitting and Rewinding Machine manufacturer and supplier in Delhi, India. We are manufacturing an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper.

Jandu PPM offers highly versatile Roll To Sheet Cutting Machine and centre drum slitting and rewinding machines suitable for slitting plastic films, paper, and metal foils. This machine comes with slitting.

Contact Jandu Printing and Packaging Machines

Company: Jandu PPM

Call: +91-9811100842, 9811510842

Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi-110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#ReelToSheetCuttingMachine#RollToSheetCuttingMachine#JanduPPM

1 note

·

View note

Text

"Optimizing Workflow: Slitting Rewinding Machines at Their Best"

Cutting and handling materials are critical among industries that routinely engage the services of slitting rewinding machines. These machines have one specialty: slicing a larger roll into narrower widths, rewinding them into a neat roll at the same time. Materials such as paper, film, and foil can be cut to specific size requirements and be ready for downstream processing or immediate use.

These overseer machines run on high technology automating every process while ensuring that materials get wasted as little as possible and encouraging quicker turnaround times. Features include eye broaches, customizable slit widths, and tension control systems; providing mass production across a wide range of industries, the above-mentioned creates a new level in quality and productivity.

To avail the world-class slitting rewinding machines, the organization needs to visit UV Graphic, which is known for making the right innovative machines that are reliable and efficient. True believers in precision engineering and superior performance, UV Graphic sponsors an unprecedented level of operational excellence for all businesses.

#uv curing systems#curing machine manufacturer#label punching machines manufacturer#uv coating machines manufacturer#Slitting Rewinding Machine

0 notes

Text

Jandu Printing and Packaging Machines Manufacturer

Jandu PPM is a trusted printing & packaging machine manufacturer and supplier in India. Which offers high-quality Heavy Duty Simplex Reel to Sheet Cutting Machines, Mill Type Paper Slitting & Rewinding Machines, Reel to Sheet Cutting Machines, Roll to Sheet Cutting Machines, Rotary Sheet Cutting Machines, Slitting Machines, Lamination Machines, Winding Machines, slitter and rewinder machines, and centre drum slitting and rewinding machines, etc., specially designed to provide a better outcome for longer and are manufactured using the high-grade materials by Jandu PPM.

Contact Jandu PPM

Company: Jandu Printing & Packaging Machines

Mobile: +91 9811100842, 9811510842

Email: [email protected]

Address: 25/18, Gali No. 6, Master Mohalla Libaspur, Delhi, India, 110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#ReelToSheetCuttingMachine#RollToSheetCuttingMachine

1 note

·

View note

Text

Optimizing Production with High-Precision Slitting Lines

In today's manufacturing landscape, efficiency and precision are paramount to maintaining competitiveness. Among the myriad of techniques employed to enhance production, high-precision slitting lines stand out as a pivotal solution. These systems are designed to cut large rolls of material into narrower strips with unparalleled accuracy. This article explores the significance of high-precision slitting lines, their operational mechanisms, benefits, and their role in optimizing production processes.

Understanding High-Precision Slitting Lines High-precision slitting line are specialized equipment used in the processing of various materials, including metals, plastics, and paper. The primary function of these lines is to convert wide coils of material into narrower strips or slits. This process is vital in various industries, including automotive, aerospace, packaging, and electronics. The machinery involved typically consists of unwinders, slitting blades, tension control systems, and rewinders, all designed to ensure a seamless and efficient slitting process.

The Mechanism of Operation The operation of high-precision slitting lines involves several critical steps. Initially, the material is unwound from a large coil and fed into the slitting machine. The material is then guided through a series of rotating blades, which slice it into the desired widths. Precision is achieved through advanced blade technology and computerized controls that adjust the positioning and speed of the blades according to the material specifications. After slitting, the narrower strips are wound back onto coils for storage or further processing. The entire process is designed to minimize waste and maximize efficiency, ensuring that the materials are cut to exact specifications.

Benefits of High-Precision Slitting Lines One of the most significant advantages of high-precision slitting lines is their ability to produce consistent and uniform strips. This uniformity is essential for industries where precise measurements are critical, such as in the production of automotive components or electronic devices. Additionally, these slitting lines reduce material waste by optimizing the cutting process to ensure that as much of the original coil as possible is utilized. This not only contributes to cost savings but also promotes sustainability by minimizing waste.

Another key benefit is the enhancement of production speed. High-precision slitting lines are engineered for rapid operation without compromising accuracy. This increased throughput allows manufacturers to meet high demand while maintaining quality standards. Furthermore, modern slitting lines are often equipped with automation features, reducing the need for manual intervention and lowering labor costs. Automation also enhances safety by minimizing human error in the slitting process.

Applications Across Industries High-precision slitting lines find applications across a wide array of industries. In the automotive sector, for instance, they are used to produce strips for various components, such as body panels and reinforcement materials. The aerospace industry also benefits from these lines, utilizing them for lightweight yet durable materials that are essential for aircraft performance. In packaging, high-precision slitting lines are crucial for creating customized sizes of packaging materials, ensuring that products are appropriately protected and presented. Furthermore, in electronics, precision slitting is vital for producing components that require exacting standards to function effectively.

Challenges and Considerations While high-precision slitting lines offer numerous advantages, manufacturers must also navigate challenges associated with their operation. One primary concern is the initial investment cost. High-precision equipment can be expensive, and companies must weigh this cost against potential long-term savings and efficiency gains. Additionally, maintaining the precision of slitting lines requires regular maintenance and calibration, which can further complicate operations. Training staff to operate and troubleshoot this sophisticated machinery is also essential to ensure optimal performance.

Future Trends in High-Precision Slitting As technology continues to advance, the future of high-precision slitting lines looks promising. Innovations in automation, such as artificial intelligence and machine learning, are expected to enhance the efficiency and accuracy of slitting processes further. These technologies can facilitate real-time monitoring and adjustments, ensuring that production runs smoothly without interruptions. Additionally, the development of more advanced materials and blades will likely improve cutting precision and durability, further optimizing production capabilities.

Conclusion In conclusion, high-precision slitting lines play a crucial role in optimizing production across various industries. Their ability to produce consistent, uniform strips while minimizing waste and enhancing speed makes them an invaluable asset in modern manufacturing. Despite the challenges associated with their operation, the benefits far outweigh the drawbacks. As technology continues to evolve, high-precision slitting lines will undoubtedly become even more integral to efficient production processes, driving innovation and competitiveness in the global market. Embracing these advanced systems is not merely an option; it is a necessity for manufacturers aiming to thrive in an increasingly demanding landscape.

0 notes

Text

Roll Slitting Machine Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The Roll Slitting Machine Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Roll Slitting Machine Market: https://www.thebusinessresearchcompany.com/report/roll-slitting-machine-global-market-report

According to The Business Research Company’s Roll Slitting Machine Global Market Report 2024, The roll slitting machine market size is expected to see strong growth in the next few years. It will grow to $2.95 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to expansion of the renewable energy sector, expansion of the printing and converting industry, growth in flexible packaging, and increased use of flexible packaging materials, development of e-commerce. Major trends in the forecast period include development of advanced automation and control systems, precision cutting technologies, development of energy-efficient and waste-reducing slitting technologies, customization and versatility, and digital control systems.

The growing e-commerce industry is expected to propel the growth of the roll-slitting machine market going forward. The e-commerce industry encompasses online platforms where goods and services are bought and sold electronically, facilitating transactions between businesses, consumers, and suppliers worldwide. The growth is supported by increased internet penetration, the convenience of online shopping, broader product availability, and evolving consumer preferences towards digital transactions. Roll slitting machines are required in the e-commerce industry for efficiently processing and packaging various materials, like packaging films and labels used in shipping and product packaging. For instance, in October 2021, according to a report published by the International Trade Administration, a US-based agency, it is anticipated that e-commerce for consumer goods will constitute approximately 22% of global retail sales in 2024, with a projected average annual growth rate exceeding 1%. Additionally, global retail e-commerce sales are expected to maintain a steady increase of 8% annually through 2024. Therefore, the growing e-commerce industry is driving the growth of the roll-slitting machine market.

Get A Free Sample Of The Report (Includes Graphs And Tables): https://www.thebusinessresearchcompany.com/sample.aspx?id=17250&type=smp

The roll slitting machine market covered in this report is segmented –

1) By Type: Roll Or Log Slitters, Slitter Rewinders 2) By Material: Paper, Polymers, Foil, Other Materials 3) By Slitter Blade: Large Circular Blade, Fixed Band Blade 4) By Distribution Channel: Direct Sales (Original Equipment Manufacturer (OEM)), Indirect Sales 5) By Industry: Paper And Pulp, Textile, Packaging, Other Industries

Major companies operating in the roll slitting machine market are developing technologically advanced products, such as high-performance rewinder slitters, to better serve customers with advanced features. A high-performance rewinder slitter is a precision machine designed to efficiently slit and rewind various materials, such as paper, film, and foil, with exceptional speed and accuracy. It is often used in industrial manufacturing processes. For instance, in February 2022, Vemax, a Brazil-based machinery company, launched the Vemax VRXS STDH Rewinder Slitter. The distinctive feature of Vemax's high-performance equipment lies in its differential axles, tailored for heavy-duty operations with paper, plastic, or self-adhesive films, serving flexible packaging, labeling, and tag industries globally. These machines integrate an advanced control system, enabling direct communication via an internal network with the machine's PLC and all electronic components. This technology facilitates remote and online programming adjustments and repairs, emphasizing innovation, safety, and quality in flexible packaging machinery.

The roll slitting machine market report table of contents includes:

1. Executive Summary

2. Roll Slitting Machine Market Characteristics

3. Roll Slitting Machine Market Trends And Strategies

4. Roll Slitting Machine Market - Macro Economic Scenario

5. Global Roll Slitting Machine Market Size and Growth .............

32. Global Roll Slitting Machine Market Competitive Benchmarking

33. Global Roll Slitting Machine Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Roll Slitting Machine Market

35. Roll Slitting Machine Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Video

youtube

Website: http://www.opecmachinery.com/ JRT Jumbo Roll Toilet Tissue Paper Converting Slitting Rewinding Making Machine Whatsapp: +86-15159281187 Contact: Kevin E-mail: [email protected]

1 note

·

View note

Text

🚀 **Breaking Ground in Innovation: Unveiling India's First Thermal Roll Slitting Rewinding Machine with 2 Colors Online Flexo Printing!**

🔗 https://youtu.be/T8yDT-HoAnM?si=FpheJDEHJF_sF7ZD

Dear Valued Customers and Industry Pioneers,

We are thrilled to announce the groundbreaking launch of our latest technological marvel – the **Webtech Thermal Roll Slitting Rewinding Machine with 2 Colors Online Flexo Printing attachment**! This is a historic moment for us as we introduce the first-ever machine of its kind in India, setting new standards in precision and efficiency.

🌐 **Key Features:**

- **Web Guide Technology:** Ensuring seamless web alignment for flawless operations.

- **Electronic Brake:** Offering advanced control and safety in the production process.

- **2 Colors Flexo Printing Units:** Unleashing a world of vibrant possibilities for your printing needs.

- **Turnbar for Reverse Printing:** Elevating flexibility in design and output.

- **Slitting Rewinding Unit:** Providing superior accuracy in the final product.

⚡ **High-Speed Precision:**

Our machine is not just about innovation; it's about performance. With high-speed capabilities and unmatched accuracy, it delivers robust results, even at accelerated production rates.

🔧 **Robust Design, Perfect Output:**

The Webtech Thermal Roll Slitting Rewinding Machine is crafted with a robust design to withstand the rigors of industrial production. Expect perfection in every roll, even at the highest speeds.

🌟 **Why Choose Webtech?**

At Webtech, we don't just manufacture machines; we engineer solutions. Our commitment to excellence, coupled with cutting-edge technology, makes us the go-to choice for industry leaders.

📅 **Availability:**

Be among the first to experience the future of printing technology! Contact us now to inquire about availability and secure your spot in revolutionizing your production process.

Thank you for choosing Webtech – Where Innovation Meets Precision!

0 notes

Text

An Overview of Stretch Film Manufacturing Machines: Types and Functions

Stretch Film Manufacturing Machines are specialized pieces of equipment used to produce stretch film, which is commonly used for packaging and securing products during transportation and storage. These machines play a crucial role in ensuring the durability, elasticity, and quality of the stretch film. Here's an overview of the types of stretch film manufacturing machines and their functions:

1. Blown Film Extrusion Machines:

Description: These machines use the blown film extrusion process to produce stretch film. The process involves melting polymer granules and extruding them through an annular slit die, followed by blowing to expand the film into a tube and cooling it to form the film.

Function: Blown film extrusion machines provide films with higher puncture resistance and more strength compared to other types. They allow for better control over film thickness and quality.

2. Cast Film Extrusion Machines:

Description: In contrast to blown film machines, cast film extrusion machines use a flat die to extrude the molten polymer. The extruded film is then cooled on chilled rollers.

Function: These machines produce films that are clearer and have better cling properties than blown films. Cast film machines generally have higher production rates and produce films with more consistent thickness.

3. Co-extrusion Film Machines:

Description: Co-extrusion machines combine multiple layers of material into a single stretch film product. These machines can have two or more extruders to process different types of polymers or the same polymer with different properties.

Function: The primary function is to produce multilayer stretch films, where each layer can impart different characteristics such as strength, cling, puncture resistance, or barrier properties.

4. Pre-stretch Film Machines:

Description: These machines are designed to stretch the film mechanically before it is wound onto rolls. The pre-stretching process improves the film's yield and can significantly reduce material costs.

Function: They elongate the film by using rollers rotating at different speeds. The resulting film is thinner but has increased strength and is more economical due to reduced material usage.

5. Rewinding Machines:

Description: After the film is extruded and wound onto large rolls, rewinding machines are used to convert these large rolls into smaller, more manageable rolls for commercial distribution.

Function: These machines rewind the film from the larger rolls to smaller ones, often adding a secondary layer of packaging. They can also be used to inspect the film for defects and ensure quality control.

6. Recycling Machines:

Description: In an effort to promote sustainability, some stretch film manufacturing setups include recycling machines that process production waste or used stretch film.

Function: These machines clean, melt, and pelletize the waste film, turning it back into a usable form for manufacturing, thus reducing waste and promoting circular economy practices.

Choosing the Right Machine:

The choice of machine depends on the desired film properties, production volume, and specific application requirements. For example, high-clarity film requirements might favor cast film machines, while high-strength films might be better produced with blown film machines.

By understanding the different types of Stretch Film Manufacturing Machines and their functions, manufacturers can select the most appropriate equipment to meet their production needs and produce high-quality stretch film for various packaging applications.

0 notes

Text

Trusted Printing & Packaging Machines Manufacturer

Jandu PPM is a trusted Printing & Packaging Machines manufacturer and supplier based in Delhi, India, We offer high-quality machines like - Heavy Duty Simplex Reel to Sheet Cutting Machine, Mill Type Paper Slitting & Rewinding Machines, roll to sheet cutting machines, Rotary Sheet Cutting Machine, Slitting Machine, Lamination Machine, Winding Machine, slitter and rewinder machine, and centre drum slitting and rewinding machines, etc specially designed to provide a better outcome for longer and are manufactured using the high-grade of materials by Jandu PPM.

Types of Printing and Packaging Machines, We offer

Slitting & Rewinding Machine Slitter & Rewinder Machine Centre Drum Slitting And Rewinding Machine Mill Type Paper Slitting and Rewinding Machine Paper Slitting and Rewinding Machine in Delhi Reel To Sheet Cutting Machine Roll To Sheet Cutting Machine Heavy Duty Simplex Reel to Sheet Cutting Machine Lamination Machine Manufacturer Rotary Sheet Cutting Machine Slitting Machine Manufacturer Slitting & Winding Machine Manufacturer

Contact Jandu PPM

Company: Jandu Printing & Packaging Machines - Mobile No: +91 9811100842, 9811510842 - Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi, India – 110042 - Email: [email protected]

#janduppm#ReelToSheetCuttingMachine#RollToSheetCuttingMachine#SlitterandRewinderMachine#SlittingandRewindingMachine

1 note

·

View note

Text

About Kingsun Machinery

Embark on a journey into the heart of precision with Kingsun's film slitting machine. Tailored for the intricacies of plastic film materials, this equipment seamlessly transforms mammoth film rolls into meticulously sliced smaller counterparts. From the unwinding mechanism to the cutting phase, witness the ballet of technology as raw materials elegantly transition through each stage. This machinery, armed with EPC control, tension detection, and a sophisticated rewinding mechanism, stands as an epitome of precision in the flexible packaging and laminating industries. Kingsun Machinery, a stalwart in China's printing and packaging arena, doesn't just supply equipment; it crafts an experience where every film slitting endeavor is a symphony of accuracy and excellence.

1 note

·

View note

Text

Top Benefits Of An Air Shaft In Manufacturing

The manufacturing industry-centric air shaft is employed for fitting into the core that wounds a variety of materials, including paper, cards, and plastic films. It readily expands on fitting into a core, leading to flawless operation during the manufacturing cycle.

Plenty of industrial converting machines employ the product. A slitting machine, widely known as a slitter rewinder has an air shaft in its core. It is basically designed to cut or slit large rolls of different types of material into smaller rollers. How does its engineering work? In this regard, you can connect with a reputed air shaft manufacturer.

An air shaft is also recognized by many other names in the industry circles, including air expandable shaft and air expanding shaft.

Salient Features of the Air Shaft

A premium quality air shaft displays the following salient features during application:

Competent to adjust to different speed variations

Proficient to adjust to different core widths

Demonstrates high speed, when repositioning of the product doesn’t happen

Efficient gripping

Efficient core centering

Manages uneven cores

For detailed information, collaborate with a prominent air shaft manufacturer in Ahmedabad.

Manufacturing Industries Drawing Benefits from the Air Shaft

Manufacturing industries galore are drawing benefits from mechanical product, including:

Packaging

Steel

Paper

As far as dimension of the air shaft is concerned, it is available in different dimensions. In case, you are searching for a custom-designed air shaft, you can collaborate with a reputed air shaft manufacturer.

Applications

An airshaft is a mechanical device designed for handling winding reels in the processing of web-fed materials.

0 notes